Optimization of Biocomposite Film Based on Whey Protein Isolate and Nanocrystalline Cellulose from Pineapple Crown Leaf Using Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

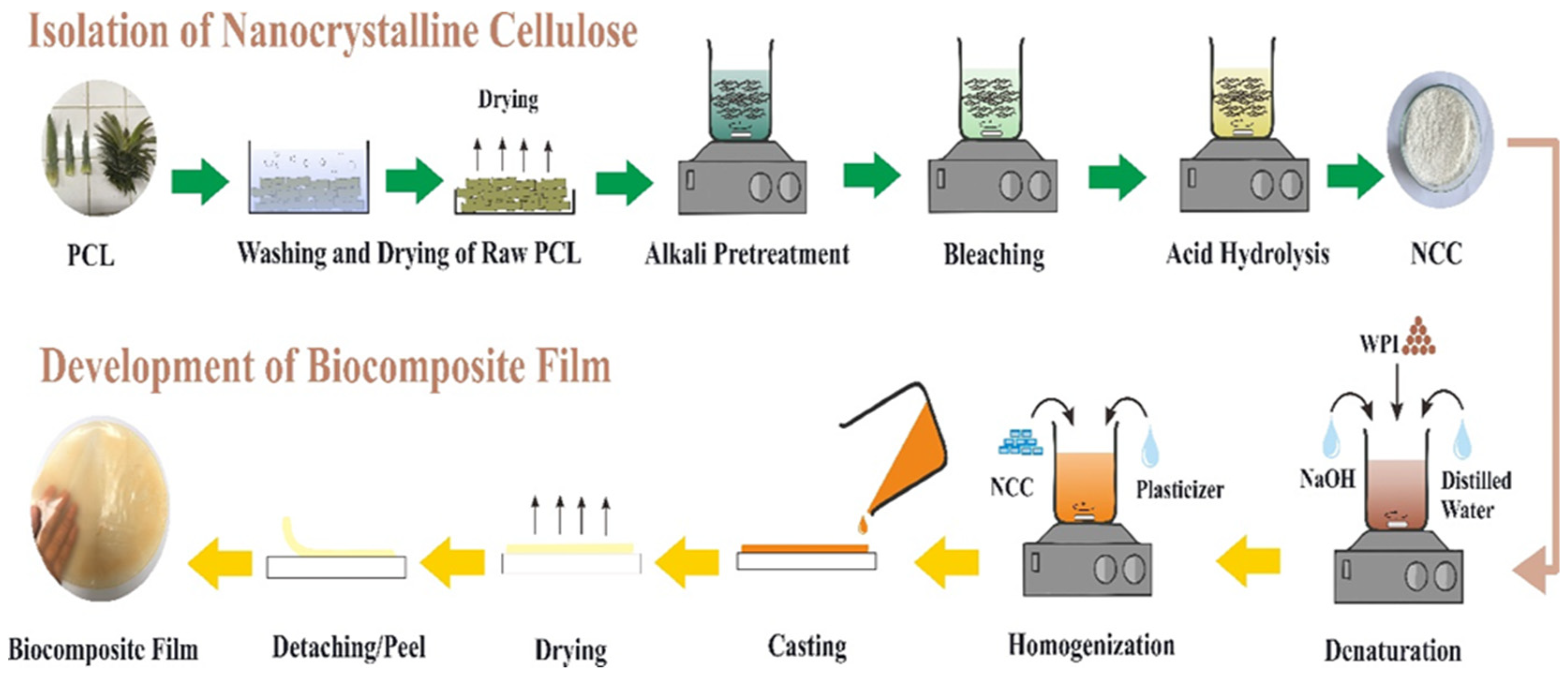

2.2. Isolation of Nanocrystalline Cellulose

2.3. Preparation of Whey Protein/Nanocrystalline Cellulose/Glycerol Biocomposite Films

2.4. Physical and Mechanical Properties

2.5. Morphological, Physical, and Crystallinilty Analysis of Optimized Biocomposite Films

2.6. Experimental Design and Statistical Analysis

3. Results and Discussion

3.1. Thickness, Tensile Strength, and Elongation of Biocomposite Films

3.2. Model Selection and Verification of Thickness, Tensile Strength, and Elongation

3.3. Analysis of Response Surface of Thickness, Tensile Strength, and Elongation

3.4. Optimization Process of the Experiment

3.5. Validation Process of the Predicted Model of Optimised Formulations

3.6. Morphological, Physical and Crystallinilty Analysis of Optimized Biocomposite Films

3.6.1. Functional Group of Optimized Biocomposite Film

3.6.2. Morphology of Optimized Biocomposite Film

3.6.3. Transparency of Optimized Biocomposite Film

3.6.4. Water Solubility of Optimized Biocomposite Film

3.6.5. Water Vapor Permeability of Optimized Biocomposite Film

3.6.6. Crystallinity of Optimized Biocomposite Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siracusa, V.; Rocculi, P.; Romani, S.; Rosa, M.D. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Vieira, M.G.A.; Da Silva, M.A.; Dos Santos, L.O.; Beppu, M.M. Natural-based plasticizers and biopolymer films: A review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef] [Green Version]

- Tharanathan, R.N. Biodegradable films and composite coatings: Past, present and future. Trends Food Sci. Technol. 2003, 14, 71–78. [Google Scholar] [CrossRef]

- González, A.; Gastelú, G.; Barrera, G.N.; Ribotta, P.D.; Igarzabal, C. Preparation and characterization of soy protein films reinforced with cellulose nanofibers obtained from soybean by-products. Food Hydrocoll. 2019, 89, 758–764. [Google Scholar] [CrossRef]

- Gonzalez-Jordan, A.; Nicolai, T.; Benyahia, L. Influence of the Protein Particle Morphology and Partitioning on the Behavior of Particle-Stabilized Water-in-Water Emulsions. Langmuir 2016, 32, 7189–7197. [Google Scholar] [CrossRef]

- Kandasamy, S.; Yoo, J.; Yun, J.; Kang, H.-B.; Seol, K.-H.; Kim, H.-W.; Ham, J.-S. Application of Whey Protein-Based Edible Films and Coatings in Food Industries: An Updated Overview. Coatings 2021, 11, 1056. [Google Scholar] [CrossRef]

- Hu, Y.; Shi, L.; Ren, Z.; Hao, G.; Chen, J.; Weng, W. Characterization of emulsion films prepared from soy protein isolate at different preheating temperatures. J. Food Eng. 2021, 309, 110697. [Google Scholar] [CrossRef]

- Wang, L.; Auty, M.A.E.; Kerry, J.P. Physical assessment of composite biodegradable films manufactured using whey protein isolate, gelatin and sodium alginate. J. Food Eng. 2010, 96, 199–207. [Google Scholar] [CrossRef]

- Ahammed, S.; Liu, F.; Wu, J.; Khin, M.N.; Yokoyama, W.H.; Zhong, F. Effect of transglutaminase crosslinking on solubility property and mechanical strength of gelatin-zein composite films. Food Hydrocoll. 2021, 116, 106649. [Google Scholar] [CrossRef]

- Sukyai, P.; Anongjanya, P.; Bunyahwuthakul, N.; Kongsin, K.; Harnkarnsujarit, N.; Sukatta, U.; Sothornvit, R.; Chollakup, R. Effect of cellulose nanocrystals from sugarcane bagasse on whey protein isolate-based films. Food Res. Int. 2018, 107, 528–535. [Google Scholar] [CrossRef]

- Sothornvit, R.; Hong, S.-I.; An, D.J.; Rhim, J.-W. Effect of clay content on the physical and antimicrobial properties of whey protein isolate/organo-clay composite films. LWT Food Sci. Technol. 2010, 43, 279–284. [Google Scholar] [CrossRef]

- Ramos, Ó.L.; Reinas, I.; Silva, S.I.; Fernandes, J.C.; Cerqueira, M.A.; Pereira, R.N.; Vicente, A.A.; Poças, M.F.; Pintado, M.E.; Malcata, F.X. Effect of whey protein purity and glycerol content upon physical properties of edible films manufactured therefrom. Food Hydrocoll. 2013, 30, 110–122. [Google Scholar] [CrossRef] [Green Version]

- Qazanfarzadeh, Z.; Kadivar, M. Properties of whey protein isolate nanocomposite films reinforced with nanocellulose isolated from oat husk. Int. J. Biol. Macromol. 2016, 91, 1134–1140. [Google Scholar] [CrossRef] [PubMed]

- Khwaldia, K.; Perez, C.; Banon, S.; Desobry, S.; Hardy, J. Milk proteins for edible films and coatings. Crit. Rev. Food Sci. Nutr. 2004, 44, 239–251. [Google Scholar] [CrossRef] [PubMed]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H. Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Res. Int. 2020, 137, 109625. [Google Scholar] [CrossRef] [PubMed]

- Garavand, F.; Rouhi, M.; Razavi, S.H.; Cacciotti, I.; Mohammadi, R. Improving the integrity of natural biopolymer films used in food packaging by crosslinking approach: A review. Int. J. Biol. Macromol. 2017, 104, 687–707. [Google Scholar] [CrossRef]

- Saba, N.; Tahir, P.M.; Jawaid, M. A Review on Potentiality of Nano Filler/Natural Fiber Filled Polymer Hybrid Composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Fitriani, F.; Aprilia, S.; Arahman, N.; Bilad, M.R.; Suhaimi, H.; Huda, N. Properties of Biocomposite Film Based on Whey Protein Isolate Filled with Nanocrystalline Cellulose from Pineapple Crown Leaf. Polymers 2021, 13, 4278. [Google Scholar] [CrossRef] [PubMed]

- Huq, T.; Salmieri, S.; Khan, A.; Khan, R.A.; Le Tien, C.; Riedl, B.; Fraschini, C.; Bouchard, J.; Uribe-Calderon, J.; Kamal, M.R. Nanocrystalline cellulose (NCC) reinforced alginate based biodegradable nanocomposite film. Carbohydr. Polym. 2012, 90, 1757–1763. [Google Scholar] [CrossRef]

- Zhao, G.; Zhou, C.; Fan, F. Preparation and Properties of Soy Protein Isolate/Cotton-Nanocrystalline Cellulose Films. Int. J. Polym. Sci. 2021, 2021, 5518136. [Google Scholar] [CrossRef]

- Aprilia, N.A.S.; Mulyati, S.; Alam, P.N.; Karmila; Ambarita, A.C. Characterization nano crystalline cellulose from sugarcane baggase for reinforcement in polymer composites: Effect of formic acid concentrations. IOP Conf. Ser. Mater. Sci. Eng. 2018, 345, 012033. [Google Scholar] [CrossRef] [Green Version]

- Fitriani, F.; Aprilia, S.; Arahman, N.; Bilad, M.R.; Amin, A.; Huda, N.; Roslan, J. Isolation and Characterization of Nanocrystalline Cellulose Isolated from Pineapple Crown Leaf Fiber Agricultural Wastes Using Acid Hydrolysis. Polymers 2021, 13, 4188. [Google Scholar] [CrossRef]

- Thakur, M.; Sharma, A.; Ahlawat, V.; Bhattacharya, M.; Goswami, S. Process optimization for the production of cellulose nanocrystals from rice straw derived α-cellulose. Mater. Sci. Energy Technol. 2020, 3, 328–334. [Google Scholar] [CrossRef]

- Aprilia, N.A.S.; Davoudpour, Y.; Zulqarnain, W.; Khalil, H.A.; Hazwan, C.M.; Hossain, M.S.; Dungani, R.; Fizree, H.M.; Zaidon, A.; Haafiz, M. Physicochemical Characterization of Microcrystalline Cellulose Extracted from Kenaf Bast. Bioresources 2016, 11, 3875–3889. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.; Jawaid, M.; Kian, L.K.; Khan, A.A.P.; Asiri, A.M. Isolation and Production of Nanocrystalline Cellulose from Conocarpus Fiber. Polymers 2021, 13, 1835. [Google Scholar] [CrossRef]

- Zheng, D.; Zhang, Y.; Guo, Y.; Yue, J. Isolation and Characterization of Nanocellulose with a Novel Shape from Walnut (Juglans regia L.) Shell Agricultural Waste. Polymers 2019, 11, 1130. [Google Scholar] [CrossRef] [Green Version]

- Prado, K.S.; Spinacé, M.A. Isolation and characterization of cellulose nanocrystals from pineapple crown waste and their potential uses. Int. J. Biol. Macromol. 2019, 122, 410–416. [Google Scholar] [CrossRef]

- Fitriani; Aprilia, N.A.S.; Arahman, N. Properties of nanocrystalline cellulose from pineapple crown leaf waste. IOP Conf. Ser. Mater. Sci. Eng. 2020, 796, 12007. [Google Scholar] [CrossRef]

- Brinchi, L.; Cotana, F.; Fortunati, E.; Kenny, J. Production of nanocrystalline cellulose from lignocellulosic biomass: Technology and applications. Carbohydr. Polym. 2013, 94, 154–169. [Google Scholar] [CrossRef]

- Dick, M.; Costa, T.M.H.; Gomaa, A.; Subirade, M.; de Oliveira Rios, A.; Flôres, S.H. Edible film production from chia seed mucilage: Effect of glycerol concentration on its physicochemical and mechanical properties. Carbohydr. Polym. 2015, 130, 198–205. [Google Scholar] [CrossRef] [Green Version]

- Zhai, X.; Zhang, X.; Ao, H.; Yin, Y.; Li, X.; Ren, D. Preparation and characterization of whey protein isolate/chitosan/microcrystalline cellulose composite films. Packag. Technol. Sci. 2021, 34, 589–599. [Google Scholar] [CrossRef]

- Dixit, S.; Yadav, V.L. Optimization of polyethylene/polypropylene/alkali modified wheat straw composites for packaging application using RSM. J. Clean. Prod. 2019, 240, 118228. [Google Scholar] [CrossRef]

- Granato, D.; de Araújo Calado, V.M. The use and importance of design of experiments (DOE) in process modelling in food science and technology. Math. Stat. Methods Food Sci. Technol. 2014, 1, 1–18. [Google Scholar]

- Nandane, A.S.; Jain, R.K. Optimization of formulation and process parameters for soy protein-based edible film using response surface methodology. J. Packag. Technol. Res. 2018, 2, 203–210. [Google Scholar] [CrossRef]

- Kalateh-Seifari, F.; Yousefi, S.; Ahari, H.; Hosseini, S.H. Corn starch-chitosan nanocomposite film containing nettle essential oil nanoemulsions and starch nanocrystals: Optimization and characterization. Polymers 2021, 13, 2113. [Google Scholar] [CrossRef]

- Fan, H.Y.; Duquette, D.; Dumont, M.J.; Simpson, B.K. Salmon skin gelatin-corn zein composite films produced via crosslinking with glutaraldehyde: Optimization using response surface methodology and characterization. Int. J. Biol. Macromol. 2018, 120, 263–273. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Khezerlou, A.; Ehsani, A. Fabrication and characterization of the bionanocomposite film based on whey protein biopolymer loaded with TiO2 nanoparticles, cellulose nanofibers and rosemary essential oil. Ind. Crops Prod. 2018, 124, 300–315. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Penjumras, P.; Abdul Rahman, R.; Talib, R.A.; Abdan, K. Response Surface Methodology for the Optimization of Preparation of Biocomposites Based on Poly(lactic acid) and Durian Peel Cellulose. Sci. World J. 2015, 2015, 293609. [Google Scholar] [CrossRef] [Green Version]

- Lv, C.; Wang, Y.; Wang, L.-j.; Li, D.; Adhikari, B. Optimization of production yield and functional properties of pectin extracted from sugar beet pulp. Carbohydr. Polym. 2013, 95, 233–240. [Google Scholar] [CrossRef]

- Said, N.S.; Sarbon, N.M. Response surface methodology (RSM) of chicken skin gelatin based composite films with rice starch and curcumin incorporation. Polym. Test. 2020, 81, 106161. [Google Scholar] [CrossRef]

- Chang, B.P.; Akil, H.M.; Affendy, M.G.; Khan, A.; Nasir, R.B.M. Comparative study of wear performance of particulate and fiber-reinforced nano-ZnO/ultra-high molecular weight polyethylene hybrid composites using response surface methodology. Mater. Des. 2014, 63, 805–819. [Google Scholar] [CrossRef]

- Wildan, M.W.; Lubis, F. Fabrication and Characterization of Chitosan/Cellulose Nanocrystal/Glycerol Bio-Composite Films. Polymers 2021, 13, 1096. [Google Scholar]

- Nazmi, N.N.M.; Sarbon, N.M. Response Surface Methodology on development and formulation optimisation of chicken skin gelatine film blended with carboxymethyl cellulose as affected by varying plasticiser concentrations. Int. Food Res. J. 2019, 26, 47–57. [Google Scholar]

- Wongphan, P.; Khowthong, M.; Supatrawiporn, T.; Harnkarnsujarit, N.J.F.P.; Life, S. Novel edible starch films incorporating papain for meat tenderization. Shelf Life 2022, 31, 100787. [Google Scholar] [CrossRef]

- Mukurumbira, A.R.; Mellem, J.J.; Amonsou, E. Effects of amadumbe starch nanocrystals on the physicochemical properties of starch biocomposite films. Carbohydr. Polym. 2017, 165, 142–148. [Google Scholar] [CrossRef]

- Phothisarattana, D.; Harnkarnsujarit, N. Characterizations of Cassava Starch and Poly (butylene adipate-co-terephthalate) Blown Film with Silicon Dioxide Nanocomposites. Int. J. Food Sci. Technol. 2022, 57, 5078–5089. [Google Scholar] [CrossRef]

- Phothapaeree, N.; Jarusaksakul, N.; Somwangthanaroj, A.; Tananuwong, K. Influence of packaging and storage conditions on quality parameters and shelf life of solar-dried banana. Songklanakarin J. Sci. Technol. 2017, 39, 253–260. [Google Scholar] [CrossRef]

- Sharma, L.; Singh, C. Sesame protein based edible films: Development and characterization. Food Hydrocoll. 2016, 61, 139–147. [Google Scholar] [CrossRef]

- Saremnezhad, S.; Azizi, M.H.; Barzegar, M.; Abbasi, S.; Ahmadi, E. Properties of a new edible film made of faba bean protein isolate. J. Agric. Sci. Technol. 2011, 13, 181–192. [Google Scholar]

- Aprilia, S.; Syamsuddin, Y.; Razali, N.; Fitriani, F.; Amin, A.; Guswara, F.; Ihsan, F. Studies on degradation of rice husk ash filled in polypropylene composite films under natural weathering condition. J. Phys. Conf. Ser. 2019, 1402, 055009. [Google Scholar] [CrossRef]

- Lara, B.R.B.; de Andrade, P.S.; Guimarães Junior, M.; Dias, M.V.; Alcântara, L.A.P. Novel Whey Protein Isolate/Polyvinyl Biocomposite for Packaging: Improvement of Mechanical and Water Barrier Properties by Incorporation of Nano-silica. J. Polym. Environ. 2021, 29, 2397–2408. [Google Scholar] [CrossRef]

- Jiang, S.j.; Zhang, T.; Song, Y.; Qian, F.; Tuo, Y.; Mu, G. Mechanical properties of whey protein concentrate based film improved by the coexistence of nanocrystalline cellulose and transglutaminase. Int. J. Biol. Macromol. 2019, 126, 1266–1272. [Google Scholar] [CrossRef] [PubMed]

- Guerrero, P.; Retegi, A.; Gabilondo, N.; De la Caba, K. Mechanical and thermal properties of soy protein films processed by casting and compression. J. Food Eng. 2010, 100, 145–151. [Google Scholar] [CrossRef]

- Yu, Z.; Sun, L.; Wang, W.; Zeng, W.; Mustapha, A.; Lin, M. Soy protein-based films incorporated with cellulose nanocrystals and pine needle extract for active packaging. Ind. Crops Prod. 2018, 112, 412–419. [Google Scholar] [CrossRef]

- Li, C.; Luo, J.; Qin, Z.; Chen, H.; Gao, Q.; Li, J. Mechanical and thermal properties of microcrystalline cellulose-reinforced soy protein isolate–gelatin eco-friendly films. RSC Adv. 2015, 5, 56518–56525. [Google Scholar] [CrossRef]

- Oymaci, P.; Altinkaya, S.A. Improvement of barrier and mechanical properties of whey protein isolate based food packaging films by incorporation of zein nanoparticles as a novel bionanocomposite. Food Hydrocoll. 2016, 54, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Al-Hassan, A.; Norziah, M. Starch–gelatin edible films: Water vapor permeability and mechanical properties as affected by plasticizers. Food Hydrocoll. 2012, 26, 108–117. [Google Scholar] [CrossRef]

- Hejazi, M.; Behzad, T.; Heidarian, P.; Nasri-Nasrabadi, B. A study of the effects of acid, plasticizer, cross-linker, and extracted chitin nanofibers on the properties of chitosan biofilm. Compos. Part A Appl. Sci. Manuf. 2018, 109, 221–231. [Google Scholar] [CrossRef]

- Abdollahi, M.; Alboofetileh, M.; Rezaei, M.; Behrooz, R. Comparing physico-mechanical and thermal properties of alginate nanocomposite films reinforced with organic and/or inorganic nanofillers. Food Hydrocoll. 2013, 32, 416–424. [Google Scholar] [CrossRef]

- Pereda, M.; Amica, G.; Rácz, I.; Marcovich, N.E. Structure and properties of nanocomposite films based on sodium caseinate and nanocellulose fibers. J. Food Eng. 2011, 103, 76–83. [Google Scholar] [CrossRef]

- Tibolla, H.; Czaikoski, A.; Pelissari, F.; Menegalli, F.; Cunha, R. Starch-based nanocomposites with cellulose nanofibers obtained from chemical and mechanical treatments. Int. J. Biol. Macromol. 2020, 161, 132–146. [Google Scholar] [CrossRef]

- Zolfi, M.; Khodaiyan, F.; Mousavi, M.; Hashemi, M. Development and characterization of the kefiran-whey protein isolate-TiO2 nanocomposite films. Int. J. Biol. Macromol. 2014, 65, 340–345. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Liu, C.; Chang, P.R.; Anderson, D.P.; Huneault, M.A. Pea starch-based composite films with pea hull fibers and pea hull fiber-derived nanowhiskers. Polym. Eng. Sci. 2009, 49, 369–378. [Google Scholar] [CrossRef]

- El-Wakil, N.A.; Hassan, E.A.; Abou-Zeid, R.E.; Dufresne, A. Development of wheat gluten/nanocellulose/titanium dioxide nanocomposites for active food packaging. Carbohydr. Polym. 2015, 124, 337–346. [Google Scholar] [CrossRef] [PubMed]

- Calva-Estrada, S.J.; Jiménez-Fernández, M.; Lugo-Cervantes, E. Protein-Based Films: Advances in the Development of Biomaterials Applicable to Food Packaging. Food Eng. Rev. 2019, 11, 78–92. [Google Scholar] [CrossRef]

- Dias, M.V.; Azevedo, V.M.; Santos, T.A.; Pola, C.C.; Lara, B.R.B.; Borges, S.V.; Soares, N.F.F.; Medeiros, É.A.A.; Sarantópoulous, C. Effect of active films incorporated with montmorillonite clay and α-tocopherol: Potential of nanoparticle migration and reduction of lipid oxidation in salmon. Packag. Technol. Sci. 2019, 32, 39–47. [Google Scholar] [CrossRef] [Green Version]

- Duval, A.; Molina-Boisseau, S.; Chirat, C. Comparison of Kraft lignin and lignosulfonates addition to wheat gluten-based materials: Mechanical and thermal properties. Ind. Crop. Prod. 2013, 49, 66–74. [Google Scholar] [CrossRef]

- Carvalho, R.A.; de Oliveira, A.C.S.; Santos, T.A.; Dias, M.V.; Yoshida, M.I.; Borges, S.V. WPI and cellulose nanofibres bio-nanocomposites: Effect of thyme essential oil on the morphological, mechanical, barrier and optical properties. J. Polym. Environ. 2020, 28, 231–241. [Google Scholar] [CrossRef]

- Bumbudsanpharoke, N.; Wongphan, P.; Promhuad, K.; Leelaphiwat, P.; Harnkarnsujarit, N. Morphology and permeability of bio-based poly(butylene adipate-co-terephthalate) (PBAT), poly(butylene succinate) (PBS) and linear low-density polyethylene (LLDPE) blend films control shelf-life of packaged bread. Food Control 2022, 132, 108541. [Google Scholar] [CrossRef]

- Aziz, S.G.-G.; Almasi, H.J.F.; Technology, B. Physical characteristics, release properties, and antioxidant and antimicrobial activities of whey protein isolate films incorporated with thyme (Thymus vulgaris L.) extract-loaded nanoliposomes. Food Bioprocess Technol. 2018, 11, 1552–1565. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Li, Y.; Zhu, L.; Fang, Z.; Shi, Q. Physicochemical, mechanical and structural properties of composite edible films based on whey protein isolate/psyllium seed gum. Int. J. Biol. Macromol. 2020, 153, 892–901. [Google Scholar] [CrossRef] [PubMed]

- Gray, D.G. Transcrystallization of polypropylene at cellulose nanocrystal surfaces. Cellulose 2008, 15, 297–301. [Google Scholar] [CrossRef]

- Mohammadian, M.; Moghaddam, A.D.; Sharifan, A.; Dabaghi, P.; Hadi, S. Characterization, Structural, physico-mechanical, and bio-functional properties of whey protein isolate-based edible films as affected by enriching with nettle (Urtica dioica L.) leaf extract. J. Food Meas. Charact. 2021, 15, 4051–4060. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Oleyaei, S.A.; Almasi, H. Nanostructured materials utilized in biopolymer-based plastics for food packaging applications. Crit. Rev. Food Sci. Nutr. 2015, 55, 1699–1723. [Google Scholar] [CrossRef] [PubMed]

- Hafizulhaq, F.; Abral, H.; Kasim, A.; Arief, S.; Affi, J. Moisture absorption and opacity of starch-based biocomposites reinforced with cellulose fiber from bengkoang. Fibers 2018, 6, 62. [Google Scholar] [CrossRef] [Green Version]

- Jooyandeh, H. Whey protein films and coatings: A review. Pak. J. Nutr. 2011, 10, 296–301. [Google Scholar] [CrossRef] [Green Version]

| Variable | Coded Levels | ||||

|---|---|---|---|---|---|

| −α | −1 | 0 a | +1 | +α | |

| X1: glycerol concentrations (%) | 3.17 | 4 | 6 | 8 | 8.82 |

| X2: NCC concentrations (%) | 2.17 | 3 | 5 | 7 | 7.82 |

| Trial | Coded Variables | Actual Variables | ||

|---|---|---|---|---|

| X1 | X2 | X1 (%) | X2 (%) | |

| 1 | 0 | 0 | 6 | 5 |

| 2 | −1 | 1 | 4 | 7 |

| 3 | −1 | −1 | 4 | 3 |

| 4 | +α | 0 | 8.82 | 5 |

| 5 | −α | 0 | 3.17 | 5 |

| 6 | 0 | 0 | 6 | 5 |

| 7 | 1 | 1 | 8 | 7 |

| 8 | 1 | −1 | 8 | 3 |

| 9 | 0 | −α | 6 | 2.17 |

| 10 | 0 | 0 | 6 | 5 |

| 11 | 0 | +α | 6 | 7.82 |

| 12 | 0 | 0 | 6 | 5 |

| 13 | 0 | 0 | 6 | 5 |

| Trial | Independent Variables | Responses | |||

|---|---|---|---|---|---|

| Glycerol Concentrations (%) | NCCC oncentrations (%) | Thickness * (mm) | Tensile Strength * (MPa) | Elongation * (%) | |

| 1 | 6 | 5 | 0.23 ± 0.05 | 3.92 ± 0.98 | 35.88 ± 14.29 |

| 2 | 4 | 7 | 0.12 ± 0.01 | 3.60 ± 0.57 | 18.29 ± 3.84 |

| 3 | 4 | 3 | 0.09 ± 0.02 | 6.87 ± 0.22 | 40.29 ± 3.11 |

| 4 | 8.82 | 5 | 0.15 ± 0.03 | 1.64 ± 0.57 | 4.71 ± 1.70 |

| 5 | 3.17 | 5 | 0.09 ± 0.01 | 7.85 ± 0.11 | 41.13 ± 4.92 |

| 6 | 6 | 5 | 0.19 ± 0.03 | 4.03 ± 0.62 | 36.54 ± 11.83 |

| 7 | 8 | 7 | 0.24 ± 0.07 | 2.62 ± 0.57 | 6.71 ± 3.72 |

| 8 | 8 | 3 | 0.07 ± 0.01 | 1.96 ± 0.38 | 18.67 ± 7.32 |

| 9 | 6 | 2.17 | 0.12 ± 0.02 | 2.62 ± 0.57 | 42.92 ± 3.35 |

| 10 | 6 | 5 | 0.21 ± 0.03 | 4.12 ± 0.34 | 30.92 ± 9.54 |

| 11 | 6 | 7.82 | 0.16 ± 0.03 | 1.96 ± 0.23 | 14.80 ± 5.25 |

| 12 | 6 | 5 | 0.19 ± 0.03 | 4.92 ± 0.12 | 36.81 ± 13.93 |

| 13 | 6 | 5 | 0.21 ± 0.03 | 4.92 ± 0.12 | 36.87 ± 13.57 |

| Source | Sum of Squares | DF | Mean Squares | F Value | Prob > F |

|---|---|---|---|---|---|

| Model | 0.0374 | 5 | 0.0075 | 13.40 | 0.0018 (significant) |

| Residual | 0.0039 | 7 | 0.0006 | ||

| Lack-of-fit | 0.0029 | 3 | 0.0010 | 3.86 | 0.1126 (not significant) |

| Pure error | 0.0010 | 4 | 0.0003 | ||

| Total | 0.0413 | 12 |

| Source | Sum of Squares | DF | Mean Squares | F Value | Prob > F |

|---|---|---|---|---|---|

| Model | 40.05 | 5 | 8.01 | 22.26 | 0.0004 significant |

| Residual | 2.52 | 7 | 0.3598 | ||

| Lack-of-fit | 1.53 | 3 | 0.5099 | 2.06 | 0.2480 not significant |

| Pure error | 0.9891 | 4 | 0.2473 | ||

| Total | 42.57 | 12 |

| Source | Sum of Squares | DF | Mean Squares | F Value | Prob > F |

|---|---|---|---|---|---|

| Model | 2077.39 | 5 | 415.48 | 24.28 | 0.0003 significant |

| Residual | 119.80 | 7 | 17.11 | ||

| Lack-of-fit | 94.04 | 3 | 31.35 | 4.87 | 0.0802 not significant |

| Pure error | 25.77 | 4 | 6.44 | ||

| Total | 2197.19 | 12 |

| Term | Thickness | Tensile Strength | Elongation at Break | |||

|---|---|---|---|---|---|---|

| Coefficient | Probability | Coefficient | Probability | Coefficient | Probability | |

| Constant | 0.2064 | 0.0018 | 4.38 | 0.0004 | 35.41 | 0.0003 |

| X1: Glycerol | 0.0235 | 0.0262 | −1.83 | <0.0001 | −10.59 | 0.0002 |

| X2: NCC | 0.0328 | 0.0057 | −0.4423 | 0.0755 | −9.21 | 0.0004 |

| X1X2 | 0.0364 | 0.0178 | 0.9812 | 0.0136 | 2.51 | 0.2643 |

| X12 | −0.0430 | 0.0020 | 0.2399 | 0.3265 | −7.47 | 0.0021 |

| X22 | −0.0352 | 0.0056 | −0.9858 | 0.0034 | −4.50 | 0.0241 |

| Response | 95% CI | 95% PI | Validation | ||

|---|---|---|---|---|---|

| Low | High | Low | High | Experimental Value | |

| Thickness (mm) | 0.06 | 0.15 | 0.04 | 0.18 | 0.13 ± 0.01 |

| Tensile strength (MPa) | 5.77 | 8.01 | 5.08 | 8.70 | 7.16 ± 0.33 |

| Elongation (%) | 38.01 | 53.48 | 33.28 | 58.22 | 39.10 ± 2.90 |

| Film | Wavelength (nm) | |||||

|---|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | 700 | 800 | |

| WPI | 0 | 6.53 ± 0.10 | 10.83 ± 0.06 | 15.53 ± 0.09 | 18.05 ± 0.55 | 22.51 ± 0.25 |

| WPI/NCC/Glycerol | 0 | 3.35 ± 0.09 | 4.99 ± 0.11 | 7.59 ± 0.03 | 11.24 ± 0.27 | 13.46 ± 0.46 |

| Film | WS (%) * | WVP (×10−11 g/m.s.Pa) * |

|---|---|---|

| WPI | 30.21 ± 0.10 | 2.21 ± 0.10 |

| WPI/NCC/Glycerol | 27.15 ± 0.16 | 2.17 ± 0.08 |

| Film | Crystallinity Index (%) |

|---|---|

| WPI | 74.82 |

| WPI/Glycerol | 76.49 |

| WPI/NCC/Glycerol | 81.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fitriani, F.; Aprilia, S.; Bilad, M.R.; Arahman, N.; Usman, A.; Huda, N.; Kobun, R. Optimization of Biocomposite Film Based on Whey Protein Isolate and Nanocrystalline Cellulose from Pineapple Crown Leaf Using Response Surface Methodology. Polymers 2022, 14, 3006. https://doi.org/10.3390/polym14153006

Fitriani F, Aprilia S, Bilad MR, Arahman N, Usman A, Huda N, Kobun R. Optimization of Biocomposite Film Based on Whey Protein Isolate and Nanocrystalline Cellulose from Pineapple Crown Leaf Using Response Surface Methodology. Polymers. 2022; 14(15):3006. https://doi.org/10.3390/polym14153006

Chicago/Turabian StyleFitriani, Fitriani, Sri Aprilia, Muhammad Roil Bilad, Nasrul Arahman, Anwar Usman, Nurul Huda, and Rovina Kobun. 2022. "Optimization of Biocomposite Film Based on Whey Protein Isolate and Nanocrystalline Cellulose from Pineapple Crown Leaf Using Response Surface Methodology" Polymers 14, no. 15: 3006. https://doi.org/10.3390/polym14153006

APA StyleFitriani, F., Aprilia, S., Bilad, M. R., Arahman, N., Usman, A., Huda, N., & Kobun, R. (2022). Optimization of Biocomposite Film Based on Whey Protein Isolate and Nanocrystalline Cellulose from Pineapple Crown Leaf Using Response Surface Methodology. Polymers, 14(15), 3006. https://doi.org/10.3390/polym14153006