Mechanical Properties, Wettability and Thermal Degradation of HDPE/Birch Fiber Composite

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of the Composite Material

2.1.1. Materials

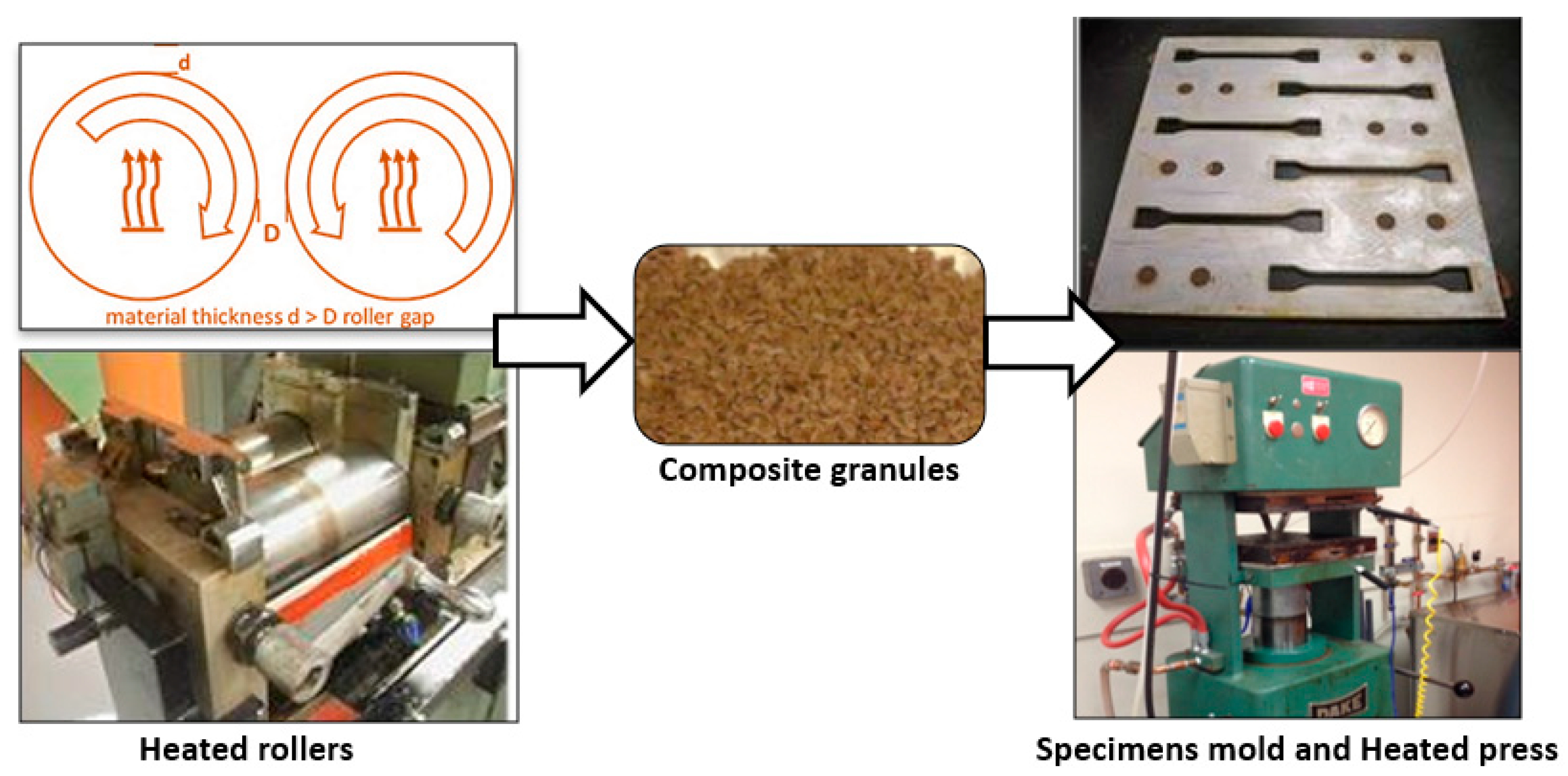

2.1.2. Compounding

2.1.3. Compression Molding

2.2. Mechanical Characterization

2.3. Surface Energy Measurement

2.4. Thermogravimetric Analysis (TGA)

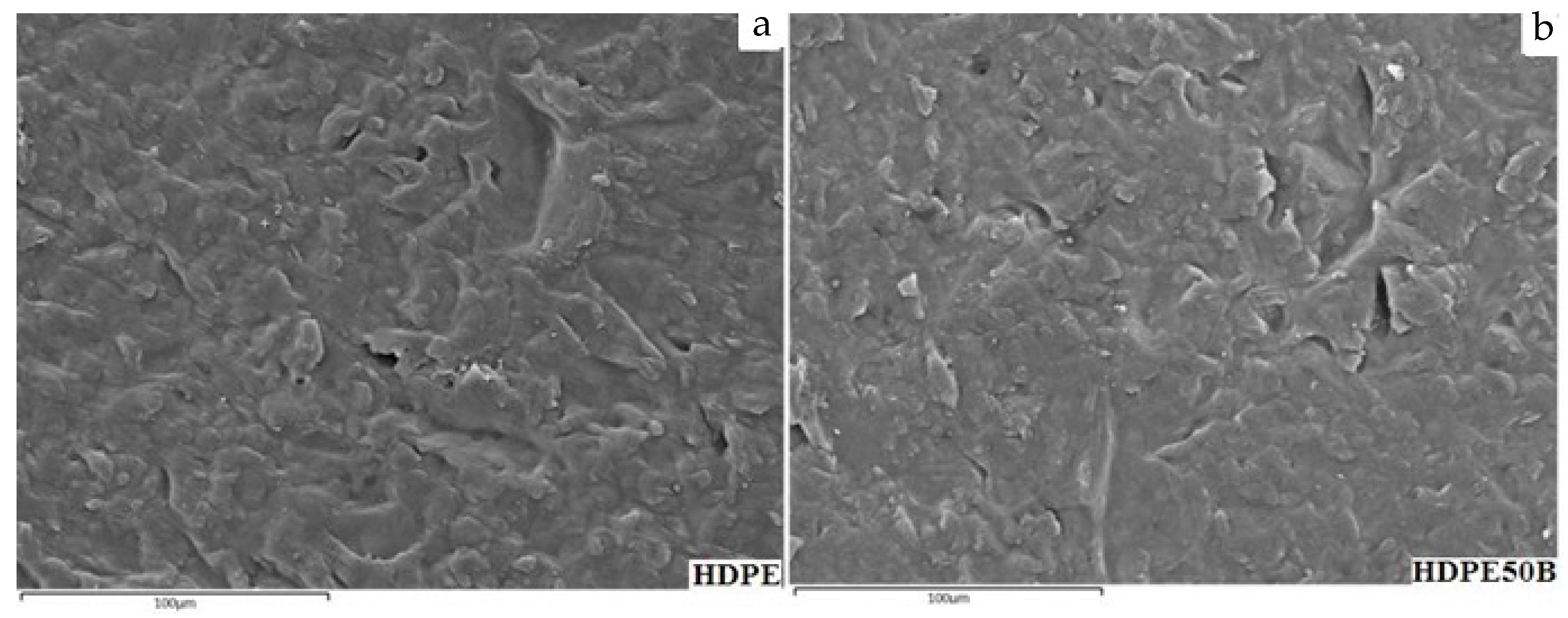

2.5. Scanning Electron Microscopy

2.6. Dynamic Thermomechanical Analysis

2.7. Differential Scanning Calorimetry (DSC)

3. Results and Discussion

3.1. Mechanical Characterization

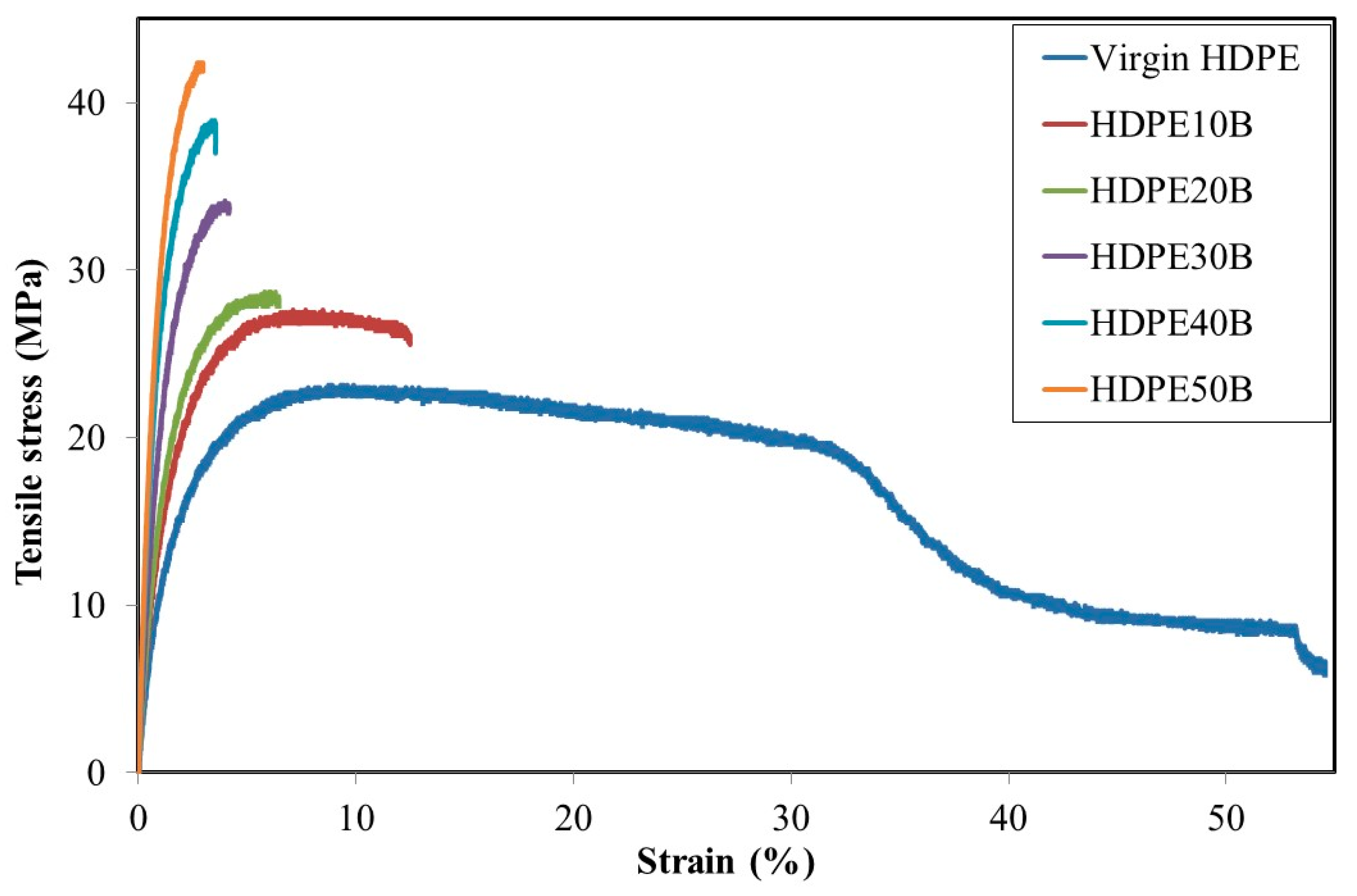

3.1.1. Tensile Test

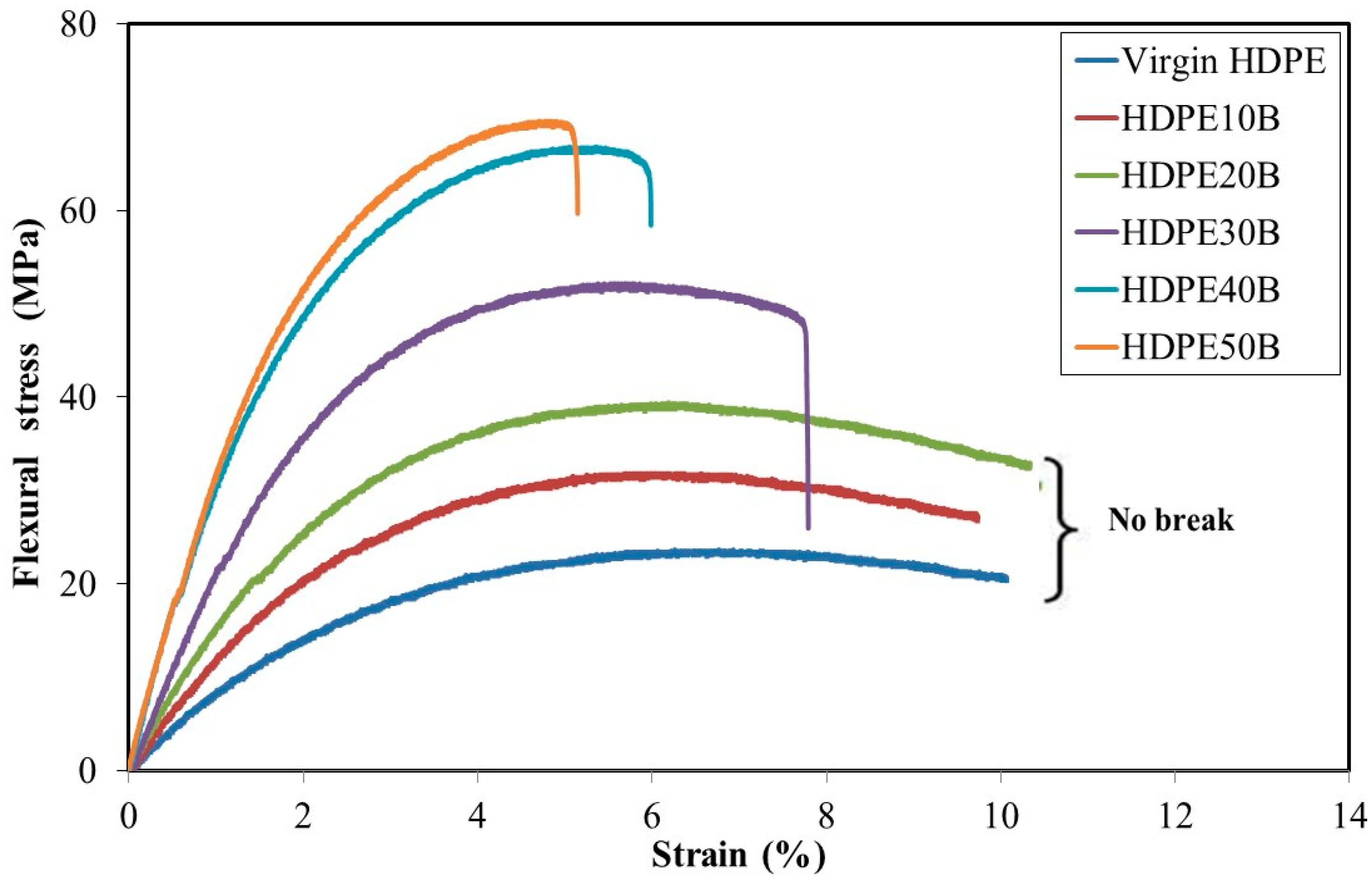

3.1.2. Bending Test

3.2. Wettability and Surface Energy

3.3. Thermogravimetric Analysis

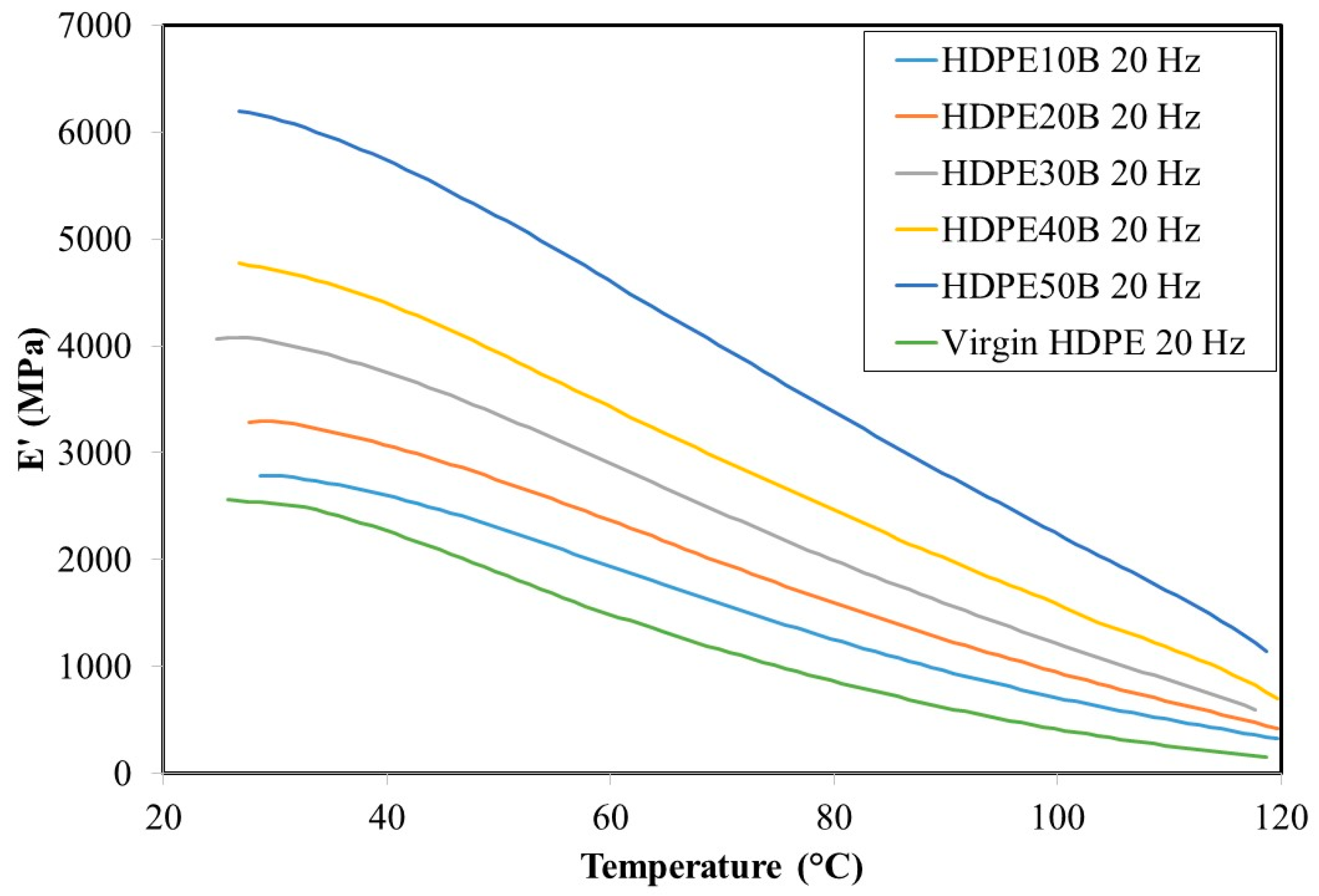

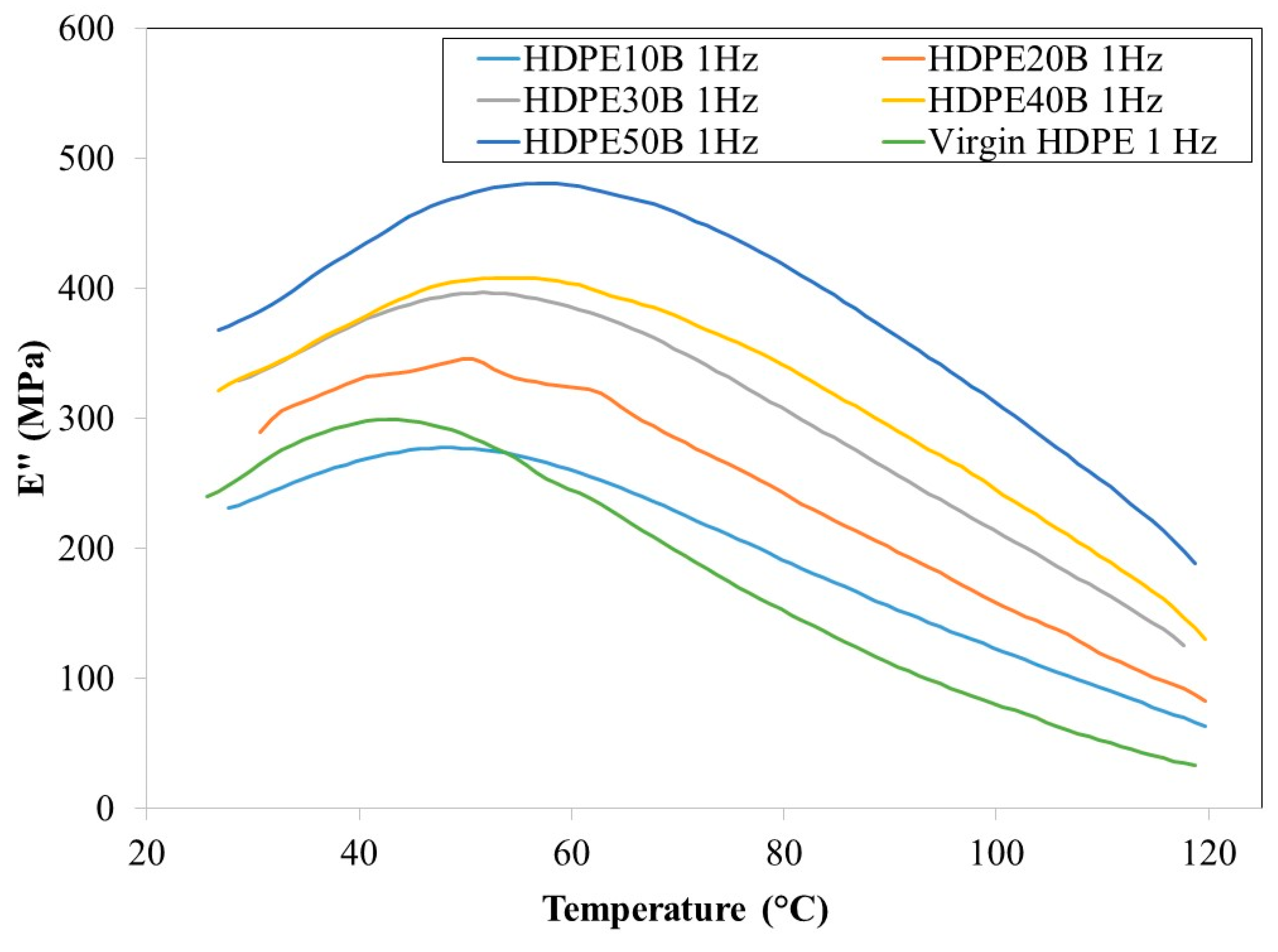

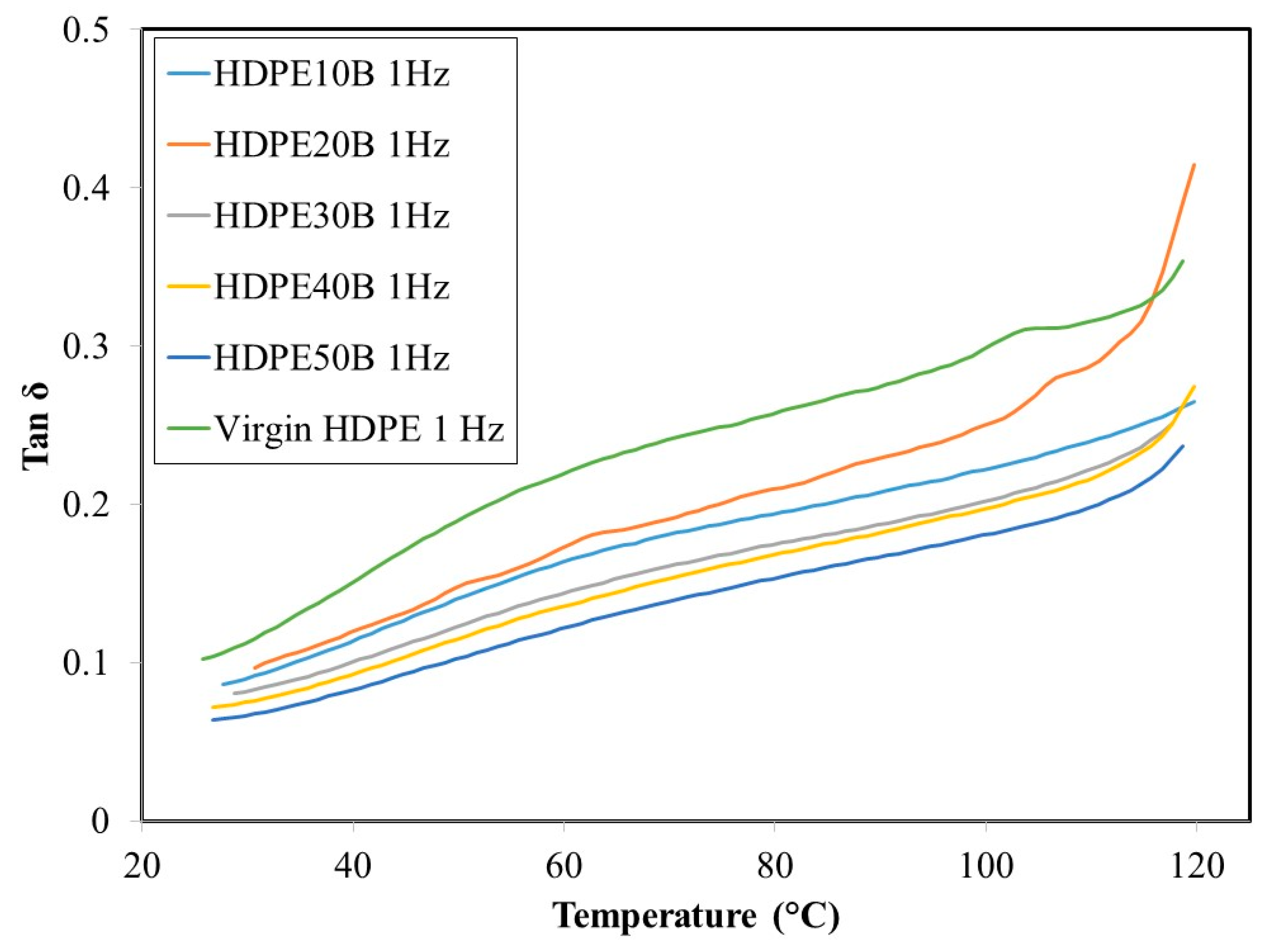

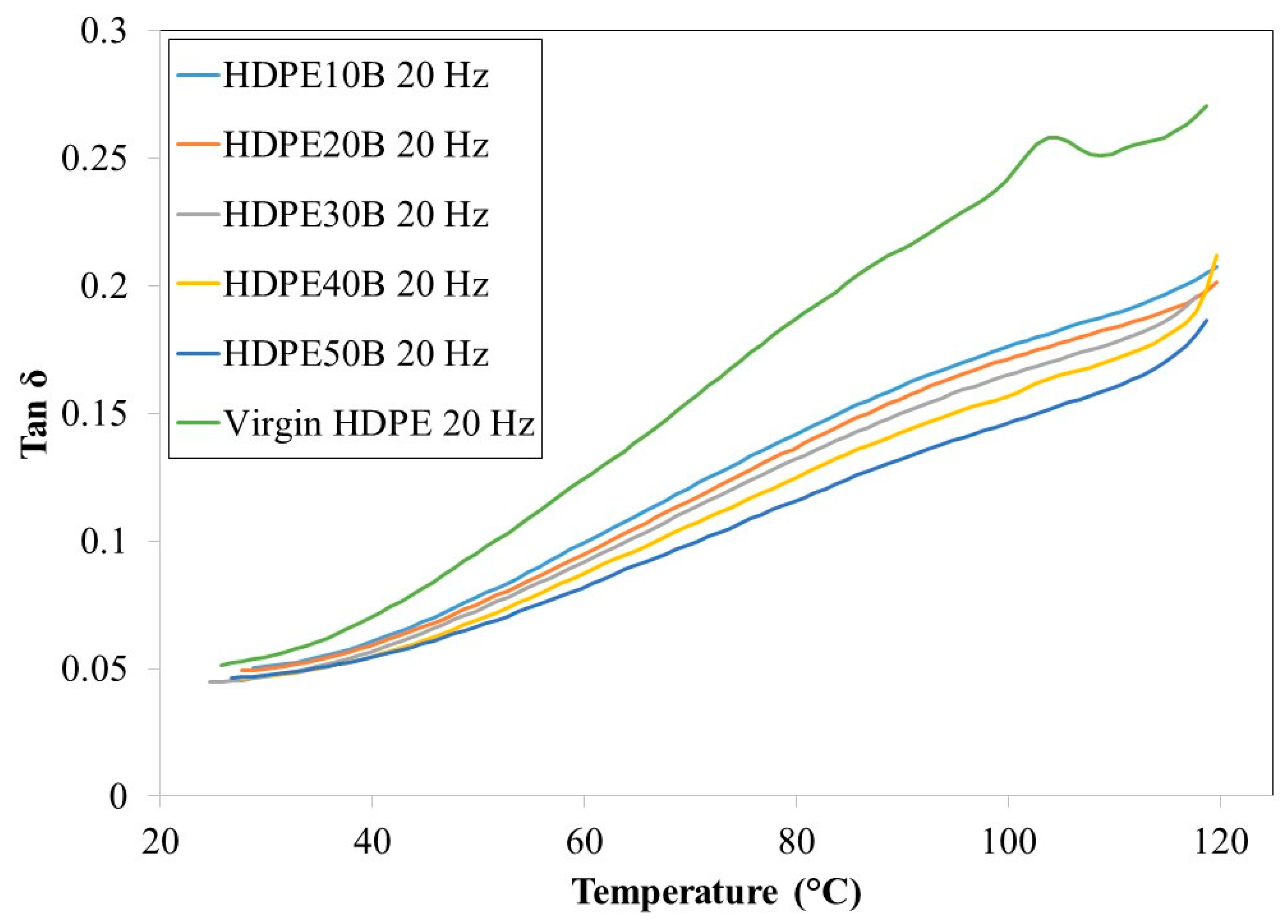

3.4. Dynamic Mechanical Analysis

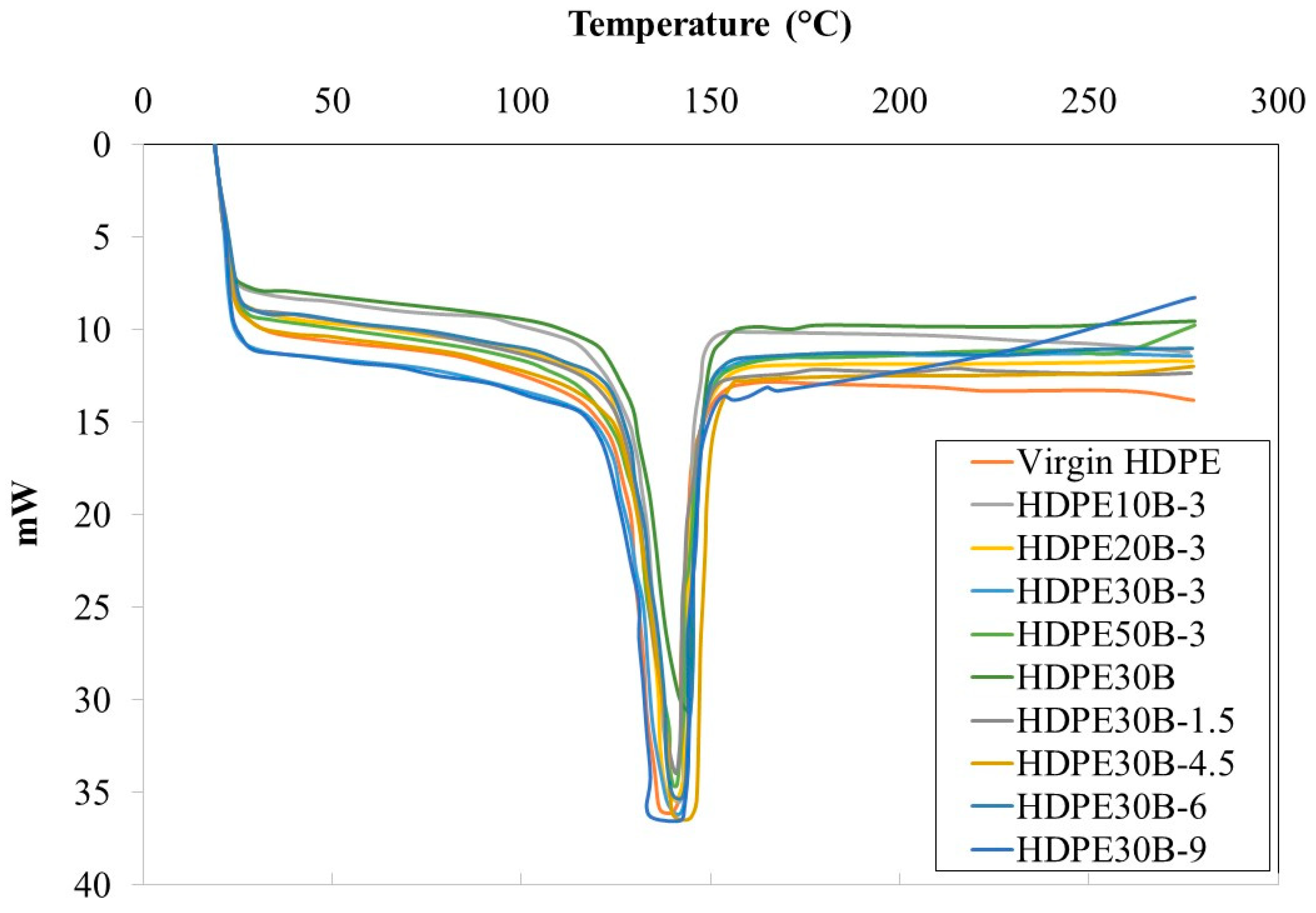

3.5. Differential Scanning Calorimetry

4. Conclusions

- The elastic modulus, the storage modulus, the loss modulus and the ultimate strength increase as a more or less linear function of the fiber content.

- The elastic modulus can be increased by over 200%, the flexural strength by 180%.

- The tensile strength and the flexural modulus are indifferent to the fiber content.

- Birch fiber has little impact on the material surface energy; the matrix remains the principal determinant of the surface properties.

- Birch fiber degrades at a lower temperature than does HDPE, giving rise to two peaks on the composite material thermal breakdown curves. The mass loss at a given temperature increases with the initial fiber content.

- Neither the birch fiber content nor the coupling agent content affects the melting temperature of the material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2006, 103, 2432–2441. [Google Scholar] [CrossRef]

- Friedrich, K.; Akpan, E.I.; Wetzel, B. Structure and mechanical/abrasive wear behavior of a purely natural composite: Black-fiber palm wood. J. Mater. Sci. 2017, 52, 10217–10229. [Google Scholar] [CrossRef]

- Huang, L.; Wu, Q.; Li, S. Toughness and crystallization enhancement in wood fiber-reinforced polypropylene composite through controlling matrix nucleation. J. Mater. Sci. 2018, 53, 6542–6551. [Google Scholar] [CrossRef]

- Arrakhiz, F.; El Achaby, M.; Benmoussa, K.; Bouhfid, R.; Essassi, E.; Qaiss, A. Evaluation of mechanical and thermal properties of Pine cone fibers reinforced compatibilized polypropylene. Mater. Des. 2012, 40, 528–535. [Google Scholar] [CrossRef]

- Freedonia Group. Natural Fiber Composites (NFC) Market Size, Share & Trends Analysis Report by Raw Material, by Matrix, by Technology (Injection Molding, Compression Molding, Pultrusion), by Application, and Segment Forecasts, 2018–2024. Available online: https://www.marketresearch.com/Grand-View-Research-v4060/Natural-Fiber-Composites-NFC-Size-11657062/ (accessed on 5 July 2020).

- Selke, S.E.; Wichman, I. Wood fiber/polyolefin composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 321–326. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, H.; Lu, F. Bamboo fibers for composite applications: A mechanical and morphological investigation. J. Mater. Sci. 2014, 49, 2559–2566. [Google Scholar] [CrossRef]

- Mijiyawa, F.; Koffi, D.; Kokta, B.V.; Erchiqui, F. Formulation and tensile characterization of wood–plastic composites Polypropylene reinforced by birch and aspen fibers for gear applications. J. Thermoplast. Compos. Mater. 2014, 28, 1675–1692. [Google Scholar] [CrossRef]

- Mejri, M.; Toubal, L.; Cuillière, J.C.; François, V. Hygrothermal aging effects on mechanical and fatigue behaviors of a short-natural-fiber-reinforced composite. Int. J. Fatigue 2018, 108, 96–108. [Google Scholar] [CrossRef]

- Toubal, L.; Cuillière, J.C.; Bensalem, K.; Francois, V.; Gning, P.B. Hygrothermal effect on moisture kinetics and mechanical properties of hemp/polypropylene composite: Experimental and numerical studies. Polym. Compos. 2016, 37, 2342–2352. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Choi, P. Effects of wood fiber content and coupling agent content on tensile properties of wood fiber polyethylene composites. Holz Roh-Und Werkst. 2008, 66, 267–274. [Google Scholar] [CrossRef]

- Habibi, Y.; El-Zawawy, W.K.; Ibrahim, M.M.; Dufresne, A. Processing and characterization of reinforced polyethylene composites made with lignocellulosic fibers from Egyptian agro-industrial residues. Compos. Sci. Technol. 2008, 68, 1877–1885. [Google Scholar] [CrossRef] [Green Version]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Krause, C. Effect of fiber length on processing and properties of extruded wood-fiber/HDPE composites. J. Appl. Polym. Sci. 2008, 110, 1085–1092. [Google Scholar] [CrossRef] [Green Version]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Effects of processing method and fiber size on the structure and properties of wood–plastic composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 80–85. [Google Scholar] [CrossRef]

- Fernando, S.; Mallinson, C.F.; Phanopolous, C. Mechanical characterisation of fibres for engineered wood products: A scanning force microscopy study. J. Mater. Sci. 2017, 52, 5072–5082. [Google Scholar] [CrossRef]

- Lee, B.J.; McDonald, A.G.; James, B. Influence of fiber length on the mechanical properties of wood-fiber/polypropylene prepreg sheets. Mater. Res. Innov. 2001, 4, 97–103. [Google Scholar] [CrossRef]

- Yemele, M.C.N.; Koubaa, A.; Cloutier, A.; Soulounganga, P.; Wolcott, M. Effect of bark fiber content and size on the mechanical properties of bark/HDPE composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 131–137. [Google Scholar] [CrossRef]

- Tisserat, B.; Reifschneider, L.; Joshee, N.; Finkenstadt, V.L. Properties of high density polyethylene–Paulownia wood flour composites via injection molding. BioResources 2013, 8, 4440–4458. [Google Scholar] [CrossRef] [Green Version]

- Aggarwal, P.K.; Chauhan, S.; Gowda, R.N.; Karmarkar, S.; Shashidhara, G. Mechanical properties of bio-fibers-reinforced high-density polyethylene composites: Effect of coupling agents and bio-fillers. J. Reinf. Plast. Compos. 2013, 32, 1722–1732. [Google Scholar] [CrossRef]

- Liu, T.; Lei, Y.; Wang, Q.; Lee, S.; Wu, Q. Effect of Fiber Type and Coupling Treatment on Properties of High-Density Polyethylene/Natural Fiber Composites. BioResources 2013, 8, 4619–4632. [Google Scholar] [CrossRef]

- Mirmehdi, S.M.; Zeinaly, F.; Dabbagh, F. Date palm wood flour as filler of linear low-density polyethylene. Compos. Part B Eng. 2014, 56, 137–141. [Google Scholar] [CrossRef]

- Li, Y. Effect of coupling agent concentration, fiber content, and size on mechanical properties of wood/HDPE composites. Int. J. Polym. Mater. Polym. Biomater. 2012, 61, 882–890. [Google Scholar] [CrossRef] [Green Version]

- Gu, R.; Kokta, B.V.; Chalupova, G. Effect of variables on the mechanical properties and maximization of polyethylene-aspen composites by statistical experimental design. J. Thermoplast. Compos. Mater. 2009, 22, 633–649. [Google Scholar] [CrossRef]

- Ashori, A.; Matini Behzad, H.; Tarmian, A. Effects of chemical preservative treatments on durability of wood flour/HDPE composites. Compos. Part B Eng. 2013, 47, 308–313. [Google Scholar] [CrossRef]

- Hamzeh, Y.; Ashori, A.; Marvast, E.H.; Rashedi, K.; Olfat, A.M. A comparative study on the effects of Coriolus versicolor on properties of HDPE/wood flour/paper sludge composites. Compos. Part B Eng. 2012, 43, 2409–2414. [Google Scholar] [CrossRef]

- Schirp, A.; Mannheim, M.; Plinke, B. Influence of refiner fibre quality and fibre modification treatments on properties of injection-moulded beech wood–plastic composites. Compos. Part A Appl. Sci. Manuf. 2014, 61, 245–257. [Google Scholar] [CrossRef]

- Raj, R.; Kokta, B.; Maldas, D.; Daneault, C. Use of wood fibers in thermoplastics. VII. The effect of coupling agents in polyethylene–wood fiber composites. J. Appl. Polym. Sci. 1989, 37, 1089–1103. [Google Scholar] [CrossRef]

- Liao, B.; Huang, Y.; Cong, G. Influence of modified wood fibers on the mechanical properties of wood fiber-reinforced polyethylene. J. Appl. Polym. Sci. 1997, 66, 1561–1568. [Google Scholar] [CrossRef]

- Bravo, A.; Toubal, L.; Koffi, D.; Erchiqui, F. Damage characterization of bio and green polyethylene–birch composites under creep and cyclic testing with multivariable acoustic emissions. Materials 2015, 8, 7322–7341. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Application of micromechanical models to tensile properties of wood-plastic composites. Wood Sci. Technol. 2011, 45, 521–532. [Google Scholar] [CrossRef]

- Hwang, C.Y.; Hse, C.Y.; Shupe, T.F. Effects of raw materials on the properties of wood fiber-polyethylene composites—Part 3: Effect of a compatibilizer and wood adhesive on the interfacial adhesion of wood/plastic composites. For. Prod. J. 2008, 58, 66–72. [Google Scholar]

- Hwang, C.Y.; Hse, C.Y.; Shupe, T.F. Effects of recycled materials on the properties of wood fiber-polyethylene composites—Part 2: Effect of a compatibilizer on the wettability of birch plywood and polyolefins. For. Prod. J. 2007, 57, 80–84. [Google Scholar]

- Gosselin, R.; Rodrigue, D.; Riedl, B. Injection molding of postconsumer wood-plastic composites II: Mechanical properties. J. Thermoplast. Compos. Mater. 2006, 19, 659–669. [Google Scholar] [CrossRef]

- Bravo, A.; Toubal, L.; Koffi, D.; Erchiqui, F. Development of novel green and biocomposite materials: Tensile and flexural properties and damage analysis using acoustic emission. Mater. Des. 2015, 66, 16–28. [Google Scholar] [CrossRef] [Green Version]

- Noorunnisa, K.P.; Mariam, A.; Ali, A. Processing and characterization of polyethylenebased composites, Advanced Manufacturing. Polym. Compos. Sci. 2015, 1, 63–79. [Google Scholar]

- Huang, X.; Ke, Q.; Kim, C.; Zhong, H.; Wei, P.; Wang, G.; Liu, F.; Jiang, P. Nonisothermal crystallization behavior and nucleation of LDPE/Al nano- and microcomposites. Polym. Eng. Sci. 2007, 47, 1052–1061. [Google Scholar] [CrossRef]

- Koffi, A.; Koffi, D.; Toubal, L. Injection Molding Parameters Influence on PE Composites Parts. Int. J. Eng. Res. Dev. 2016, 12, 29–39. [Google Scholar]

- ISO Standard. Plastics—Determination of tensile properties—Part 2: Test conditions for moulding and extrusion plastics. Ref. ISO 2012, 527, 2. [Google Scholar]

- ASTM D790-10. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ISO 527-1:2012. Plastics—Determination of Tensile Properties—Part 1: General Principles; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- Cantero, G.; Arbelaiz, A.; Llano-Ponte, R.; Mondragon, I. Effects of fibre treatment on wettability and mechanical behaviour of flax/polypropylene composites. Compos. Sci. Technol. 2003, 63, 1247–1254. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M. Performance of biocomposites from surface modified regenerated cellulose fibers and lactic acid thermoset bioresin. Cellulose 2015, 22, 2507–2528. [Google Scholar] [CrossRef] [Green Version]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the elastic modulus of natural fibre reinforced thermoplastics. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1660–1671. [Google Scholar] [CrossRef]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the tensile strength of natural fibre reinforced thermoplastics. Compos. Sci. Technol. 2007, 67, 2454–2466. [Google Scholar] [CrossRef]

- Xue, Y.; Veazie, D.R.; Glinsey, C.; Horstemeyer, M.F.; Rowell, R.M. Environmental effects on the mechanical and thermomechanical properties of aspen fiber-polypropylene composites. Compos. Part B Eng. 2007, 38, 152–158. [Google Scholar] [CrossRef]

- Kuan, C.F.; Kuan, H.C.; Ma, C.C.M.; Huang, C.M. Mechanical, thermal and morphological properties of water-crosslinked wood flour reinforced linear low-density polyethylene composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1696–1707. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, W.; Wang, Q.; Wang, H. Application of mechanical models to flax fiber /wood fiber/ plastic composites. BioResources 2013, 8, 3276–3288. [Google Scholar] [CrossRef]

- Cui, Y.H.; Tao, J.; Noruziaan, B.; Cheung, M.; Lee, S. DSC analysis and mechanical properties of wood-plastic composites. J. Reinf. Plast. Compos. 2010, 29, 278–289. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Jakab, E.; Faix, O.; Till, F. Thermal decomposition of milled wood lignins studied by thermogravimetry/mass spectrometry. J. Anal. Appl. Pyrolysis 1997, 40–41, 171–186. [Google Scholar] [CrossRef]

- Mijiyawa, F.; Koffi, D.; Kokta, B.V.; Erchiqui, F. Effects of wood fibers on tensile properties, wettability and thermal degradation behaviour of polyethylene-wood composites. In Proceedings of the Polymer Processing Society PPS, Nuremberg, Germany, 15–19 July 2013. [Google Scholar]

- Min, K.; Yang, B.; Miao, J.-B.; Xia, R.; Chen, P.; Qian, J.-S. Thermorheological Properties and Thermal Stability of Polyethylene/Wood Composites. J. Macromol. Sci. Part B 2013, 52, 1100–1112. [Google Scholar] [CrossRef]

- Lu, N.; Oza, S. Thermal stability and thermo-mechanical properties of hemp-high density polyethylene composites: Effect of two different chemical modifications. Compos. Part B Eng. 2013, 44, 484–490. [Google Scholar] [CrossRef]

- Sewda, K.; Maiti, S. Dynamic mechanical properties of high density polyethylene and teak wood flour composites. Polym. Bull. 2013, 70, 2657–2674. [Google Scholar] [CrossRef]

- Ndlovu, S.S.; van Reenen, A.J.; Luyt, A.S. LDPE-wood composites utilizing degraded LOPE as compatibilizer. Compos. Part A Appl. Sci. Manuf. 2013, 51, 80–88. [Google Scholar] [CrossRef]

- Liu, T.; Ju, J.; Chen, F.; Wu, B.; Yang, J.; Zhong, M.; Peng, X.; Kuang, T. Superior mechanical performance of in-situ nanofibrillar HDPE/PTFE composites with highly oriented and compacted nanohybrid shish-kebab structure. Compos. Sci. Technol. 2021, 207, 108715. [Google Scholar] [CrossRef]

- Liu, T.; Huang, K.; Li, L.; Gu, Z.; Lui, X.; Peng, X.; Kuang, T. High performance high-density polyethylene/hydroxyapatite nanocomposites for load-bearing bone substitute: Fabrication, in vitro and in vivo biocompatibility evaluation. Compos. Sci. Technol. 2019, 175, 100–110. [Google Scholar] [CrossRef]

| Dimension | Measured |

|---|---|

| Mean length: L (mm) | 0.49 |

| Mean width: D (µm) | 24.7 |

| Aspect ratio: L/D | 19.79 |

| Fiber count | 5000 |

| Nomenclature | Fiber Content (%) | Tensile Properties | Flexural Properties | ||||

|---|---|---|---|---|---|---|---|

| Modulus (GPa) | Strength (MPa) | Strain at Break (%) | Modulus (GPa) | Strength (MPa) | Strain at Break (%) | ||

| Virgin HDPE | 0 | 1.34 (±0.06) | 22 (±0.85) | No break | 1.04 (±0.16) | 23.90 (±0.93) | No break |

| HDPE10B | 10 | 1.71 (±0.05) | 27.07 (±0.52) | 10.76 (±1.88) | 1.39 (±0.09) | 33.19 (±2.93) | No break |

| HDPE20B | 20 | 1.83 (±0.44) | 28.53 (±0.48) | 6.60 (±0.24) | 1.99 (±0.19) | 42.40 (±2.15) | No break |

| HDPE30B | 30 | 2.7 (±0.10) | 34.98 (±1.70) | 3.85 (±0.57) | 2.38 (±0.26) | 50.49 (±1.12) | 8.23 (±0.53) |

| HDPE40B | 40 | 3.45 (±0.33) | 38.05 (±2.83) | 3.57 (±0.037) | 3.22 (±0.32) | 63.83 (±2.01) | 5.44 (±0.54) |

| HDPE50B | 50 | 4.19 (±0.40) | 42.65 (±3.2) | 2.76 (±0.46) | 3.47 (±0.41) | 66.70 (±3.58) | 4.95 (±0.23) |

| Nomenclature | Fiber Content (%) | Contact Angle (°) | Surface Energy (mJ m−2) | ||||

|---|---|---|---|---|---|---|---|

| Water | Bromo | Owens-Wendt | Zisman | ||||

| Disp. | Polar | Total | Total | ||||

| Virgin HDPE | 0 | 110.70 (±2.05) | 41 (±0.00) | 33.90 | 0.00 | 33.90 | 38.11 |

| HDPE10B | 10 | 100.00 (±2.24) | 27.50 (±1.12) | 39.52 | 0.01 | 39.53 | 42.37 |

| HDPE20B | 20 | 106.60 (±1.96) | 31.80 (±2.28) | 37.83 | 0.00 | 37.83 | 40.65 |

| HDPE30B | 30 | 101.00 (±1.41) | 33.00 (±1.87) | 37.53 | 0.01 | 37.54 | 39.95 |

| HDPE40B | 40 | 84.8 (±1.92) | 33.50 (±1.80) | 37.33 | 2.45 | 39.78 | 38.05 |

| HDPE50B | 50 | 92.2 (±1.24) | 38.30 (±1.89) | 35.36 | 1.03 | 36.39 | 36.97 |

| Nomenclature | Material | First Peak (°C) | Second Peak (°C) | Fiber Rmax (%/s) | HDPE Rmax (%/s) |

|---|---|---|---|---|---|

| Virgin HDPE | HDPE | None | 475 | - | 0.33 |

| B | Birch fiber | 360 | None | 0.14 | - |

| HDPE10B | HDPE + 10 * | 350 | 470 | 0.03 | 0.29 |

| HDPE30B | HDPE + 30 * | 353 | 476 | 0.04 | 0.19 |

| HDPE50B | HDPE + 50 * | 360 | 475 | 0.05 | 0.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koffi, A.; Mijiyawa, F.; Koffi, D.; Erchiqui, F.; Toubal, L. Mechanical Properties, Wettability and Thermal Degradation of HDPE/Birch Fiber Composite. Polymers 2021, 13, 1459. https://doi.org/10.3390/polym13091459

Koffi A, Mijiyawa F, Koffi D, Erchiqui F, Toubal L. Mechanical Properties, Wettability and Thermal Degradation of HDPE/Birch Fiber Composite. Polymers. 2021; 13(9):1459. https://doi.org/10.3390/polym13091459

Chicago/Turabian StyleKoffi, Agbelenko, Fayçal Mijiyawa, Demagna Koffi, Fouad Erchiqui, and Lotfi Toubal. 2021. "Mechanical Properties, Wettability and Thermal Degradation of HDPE/Birch Fiber Composite" Polymers 13, no. 9: 1459. https://doi.org/10.3390/polym13091459

APA StyleKoffi, A., Mijiyawa, F., Koffi, D., Erchiqui, F., & Toubal, L. (2021). Mechanical Properties, Wettability and Thermal Degradation of HDPE/Birch Fiber Composite. Polymers, 13(9), 1459. https://doi.org/10.3390/polym13091459