Laboratory Experiments and Numerical Simulation Study of Composite-Material-Modified Loess Improving High-Speed Railway Subgrade

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Program and Procedure

3. Results

3.1. Test Results

3.2. The Extreme Difference Analysis Results

3.3. The Variance Analysis Results

4. Numerical Simulation of Settlement of High Railway Foundation

4.1. Model Description

4.2. Numerical Simulation Results

5. Discussion

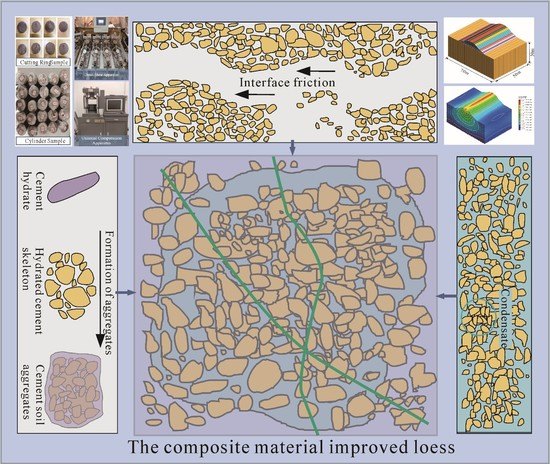

5.1. Influence Mechanism of Different Materials on the Strength Properties of Modified Loess

5.2. Influence of Loess strength Characteristics on Subgrade Settlement

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Radampola, S.S.; Gurung, N.; Mcsweeney, T.; Dhanasekar, M. Evaluation of the properties of railway capping layer soil. Comput. Geotech. 2008, 35, 719–728. [Google Scholar] [CrossRef]

- Liu, J.; Xiao, J. Experimental study on the stability of railroad silt subgrade with increasing train speed. J. Geotech. Geoenviron. Eng. 2010, 136, 833–841. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Khakiev, Z.; Yavna, V. Dynamic behavior and stability of soil foundation in heavy haul railway tracks: A review. Constr. Build. Mater. 2019, 205, 111–136. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, Z.; Zhang, P.; Wang, X. Long-term dynamic stability of improved loess subgrade for high-speed railways. P. I. Civil. Eng-Geotec. 2019, 173, 217–227. [Google Scholar] [CrossRef]

- Xu, Z.; Lin, Z.; Zhang, M. Loess in China and loess landslides. Chin. J. Rock Mech. Eng. 2007, 26, 1297–1312. [Google Scholar]

- Li, Y. A review of shear and tensile strengths of the Malan Loess in China. Eng. Geol. 2018, 236, 4–10. [Google Scholar] [CrossRef]

- Assallay, A.M.; Rogers, C.D.F.; Smalley, I.J. Formation and collapse of metastable particle packings and open structures in loess deposits. Eng. Geol. 1997, 48, 101–115. [Google Scholar] [CrossRef]

- Peng, J.; Lin, H.; Wang, Q.; Zhuang, J.; Cheng, Y.; Zhu, X. The critical issues and creative concepts in mitigation research of loess geological hazards. Eng. Geol. 2014, 22, 684–691. [Google Scholar]

- Juang, C.H.; Dijkstra, T.; Wasowski, J.; Meng, X. Loess geohazards research in China: Advances and challenges for mega engineering projects. Eng. Geol. 2019, 251, 1–10. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, D.; Wang, S.; Liang, C.; Zhao, D. Dynamic-response characteristics and deformation evolution of loess slopes under seismic loads. Eng. Geol. 2020, 267, 105507. [Google Scholar] [CrossRef]

- Li, G.; Ma, W.; Mu, Y.; Wang, F.; Fan, S.; Wu, Y. Effects of freeze-thaw cycle on engineering properties of loess used as road fills in seasonally frozen ground regions, North China. J. Mt. Sci. 2017, 14, 356–368. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Wang, J.; Xu, S. Characteristics of the Interface between Bamboo Grids and Reinforced Soil of High-Filled Embankments in Loess Areas. Adv. Civ. Eng. 2021, 2021, 5135756. [Google Scholar] [CrossRef]

- Mariri, M.; Ziaie Moayed, R.; Kordnaeij, A. Stress–strain behavior of loess soil stabilized with cement, zeolite, and recycled polyester fiber. J. Mater. Civ. Eng. 2019, 31, 04019291. [Google Scholar] [CrossRef]

- Chen, R.; Cai, G.; Dong, X.; Duan, W. Mechanical properties and micro-mechanism of loess roadbed filling using by-product red mud as a partial alternative. Constr. Build. Mater. 2019, 216, 188–201. [Google Scholar] [CrossRef]

- Salehi, M.; Bayat, M.; Saadat, M.; Nasri, M. Experimental study on mechanical properties of cement-stabilized soil blended with crushed stone waste. KSCE J. Civ. Eng. 2021, 25, 1974–1984. [Google Scholar] [CrossRef]

- Wang, F.; Pang, W.; Qin, X.; Han, L.; Jiang, Y. Durability-Aimed Design Criteria of Cement-Stabilized Loess Subgrade for Railway. Appl. Sci. 2021, 11, 5061. [Google Scholar] [CrossRef]

- Gu, K.; Chen, B. Loess stabilization using cement, waste phosphogypsum, fly ash and quicklime for self-compacting rammed earth construction. Constr. Build. Mater. 2020, 231, 117195. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, W.; Jiang, P.; Li, C. The Elastic Modulus and Damage Stress–Strain Model of Polypropylene Fiber and Nano Clay Modified Lime Treated Soil under Axial Load. Polymers. 2022, 14, 2606. [Google Scholar] [CrossRef]

- Tang, C.; Li, H.; Pan, X.; Yin, L.; Cheng, L.; Cheng, Q. Coupling effect of biocementation-fiber reinforcement on mechanical behavior of calcareous sand for ocean engineering. Bull. Eng. Geol. Environ. 2022, 81, 1–15. [Google Scholar] [CrossRef]

- Wang, X.; Liu, K.; Lian, B. Experimental study on ring shear properties of fiber-reinforced loess. Bull. Eng. Geol. Environ. 2021, 80, 5021–5029. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, G.; Su, L.; Zhou, G. Effect of cement on the stabilization of loess. J. Mt. Sci. 2017, 14, 2325–2336. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, Q.; Yi, Y.; Yuan, K.; Deng, C.; Tian, T. Cement-modified loess base for intercity railways: Mechanical strength and influencing factors based on the vertical vibration compaction method. Materials. 2020, 13, 3643. [Google Scholar] [CrossRef]

- Tabarsa, A.; Latifi, N.; Meehan, C.L.; Manahiloh, K.N. Laboratory investigation and field evaluation of loess improvement using nanoclay–A sustainable material for construction. Constr. Build. Mater. 2018, 158, 454–463. [Google Scholar] [CrossRef]

- Puppala, A.J.; Musenda, C. Effects of fiber reinforcement on strength and volume change in expansive soils. Transp. Res. Rec. 2000, 1736, 134–140. [Google Scholar] [CrossRef]

- Gu, L.; Lv, Q.; Wang, S.; Xiang, J.; Guo, L.; Jiang, J. Effect of sodium silicate on the properties of loess stabilized with alkali-activated fly ash-based. Constr. Build. Mater. 2021, 280, 122515. [Google Scholar] [CrossRef]

- Wang, Q.; Zhong, X.; Ma, H.; Wang, S.; Liu, Z.; Guo, P. Microstructure and reinforcement mechanism of lignin-modified loess. J. Mater. Civ. Eng. 2020, 32, 04020319. [Google Scholar] [CrossRef]

- Zhang, Y.; Ye, W.; Wang, Z. Study on the compaction effect factors of lime-treated loess highway embankments. Civ. Eng. J. 2017, 3, 1008–1019. [Google Scholar] [CrossRef] [Green Version]

- Wei, L.; Chai, S.; Zhang, H.; Shi, Q. Mechanical properties of soil reinforced with both lime and four kinds of fiber. Constr. Build. Mater. 2018, 172, 300–308. [Google Scholar] [CrossRef]

- Liu, H.; Wang, L.; Gao, P. The mechanical properties of cement reinforced loess and pore microstructure characteristics. Applied Mechanics and Materials. Trans. Tech. Publications. Ltd. 2014, 527, 25–30. [Google Scholar]

- Mahedi, M.; Cetin, B.; Cetin, K.S. Freeze-thaw performance of phase change material (PCM) incorporated pavement subgrade soil. Constr. Build. Mater. 2019, 202, 449–464. [Google Scholar] [CrossRef]

- Yang, B.; Weng, X.; Liu, J.; Kou, Y.; Jiang, L.; Li, H.; Yan, X. Strength characteristics of modified polypropylene fiber and cement-reinforced loess. J. Cent. South Univ. 2017, 24, 560–568. [Google Scholar] [CrossRef]

- Chen, C.; Wei, K.; Gu, J.; Huang, X.; Dai, X.; Liu, Q. Combined Effect of Biopolymer and Fiber Inclusions on Unconfined Compressive Strength of Soft Soil. Polymers. 2022, 14, 787. [Google Scholar] [CrossRef] [PubMed]

- GB/T 50123—1999; Standard for soil test method. The State Bureau of Quality and Technical Supervision; Ministry of Construction: Beijing, China, 1999.

- Ren, W.; Yang, T.; Huang, M.; Zhang, A.; Wei, H.; Mi, W.; Wang, Y.; Hu, J. Optimal mixing ratio and SWCC fitting of lightweight soil with cotton stalk fibres. Soils. Found. 2021, 61, 453–464. [Google Scholar] [CrossRef]

- Wang, L. Orthogonal Test and Multi-Element Linear Regression Analysis of Compressive Strength of Nanometer Silicon Cemented Soil. Adv. Mater. Res. 2011, 317, 34–41. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, Z.; Li, A.; Wang, C. Analysis of influence factors on end soil reinforcement effect of rectangular pipe jacking. P. I. Civil. Eng-Geotec. 2021, 1–10. [Google Scholar] [CrossRef]

- TB10001—2016; China Railway Press. Standard of Railway Subgrade Design. State Railway Administration: Beijing, China, 2016.

- Tai, B.; Yue, Z.; Sun, T.; Qi, S.; Li, L.; Yang, Z. Novel anti-frost subgrade bed structures a high speed railways in deep seasonally frozen ground regions: Experimental and numerical studies. Constr. Build. Mater. 2020, 269, 121266. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Study on strength behavior of basalt fiber-reinforced loess by digital image technology (DIT) and scanning electron microscope (SEM). Arabian J. Sci. Eng. 2021, 46, 11319–11338. [Google Scholar] [CrossRef]

- Wahab, N.A.; Roshan, M.J.; Rashid, A.S.A.; Hezmi, M.A.; Jusoh, S.N.; Nik, N.N.D.; Tamassoki, S. Strength and Durability of Cement-Treated Lateritic Soil. Sustainability. 2021, 13, 6430. [Google Scholar] [CrossRef]

- Ruan, B.; Ding, H.; Teng, J.; Deng, W.; Zheng, S.; Ruan, C. Mechanical properties and microstructure of polypropylene fiber reinforced cement mortar soil. KSCE J. Civ. Eng. 2021, 25, 1985–1997. [Google Scholar] [CrossRef]

- Yan, C.; An, N.; Wang, Y.; Sun, W. Effect of dry-wet cycles and freeze-thaw cycles on the antierosion ability of fiber-reinforced loess. Adv. Mater. Sci. Eng. 2021, 2021, 8834598. [Google Scholar] [CrossRef]

- Zhang, B.; Jiang, W.; Xu, Q.; Yuan, D.; Shan, J.; Lu, R. Experimental feasibility study of ethylene-vinyl acetate copolymer (EVA) as cement stabilized soil curing agent. Road Mater. Pavement Des. 2022, 23, 617–638. [Google Scholar] [CrossRef]

- Ma, X.; Wang, X. Comparative study on settlement prediction of railway subgrade on collapsible loess area. Appl. Mech. Mater. 2012, 188, 49–53. [Google Scholar]

| ρd | W | ρ | GS | WL | Wp | Grain Size Fractions (%) | ||

|---|---|---|---|---|---|---|---|---|

| <0.005 mm | 0.005–0.075 mm | 0.075–0.05 mm | ||||||

| 1.35 | 12 | 1.51 | 2.70 | 27.1 | 17.6 | 26.4 | 71.3 | 2.3 |

| Raw Material | Chemical Composition (%) | ||||||

|---|---|---|---|---|---|---|---|

| CaO | Fe2O3 | SiO2 | Al2O3 | MgO | SO3 | LOI | |

| Cement | 63.89 | 4.53 | 22.78 | 5.46 | 0.79 | 1.31 | 1.24 |

| Type | Density (g/cm3) | Diameter (mm) | Tensile Strength (MPa) | Elastic Modulus (MPa) | Melting Point (°C) |

|---|---|---|---|---|---|

| Bundle monofilament | 0.91 | 0.045~0.18 | ≥350 | ≥3600 | 165~175 |

| Sample No. | Cement Content (%) | Fiber Content (%) | Curing Agent Content (%) | Sample No. | Cement Content (%) | Fiber Content (%) | Curing Agent Content (%) |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 14 | 8 | 0.75 | 0 |

| 2 | 0 | 0.25 | 4 | 15 | 8 | 1 | 4 |

| 3 | 0 | 0.5 | 8 | 16 | 12 | 0 | 12 |

| 4 | 0 | 0.75 | 12 | 17 | 12 | 0.25 | 16 |

| 5 | 0 | 1 | 16 | 18 | 12 | 0.5 | 0 |

| 6 | 4 | 0 | 4 | 19 | 12 | 0.75 | 4 |

| 7 | 4 | 0.25 | 8 | 20 | 12 | 1 | 8 |

| 8 | 4 | 0.5 | 12 | 21 | 16 | 0 | 16 |

| 9 | 4 | 0.75 | 16 | 22 | 16 | 0.25 | 0 |

| 10 | 4 | 1 | 0 | 23 | 16 | 0.5 | 4 |

| 11 | 8 | 0 | 8 | 24 | 16 | 0.75 | 8 |

| 12 | 8 | 0.25 | 12 | 25 | 16 | 1 | 12 |

| 13 | 8 | 0.5 | 16 | — | — | — | — |

| Class III Sum of Squares | Degrees of Freedom | Mean Square | F | p | |

|---|---|---|---|---|---|

| Modified model | 1492.3 | 12 | 124.4 | 5.0 | 0.005 |

| Intercept | 20,793.1 | 1 | 20,793.4 | 833.1 | 0.000 |

| Cement | 918.4 | 4 | 229.64 | 9.2 | 0.001 |

| Fiber | 490.2 | 4 | 122.6 | 4.9 | 0.014 |

| Curing agent | 83.6 | 4 | 20.9 | 0.8 | 0.527 |

| Error | 299.5 | 12 | 25.0 |

| Class III Sum of Squares | Degrees of Freedom | Mean Square | F | p | |

|---|---|---|---|---|---|

| Modified model | 23,171.4 | 12.0 | 1930.9 | 1.8 | 0.162 |

| Intercept | 106,268.4 | 1.0 | 106,268.4 | 98.7 | 0.000 |

| Cement | 13,730.7 | 4.0 | 3432.7 | 3.2 | 0.043 |

| Fiber | 3239.1 | 4.0 | 809.8 | 0.8 | 0.575 |

| Curing agent | 6201.6 | 4.0 | 1550.4 | 1.4 | 0.280 |

| Error | 12,918.0 | 12.0 | 1076.5 |

| Class III Sum of Squares | Degrees of Freedom | Mean Square | F | p | |

|---|---|---|---|---|---|

| Modified model | 15,366.6 | 12.0 | 1280.6 | 10.0 | 0.000 |

| Intercept | 38,181.2 | 1.0 | 38,181.2 | 299.6 | 0.000 |

| Cement | 12,511.4 | 4.0 | 3127.9 | 24.5 | 0.001 |

| Fiber | 1606.6 | 4.0 | 401.7 | 3.2 | 0.048 |

| Curing agent | 1248.5 | 4.0 | 312.1 | 2.4 | 0.103 |

| Error | 1529.2 | 12.0 | 127.4 |

| Parameter | h | c | φ | E | μ | γ |

|---|---|---|---|---|---|---|

| Track board | 0.3 | — | — | 325,00 | 0.18 | 26 |

| Ballast bed | 0.5 | 40 | — | 220 | 0.23 | 22 |

| Surface layer of subgrade | 1.5 | 30 | 20 | 200 | 0.32 | 22 |

| Bottom layer of subgrade | 3 | 42 | 28 | 150 | 0.32 | 21 |

| Embankment (Loess) | 3 | 26.21 | 13.7 | 21.07 | 0.4 | 17 |

| (Scheme X) | — | 117.35 | 35.78 | 64.87 | 0.37 | 18 |

| (Scheme Y) | — | 140.86 | 27.42 | 71.92 | 0.37 | 18 |

| (Scheme Z) | — | 135.66 | 30.43 | 85.37 | 0.37 | 18 |

| (Scheme W) | — | 131.17 | 32.36 | 79.46 | 0.37 | 18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, L.; Wang, X.; Xue, C.; Wang, D.; Lian, B. Laboratory Experiments and Numerical Simulation Study of Composite-Material-Modified Loess Improving High-Speed Railway Subgrade. Polymers 2022, 14, 3215. https://doi.org/10.3390/polym14153215

Luo L, Wang X, Xue C, Wang D, Lian B. Laboratory Experiments and Numerical Simulation Study of Composite-Material-Modified Loess Improving High-Speed Railway Subgrade. Polymers. 2022; 14(15):3215. https://doi.org/10.3390/polym14153215

Chicago/Turabian StyleLuo, Li, Xingang Wang, Chen Xue, Daozheng Wang, and Baoqin Lian. 2022. "Laboratory Experiments and Numerical Simulation Study of Composite-Material-Modified Loess Improving High-Speed Railway Subgrade" Polymers 14, no. 15: 3215. https://doi.org/10.3390/polym14153215

APA StyleLuo, L., Wang, X., Xue, C., Wang, D., & Lian, B. (2022). Laboratory Experiments and Numerical Simulation Study of Composite-Material-Modified Loess Improving High-Speed Railway Subgrade. Polymers, 14(15), 3215. https://doi.org/10.3390/polym14153215