Durability and Long-Term Performance Prediction of Carbon Fiber Reinforced Polymer Laminates

Abstract

:1. Introduction

2. Experimental Program

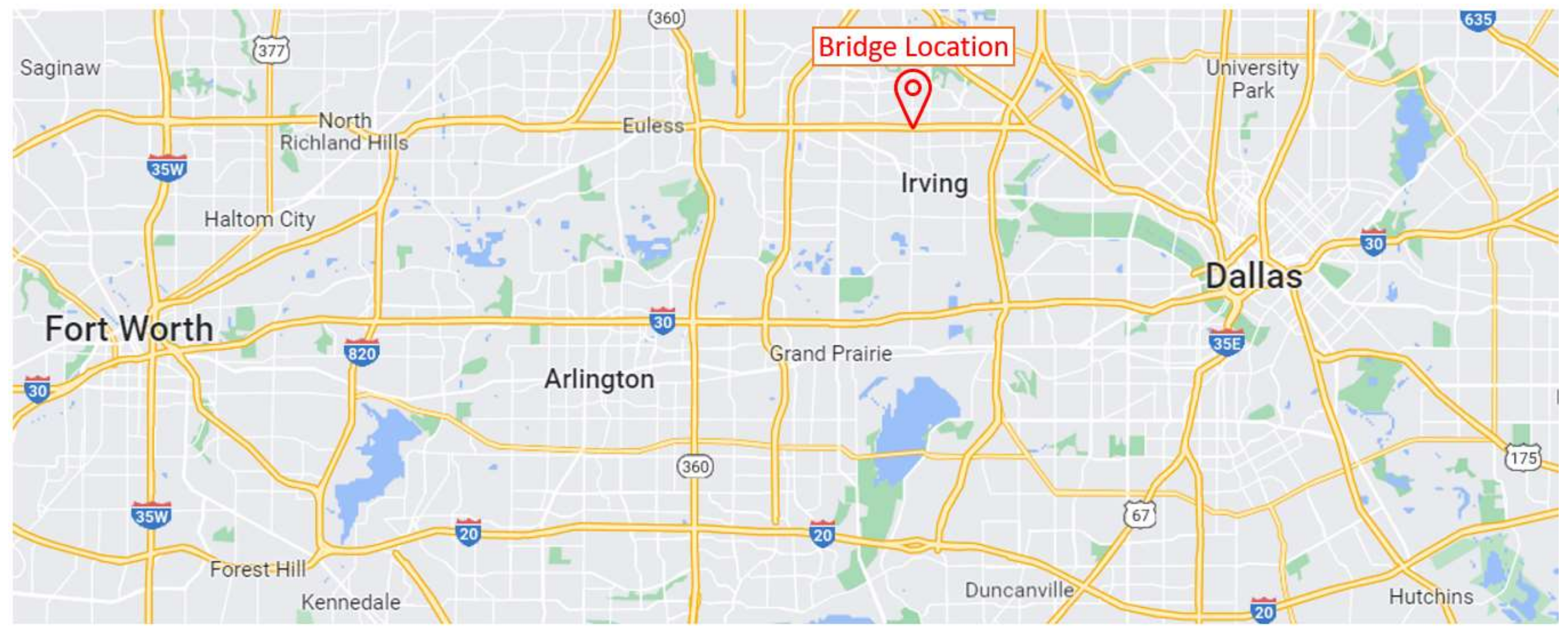

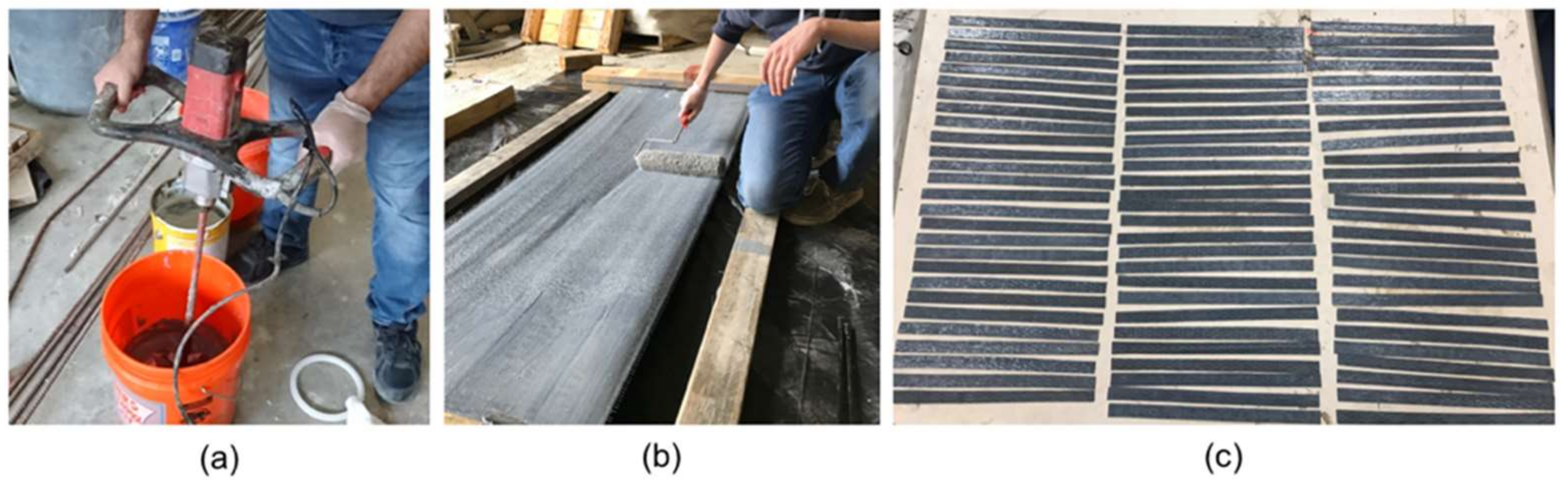

2.1. Field Samples Collection

2.2. Field Samples Dimensions Preparation

- and = volume ratio of fiber and epoxy, respectively.

- , , and = longitudinal elastic modulus of laminate, fiber, and epoxy, respectively.

2.3. Materials and Specimens, New Samples

2.4. Environmental Exposure, New Samples

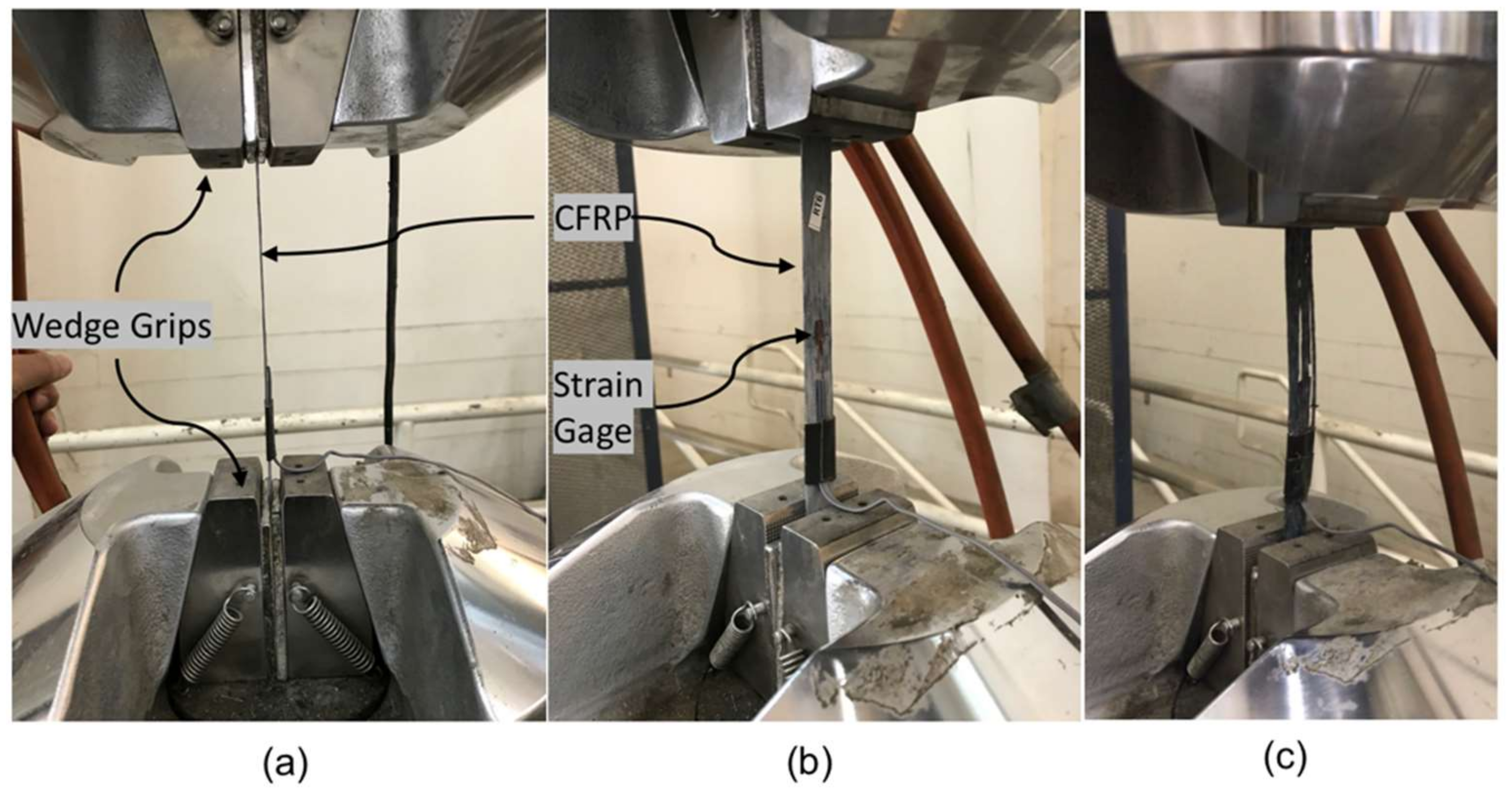

2.5. Tensile Test

3. Results

3.1. Field Samples

3.2. Tensile Strength

3.3. Strain Performance

3.4. Tensile Modulus

4. Prediction Model of Long-Term Effects

- k = degradation rate (1/time).

- A = constant of the material and degradation process.

- = activation energy associated with the set of mechanisms.

- R = universal gas constant (8.3143 × 10−3 kJ/mol K).

- T = temperature (K).

4.1. Prediction Procedure

- Y = percentage of tensile strength retention.

- t = exposure time.

- = = fitted parameter.

- and = required times for a property to reach a given value at temperatures of and , respectively.

- c = constant.

- and = degradation rates at temperatures and , respectively.

- and = performance attributes at time t (in days) and zero time, respectively.

- = constant denoting degradation rate.

- = material constant reflecting the early effects of post-cure progression.

4.2. Prediction Model Calibration

5. Discussion

5.1. Environmental Reduction Factor

- .

- = mean ultimate strength.

- = standard deviation.

- = mean ultimate strength.

- = partial safety factor for the strength of FRP.

- = partial safety factor for the method of manufacturing and application.

- = partial safety factor for modulus of elasticity of FRP.

- .

- = mean ultimate strength.

- = standard deviation.

- = reliability index and brittle failure behavior of FRP materials.

- = environmental influence factor.

- = CFRP safety factor (1.35 for wet lay-up).

- , = effective and mean ultimate FRP strain, respectively.

5.2. Comparison of Calibrated Prediction Model with ACI 440.2R-17

- CE = environmental reduction factor.

- T = design life (days).

5.3. Comparison of Calibrated Prediction Model with International Codes

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- American Society of Civil Engineers. A comprehensive assessment of America’s Infrastructure; ASCE: Reston, VA, USA, 2017. [Google Scholar]

- Karbhari, V.M.; Seible, F. Fiber Reinforced Composites—Advanced Materials for the Renewal of Civil Infrastructure. Appl. Compos. Mater. 2000, 7, 95–124. [Google Scholar] [CrossRef]

- Pendhari, S.S.; Kant, T.; Desai, Y.M. Application of polymer composites in civil construction: A general review. Compos. Struct. 2008, 84, 114–124. [Google Scholar] [CrossRef]

- Breña, S.F.; Bramblett, R.M.; Benouaich, M.A.; Wood, S.L.; Kreger, M.E. Use of Carbon Fiber Reinforced Polymer Composites to Increase the Flextural Capacity of Reinforced Concrete Beams; No. Research Report 1776-1; University of Texas at Austin: Austin, TX, USA, 2001. [Google Scholar]

- Silva, M.A.L.; Gamage, J.C.P.H.; Fawzia, S. Performance of slab-column connections of flat slabs strengthened with carbon fiber reinforced polymers. Case Stud. Constr. Mater. 2019, 11, e00275. [Google Scholar] [CrossRef]

- Al-Akhras, N.; Al-Mashraqi, M. Repair of corroded self-compacted reinforced concrete columns loaded eccentrically using carbon fiber reinforced polymer. Case Stud. Constr. Mater. 2021, 14, e00476. [Google Scholar] [CrossRef]

- Esfahani, M.R.; Kianoush, M.R.; Tajari, A.R. Flexural behaviour of reinforced concrete beams strengthened by CFRP sheets. Eng. Struct. 2007, 29, 2428–2444. [Google Scholar] [CrossRef]

- Matthys, S. Structural Behaviour and Design of Concrete Members Strengthened with Externally Bonded FRP Reinforcement. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2000; p. 367. [Google Scholar]

- Abanilla, M.A.; Li, Y.; Karbhari, V.M. Durability characterization of wet layup graphite/epoxy composites used in external strengthening. Compos. Part B Eng. 2005, 37, 200–212. [Google Scholar] [CrossRef]

- Chen, Y.; Davalos, J.F.; Ray, I. Durability Prediction for GFRP Reinforcing Bars Using Short-Term Data of Accelerated Aging Tests. J. Compos. Constr. 2006, 10, 279–286. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, Y.; Dong, Z.-Q.; Wu, Z.-S.; Wu, G. Prediction of Long-Term Performance and Durability of BFRP Bars under the Combined Effect of Sustained Load and Corrosive Solutions. J. Compos. Constr. 2014, 19, 04014058. [Google Scholar]

- Li, S.; Hu, J.; Ren, H. The combined effects of environmental conditioning and sustained load on mechanical properties of wet lay-up fiber reinforced polymer. Polymers 2017, 9, 244. [Google Scholar] [CrossRef] [Green Version]

- Silva, M.A.G.; da Fonseca, B.S.; Biscaia, H. On estimates of durability of FRP based on accelerated tests. Compos. Struct. 2014, 116, 377–387. [Google Scholar] [CrossRef]

- Silva, M.A.G.; Biscaia, H. Degradation of bond between FRP and RC beams. Compos. Struct. 2008, 85, 164–174. [Google Scholar] [CrossRef]

- Xie, J.; Lu, Z.; Guo, Y.; Huang, Y. Durability of CFRP sheets and epoxy resin exposed to natural hygrothermal or cyclic wet-dry environment. Polym. Compos. 2019, 40, 553–567. [Google Scholar] [CrossRef]

- Uthaman, A.; Xian, G.; Thomas, S.; Wang, Y.; Zheng, Q.; Liu, X. Durability of an epoxy resin and its carbon fiber-reinforced polymer composite upon immersion in water, acidic, and alkaline solutions. Polymers 2020, 12, 614. [Google Scholar] [CrossRef] [Green Version]

- Karbhari, V.M.; Abanilla, M.A. Design factors, reliability, and durability prediction of wet layup carbon/epoxy used in external strengthening. Compos. Part B Eng. 2007, 38, 10–23. [Google Scholar] [CrossRef]

- Homam, S.M.; Sheikh, S.A.; Collins, P.; Pernica, G.; Daoud, J. Durability of fibre reinforced polymers used in concrete structures. In Proceedings of the 3rd Advanced Composite Materials in Bridges and Structures, Ottawa, ON, Canada, 15–18 August 2000; pp. 751–758. [Google Scholar]

- Cromwell, J.R.; Harries, K.A.; Shahrooz, B.M. Environmental durability of externally bonded FRP materials intended for repair of concrete structures. Constr. Build. Mater. 2011, 25, 2528–2539. [Google Scholar] [CrossRef]

- Soudki, K.; Alkhrdaji, T. ACI 440.2R-17, Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures; American Concrete Institute: Farmington Hills, MI, USA, 2017. [Google Scholar]

- Bank, L.C.; Gentry, T.R.; Thompson, B.P.; Russell, J.S. A model specification for FRP composites for civil engineering structures. Constr. Build. Mater. 2003, 17, 405–437. [Google Scholar] [CrossRef]

- Timilsina, S.; Yazdani, N.; Beneberu, E.; Mulenga, A. Analysis of a Fire Damaged and FRP Laminate Strengthened Reinforced Concrete Bridge. ACI Struct. J. 2020, 340, 179–196. [Google Scholar]

- Timilsina, S. In-Service Performance Evaluation of Fire and Impact Damaged Bridges with CFRP Laminate Strengthening. Ph.D. Thesis, The University of Texas at Arlington, Arlington, TX, USA, 2018. [Google Scholar]

- Timilsina, S.; Yazdani, N.; Beneberu, E. Post-fire analysis and numerical modeling of a fire-damaged concrete bridge. Eng. Struct. 2021, 244, 112764. [Google Scholar] [CrossRef]

- ASTM D3039; Standard test method for tensile properties of polymer matrix composite materials. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–13.

- Lu, Z.; Xian, G. Resistance of basalt fibers to elevated temperatures and water or alkaline solution immersion. Polym. Compos. 2018, 39, 2385–2393. [Google Scholar] [CrossRef]

- Hassan, S.A.; Gholami, M.; Ismail, Y.S.; Sam, A.R.M. Characteristics of concrete/CFRP bonding system under natural tropical climate. Constr. Build. Mater. 2015, 77, 297–306. [Google Scholar] [CrossRef]

- Pan, Y.; Xian, G.; Silva, M.A.G. Effects of water immersion on the bond behavior between CFRP plates and concrete substrate. Constr. Build. Mater. 2015, 101, 326–337. [Google Scholar] [CrossRef]

- Borrie, D.; Liu, H.B.; Zhao, X.L.; Raman, R.K.S.; Bai, Y. Bond durability of fatigued CFRP-steel double-lap joints pre-exposed to marine environment. Compos. Struct. 2015, 131, 799–809. [Google Scholar] [CrossRef]

- Böer, P.; Holliday, L.; Kang, T.H.K. Independent environmental effects on durability of fiber-reinforced polymer wraps in civil applications: A review. Constr. Build. Mater. 2013, 48, 360–370. [Google Scholar] [CrossRef]

- Nelson, W. Applied Life Data Analysis, Accelerated Testing: Statistical Models, Test Plans, and Data Analysis; John Wiley & Sons: New York, NY, USA, 2004; Volume 47. [Google Scholar]

- Dejke, V. Durability of FRP Reinforcement in Concrete-Literature Review and Experiments. Ph.D. Thesis, Department of Building Materials, Chalmers University of Technology, Gothenburg, Sweden, 2001. [Google Scholar]

- WorldClimate.com, Average Weather Data for Irving, Texas. 2020. Available online: http://www.worldclimate.com/climate/us/texas/irving (accessed on 15 May 2020).

- The Concrete Society. TR55, Design Guidance for Strengthening Concrete Structures Using Fiber Composite Materials; The Concrete Society: Surrey, UK, 2012. [Google Scholar]

- China Architecture & Building Press. GB 50608-2010, Technical Code for Infrastructure Application of FRP Composites; China Architecture & Building Press: Beijing, China, 2011. [Google Scholar]

- FIB. FIB Bulletin 14, CEB FIB Bulletin 14, Externally Bonded FRP Reinforcement for RC Structures 14; FIB: Lausanne, Switzerland, 2001. [Google Scholar]

- National Research Council. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures; National Research Council: Roma, Italy, 2014. [Google Scholar]

- Ministry of Housing Utilities and Urban Utilities, Arab Republic of Egypt Ministry of Housing. Utilities and Urban Utilities Egyptian Code of Practice the Use of Fiber Reinforced Polymer (Frp); Ministry of Housing Utilities and Urban Utilities, Arab Republic of Egypt Ministry of Housing: Cairo, Egypt, 2005. [Google Scholar]

- AASHTO. AASHTO LRFD Bridge Design Specifications, 8th ed.; AASHTO: Washington, DC, USA, 2017. [Google Scholar]

- Eamon, C.D.; Wu, H.-C.; Makkawy, A.A.; Siavashi, S. Construction Guidelines for Strengthening Bridges Using Fiber Reinforced Polymers (FRP); Wayne State University: Detroit, MI, USA, 2014. [Google Scholar]

| Material | Tensile Strength (MPa) | Young’s Modulus (GPa) | Failure Strain (%) |

|---|---|---|---|

| Dry carbon fiber | 3793 | 234 | 1.5 |

| Epoxy | 33.8 | 4.5 | 1.2 |

| CFRP laminate | 724 | 56.5 | 1.0 |

| Environmental Exposure | Duration (Days) | No. of Samples |

|---|---|---|

| Immersion in water at 23 °C (RT) | 28, 56, 84, 112, and 224 | 25 |

| Immersion in water at 45 °C (MT) | 28, 56, 84, 112, and 224 | 25 |

| Immersion in water at 60 °C (HT) | 28, 56, 84, 112, and 224 | 25 |

| Control samples (no exposure) | - | 8 |

| Total No. of samples | 83 |

| Environmental Exposure | Exposure Time (Days) | No. of Specimens | Average Failure Stress (MPa) | CV (%) | Tensile Strength Retention (%) |

|---|---|---|---|---|---|

| Unconditioned (Control samples) | 0 | 8 | 678 | 6.99 | 100 |

| RT (23 °C) | 28 | 5 | 637 | 8.89 | 94 |

| 56 | 5 | 612 | 9.72 | 90 | |

| 84 | 5 | 581 | 6.29 | 86 | |

| 112 | 4 | 551 | 7.17 | 81 | |

| 224 | 5 | 506 | 11.72 | 75 | |

| MT (45 °C) | 28 | 4 | 604 | 4.95 | 89 |

| 56 | 5 | 592 | 5.74 | 87 | |

| 84 | 5 | 553 | 9.90 | 82 | |

| 112 | 4 | 533 | 10.00 | 79 | |

| 224 | 5 | 493 | 14.16 | 73 | |

| HT (60 °C) | 28 | 5 | 576 | 13.75 | 85 |

| 56 | 5 | 559 | 10.55 | 82 | |

| 84 | 5 | 542 | 2.72 | 80 | |

| 112 | 4 | 506 | 5.65 | 75 | |

| 224 | 5 | 457 | 15.33 | 67 |

| Water Temperature (°C) | R2 | |

|---|---|---|

| 23 | 554 | 0.99 |

| 45 | 494 | 0.94 |

| 60 | 434 | 0.88 |

| Environmental Exposure | Time Shift Factor |

|---|---|

| RT (23 °C) | 1.02 |

| MT (45 °C) | 1.14 |

| HT (60 °C) | 1.22 |

| Source | Country | Publishing Entity and Year | Environmental Reduction Factor |

|---|---|---|---|

| ACI 440.2R | USA | American Concrete Institute (ACI), 2017 | 0.85 |

| TR55 | UK | The Concrete Society, 2012 | 0.51 |

| GB 50608 | China | China Architecture & Building Press, 2011 | 0.60 |

| Fib Bulletin 14 | Europe | International Federation for Structural Concrete (Fib), 2001 | 0.74 |

| CNR-DT 200 | Italy | Advisory Committee on Technical Recommendations for Construction, 2014 | 0.85 |

| ECP 208 | Egypt | Egyptian Housing and Building National Research Center, 2005 | 0.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsuhaibani, E.; Yazdani, N.; Beneberu, E. Durability and Long-Term Performance Prediction of Carbon Fiber Reinforced Polymer Laminates. Polymers 2022, 14, 3207. https://doi.org/10.3390/polym14153207

Alsuhaibani E, Yazdani N, Beneberu E. Durability and Long-Term Performance Prediction of Carbon Fiber Reinforced Polymer Laminates. Polymers. 2022; 14(15):3207. https://doi.org/10.3390/polym14153207

Chicago/Turabian StyleAlsuhaibani, Eyad, Nur Yazdani, and Eyosias Beneberu. 2022. "Durability and Long-Term Performance Prediction of Carbon Fiber Reinforced Polymer Laminates" Polymers 14, no. 15: 3207. https://doi.org/10.3390/polym14153207

APA StyleAlsuhaibani, E., Yazdani, N., & Beneberu, E. (2022). Durability and Long-Term Performance Prediction of Carbon Fiber Reinforced Polymer Laminates. Polymers, 14(15), 3207. https://doi.org/10.3390/polym14153207