Physical Property of 3D-Printed N-Pointed Star-Shaped Outsole Prepared by FDM 3D Printer Using the Lightweight TPU

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Preparations of LW 3-, 4-, and 6-Pointed SP Outsole with Various Thicknesses

2.3. 3D FDM Printing Conditions

2.4. Characterization

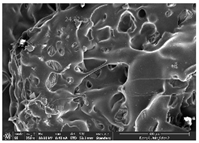

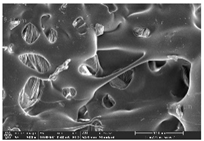

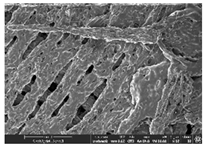

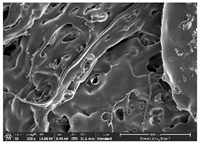

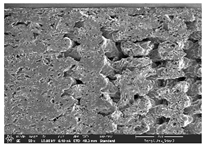

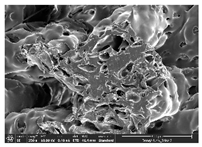

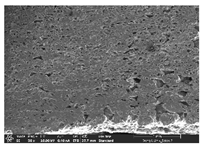

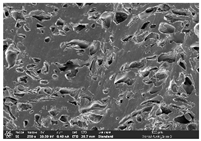

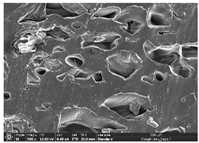

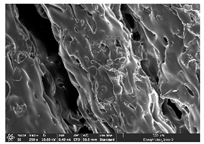

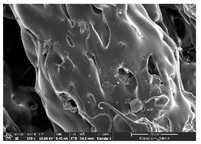

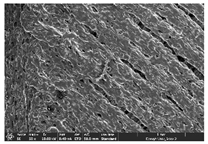

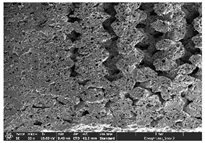

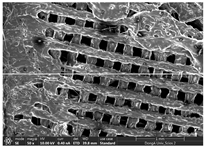

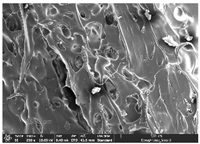

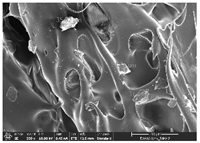

2.4.1. Morphology

2.4.2. Specific Gravity

2.4.3. Static Compressive Test

2.4.4. Static/Dynamic Coefficient of Friction Test

2.4.5. NBS and DIN Abrasion Test

2.4.6. Ball Drop and Pendulum Resilience Test

2.4.7. Surface Area and Surface Force Test

3. Results and Discussion

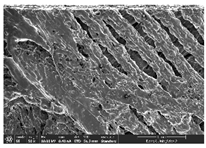

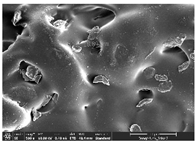

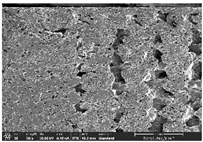

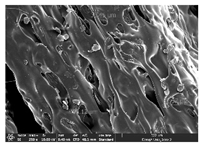

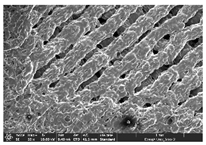

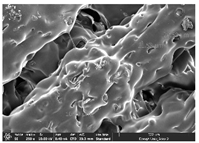

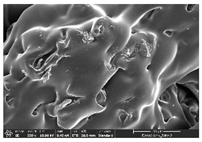

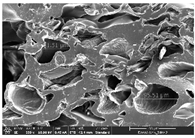

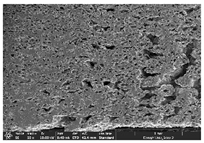

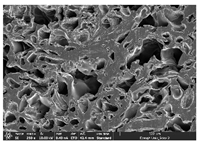

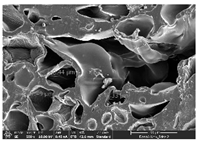

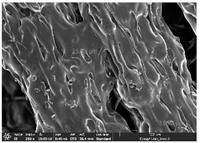

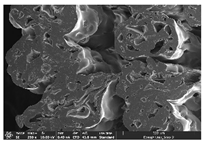

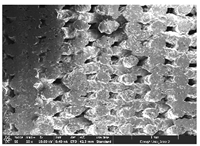

3.1. Morphology

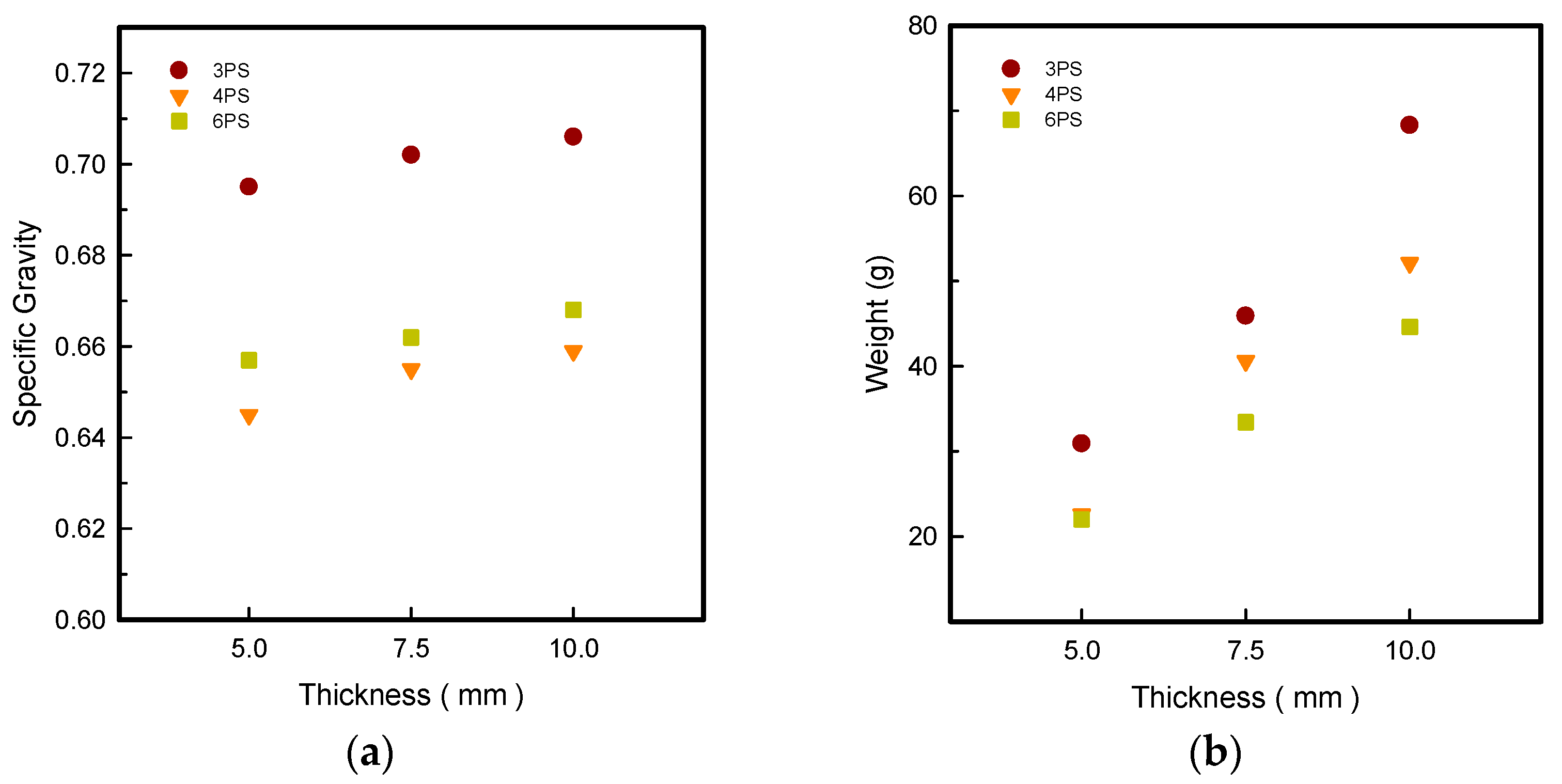

3.2. Specific Gravity and Weight

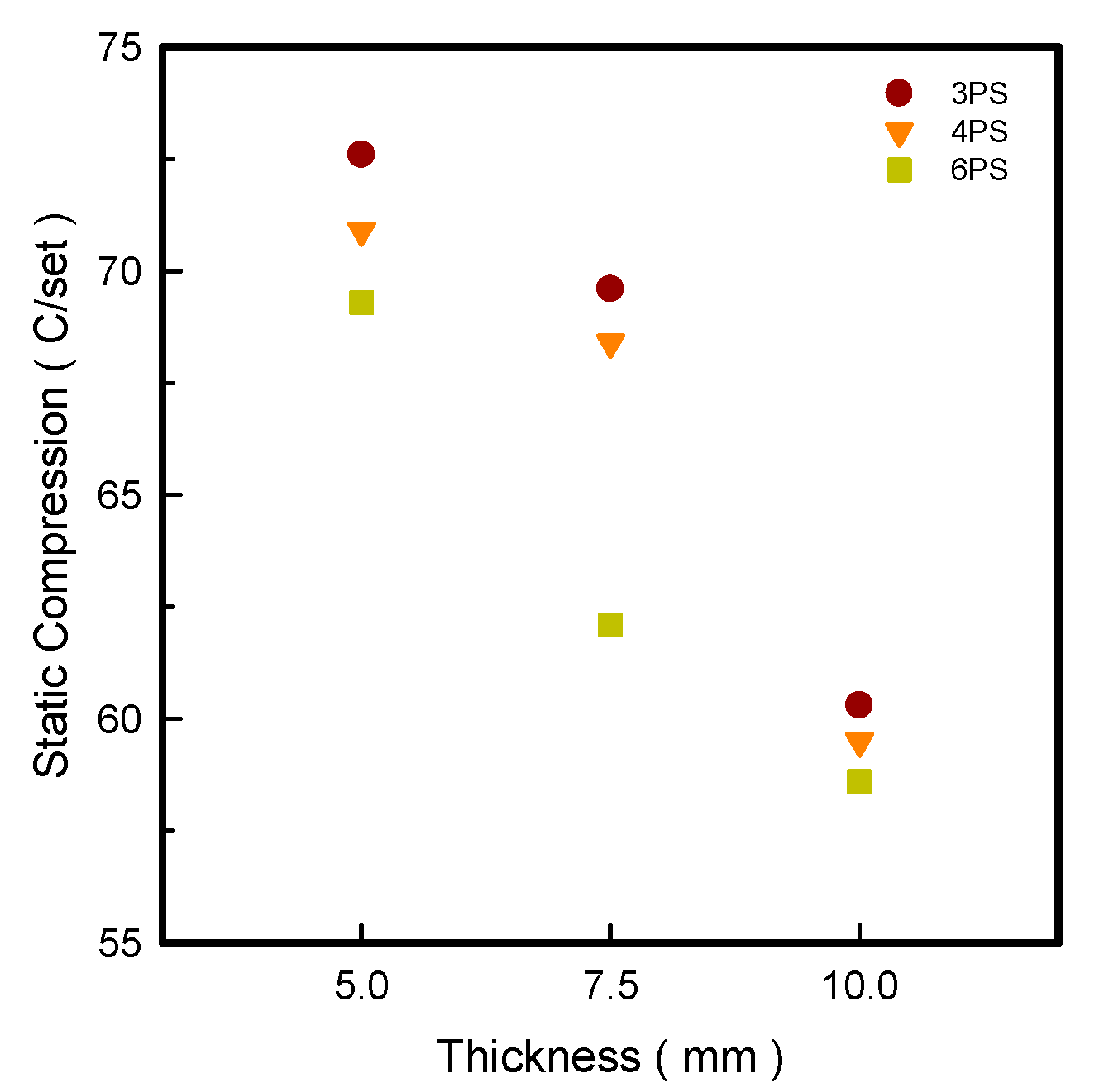

3.3. Static Compressive

3.4. Static and Dynamic Coefficient of Friction

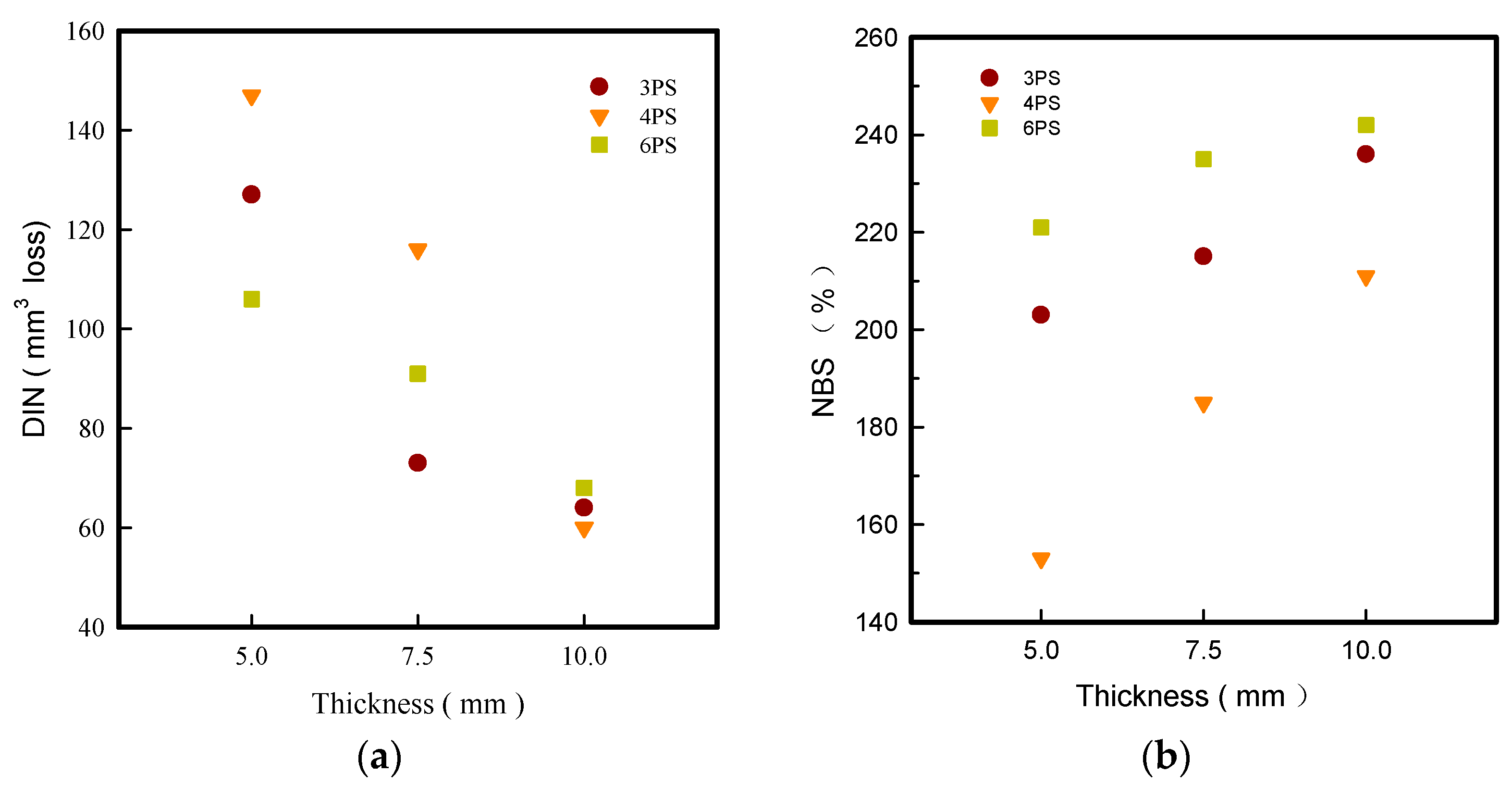

3.5. DIN and NBS Abrasion

3.6. Ball Drop and Pendulum Resilience

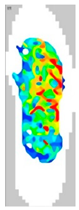

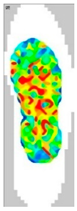

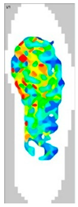

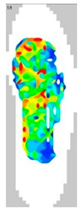

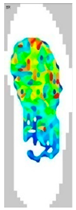

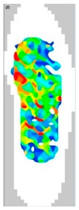

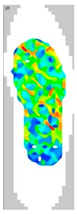

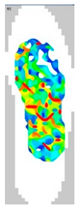

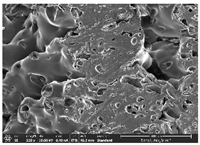

3.7. Surface Area and Surface Force

| Prototypes | 3PS | 4PS | 6PS | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Thickness | 5.0 | 7.5 | 10.0 | 5.0 | 7.5 | 10.0 | 5.0 | 7.5 | 10.0 |

| Surface Area (mm2) | 16.26 | 16.46 | 16.83 | 16.26 | 15.73 | 16.28 | 17.52 | 15.71 | 15.34 |

| Surface Pressure (kPa) | 28.11 | 30.72 | 29.70 | 30.12 | 28.87 | 29.60 | 26.81 | 25.33 | 25.61 |

| Image of plantar pressure distribution |  |  |  |  |  |  |  |  |  |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davia-Aracil, M.; Hinojo-Pérez, J.J.; Jimeno-Morenilla, A.; Mora-Mora, H. 3D printing of functional anatomical insoles. Comput. Ind. 2018, 95, 38–53. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Y.-Q.; Kan, C.-W. Review on Development and Application of 3D-Printing Technology in Textile and Fashion Design. Coatings 2022, 12, 277. [Google Scholar] [CrossRef]

- Kim, S.G.; Kim, H.R. The Recent Tendency of Fashion Textiles by 3D Printing. Fash. Text. Res. J. 2018, 20, 117–127. [Google Scholar] [CrossRef]

- Dillek, E.; Yildirim, M.; Uzun, M. Additive manufacturing (3D printing) in technical fashion industry applications. Tekst. Ind. 2021, 69, 4–15. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Lakhi, M.; Ranjbar, S.; Bodaghi, M. Custom Shoe Sole Design and Modeling Toward 3D Printing. Int. J. Bioprint. 2021, 7, 396. [Google Scholar] [CrossRef]

- Kasović, M.; Štefan, L.; Zvonár, M. Foot characteristics during walking in 6–14-year-old children. Sci. Rep. 2020, 10, 9501. [Google Scholar] [CrossRef]

- Putra, Y.E.A.; Anggoro, P.; Yuniarto, T.; Bayuseno, A.P.; Jamari, J.; Bawono, B. Optimization of Mechanical Parameters on Outsole Shoes Orthotic Comfort Using Finite Element Analysis. In Proceedings of the 2019 International Biomedical Instrumentation and Technology Conference (IBITeC), Special Region of Yogyakarta, Indonesia, 23–24 October 2019. [Google Scholar] [CrossRef]

- Shen, F.; Yuan, S.; Guo, Y.; Zhao, B.; Bai, J.; Qwamizadeh, M.; Chua, C.K.; Wei, J.; Zhou, K. Energy Absorption of Thermoplastic Polyurethane Lattice Structures via 3D Printing: Modeling and Prediction. Int. J. Appl. Mech. 2016, 8, 1640006. [Google Scholar] [CrossRef]

- Mizzi, L.; Mahdi, E.M.; Titov, K.; Gatt, R.; Attard, D.; Evans, K.E.; Grima, J.N.; Tan, J.-C. Mechanical metamaterials with star-shaped pores exhibiting negative and zero Poisson’s ratio. Mater. Des. 2018, 146, 28–37. [Google Scholar] [CrossRef]

- Cross, M.T. Footwear with Flexible Auxetic Sole Structure. WO2016093949A1, 16 June 2016. Available online: https://patents.google.com/patent/WO2016093949A1/en (accessed on 1 July 2022).

- Liu, F.; Zhao, Z.; Yang, X.; Shi, T.; Xu, D.; Zhai, W. Relationship between apparent density and mechanical properties of micro-cellular thermoplastic polyurethane foam. Acta Polym. Sin. 2021, 52, 388–398. [Google Scholar]

- Rodríguez-Parada, L.; de la Rosa, S.; Mayuet, P. Influence of 3D-Printed TPU Properties for the Design of Elastic Products. Polymers 2021, 13, 2519. [Google Scholar] [CrossRef]

- Ames, K.A. Elastomers for Shoe Applications. Rubber Chem. Technol. 2004, 77, 413–475. [Google Scholar] [CrossRef]

- Tsai, Y.-J.; Powers, C.M. The Influence of Footwear Sole Hardness on Slip Initiation in Young Adults. J. Forensic Sci. 2008, 53, 884–888. [Google Scholar] [CrossRef] [PubMed]

- Park, D.-B.; Kim, D.H.; Lee, W.-K. Study on synthesis and abrasion resistance of thermoplastic polyurethanes using hydroxyl-terminated polydimethylsiloxane and polyether polyols. Mol. Cryst. Liq. Cryst. 2020, 707, 94–100. [Google Scholar] [CrossRef]

- Hemler, S.L.; Sider, J.R.; Redfern, M.S.; Beschorner, K.E. Gait kinetics impact shoe tread wear rate. Gait Posture 2012, 86, 157–161. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Jin, J.; Lou, E. Toward Slip and Fall Prevention: Exploring the Guidance and Challenges of Anti-slip Footwear. Procedia Eng. 2012, 43, 364–368. [Google Scholar] [CrossRef] [Green Version]

- Limon, I.K.; Hasan, M.N. Rebound effect evaluation of commonly used footbeds under repeated foot pressure. Int. J. Sci. 2017, 8, 1694–1698. [Google Scholar]

- Wang, Z.; Liu, Y.; Zhang, S. Preparation Method of High Resilience Nonslip Basketball Sole Composite Material. J. Nanomat. 2022, 2022, 4988169. [Google Scholar] [CrossRef]

- Lam, W.K.; Ng, W.X.; Kong, P.W. Influence of shoe midsole hardness on plantar pressure distribution in four basketball-related movements. Res. Sports Med. 2016, 25, 37–47. [Google Scholar] [CrossRef]

- Che, H.; Nigg, B.M.; de Koning, J. Relationship between plantar pressure distribution under the foot and insole comfort. Clin. Biomech. 1994, 9, 335–341. [Google Scholar] [CrossRef]

- Outsole Design for Footwear. Available online: https://www.sneakerfactory.net/2020/03/outsole-design-for-footwear (accessed on 3 July 2022).

- Serweta, W.; Olejniczak, Z.; Woźniak, B. Analysis of Insole Material Impact on Comfort During Physical Exertion. Fibres Text. East. Eur. 2018, 26, 100–103. [Google Scholar] [CrossRef]

- Liu, X.; Yue, Y.; Wu, X.; Hao, Y.; Lu, Y. Finite Element Analysis of Shock Absorption of Porous Soles Established by Grasshopper and UG Secondary Development. Math. Probl. Eng. 2020, 2020, 2652137. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Z.; Phule, A.D.; Zhao, Y.; Wen, S.; Zhang, Z.X. A Lightweight, Abrasion-Resistant Polybutadiene Rubber/Styrene Butadiene Rubber Foam Prepared by Three-Step Process for Footwear Outsole Applications. Macromol. Mater. Eng. 2021, 307, 2100702. [Google Scholar] [CrossRef]

- Iraqi, A.; Vidic, N.S.; Redfern, M.S.; Beschorner, K.E. Prediction of coefficient of friction based on footwear outsole features. Appl. Ergon. 2020, 82, 102963. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Lee, S. Auxetic Characteristic of 3D Printed n-Pointed Star Shape Outsole Prepared with Various Thicknesses. Advanced Materials. Smart wearables. In Proceedings of the Industry 4.0 of the TBIS 2021 Conference, Online, France, 9 July 2021. [Google Scholar]

- Chen, X.; Lee, S. Morphology and Compressive Property of 3D-printed 3-pointed Star Shape Prepared Using Lightweight Thermoplastic Polyurethane. Fibers Polym. 2022, 23, 1779–1788. [Google Scholar] [CrossRef]

- Kabir, S.; Lee, S. Study of Shape Memory and Tensile Property of 3D Printed Sinusoidal Sample/Nylon Composite Focused on Various Thicknesses and Shape Memory Cycles. Polymers 2020, 12, 1600. [Google Scholar] [CrossRef]

- Standard Test Methods for Rubber Products—Chemical Analysis. Available online: https://www.astm.org/d0297-21.html (accessed on 1 July 2022).

- Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting. Available online: https://www.astm.org/d1894-14.html (accessed on 1 July 2022).

- Testing Methods for Abrasion of Vulcanized Rubber (NBS Method). Available online: https://www.antpedia.com/standard/7038936.html (accessed on 1 July 2022).

- Testing of Rubber and Elastomers; Determination of Abrasion Resistance. Available online: https://global.ihs.com/doc_detail.cfm?document_name=DIN%2053516&item_s_key=00028739 (accessed on 1 July 2022).

- Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams. Available online: https://www.astm.org/d3574-17.html (accessed on 1 July 2022).

- Determination the Rebound Resilience of Rubber Using the Schob Pendulum. Available online: https://webstore.ansi.org/Standards/DIN/din535122000 (accessed on 1 July 2022).

| Model | Thickness (mm) | |||

|---|---|---|---|---|

| Code | ||||

| 3PS-50 | 3PS-75 | 3PS-100 | ||

| 3-pointed star-shaped porous outsole |  | |||

| 4PS-50 | 4PS-75 | 4PS-100 | ||

| 4-pointed star-shaped porous outsole |  | |||

| 6PS-50 | 6PS-75 | 6PS-100 | ||

| 6-pointed star-shaped porous outsole |  | |||

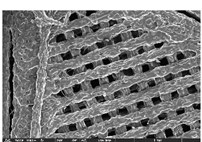

| Code | Thickness (mm) | Surface | ||

|---|---|---|---|---|

| ×50 | ×250 | ×500 | ||

| 3PS-50 | 5.0 |  |  |  |

| 3PS-75 | 7.5 |  |  |  |

| 3PS-100 | 10.0 |  |  |  |

| Cross-side | ||||

| 3PS-50 | 5.0 |  |  |  |

| 3PS-75 | 7.5 |  |  |  |

| 3PS-100 | 10.0 |  |  |  |

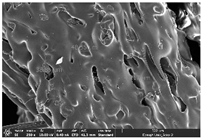

| Code | Thickness (mm) | Surface | ||

|---|---|---|---|---|

| ×50 | ×250 | ×500 | ||

| 4PS-50 | 5.0 |  |  |  |

| 4PS-75 | 7.5 |  |  |  |

| 4PS-100 | 10.0 |  |  |  |

| Cross-side | ||||

| 4PS-50 | 5.0 |  |  |  |

| 4PS-75 | 7.5 |  |  |  |

| 4PS-100 | 10.0 |  |  |  |

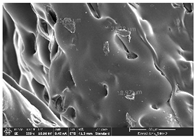

| Code | Thickness (mm) | Surface | ||

|---|---|---|---|---|

| ×50 | ×250 | ×500 | ||

| 6PS-50 | 5.0 |  |  |  |

| 6PS-75 | 7.5 |  |  |  |

| 6PS-100 | 10.0 |  |  |  |

| Cross-side | ||||

| 6PS-50 | 5.0 |  |  |  |

| 6PS-75 | 7.5 |  |  |  |

| 6PS-100 | 10.0 |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Lee, S. Physical Property of 3D-Printed N-Pointed Star-Shaped Outsole Prepared by FDM 3D Printer Using the Lightweight TPU. Polymers 2022, 14, 3189. https://doi.org/10.3390/polym14153189

Chen X, Lee S. Physical Property of 3D-Printed N-Pointed Star-Shaped Outsole Prepared by FDM 3D Printer Using the Lightweight TPU. Polymers. 2022; 14(15):3189. https://doi.org/10.3390/polym14153189

Chicago/Turabian StyleChen, Xiaokui, and Sunhee Lee. 2022. "Physical Property of 3D-Printed N-Pointed Star-Shaped Outsole Prepared by FDM 3D Printer Using the Lightweight TPU" Polymers 14, no. 15: 3189. https://doi.org/10.3390/polym14153189

APA StyleChen, X., & Lee, S. (2022). Physical Property of 3D-Printed N-Pointed Star-Shaped Outsole Prepared by FDM 3D Printer Using the Lightweight TPU. Polymers, 14(15), 3189. https://doi.org/10.3390/polym14153189