Novel Bending Test Method for Polymer Railway Sleeper Materials

Abstract

1. Introduction

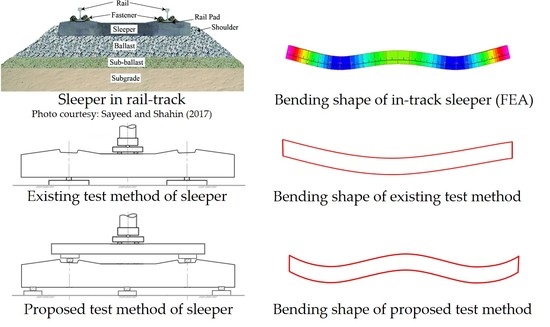

2. Evaluation of the Existing Test Standards

3. The Concept of Five-Point Static Bending for Railway Sleepers

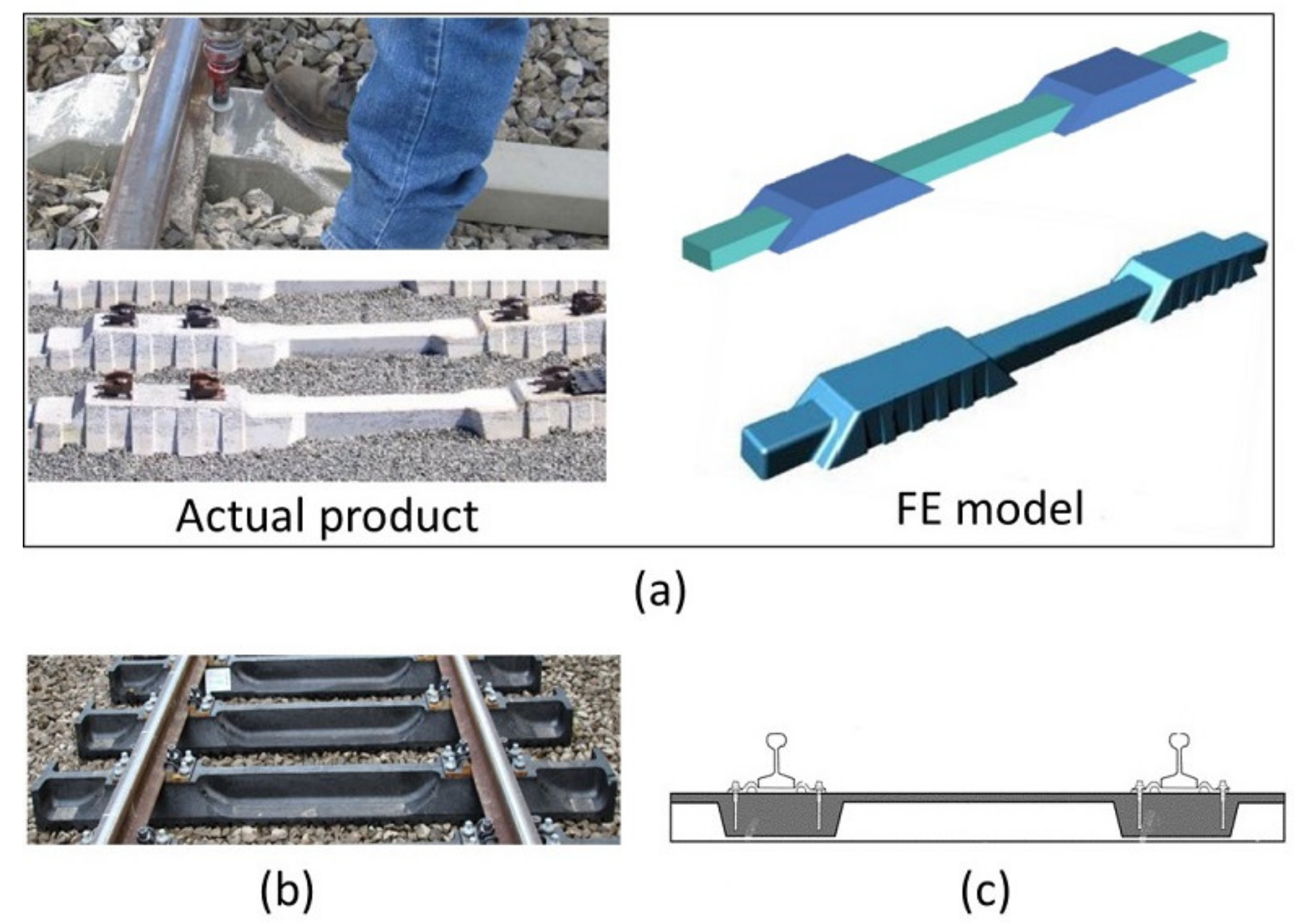

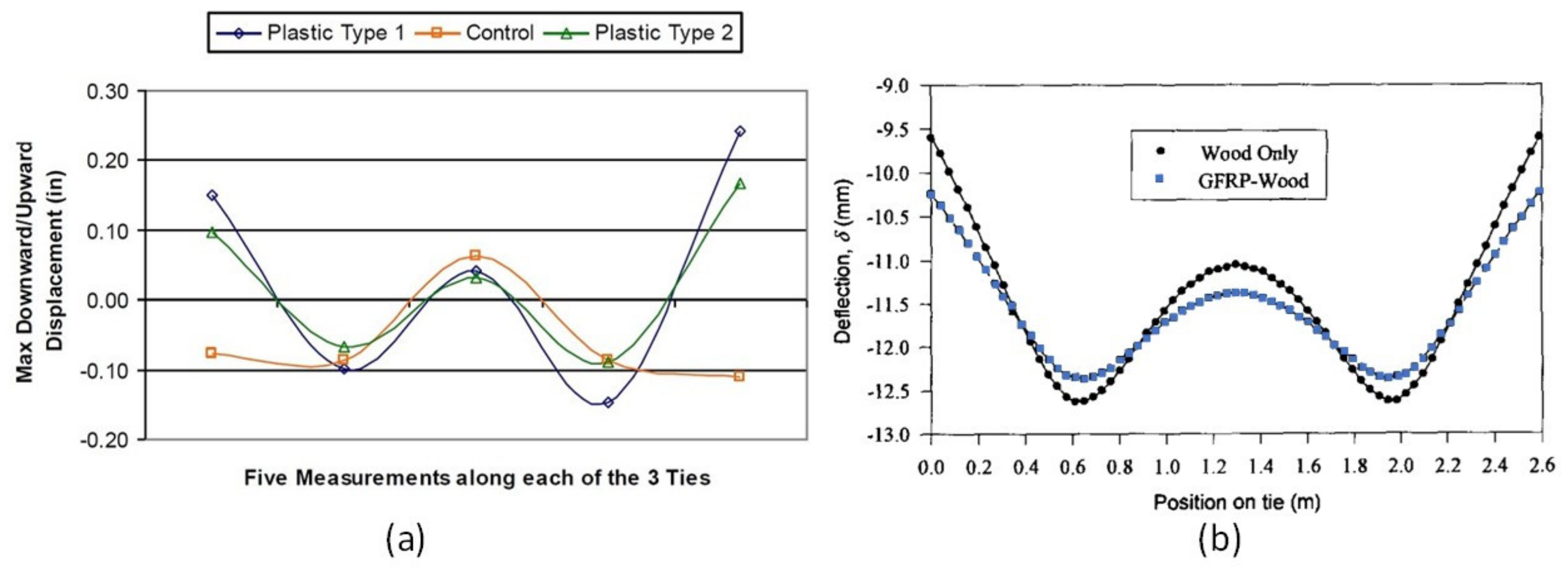

3.1. Previous Works on Five-Point Static Bending Test

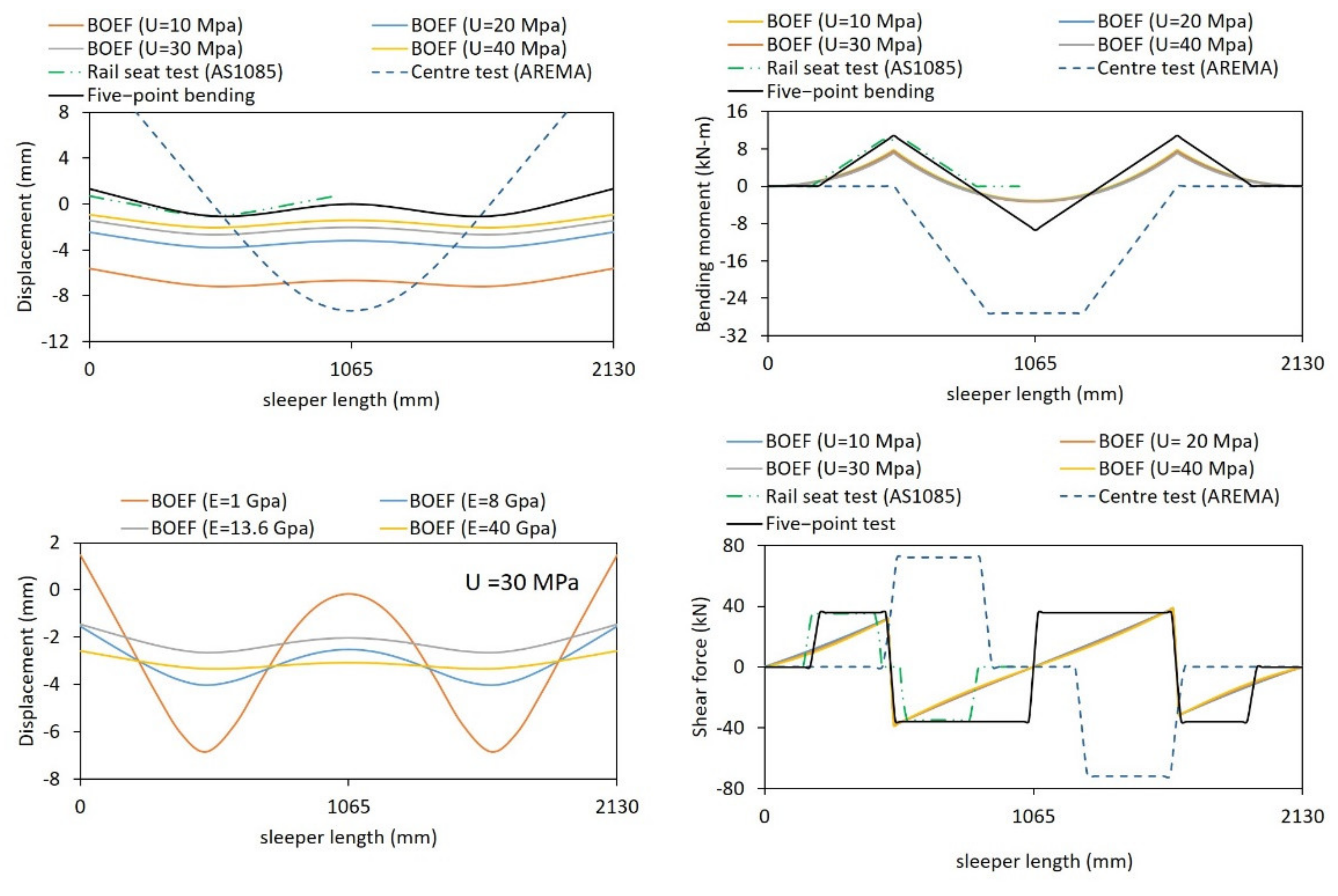

3.2. Determination of the Appropriate 5-Point Static Test Configuration

4. Experimental Verification of the 5-Point Static Bending Test

4.1. Sleeper Properties and Preparation for DIC Measurements

4.2. Non-Destructive Five-Point Static Bending Tests

5. Results and Discussion

5.1. Effect of Materials at the Middle Support

5.2. Effect of Sleeper Stiffness

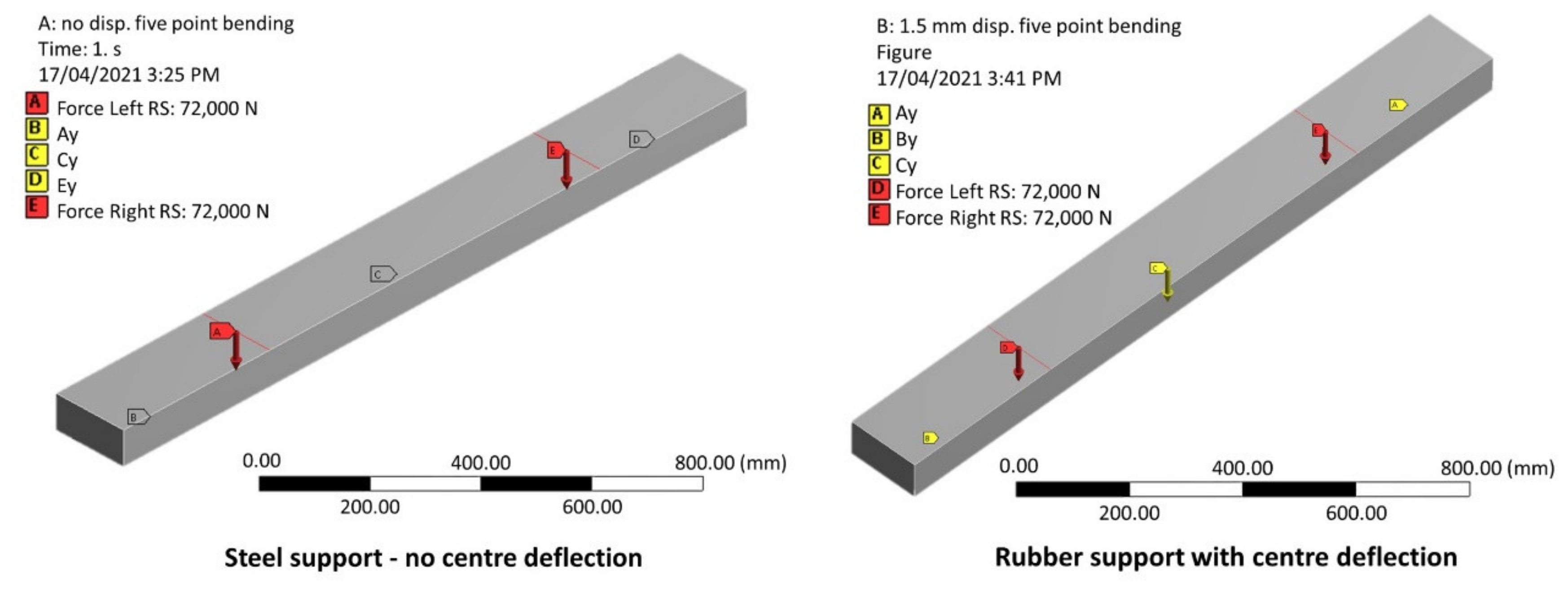

6. Analytical Solution of Five-Point Bending and FEA Verification

7. Conclusions

- The five-point static bending test is a simple test method to simulate the sleeper behaviour supported by ballast and subject to simultaneous positive and negative bending moments. The closeness of this testing method to that of the in-situ situation is limited to the sleeper behaviour according to BOEF theory and the shear span of 300 mm to prevent high shear stress beyond that of the AS1085.14 standard. The deflected profiles from the five-point static bending test are very similar to that of the deformation behaviour from analysis using the beam on elastic foundation except for the concrete sleepers.

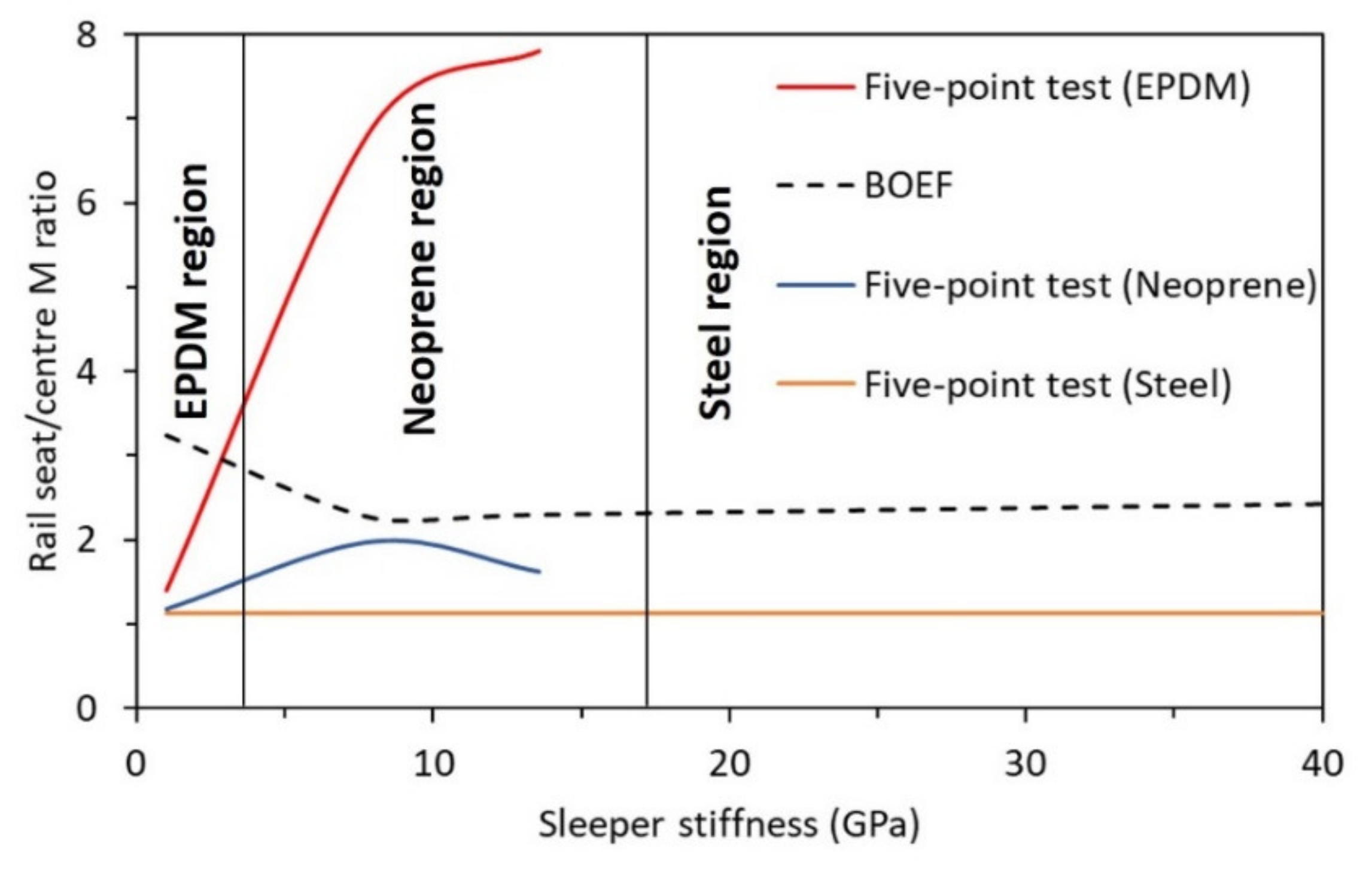

- The bending modulus of the sleeper is a more influential parameter than the support modulus (ballast) when determining the bending moment, shear force and deflected shape of the sleepers. The ratio of bending moment at the rail seat (sagging) to the centre bending moment (hogging) increases with the increase in the modulus of elasticity of the sleepers. The sagging to hogging moment ratio of recycled plastic sleeper (Es = 1.0 GPa) increases due to higher bending at the rail seat due to its significantly low elastic modulus.

- The hardness or elasticity of the middle support in a 5-point bending test has a significant influence in inducing appropriately the magnitude of the positive and negative bending moments experienced by railway sleepers. Neoprene rubber is found suitable for timber and FFU sleepers, EPDM rubber seemed suitable for plastic sleepers and steel support for low-profile prestressed concrete sleepers. This indicates the type of middle support is very much dependant on the elastic modulus of the sleeper materials, i.e., the higher the elastic modulus of the sleeper, the stronger the middle support material is required. Neoprene support is however suggested to standardise the five-point bending for polymeric-based railway sleepers.

- The modulus of railway sleepers directly affects the bending moment distribution between the rail seat and centre of the sleepers. The positive-to-negative bending moment increases as the sleeper stiffness increases for neoprene and EPDM support. The high elasticity of the low-profile prestressed concrete sleeper requires a steel pad to induce a negative bending moment at the middle of the sleeper. This was however limited to the loading intensity and type (static) applied in this investigation.

- The developed theoretical equation based on the force method analysis of indeterminate beam and considering the settlement of the middle support and modulus of elasticity of the sleepers can calculate directly the reactions at supports and bending moments along the length of the sleeper. The verification with FEA analysis for timber sleeper showed that the analytical solution can accurately predict the magnitude of the bending moments at the rail seat and centre of the sleeper under 5-point static bending tests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zakeri, J.-A.; Rezvani, F.H. Failures of railway concrete sleepers during service life. Int. J. Constr. Eng. Manag. 2012, 1, 1–5. [Google Scholar]

- Ferdous, W.; Manalo, A.; Van Erp, G.; Aravinthan, T.; Kaewunruen, S.; Remennikov, A. Composite railway sleepers–Recent developments, challenges and future prospects. Compos. Struct. 2015, 134, 158–168. [Google Scholar] [CrossRef]

- Nosker, T.; Renfree, R.; Lynch, J.; Lutz, M.; Gillespie, B.; Lampo, R.; Van Ness, K.E. A performance-based approach to the development of a recycled plastic/composite crosstie. In Proceedings of the Technical Papers of The Annual Technical Conference-Society of Plastics Engineers Incorporated; Society of Plastics Engineers Inc.: Brookfield, CT, USA, 1998; pp. 2912–2915. [Google Scholar]

- Ju, S.; Yoon, J.; Sung, D.; Pyo, S. Mechanical Properties of Coal Ash Particle-Reinforced Recycled Plastic-Based Composites for Sustainable Railway Sleepers. Polymers 2020, 12, 2287. [Google Scholar] [CrossRef] [PubMed]

- Nairn, J.; Stevens, N. Rational design method for prestressed concrete sleepers. In CORE 2010: Rail, Rejuvenation and Renaissance; Engineers Australia: Wellington, Australia, 2010; p. 174. [Google Scholar]

- Ahn, S.; Kwon, S.; Hwang, Y.-T.; Koh, H.-I.; Kim, H.-S.; Park, J. Complex structured polymer concrete sleeper for rolling noise reduction of high-speed train system. Compos. Struct. 2019, 223, 110944. [Google Scholar] [CrossRef]

- Brown, J. Design refinements make the steel sleeper viable. Railw. Gaz. Int. 1979, 135, 902–906. [Google Scholar]

- Manalo, A.; Aravinthan, T.; Karunasena, W.; Ticoalu, A. A review of alternative materials for replacing existing timber sleepers. Compos. Struct. 2010, 92, 603–611. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Rahmat, M. On the reinforcement of concrete sleepers by composite materials. Compos. Struct. 2006, 76, 326–337. [Google Scholar] [CrossRef]

- Lampo, R.; Nosker, T.; Sullivan, H. Development, testing, and applications of recycled-plastic composite cross ties. In Proceedings of the DoD Transportation 2000 Workshop, San Antonio, TX, USA, 15 January 2000. [Google Scholar]

- Jeon, E.-B.; Ahn, S.; Lee, I.-G.; Koh, H.-I.; Park, J.; Kim, H.-S. Investigation of mechanical/dynamic properties of carbon fiber reinforced polymer concrete for low noise railway slab. Compos. Struct. 2015, 134, 27–35. [Google Scholar] [CrossRef]

- Composites in the Passenger Rail Market Report: Trends, Forecast and Competitive Analysis, Market Share Report; Lucintel: Dallas, TX, USA, 2020.

- Expression of Interest for Alternative Composite Sleeper Product, Tender Number: QRP15150A; Queensland Rail Limited: Brisbane, Australia, 2016.

- Silva, É.A.; Pokropski, D.; You, R.; Kaewunruen, S. Comparison of structural design methods for railway composites and plastic sleepers and bearers. Aust. J. Struct. Eng. 2017, 18, 160–177. [Google Scholar] [CrossRef]

- Qiu, C.; Tew, G.; Trevaskis, R. The application of composite sleepers contributing to the sustainability of railway: Material performance and standard development. In Proceedings of the CORE 2018: Conference on Railway Excellence; Railway Technical Society of Australasia: Barton, ACT, Australia, 2018; p. 139. [Google Scholar]

- AREMA. Chapter 30—Ties; AREMA: Lanham, MD, USA, 2014; pp. 1–202. [Google Scholar]

- Japanese Industrial Standard. JIS E 1203:2007, Synthetic Sleepers—Made from Fibre Reinforced Foamed Urethane; Japanese Standards Association: Tokyo, Japan, 2007; pp. 1–23. [Google Scholar]

- International Organization for Standardization. ISO 12856-1: Plastics—Plastic Railway Sleepers for Railway Applications (Railroad ties); Part 1: Material characteristics; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Standard Australia. AS 1085.22: 2019, Railway Track Materials: Alternative Material Sleepers, RISSB; Standard Australia: Sydney, Australia, 2020. [Google Scholar]

- Zakeri, J.A.; Sadeghi, J. Field investigation on load distribution and deflections of railway track sleepers. J. Mech. Sci. Technol. 2007, 21, 1948. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Remennikov, A.M. Effect of a large asymmetrical wheel burden on flexural response and failure of railway concrete sleepers in track systems. Eng. Fail. Anal. 2008, 15, 1065–1075. [Google Scholar] [CrossRef]

- Edwards, J.R.; Gao, Z.; Wolf, H.E.; Dersch, M.S.; Qian, Y. Quantification of concrete railway sleeper bending moments using surface strain gauges. Measurement 2017, 111, 197–207. [Google Scholar] [CrossRef]

- Van Dyk, B. Characterization of the Loading Environment for Shared-Use Railway Superstructure in North America; University of Illinois at Urbana-Champaign: Champaign, IL, USA, 2015. [Google Scholar]

- Wolf, H.E.; Edwards, J.R.; Dersch, M.S.; Qian, Y.; Lange, D.A. Field measurement of bending moments in prestressed concrete monoblock sleepers. In Proceedings of the 11th World Congress Railway Research, Milan, Italy, 30 May–2 June 2016; pp. 1–6. [Google Scholar]

- McHenry, M.; Gao, Y.; Billargeon, J.P. Implementing Improved Composite Tie Design and Testing Guidelines. In Proceedings of the American Railway Engineering and Maintenance-of-Way Association Annual Conference; Chicago, IL, USA, 2018; pp. 206–227. [Google Scholar]

- Bolin, C.A.; Smith, S.T. Life cycle assessment of creosote-treated wooden railroad crossties in the US with comparisons to concrete and plastic composite railroad crossties. J. Transp. Technol. 2013, 3, 149. [Google Scholar] [CrossRef][Green Version]

- Kaewunruen, S.; Ngamkhanong, C.; Sengsri, P.; Ishida, M. On Hogging Bending Test Specifications of Railway Composite Sleepers and Bearers. Front. Built Environ. 2020, 6, 592014. [Google Scholar]

- Aravinthan, T.; Manalo, A. Field applications and case studies of FRP in civil infrastructure: The Australian experience. In Proceedings of the 6th International Conference on FRP Composites in Civil Engineering (CICE 2012), Rome, Italy, 13–15 June 2012; pp. 1–8. [Google Scholar]

- Ferdous, W.; Manalo, A.; Van Erp, G.; Aravinthan, T.; Ghabraie, K. Evaluation of an innovative composite railway sleeper for a narrow-gauge track under static load. J. Compos. Constr. 2018, 22, 04017050. [Google Scholar] [CrossRef]

- Van Erp, G.; Mckay, M. Recent Australian developments in fibre composite railway sleepers. Electron. J. Struct. Eng. 2013, 13, 62–66. [Google Scholar]

- KLP® Hybrid Polymer Sleepers. Available online: https://www.hirdrail.com/klp-polymer-sleepers.html (accessed on 5 July 2020).

- Nose, G.L.; Trevizan, D.W. Railway Sleeper and Railway-Sleeper Manufacturing Method. U.S. Patent 10,704,204 B2, 16 May 2020. [Google Scholar]

- Zakeri, J.A.; Fattahi, M.; Ghanimoghadam, M.M. Influence of unsupported and partially supported sleepers on dynamic responses of train–track interaction. J. Mech. Sci. Technol. 2015, 29, 2289–2295. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Rahmat, M. Effects of Young’s modulus on response of railway sleeper. Appl. Math. Model. 2007, 31, 700–711. [Google Scholar] [CrossRef]

- Ferro, E.; Harkness, J.; Le Pen, L. The influence of sleeper material characteristics on railway track behaviour: Concrete vs. composite sleeper. Transp. Geotech. 2020, 23, 100348. [Google Scholar] [CrossRef]

- Abadi, T.; Pen, L.L.; Zervos, A.; Powrie, W. Effect of Sleeper Interventions on Railway Track Performance. J. Geotech. Geoenviron. Eng. 2019, 145, 04019009. [Google Scholar] [CrossRef]

- Standards Australia. AS 1085.14-2012: Railway Track Material. In Prestressed Concrete Sleepers; Standards Australia: Sydney, Australia, 2012. [Google Scholar]

- International Organization for Standardization. ISO 12856-2, Railway Applications-Polymeric Composite Sleepers, Bearers and Transoms; Part 2: Product testing; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- Janeliukstis, R.; Clark, A.; Papaelias, M.; Kaewunruen, S. Flexural cracking-induced acoustic emission peak frequency shift in railway prestressed concrete sleepers. Eng. Struct. 2019, 178, 493–505. [Google Scholar] [CrossRef]

- Jeffs, T.; Tew, G. A Review of Track Design Procedures: Sleepers and Ballast; Railw. Aust.: Melbourne, VIC, Australia, 1991; Volume 2. [Google Scholar]

- Hetenyi, M. Beams on Elastic Foundation, 8th ed.; University of Michigan Press: Ann Arbor, MI, USA, 1967. [Google Scholar]

- Sadeghi, J.; Barati, P. Evaluation of conventional methods in Analysis and Design of Railway Track System. Int. J. Civ. Eng. 2010, 8, 44–55. [Google Scholar]

- U.S. Department of Transportation, Federal Railroad Administration. Performance of Plastic Composite Ties in Revenue Service; U.S. Department of Transportation, Federal Railroad Administration: Washington, DC, USA, 2011; pp. 1–4.

- Qiao, P.; Davalos, J.F.; Zipfel, M.G. Modeling and optimal design of composite-reinforced wood railroad crosstie. Compos. Struct. 1998, 41, 87–96. [Google Scholar] [CrossRef]

- Kim, W.; Dharan, C. Analysis of five-point bending for determination of the interlaminar shear strength of unidirectional composite materials. Compos. Struct. 1995, 30, 241–251. [Google Scholar] [CrossRef]

- Pouget, S.; Sauzéat, C.; Di Benedetto, H.; Olard, F. Numerical simulation of the five-point bending test designed to study bituminous wearing courses on orthotropic steel bridge. Mater. Struct. 2010, 43, 319–330. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Scarpas, A.; Tzimiris, G.; Kasbergen, C.; Hofman, R.; Voskuilen, J. Analysis of five-point bending test for multilayer surfacing system on orthotropic steel bridges. Transp. Res. Rec. 2013, 2370, 137–144. [Google Scholar] [CrossRef]

- Su, M.-N.; Young, B.; Gardner, L. Continuous beams of aluminum alloy tubular cross sections. I: Tests and FE model validation. J. Struct. Eng. 2015, 141, 04014232. [Google Scholar] [CrossRef]

- Su, M.-N.; Young, B.; Gardner, L. Continuous beams of aluminum alloy tubular cross sections. II: Parametric study and design. J. Struct. Eng. 2015, 141, 04014233. [Google Scholar] [CrossRef]

- Mujika, F.; Asensio, M.; Vargas, G.; Boyano, A.; De Gracia, J. Analysis of a reversible five-point bending configuration based on a novel two-sense support. Polym. Test. 2015, 43, 108–122. [Google Scholar] [CrossRef]

- Strand7 Software, Strand7 Release 2.4.6. Available online: https://www.strand7.com/WhatsNew/release240.htm (accessed on 10 February 2020).

- ASTM D790-17—Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; American Society for Testing Materials: West Conshohocken, PA, USA, 2017.

- Queensland Rail. Material Supply Specification TRACK-CT.169. In Civil—Sleepers—115 mm and 150 mm Thickness; Queensland Rail: Queensland, Australia, 2018. [Google Scholar]

- Yu, L.; Pan, B. Experimental study of tensile properties and deformation evolutions of 2D and 2.5 D woven SiO2f/SiO2 composites using single-camera stereo-digital image correlation. Compos. Struct. 2018, 200, 589–598. [Google Scholar] [CrossRef]

- Pannier, Y.; Foti, F.; Gigliotti, M. High Temperature Fatigue of Carbon/Polyimide 8-harness Satin Woven Composites. Part I: Digital Image Correlation and Micro-Computed Tomography Damage Characterization. Compos. Struct. 2020, 244, 112255. [Google Scholar] [CrossRef]

- Szebényi, G.; Hliva, V. Detection of Delamination in Polymer Composites by Digital Image Correlation—Experimental Test. Polymers 2019, 11, 523. [Google Scholar] [CrossRef] [PubMed]

- Statnik, E.S.; Dragu, C.; Besnard, C.; Lunt, A.J.G.; Salimon, A.I.; Maksimkin, A.; Korsunsky, A.M. Multi-Scale Digital Image Correlation Analysis of In Situ Deformation of Open-Cell Porous Ultra-High Molecular Weight Polyethylene Foam. Polymers 2020, 12, 2607. [Google Scholar] [CrossRef]

- Sui, L.; Zhong, Q.; Yu, K.; Xing, F.; Li, P.; Zhou, Y. Flexural Fatigue Properties of Ultra-High Performance Engineered Cementitious Composites (UHP-ECC) Reinforced by Polymer Fibers. Polymers 2018, 10, 892. [Google Scholar] [CrossRef] [PubMed]

- Xiang-rong, Y. Beam deflection measurement using one dimension digital image correlation. J. Guangzhou Univ. (Nat. Sci. Ed.) 2010, 9, 54–56. [Google Scholar]

- Sładek, J.; Ostrowska, K.; Kohut, P.; Holak, K.; Gąska, A.; Uhl, T. Development of a vision based deflection measurement system and its accuracy assessment. Measurement 2013, 46, 1237–1249. [Google Scholar] [CrossRef]

- iMetrum. Video Gauge—How It Works. Available online: https://www.imetrum.com/video-gauge/how-it-works (accessed on 25 March 2020).

- El-Nashar, D.; Gomaa, E.; Abd-El-Messieh, S. Study of electrical, mechanical, and nanoscale free-volume properties of NBR and EPDM rubber reinforced by bentonite or kaolin. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 1825–1838. [Google Scholar] [CrossRef]

- Özdemir, T.; Akbay, I.; Uzun, H.; Reyhancan, I. Neutron shielding of EPDM rubber with boric acid: Mechanical, thermal properties and neutron absorption tests. Prog. Nucl. Energy 2016, 89, 102–109. [Google Scholar] [CrossRef]

- Stelescu, M.D.; Airinei, A.; Manaila, E.; Craciun, G.; Fifere, N.; Varganici, C.; Pamfil, D.; Doroftei, F. Effects of Electron Beam Irradiation on the Mechanical, Thermal, and Surface Properties of Some EPDM/Butyl Rubber Composites. Polymers 2018, 10, 1206. [Google Scholar] [CrossRef] [PubMed]

- Manaila, E.; Airinei, A.; Stelescu, M.D.; Sonmez, M.; Alexandrescu, L.; Craciun, G.; Pamfil, D.; Fifere, N.; Varganici, C.-D.; Doroftei, F.; et al. Radiation Processing and Characterization of Some Ethylene-propylene-diene Terpolymer/Butyl (Halobutyl) Rubber/Nanosilica Composites. Polymers 2020, 12, 2431. [Google Scholar] [CrossRef]

- Carrasco, E.; Passos, L.; Mantilla, J. Structural behavior evaluation of Brazilian glulam wood sleepers when submitted to static load. Constr. Build. Mater. 2012, 26, 334–343. [Google Scholar] [CrossRef]

- Derucher, K.; Kim, U.; Putcha, C. Indeterminate Structural Analysis; The Edwin Mellen Press: New York, NY, USA, 2013. [Google Scholar]

- Sedaghati, R.; Suleman, A.; Tabarrok, B. Structural optimization with frequency constraints using the finite element force method. Aiaa J. 2002, 40, 382–388. [Google Scholar] [CrossRef]

- Standards Australia. 1720.1-2010: Timber Structures—Desing Methods; Standards Australia: Sydney, Australia, 2010. [Google Scholar]

| Origin Country | Sleeper/Material Type Co | Es (GPa) | Full-Size Bending Test | Type of Resilient Support | |

|---|---|---|---|---|---|

| AREMA- chapter 30-5 | USA | ECP and EWP, but mostly deal with HDPE polymer-based composite products. | 1.17 | Rail seat positive, rail seat negative and centre negative. | 140 mm × width of sleeper × 25 mm thick (50 Shore A hardness) |

| JIS E 1203:2007 | Japan | Fibre-reinforced foamed urethane. | 6.0 | No full-size testing | - |

| ISO 12856 | International | Plastic and reinforced plastic | 1.17–6.0 | Rail seat positive, centre positive and centre negative. | 140 mm × width of sleeper × 15 mm thick (static bedding modulus: 1 < C < 4 N/mm3) |

| AS1085.22 | Australia | Not specified | - | Rail seat positive, rail seat negative, centre positive and centre negative. | Neoprene Shore A hardness 90. Top: 25 mm width × 12 mm thick × width of sleeper Bottom: 50 mm width × 25 mm thick × width of sleeper |

| Distance ‘a’ | Bending Moment (kN-m) | ||

|---|---|---|---|

| Positive | Negative | Ratio | |

| BOEF (timber) | 7.3 | 3.22 | 2.27 |

| 400 mm | 11.91 | 11.92 | 0.999 |

| 350 mm | 11.44 | 10.76 | 1.063 |

| 300 mm | 10.81 | 9.5 | 1.137 |

| Sleeper Type | Cross-Sectional Area (mm2) | Length (mm) | Second Moment of Inertia (mm4) | Es (GPa) |

|---|---|---|---|---|

| Timber | 26,450 | 2130 | 29,150,104 | 13.6 |

| Recycled plastic | 28,125 | 2050 | 36,621,094 | 1.0 |

| Synthetic composite | 25,760 | 2120 | 28,389,667 | 8.1 |

| Prestressed concrete | 31,168 | 2130 | 48,699,500 | 38.0 |

| Sleeper Type | Support Type | Middle Support Settlement (ΔCR) mm | B.M @ RS (kN-m) | B.M @ Centre (kN-m) | RS/Centre B.M Ratio | Remarks/Most Suitable Support |

|---|---|---|---|---|---|---|

| Timber | Steel | 0.00 | 10.81 | −9.50 | 1.14 | Low |

| EPDM | 4.89 | 13.51 | −1.73 | 7.81 | High | |

| Neoprene | 1.50 | 11.64 | −7.12 | 1.64 | ✓ | |

| BOEF | - | 7.3 | −3.22 | 2.27 | Target | |

| Plastic | Steel | 0.00 | 10.81 | −9.50 | 1.14 | Low |

| EPDM | 9.80 | 11.32 | −8.10 | 1.40 | ✓ | |

| Neoprene | 2.40 | 10.94 | −9.15 | 1.20 | Low | |

| BOEF | - | 4.94 | −1.6 | 3.09 | Target | |

| Synthetic | Steel | 0.00 | 10.81 | −9.5 | 1.14 | Low |

| EPDM | 8.20 | 13.43 | −1.94 | 6.92 | High | |

| Neoprene | 3.75 | 12.01 | −6.04 | 1.99 | ✓ | |

| BOEF | - | 6.94 | −3.11 | 2.23 | Target | |

| Concrete | Steel | 0.00 | 10.81 | −9.5 | 1.14 | ✓ |

| EPDM | 2.80 | 18.40 | 12.36 | - | ‘No negative moment’ | |

| Neoprene | 2.55 | 17.72 | 10.42 | - | ||

| BOEF | - | 8.00 | −3.41 | 2.34 | Target |

| Middle Support Condition | Type of Analysis | Ay and Ey (kN) | Cy (kN) | Moment at Rail Seats, RS (kN-m) | Moment at Centre, C (kN-m) | RS/C Ratio |

|---|---|---|---|---|---|---|

| No settlement | Analytical | 36.05 | 71.91 | 10.81 | −9.50 | −1.138 |

| FEA | 36.07 | 71.85 | 10.82 | −9.47 | −1.142 | |

| 1.5 mm settlement | Analytical | 38.80 | 66.40 | 11.64 | −7.12 | −1.635 |

| FEA | 38.70 | 66.59 | 11.61 | −7.20 | −1.613 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salih, C.; Manalo, A.; Ferdous, W.; Abousnina, R.; Yu, P.; Heyer, T.; Schubel, P. Novel Bending Test Method for Polymer Railway Sleeper Materials. Polymers 2021, 13, 1359. https://doi.org/10.3390/polym13091359

Salih C, Manalo A, Ferdous W, Abousnina R, Yu P, Heyer T, Schubel P. Novel Bending Test Method for Polymer Railway Sleeper Materials. Polymers. 2021; 13(9):1359. https://doi.org/10.3390/polym13091359

Chicago/Turabian StyleSalih, Choman, Allan Manalo, Wahid Ferdous, Rajab Abousnina, Peng Yu, Tom Heyer, and Peter Schubel. 2021. "Novel Bending Test Method for Polymer Railway Sleeper Materials" Polymers 13, no. 9: 1359. https://doi.org/10.3390/polym13091359

APA StyleSalih, C., Manalo, A., Ferdous, W., Abousnina, R., Yu, P., Heyer, T., & Schubel, P. (2021). Novel Bending Test Method for Polymer Railway Sleeper Materials. Polymers, 13(9), 1359. https://doi.org/10.3390/polym13091359