Investigation on the Thermoforming of Pmsq-Hdpe for the Manufacture of a NACA Profile of Small Dimensions

Abstract

1. Introduction

2. Polymethylsilsesquioxane High-Density Polyethylene (PMSQ-HDPE) Composite and Characterization

2.1. PMSQ-HDPE Composites Elaboration

- −

- The PMSQ nanoparticles has a size of 15 to 20 nm, a hydrophobic surface and good thermal stability. These nanoparticles have a very large surface area (39.721 m2/g−1) offering a very good ability to interact specifically with other hydrophobic surfaces [4].

- −

- HDPE Hival-500354 with a melt flow index of 0.03 g min−1 (ASTM D1505) and a density of 0.954 g cm−3 (ASTM D1238) was supplied by IDES Prospector North America.

2.2. Mechanical Properties of PMSQ-HDPE Nanocomposites

2.3. Thermal Analysis of HDPE–PMSQ Nanocomposites

2.4. Morphology of HDPE–PMSQ Nanocomposites

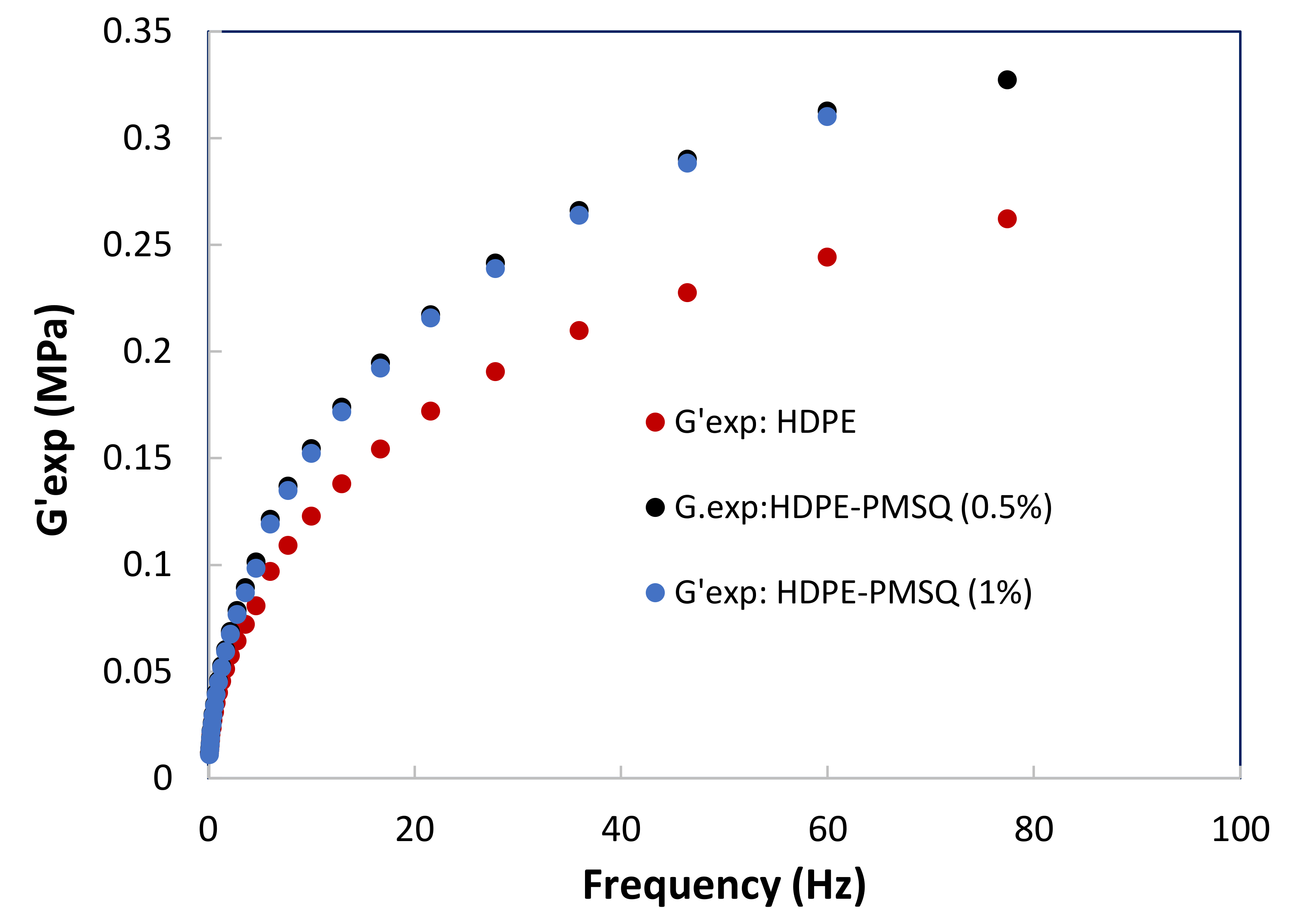

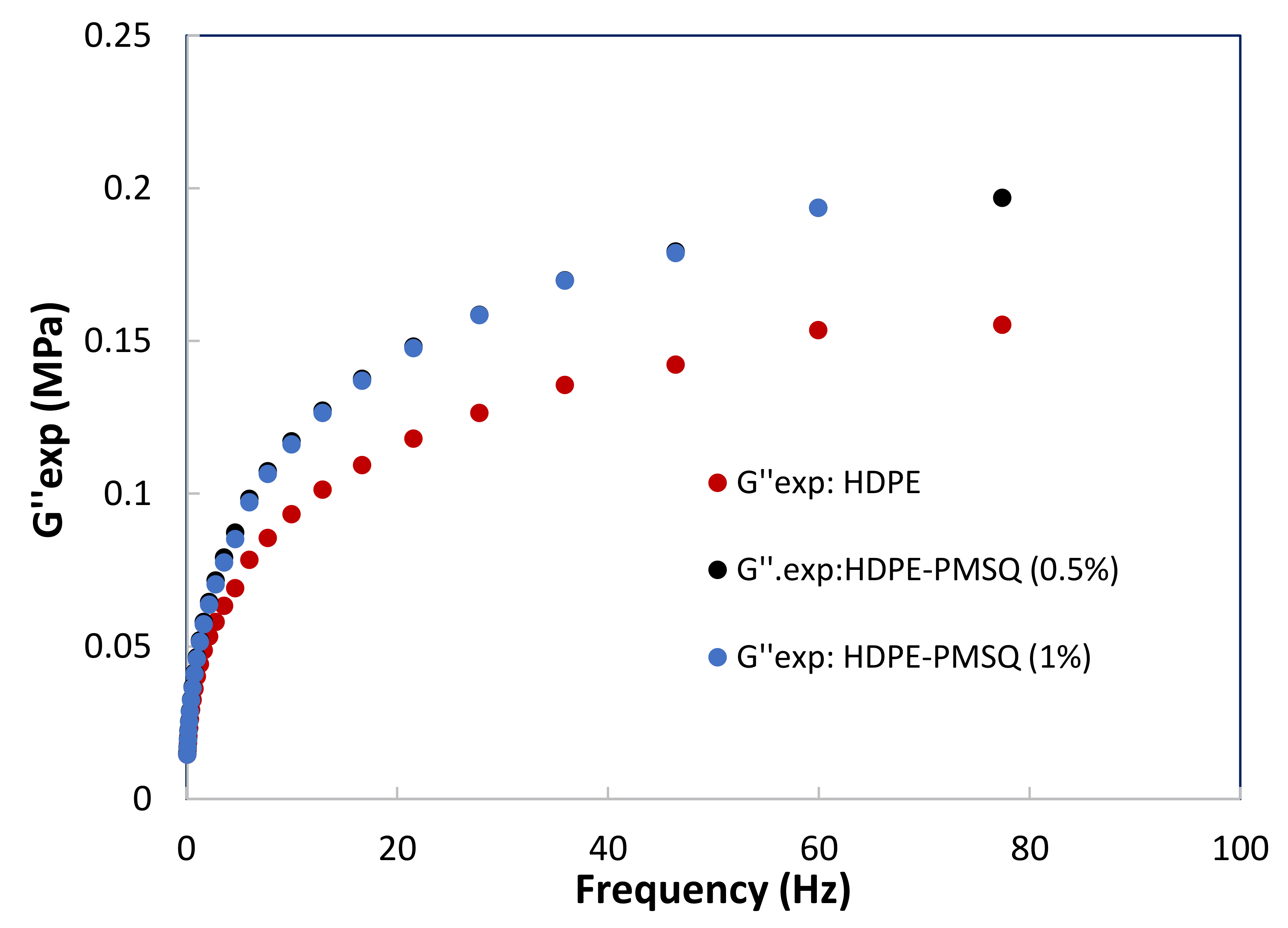

2.5. Rheological Properties of the HDPE-PMSQ Nanocomposites

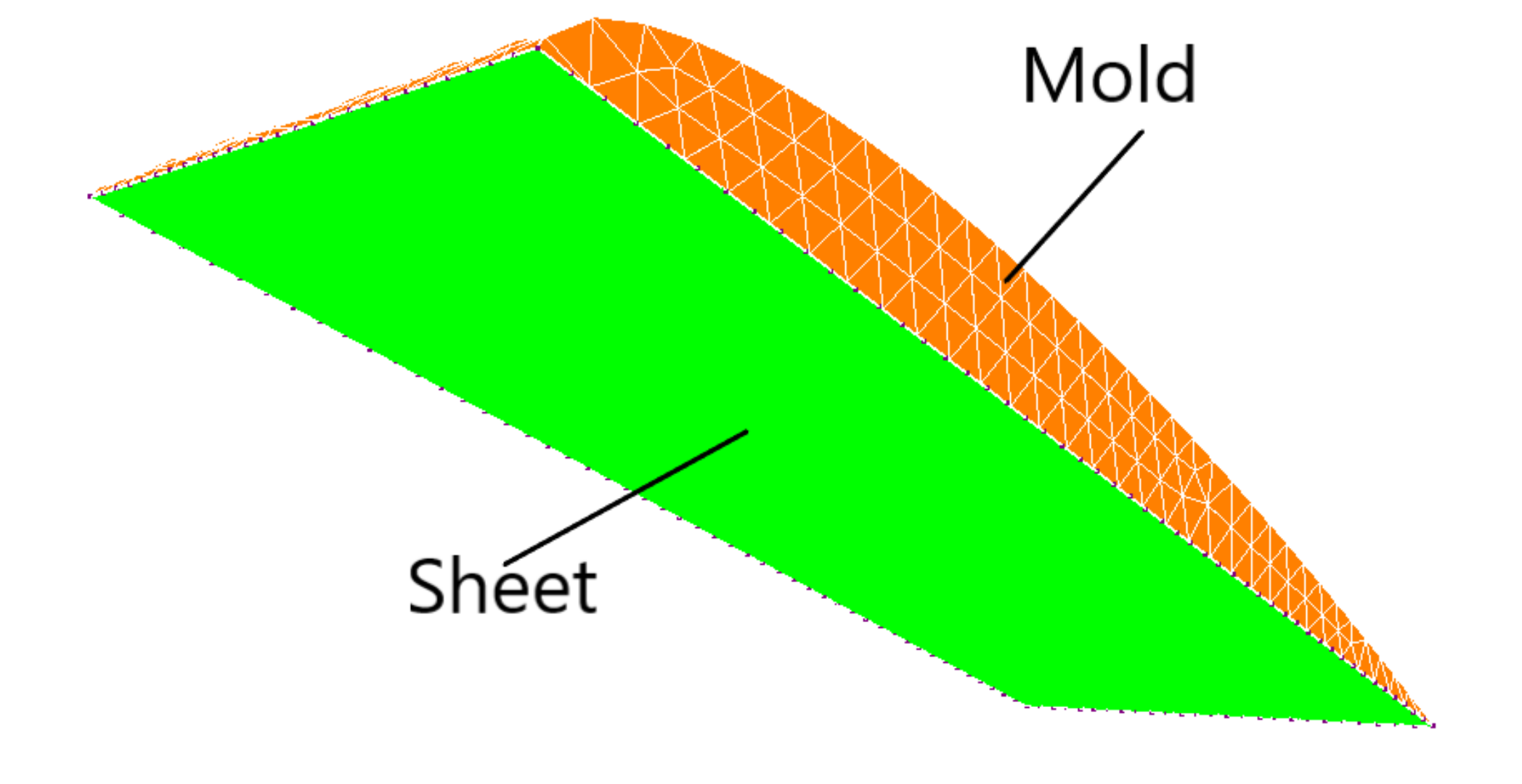

3. Numerical Modelling of the Blade’s Thermoforming Process

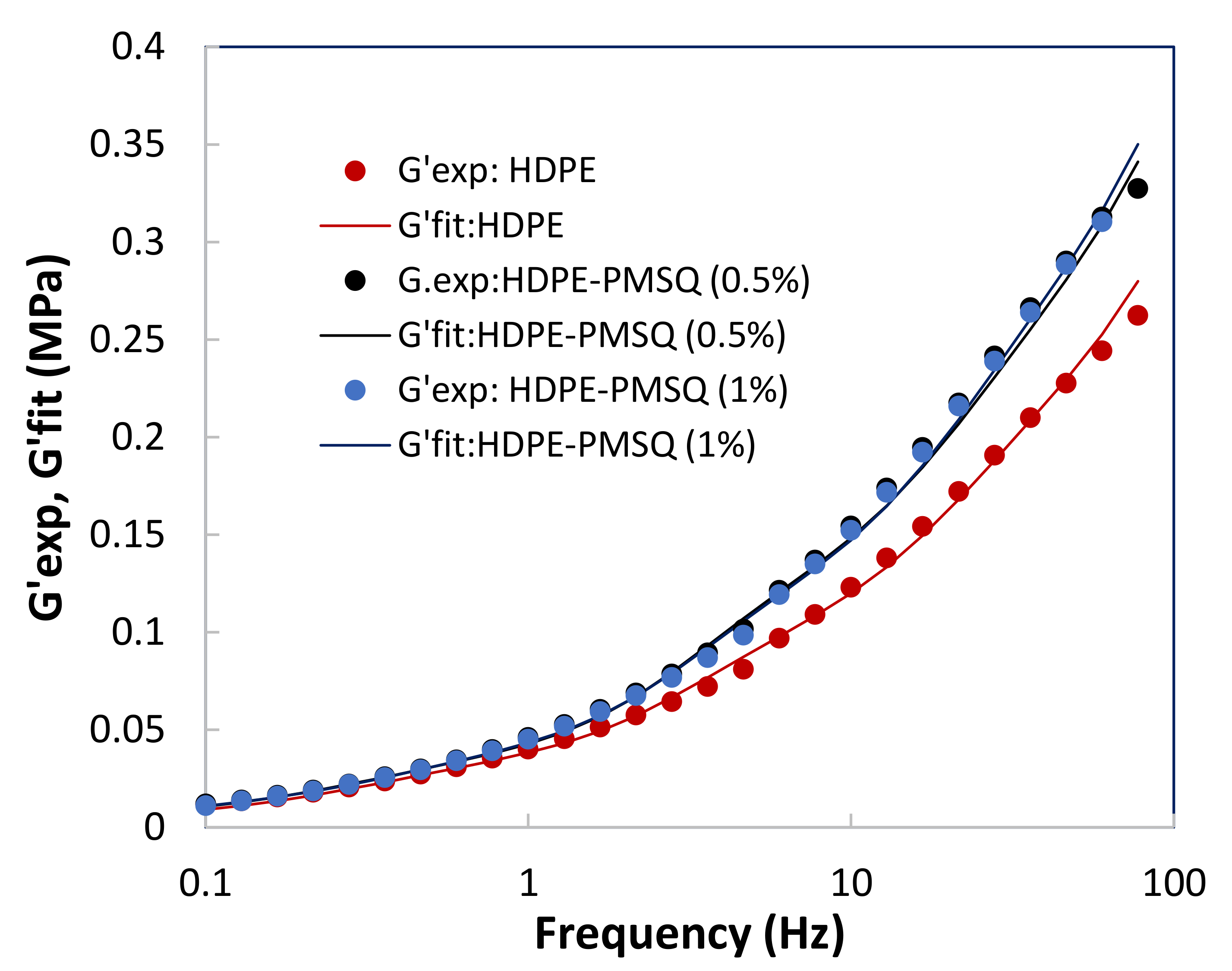

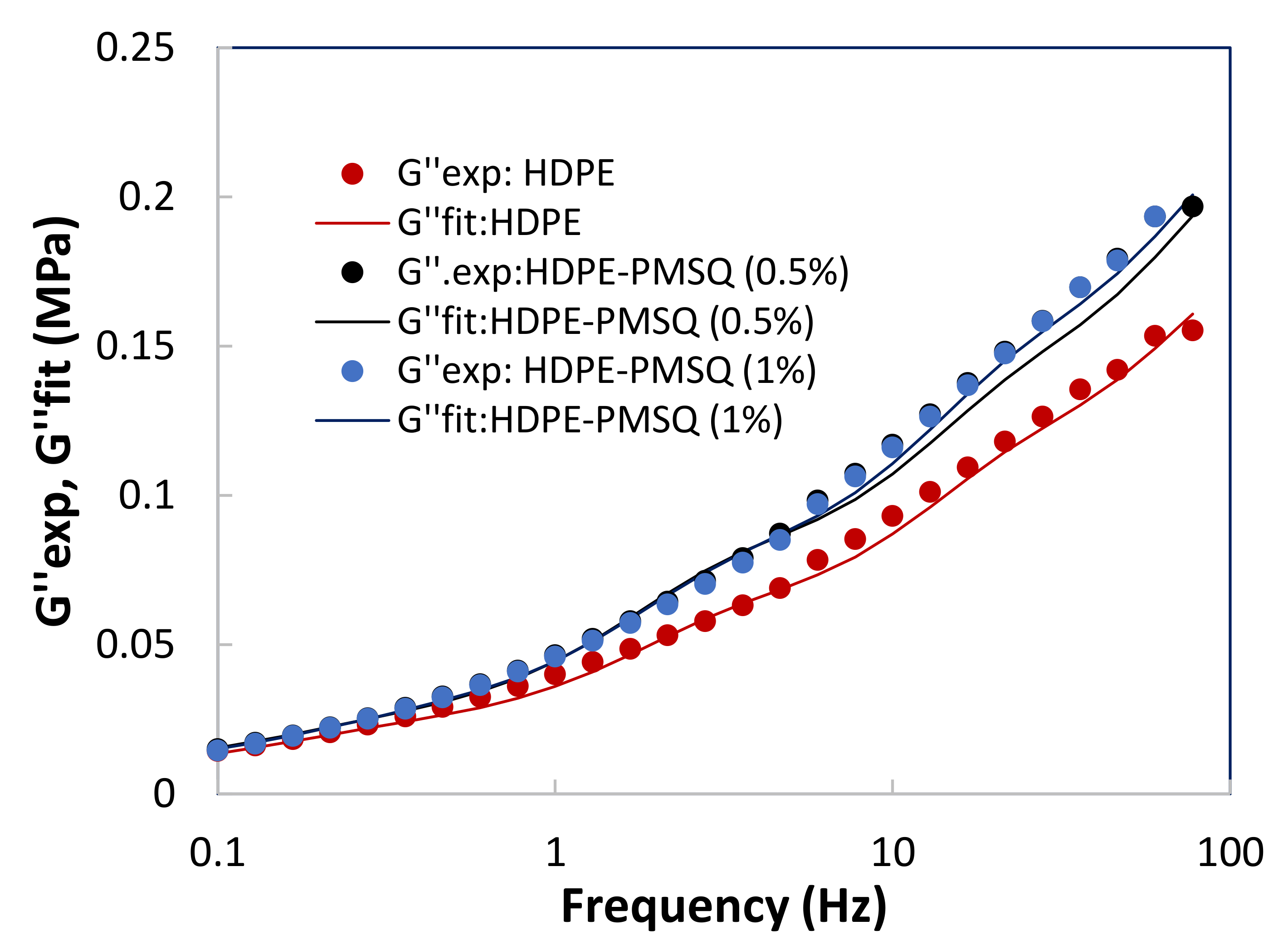

3.1. Characterization of HDPE-PMSQ’s Viscoelastic Behavior

3.2. Finite Element Formulations

3.2.1. Finite Element Discretization

3.2.2. Convergence Stability Criteria

3.2.3. Plane-Stress Assumption

3.2.4. Constitutive Equation

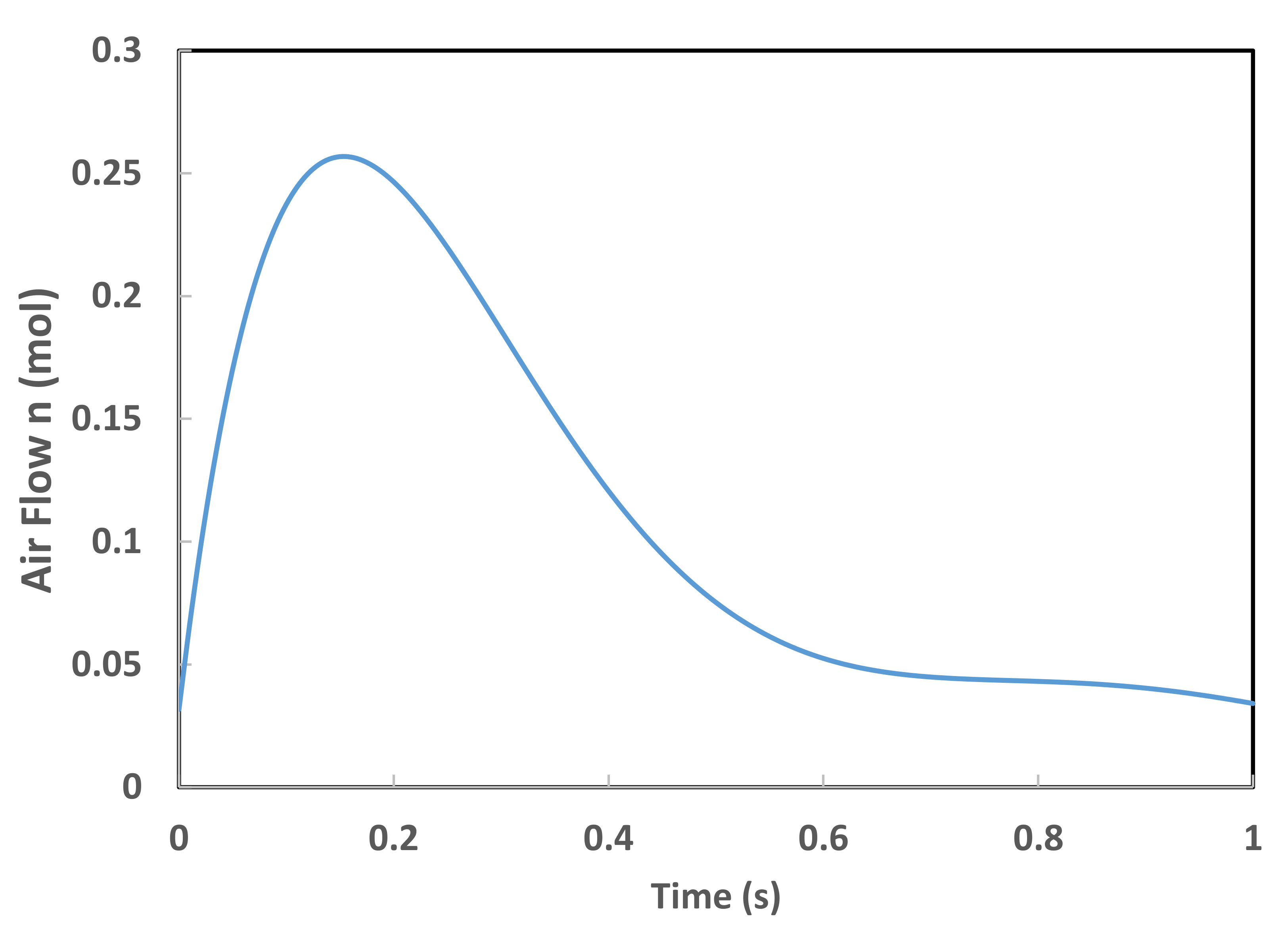

3.2.5. Van der Waals Equation of State and Pressure Loading

- (i)

- Gas temperature is assumed constant (Tgas)

- (ii)

- The Composite sheet temperature is assumed constant (Tsheet = Tgas)

- (iii)

- At every moment, the pressure between the sheet and the mold is assumed constant

- (iv)

- The contact between the composite sheet and the mold is assumed to be a sticky contact as the polymer cools and stiffens rapidly during the sheet/mold contact.

3.2.6. Work and Power for the Thermoforming of the Unmanned Aerial Vehicle (UAV) Blade

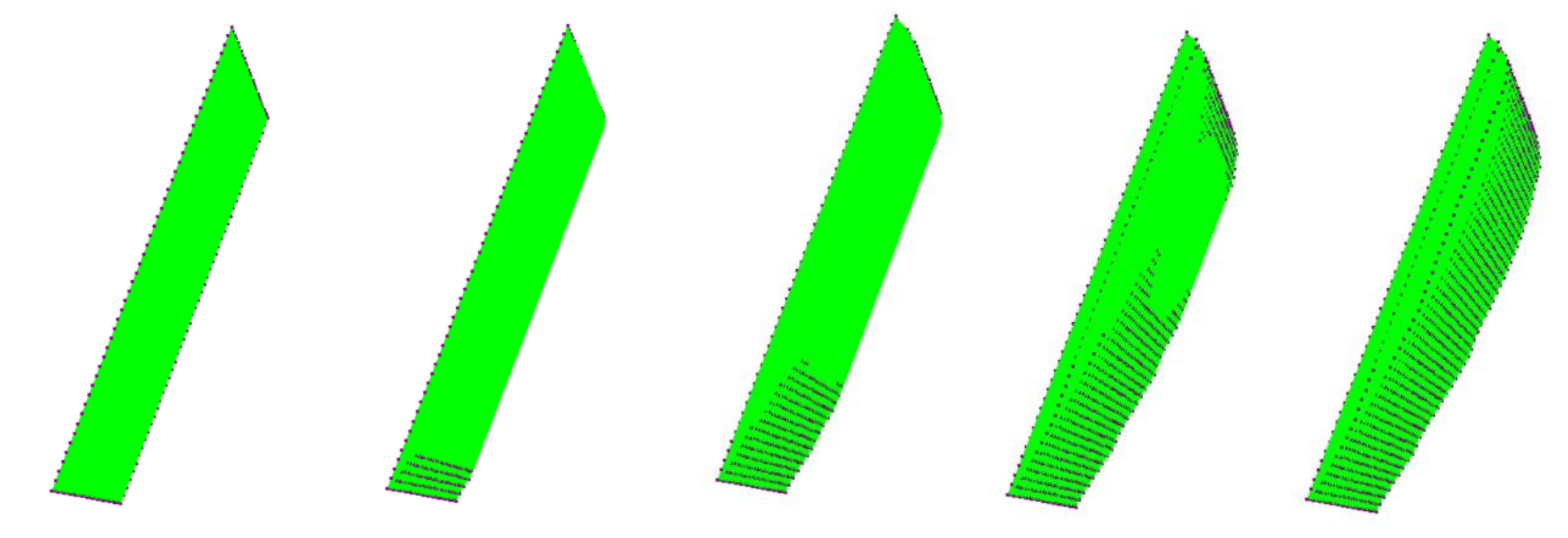

4. Thermoforming of a Thin National Advisory Committee for Aeronautics (NACA) Profile for UAVs

- −

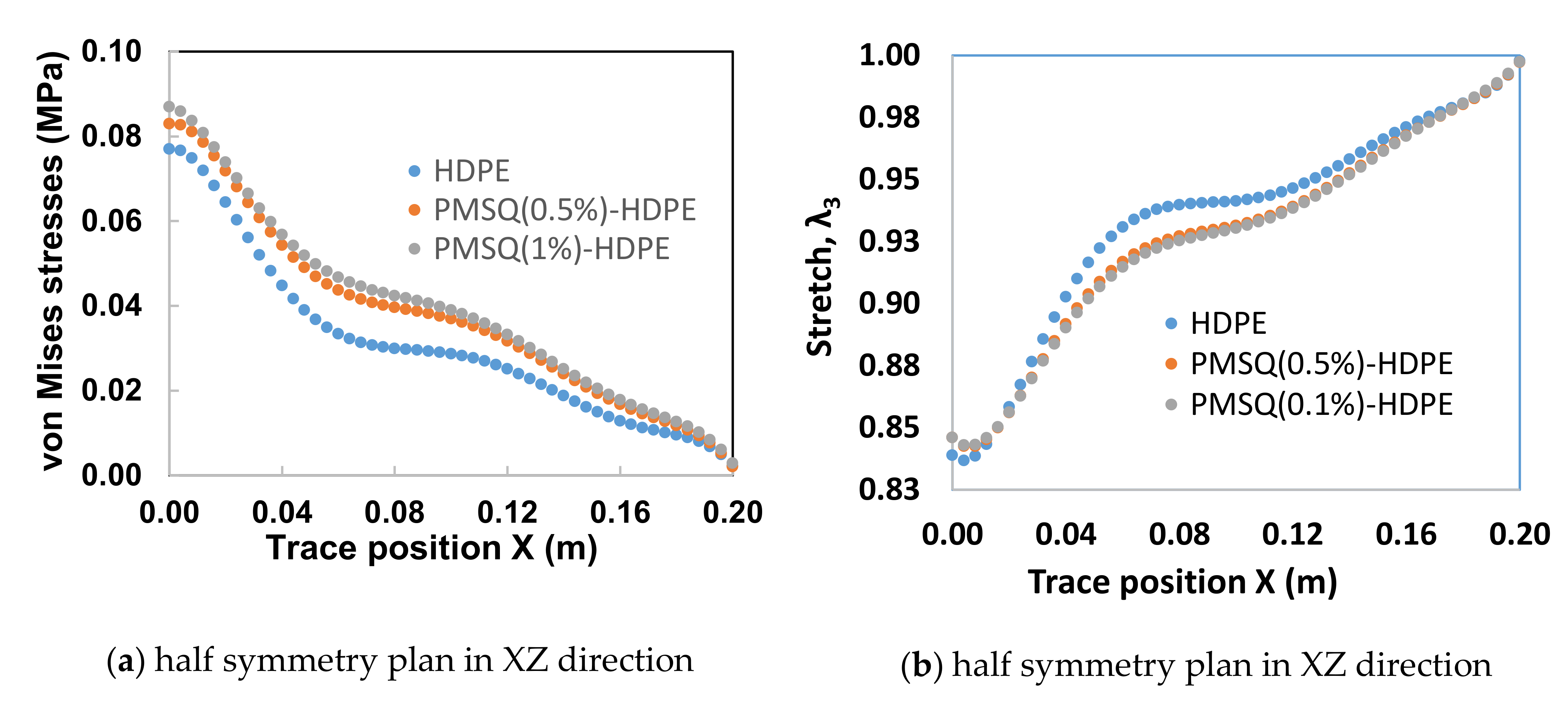

- The numerical results show the potential use of HDPE-PMSQ composites for the manufacture of UAV blades by thermoforming.

- −

- The moduli of elasticity of HDPE-PMSQ composites (1064 MPa in the case of 0.5% PMSQ and 1115 MPa in the case of 1.0% PMSQ) are more interesting than those of virgin PHDE which is 1031 MP.

- −

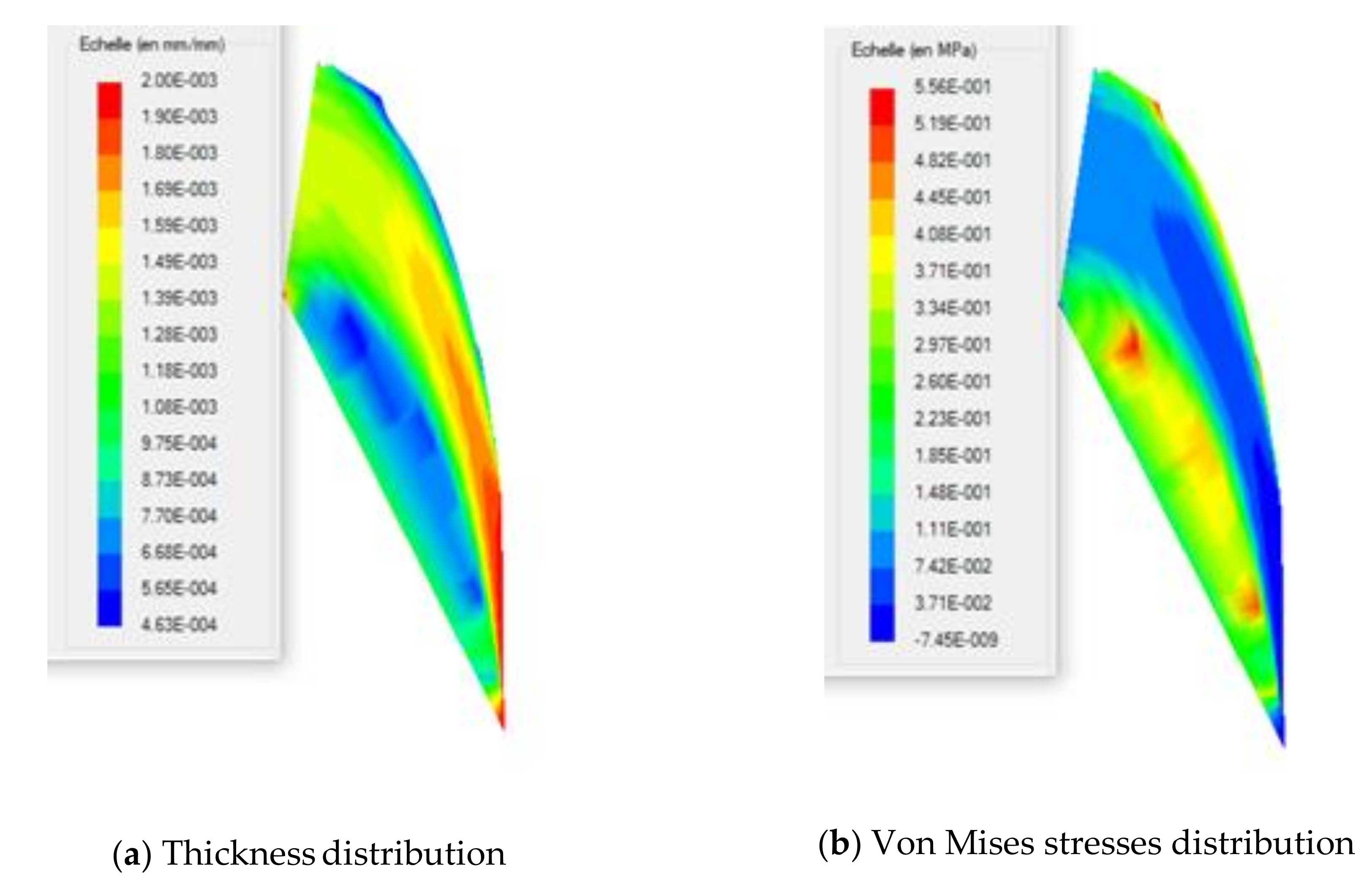

- The viscoelastic behavior of HDPE-PMSQ composites shows little influence on the thickness and stress distributions in the final product.

- −

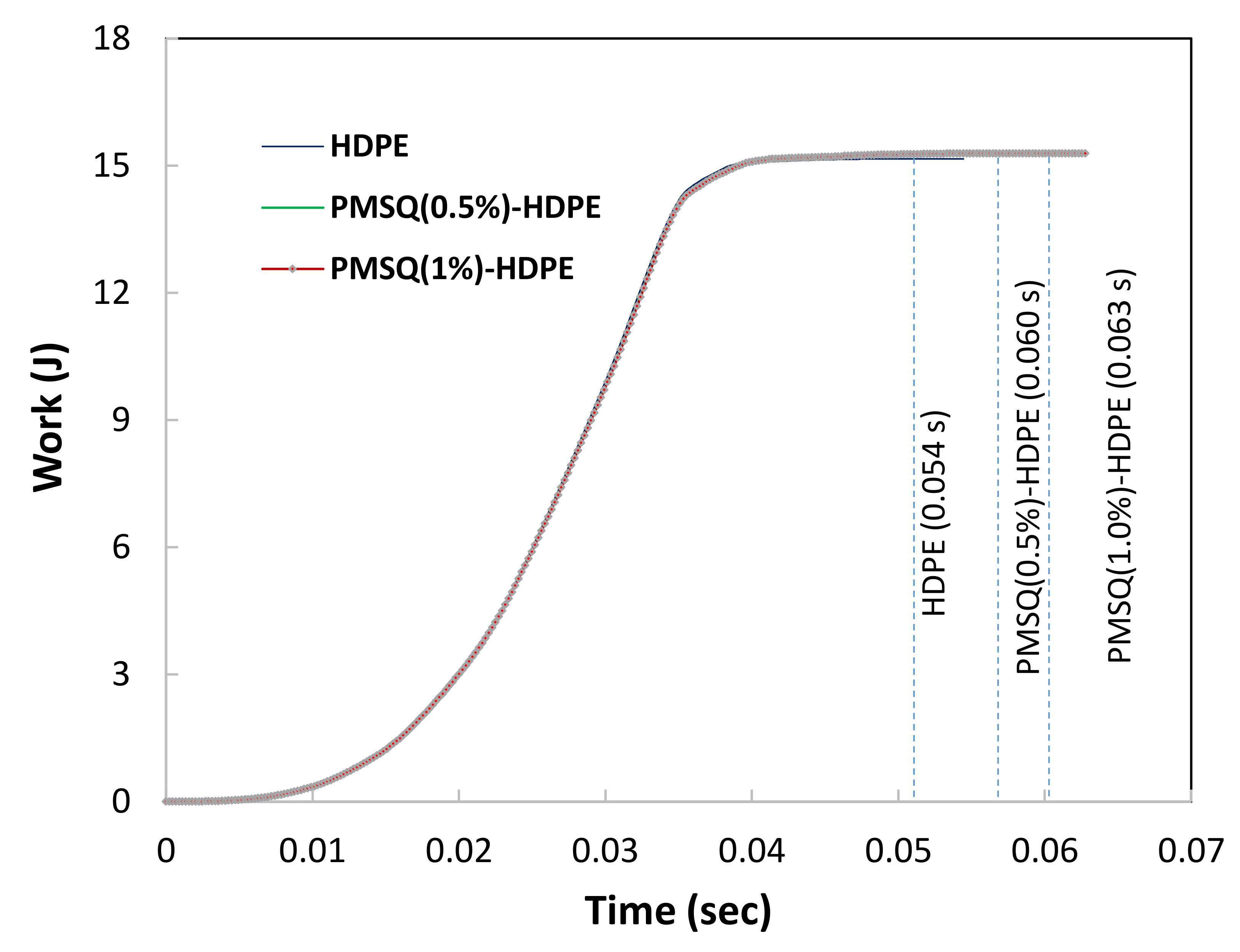

- The work and power required to form the UAV blade for the virgin polymer and composites are almost similar.

- −

- The thickness and von Mises stresses obtained from the different composites are not similar, especially the stress distribution.

- −

- The amount of material in the central area of the UAV blade increases slightly compared to the virgin polymer.

5. Conclusions

- (i)

- The constitutive behavior of HDPE reinforced with PMSQ nanoparticles (with mass concentrations of 0.5 and 1%) has little influence on the final thickness and stress distribution in the blade;

- (ii)

- The time required to thermoform a composite part based on HDPE and PMSQ (with mass concentrations of 0.5 and 1%) is practically unchanged;

- (iii)

- The energy used for the thermoforming of the composite blade is practically the same for the mass concentrations of 0.5 and 1% PMSQ;

- (iv)

- The numerical results show the potential use of composites for the manufacture of drone blades by thermoforming.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Soundararajah, Q.; Karunaratne, B.; Rajapakse, R. Montmorillonite polyaniline nanocomposites: Preparation, characterization and investigation of mechanical properties. Mater. Chem. Phys. 2009, 113, 850–855. [Google Scholar] [CrossRef]

- Hua, J.; Wang, Z.; Xu, L.; Wang, X.; Zhao, J.; Li, F. Preparation polystyrene/multiwalled carbon nanotubes nanocomposites by copolymerization of styrene and styryl-functionalized multiwalled carbon nanotubes. Mater. Chem. Phys. 2013, 137, 694–698. [Google Scholar] [CrossRef]

- Owpradit, W.; Jongsomjit, B. A comparative study on synthesis of LLDPE/TiO2 nanocomposites using different TiO2 by in situ polymerization with zirconocene/dMMAO catalyst. Mater. Chem. Phys. 2008, 112, 954–961. [Google Scholar] [CrossRef]

- Baatti, A.; Erchiqui, F.; Bébin, P.; Godard, F.; Bussières, D. A two-step Sol-Gel method to synthesize a ladder polymethylsilsesquioxane nanoparticles, D. Adv. Powder Technol. 2017, 28, 1038–1469. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Z.; Fu, W.; Xie, P.; Li, Z.; Yan, S. Supramolecular template-directed synthesis of stable and high-efficiency photoluminescence 9,10-diphenylanthryl-bridged ladder polysiloxane. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 2491–2497. [Google Scholar] [CrossRef]

- Abe, Y.; Kagayama, K.; Takamura, N.; Gunji, T.; Yoshihara, T.; Takahashi, N. Preparation and properties of polysilsesquioxanes. Function and characterization of coating agents and films. J. Non. Cryst. Solids 2000, 261, 39–51. [Google Scholar] [CrossRef]

- Tiwari, A.; Liskiewicz, T.W.; Hihara, L. Studies of wear and tear and hydrogen bonding in dendrimeric fluorinated polysilsequioxanes coatings on an aluminum surface. Ind. Eng. Chem. Res. 2016, 55, 6085–6105. [Google Scholar] [CrossRef]

- Kuttner, C.; Maier, P.C.; Kunert, C.; Schlaad, H.; Fery, A. Direct Thiol–Ene Photocoating of Polyorganosiloxane Microparticles. Langmuir 2013, 29, 16119–16126. [Google Scholar] [CrossRef]

- Tolbert, S.H.; McFadden, P.D.; Loy, D.A. New hybrid organic/inorganic polysilsesquioxane–silica particles as sunscreens. ACS Appl. Mater. Interfaces 2016, 8, 3160–3174. [Google Scholar] [CrossRef]

- Chinnam, P.R.; Wunder, S.L. Polyoctahedral silsesquioxane-nanoparticle electrolytes for lithium batteries: POSS-lithium salts and POSS-PEGs. Chem. Mater. 2011, 23, 5111–5121. [Google Scholar] [CrossRef]

- Joseph, A.M.; Nagendra, B.; Surendran, K.P.; Bhoje Gowd, E. Syndiotactic polystyrene/hybrid silica spheres of POSS siloxane composites exhibiting ultralow dielectric constant. Gowd. ACS Appl. Mater. Interfaces 2015, 7, 19474–19483. [Google Scholar] [CrossRef]

- Dong, F.; Guo, W.; Chu, S.W.; Ha, C.S. Novel fluorinated polysilsesquioxane hollow spheres: Synthesis and application in drug release. Chem. Commun. 2010, 46, 7498–7500. [Google Scholar] [CrossRef] [PubMed]

- Rocca, J.D.; Huxford, R.C.; Comstock-Duggan, E.; Lin, W. Polysilsesquioxane nanoparticles for targeted platin-based cancer chemotherapy by triggered release. Angew. Chem. Int. Ed. 2011, 50, 10330–10334. [Google Scholar] [CrossRef]

- Yu, L.; Zhou, X.; Jiang, W. Low-cost and superhydrophobic magnetic foam as an absorbent for oil and organic solvent removal. Ind. Eng. Chem. Res. 2016, 55, 9498–9506. [Google Scholar] [CrossRef]

- Xiang, L.; Zhang, Z.; Wang, X.; Yu, Y.; Long, X.; Zhang, N.; Zhao, J.; Xu, J. Multifunctional polymethylsilsesquioxane (PMSQ) surfaces prepared by electrospinning at the sol–gel transition: Superhydrophobicity, excellent solvent resistance, thermal stability and enhanced sound absorption property. Colloid Interface Sci. 2011, 359, 296–303. [Google Scholar] [CrossRef] [PubMed]

- Baatti, A.; Erchiqui, F.; Godard, F.; Bussières, D.; Bébin, P. DMA analysis, thermal study and morphology of polymethylsilsesquioxane nanoparticles-reinforced HDPE nanocomposite. J. Therm. Anal. Calorim. 2020, 139, 789–797. [Google Scholar] [CrossRef]

- Lodge, A.S. Elastic Liquids; Academic Press: London, UK, 1964. [Google Scholar]

- Erchiqui, F.; Gakwaya, A.; Rachik, M. Dynamic finite element analysis of nonlinear isotropic hyperelastic and viscoelastic materials for thermoforming applications. Polym. Eng. Sci. 2005, 45, 125. [Google Scholar] [CrossRef]

- Sukiman, M.S.; Erchiqui, F.; Kanit, T.; Imad, A. Design and numerical modeling of the thermoforming process of a WPC based formwork structure. Mater. Today Commun. 2020, 22, 100805. [Google Scholar] [CrossRef]

- Erchiqui Godard, F.; Gakwaya, A.; Koubaa, A.; Vincent, H.; Kaddami, H. Engineering investigations on the potentiality of the thermoformability of HDPE charged by wood flours in the thermoforming part. Polym. Eng. Sci. 2009, 49, 1594. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers; John-Wiley & Sons: New York, NY, USA, 1980. [Google Scholar]

- Redlich, O.; Kwong, J.N. On the thermodynamics of solutions. V. An equation of state. Fugacities of gaseous solutions. Chem. Rev. 1949, 44, 233. [Google Scholar] [CrossRef]

- Erchiqui, F.; Souli, M.; Yedder, R.B. Nonisothermal finite-element analysis of thermoforming of polyethylene terephthalate sheet: Incomplete effect of the forming stage. Polym. Eng. Sci. 2007, 47, 2130. [Google Scholar] [CrossRef]

| Specific Area BET (m2/g) | Density (g/cm3) | Size (nm) | Contact Angle (Degree) |

|---|---|---|---|

| 0.1154 | 1.42 | 15–20 | 148 ± 3 |

| % PMSQ-HDPE | Elastic Modulus (MPa) | Yield Stress (MPa) | Elongation at Beak (%) |

|---|---|---|---|

| 0.0% | 1031 ± 26 | 26.8 ± 0.2 | 39.2 ± 2.3 |

| 0.5% | 1064 ± 60 | 27.9 ± 0.3 | 47.2 ± 3.1 |

| 1.0% | 1115 ± 54 | 30.1 ± 0.1 | 41.1 ± 2.3 |

| Parameters | HDPE | HDPE-0.5% | HDPE-1% |

|---|---|---|---|

| Tm/K | 404.5 | 404.5 | 405.5 |

| Tc/K | 390.8 | 390.5 | 391.9 |

| ΔH/J g−1 (melting) | 189.8 | 190.9 | 194.3 |

| Xc% | 64.9 | 65.0 | 66.4 |

| τk (s) | HDPE | HDPE-PMSQ (0.5%) | HDPE-PMSQ (1%) |

|---|---|---|---|

| τk (s) | gk (MPa) | gk (MPa) | gk (MPa) |

| 0.01249 | 0.314674 | 0.378765 | 0.389422 |

| 0.08746 | 0.123293 | 0.147477 | 0.158700 |

| 0.61220 | 0.069532 | 0.093907 | 0.088718 |

| 4.28570 | 0.016151 | 0.014978 | 0.019317 |

| 10.0000 | 0.012357 | 0.014191 | 0.010610 |

| 50.0000 | 0.006604 | 0.007997 | 0.008955 |

| % PMSQ | σcrit (Mpa) | hcr (mm) |

|---|---|---|

| 0% | 0.077 | 1.674 |

| 0.5% | 0.083 | 1.686 |

| 1.0% | 0.087 | 1.686 |

| % PMSQ | σcrit (Mpa) | hcr (mm) |

|---|---|---|

| 0% | 0.270 | 1.190 |

| 0.5% | 0.274 | 1.204 |

| 1.0% | 0.304 | 1.213 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fouad, E.; Baatti, A.; Ben Hamou, K.; Kaddami, H.; Souli, M.; Imad, A. Investigation on the Thermoforming of Pmsq-Hdpe for the Manufacture of a NACA Profile of Small Dimensions. Polymers 2021, 13, 1622. https://doi.org/10.3390/polym13101622

Fouad E, Baatti A, Ben Hamou K, Kaddami H, Souli M, Imad A. Investigation on the Thermoforming of Pmsq-Hdpe for the Manufacture of a NACA Profile of Small Dimensions. Polymers. 2021; 13(10):1622. https://doi.org/10.3390/polym13101622

Chicago/Turabian StyleFouad, Erchiqui, Abdessamad Baatti, Karima Ben Hamou, Hamid Kaddami, Mhamed Souli, and Abdellatif Imad. 2021. "Investigation on the Thermoforming of Pmsq-Hdpe for the Manufacture of a NACA Profile of Small Dimensions" Polymers 13, no. 10: 1622. https://doi.org/10.3390/polym13101622

APA StyleFouad, E., Baatti, A., Ben Hamou, K., Kaddami, H., Souli, M., & Imad, A. (2021). Investigation on the Thermoforming of Pmsq-Hdpe for the Manufacture of a NACA Profile of Small Dimensions. Polymers, 13(10), 1622. https://doi.org/10.3390/polym13101622