Experimental Analysis of Matrix Cracking in Glass Fiber Reinforced Composite Off-Axis Plies under Static and Fatigue Loading

Abstract

:1. Introduction

2. Experimental Procedure for Matrix Crack Density Measurements

2.1. Materials and Specimen Preparation

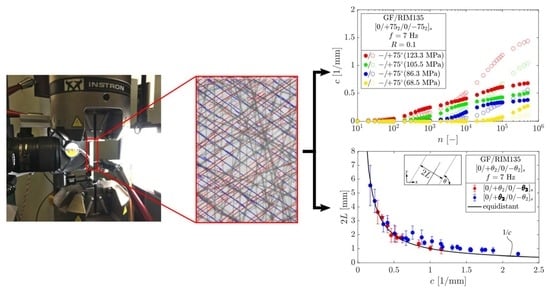

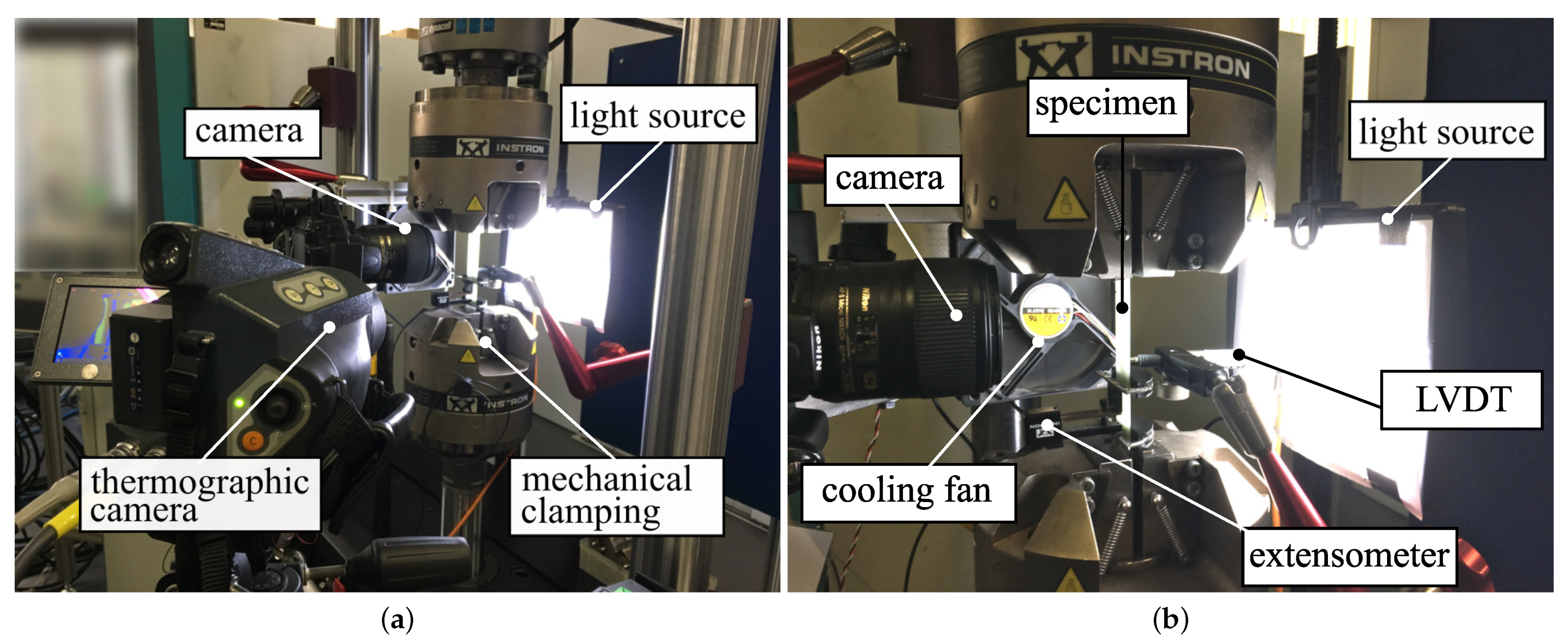

2.2. Experimental Setup for Microcracking Analysis

3. Matrix Crack Detection by Transmitted White Light Imaging

3.1. Crack Detection Procedure

- Image acquisition

- Displacement compensation and image normalization

- Anisotropic image filtering

- Thresholding and crack measurement

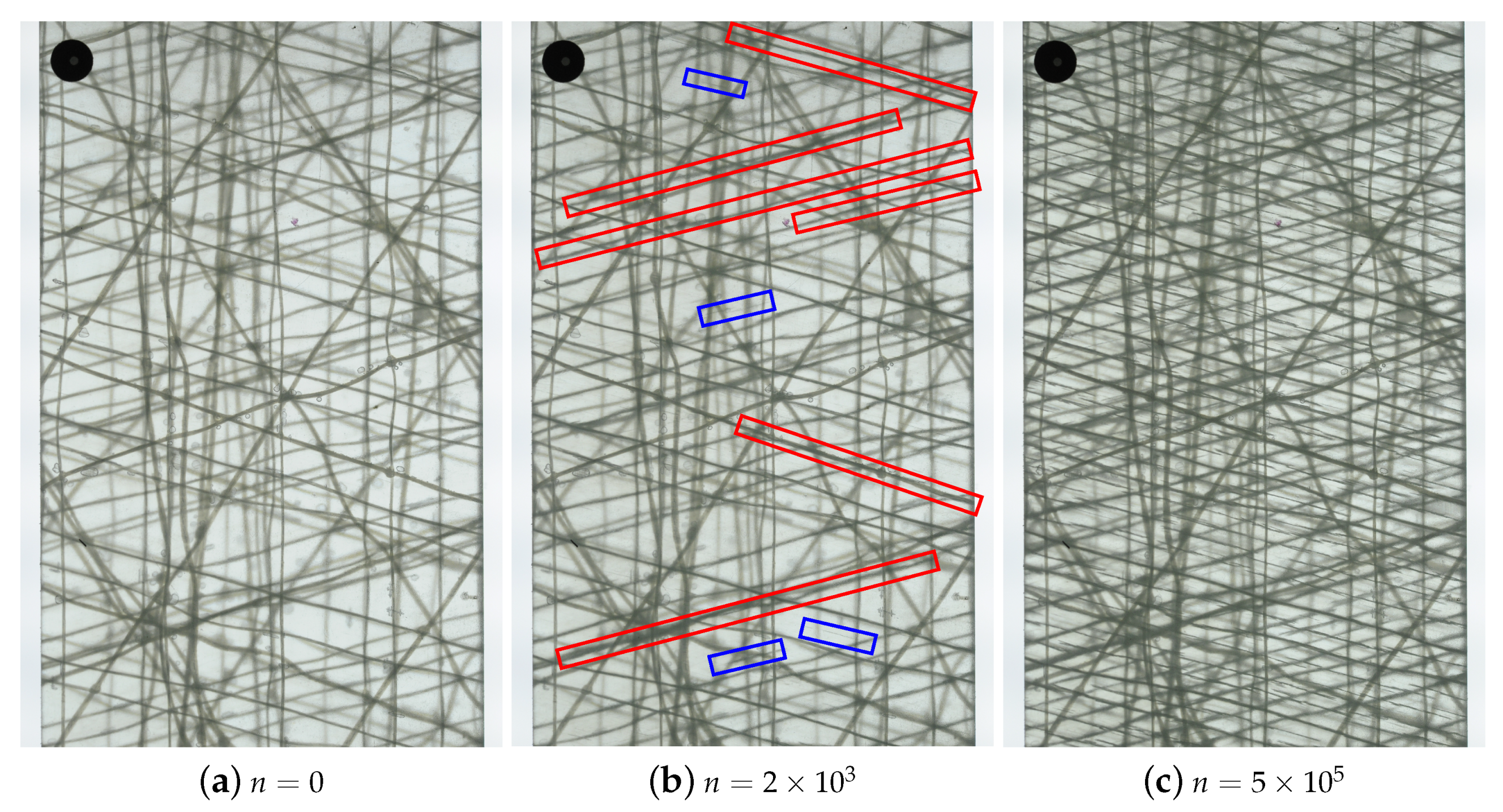

3.1.1. Image Acquisition

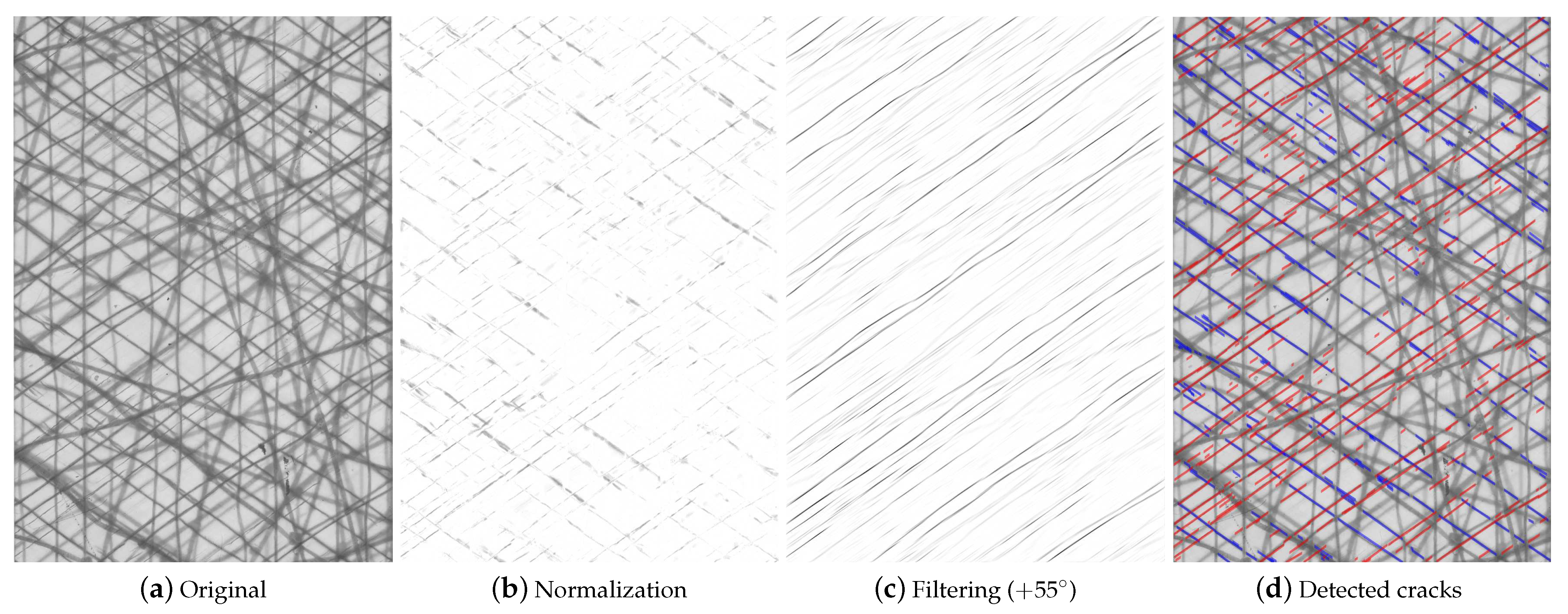

3.1.2. Displacement Compensation and Image Normalization

3.1.3. Filtering and Crack Detection

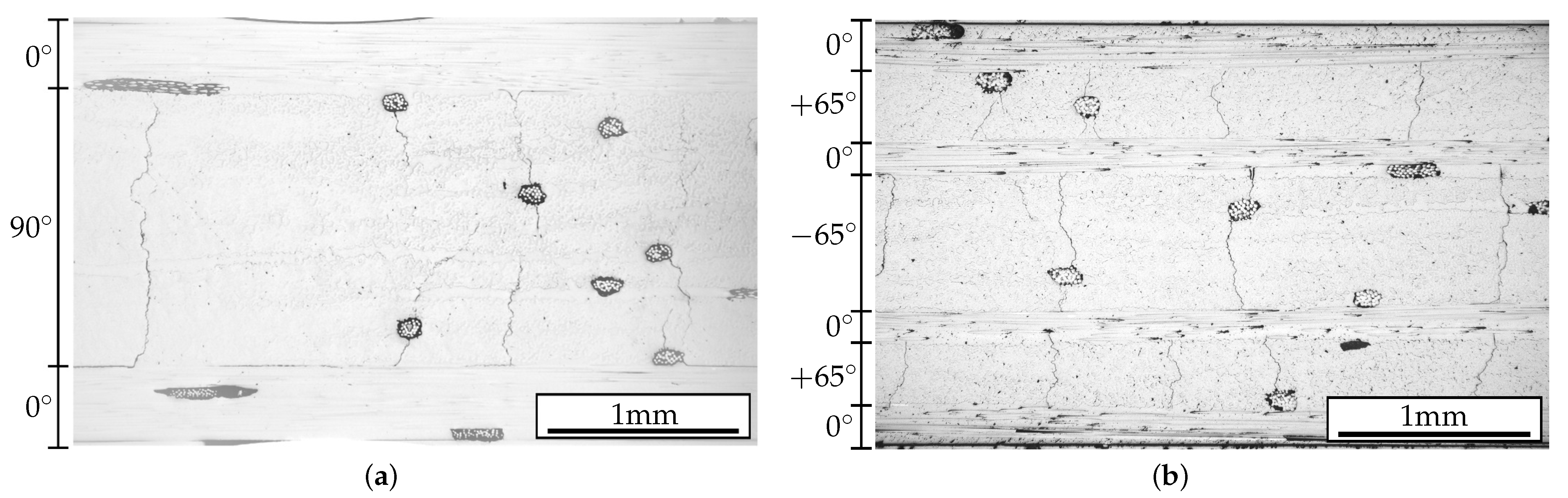

3.2. Experimental Validation

4. Results and Discussion

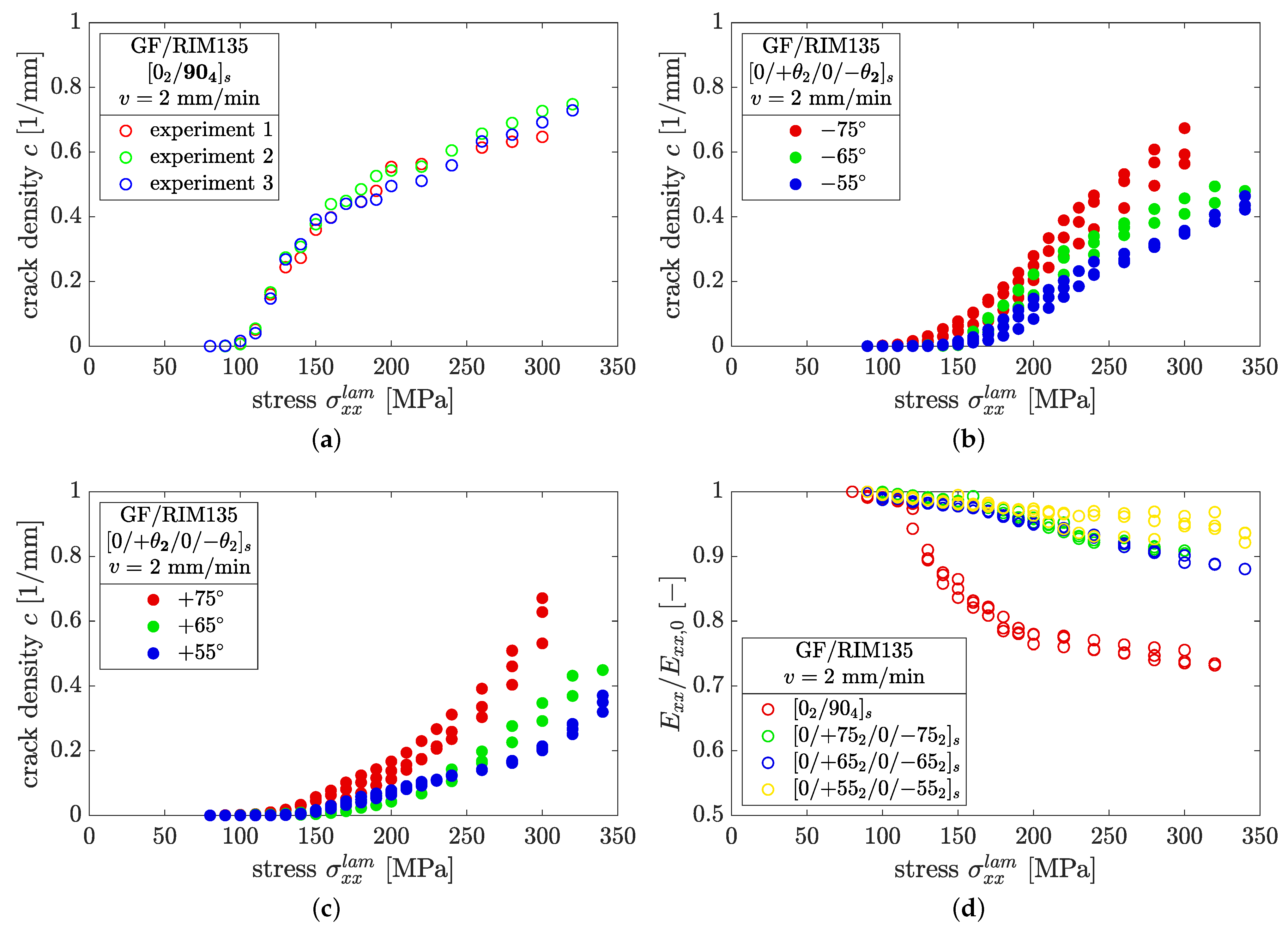

4.1. Static Loading

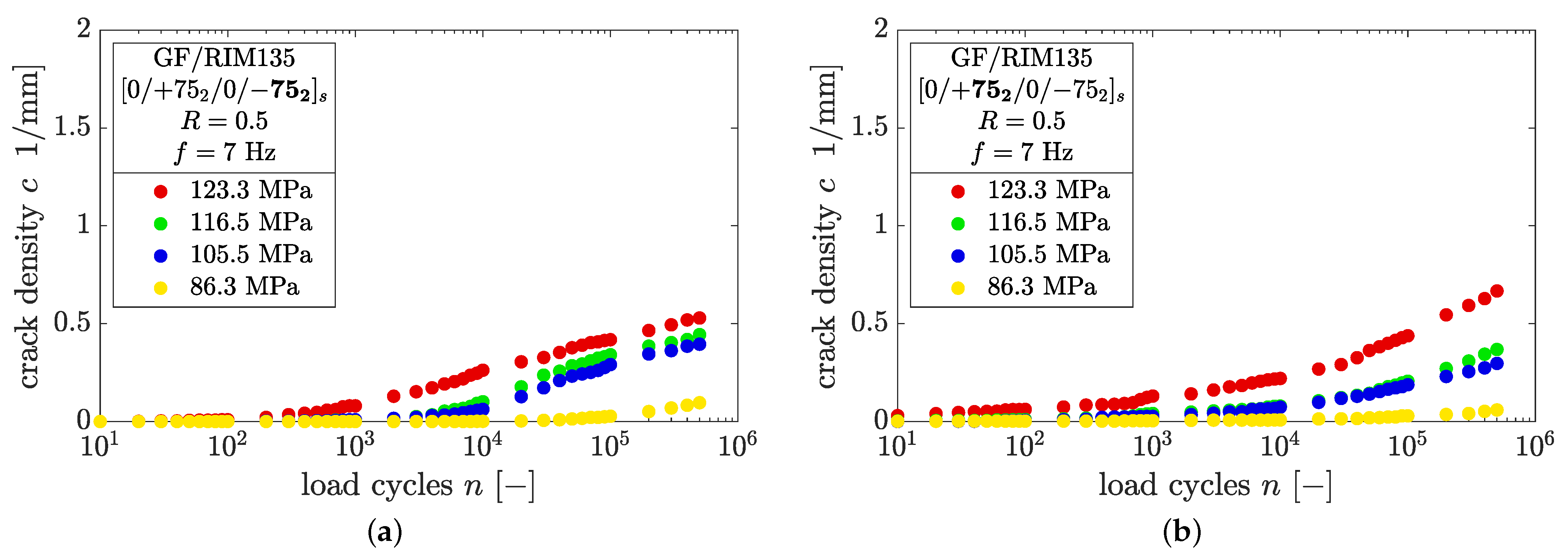

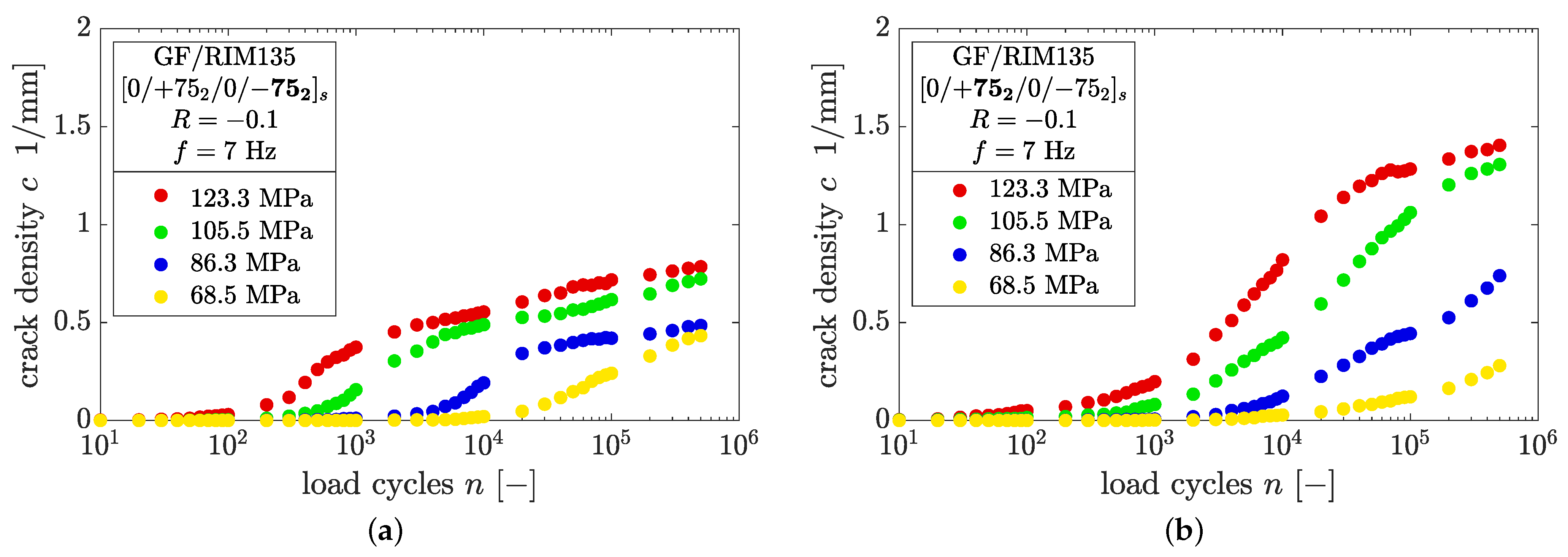

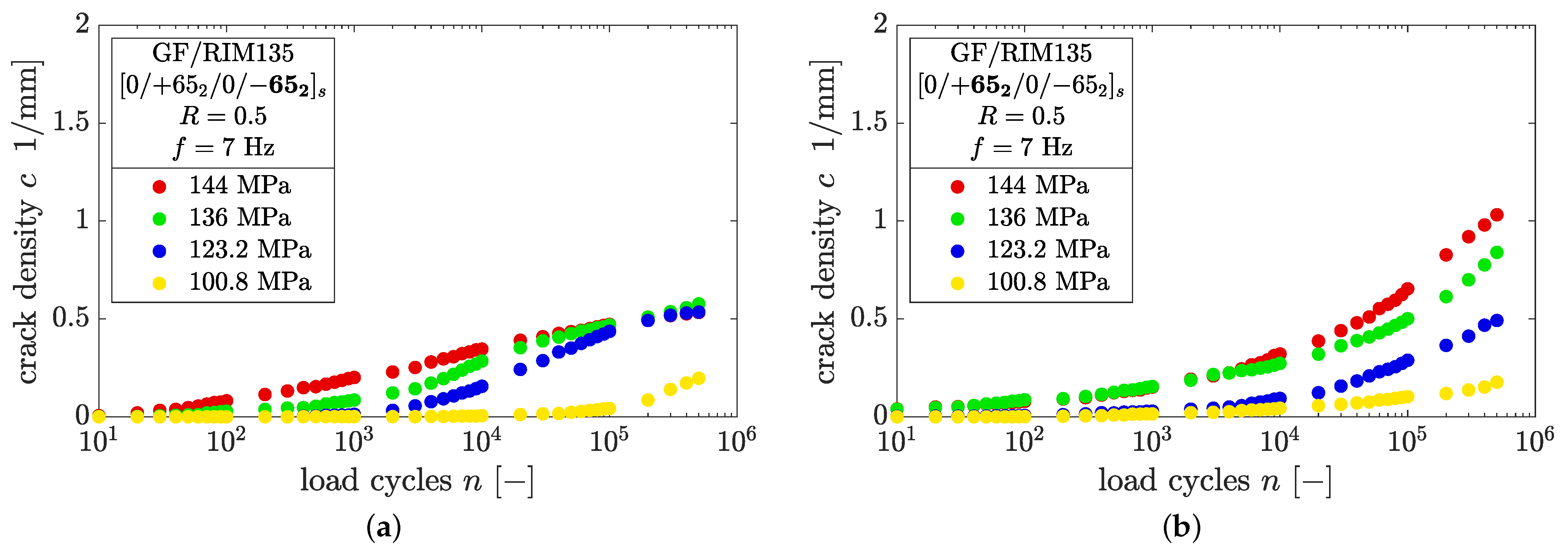

4.2. Fatigue Loading

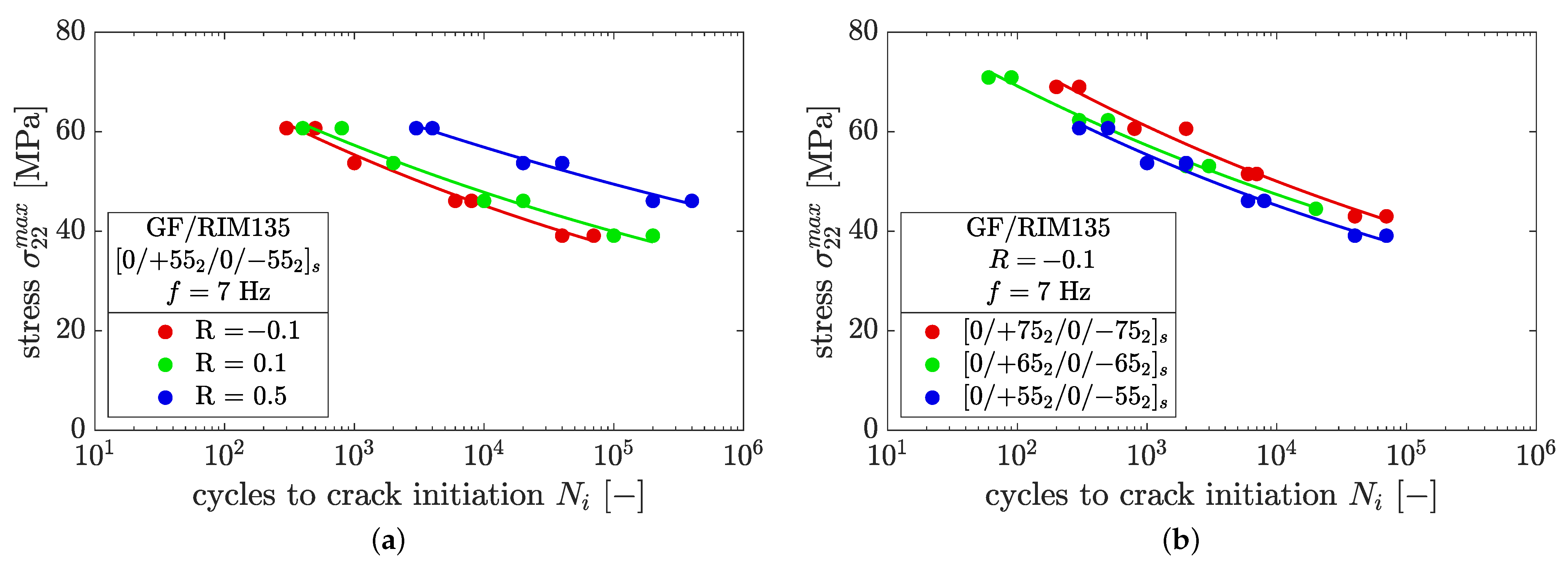

4.2.1. Fatigue Crack Initiation

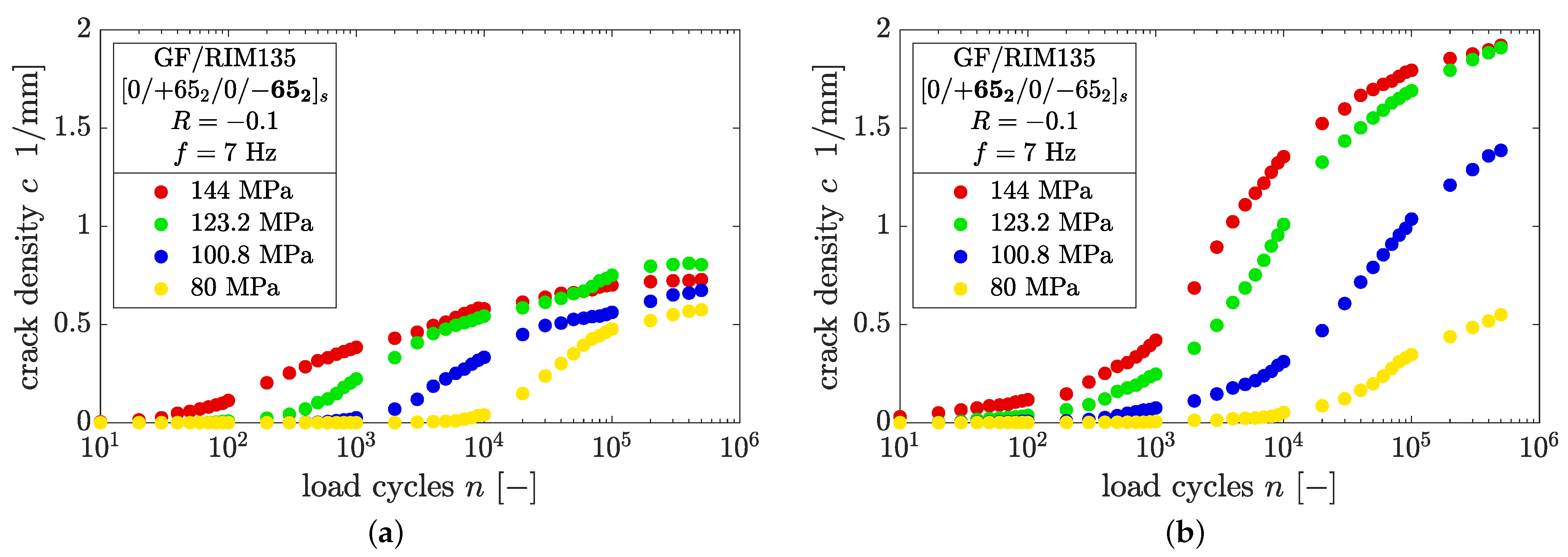

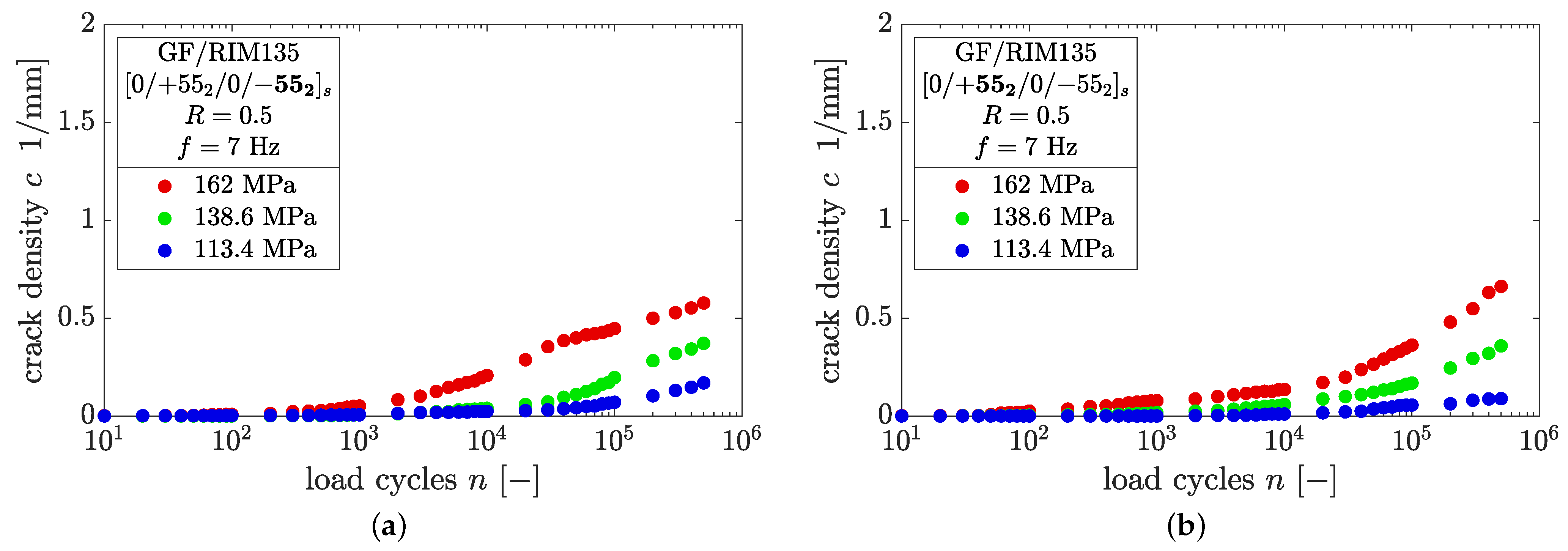

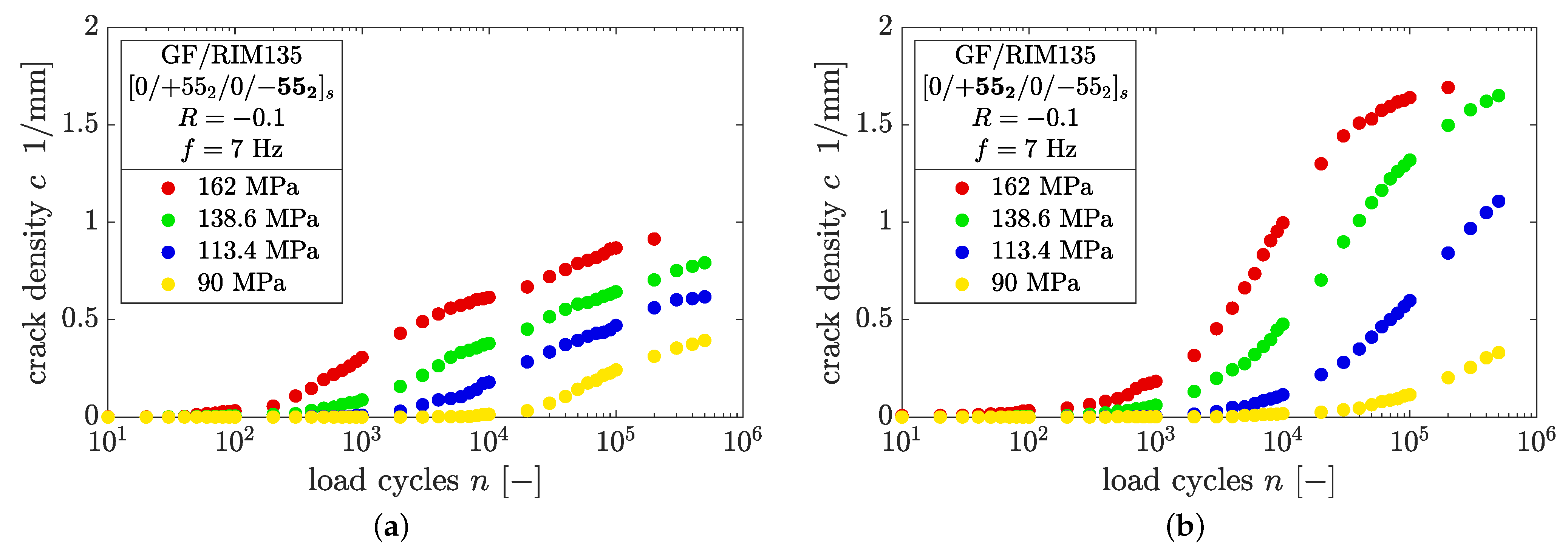

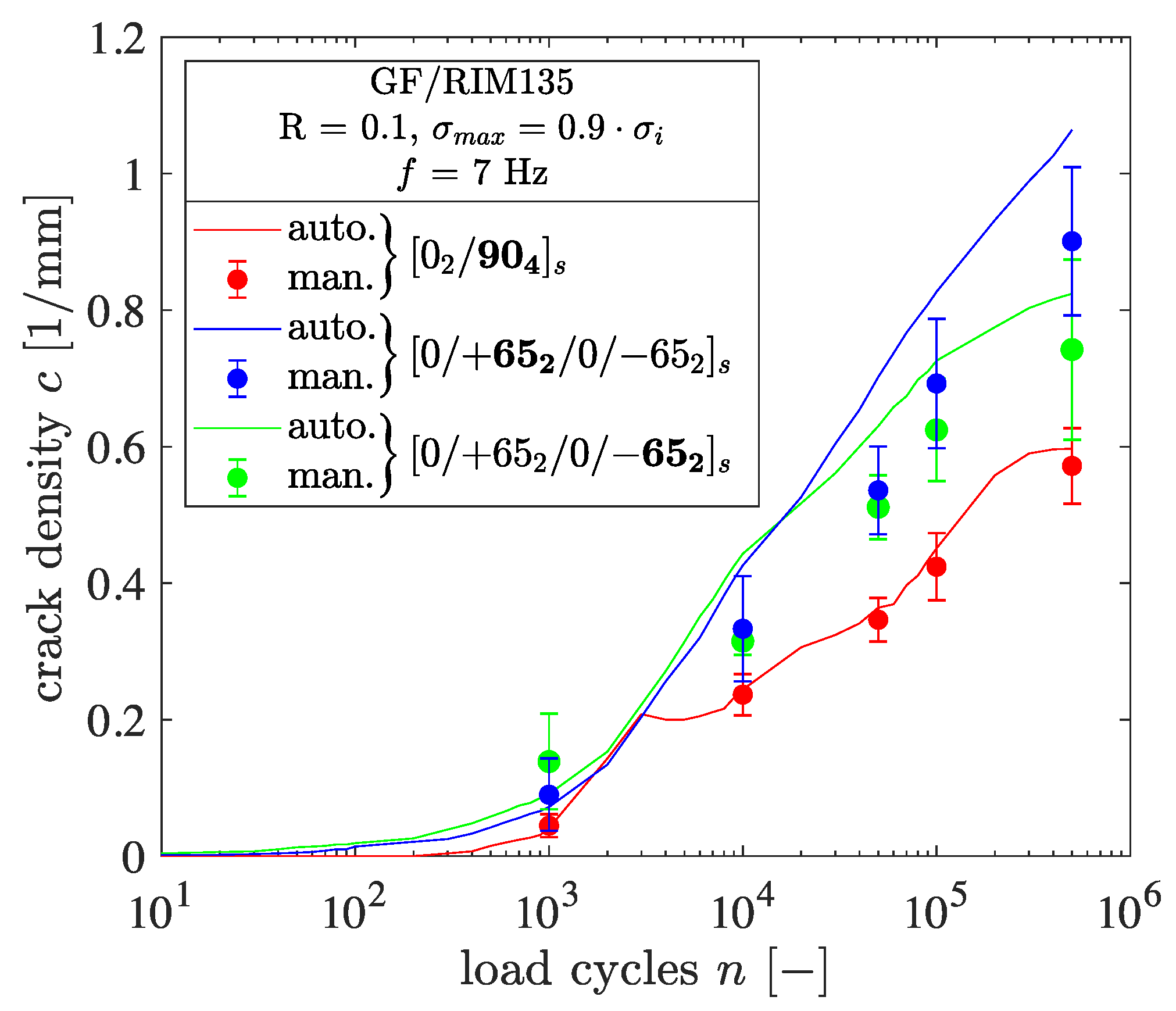

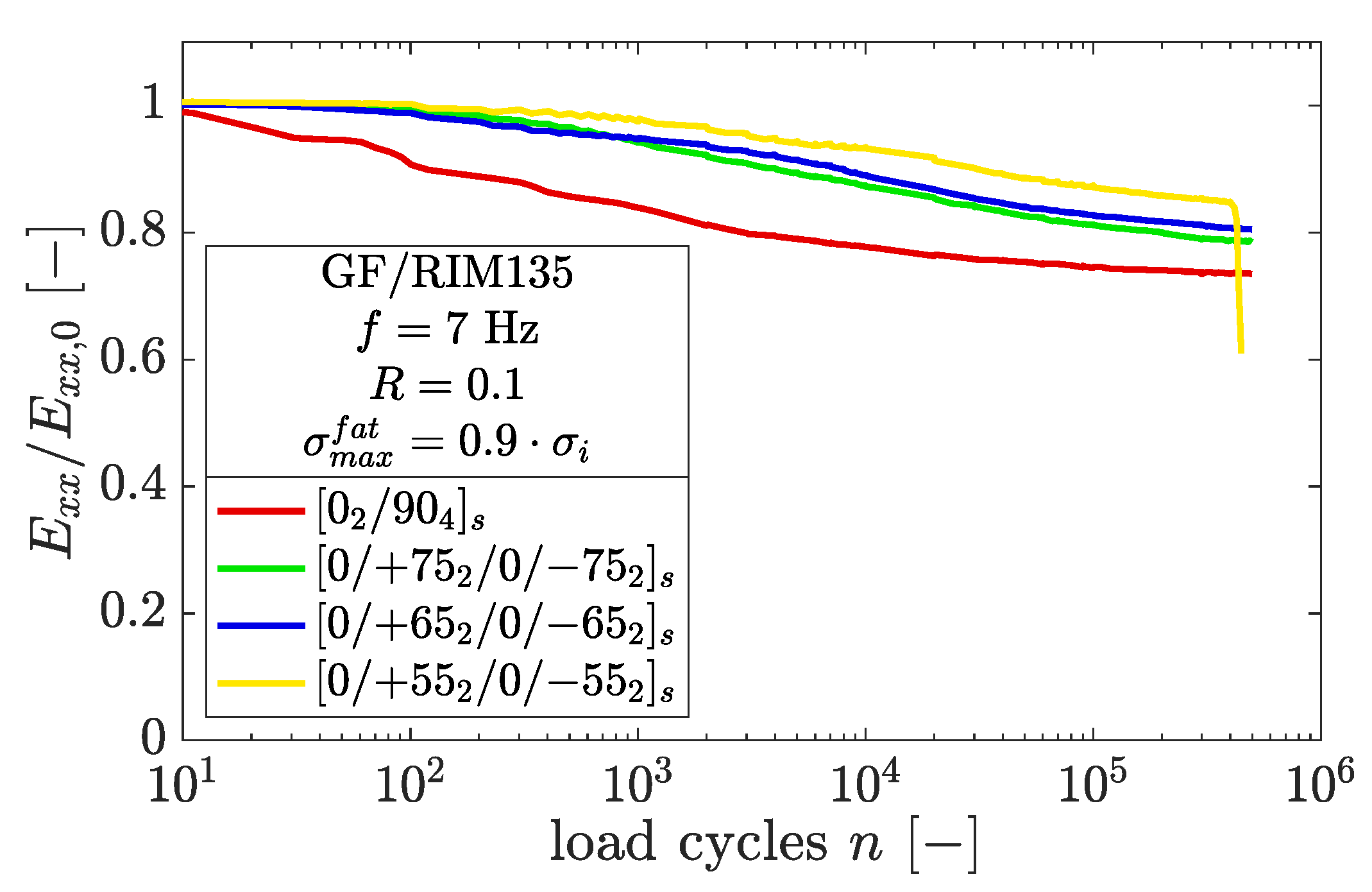

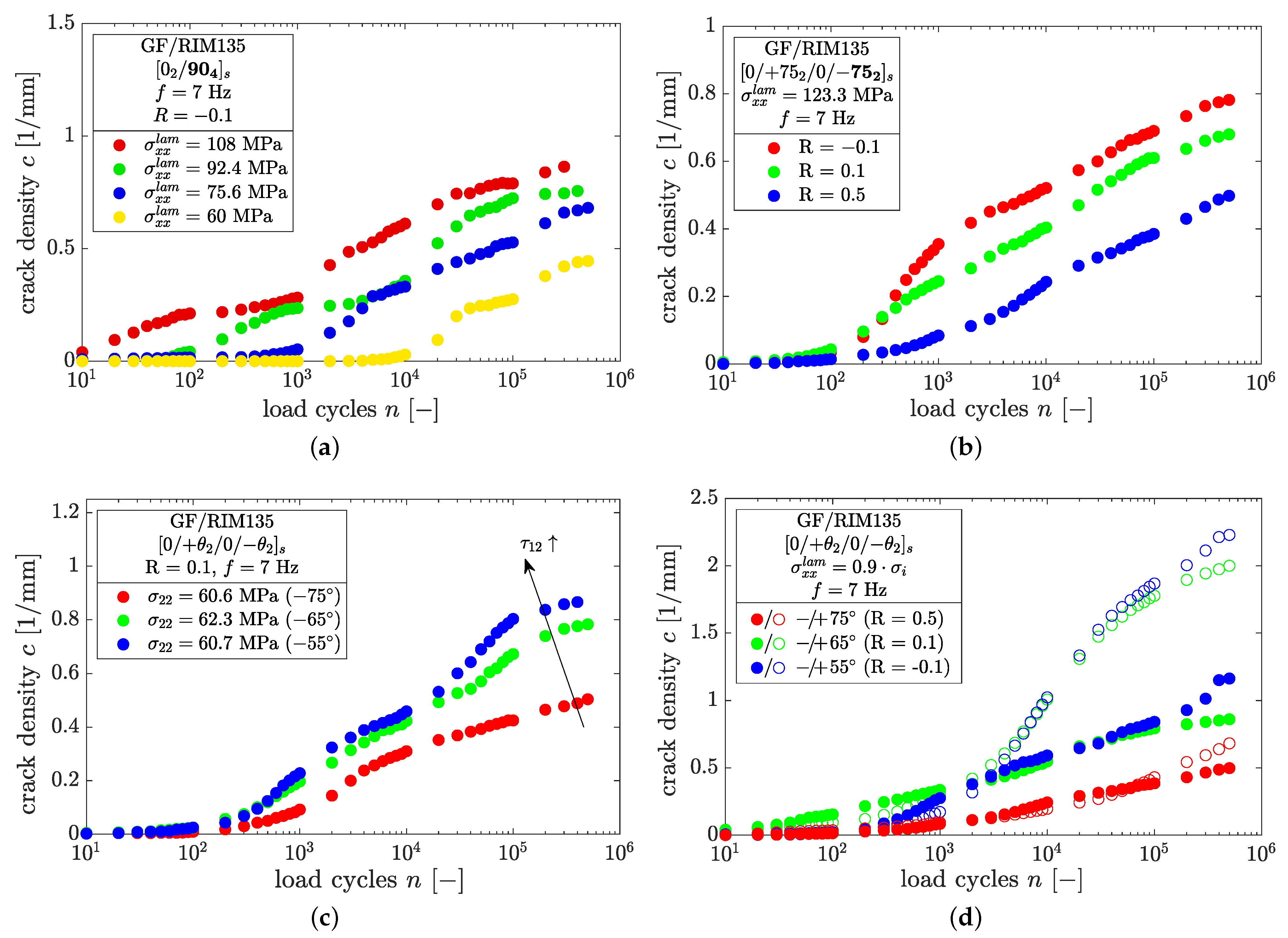

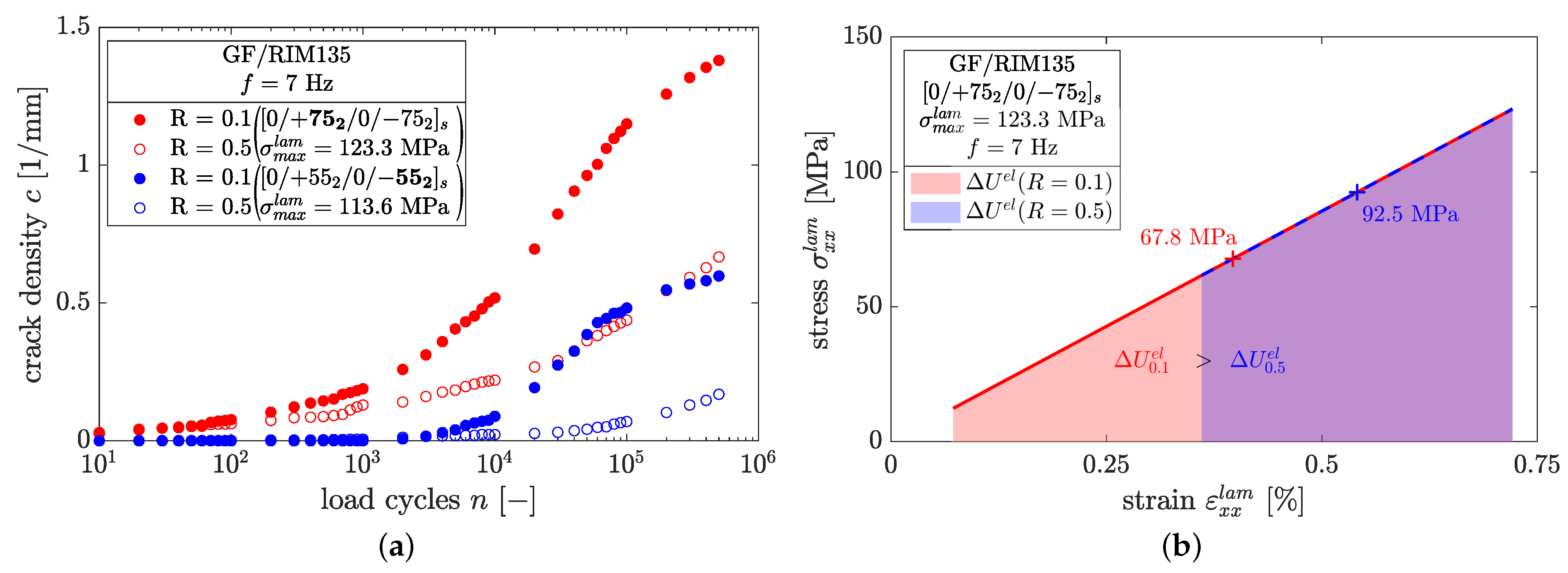

4.2.2. Fatigue Crack Evolution

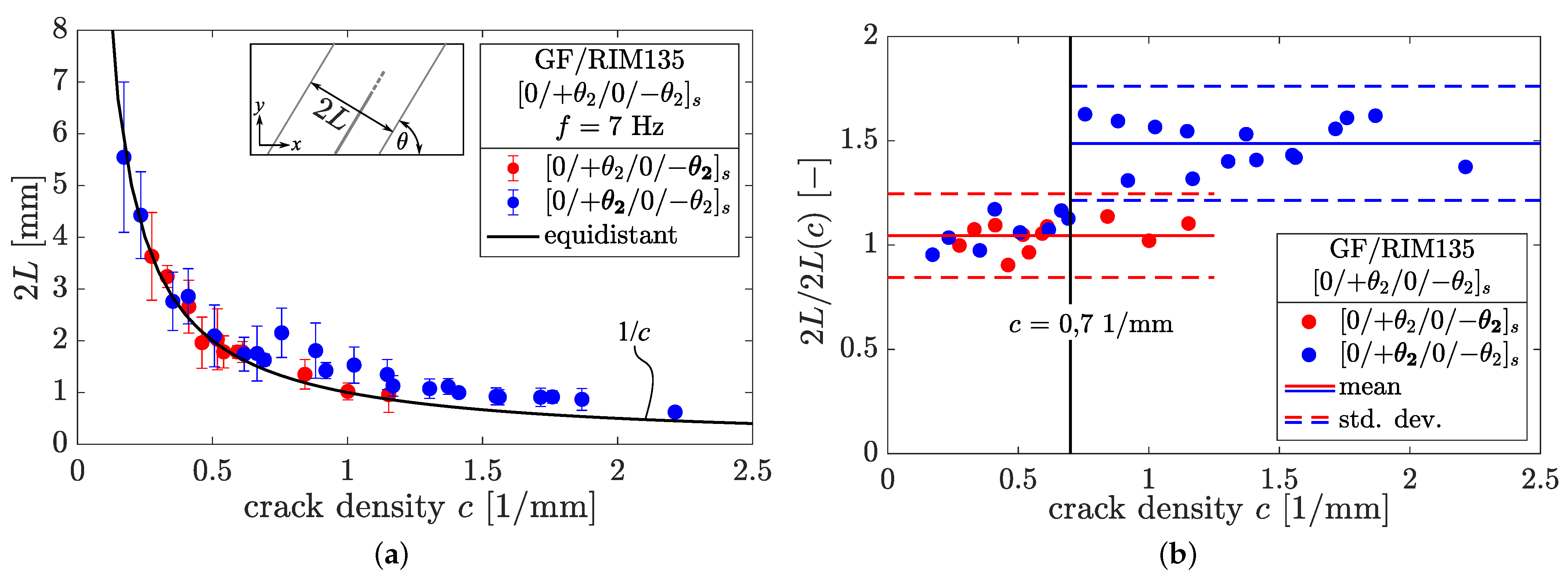

4.2.3. Crack Interaction

5. Conclusions

- Increasing the maximum applied stress leads to faster and more pronounced evolution of cracks in fatigue loading due to higher stresses and resulting higher strain energy within the off-axis plies. The observed crack densities after loading cycles were between 0.25 to 1 cracks/mm for thick layers, while for thin layers the dependence on the load level was even more pronounced. In that case, the crack densities ranged from 0.15 to 2 cracks/mm.

- High load ratios lead to less crack growth, even when the specimen is loaded with the same maximum stress, which is an effect of the smaller range of elastic strain energy stored in the material within a cycle. It is therefore recommended to adopt the range of the strain energy release rate, , as the driving force for cyclic crack growth.

- Fiber orientations other than 0° and 90° lead to shear stresses which have a detrimental effect on crack growth in fatigue, leading to higher crack densities when experiments with nearly the same normal ply-stresses are compared. On the contrary, the detrimental effect has been observed in static loading, where lower fiber angles lead to less crack initiation and growth up to specimen failure. This might be due to increased fracture toughness from the higher mode mix.

- Ply thickness affects the number of cracks forming in fatigue, and has little influence on fatigue crack initiation. This might be due to the bonding yarns, which can be seen as initial defects. Such defects trigger failure at very low loads and loading cycles.

- In case of high crack densities (), individual cracks tend to grow within areas of locally larger crack spacings due to crack interaction. These crack spacings are on average 1.5 times the size of the corresponding equidistant crack spacing. This finding is in very good agreement with the theoretical estimations in [36], and provides experimental evidence for the physical meaning of scaling factors for crack spacings at high crack densities.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FRP | Fiber-reinforced plastic |

| GF | Glass fiber |

| GFRP | Glass fiber-reinforced plastic |

| LUR | Loading–unloading–reloading |

| LVDT | Linear variable differential transformer |

| RTM | Resin transfer molding |

| TWLI | Transmitted white light imaging |

| UD | Unidirectional |

| VNRS | V-notched rail shear |

Appendix A. Summary of Experimental Fatigue Results for R = 0.5 and R = −0.1

References

- Liang, M.; Fu, C.; Xiao, B.; Luo, L.; Wang, Z. A fractal study for the effective electrolyte diffusion through charged porous media. Int. J. Heat Mass Transf. 2019, 137, 365–371. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, W.; Zhang, X.; Long, G.; Fan, J.; Chen, H.; Deng, L. A novel fractal solution for permeability and Kozeny-Carman constant of fibrous porous media made up of solid particles and porous fibers. Powder Technol. 2019, 349, 92–98. [Google Scholar] [CrossRef]

- Hashin, Z.; Rotem, A. A Fatigue Failure Criterion for Fiber Reinforced Materials. J. Compos. Mater. 1973, 7, 448–464. [Google Scholar] [CrossRef] [Green Version]

- Kawai, M.; Honda, N. Off-axis fatigue behavior of a carbon/epoxy cross-ply laminate and predictions considering inelasticity and in situ strength of embedded plies. Int. J. Fatigue 2008, 30, 1743–1755. [Google Scholar] [CrossRef]

- Kawai, M.; Itoh, N. A failure-mode based anisomorphic constant life diagram for a unidirectional carbon/epoxy laminate under off-axis fatigue loading at room temperature. J. Compos. Mater. 2014, 48, 571–592. [Google Scholar] [CrossRef]

- Quaresimin, M.; Susmel, L.; Talreja, R. Fatigue behaviour and life assessment of composite laminates under multiaxial loadings. Int. J. Fatigue 2010, 32, 2–16. [Google Scholar] [CrossRef]

- Shokrieh, M.; Taheri-Behrooz, F. A unified fatigue life model based on energy method. Compos. Struct. 2006, 75, 444–450. [Google Scholar] [CrossRef]

- Adam, T.; Horst, P. Experimental investigation of the very high cycle fatigue of GFRP [90/0]s cross-ply specimens subjected to high-frequency four-point bending. Compos. Sci. Technol. 2014, 101, 62–70. [Google Scholar] [CrossRef]

- Carraro, P.A.; Maragoni, L.; Quaresimin, M. Prediction of the crack density evolution in multidirectional laminates under fatigue loadings. Compos. Sci. Technol. 2017, 145, 24–39. [Google Scholar] [CrossRef]

- Garrett, K.W.; Bailey, J.E. Multiple transverse fracture in 90° cross-ply laminates of a glass fibre-reinforced polyester. J. Mater. Sci. 1977, 12, 157–168. [Google Scholar] [CrossRef]

- Singh, C.V.; Talreja, R. Analysis of multiple off-axis ply cracks in composite laminates. Int. J. Solids Struct. 2008, 45, 4574–4589. [Google Scholar] [CrossRef] [Green Version]

- Singh, C.V.; Talreja, R. A synergistic damage mechanics approach for composite laminates with matrix cracks in multiple orientations. Mech. Mater. 2009, 41, 954–968. [Google Scholar] [CrossRef]

- Van Paepegem, W. Developement and Finite Element Implementation of a Damage Model for Fatigue of Fibre-Reinforced Polymers. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2002. [Google Scholar]

- Carraro, P.A. Multiaxial Fatigue Behaviour of Composite Materials: Characterisation and Modelling. Ph.D. Thesis, University of Padua, Padua, Italy, 2014. [Google Scholar]

- Fikry, M.M.; Ogihara, S.; Vinogradov, V. The effect of matrix cracking on mechanical properties in FRP laminates. Mech. Adv. Mater. Mod. Process. 2018, 4, 1–16. [Google Scholar] [CrossRef]

- Glud, J.; Dulieu-Barton, J.; Thomsen, O.; Overgaard, L. Automated counting of off-axis tunnelling cracks using digital image processing. Compos. Sci. Technol. 2016, 125, 80–89. [Google Scholar] [CrossRef] [Green Version]

- Just, G.; Koch, I.; Brod, M.; Jansen, E.; Gude, M.; Rolfes, R. Influence of Reversed Fatigue Loading on Damage Evolution of Cross-Ply Carbon Fibre Composites. Materials 2019, 12, 1153. [Google Scholar] [CrossRef] [Green Version]

- Sket, F.; Enfedaque, A.; Alton, C.; González, C.; Molina-Aldareguia, J.M.; Llorca, J. Automatic quantification of matrix cracking and fiber rotation by X-ray computed tomography in shear-deformed carbon fiber-reinforced laminates. Compos. Sci. Technol. 2014, 90, 129–138. [Google Scholar] [CrossRef] [Green Version]

- Shen, H.; Yao, W.; Qi, W.; Zong, J. Experimental investigation on damage evolution in cross-ply laminates subjected to quasi-static and fatigue loading. Compos. Part B Eng. 2017, 120, 10–26. [Google Scholar] [CrossRef]

- Talreja, R.; Singh, C. Damage and Failure of Composite Materials; Cambridge University Press: New York, NY, USA, 2012. [Google Scholar]

- Varna, J. Modelling mechanical performance of damaged laminates. J. Compos. Mater. 2013, 47, 2443–2474. [Google Scholar] [CrossRef]

- Hajikazemi, M.; McCartney, L.; Ahmadi, H.; Van Paepegem, W. Variational analysis of cracking in general composite laminates subject to triaxial and bending loads. Compos. Struct. 2020, 239, 111993. [Google Scholar] [CrossRef]

- Kalteremidou, K.A.; Hajikazemi, M.; Van Paepegem, W.; Van Hemelrijck, D.; Pyl, L. Effect of multiaxiality, stacking sequence and number of off-axis layers on the mechanical response and damage sequence of carbon/epoxy composite laminates under static loading. Compos. Sci. Technol. 2020, 190, 108044. [Google Scholar] [CrossRef]

- Hashin, Z. Analysis of cracked laminates: A variational approach. Mech. Mater. 1985, 4, 121–136. [Google Scholar] [CrossRef]

- Tan, S.; Nuismer, R. A Theory for Progressive Matrix Cracking in Composites. J. Compos. Mater. 1989, 23, 1029–1047. [Google Scholar] [CrossRef]

- Nuismer, R.; Tan, S. Constitutive Relations of a Cracked Composite Lamina. J. Compos. Mater. 1988, 22, 306–321. [Google Scholar] [CrossRef]

- Nairn, J.A. Microcracking, Microcrack-Induced Delaminations, and Longitudinal Splitting of Advanced Composite Structures; Technical Report 4472; NASA: Washington, DC, USA, 1992. [Google Scholar]

- Berthelot, J.M. Transverse cracking and delamination in cross-ply glass-fiber and carbon-fiber reinforced plastic laminates: Static and fatigue loading. Appl. Mech. Rev. 2003, 56, 111–147. [Google Scholar] [CrossRef]

- Vinogradov, V.; Hashin, Z. Probabilistic energy based model for prediction of transverse cracking in cross-ply laminates. Int. J. Solids Struct. 2005, 42, 365–392. [Google Scholar] [CrossRef]

- Glud, J.A.; Dulieu-Barton, J.M.; Thomsen, O.T.; Overgaard, L.C.T. A stochastic multiaxial fatigue model for off-axis cracking in FRP laminates. Int. J. Fatigue 2017, 103, 576–590. [Google Scholar] [CrossRef] [Green Version]

- Jagannathan, N.; Gururaja, S.; Manjunatha, C. Probabilistic strength based matrix crack evolution model in multi-directional composite laminates under fatigue loading. Int. J. Fatigue 2018, 117, 135–147. [Google Scholar] [CrossRef]

- Ben Kahla, H.; Ayadi, Z.; Edgren, F.; Pupurs, A.; Varna, J. Statistical model for initiation governed intralaminar cracking in composite laminates during tensile quasi-static and cyclic tests. Int. J. Fatigue 2018, 116, 1–12. [Google Scholar] [CrossRef]

- Adam, T.J.; Horst, P. Fatigue damage and fatigue limits of a GFRP angle-ply laminate tested under very high cycle fatigue loading. Int. J. Fatigue 2017, 99 Pt 1, 202–214. [Google Scholar] [CrossRef]

- Quaresimin, M.; Carraro, P. Damage initiation and evolution in glass/epoxy tubes subjected to combined tension–torsion fatigue loading. Int. J. Fatigue 2014, 63, 25–35. [Google Scholar] [CrossRef]

- Quaresimin, M.; Carraro, P.; Maragoni, L. Influence of load ratio on the biaxial fatigue behaviour and damage evolution in glass/epoxy tubes under tension–torsion loading. Compos. Part A Appl. Sci. Manuf. 2015, 78, 294–302. [Google Scholar] [CrossRef]

- Liu, S.; Nairn, J.A. The Formation and Propagation of Matrix Microcracks in Cross-Ply Laminates during Static Loading. J. Reinf. Plast. Compos. 1992, 11, 158–178. [Google Scholar] [CrossRef]

- Bender, J.J.; Glud, J.A.; Lindgaard, E. Optical HDR Acquisition of Crack Density Evolution in Cyclic Loaded GFRP Cross-Ply Laminates Affected by Stitching. Compos. Part A Appl. Sci. Manuf. 2018, 112, 207–215. [Google Scholar] [CrossRef]

- Quaresimin, M.; Carraro, P.A.; Mikkelsen, L.P.; Lucato, N.; Vivian, L.; Brøndsted, P.; Sørensen, B.F.; Varna, J.; Talreja, R. Damage evolution under cyclic multiaxial stress state: A comparative analysis between glass/epoxy laminates and tubes. Compos. Part B Eng. 2014, 61, 282–290. [Google Scholar] [CrossRef]

- Thirion, J.P. Image matching as a diffusion process: An analogy with Maxwell’s demons. Med Image Anal. 1998, 2, 243–260. [Google Scholar] [CrossRef] [Green Version]

- Vercauteren, T.; Pennec, X.; Perchant, A.; Ayache, N. Diffeomorphic demons: Efficient non-parametric image registration. NeuroImage 2009, 45, S61–S72. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Daugman, J.G. Uncertainty relation for resolution in space, spatial frequency, and orientation optimized by two-dimensional visual cortical filters. JOSA A 1985, 2, 1160–1169. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man, Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef] [Green Version]

- Krasnikovs, A.; Varna, J. Transverse cracks in cross-ply laminates. 1. Stress analysis. Mech. Compos. Mater. 1997, 33, 565–582. [Google Scholar] [CrossRef]

| Parameter | (1) | (1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Units | GPa | GPa | GPa | − | MPa | MPa | MPa | °C | 10−6/K | 10−6/K |

| 37.2 | 9.59 | 3.09 | 0.292 | 1059.6 | 33.6 | 48.9 | 83.7 | 8.25 | 38.90 | |

| ±0.3 | ±0.13 | ±0.12 | ±0.07 | ±19.9 | ±3.3 | ±0.7 | ±0.8 | ±0.45 | ±1.08 | |

| 5 | 4 | 5 | 5 | 5 | 4 | 5 | 6 | 4 | 4 |

| Parameter | |||||

|---|---|---|---|---|---|

| Units | mm | % | GPa | MPa | − |

| 3 | |||||

| 3 | |||||

| 3 | |||||

| 3 |

| Lay-Up | R | (1) | |||||

|---|---|---|---|---|---|---|---|

| − | MPa | MPa | MPa | MPa | MPa | − | |

| 0.1 | 108 | 64.1 | 0.0 | 10.1 | 0.0 | 0.0 | |

| 0.5 | 92.4 | 57.2 | 0.0 | 0.0 | |||

| −0.1 | 75.6 | 47.9 | 0.0 | 0.0 | |||

| 60 (102) | 40.1 (61.1) | 0.0 (0.0) | 0.0 (0.0) | ||||

| 0.1 | 123.3 | 69 | 11.7 | 10.7 | 0.5 | 0.170 | |

| 0.5 | 105.5 | 60.6 | 10.1 | 0.166 | |||

| −0.1 | 86.3 | 51.5 | 8.3 | 0.161 | |||

| 68.5 (116.5) | 43.0 (65.8) | 6.7 (11.1) | 0.156 (0.169) | ||||

| 0.1 | 144 | 70.9 | 23.4 | 11.5 | 0.3 | 0.330 | |

| 0.5 | 123.2 | 62.3 | 20.1 | 0.323 | |||

| −0.1 | 100.8 | 53.1 | 16.5 | 0.311 | |||

| 80 (136) | 44.5 (67.6) | 13.1 (22.1) | 0.294 (0.327) | ||||

| 0.1 | 162 | 60.7 | 36.9 | 12 | 0.7 | 0.608 | |

| 0.5 | 138.6 | 53.7 | 31.7 | 0.590 | |||

| −0.1 | 113.4 | 46.1 | 26 | 0.564 | |||

| 90 (2) | 39.1 | 20.8 | 0.532 |

| Parameter | |||||||

|---|---|---|---|---|---|---|---|

| Units | px | px | − | px | px | px/mm | |

| Value | 90 | 12 | 10 | 0.11 | 2848 | 4288 | 128 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Just, G.; Koch, I.; Gude, M. Experimental Analysis of Matrix Cracking in Glass Fiber Reinforced Composite Off-Axis Plies under Static and Fatigue Loading. Polymers 2022, 14, 2160. https://doi.org/10.3390/polym14112160

Just G, Koch I, Gude M. Experimental Analysis of Matrix Cracking in Glass Fiber Reinforced Composite Off-Axis Plies under Static and Fatigue Loading. Polymers. 2022; 14(11):2160. https://doi.org/10.3390/polym14112160

Chicago/Turabian StyleJust, Gordon, Ilja Koch, and Maik Gude. 2022. "Experimental Analysis of Matrix Cracking in Glass Fiber Reinforced Composite Off-Axis Plies under Static and Fatigue Loading" Polymers 14, no. 11: 2160. https://doi.org/10.3390/polym14112160

APA StyleJust, G., Koch, I., & Gude, M. (2022). Experimental Analysis of Matrix Cracking in Glass Fiber Reinforced Composite Off-Axis Plies under Static and Fatigue Loading. Polymers, 14(11), 2160. https://doi.org/10.3390/polym14112160