Multi-Stressed Nano and Micro-Silica/Silicone Rubber Composites with Improved Dielectric and High-Voltage Insulation Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Samples

2.2. Aging Setup

2.3. Instruments and Conditions

2.3.1. Scanning Electron Microscopy (SEM)

2.3.2. Dielectric Properties

3. Results and Discussion

3.1. Dispersion of Fillers and Other Additives

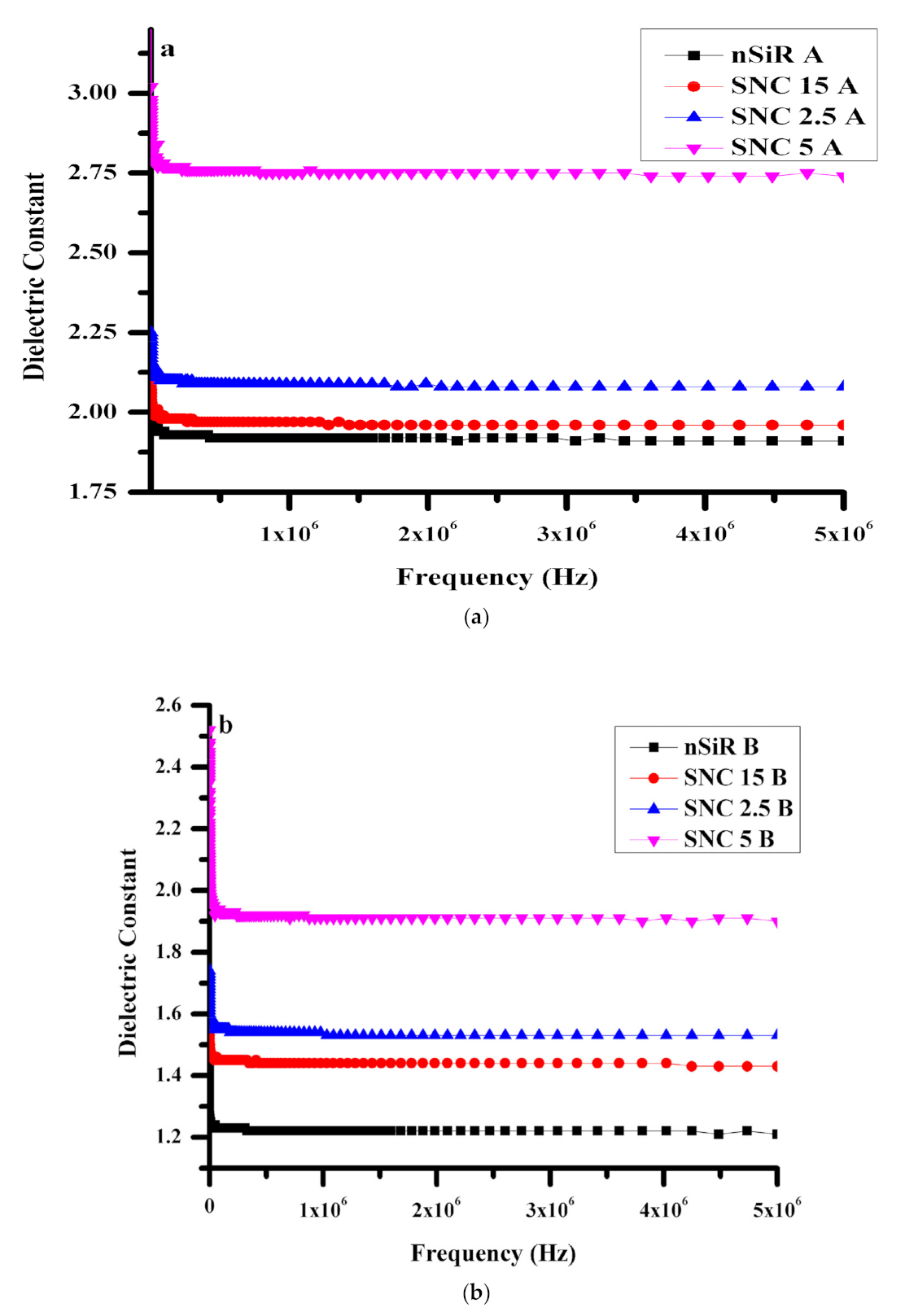

3.2. Dielectric Constant (ε′)

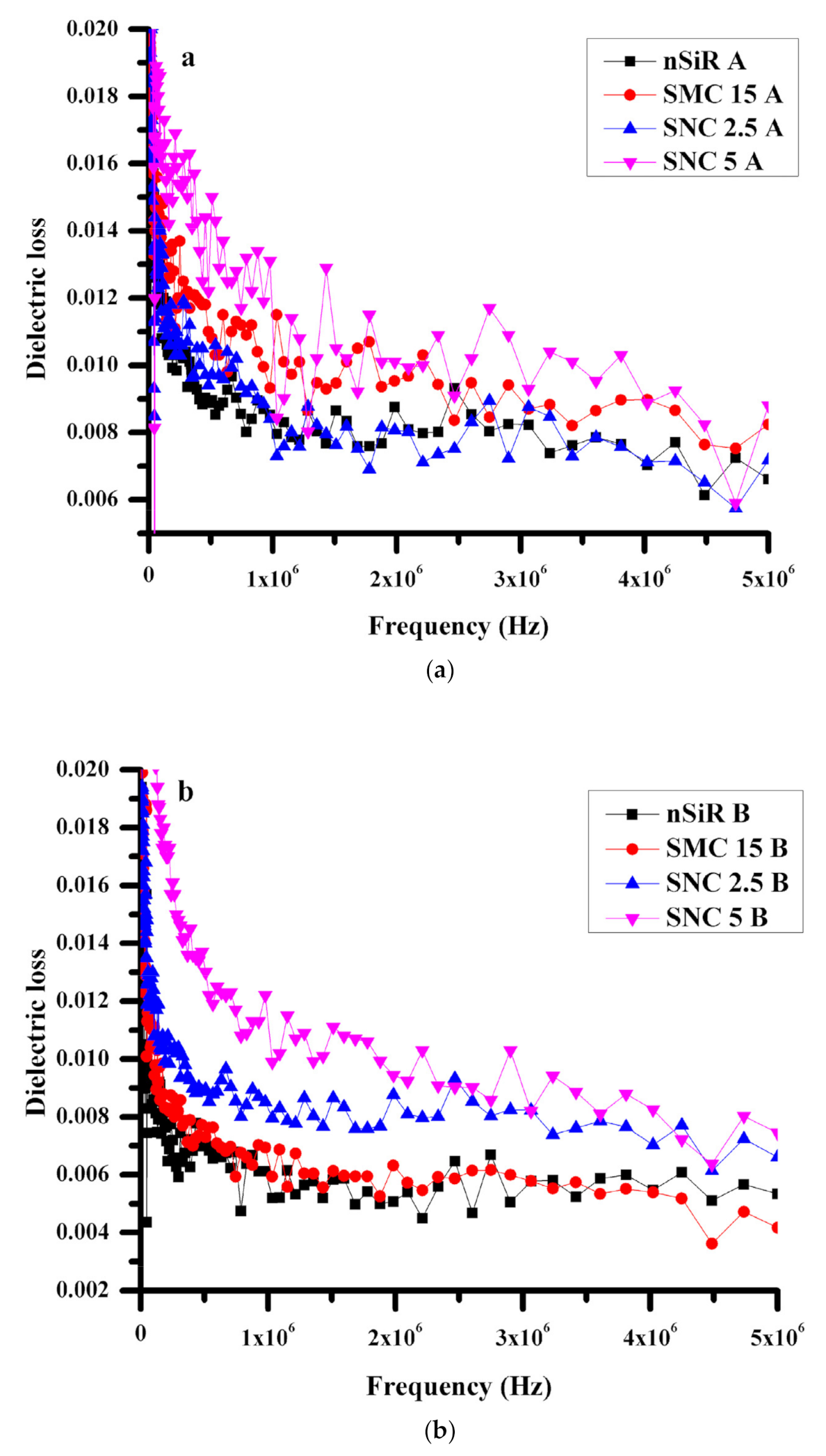

3.2.1. Dielectric Loss (ε′′)

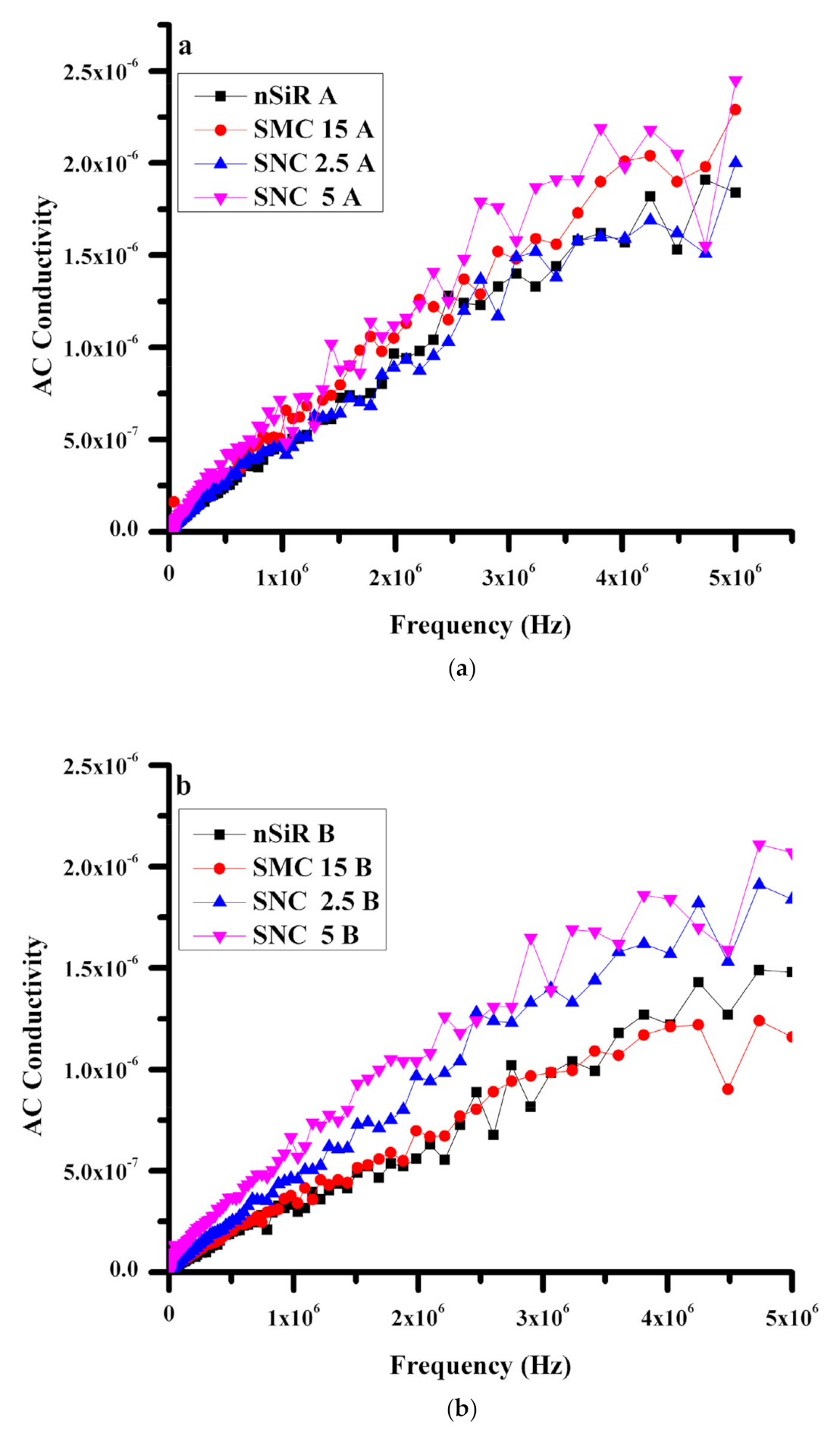

3.2.2. Conductivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barua, S.; Gogoi, S.; Khan, R.; Karak, N. Silicon-based nanomaterials and their polymer nanocomposites. In Nanomaterials and Polymer Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 261–305. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; He, X.W.; Li, W.Y.; Zhang, Y.K. Multifunctional mesoporous silica nanoplatform based on silicon nanoparticles for targeted two-photon-excited fluorescence imaging-guided chemo/photodynamic synergetic therapy in vitro. Talanta 2020, 209, 120552. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Li, S.; Akram, S.; Mehmood, M.A.; Yeoh, G.H.; Hussain, S. Effect of micro-nano additives on breakdown, surface tracking and mechanical performance of ethylene propylene diene monomer for high voltage insulation. J. Mater. Sci. Mater. Electron. 2019, 30, 14061–14071. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T. Accelerated ultraviolet weathering investigation on micro-/nano-SiO2 filled silicone rubber composites. High Volt. 2018, 3, 295–302. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Yu, S.; Zhang, Y.; Li, S. Tracking, erosion and thermal distribution of micro-AlN+ nano-SiO2 co-filled silicone rubber for high-voltage outdoor insulation. High Volt. 2018, 3, 289–294. [Google Scholar] [CrossRef]

- Dwarakanath, S.; Raj, P.M.; Kondekar, N.; Losego, M.D.; Tummala, R. Vapor phase infiltration of aluminum oxide into benzocyclobutene-based polymer dielectrics to increase adhesion strength to thin film metal interconnects. J. Vac. Sci. Technol. A Vac. Surfaces Films 2020, 38, 033210. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Yu, S.; Li, S. Effects of thermal properties on tracking and erosion resistance of micro-ATH/AlN/BN filled silicone rubber composites. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2076–2085. [Google Scholar] [CrossRef]

- Amin, M.; Khattak, A.; Ali, M. Accelerated aging investigation of silicone rubber/silica composites for coating of high-voltage insulators. Electr. Eng. 2018, 100, 217–230. [Google Scholar] [CrossRef]

- Khattak, A.; Amin, M. Influence of stresses and fillers on the aging behaviour of polymeric insulators. Rev. Adv. Mater. Sci. 2016, 44, 194–205. [Google Scholar]

- Gubanski, S.M.; Dernfalk, A.; Andersson, J.; Hillborg, H. Diagnostic methods for outdoor polymeric insulators. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 1065–1080. [Google Scholar] [CrossRef]

- Zou, W.; Zhou, G.; He, W.; Wang, S.; Hong, Y.; Chen, Y.; Zhou, J. Process, fundamental and application of one-step molten-salt synthezed BaTi2O5 nanorods. J. Alloys Compd. 2020, 826, 154064. [Google Scholar] [CrossRef]

- Reed, C.W.; Cichanowski, S.W. The Fundamentals of Aging in HV Polymer-Film Capacitors. IEEE Trans. Dielectr. Electr. Insul. 1994, 5, 904–922. [Google Scholar] [CrossRef]

- Sarjeant, W.J.; MacDougall, F.W.; Larson, D.W. Energy Storage in Polymer Laminate Structures-Ageing and Diagnostic Approaches for Life Validation. IEEE Electr. Insul. Mag. 1996, 2, 803–807. [Google Scholar] [CrossRef]

- Huang, X.Y.; Kim, C.U.; Jiang, P.K.; Yin, Y.; Li, Z. Influence of aluminum nanoparticle surface treatment on the electrical properties of polyethylene composites. J. Appl. Phys. 2009, 105, 014105. [Google Scholar] [CrossRef]

- Huang, X.Y.; Jiang, P.K.; Kim, C.U. Electrical properties of polyethylene/aluminumnanocomposites. J. Appl. Phys. 2007, 102, 124103. [Google Scholar] [CrossRef]

- Stauffer, D.; Aharony, A. Introduction to Percolation Theory; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Robertson, J.; Hall, D.A. Nonlinear dielectric properties of particulate barium titanate-polymer composites. J. Phys. 2008, 41, 115407. [Google Scholar] [CrossRef]

- Brosseau, C. Modelling and simulation of dielectric heterostructures: A physical survey from an historical perspective. J. Phys. D Appl. Phys. 2006, 39, 1277. [Google Scholar] [CrossRef]

- Starke, T.K.H.; Johnston, C.; Hill, S.; Dobson, P.; Grant, P.S. The effect of inhomogeneities in particle distribution on the dielectric properties of composite films. J. Phys. D 2006, 39, 1305. [Google Scholar] [CrossRef]

- Amin, M.; Mahmood, A.; Khattak, A. Accelerated Multi Stress Aging and Life Estimation of Polymeric Insulators. In Proceedings of the 17th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 14–18 January 2020; pp. 55–61. [Google Scholar] [CrossRef]

- Nazir, M.T.; Butt, F.T.; Phung, B.T.; Yeoh, G.H.; Yasin, G.; Akram, S.; Nguyen, T.A. Simulation and Experimental Investigation on Carbonized Tracking Failure of EPDM/BN-Based Electrical Insulation. Polymers 2020, 12, 582. [Google Scholar] [CrossRef]

- Zhang, J.; Weng, G.J.; Xia, X.; Fang, C. A theory of frequency dependence and sustained high dielectric constant in functionalized graphene-polymer nanocomposites. Mech. Mater. 2020, 144, 103352. [Google Scholar] [CrossRef]

- Sunanda, C.; Dinesh, M.N.; Vasudev, N. Ageing Study of High Voltage Insulator with Nano Fillers. Int. J. Electr. Eng. Technol. 2019, 10, 7–16. [Google Scholar] [CrossRef]

- Glaskova-Kuzmina, T.; Aniskevich, A.; Papanicolaou, G.; Portan, D.; Zotti, A.; Borriello, A.; Zarrelli, M. Hydrothermal Aging of an Epoxy Resin Filled with Carbon Nanofillers. Polymers 2020, 12, 1153. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Dao, P.H.; Nguyen, T.A.; Dang, V.H.; Ha, M.N.; Nguyen, T.T.T.; Vu, Q.T.; Nguyen, N.L.; Dang, T.C.; Nguyen-Tri, P.; et al. Photocatalytic degradation and heat reflectance recovery of waterborne acrylic polymer/ZnOnanocomposite coating. J. Appl. Polym. Sci. 2020, 49116. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Yin, Y.; Han, T. Effect of micro and nano-size boron nitride and silicone carbide on thermal properties and partial discharge resistance of silicone elastomer composite. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 377–385. [Google Scholar] [CrossRef]

- Rubab, Z.; Afzal, A.; Siddiqi, H.M.; Saeed, S. Preparation, characterization, and enhanced thermal and mechanical properties of epoxy-titania composites. Sci. World J. 2014. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, C.; An, Q.; Ou, H. Thermal properties of heat conductive silicone rubber filled with hybrid fillers. J. Compos. Mater. 2008, 42, 173–187. [Google Scholar] [CrossRef]

- Akram, S.; Ruijin, L.; Nazir, M.T.; Yang, L. Space Charge Characteristics of LDPE/MMT Nano-Composite Insulation Material under different Fields and Temperatures. Int. J. Electr. Comput. Sci. IJECS-IJENS 2012, 12, 50–56. [Google Scholar]

- Amin, M.; Khattak, A.; Ali, M. Life estimation and investigation of dielectric strength of multistressed high-voltage epoxy micro and nanocomposites. Micro Nano Lett. 2016, 11, 765–768. [Google Scholar] [CrossRef]

- Khattak, A.; Amin, M. Accelerated aging investigation of high voltage EPDM/silica composite insulators. J. Polym. Eng. 2016, 36, 199–209. [Google Scholar] [CrossRef]

- He, Q.; Wang, G.; Zhang, Y.; Li, Z.; Kong, L.; Zhou, W. Thermo-oxidative ageing behaviour of cerium oxide/silicone rubber. J. Rare Earths 2019. [Google Scholar] [CrossRef]

- Nasib AH, M.; Ahmad, M.H.; Nawawi, Z.; Sidik MA, B.; Jambak, M.I. Electrical treeing and partial discharge characteristics of silicone rubber filled with nitride and oxide based nanofillers. Int. J. Electr. Comput. Eng. 2020, 10, 1682. [Google Scholar] [CrossRef]

- Trachevskyi, V.V. Modification of Operational Characteristics of Cold Curing Silicone Rubber. J. Mater. Sci. Chem. Eng. 2019, 7, 21. [Google Scholar] [CrossRef]

- Gonon, P.; Sylvestre, A.; Teysseyre, J.; Prior, C. Dielectric properties of epoxy/silica composites used for microlectronic packaging, and their dependence on post-curing. J. Mater. Sci. Mater. Electr. 2001, 12, 81–86. [Google Scholar] [CrossRef]

- Peng, C.C.; Göpfert, A.; Drechsler, M.; Abetz, V. “Smart” silica-rubber nanocomposites in virtue of hydrogen bonding interaction. Polym. Adv. Technol. 2005, 16, 770–782. [Google Scholar] [CrossRef]

- Akram, S.; Castellon, J.; Agnel, S.; Zhou, K.; Habas, J.P.; Nazir, M.T. Multilayer polyimide nanocomposite films synthesis process optimization impact on nanoparticles dispersion and their dielectric performance. J. Appl. Polym. Sci. 2021, 138, 49715. [Google Scholar] [CrossRef]

- Zhang, W.; Blackburn, R.S.; Dehghani-Sanij, A. Electrical conductivity of epoxy resin–carbon black–silica nanocomposites: Effect of silica concentration and analysis of polymer curing reaction by FTIR. Scriptamaterialia 2007, 57, 949–952. [Google Scholar] [CrossRef]

- Akram, S.; Castellon, J.; Agnel, S.; Habas, J.P.; Kai, Z.; Nazir, M.T. Impact of Nanocomposite Thin Layer on Nanoparticles Dispersion and their Dielectric Properties. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Richland, WA, USA, 20–23 October2019; pp. 336–339. [Google Scholar] [CrossRef]

- Khattak, A. Long Term Multistress Aging of High VoltageNanocomposites. Ph.D. Thesis, COMSATS Institute of Information Technology, Islamabad, Pakistan, 2017. [Google Scholar]

- Akram, S.; Nazir, M.T.; Castellon, J.; Agnel, S.; Zhou, K.; Bhutta, M.S. Preparation and distinguish dielectric properties of multi-layer nanoparticles-based polyimide films. Mater. Res. Express 2019, 6, 125092. [Google Scholar] [CrossRef]

- Khattak, A.; Amin, M.; Iqbal, M.; Abbas, N. Life estimation and analysis of dielectric strength, hydrocarbon backbone and oxidation of high voltage multi stressed EPDM composites. Mater. Res. Express 2018, 5, 025003. [Google Scholar] [CrossRef]

- Amin, M.; Ali, M.; Khattak, A. Fabrication, mechanical, thermal, and electrical characterization of epoxy/silica composites for high-voltage insulation. Sci. Eng. Compos. Mater. 2018, 25, 753–759. [Google Scholar] [CrossRef]

- Akram, S.; Wang, P.; Nazir, M.T.; Zhou, K.; Bhutta, M.S.; Hussain, H. Impact of impulse voltage frequency on the partial discharge characteristic of electric vehicles motor insulation. Eng. Fail. Anal. 2020, 104767. [Google Scholar] [CrossRef]

- Afzal, A.; Siddiqi, H.M.; Iqbal, N.; Ahmad, Z. The effect of SiO 2 filler content and its organic compatibility on thermal stability of epoxy resin. J. Therm. Anal. Calorim. 2013, 111, 247–252. [Google Scholar] [CrossRef]

- Amin, M.; Khattak, A.; Ali, M. Influence of silica (SiO2) loading on the thermal and swelling properties of hydrogenated-nitrile-butadiene-rubber/silica (HNBR/Silica) composites. Open Eng. 2018, 8, 205–212. [Google Scholar] [CrossRef]

- Nair, A.B.; George, N.; Joseph, R. Non-linear viscoelastic behaviour of rubber-rubber blend composites and nanocomposites: Effect of spherical, layered and tubular fillers. In Non-Linear Viscoelasticity of Rubber Composites and Nanocomposites; Springer: Cham, Switzerland, 2014; pp. 85–134. [Google Scholar]

- Yasin, S.; Hussain, M.; Zheng, Q.; Song, Y. Large amplitude oscillatory rheology of silica and cellulose nanocrystals filled natural rubber compounds. J. Colloid Interface Sci. 2020. [Google Scholar] [CrossRef]

- Yasin, S.; Hussain, M.; Zheng, Q.; Song, Y. Effects of ionic liquid on cellulosic nanofiller filled natural rubber bionanocomposites. J. Colloid Interface Sci. 2021, 591, 409–417. [Google Scholar] [CrossRef]

- Fröhlich, J.; Niedermeier, W.; Luginsland, H.D. The effect of filler–filler and filler–elastomer interaction on rubber reinforcement. Compos. Part A Appl. Sci. Manuf. 2005, 36, 449–460. [Google Scholar] [CrossRef]

- Singha, S.; Thomas, M.J. Dielectric properties of epoxy nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 12–23. [Google Scholar] [CrossRef]

- Akram, S.; Castellon, J.; Kai, Z.; Agnel, S.; Habas, J.P.; Nazir, M.T. Dielectric properties and modeling of multilayer polyimide nanocomposite to highlight the impact of nanoparticles dispersion. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1238–1246. [Google Scholar] [CrossRef]

- Ashiq, M.N.; Iqbal, M.J.; Gul, I.H. Structural, magnetic and dielectric properties of Zr–Cd substituted strontium hexaferrite (SrFe12O19) nanoparticles. J. Alloys Compd. 2009, 487, 341–345. [Google Scholar] [CrossRef]

- Hussain, M.; Yasin, S.; Memon, H.; Li, Z.; Fan, X.; Akram, M.A.; Zheng, Q. Rheological and Mechanical Properties of Silica/Nitrile Butadiene Rubber Vulcanizates with Eco-Friendly Ionic Liquid. Polymers 2020, 12, 2763. [Google Scholar] [CrossRef] [PubMed]

| Sample | Code |

|---|---|

| Neat SiR | NS |

| SiR with 15% micro-silica | SMC15 |

| SiR with 2.5% nano-silica | SNC2.5 |

| SiR with 5% nano-silica | SNC5 |

| Applied Stress | Summer | Winter |

|---|---|---|

| Test voltage | 2.5 kV | 2.5 kV |

| Length of cycle (days) | 11 | 17 |

| Temperature (°C) | 47.2 | 35.3 |

| Ultraviolet-A (hours) | 10 | 8 |

| Acid rain (4.5 pH) | 6 times | 2 times |

| Salt fog (5000 µS/cm) | 0 times | 4 times |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faiza; Khattak, A.; Rehman, A.U.; Ali, A.; Mahmood, A.; Imran, K.; Ulasyar, A.; Sheh Zad, H.; Ullah, N.; Khan, A. Multi-Stressed Nano and Micro-Silica/Silicone Rubber Composites with Improved Dielectric and High-Voltage Insulation Properties. Polymers 2021, 13, 1400. https://doi.org/10.3390/polym13091400

Faiza, Khattak A, Rehman AU, Ali A, Mahmood A, Imran K, Ulasyar A, Sheh Zad H, Ullah N, Khan A. Multi-Stressed Nano and Micro-Silica/Silicone Rubber Composites with Improved Dielectric and High-Voltage Insulation Properties. Polymers. 2021; 13(9):1400. https://doi.org/10.3390/polym13091400

Chicago/Turabian StyleFaiza, Abraiz Khattak, Aqeel Ur Rehman, Asghar Ali, Azhar Mahmood, Kashif Imran, Abasin Ulasyar, Haris Sheh Zad, Nasim Ullah, and Adam Khan. 2021. "Multi-Stressed Nano and Micro-Silica/Silicone Rubber Composites with Improved Dielectric and High-Voltage Insulation Properties" Polymers 13, no. 9: 1400. https://doi.org/10.3390/polym13091400

APA StyleFaiza, Khattak, A., Rehman, A. U., Ali, A., Mahmood, A., Imran, K., Ulasyar, A., Sheh Zad, H., Ullah, N., & Khan, A. (2021). Multi-Stressed Nano and Micro-Silica/Silicone Rubber Composites with Improved Dielectric and High-Voltage Insulation Properties. Polymers, 13(9), 1400. https://doi.org/10.3390/polym13091400