Constitutive Equations for Analyzing Stress Relaxation and Creep of Viscoelastic Materials Based on Standard Linear Solid Model Derived with Finite Loading Rate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overview

2.2. Two Constitutive Equation Forms for Analyzing Stress Relaxation Behavior Based on the Standard Linear Solid Model

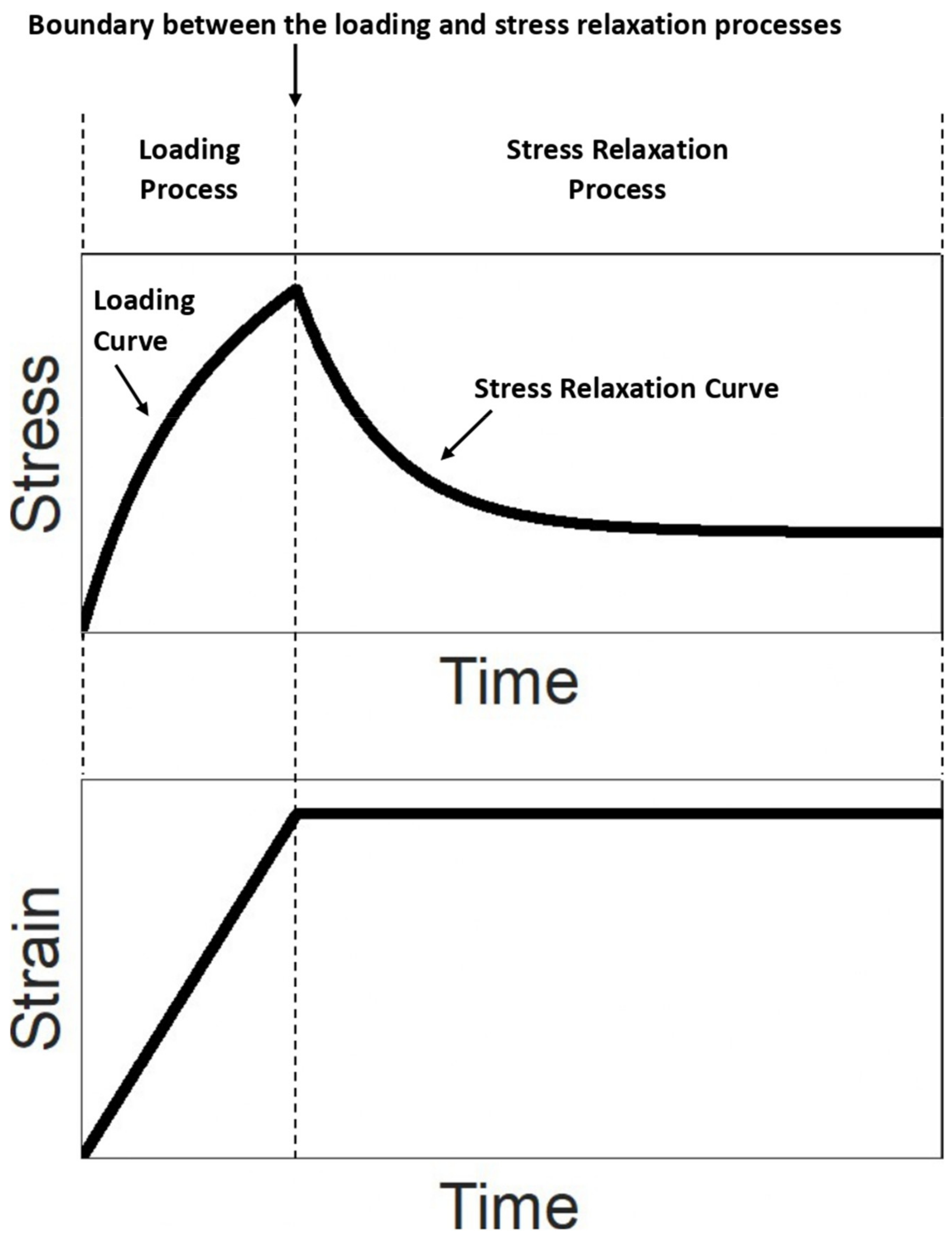

2.2.1. Introduction to the Stress Relaxation Test

2.2.2. Constitutive Equation Derived with “Finite” Loading Rate for Analyzing Stress Relaxation Behavior

2.2.3. Constitutive Equation Derived with “Infinite” Loading Rate for Analyzing Stress Relaxation Behavior

2.3. Two Constitutive Equation Forms for Analyzing Creep Behavior Based on the Standard Linear Solid Model

2.3.1. Introduction to the Creep Test

2.3.2. Constitutive Equation Derived with “Finite” Loading Rate for Analyzing Creep Behavior

2.3.3. Constitutive Equation Form Derived with “Infinite” Loading Rate for Analyzing Creep Behavior

2.4. Finite Element Computational Simulation

3. Results

3.1. Results: Stress Relaxation

- (1)

- The constitutive equation derived with a finite loading rate can always produce accurate results in the evaluation of all of the viscoelastic properties , and , regardless of the strain rate (Figure 6 and Figure 7). In the evaluation of , and , the results are dependent on both the strain rate and the relaxation time constant of the material; some significant trends can be observed (Figure 7). However, these dependencies might not be important for practical applications since the errors are already very low regardless of the strain rate, and the error values at different strain rates do not differ significantly.

- (2)

- For the constitutive equation derived with infinite loading rate in the evaluation of and , the higher the strain rate, the more accurate the result is (the second and third columns in Figure 6). This equation form can produce accurate evaluations if and only if when the strain rate is higher than a threshold (which is the strain rate value at the intersection of the green dotted line and the red curves in Figure 6). It can be observed that the threshold is dependent on the relaxation time constant of the material; the lower the relaxation time constant, the higher the threshold.

- (3)

- In the evaluation of , the two equation forms can produce accurate and identical evaluations regardless of the strain rate (the first column in Figure 6). The results are dependent on both the strain rate and the relaxation time constant; some significant trends can be observed. However, these dependencies might not be important for practical applications since the errors are already very low regardless of the strain rate, and the error values at different strain rates do not differ significantly.

- (4)

- No matter what the modulus of elasticity () of the material is (5000, 10,000, or 30,000 Pa), the analysis results are identical (three rows in Figure 6). That is to say, the analysis results are independent of the modulus of elasticity.

3.2. Results: Creep

- (1)

- The constitutive equation derived with a finite loading rate can always produce accurate results in the evaluation of and , regardless of the stress rate (Figure 8 and Figure 9). However, in the evaluation of , this equation form can produce accurate results if and only if when the stress rate is higher than a threshold (which is the stress rate value at the intersection of the green dotted line and the red curves in Figure 9). It can be observed that the threshold is dependent on the relaxation time constant of the material; the lower the relaxation time constant, the higher the threshold.

- (2)

- For the constitutive equation derived with infinite loading rate in the evaluation of and , the higher the stress rate, the more accurate the result is (the second and third columns in Figure 8). This equation form can produce accurate evaluations if and only if when the stress rate is higher than a threshold (which is the stress rate value at the intersection of the green dotted line and the red curves in Figure 8). It can be observed that the threshold is dependent on the relaxation time constant of the material; the lower the relaxation time constant, the higher the threshold.

- (3)

- In the evaluation of , the two equation forms can produce accurate and identical evaluations regardless of the stress rate (the first column in Figure 8). The results are dependent on both the stress rate and the relaxation time constant; some significant trends can be observed. However, these dependencies might not be important for practical applications since the errors are already very low regardless of the stress rate, and the error values at different stress rates do not differ significantly.

- (4)

- The analysis results are dependent on the modulus of elasticity () of the material. Generally speaking, the higher the modulus of elasticity, the larger the error (three rows in Figure 8).

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Brinson, H.F.; Brinson, L.C. Polymer Engineering Science and Viscoelasticity: An Introduction; Springer: New York, NY, USA, 2008. [Google Scholar]

- Huang, D.; Huang, Y.; Xiao, Y.; Yang, X.; Lin, H.; Feng, G.; Xiangdong, Z.; Zhang, X. Viscoelasticity in natural tissues and engi-neered scaffolds for tissue reconstruction. Acta Biomater. 2019, 97, 74–92. [Google Scholar] [CrossRef] [PubMed]

- Münstedt, H. Rheological Measurements and Structural Analysis of Polymeric Materials. Polymers 2021, 13, 1123. [Google Scholar] [CrossRef] [PubMed]

- Kulichikhin, V.G.; Malkin, A.Y. The Role of Structure in Polymer Rheology: Review. Polymers 2022, 14, 1262. [Google Scholar] [CrossRef] [PubMed]

- Abramowitch, S.D.; Woo, S.L.-Y.; Clineff, T.D.; Debski, R.E. An evaluation of the quasi-linear viscoelastic properties of the healing medial collateral ligament in a goat model. Ann. Biomed. Eng. 2004, 32, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-Y.; Shau, Y.-W.; Wang, C.-L.; Chai, H.-M.; Kang, J.-H. Quantitative evaluation of the viscoelastic properties of the ankle joint complex in patients suffering from ankle sprain by the anterior drawer test. Knee Surg. Sports Traumatol. Arthrosc. 2013, 21, 1396–1403. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-Y. Alternative form of standard linear solid model for characterizing stress relaxation and creep: Including a novel parameter for quantifying the ratio of fluids to solids of a viscoelastic solid. Front. Mater. 2020, 7, 11. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Lin, S.-R. Investigating the accuracy of ultrasound viscoelastic creep imaging for measuring the viscoelastic properties of a single-inclusion phantom. Int. J. Mech. Sci. 2021, 199, 106409. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Chen, W.-C. How complex viscoelastic behaviors within a viscoelastic three-layer structure affect the measurement accuracy of ultrasound viscoelastic creep imaging. Mech. Adv. Mater. Struct. 2022, 1–23. [Google Scholar] [CrossRef]

- Bonfanti, A.; Kaplan, J.L.; Charras, G.; Kabla, A. Fractional viscoelastic models for power-law materials. Soft Matter 2020, 16, 6002–6020. [Google Scholar] [CrossRef]

- Hata, N.; Tobolsky, A.V.; Bondi, A. Effect of plasticizers on the viscoelastic properties of poly(vinyl chloride). J. Appl. Polym. Sci. 1968, 12, 2597–2613. [Google Scholar] [CrossRef]

- Van Ruymbeke, E.; Coppola, S.; Balacca, L.; Righi, S.; Vlassopoulos, D. Decoding the viscoelastic response of poly-disperse star/linear polymer blends. J. Rheol. 2010, 54, 507–538. [Google Scholar] [CrossRef]

- Wang, Y.; Shang, L.; Zhang, P.; Yan, X.; Zhang, K.; Dou, S.; Zhao, J.; Li, Y. Measurement of viscoelastic properties for polymers by nanoindentation. Polym. Test. 2020, 83, 106353. [Google Scholar] [CrossRef]

- Qiu, Y.; Sridhar, M.; Tsou, J.K.; Lindfors, K.K.; Insana, M.F. Ultrasonic viscoelasticity imaging of nonpalpable breast tumors: Preliminary results. Acad. Radiol. 2008, 15, 1526–1533. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palacio-Torralba, J.; Hammer, S.; Good, D.W.; McNeill, S.A.; Stewart, G.D.; Reuben, R.L.; Chen, Y. Quantitative diagnostics of soft tissue through viscoelastic characterization using time-based instrumented palpation. J. Mech. Behav. Biomed. Mater. 2015, 41, 149–160. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baghban, M.; Mojra, A. Early relaxation time assessment for characterization of breast tissue and diagnosis of breast tumors. J. Mech. Behav. Biomed. Mater. 2018, 87, 325–335. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Denis, M.; Gregory, A.; Bayat, M.; Mehrmohammadi, M.; Fazzio, R.; Fatemi, M.; Alizad, A. Viscoelastic parameters as discriminators of breast masses: Initial human study results. PLoS ONE 2018, 13, e0205717. [Google Scholar] [CrossRef] [Green Version]

- Park, K.; Lonsberry, G.E.; Gearing, M.; Levey, A.I.; Desai, J.P. Viscoelastic Properties of Human Autopsy Brain Tissues as Biomarkers for Alzheimer’s Diseases. IEEE Trans. Biomed. Eng. 2018, 66, 1705–1713. [Google Scholar] [CrossRef]

- Nabavizadeh, A.; Bayat, M.; Kumar, V.; Gregory, A.; Webb, J.; Alizad, A.; Fatemi, M. Viscoelastic biomarker for differentiation of benign and malignant breast lesion in ultra-low frequency range. Sci. Rep. 2019, 9, 5737. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Guo, Y.; Zhou, Y.; Zhu, H.; Wu, P.; Wang, K.; Ruan, L.; Wan, M.; Insana, M.F. Fluidity and elasticity form a concise set of viscoelastic biomarkers for breast cancer diagnosis based on Kelvin–Voigt fractional derivative modeling. Biomech. Model. Mechanobiol. 2020, 19, 2163–2177. [Google Scholar] [CrossRef]

- Deng, C.X.; Hong, X.; Stegemann, J.P. Ultrasound imaging techniques for spatiotemporal characterization of composition, microstructure, and mechanical properties in tissue engineering. Tissue Eng. Part B Rev. 2016, 22, 311–321. [Google Scholar] [CrossRef] [Green Version]

- Hong, X.; Stegemann, J.P.; Deng, C.X. Microscale characterization of the viscoelastic properties of hydrogel biomaterials using dual-mode ultrasound elastography. Biomaterials 2016, 88, 12–24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hong, X.; Annamalai, R.T.; Kemerer, T.S.; Deng, C.X.; Stegemann, J.P. Multimode ultrasound viscoelastography for three-dimensional interrogation of microscale mechanical properties in heterogeneous biomaterials. Biomaterials 2018, 178, 11–22. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.; Best, C.A.; Badizadegan, K.; Dasari, R.R.; Feld, M.S.; Kuriabova, T.; Henle, M.L.; Levine, A.J.; Popescu, G. Measurement of red blood cell mechanics during morphological changes. Proc. Natl. Acad. Sci. USA 2010, 107, 6731–6736. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Messal, H.A.; Alt, S.; Ferreira, R.M.M.; Gribben, C.; Wang, V.M.; Cotoi, C.G.; Salbreux, G.; Behrens, A. Tissue curvature and apicobasal mechanical tension imbalance instruct cancer morphogenesis. Nature 2019, 566, 126–130. [Google Scholar] [CrossRef]

- Findley, W.N.; Lai, J.S.; Onaran, K.; Christensen, R.M. Creep and Relaxation of Nonlinear Viscoelastic Materials with an Introduction to Linear Viscoelasticity; Dover Publications: New York, NY, USA, 1977. [Google Scholar]

- Wineman, A. Nonlinear viscoelastic solids—A review. Math. Mech. Solids 2009, 14, 300–366. [Google Scholar] [CrossRef]

- Banks, H.T.; Hu, S.; Kenz, Z.R. A brief review of elasticity and viscoelasticity for solids. Adv. Appl. Math. Mech. 2011, 3, 1–51. [Google Scholar] [CrossRef] [Green Version]

- Fung, Y.C. Biomechanics: Mechanical Properties of Living Tissues; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- David, N.V.; Gao, X.L.; Zheng, J.Q. Creep of a Twaron®/natural rubber composite. Mech. Adv. Mater. Struct. 2013, 20, 464–477. [Google Scholar]

- Nguyen-Sy, T.; Nguyen, T.-D. On the effective properties of composites made of viscoelastic constituents. Mech. Adv. Mater. Struct. 2021, 28, 1328–1336. [Google Scholar] [CrossRef]

- Renaud, F.; Dion, J.-L.; Chevallier, G.; Tawfiq, I.; Lemaire, R. A new identification method of viscoelastic behavior: Application to the generalized Maxwell model. Mech. Syst. Signal Process. 2011, 25, 991–1010. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, S. Generalized Kelvin model for micro-cracked viscoelastic materials. Eng. Fract. Mech. 2014, 127, 226–234. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, X.; Liu, X.; Luo, Y. Viscoelastic model of asphalt mixtures under repeated load. J. Mater. Civ. Eng. 2015, 27, 04015007. [Google Scholar] [CrossRef]

- Babaei, B.; Davarian, A.; Pryse, K.M.; Elson, E.L.; Genin, G.M. Efficient and optimized identification of generalized Maxwell viscoelastic relaxation spectra. J. Mech. Behav. Biomed. Mater. 2015, 55, 32–41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gu, J.; Xie, Z.; Wang, S.; Sun, H.; Zhang, X. Thermo-mechanical modeling of woven fabric reinforced shape memory polymer composites. Mech. Adv. Mater. Struct. 2018, 26, 1042–1052. [Google Scholar] [CrossRef]

- Blanco, S.; You, H.; Kerekes, T.W.; Yun, G.J. Cure-induced residual stress buildup and distortions of CFRP laminates with stochastic thermo-chemical and viscoelastic models: Experimental verifications. Mech. Adv. Mater. Struct. 2021, 1–17. [Google Scholar] [CrossRef]

- He, G.; Liu, Y.; Hammi, Y.; Bammann, D.J.; Horstemeyer, M.F. A combined viscoelasticity-viscoplasticity-anisotropic damage model with evolving internal state variables applied to fiber reinforced polymer composites. Mech. Adv. Mater. Struct. 2021, 28, 1775–1796. [Google Scholar] [CrossRef]

- Sebastian, M.S.; Rajan, S.; Jithu, S.; Narayanan, S. Longitudinal Vibration Response of a Vibration Isolation Module with Kevlar-29 Fabric Strength Member. Mech. Adv. Mater. Struct. 2014, 21, 457–467. [Google Scholar] [CrossRef]

- Xiao, H.; Wu, J.; Ye, W.; Wang, Y. Dynamic modeling of dielectric elastomer actuators based on thermodynamic theory. Mech. Adv. Mater. Struct. 2020, 29, 1543–1552. [Google Scholar] [CrossRef]

- Da Costa-Haveroth, T.C.; Haveroth, G.A.; Kühl, A.; Boldrini, J.L.; Bittencourt, M.L.; Sasse, F.D.; Polak, M.A.; Muñoz-Rojas, P.A. Aspects on viscoelasticity modeling of HDPE using fractional derivatives: Interpolation procedures and efficient numerical scheme. Mech. Adv. Mater. Struct. 2021, 2021, 1–16. [Google Scholar] [CrossRef]

- He, G.; Liu, Y.; Lacy, T.E.; Horstemeyer, M.F. A historical review of the traditional methods and the internal state variable theory for modeling composite materials. Mech. Adv. Mater. Struct. 2021, 2021, 1–22. [Google Scholar] [CrossRef]

- Kühl, A.; Muñoz-Rojas, P.A. Application of a master curve and the modified superposition principle for modeling creep and loading rate effects at small strains in high-density polyethylene. Mech. Adv. Mater. Struct. 2021, 28, 891–903. [Google Scholar] [CrossRef]

- Schiessel, H.; Metzler, R.; Blumen, A.; Nonnenmacher, T.F. Generalized viscoelastic models: Their fractional equations with solutions. J. Phys. A Math. Gen. 1995, 28, 6567–6584. [Google Scholar] [CrossRef]

- Katicha, S.W.; Flintsch, G.W. Fractional viscoelastic models: Master curve construction, interconversion, and numerical approximation. Rheol. Acta 2012, 51, 675–689. [Google Scholar] [CrossRef]

- Matlob, M.A.; Jamali, Y. The concepts and applications of fractional order differential calculus in modeling of viscoelastic systems: A primer. Crit. Rev.™ Biomed. Eng. 2019, 47, 249–276. [Google Scholar] [CrossRef] [PubMed]

- Zhou, E.H.; Lim, C.T.; Quek, S.T. Finite element simulation of the micropipette aspiration of a living cell undergoing large viscoelastic deformation. Mech. Adv. Mater. Struct. 2005, 12, 501–512. [Google Scholar] [CrossRef]

- Plaseied, A.; Fatemi, A. Deformation response and constitutive modeling of vinyl ester polymer including strain rate and temperature effects. J. Mater. Sci. 2008, 43, 1191–1199. [Google Scholar] [CrossRef]

- Takagi, H.; Takahashi, M.; Maeda, R.; Onishi, Y.; Iriye, Y.; Iwasaki, T.; Hirai, Y. Analysis of time dependent polymer deformation based on a viscoelastic model in thermal imprint process. Microelectron. Eng. 2008, 85, 902–906. [Google Scholar] [CrossRef]

- Ge, Q.; Yu, K.; Ding, Y.; Qi, H.J. Prediction of temperature-dependent free recovery behaviors of amorphous shape memory polymers. Soft Matter 2012, 8, 11098–11105. [Google Scholar] [CrossRef]

- Yu, K.; Xie, T.; Leng, J.; Ding, Y.; Qi, H.J. Mechanisms of multi-shape memory effects and associated energy release in shape memory polymers. Soft Matter 2012, 8, 5687–5695. [Google Scholar] [CrossRef]

- Solares, S.D. Nanoscale effects in the characterization of viscoelastic materials with atomic force microscopy: Coupling of a quasi-three-dimensional standard linear solid model with in-plane surface interactions. Beilstein J. Nanotechnol. 2016, 7, 554–571. [Google Scholar] [CrossRef] [Green Version]

- Ganser, C.; Czibula, C.; Tscharnuter, D.; Schöberl, T.; Teichert, C.; Hirn, U. Combining adhesive contact mechanics with a viscoelastic material model to probe local material properties by AFM. Soft Matter 2018, 14, 140–150. [Google Scholar] [CrossRef] [Green Version]

- Cacopardo, L.; Guazzelli, N.; Nossa, R.; Mattei, G.; Ahluwalia, A. Engineering hydrogel viscoelasticity. J. Mech. Behav. Biomed. Mater. 2019, 89, 162–167. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.-W.; Lee, W.-S.; Chuang, Y.-F.; Cao, W.; Yang, F.; Lee, S. Time-dependent deformation of artificial muscles based on Nylon 6. Mater. Sci. Eng. C 2019, 98, 445–451. [Google Scholar] [CrossRef] [PubMed]

- Pei, Z.; Wang, L.; Wu, P.; Zhang, J.; Zhou, D. Analytical solution of deformations for two-layer Timoshenko beams glued by a viscoelastic interlayer. Math. Probl. Eng. 2019, 2019, 7620816. [Google Scholar] [CrossRef]

- Bazli, L.; Bagherian, M.H.; Karrabi, M.; Abbassi-Sourki, F.; Azizi, H. Effect of starch ratio and compatibilization on the viscoelastic behavior of POE/starch blends. J. Appl. Polym. Sci. 2020, 137, 48877. [Google Scholar] [CrossRef]

- Zhao, G.; Xu, J.; Feng, Y.; Tang, J.; Chen, Y.; Xin, S.; Jian, X.; Li, S.; Zhang, S.; Xu, J. A rate-dependent cohesive zone model with the effects of interfacial viscoelasticity and progressive damage. Eng. Fract. Mech. 2021, 248, 107695. [Google Scholar] [CrossRef]

- Güven, U. Effects of lateral inertia on the group velocities and specific damping capacities of viscoelastic polymeric rods. Int. J. Impact Eng. 2022, 162, 104156. [Google Scholar] [CrossRef]

- Wu, H.W.; Kuhn, T.; Moy, V.T. Mechanical properties of L929 cells measured by atomic force microscopy: Effects of anticytoskeletal drugs and membrane crosslinking. Scanning 1998, 20, 389–397. [Google Scholar] [CrossRef]

- Trickey, W.R.; Lee, G.M.; Guilak, F. Viscoelastic properties of chondrocytes from normal and osteoarthritic human cartilage. J. Orthop. Res. 2000, 18, 891–898. [Google Scholar] [CrossRef]

- Koay, E.J.; Shieh, A.C.; Athanasiou, K.A. Creep indentation of single cells. J. Biomech. Eng. 2003, 125, 334–341. [Google Scholar] [CrossRef]

- Peeters, E.A.; Oomens, C.W.; Bouten, C.V.; Bader, D.L.; Baaijens, F.P. Viscoelastic properties of single attached cells under compression. J. Biomech. Eng. 2005, 127, 237–243. [Google Scholar] [CrossRef]

- Lim, C.T.; Zhou, E.H.; Quek, S.T. Mechanical models for living cells—A review. J. Biomech. 2006, 39, 195–216. [Google Scholar] [CrossRef] [PubMed]

- Skalak, T.C.; Schmid-Schönbein, G.W. Viscoelastic properties of microvessels in rat spinotrapezius muscle. J. Biomech. Eng. 1986, 108, 193–200. [Google Scholar] [CrossRef] [PubMed]

- Bessems, D.; Giannopapa, C.G.; Rutten, M.C.; van de Vosse, F.N. Experimental validation of a time-domain-based wave propagation model of blood flow in viscoelastic vessels. J. Biomech. 2008, 41, 284–291. [Google Scholar] [CrossRef] [PubMed]

- Siami, M.; Jahani, K.; Rezaee, M. Identifying the parameters of viscoelastic model for a gel-type material as representative of cardiac muscle in dynamic tests. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2021, 235, 1205–1216. [Google Scholar] [CrossRef]

- Argatov, I.I. Mathematical modeling of linear viscoelastic impact: Application to drop impact testing of articular cartilage. Tribol. Int. 2013, 63, 213–225. [Google Scholar] [CrossRef] [Green Version]

- Quiroga, J.M.P.; Wilson, W.; Ito, K.; van Donkelaar, C.C. The effect of loading rate on the development of early damage in articular cartilage. Biomech. Model. Mechanobiol. 2017, 16, 263–273. [Google Scholar] [CrossRef]

- Li, S.; Patwardhan, A.G.; Amirouche, F.M.; Havey, R.; Meade, K.P. Limitations of the standard linear solid model of intervertebral discs subject to prolonged loading and low-frequency vibration in axial compression. J. Biomech. 1995, 28, 779–790. [Google Scholar] [CrossRef]

- Groth, K.M.; Granata, K.P. The viscoelastic standard nonlinear solid model: Predicting the response of the lumbar intervertebral disk to low-frequency vibrations. J. Biomech. Eng. 2008, 130, 031005. [Google Scholar] [CrossRef]

- Shazly, T.M.; Artzi, N.; Boehning, F.; Edelman, E.R. Viscoelastic adhesive mechanics of aldehyde-mediated soft tissue sealants. Biomaterials 2008, 29, 4584–4591. [Google Scholar] [CrossRef] [Green Version]

- Feng, Z.; Seya, D.; Kitajima, T.; Kosawada, T.; Nakamura, T.; Umezu, M. Viscoelastic characteristics of contracted collagen gels populated with rat fibroblasts or cardiomyocytes. J. Artif. Organs 2010, 13, 139–144. [Google Scholar] [CrossRef]

- Tirella, A.; Mattei, G.; Ahluwalia, A. Strain rate viscoelastic analysis of soft and highly hydrated biomaterials. J. Biomed. Mater. Res. Part A 2014, 102, 3352–3360. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Riande, E.; Diaz-Calleja, R.; Prolongo, M.; Masegosa, R.; Salom, C. Polymer Viscoelasticity: Stress and Strain in Practice; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Lakes, R.S. Viscoelastic Materials; Cambridge University Press: New York, NY, USA, 2009. [Google Scholar]

- Zu, M.; Li, Q.; Zhu, Y.; Zhu, Y.; Wang, G.; Byun, J.-H.; Chou, T.-W. Stress relaxation in carbon nanotube-based fibers for load-bearing applications. Carbon 2013, 52, 347–355. [Google Scholar] [CrossRef]

- Nam, S.; Hu, K.H.; Butte, M.J.; Chaudhuri, O. Strain-enhanced stress relaxation impacts nonlinear elasticity in collagen gels. Proc. Natl. Acad. Sci. USA 2016, 113, 5492–5497. [Google Scholar] [CrossRef] [Green Version]

- Yasin, S.; Hussain, M.; Zheng, Q.; Song, Y. Large amplitude oscillatory rheology of silica and cellulose nanocrystals filled natural rubber compounds. J. Colloid Interface Sci. 2021, 588, 602–610. [Google Scholar] [CrossRef]

- Yasin, S.; Hussain, M.; Zheng, Q.; Song, Y. Effects of ionic liquid on cellulosic nanofiller filled natural rubber bionanocomposites. J. Colloid Interface Sci. 2021, 591, 409–417. [Google Scholar] [CrossRef] [PubMed]

- Lakes, R.S.; Vanderby, R. Interrelation of creep and relaxation: A modeling approach for ligaments. J. Biomech. Eng. 1999, 121, 612–615. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oza, A.; Vanderby, R.; Lakes, R.S. Interrelation of creep and relaxation for nonlinearly viscoelastic materials: Application to ligament and metal. Rheol. Acta 2003, 42, 557–568. [Google Scholar] [CrossRef]

- Oza, A.; Vanderby, R., Jr.; Lakes, R.S. Generalized solution for predicting relaxation from creep in soft tissue: Application to ligament. Int. J. Mech. Sci. 2006, 48, 662–673. [Google Scholar] [CrossRef]

- Wells, P.N.T.; Liang, H.-D. Medical ultrasound: Imaging of soft tissue strain and elasticity. J. R. Soc. Interface 2011, 8, 1521–1549. [Google Scholar] [CrossRef] [Green Version]

- Walker, W.F.; Fernandez, F.J.; Negron, L.A. A method of imaging viscoelastic parameters with acoustic radiation force. Phys. Med. Biol. 2000, 45, 1437–1447. [Google Scholar] [CrossRef]

- Amadei, A.; Roccatano, D.; Apol, M.E.F.; Berendsen, H.J.C.; Di Nola, A. Prediction of the liquid–vapor equilibrium pressure using the quasi-Gaussian entropy theory. J. Chem. Phys. 1996, 105, 7022–7025. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Luo, X.G.; He, K.; Huo, D.Q.; Liu, J.; Liu, P.; Shi, X.-J.; Hou, C.J. Colorimetric artificial nose and pattern recognition methods for the concentration analysis of NH3. Water Air Soil Pollut. 2012, 223, 2969–2977. [Google Scholar] [CrossRef]

- Altet, J.; Gomez, D.; Perpinyà, X.; Mateo, D.; González, J.L.; Vellvehi, M.; Jordà, X. Efficiency determination of RF linear power amplifiers by steady-state temperature monitoring using built-in sensors. Sens. Actuators A Phys. 2013, 192, 49–57. [Google Scholar] [CrossRef]

- Lützner, C.; Voigt, H.; Roeder, I.; Kirschner, S.; Lützner, J. Placement makes a difference: Accuracy of an accelerometer in measuring step number and stair climbing. Gait Posture 2014, 39, 1126–1132. [Google Scholar] [CrossRef]

- Marugan-Cruz, C.; Flores, O.; Santana, D.; Garcia-Villalba, M. Heat transfer and thermal stresses in a circular tube with a non-uniform heat flux. Int. J. Heat Mass Transf. 2016, 96, 256–266. [Google Scholar] [CrossRef]

- Ya, W.; Pathiraj, B.; Liu, S. 2D modelling of clad geometry and resulting thermal cycles during laser cladding. J. Mater. Process. Technol. 2016, 230, 217–232. [Google Scholar] [CrossRef]

- Coenen, A.; Batterham, M.J.; Beck, E.J. Statistical methods and software used in nutrition and dietetics research: A review of the published literature using text mining. Nutr. Diet. 2021, 78, 333–342. [Google Scholar] [CrossRef]

- Rafiq, W.; Napiah, M.; Habib, N.Z.; Sutanto, M.H.; Alaloul, W.S.; Khan, M.I.; Musarat, M.A.; Memon, A.M. Modeling and design optimization of reclaimed asphalt pavement containing crude palm oil using response surface methodology. Constr. Build. Mater. 2021, 291, 123288. [Google Scholar] [CrossRef]

- Lin, C.Y.; Chang, K.V. Effects of Loading and Boundary Conditions on the Performance of Ultrasound Compres-sional Viscoelastography: A Computational Simulation Study to Guide Experimental Design. Materials 2021, 14, 2590. [Google Scholar] [CrossRef]

- Brandenburg, J.E.; Eby, S.F.; Song, P.; Zhao, H.; Brault, J.S.; Chen, S.; An, K.-N. Ultrasound Elastography: The New Frontier in Direct Measurement of Muscle Stiffness. Arch. Phys. Med. Rehab. 2014, 95, 2207–2219. [Google Scholar] [CrossRef] [Green Version]

| Mechanical Properties Set in ABAQUS | Corresponding Parameters in the Standard Linear Solid Model | |||||

|---|---|---|---|---|---|---|

| Number of Material Models | (kPa) | (s) | (kPa) | (kPa) | (Pa s) | |

| 1 | 5 | 0.5 | 0.8 | 5 | 20 | 10 |

| 2 | 5 | 2 | 0.8 | 5 | 20 | 40 |

| 3 | 5 | 5 | 0.8 | 5 | 20 | 100 |

| 4 | 10 | 0.5 | 0.8 | 10 | 40 | 20 |

| 5 | 10 | 2 | 0.8 | 10 | 40 | 80 |

| 6 | 10 | 5 | 0.8 | 10 | 40 | 200 |

| 7 | 30 | 0.5 | 0.8 | 30 | 120 | 60 |

| 8 | 30 | 2 | 0.8 | 30 | 120 | 240 |

| 9 | 30 | 5 | 0.8 | 30 | 120 | 600 |

| Physical Significances | Equation (1) | Equation (7) |

|---|---|---|

| The term involving the time-dependent exponential function that characterizes the time-dependent viscoelastic behavior | ||

| The constant term that characterizes the time-independent elastic solid behavior (which is also the equilibrium stress when ) | ||

| The initial stress at the beginning of the stress relaxation process at ) |

| Physical Significances | Equation (2) | Equation (12) |

|---|---|---|

| The term involving the time-dependent exponential function that characterizes the time-dependent viscoelastic behavior | ||

| The constant term that characterizes the time-independent elastic solid behavior (which is also the equilibrium strain when ) | ||

| The initial strain at the beginning of the creep process at ) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-Y.; Chen, Y.-C.; Lin, C.-H.; Chang, K.-V. Constitutive Equations for Analyzing Stress Relaxation and Creep of Viscoelastic Materials Based on Standard Linear Solid Model Derived with Finite Loading Rate. Polymers 2022, 14, 2124. https://doi.org/10.3390/polym14102124

Lin C-Y, Chen Y-C, Lin C-H, Chang K-V. Constitutive Equations for Analyzing Stress Relaxation and Creep of Viscoelastic Materials Based on Standard Linear Solid Model Derived with Finite Loading Rate. Polymers. 2022; 14(10):2124. https://doi.org/10.3390/polym14102124

Chicago/Turabian StyleLin, Che-Yu, Yi-Cheng Chen, Chen-Hsin Lin, and Ke-Vin Chang. 2022. "Constitutive Equations for Analyzing Stress Relaxation and Creep of Viscoelastic Materials Based on Standard Linear Solid Model Derived with Finite Loading Rate" Polymers 14, no. 10: 2124. https://doi.org/10.3390/polym14102124

APA StyleLin, C.-Y., Chen, Y.-C., Lin, C.-H., & Chang, K.-V. (2022). Constitutive Equations for Analyzing Stress Relaxation and Creep of Viscoelastic Materials Based on Standard Linear Solid Model Derived with Finite Loading Rate. Polymers, 14(10), 2124. https://doi.org/10.3390/polym14102124