Optimization of Alkaline Activator on the Strength Properties of Geopolymer Concrete

Abstract

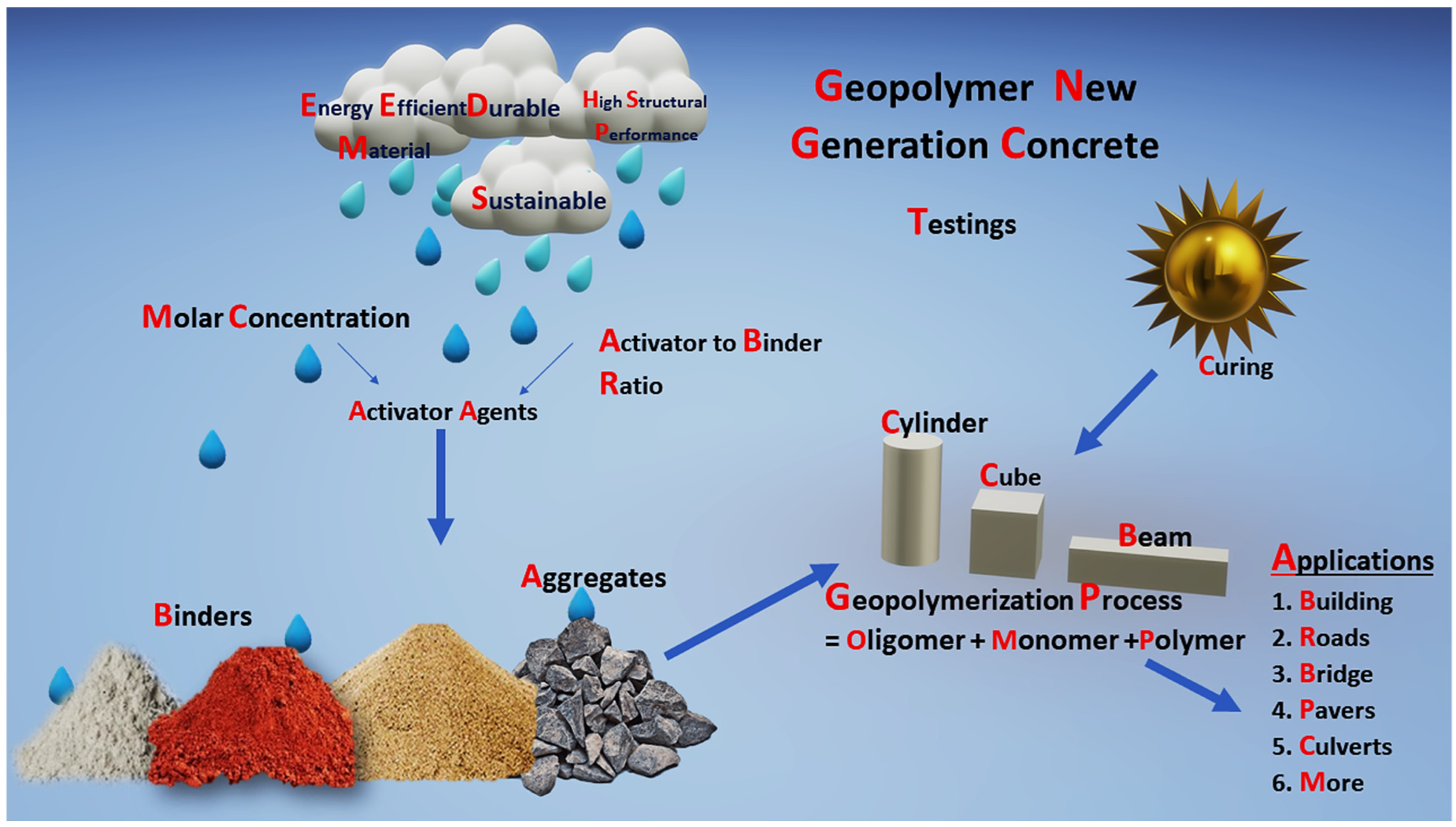

:1. Introduction

2. Materials Used

3. Preparation of GPC

4. Setting Time

4.1. Initial and Final Setting

4.2. Soundness Test

4.3. Workability

4.4. Hardened Properties of Geopolymer

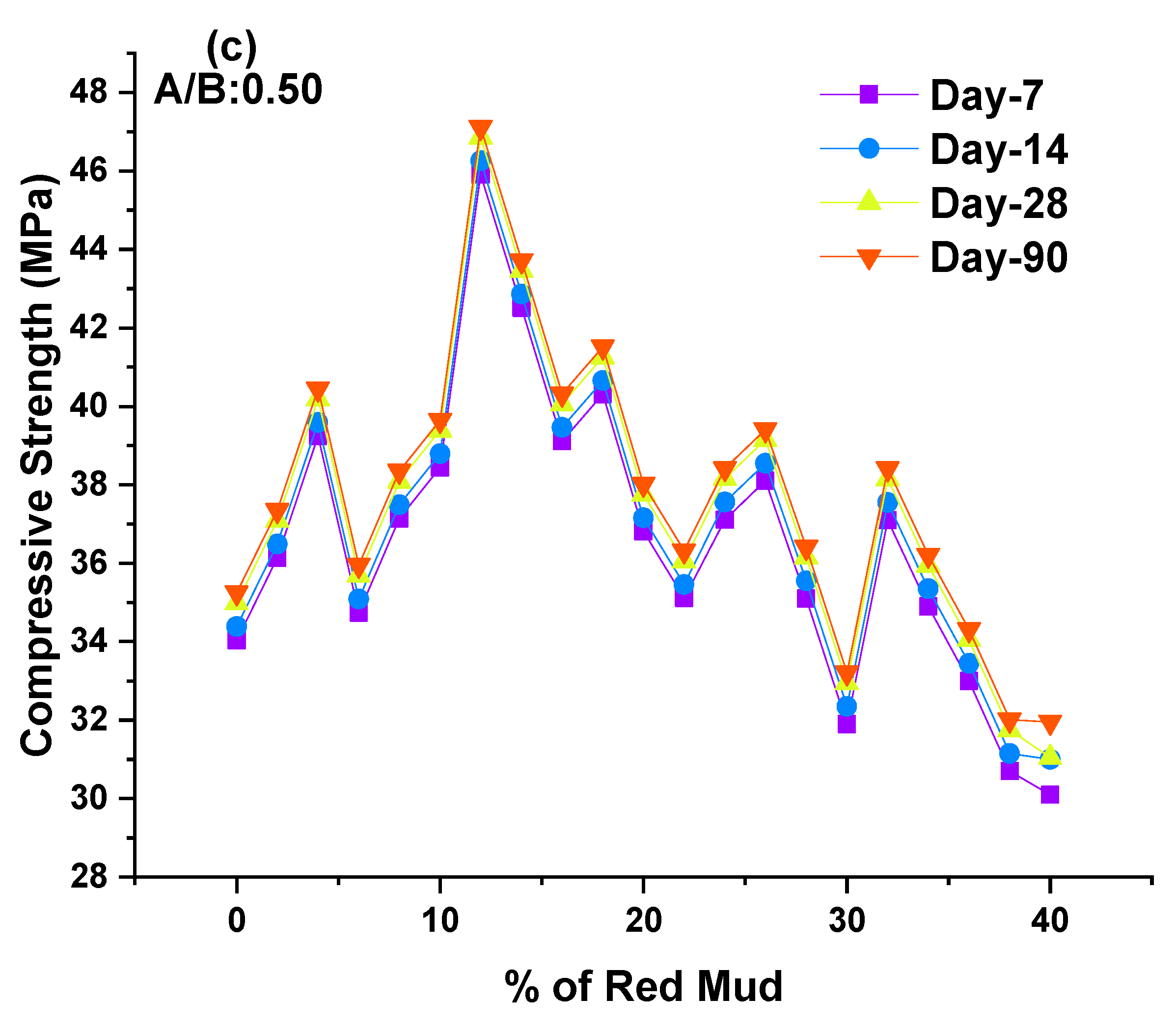

4.4.1. Compressive Strength

4.4.2. Split Tensile Strength and Flexural Strength

4.4.3. Water Absorption and Bulk Density

4.4.4. Modulus of Elasticity (MoE)

4.4.5. Impact Energy

4.4.6. ANOVA

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature/Abbreviations/Symbols

| A/B | Alkali/Binder Ratio |

| Al | Alumina |

| ASTM | American Society for Testing and Materials |

| Al2O3 | Aluminum oxide |

| CA | Calcium |

| CASH | Calcium Alumina Silica Hydrate |

| CE | Carbon Emission |

| CS | Compressive Strength |

| CTM | Compression Testing Machine |

| EE | Embodied Energy |

| FA | Fly Ash |

| GGBS | Ground Granulated Blast-Furnace Slag |

| GPB | Geopolymer Brick |

| IS | Indian Standard |

| K | Potassium |

| Kg | Kilogram |

| MPa | Mega Pascal |

| MJ | Mega Joule |

| Na | Sodium |

| Na2SiO3 | Sodium Silicate |

| NaOH | Sodium Hydroxide |

| NASH | Sodium Alumina Silica Hydrate |

| O | Oxygen |

| RHA | Rich Husk Ash |

| Si | Silica |

| SiO2 | Silicon Oxide |

| SiO4 | Silicon Oxygen Tetrahedron |

| WA | Water Absorption |

| °C | Degree Celsius |

References

- Babu, D.V. Assessing the performance of molarity and alkaline activator ratio on engineering properties of self-compacting alkaline activated concrete at ambient temperature. J. Build. Eng. 2018, 20, 137–155. [Google Scholar] [CrossRef]

- Topçu, I.B.; Toprak, M.U.; Uygunoğlu, T. Durability and microstructure characteristics of alkali activated coal bottom ash geopolymer cement. J. Clean. Prod. 2014, 81, 211–217. [Google Scholar] [CrossRef]

- Ismail, S.; Razali, M.F.M.; Johari, I.; Ahmad, Z.A.; Kasim, S.R. Effect of Curing Time and Sintering to the Properties of Geopolymer Mortars. Mater. Sci. Forum 2017, 888, 184–187. [Google Scholar] [CrossRef]

- Haruna, S.; Mohammed, B.S.; Wahab, M.; Liew, M. Effect of paste aggregate ratio and curing methods on the performance of one-part alkali-activated concrete. Constr. Build. Mater. 2020, 261, 120024. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Van Deventer, J.S.J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Rao, A.K.; Kumar, D.R. Effect of various alkaline binder ratio on geopolymer concrete under ambient curing condition. Mater. Today Proc. 2020, 27, 1768–1773. [Google Scholar] [CrossRef]

- Ghafoor, M.T.; Khan, Q.S.; Qazi, A.U.; Sheikh, M.N.; Hadi, M. Influence of alkaline activators on the mechanical properties of fly ash based geopolymer concrete cured at ambient temperature. Constr. Build. Mater. 2020, 273, 121752. [Google Scholar] [CrossRef]

- Medri, V.; Papa, E.; Mazzocchi, M.; Laghi, L.; Morganti, M.; Francisconi, J.; Landi, E. Production and characterization of lightweight vermiculite/geopolymer-based panels. Mater. Des. 2015, 85, 266–274. [Google Scholar] [CrossRef]

- Shi, C.; Qu, B.; Provis, J.L. Recent progress in low-carbon binders. Cem. Concr. Res. 2019, 122, 227–250. [Google Scholar] [CrossRef]

- Karthik, A.; Sudalaimani, K.; Vijayakumar, C.; Saravanakumar, S. Effect of bio-additives on physico-chemical properties of fly ash-ground granulated blast furnace slag based self cured geopolymer mortars. J. Hazard. Mater. 2019, 361, 56–63. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Alipour, P.; Tahmouresi, B.; Mohseni, E.; Saradar, A.; Sarker, P.K. Influence of different monomer ratios and recycled concrete aggregate on mechanical properties and durability of geopolymer concretes. Constr. Build. Mater. 2019, 205, 519–528. [Google Scholar] [CrossRef]

- Poloju, K.K.; Sinivasu, K. Influence of GGBS and Alkaline Ratio on Compression Strength of Geopolymer Concrete: Influence of GGBS and Alkaline Ratio on Compression Strength of Geopolymer Concrete. SPAST Abstracts 1.01. 2021, Volume 1. Available online: https://spast.org/techrep/article/view/2900 (accessed on 7 June 2022).

- El Alouani, M.; Alehyen, S.; El Achouri, M.; Hajjaji, A.; Ennawaoui, C.; Taibi, M. Influence of the Nature and Rate of Alkaline Activator on the Physicochemical Properties of Fly Ash-Based Geopolymers. Adv. Civ. Eng. 2020, 2020, e8880906. [Google Scholar] [CrossRef]

- Kurtoglu, A.E.; Alzeebaree, R.; Aljumaili, O.; Nis, A.; Gulsan, M.E.; Humur, G.; Cevik, A. Mechanical and durability properties of fly ash and slag based geopolymer concrete. Adv. Concr. Constr. 2018, 6, 345–362. [Google Scholar]

- Liang, X.; Ji, Y. Mechanical properties and permeability of red mud-blast furnace slag-based geopolymer concrete. SN Appl. Sci. 2021, 3, 23. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sustainable geopolymer concrete using ground granulated blast furnace slag and rice husk ash: Strength and permeability properties. J. Clean. Prod. 2018, 205, 49–57. [Google Scholar] [CrossRef]

- Luo, Z.; Li, W.; Gan, Y.; He, X.; Castel, A.; Sheng, D. Nanoindentation on micromechanical properties and microstructure of geopolymer with nano-SiO2 and nano-TiO2. Cem. Concr. Compos. 2020, 117, 103883. [Google Scholar] [CrossRef]

- Phummiphan, I.; Horpibulsuk, S.; Rachan, R.; Arulrajah, A.; Shen, S.-L.; Chindaprasirt, P. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material. J. Hazard. Mater. 2018, 341, 257–267. [Google Scholar] [CrossRef]

- Santa, R.A.A.B.; Soares, C.; Riella, H.G. Geopolymers with a high percentage of bottom ash for solidification/immobilization of different toxic metals. J. Hazard. Mater. 2016, 318, 145–153. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A. 2-An overview of the chemistry of alkali-activated cement-based binders. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Pacheco-Torgal, F., Labrincha, J.A., Leonelli, C., Palomo, A., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 19–47. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Chiranjeevi, K.; Vijayalakshmi, M.M.; Praveenkumar, T.R. Investigation of fly ash and rice husk ash-based geopolymer concrete using nano particles. Appl. Nanosci. 2021, 1–8. [Google Scholar] [CrossRef]

- Das, S.K.; Shrivastava, S. Siliceous fly ash and blast furnace slag based geopolymer concrete under ambient temperature curing condition. Struct. Concr. 2021, 22, E341–E351. [Google Scholar] [CrossRef]

- Yip, C.K.; Lukey, G.C.; Provis, J.; Van Deventer, J.S. Effect of calcium silicate sources on geopolymerisation. Cem. Concr. Res. 2008, 38, 554–564. [Google Scholar] [CrossRef]

- Anbarasan, I.; Soundarapandian, N. Investigation of mechanical and micro structural properties of geopolymer concrete blended by dredged marine sand and manufactured sand under ambient curing conditions. Struct. Concr. 2020, 21, 992–1003. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Age-dependent compressive strength and elastic modulus of fly ash-based geopolymer concrete. Struct. Concr. 2020, 23, 473–487. [Google Scholar] [CrossRef]

- Bakthavatchalam, K.; Rajendran, M. An experimental investigation on potassium activator based geopolymer concrete incorporated with hybrid fibers. Mater. Today Proc. 2021, 46, 8494–8501. [Google Scholar] [CrossRef]

- Jayarajan, G.; Arivalagan, S. An experimental studies of geopolymer concrete incorporated with fly-ash & GGBS. Mater. Today Proc. 2021, 45, 6915–6920. [Google Scholar] [CrossRef]

- Padmakar, M.; Barhmaiah, B.; Priyanka, M.L. Characteristic compressive strength of a geo polymer concrete. Mater. Today Proc. 2021, 37, 2219–2222. [Google Scholar] [CrossRef]

- Das, S.K.; Mishra, J.; Singh, S.K.; Mustakim, S.M.; Patel, A.; Das, S.K.; Behera, U. Characterization and utilization of rice husk ash (RHA) in fly ash–Blast furnace slag based geopolymer concrete for sustainable future. Mater. Today Proc. 2020, 33, 5162–5167. [Google Scholar] [CrossRef]

- Lee, W.; van Deventer, J. Chemical interactions between siliceous aggregates and low-Ca alkali-activated cements. Cem. Concr. Res. 2007, 37, 844–855. [Google Scholar] [CrossRef]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Chalee, W.; Rattanasak, U. Comparative study on the characteristics of fly ash and bottom ash geopolymers. Waste Manag. 2009, 29, 539–543. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Lodeiro, I.; Palomo, A.; Jimenez, A.M.F.; Macphee, D. Compatibility studies between N-A-S-H and C-A-S-H gels. Study in the ternary diagram Na2O–CaO–Al2O3–SiO2–H2O. Cem. Concr. Res. 2011, 41, 923–931. [Google Scholar] [CrossRef]

- Huseien, G.F.; Ismail, M.; Khalid, N.H.A.; Hussin, M.W.; Mirza, J. Compressive strength and microstructure of assorted wastes incorporated geopolymer mortars: Effect of solution molarity. Alex. Eng. J. 2018, 57, 3375–3386. [Google Scholar] [CrossRef]

- Xie, J.; Chen, W.; Wang, J.; Fang, C.; Zhang, B.; Liu, F. Coupling effects of recycled aggregate and GGBS/metakaolin on physicochemical properties of geopolymer concrete. Constr. Build. Mater. 2019, 226, 345–359. [Google Scholar] [CrossRef]

- Meesala, C.R.; Verma, N.K.; Kumar, S. Critical review on fly-ash based geopolymer concrete. Struct. Concr. 2020, 21, 1013–1028. [Google Scholar] [CrossRef]

- Ding, Y.-C.; Cheng, T.-W.; Dai, Y.-S. Application of geopolymer paste for concrete repair. Struct. Concr. 2017, 18, 561–570. [Google Scholar] [CrossRef]

- Their, J.M.; Özakça, M. Developing geopolymer concrete by using cold-bonded fly ash aggregate, nano-silica, and steel fiber. Constr. Build. Mater. 2018, 180, 12–22. [Google Scholar] [CrossRef]

- Ganesh, A.C.; Muthukannan, M. Development of high performance sustainable optimized fiber reinforced geopolymer concrete and prediction of compressive strength. J. Clean. Prod. 2021, 282, 124543. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Development of rubberized geopolymer concrete: Strength and durability studies. Constr. Build. Mater. 2019, 204, 740–753. [Google Scholar] [CrossRef]

- Siyal, A.A.; Shamsuddin, M.R.; Khahro, S.H.; Low, A.; Ayoub, M. Optimization of synthesis of geopolymer adsorbent for the effective removal of anionic surfactant from aqueous solution. J. Environ. Chem. Eng. 2021, 9, 104949. [Google Scholar] [CrossRef]

- Luo, Z.; Li, W.; Wang, K.; Castel, A.; Shah, S.P. Comparison on the properties of ITZs in fly ash-based geopolymer and Portland cement concretes with equivalent flowability. Cem. Concr. Res. 2021, 143, 106392. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K.; Rangan, V.B. Early Age Properties of Low-calcium Fly Ash Geopolymer Concrete Suitable for Ambient Curing. Procedia Eng. 2015, 125, 601–607. [Google Scholar] [CrossRef] [Green Version]

- Sethi, H.; Bansal, P.P.; Sharma, R. Effect of Addition of GGBS and Glass Powder on the Properties of Geopolymer Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 607–617. [Google Scholar] [CrossRef]

- Bernal, S.A.; DE Gutierrez, R.M.; Pedraza, A.L.; Provis, J.; Rodriguez, E.; Delvasto, S. Effect of binder content on the performance of alkali-activated slag concretes. Cem. Concr. Res. 2011, 41, 1–8. [Google Scholar] [CrossRef]

- Singh, S.; Aswath, M.; Ranganath, R. Effect of mechanical activation of red mud on the strength of geopolymer binder. Constr. Build. Mater. 2018, 177, 91–101. [Google Scholar] [CrossRef]

- Wang, J.; Huang, T.; Han, L.; Xie, F.; Liu, Z.; Wang, D. Optimization of alkali-activated concrete based on the characteristics of binder systems. Constr. Build. Mater. 2021, 300, 123952. [Google Scholar] [CrossRef]

- Chithambaram, S.J.; Kumar, S.; Prasad, M.M.; Adak, D. Effect of parameters on the compressive strength of fly ash based geopolymer concrete. Struct. Concr. 2018, 19, 1202–1209. [Google Scholar] [CrossRef]

- Singh, K. Experimental study on metakolin and baggashe ash based geopolymer concrete. Mater. Today Proc. 2021, 37, 3289–3295. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chalee, W. Effect of sodium hydroxide concentration on chloride penetration and steel corrosion of fly ash-based geopolymer concrete under marine site. Constr. Build. Mater. 2014, 63, 303–310. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Salem, H.A. Effect of water addition, plasticizer and alkaline solution constitution on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 121, 694–703. [Google Scholar] [CrossRef]

- Yeoh, M.L.; Ukritnukun, S.; Rawal, A.; Davies, J.; Kang, B.J.; Burrough, K.; Aly, Z.; Dayal, P.; Vance, E.R.; Gregg, D.J.; et al. Mechanistic impacts of long-term gamma irradiation on physicochemical, structural, and mechanical stabilities of radiation-responsive geopolymer pastes. J. Hazard. Mater. 2021, 407, 124805. [Google Scholar] [CrossRef] [PubMed]

- Anshul, A.; Moinuddin, A.A.; Azad, A.M.; Khera, P.; Dehariya, K.; Bherwani, H.; Gupta, A.; Kumar, S. Morphologically designed micro porous zeolite-geopolymers as cool coating materials. J. Hazard. Mater. 2020, 398, 123022. [Google Scholar] [CrossRef] [PubMed]

- Ravikumar, D.; Neithalath, N. Effects of activator characteristics on the reaction product formation in slag binders activated using alkali silicate powder and NaOH. Cem. Concr. Compos. 2012, 34, 809–818. [Google Scholar] [CrossRef]

- Nie, Q.; Hu, W.; Huang, B.; Shu, X.; He, Q. Synergistic utilization of red mud for flue-gas desulfurization and fly ash-based geopolymer preparation. J. Hazard. Mater. 2019, 369, 503–511. [Google Scholar] [CrossRef] [PubMed]

- Malkawi, A.B.; Nuruddin, M.F.; Fauzi, A.; Al-Mattarneh, H.; Mohammed, B.S. Effects of Alkaline Solution on Properties of the HCFA Geopolymer Mortars. Procedia Eng. 2016, 148, 710–717. [Google Scholar] [CrossRef] [Green Version]

- Yaowarat, T.; Sudsaynate, W.; Horpibulsuk, S.; Chinkulkijniwat, A.; Arulrajah, A.; Horpibulsuk, J. Mechanical Properties of Fly Ash–Asphalt Emulsion Geopolymer Stabilized Crushed Rock for Sustainable Pavement Base. J. Mater. Civ. Eng. 2021, 33, 04021220. [Google Scholar] [CrossRef]

- Galiano, Y.L.; Pereira, C.F.; Vale, J. Stabilization/solidification of a municipal solid waste incineration residue using fly ash-based geopolymers. J. Hazard. Mater. 2011, 185, 373–381. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Gashti, M.F. Effects of alkaline solution/binder and Na2SiO3/NaOH ratios on fracture properties and ductility of ambient-cured GGBFS based heavyweight geopolymer concrete. Structures 2021, 32, 2118–2129. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- Sofi, M.; van Deventer, J.; Mendis, P.; Lukey, G. Engineering properties of inorganic polymer concretes (IPCs). Cem. Concr. Res. 2007, 37, 251–257. [Google Scholar] [CrossRef]

- Álvarez-Ayuso, E.; Querol, X.; Plana, F.; Alastuey, A.; Moreno, N.; Izquierdo, M.; Font, O.; Moreno, T.; Díez, S.; Vázquez, E.; et al. Environmental, physical and structural characterisation of geopolymer matrixes synthesised from coal (co-)combustion fly ashes. J. Hazard. Mater. 2008, 154, 175–183. [Google Scholar] [CrossRef] [PubMed]

- Pasupathy, K.; Sanjayan, J.; Rajeev, P. Evaluation of alkalinity changes and carbonation of geopolymer concrete exposed to wetting and drying. J. Build. Eng. 2021, 35, 102029. [Google Scholar] [CrossRef]

- Muraleedharan, M.; Nadir, Y. Factors affecting the mechanical properties and microstructure of geopolymers from red mud and granite waste powder: A review. Ceram. Int. 2021, 47, 13257–13279. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Cortes, P.P.; Escalante-Garcia, J.I. Gel composition and molecular structure of alkali-activated metakaolin-limestone cements. Cem. Concr. Res. 2020, 137, 106211. [Google Scholar] [CrossRef]

- Raijiwala, D.; Patil, H.S. Geopolymer concrete A green concrete. In Proceedings of the 2010 2nd International Conference on Chemical, Biological and Environmental Engineering, Cairo, Egypt, 2–4 November 2010; pp. 202–206. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers Based on Natural and Synthetic Metakaolin a Critical Review. In Proceedings of the 41st International Conference on Advanced Ceramics and Composites; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2018; pp. 201–214. [Google Scholar] [CrossRef]

- Oyebisi, S.O.; Ede, A.N.; Olutoge, F.A.; Ofuyatan, O.M.; Oluwafemi, J. Influence of alkali concentrations on the mechanical properties of geopolymer concrete. Int. J. Civ. Eng. Technol. 2018, 9, 734–743. [Google Scholar]

- Lee, N.; Lee, H. Influence of the slag content on the chloride and sulfuric acid resistances of alkali-activated fly ash/slag paste. Cem. Concr. Compos. 2016, 72, 168–179. [Google Scholar] [CrossRef]

- Pilehvar, S.; Cao, V.D.; Szczotok, A.M.; Valentini, L.; Salvioni, D.; Magistri, M.; Pamies, R.; Kjøniksen, A.-L. Mechanical properties and microscale changes of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Cem. Concr. Res. 2017, 100, 341–349. [Google Scholar] [CrossRef]

- Shehab, H.K.; Eisa, A.S.; Wahba, A.M. Mechanical properties of fly ash based geopolymer concrete with full and partial cement replacement. Constr. Build. Mater. 2016, 126, 560–565. [Google Scholar] [CrossRef]

- Moya, J.S.; Cabal, B.; Sanz, J.; Torrecillas, R. Metakaolin-Nanosilver as Biocide Agent in Geopolymer. In Developments in Strategic Materials and Computational Design III; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 1–11. [Google Scholar] [CrossRef]

- Haruna, S.; Mohammed, B.S.; Wahab, M.M.A.; Kankia, M.U.; Amran, M.; Gora, A.M. Long-Term Strength Development of Fly Ash-Based One-Part Alkali-Activated Binders. Materials 2021, 14, 4160. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.B.; Kamarudin, H.; Abdulkareem, O.A.; Ghazali, C.M.R.; Rafiza, A.; Norazian, M. Optimization of Alkaline Activator/Fly ASH Ratio on the Compressive Strength of Manufacturing Fly ASH-BASED Geopolymer. Appl. Mech. Mater. 2011, 110–116, 734–739. [Google Scholar] [CrossRef]

- Vora, P.R.; Dave, U.V. Parametric Studies on Compressive Strength of Geopolymer Concrete. Procedia Eng. 2013, 51, 210–219. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, M.; Dana, K. Partial replacement of metakaolin with red ceramic waste in geopolymer. Ceram. Int. 2021, 47, 3473–3483. [Google Scholar] [CrossRef]

- Aly, A.M.; El-Feky, M.; Kohail, M.; Nasr, E.-S.A. Performance of geopolymer concrete containing recycled rubber. Constr. Build. Mater. 2019, 207, 136–144. [Google Scholar] [CrossRef]

- Saloni; Parveen; Pham, T.M.; Lim, Y.Y.; Pradhan, S.; Jatin; Kumar, J. Performance of rice husk Ash-Based sustainable geopolymer concrete with Ultra-Fine slag and Corn cob ash. Constr. Build. Mater. 2021, 279, 122526. [Google Scholar] [CrossRef]

- Liew, Y.M.; Kamarudin, H.; Al Bakri, A.M.M.; Binhussain, M.; Luqman, M.; Nizar, I.K.; Ruzaidi, C.M.; Heah, C.Y. Correlating Composition Design and Properties of Calcined Kaolin Geopolymeric Powder. Adv. Sci. Lett. 2013, 19, 3671–3674. [Google Scholar] [CrossRef] [Green Version]

- Liew, Y.; Kamarudin, H.; Al Bakri, A.M.; Binhussain, M.; Musa, L.; Nizar, I.K.; Ghazali, C.M.R.; Heah, C. Calcined Kaolin Geopolymeric Powder: Influence of Water-to-Geopolymeric Powder Ratio. Adv. Mater. Res. 2012, 548, 48–53. [Google Scholar] [CrossRef]

- Mendes, B.C.; Pedroti, L.G.; Vieira, C.M.F.; Marvilla, M.; Azevedo, A.R.; de Carvalho, J.M.F.; Ribeiro, J.C.L. Application of eco-friendly alternative activators in alkali-activated materials: A review. J. Build. Eng. 2021, 35, 102010. [Google Scholar] [CrossRef]

| Composition Binder | SiO2 | Al2O3 | CaO | MgO | K2O | Fe2O3 | Na2O | SO3 | Others | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| GGBS | 34.80 | 15.78 | 36.81 | 7.09 | 0.44 | 0.38 | 0.27 | 2.53 | - | 1.50 |

| RM | 6.95 | 16.18 | 11.24 | - | - | 42.35 | 3.45 | - | - | 4.25 |

| Materials | GGBS | Red Mud | Aggregate | R. Sand |

|---|---|---|---|---|

| Physical Properties | ||||

| Specific gravity | 2.88 | 2.68 | 2.8 | 2.6 |

| Zone | - | - | - | II |

| Fineness modulus | - | - | 7.0 | 3.0 |

| Silt content | - | - | - | 4% |

| Mix ID | GGBS % | RM % | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Alkali/Binder Ratio | Alkaline Solution | |

|---|---|---|---|---|---|---|---|

| KOH (kg/m3) | K2SiO3 (kg/m3) | ||||||

| G0 | 100 | 0 | 554 | 1295 | 0.30, 0.40, 0.50 | 14.66 | 52.4 |

| GR1 | 98 | 2 | 554 | 1295 | 14.66 | 52.4 | |

| GR2 | 96 | 4 | 554 | 1295 | 14.66 | 52.4 | |

| GR3 | 94 | 6 | 554 | 1295 | 14.66 | 52.4 | |

| GR4 | 92 | 8 | 554 | 1295 | 14.66 | 52.4 | |

| GR5 | 90 | 10 | 554 | 1295 | 14.66 | 52.4 | |

| GR6 | 88 | 12 | 554 | 1295 | 14.66 | 52.4 | |

| GR7 | 86 | 14 | 554 | 1295 | 14.66 | 52.4 | |

| GR8 | 84 | 16 | 554 | 1295 | 14.66 | 52.4 | |

| GR9 | 82 | 18 | 554 | 1295 | 14.66 | 52.4 | |

| GR10 | 80 | 20 | 554 | 1295 | 14.66 | 52.4 | |

| GR11 | 78 | 22 | 554 | 1295 | 14.66 | 52.4 | |

| GR12 | 76 | 24 | 554 | 1295 | 14.66 | 52.4 | |

| GR13 | 74 | 26 | 554 | 1295 | 14.66 | 52.4 | |

| GR14 | 72 | 28 | 554 | 1295 | 14.66 | 52.4 | |

| GR15 | 70 | 30 | 554 | 1295 | 14.66 | 52.4 | |

| GR16 | 68 | 32 | 554 | 1295 | 14.66 | 52.4 | |

| GR17 | 66 | 34 | 554 | 1295 | 14.66 | 52.4 | |

| GR18 | 64 | 36 | 554 | 1295 | 14.66 | 52.4 | |

| GR19 | 62 | 38 | 554 | 1295 | 14.66 | 52.4 | |

| GR20 | 60 | 40 | 554 | 1295 | 14.66 | 52.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Khan, T.M.Y.; Javed, S.; Baig, R.U. Optimization of Alkaline Activator on the Strength Properties of Geopolymer Concrete. Polymers 2022, 14, 2434. https://doi.org/10.3390/polym14122434

Shilar FA, Ganachari SV, Patil VB, Khan TMY, Javed S, Baig RU. Optimization of Alkaline Activator on the Strength Properties of Geopolymer Concrete. Polymers. 2022; 14(12):2434. https://doi.org/10.3390/polym14122434

Chicago/Turabian StyleShilar, Fatheali A., Sharanabasava V. Ganachari, Veerabhadragouda B. Patil, T. M. Yunus Khan, Syed Javed, and Rahmath Ulla Baig. 2022. "Optimization of Alkaline Activator on the Strength Properties of Geopolymer Concrete" Polymers 14, no. 12: 2434. https://doi.org/10.3390/polym14122434

APA StyleShilar, F. A., Ganachari, S. V., Patil, V. B., Khan, T. M. Y., Javed, S., & Baig, R. U. (2022). Optimization of Alkaline Activator on the Strength Properties of Geopolymer Concrete. Polymers, 14(12), 2434. https://doi.org/10.3390/polym14122434