Systematic Experimental Assessment of POFA Concrete Incorporating Waste Tire Rubber Aggregate

Abstract

:1. Introduction

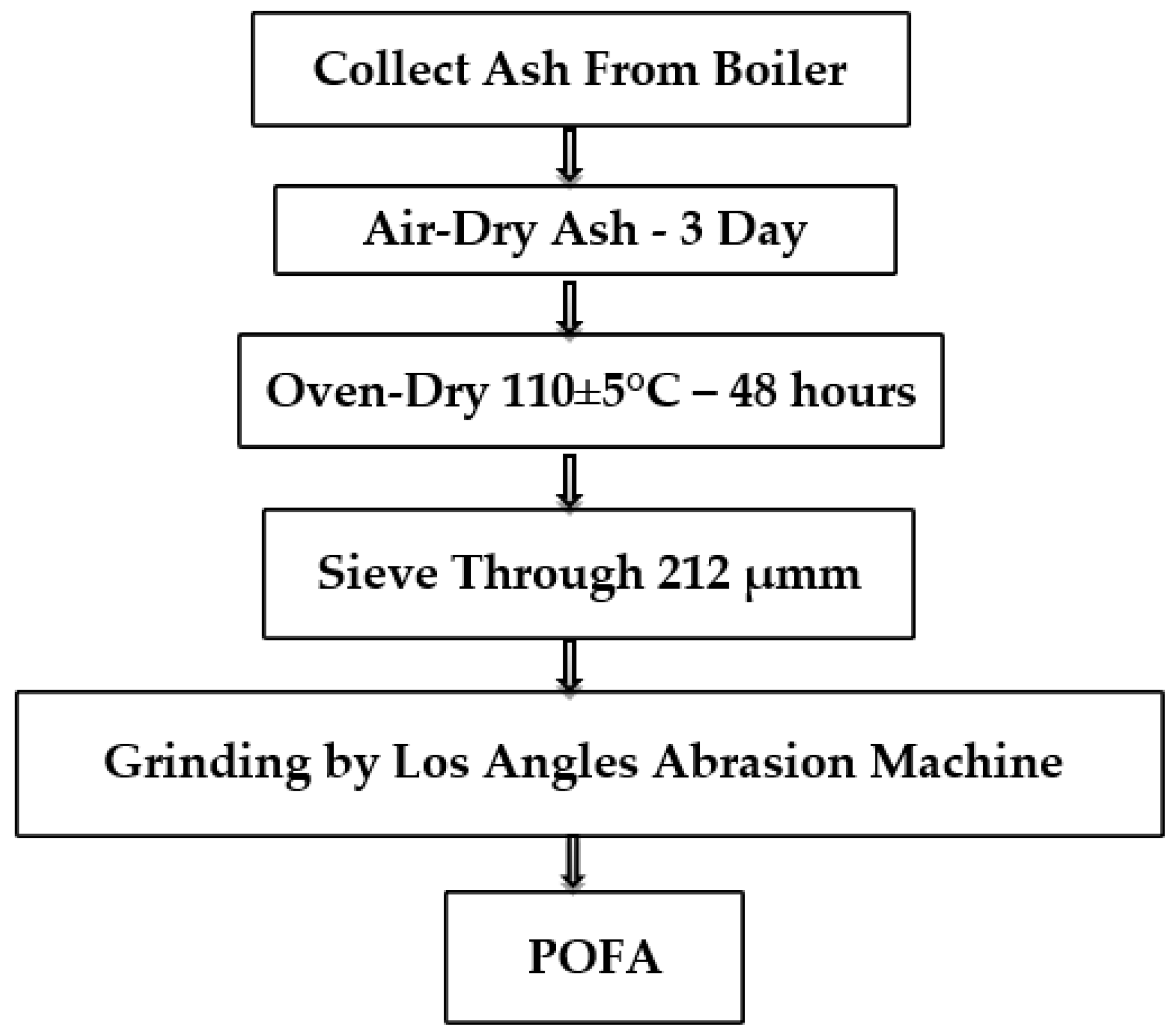

2. Materials and Process Technology Standardization

2.1. Materials’ Properties

2.2. Concrete Mix Design for Rubberized Concrete

2.3. Experimental Program

2.4. Experimental Design Using RSM Model

3. Results and Discussion

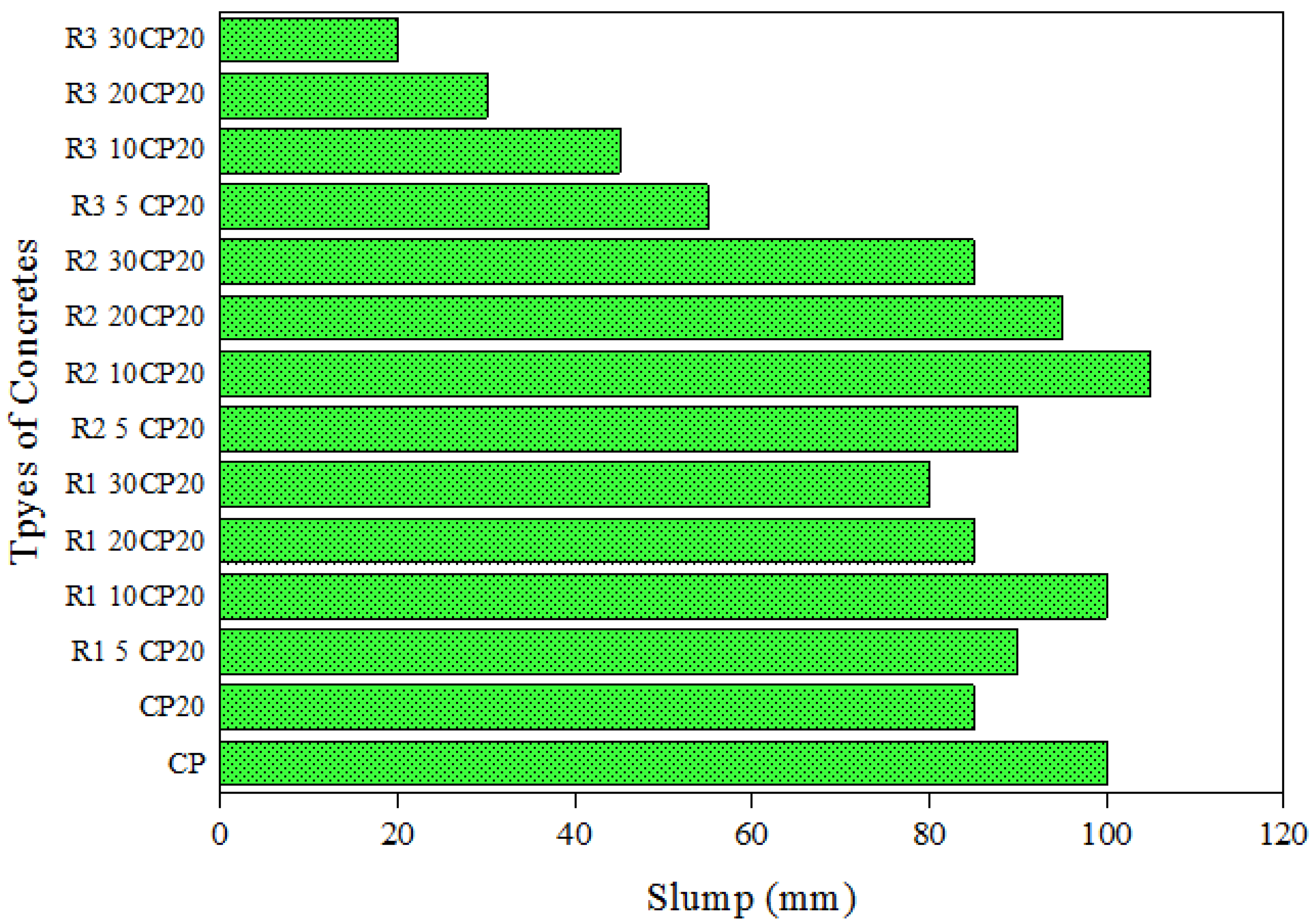

3.1. Workability

3.2. Air Content

3.3. Compressive Strength

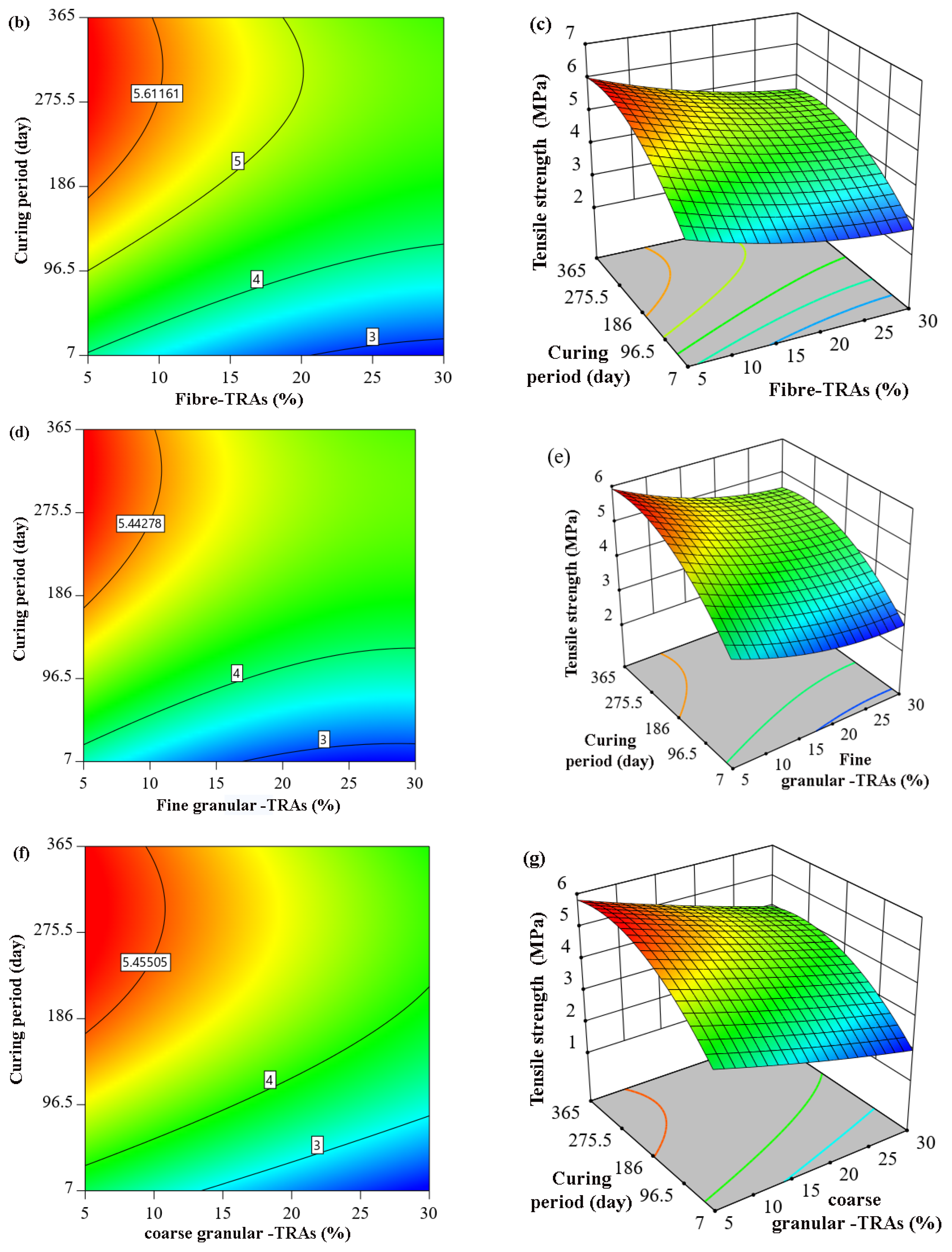

3.4. Splitting Tensile Strength

3.5. Flexural Strength

3.6. RSM Model Verification

3.7. XRD Results

3.8. Scanning Electron Micrographs

4. Conclusions

- The workability of rubberized concrete made with fine and fibre TRAs is much closer to that of conventional concrete if the rubber replacement level is limited to 10%. Increasing the size and percentage of TRAs decreased the workability due to the increased friction by rubber particles.

- The air content in R130CP20 was 2.88 times higher than that of concrete containing 20% POFA alone, indicating that the air content increased by increasing the fraction of rubber aggregate, which is attributed to the geometry and specific gravity of rubber particles.

- A significant decrease in strength with a higher level of rubber replacement especially beyond 20% can be ascribed to the softer and non-polar nature of TRAs which leads to reducing the cohesion of the concrete matrix. Meanwhile, the influence of the type of rubber particles on strength was minimal.

- The compressive strength of POFA-influenced concrete started to exceed that of OPC concrete at 28 days by 2%, confirming that the pozzolanic reaction of POFA is less influential at early ages and increases with time.

- The pozzolanic reaction of POFA enables the increase in the strength of concrete, as a consequence of denser concrete by generating more (C–S–H) gel and enhancing the bond between the TRA particles and cement paste.

- The non-linear equations proposed here proved their ability to predict the compressive, tensile, and flexural strength with minimum error and high correlation between the actual and predicted data (R2 > 0.99, R > 0.994), thus confirming both the robustness and reliability of the models.

- A reasonable difference (less than 0.2) between and was achieved for all data sets. The predicted mechanical properties of POFA concrete incorporating TRAs were consistent with the actual result in which a minimum error and high correlation were obtained, indicating that the models could be used for further observation in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Sofi, A. Effect of waste tyre rubber on mechanical and durability properties of concrete–A review. Ain Shams Eng. J. 2018, 9, 2691–2700. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.M.; Aslani, F.; Alabduljabbar, H. Properties and utilizations of waste tire rubber in concrete: A review. Constr. Build. Mater. 2019, 224, 711–731. [Google Scholar] [CrossRef]

- Gregori, A.; Castoro, C.; Marano, G.C.; Greco, R. Strength reduction factor of concrete with recycled rubber aggregates from tires. J. Mater. Civ. Eng. 2019, 31, 04019146. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Huseien, G.F.; Abidin, A.R.Z.; Ismail, M. Long-term mechanical and durable properties of waste tires rubber crumbs replaced GBFS modified concretes. Constr. Build. Mater. 2020, 256, 119505. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Cheng, Y.; Huseien, G.F.; Shah, K.W. Shrinkage mechanisms and shrinkage-mitigating strategies of alkali-activated slag composites: A critical review. Constr. Build. Mater. 2022, 318, 125993. [Google Scholar] [CrossRef]

- Huseien, G.F.; Shah, K.W.; Sam, A.R.M. Sustainability of nanomaterials based self-healing concrete: An all-inclusive insight. J. Build. Eng. 2019, 23, 155–171. [Google Scholar] [CrossRef]

- Hamzah, N.; Mohd Saman, H.; Baghban, M.H.; Mohd Sam, A.R.; Faridmehr, I.; Muhd Sidek, M.N.; Benjeddou, O.; Huseien, G.F. A Review on the Use of Self-Curing Agents and Its Mechanism in High-Performance Cementitious Materials. Buildings 2022, 12, 152. [Google Scholar] [CrossRef]

- Alabduljabbar, H.; Huseien, G.F.; Sam, A.R.M.; Alyouef, R.; Algaifi, H.A.; Alaskar, A. Engineering Properties of Waste Sawdust-Based Lightweight Alkali-Activated Concrete: Experimental Assessment and Numerical Prediction. Materials 2020, 13, 5490. [Google Scholar] [CrossRef]

- Dehdezi, P.K.; Erdem, S.; Blankson, M.A. Physico-mechanical, microstructural and dynamic properties of newly developed artificial fly ash based lightweight aggregate–Rubber concrete composite. Compos. Part B: Eng. 2015, 79, 451–455. [Google Scholar] [CrossRef]

- Miller, N.M.; Tehrani, F.M. Mechanical properties of rubberized lightweight aggregate concrete. Constr. Build. Mater. 2017, 147, 264–271. [Google Scholar] [CrossRef]

- Sun, J. Study of effects of ground steel slag on mechanical performance and soundness of concrete. Coal Ash China 2003, 15, 7–9. [Google Scholar]

- Al Zand, A.W.; Hosseinpour, E.; Badaruzzaman, W.H.W.; Ali, M.M.; Yaseen, Z.M.; Hanoon, A.N. Performance of the novel C-purlin tubular beams filled with recycled-lightweight concrete strengthened with CFRP sheet. J. Build. Eng. 2021, 43, 102532. [Google Scholar] [CrossRef]

- Huseien, G.F.; Tahir, M.M.; Mirza, J.; Ismail, M.; Shah, K.W.; Asaad, M.A. Effects of POFA replaced with FA on durability properties of GBFS included alkali activated mortars. Constr. Build. Mater. 2018, 175, 174–186. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Fahim Huseien, G.; Faridmehr, I.; Razin Zainal Abidin, A.; Alyousef, R.; Ismail, M. Evaluating mechanical properties and impact resistance of modified concrete containing ground Blast Furnace slag and discarded rubber tire crumbs. Constr. Build. Mater. 2021, 295, 123603. [Google Scholar] [CrossRef]

- Al-Fasih, M.Y.M.; Huseien, G.F.; bin Ibrahim, I.S.; Sam, A.R.M.; Algaifi, H.A.; Alyousef, R. Synthesis of rubberized alkali-activated concrete: Experimental and numerical evaluation. Constr. Build. Mater. 2021, 303, 124526. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Recycling Waste Tires into Ground Tire Rubber (GTR)/Rubber Compounds: A Review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Mensah, B.; Agyei-Tuffour, B.; Nyankson, E.; Bensah, Y.D.; Dodoo-Arhin, D.; Bediako, J.K.; Onwona-Agyeman, B.; Yaya, A. Preparation and Characterization of Rubber Blends for Industrial Tire Tread Fabrication. Int. J. Polym. Sci. 2018, 2018, 2473286. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, Y.; Li, J. Performance Investigation and Cost–Benefit Analysis of Recycled Tire Polymer Fiber-Reinforced Cemented Paste Backfill. Polymers 2022, 14, 708. [Google Scholar] [CrossRef]

- Akbas, A.; Yuhana, N.Y. Recycling of Rubber Wastes as Fuel and Its Additives. Recycling 2021, 6, 78. [Google Scholar] [CrossRef]

- Milad, A.; Ahmeda, A.G.F.; Taib, A.M.; Rahmad, S.; Solla, M.; Yusoff, N.I.M. A review of the feasibility of using crumb rubber derived from end-of-life tire as asphalt binder modifier. J. Rubber Res. 2020, 23, 203–216. [Google Scholar] [CrossRef]

- Rashad, A.M. A comprehensive overview about recycling rubber as fine aggregate replacement in traditional cementitious materials. Int. J. Sustain. Built Environ. 2016, 5, 46–82. [Google Scholar] [CrossRef] [Green Version]

- Mhaya, A.; Abidin, A.; Sarbini, N.; Ismail, M. Role of crumb tyre aggregates in rubberised concrete contained granulated blast-furnace slag. IOP Conf. Ser. Earth Environ. Sci. 2019, 220, 012029. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Jalal, M.; Grasley, Z.; Nassir, N.; Jalal, H. Strength and dynamic elasticity modulus of rubberized concrete designed with ANFIS modeling and ultrasonic technique. Constr. Build. Mater. 2020, 240, 117920. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Hossain, K.M.A.; Swee, J.T.E.; Wong, G.; Abdullahi, M. Properties of crumb rubber hollow concrete block. J. Clean. Prod. 2012, 23, 57–67. [Google Scholar] [CrossRef]

- Sukontasukkul, P. Use of crumb rubber to improve thermal and sound properties of pre-cast concrete panel. Constr. Build. Mater. 2009, 23, 1084–1092. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A. Impact Resistance and Acoustic Absorption Capacity of Self-Consolidating Rubberized Concrete. ACI Mater. J. 2016, 113, 725–736. [Google Scholar] [CrossRef]

- Hassan, I.; Ismail, M.; Noruzman, A.H.; Yusuf, T.O.; Mehmannavaz, T.; Usman, J. Characterization of some key Industrial Waste products for sustainable Concrete production. In Advanced Materials Research; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2013; pp. 1091–1094. [Google Scholar]

- Rashid, K.; Yazdanbakhsh, A.; Rehman, M.U. Sustainable selection of the concrete incorporating recycled tire aggregate to be used as medium to low strength material. J. Clean. Prod. 2019, 224, 396–410. [Google Scholar] [CrossRef]

- Snelson, D.; Kinuthia, J.; Davies, P.; Chang, S.-R. Sustainable construction: Composite use of tyres and ash in concrete. Waste Manag. 2009, 29, 360–367. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Rubber-tire particles as concrete aggregate. J. Mater. Civ. Eng. 1993, 5, 478–496. [Google Scholar] [CrossRef]

- Emiroglu, M.; Kelestemur, M.H.; Yildiz, S. An investigation on ITZ microstructure of the concrete containing waste vehicle tire. In Proceedings of the 8th International Fracture Conference, Istanbul, Turkey, 7–9 November 2007. [Google Scholar]

- Reda Taha, M.M.; El-Dieb, A.; Abd El-Wahab, M.; Abdel-Hameed, M. Mechanical, fracture, and microstructural investigations of rubber concrete. J. Mater. Civ. Eng. 2008, 20, 640–649. [Google Scholar] [CrossRef]

- Turatsinze, A.; Bonnet, S.; Granju, J.-L. Mechanical characterisation of cement-based mortar incorporating rubber aggregates from recycled worn tyres. Build. Environ. 2005, 40, 221–226. [Google Scholar] [CrossRef]

- Si, R.; Guo, S.; Dai, Q. Durability performance of rubberized mortar and concrete with NaOH-Solution treated rubber particles. Constr. Build. Mater. 2017, 153, 496–505. [Google Scholar] [CrossRef]

- Grinys, A.; Balamurugan, M.; Augonis, A.; Ivanauskas, E. Mechanical Properties and Durability of Rubberized and Glass Powder Modified Rubberized Concrete for Whitetopping Structures. Materials 2021, 14, 2321. [Google Scholar] [CrossRef] [PubMed]

- Roychand, R.; Gravina, R.J.; Zhuge, Y.; Ma, X.; Youssf, O.; Mills, J.E. A comprehensive review on the mechanical properties of waste tire rubber concrete. Constr. Build. Mater. 2020, 237, 117651. [Google Scholar] [CrossRef]

- Kundan, P.; Sharma, S. Rubberized cemented concrete composites: A review. Mater. Today Proc. 2021, 44, 4838–4842. [Google Scholar] [CrossRef]

- Allujami, H.M.; Jassam, T.M.; Al-Mansob, R.A. Nanomaterials characteristics and current utilization status in rigid pavements: Mechanical features and Sustainability. A review. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Bušić, R.; Benšić, M.; Miličević, I.; Strukar, K. Prediction Models for the Mechanical Properties of Self-Compacting Concrete with Recycled Rubber and Silica Fume. Materials 2020, 13, 1821. [Google Scholar] [CrossRef] [Green Version]

- Al-mulali, M.Z.; Awang, H.; Khalil, H.A.; Aljoumaily, Z.S. The incorporation of oil palm ash in concrete as a means of recycling: A review. Cem. Concr. Compos. 2015, 55, 129–138. [Google Scholar] [CrossRef]

- Alaskar, A.; Shah, S.; Keerio, M.A.; Phulpoto, J.A.; Baharom, S.; Assilzadeh, H.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Development of Pozzolanic material from clay. Adv. Concr. Constr. 2020, 10, 301–310. [Google Scholar]

- Muhammad, N.; Baharom, S.; Amirah, N.; Ghazali, M.; Alias, N. Effect of heat curing temperatures on fly ash-based geopolymer concrete. Int. J. Eng. Technol 2019, 8, 15. [Google Scholar]

- Abutaha, F.; Razak, H.A.; Kanadasan, J. Effect of palm oil clinker (POC) aggregates on fresh and hardened properties of concrete. Constr. Build. Mater. 2016, 112, 416–423. [Google Scholar] [CrossRef]

- Hossain, M.; Karim, M.; Hasan, M.; Hossain, M.; Zain, M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mater. 2016, 116, 128–140. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Jamil, M.; Karim, M.R.; Zain, M.F.M.; Kaish, A.B.M.A. Filler effect of pozzolanic materials on the strength and microstructure development of mortar. KSCE J. Civ. Eng. 2017, 21, 274–284. [Google Scholar] [CrossRef]

- Lim, J.L.G.; Raman, S.N.; Lai, F.-C.; Zain, M.F.M.; Hamid, R. Synthesis of nano cementitious additives from agricultural wastes for the production of sustainable concrete. J. Clean. Prod. 2018, 171, 1150–1160. [Google Scholar] [CrossRef]

- Safa, M.; Shariati, M.; Ibrahim, Z.; Toghroli, A.; Baharom, S.B.; Nor, N.M.; Petkovic, D. Potential of adaptive neuro fuzzy inference system for evaluating the factors affecting steel-concrete composite beam’s shear strength. Steel Compos. Struct. 2016, 21, 679–688. [Google Scholar] [CrossRef]

- Megat Johari, M.A.; Zeyad, A.M.; Muhamad Bunnori, N.; Ariffin, K.S. Engineering and transport properties of high-strength green concrete containing high volume of ultrafine palm oil fuel ash. Constr. Build. Mater. 2012, 30, 281–288. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of Palm Oil Fuel Ash in High-Strength Concrete. J. Mater. Civ. Eng. 2004, 16, 623–628. [Google Scholar] [CrossRef]

- Khankhaje, E.; Hussin, M.W.; Mirza, J.; Rafieizonooz, M.; Salim, M.R.; Siong, H.C.; Warid, M.N.M. On blended cement and geopolymer concretes containing palm oil fuel ash. Mater. Des. 2016, 89, 385–398. [Google Scholar] [CrossRef]

- Huseien, G.F.; Sam, A.R.M.; Algaifi, H.A.; Alyouef, R. Development of a sustainable concrete incorporated with effective microorganism and fly Ash: Characteristics and modeling studies. Constr. Build. Mater. 2021, 285, 122899. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Musarat, M.A.; Haruna, S.; Law, K.; Tayeh, B.A.; Rafiq, W.; Ayub, S. Mechanical Properties of Silica Fume Modified High-Volume Fly Ash Rubberized Self-Compacting Concrete. Sustainability 2021, 13, 5571. [Google Scholar] [CrossRef]

- Toma, I.-O.; Alexa-Stratulat, S.-M.; Mihai, P.; Toma, A.-M.; Taranu, G. Experimental Investigations on the Long Term Material Properties of Rubberized Portland Cement Concrete. Appl. Sci. 2021, 11, 868. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Baghban, M.H.; Faridmehr, I.; Huseien, G.F.; Abidin, A.R.Z.; Ismail, M. Performance Evaluation of Modified Rubberized Concrete Exposed to Aggressive Environments. Materials 2021, 14, 1900. [Google Scholar] [CrossRef]

- Huang, J.; Alyousef, R.; Suhatril, M.; Baharom, S.; Alabduljabbar, H.; Alaskar, A.; Assilzadeh, H. Influence of porosity and cement grade on concrete mechanical properties. Adv. Concr. Constr. 2020, 10, 393–402. [Google Scholar]

- Algaifi, H.A.; Bakar, S.A.; Alyousef, R.; Sam, A.R.M.; Alqarni, A.S.; Ibrahim, M.; Shahidan, S.; Ibrahim, M.; Salami, B.A. Machine learning and RSM models for prediction of compressive strength of smart bio-concrete. Smart Struct. Syst 2021, 28, 535–551. [Google Scholar]

- Ibrahim, M.; Salami, B.A.; Algaifi, H.A.; Rahman, M.K.; Nasir, M.; Ewebajo, A.O. Assessment of acid resistance of natural pozzolan-based alkali-activated concrete: Experimental and optimization modelling. Constr. Build. Mater. 2021, 304, 124657. [Google Scholar] [CrossRef]

- Mokhtar, N.; Johari, M.A.M.; Tajarudin, H.A.; Al-Gheethi, A.A.; Algaifi, H.A. A sustainable enhancement of bio-cement using immobilised Bacillus sphaericus: Optimization, microstructural properties, and techno-economic analysis for a cleaner production of bio-cementitious mortars. J. Clean. Prod. 2021, 318, 128470. [Google Scholar] [CrossRef]

- Algaifi, H.A.; Mustafa Mohamed, A.; Alsuhaibani, E.; Shahidan, S.; Alrshoudi, F.; Huseien, G.F.; Bakar, S.A. Optimisation of GBFS, Fly Ash, and Nano-Silica Contents in Alkali-Activated Mortars. Polymers 2021, 13, 2750. [Google Scholar] [CrossRef]

- Jalal, M.; Grasley, Z.; Gurganus, C.; Bullard, J.W. Experimental investigation and comparative machine-learning prediction of strength behavior of optimized recycled rubber concrete. Constr. Build. Mater. 2020, 256, 119478. [Google Scholar] [CrossRef]

- Rukzon, S.; Chindaprasirt, P. An experimental investigation of the carbonation of blended portland cement palm oil fuel ash mortar in an indoor environment. Indoor Built Environ. 2009, 18, 313–318. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Specification for Concrete Aggregates; American Society for Testing and Materials: Philadelphia, PA, USA, 2003. [Google Scholar]

- Yilmaz, A.; Degirmenci, N. Possibility of using waste tire rubber and fly ash with Portland cement as construction materials. Waste Manag. 2009, 29, 1541–1546. [Google Scholar] [CrossRef] [PubMed]

- Aiello, M.A.; Leuzzi, F. Waste tyre rubberized concrete: Properties at fresh and hardened state. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef] [PubMed]

- Issa, C.A.; Salem, G. Utilization of recycled crumb rubber as fine aggregates in concrete mix design. Constr. Build. Mater. 2013, 42, 48–52. [Google Scholar] [CrossRef]

- Grinys, A.; Sivilevičius, H.; Daukšys, M. Tyre rubber additive effect on concrete mixture strength. J. Civ. Eng. Manag. 2012, 18, 393–401. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Tiamlom, K. Expansion under water and drying shrinkage of rubberized concrete mixed with crumb rubber with different size. Constr. Build. Mater. 2012, 29, 520–526. [Google Scholar] [CrossRef]

- Oyebisi, S.O.; Ede, A.N.; Olutoge, F.A. Optimization of design parameters of slag-corncob ash-based geopolymer concrete by the central composite design of the response surface methodology. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 27–42. [Google Scholar] [CrossRef]

- Habibi, A.; Ramezanianpour, A.M.; Mahdikhani, M.; Bamshad, O. RSM-based evaluation of mechanical and durability properties of recycled aggregate concrete containing GGBFS and silica fume. Constr. Build. Mater. 2021, 270, 121431. [Google Scholar] [CrossRef]

- Shahmansouri, A.A.; Nematzadeh, M.; Behnood, A. Mechanical properties of GGBFS-based geopolymer concrete incorporating natural zeolite and silica fume with an optimum design using response surface method. J. Build. Eng. 2021, 36, 102138. [Google Scholar] [CrossRef]

- Ferdosian, I.; Camões, A. Eco-efficient ultra-high performance concrete development by means of response surface methodology. Cem. Concr. Compos. 2017, 84, 146–156. [Google Scholar] [CrossRef]

- Foroughi, M.; Rahmani, A.R.; Asgari, G.; Nematollahi, D.; Yetilmezsoy, K.; Samarghandi, M.R. Optimization of a three-dimensional electrochemical system for tetracycline degradation using box-behnken design. Fresenius Environ. Bull. 2018, 27, 1914–1922. [Google Scholar]

- Mukhopadhyay, T.; Dey, T.K.; Chowdhury, R.; Chakrabarti, A. Structural damage identification using response surface-based multi-objective optimization: A comparative study. Arab. J. Sci. Eng. 2015, 40, 1027–1044. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Yen, L.Y.; Haruna, S.; Huat, S.; Lim, M.; Abdulkadir, I.; Al-Fakih, A.; Liew, M.; Zawawi, A.; Wan, N.A. Effect of Elevated Temperature on the Compressive Strength and Durability Properties of Crumb Rubber Engineered Cementitious Composite. Materials 2020, 13, 3516. [Google Scholar] [CrossRef] [PubMed]

- Dan, S.; Banivaheb, S.; Hashemipour, H. Synthesis, characterization and absorption study of chitosan-g-poly (acrylamide-co-itaconic acid) hydrogel. Polym. Bull. 2021, 78, 1887–1907. [Google Scholar] [CrossRef]

- Oyebisi, S.; Ede, A.; Owamah, H.; Igba, T.; Mark, O.; Odetoyan, A. Optimising the Workability and Strength of Concrete Modified with Anacardium Occidentale Nutshell Ash. Fibers 2021, 9, 41. [Google Scholar] [CrossRef]

- Al-Mutairi, N.; Al-Rukaibi, F.; Bufarsan, A. Effect of microsilica addition on compressive strength of rubberized concrete at elevated temperatures. J. Mater. Cycles Waste Manag. 2010, 12, 41–49. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J. Concrete made with used tyre aggregate: Durability-related performance. J. Clean. Prod. 2012, 25, 42–50. [Google Scholar] [CrossRef]

- Khatib, Z.K.; Bayomy, F.M. Rubberized Portland cement concrete. J. Mater. Civ. Eng. 1999, 11, 206–213. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Jaturapitakkul, C.; Chindaprasirt, P. Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Constr. Build. Mater. 2009, 23, 2641–2646. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Khamklai, S.; Jaturapitakkul, C. Use of ground palm oil fuel ash to improve strength, sulfate resistance, and water permeability of concrete containing high amount of recycled concrete aggregates. Mater. Des. 2012, 41, 150–157. [Google Scholar] [CrossRef]

- Bignozzi, M.; Sandrolini, F. Tyre rubber waste recycling in self-compacting concrete. Cem. Concr. Res. 2006, 36, 735–739. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Li, G.; Stubblefield, M.A.; Garrick, G.; Eggers, J.; Abadie, C.; Huang, B. Development of waste tire modified concrete. Cem. Concr. Res. 2004, 34, 2283–2289. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Valadares, F.; Bravo, M.; de Brito, J. Concrete with used tire rubber aggregates: Mechanical performance. ACI Mater. J. -Am. Concr. Inst. 2012, 109, 283. [Google Scholar]

- Hou, D.; Chen, D.; Wang, X.; Wu, D.; Ma, H.; Hu, X.; Zhang, Y.; Wang, P.; Yu, R. RSM-based modelling and optimization of magnesium phosphate cement-based rapid-repair materials. Constr. Build. Mater. 2020, 263, 120190. [Google Scholar] [CrossRef]

- Jitendra, K.; Khed, V.C. Optimization of concrete blocks with high volume fly ash and foundry sand. Mater. Today: Proc. 2020, 27, 1172–1179. [Google Scholar] [CrossRef]

- Altwair, N.M.; Johari, M.A.M.; Hashim, S.F.S. Strength activity index and microstructural characteristics of treated palm oil fuel ash. Structure 2011, 5, 6. [Google Scholar]

- Chindaprasirt, P.; Homwuttiwong, S.; Jaturapitakkul, C. Strength and water permeability of concrete containing palm oil fuel ash and rice husk–bark ash. Constr. Build. Mater. 2007, 21, 1492–1499. [Google Scholar] [CrossRef]

- Turatsinze, A.; Bonnet, S.; Granju, J.-L. Potential of rubber aggregates to modify properties of cement based-mortars: Improvement in cracking shrinkage resistance. Constr. Build. Mater. 2007, 21, 176–181. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Mazzoli, A.; Moriconi, G. Mechanical behaviour and thermal conductivity of mortars containing waste rubber particles. Mater. Des. 2011, 32, 1646–1650. [Google Scholar] [CrossRef]

| Physical Properties | OPC | POFA |

|---|---|---|

| Specific gravity | 3.15 | 2.43 |

| Particle retained on 45 µm sieve | 4.58% | 0.73% |

| Median particle d10 (µm) | 2.86 | 1.32 |

| Median particle d30 (µm) | 9.13 | 5.24 |

| Median particle d60 (µm) | 20.09 | 14.69 |

| Specific surface (cm2/g) | 5137.11 | 7796.17 |

| Strength Activity Index (%) | ||

| At 7 days | - | 98.6 |

| At 28 days | - | 103.4 |

| Chemical combination | OPC—Mass content (%) | POFA—Mass content (%) |

| SiO2 | 16.40 | 63.70 |

| Al2O3 | 4.24 | 3.68 |

| Fe2O3 | 3.53 | 6.27 |

| CaO | 66.85 | 5.97 |

| K2O | 0.22 | 9.15 |

| MgO | 2.39 | 4.11 |

| CO2 | 0.10 | 0.10 |

| SO3 | 4.39 | 1.59 |

| Cl | - | 0.50 |

| TiO2 | - | 0.30 |

| LOI | 1.67 | 4.46 |

| SiO2 + Al2O3 + Fe2O3 | - | 73.65 |

| Physical Properties | Unit | Values |

|---|---|---|

| Size (ASTM D5644) | mm | Fibre 0.84–3.36, Granules 1–4 and 5–8 |

| Heat Loss (ASTM D1509) | % in mass | <1 |

| Metal Content (ASTM D5603) | % in mass | <0.5 |

| Fibre Content (ASTM D5603) | % in mass | <1 |

| Chemical Composition | Values (percent in mass) | |

| Acetone Extract (ISO 1407:2009) | 10 ± 3 | |

| Ash Content (ISO 247:2006) | 6 ± 1.7 | |

| Carbon Black (ISO 1408:1995) | 14 ± 8 | |

| Rubber Hydrocarbon (RHC) | 52 ± 5 | |

| Colour | Dark-Brown Liquid |

|---|---|

| Specific Gravity | 1.210 at 25 °C |

| Chloride Content | Chloride-free to BS 5075: Part 1 and 3 |

| Freezing Point | 0 °C—can be reconstituted if stirred after thawing |

| Air-entrainment | Maximum 1% |

| Mixes | Binder | Tire Rubber Aggregates | Natural Aggregates | |||||

|---|---|---|---|---|---|---|---|---|

| OPC (kg/m3) | POFA (kg/m3) | Fine Fibre Rubber (kg/m3) | Fine Granular Rubber (kg/m3) | Coarse Rubber Granular (kg/m3) | River Sand (kg/m3) | Crushed Stone (kg/m3) | ||

| Batch A | CP | 450 | - | 0 | 0 | 0 | 782 | 874.5 |

| CP20 | 405 | 135 | 0 | 0 | 0 | 0 | 0 | |

| Batch B | R15 CP20 | 405 | 135 | 13.17 | 0 | 0 | 742.8 | 874.5 |

| R110 CP20 | 26.35 | 703.6 | ||||||

| R120 CP20 | 52.68 | 625.25 | ||||||

| R130 CP20 | 79 | 546.9 | ||||||

| Batch C | R25 CP20 | 405 | 135 | 0 | 19.85 | 0 | 742.8 | 874.5 |

| R210 CP20 | 39.7 | 703.6 | ||||||

| R220 CP20 | 79.4 | 625.25 | ||||||

| R230 CP20 | 119.1 | 546.9 | ||||||

| Batch D | R35 CP20 | 405 | 135 | 0 | 0 | 22.23 | 782 | 830.77 |

| R310 CP20 | 44.46 | 787.1 | ||||||

| R320 CP20 | 88.93 | 699.6 | ||||||

| R330 CP20 | 133.92 | 612.1 | ||||||

| Run NO. | Coded Value | Real Value (%) | CCD Division | ||

|---|---|---|---|---|---|

| Rubber Content % | Age (Days) | ||||

| 1 | −1 | −1 | 5 | 7 | Factorial points (2n) |

| 2 | 1 | −1 | 30 | 7 | |

| 3 | −1 | 1 | 5 | 365 | |

| 4 | 1 | 1 | 30 | 365 | |

| 5 | 1 | 0 | 5 | 180 | Axial points (2n) |

| 6 | −1 | 0 | 30 | 180 | |

| 7 | 0 | −1 | 20 | 7 | |

| 8 | 0 | 1 | 20 | 365 | |

| 9 | 0 | 0 | 20 | 180 | Centre points |

| Type of Test | ||

|---|---|---|

| Mechanical properties of POFA concrete incorporating fibre rubber | Compressive strength (CS) | |

| Flexural strength (FS) | ||

| Tensile strength (TS) | ||

| Mechanical properties of POFA concrete containing fine rubber | Compressive strength (CS) | |

| Flexural strength (FS) | ||

| Tensile strength (TS) | ||

| Mechanical properties of POFA concrete containing coarse rubber | Compressive strength (CS) | |

| Flexural strength (FS) | ||

| Tensile strength (TS) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mhaya, A.M.; Baharom, S.; Baghban, M.H.; Nehdi, M.L.; Faridmehr, I.; Huseien, G.F.; Algaifi, H.A.; Ismail, M. Systematic Experimental Assessment of POFA Concrete Incorporating Waste Tire Rubber Aggregate. Polymers 2022, 14, 2294. https://doi.org/10.3390/polym14112294

Mhaya AM, Baharom S, Baghban MH, Nehdi ML, Faridmehr I, Huseien GF, Algaifi HA, Ismail M. Systematic Experimental Assessment of POFA Concrete Incorporating Waste Tire Rubber Aggregate. Polymers. 2022; 14(11):2294. https://doi.org/10.3390/polym14112294

Chicago/Turabian StyleMhaya, Akram M., S. Baharom, Mohammad Hajmohammadian Baghban, Moncef L. Nehdi, Iman Faridmehr, Ghasan Fahim Huseien, Hassan Amer Algaifi, and Mohammad Ismail. 2022. "Systematic Experimental Assessment of POFA Concrete Incorporating Waste Tire Rubber Aggregate" Polymers 14, no. 11: 2294. https://doi.org/10.3390/polym14112294

APA StyleMhaya, A. M., Baharom, S., Baghban, M. H., Nehdi, M. L., Faridmehr, I., Huseien, G. F., Algaifi, H. A., & Ismail, M. (2022). Systematic Experimental Assessment of POFA Concrete Incorporating Waste Tire Rubber Aggregate. Polymers, 14(11), 2294. https://doi.org/10.3390/polym14112294