Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials

Abstract

:1. Introduction

2. Materials and Methods

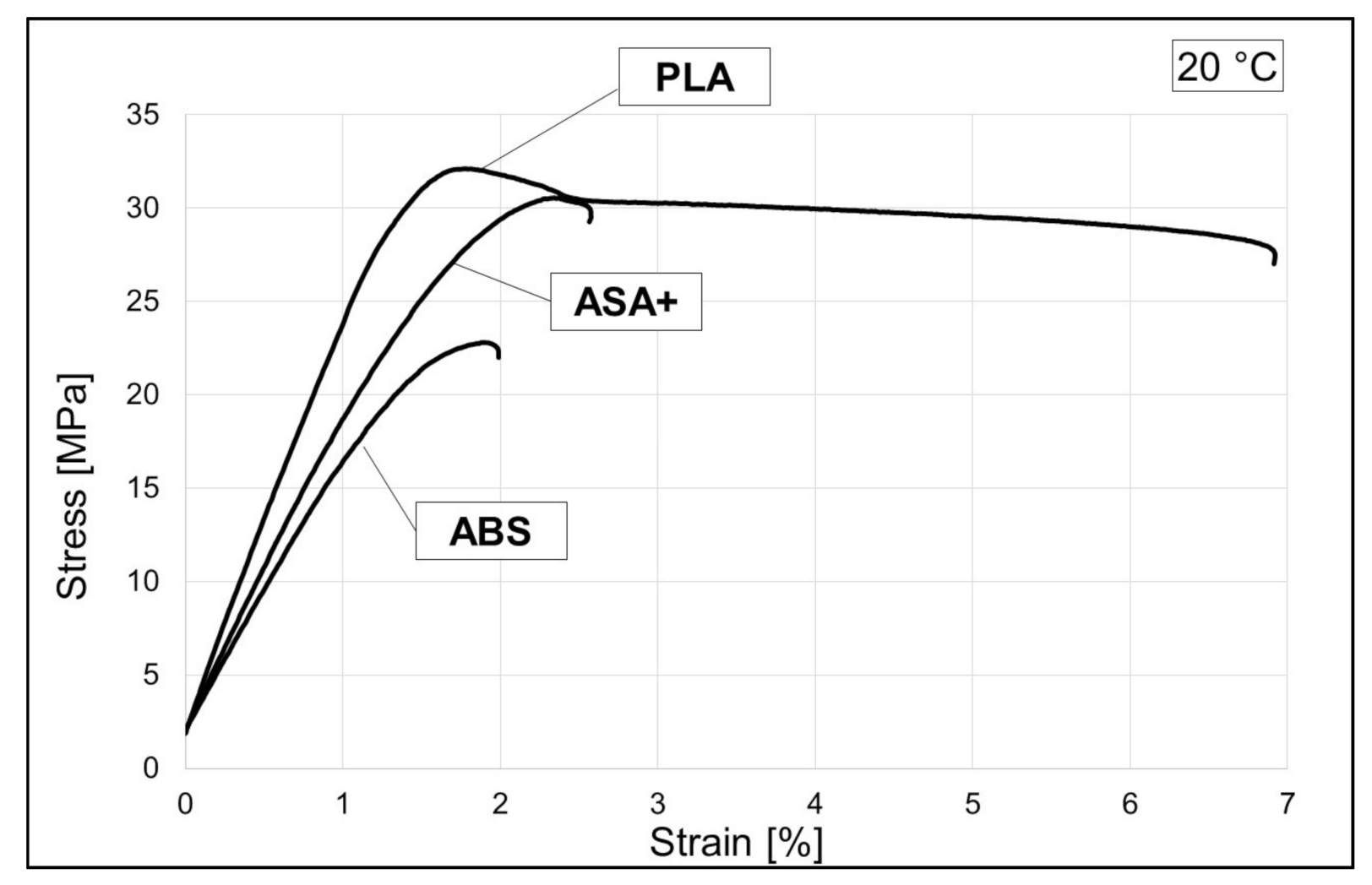

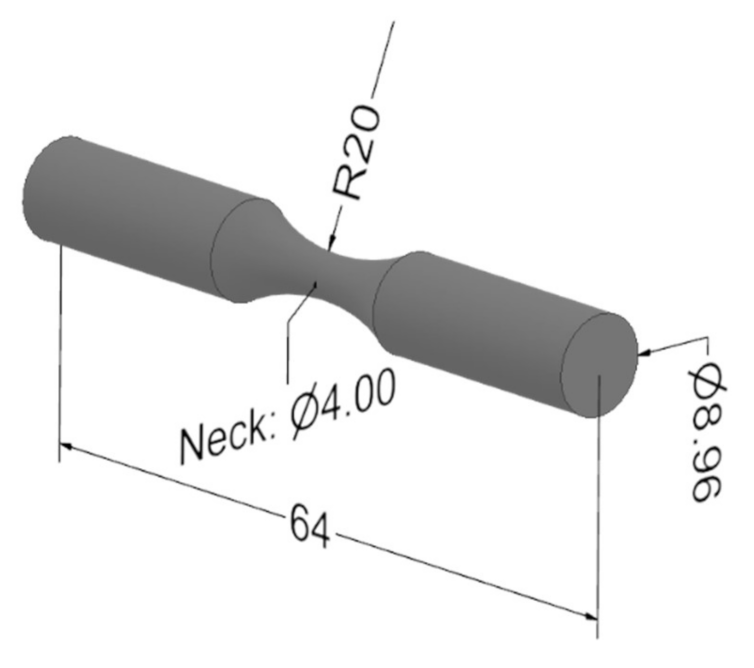

2.1. Tensile Tests

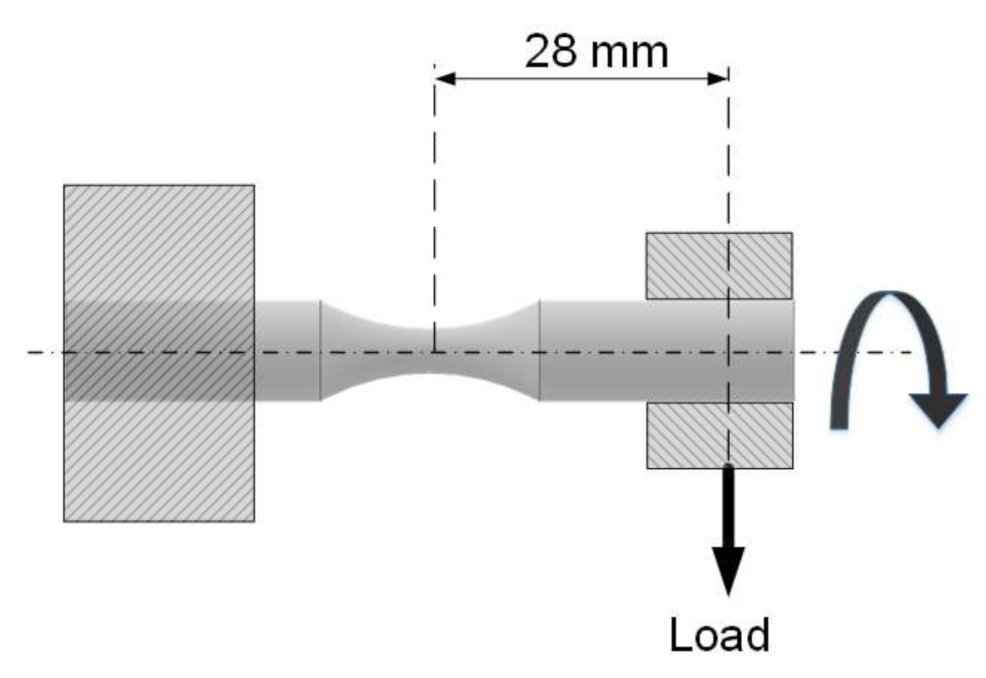

2.2. Rotating Fatigue Tests

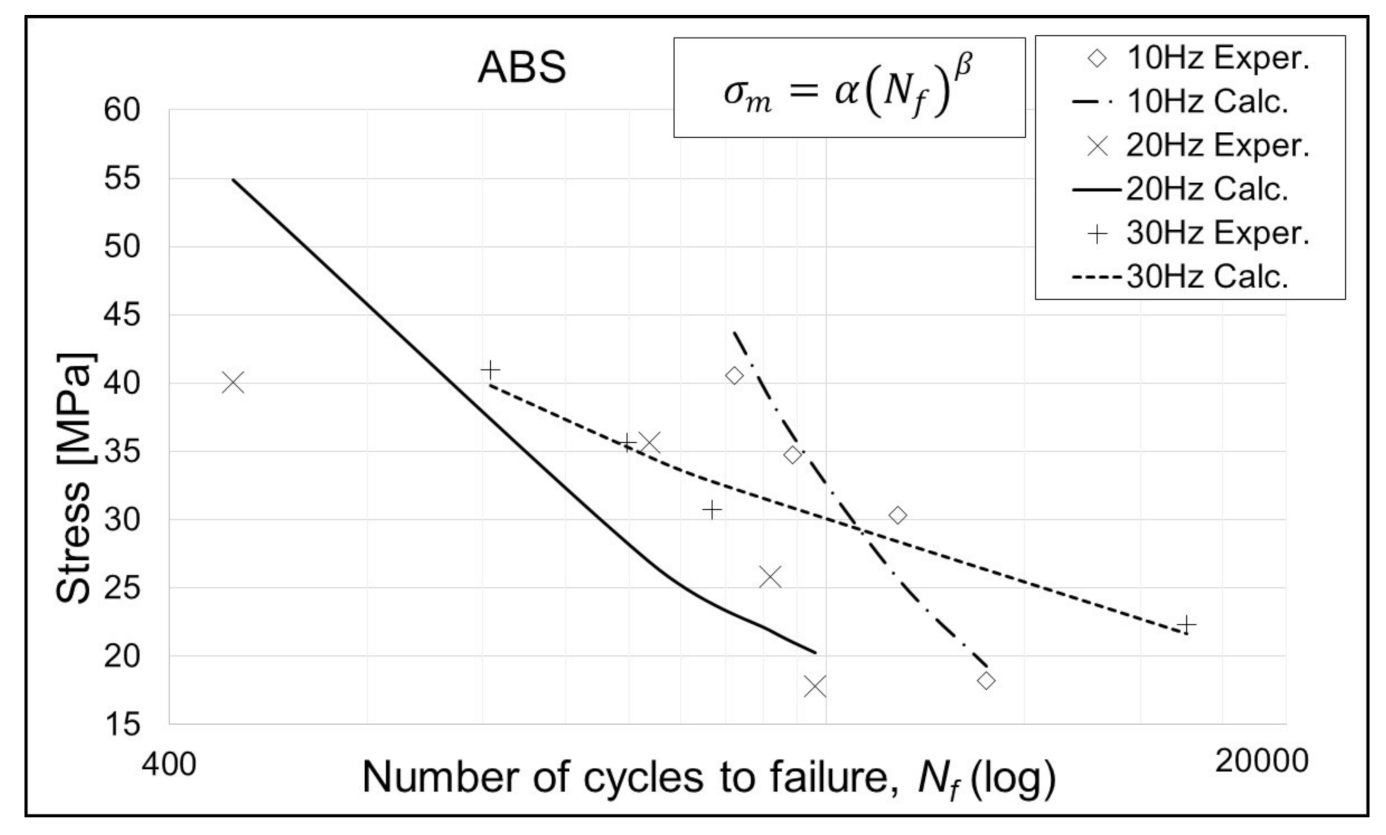

3. Fatigue Test Results and Discussion

4. Conclusions

- Comparison of different infill densities of FFF (3D printed) specimens and infill patterns and their influence on mechanical and fatigue properties;

- Different cycle rate values;

- Numerical modelling, using finite element method, based on proposed analytical models and findings;

- Fracture surface analysis;

- Surface roughness influence on fatigue fracture and cyclic durability;

- Influence of ultraviolet radiation and temperature on FFF polymer specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASTM F2792-12a. Standard Terminology for Additive Manufacturing Technologies. Available online: www.astm.org (accessed on 1 March 2021).

- Caulfield, B.; McHugh, P.; Lohfeld, S. Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- Sharma, M.; Ziemian, C. Anisotropic Mechanical Properties of ABS Parts Fabricated by Fused Deposition Modelling. Mech. Eng. 2012. [Google Scholar] [CrossRef] [Green Version]

- Rendeki, S.; Nagy, B.; Bene, M.; Pentek, A.; Toth, L.; Szanto, Z.; Told, R.; Maroti, P. An Overview on Personal Protective Equipment (PPE) Fabricated with Additive Manufacturing Technologies in the Era of COVID-19 Pandemic. Polymers 2020, 12, 2703. [Google Scholar] [CrossRef] [PubMed]

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- Barkhad, M.S.; Abu-Jdayil, B.; Mourad, A.H.I.; Iqbal, M.Z. Thermal Insulation and Mechanical Properties of Polylactic Acid (PLA) at Different Processing Conditions. Polymers 2020, 12, 2091. [Google Scholar] [CrossRef] [PubMed]

- Gong, B.; Cui, S.; Zhao, Y.; Sun, Y.; Ding, Q. Strain-controlled fatigue behaviors of porous PLA-based scaffolds by 3D-printing technology. J. Biomater. Sci. Polym. Ed. 2017, 28, 2196–2204. [Google Scholar] [CrossRef] [PubMed]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of poly(lactide). Appl. Microbiol. Biotechnol. 2006, 72, 244–251. [Google Scholar] [CrossRef]

- Senatov, F.; Niaza, K.; Stepashkin, A.; Kaloshkin, S. Low-cycle fatigue behavior of 3d-printed PLA-based porous scaffolds. Compos. Part B Eng. 2016, 97, 193–200. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef] [Green Version]

- Johnson, G.A.; French, J.J. Evaluation of Infill Effect on Mechanical Properties of Consumer 3D Printing Materials. Adv. Technol. Innov. 2018, 3, 179–184. [Google Scholar]

- Ma, Y.-Q.; Pang, Y.-Y. Mechanism study on char formation of zinc acetylacetonate on ABS resin. Chin. J. Polym. Sci. 2015, 33, 772–782. [Google Scholar] [CrossRef]

- Datta, P.; Guha, C.; Sarkhel, G. Effect of Na-ionomer on dynamic rheological, dynamic mechanical and creep properties of acrylonitrile styrene acrylate (ASA)/Na+1poly (ethylene-co-methacrylic acid) ionomer blend. Polym. Adv. Technol. 2014, 25, 1454–1463. [Google Scholar] [CrossRef]

- Datta, P.; Guha, C.; Sarkhel, G. Study of Dynamic Rheological, Dynamic Mechanical and Creep Properties of Acrylonitrile Styrene Acrylate (ASA)/Zn+2poly(ethylene-co-methacrylic acid) Ionomer Blend. J. Macromol. Sci. Part A 2014, 51, 820–830. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef] [PubMed]

- Van Der Klift, F.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D Printing of Continuous Carbon Fibre Reinforced Thermo-Plastic (CFRTP) Tensile Test Specimens. Open J. Compos. Mater. 2016, 6, 18–27. [Google Scholar] [CrossRef] [Green Version]

- Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices. Polymers 2018, 10, 666. [Google Scholar] [CrossRef] [Green Version]

- Blanco, I. The Use of Composite Materials in 3D Printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef] [Green Version]

- Stoof, D.; Pickering, K.; Zhang, Y. Fused Deposition Modelling of Natural Fibre/Polylactic Acid Composites. J. Compos. Sci. 2017, 1, 8. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Shapiro, V. Homogenization of material properties in additively manufactured structures. Comput. Des. 2016, 78, 71–82. [Google Scholar] [CrossRef] [Green Version]

- Afrose, M.F.; Masood, S.H.; Nikzad, M.; Iovenitti, P.G. Effects of Build Orientations on Tensile Properties of PLA Material Processed by FDM. Adv. Mater. Res. 2014, 1044–1045, 31–34. [Google Scholar] [CrossRef]

- Tymrak, B.; Kreiger, M.; Pearce, J. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef] [Green Version]

- Galeja, M.; Hejna, A.; Kosmela, P.; Kulawik, A. Static and Dynamic Mechanical Properties of 3D Printed ABS as a Function of Raster Angle. Materials 2020, 13, 297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Montero, M.; Roundy, S.; Odell, D. Material characterization of fused deposition modeling (FDM) ABS by designed experiments. Proc. Rapid Prototyp. Manuf. Conf. 2001, 1–21. [Google Scholar]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the Mechanical Properties of FFF Structures and Materials: A Review on the Experimental, Computational and Theoretical Approaches. Materials 2019, 12, 895. [Google Scholar] [CrossRef] [Green Version]

- Ezeh, O.; Susmel, L. On the fatigue strength of 3D-printed polylactide (PLA). Procedia Struct. Integr. 2018, 9, 29–36. [Google Scholar] [CrossRef]

- Ziemian, S.; Okwara, M.; Ziemian, C.W. Tensile and fatigue behavior of layered acrylonitrile butadiene styrene. Rapid Prototyp. J. 2015, 21, 270–278. [Google Scholar] [CrossRef]

- Domingo-Espin, M.; Travieso-Rodriguez, J.A.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue Performance of ABS Specimens Obtained by Fused Filament Fabrication. Materials 2018, 11, 2521. [Google Scholar] [CrossRef] [Green Version]

- Gomez-Gras, G.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Lluma-Fuentes, J. Fatigue performance of fused filament fabrication PLA specimens. Mater. Des. 2018, 140, 278–285. [Google Scholar] [CrossRef] [Green Version]

- Raise3D. PLA Filament—Premium Filament. Raise3D. Premium PLA Safety and Technical Data Sheet. 2019. Available online: https://s1.raise3d.com/2020/12/PLA-Data-Sheet.zip (accessed on 1 March 2021).

- Raise3D. ABS Filament—Premium Filament. Raise3D Premium ABS Safety and Technical Data Sheet. 2017. Available online: https://s1.raise3d.com/2020/12/ABS-Data-Sheet.zip (accessed on 1 March 2021).

- Prima Creator. PrimaSelect ASA+ PrimaCreator. PrimaSelect Safety and Technical Data Sheet. 2019. Available online: https://cdn.shopify.com/s/files/1/2424/8853/files/Prima_ASA__webb.pdf?293 (accessed on 1 March 2021).

- Kampker, A.; Triebs, J.B.; Ayvaz, P.; Ilic, D. Investigation of FLM materials for application in high-temperature and high-vibration automotive environments. Procedia CIRP 2019, 81, 358–362. [Google Scholar] [CrossRef]

- Ibrahim, D.; Ding, S.; Sun, S. Roughness Prediction for FDM Produced Surfaces. In Proceedings of the International Conference Recent treads in Engineering & Technology (ICRET’2014), Batam, Indonesia, 13–14 February 2014; pp. 13–17. [Google Scholar]

- Alsoufi, M.S.; Elsayed, A.E. How Surface Roughness Performance of Printed Parts Manufactured by Desktop FDM 3D Printer with PLA+ is Influenced by Measuring Direction. Am. J. Mech. Eng. 2017, 5, 211–222. [Google Scholar] [CrossRef]

- Burhan, I.; Kim, H.S. S-N Curve Models for Composite Materials Characterisation: An Evaluative Review. J. Compos. Sci. 2018, 2, 38. [Google Scholar] [CrossRef] [Green Version]

- Poberezhnyi, L.; Maruschak, P.; Prentkovskis, O.; Danyliuk, I.; Pyrig, T.; Brezinová, J. Fatigue and failure of steel of offshore gas pipeline after the laying operation. Arch. Civ. Mech. Eng. 2016, 16, 524–536. [Google Scholar] [CrossRef]

| Material/Property | PLA | ABS | ASA+ |

|---|---|---|---|

| Density (g/cm3 at 21.5 °C; ISO 1183) | 1.20 | 1.10–1.15 | 1.10 |

| Melt Flow Rate (g/10 min) | 210 °C/2.16 kg = 7 ÷ 11 | 220 °C/10 kg = 9 ÷ 14 | 260 °C/5 kg = 45 |

| Melting temperature (°C) | 150 | - | 228 |

| Glass transition temperature (°C) | 61 | 98.1 | 98 |

| Property | This paper | Manufacturer [31] | [Reference] |

|---|---|---|---|

| Young’s modulus (MPa) | 2923 | 2623 ± 330 | 3340 [22] |

| Tensile strength (MPa) | 32.1 | 46.6 ± 0.9 | 48.5 [22] |

| Property | This paper | Manufacturer [32] | [Reference] |

|---|---|---|---|

| Young’s modulus (MPa) | 2182 | 2174 ± 285 | 1960 ± 60 [5]; 1538 [21] |

| Tensile strength (MPa) | 22.8 | 33.3 ± 0.8 | 32.8 ± 0.6 [5] 38.65 [21] |

| Property | This paper | Manufacturer [33] | [Reference] |

|---|---|---|---|

| Young’s modulus (MPa) | 1996 | 2020 | 1398.3 [34] |

| Tensile strength (MPa) | 29.9 | 48 | 23 [34] |

| Coefficient/Cycle Rate | 10 Hz | 20 Hz | 30 Hz |

|---|---|---|---|

| α | 1488.2 | 349.6 | 474.5 |

| β | −0.4219 | −0.227 | −0.284 |

| Coefficient/Cycle Rate | 10 Hz | 20 Hz | 30 Hz |

|---|---|---|---|

| α | 70,213.8 | 1133.9 | 236.8 |

| β | −0.926 | −0.487 | −0.250 |

| Coefficient/Cycle Rate | 10 Hz | 20 Hz | 30 Hz |

|---|---|---|---|

| α | 3797.1 | 6574.1 | 753.6 |

| β | −0.561 | −0.671 | −0.361 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brčić, M.; Kršćanski, S.; Brnić, J. Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials. Polymers 2021, 13, 1020. https://doi.org/10.3390/polym13071020

Brčić M, Kršćanski S, Brnić J. Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials. Polymers. 2021; 13(7):1020. https://doi.org/10.3390/polym13071020

Chicago/Turabian StyleBrčić, Marino, Sanjin Kršćanski, and Josip Brnić. 2021. "Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials" Polymers 13, no. 7: 1020. https://doi.org/10.3390/polym13071020

APA StyleBrčić, M., Kršćanski, S., & Brnić, J. (2021). Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials. Polymers, 13(7), 1020. https://doi.org/10.3390/polym13071020

.JPG)