On the Mechanical Properties of Hybrid Dental Materials for CAD/CAM Restorations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Specimen Preparation

2.2. Ageing Procedure

2.3. Micro-Struture and Fracture Surface Characterisation

2.4. X-ray Fluorescence Analysis

2.5. Density Measurement

2.6. Vickers Tests

2.7. Nano-Indentation Tests

2.8. Three-Point Bending Tests

3. Results

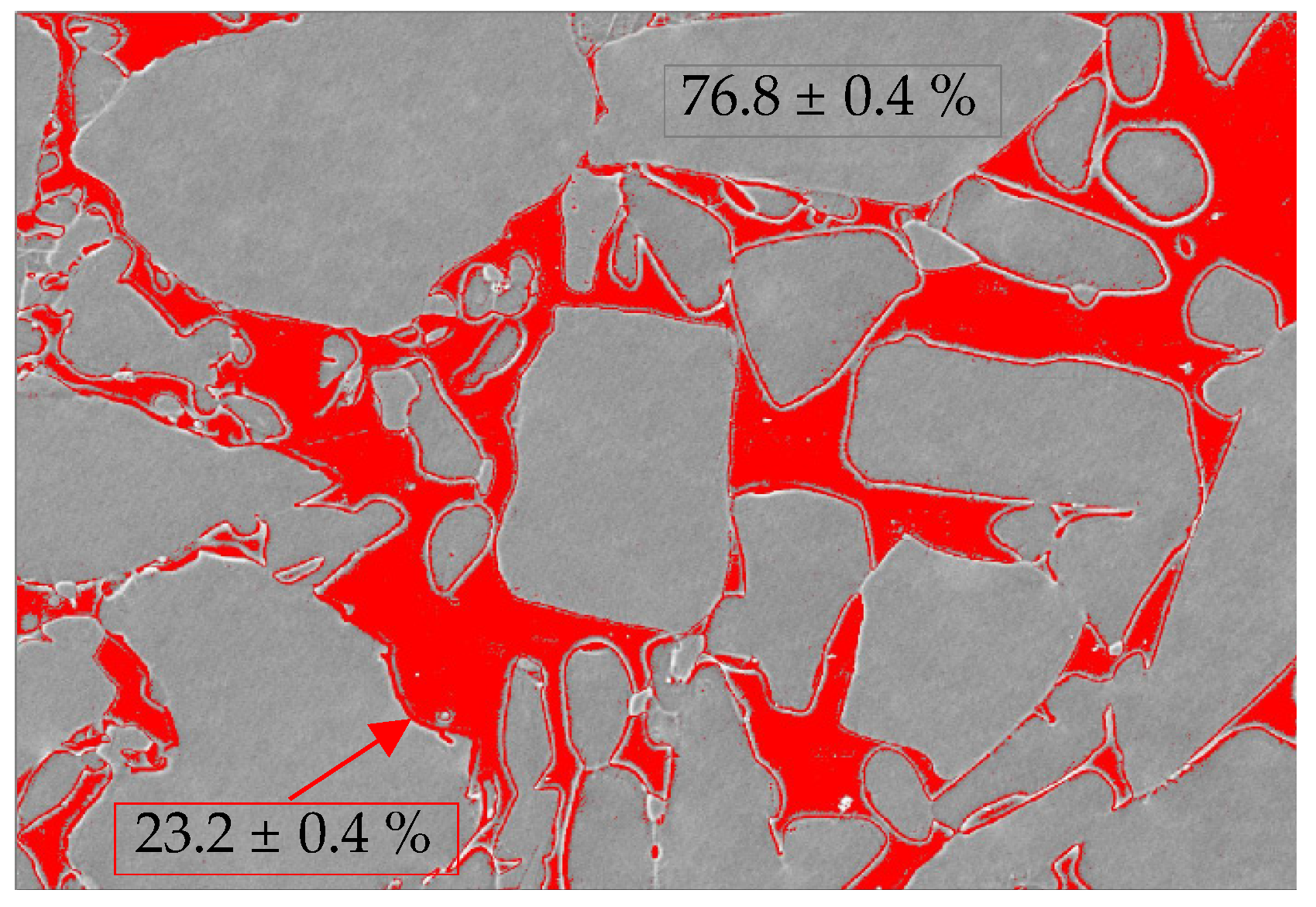

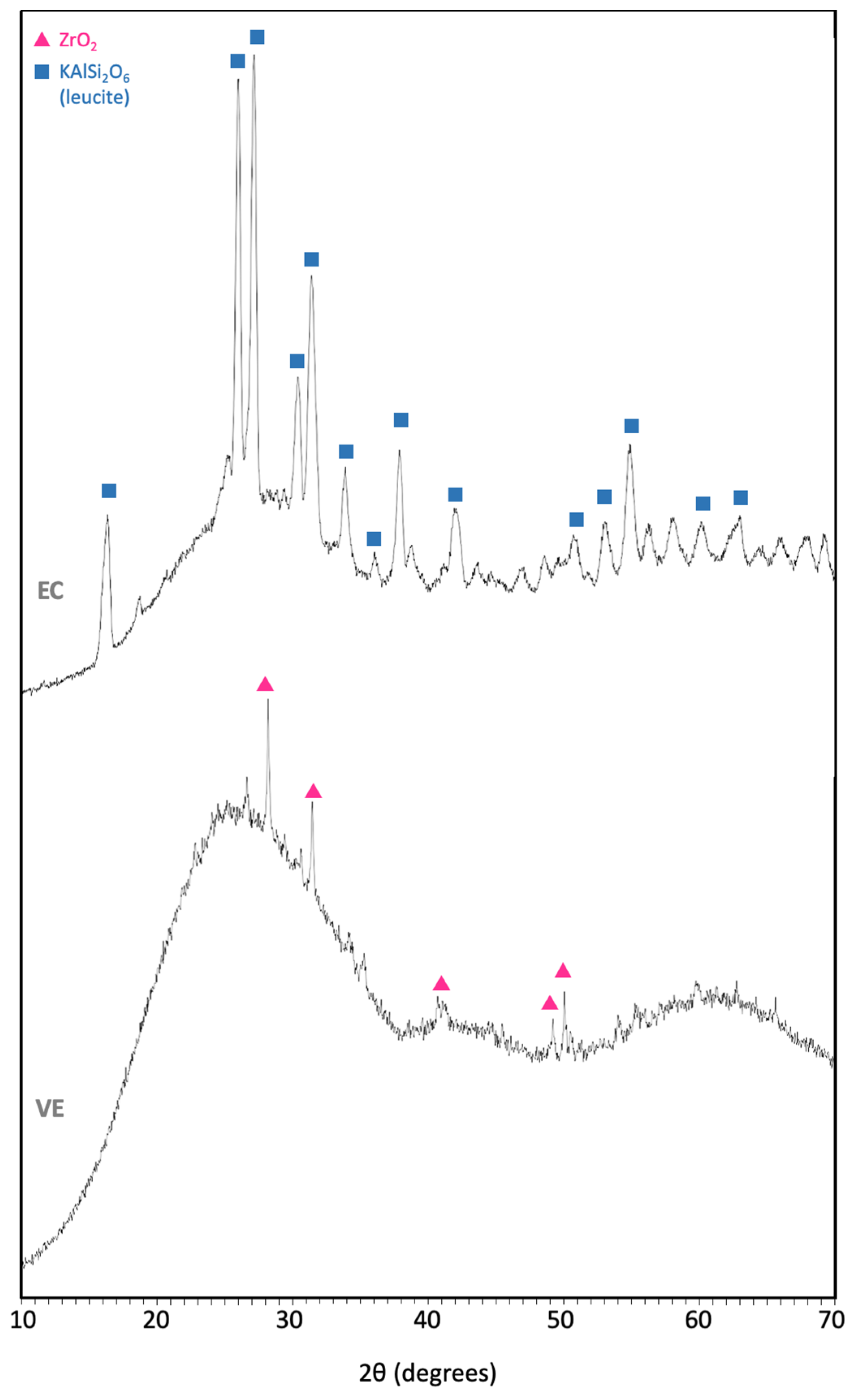

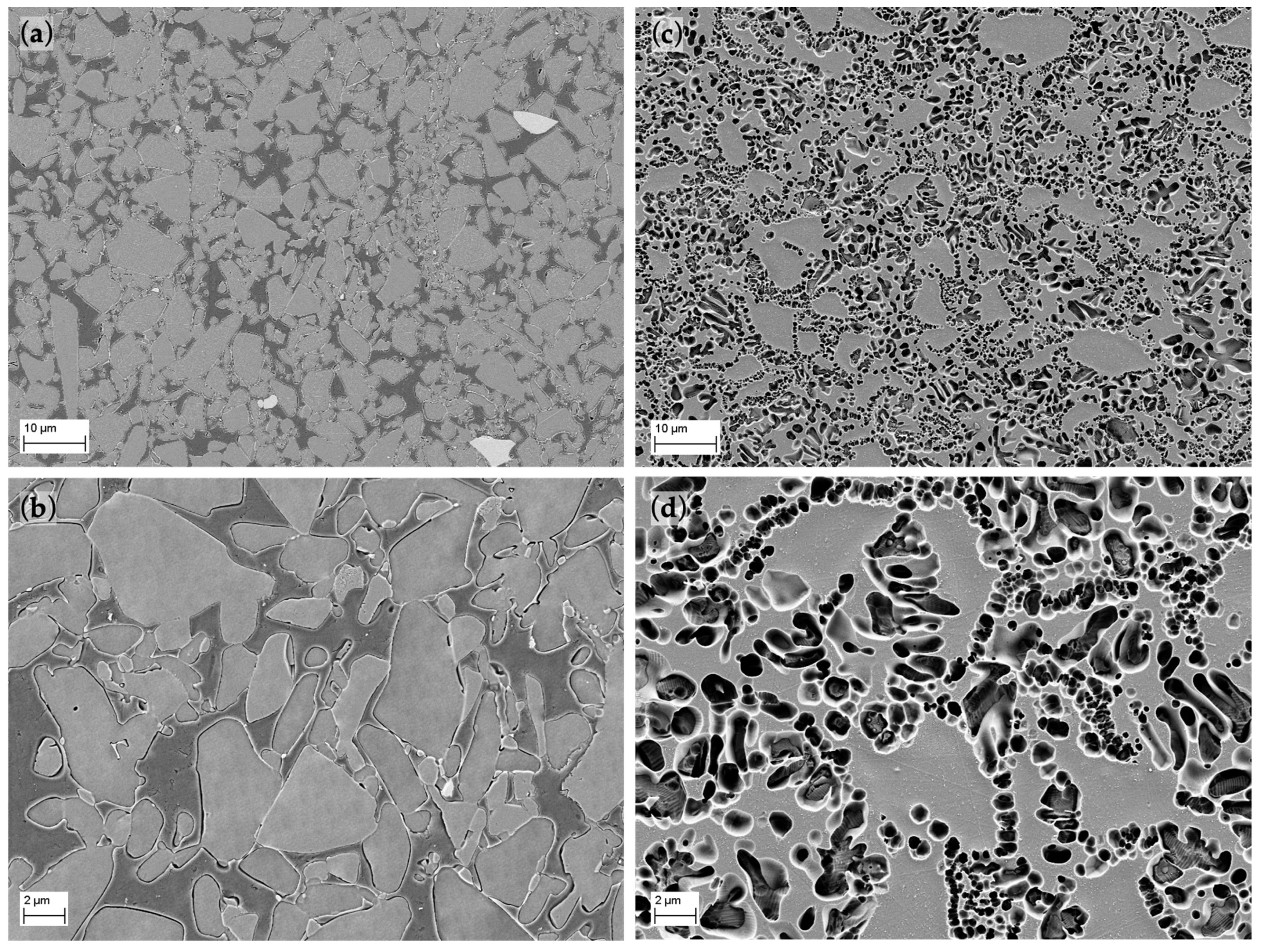

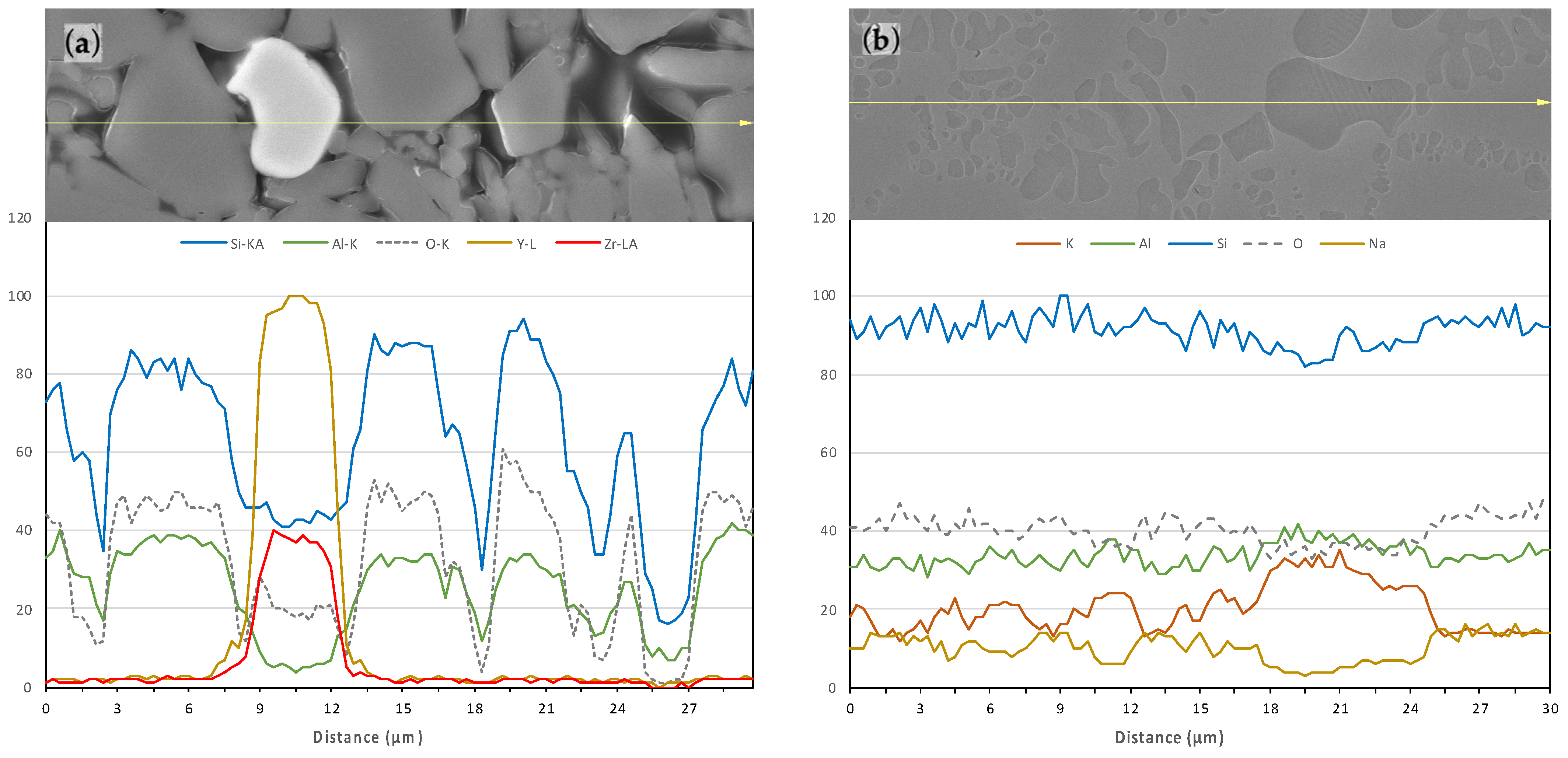

3.1. Composition and Micro-Structure

3.2. Density

3.3. Micro- and Nano-Hardness

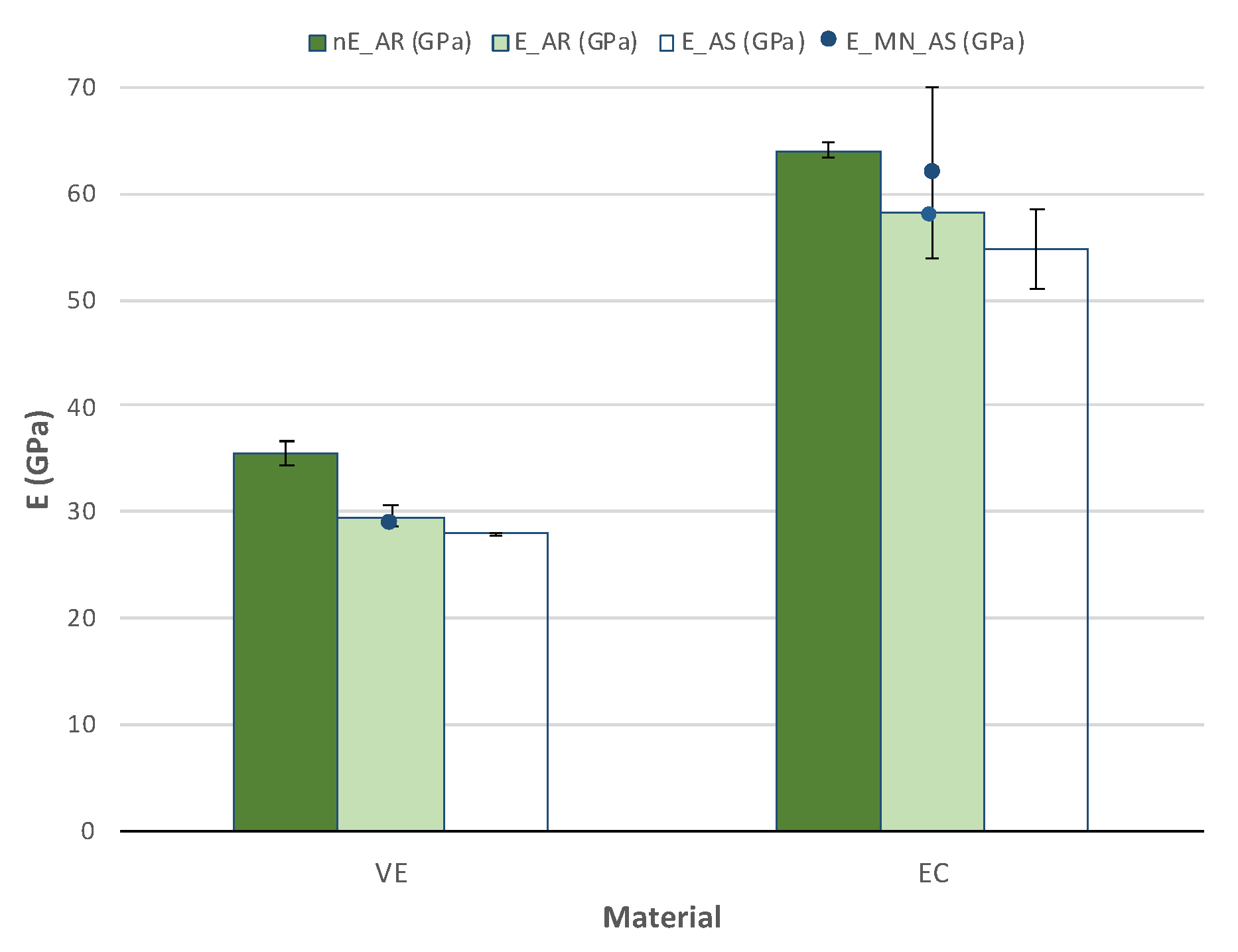

3.4. Elastic Modulus

3.5. Flexural Strength

3.6. Fracture Toughness

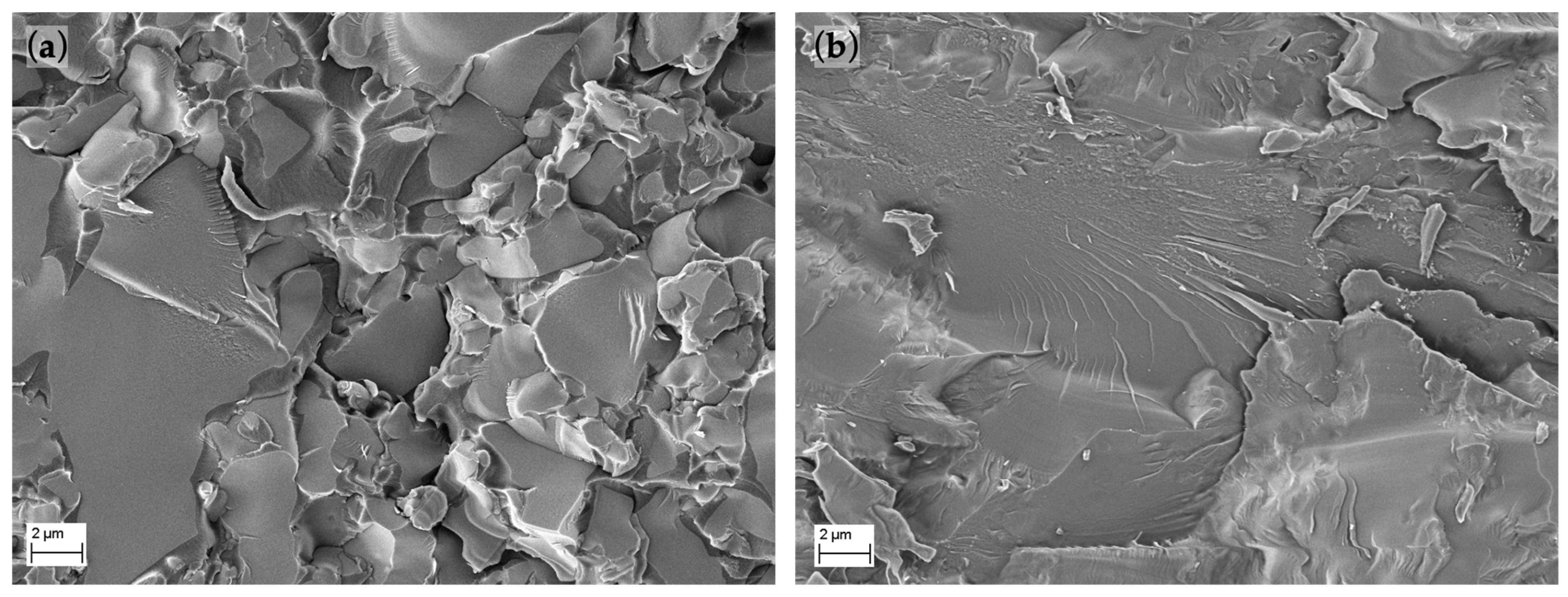

3.7. Fracture Surfaces

4. Discussion

5. Conclusions

- Although results for XRF analysis exhibit similar composition of the crystalline phase for both materials (mainly composed of SiO2 and Al2O3), the micro-structure is dissimilar. EC exhibits a smaller grain size distribution. There is no evidence of significative porosity on the materials.

- The hybrid material VE presents a 25 vol.% polymer phase, and although it exhibits a coarser micro-structure, and generally a lower mechanical performance, its mechanical properties have a better approach to human dentin and enamel.

- The mechanical properties of EC exhibit higher density, hardness (about 6 GPa) and elastic modulus (about 60 GPa), but very similar flexural strength (around 125 MPa) and fracture toughness (under 1 MPa⋅m1/2). However, it exhibits a higher dispersion of results too.

- The most precise and representative values for the elastic modulus measurements were obtained from the force-displacement curves from TPB strength test. Size effect was observed in the indentation tests, but values with 9.8 N load are the most accurate ones.

- Measured flexural strength and fracture toughness show significantly lower values than those advertised by manufacturers. However, the information they provide is normally incomplete and poor, so it should be related to the accuracy of the measuring devices.

- Fracture surfaces show brittle macro- and micro-mechanisms of failure in accordance with the linear stress–strain flexural TPB curves and fracture toughness results, under 1 MPa⋅m1/2.

- In general, both materials exhibit a good performance after the ageing process, which predicts maintenance of the materials’ mechanical properties inside the mouth. It was only observed a detrimental effect of 20% on the hardness of EC and the flexural strength of VE.

- The technical data provided by manufacturers was found incomplete for some mechanical behavior properties. Specially results obtained for flexural strength and fracture toughness were far from the manufacturer’s report due to the improper test method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fasbinder, D.J. Materials for chairside CAD/CAM restorations. Compend. Contin. Educ. Dent. 2010, 31, 702–709. [Google Scholar] [CrossRef] [PubMed]

- Ritzberger, C.; Apel, E.; Höland, W.; Peschke, A.; Rheinberger, V.M. Properties and clinical application of three types of dental glass-ceramics and ceramics for CAD-CAM technologies. Materials 2010, 3, 3700–3713. [Google Scholar] [CrossRef] [Green Version]

- Montazerian, M.; Zanotto, E.D. Bioactive and inert dental glass-ceramics. J. Biomed. Mater. Res. Part A 2016, 1, 619–639. [Google Scholar] [CrossRef] [PubMed]

- Rekow, D.E.D.; Silva, N.R.F.A.; Coelho, P.G.; Zhang, Y.; Guess, P.; Thompson, V.P. Performance of dental ceramics: Challenges for improvements. J. Dent. Res. 2011, 90, 937–952. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pratap, B.; Gupta, R.K.; Bhardwaj, B.; Nag, M. Resin based restorative dental materials: Characteristics and future perspectives. Jpn. Dent. Sci. Rec. 2019, 55, 126–138. [Google Scholar] [CrossRef] [PubMed]

- Cho, K.; Rajan, G.; Farrar, P.; Prentice, L.; Gangadhara Prusty, B. Dental resin composites: A review on materials to product realizations. Compos. B Eng. 2022, 230, 209495. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, N.; Weir, M.D.; Reynolds, M.A.; Bai, Y.; Xu, H.H.K. Bioactive dental composites and bonding agents having remineralizing and antibacterial characteristics. Dent. Clin. 2017, 61, 669–687. [Google Scholar] [CrossRef]

- Demarco, F.F.; Collares, K.; Correa, M.B.; Cenci, M.S.; Moraes, R.R.; Opdam, N.J. Should my composite restorations last forever? Why are they failing? Braz. Oral Res. 2017, 31 (Suppl. S1), e56. [Google Scholar] [CrossRef] [Green Version]

- Edelhoff, D.; Beuer, F.; Schweiger, J.; Brix, O.; Stimmelmayr, M.; Guth, J.F. CAD/CAM-generated high-density polymer restorations for the pretreatment of complex cases: A case report. Quintessence Int. 2012, 43, 457–467. [Google Scholar]

- Güth, J.F.; Ihloff, H.; Edelhoff, D.; Mast, G. Complete mouth rehabilitation after transposition osteotomy based on intraoral scanning: An experimental approach. J. Prosthet. Dent. 2014, 112, 89–93. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Liebermann, A.; Eichberger, M.; Güth, J.-F. Evaluation of mechanical and optical behavior of current esthetic dental restorative CAD/CAM composites. J. Mech. Behav. Biomed. Mater. 2016, 55, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Scientific Documentation IPS Empress® CAD Direct. Ivoclar Vivadent AG, Schaan, Liechtenstein. 2010 Edition. Available online: https://www.ivoclar.com/es_ES/downloadcenter/# (accessed on 5 July 2022).

- He, L.H.; Swain, M.V. Understanding the mechanical behaviour of human enamel from its structural and compositional characteristics. J. Mech. Behav. Biomed. Mater. 2008, 1, 18–29. [Google Scholar] [CrossRef] [PubMed]

- Hammarström, L. Enamel matrix, cementum development and regeneration. J. Clin. Periodontal. 1997, 24, 658–668. [Google Scholar] [CrossRef] [PubMed]

- Vita Enamic®. Scientific-Technical Documentation; VITA Zahnfabrik, H. Rauter GmbH &. Co. KG: Bad Säckingen, Germany; Available online: https://www.vita-zahnfabrik.com (accessed on 5 July 2022).

- Available online: https://www.ivoclar.com/en_gb/products/digital-processes/ips-empress-cad (accessed on 5 July 2022).

- Palacios, T.; Pastor, J.Y. Influence of the notch root radius on the fracture toughness of brittle metals: Nanostructure tungsten alloy, a case study. Int. J. Refract. Met. Hard Mater. 2015, 52, 44–49. [Google Scholar] [CrossRef]

- Palacios, T.; Pastor, J.Y. Tungsten-vanadium-yttria alloys for fusion power reactors (II): Mechanical characterisation. Int. J. Refract. Met. Hard Mater. 2016, 54, 159–164. [Google Scholar] [CrossRef]

- Fan, K.; Pastor, J.Y.; Ruiz-Hervías, J.; Gurauskis, J.; Baudín, C. Determination of mechanical properties of Al2O3/Y-TZP ceramic composites: Influence of testing method and residual stress. Ceram. Int. 2016, 42, 18700–18710. [Google Scholar] [CrossRef]

- Palacios, T.; Tarancón, S.; Abad, C.; Pastor, J.Y. Saliva Influence on the Mechanical Properties of Advanced CAD/CAM Composites for Indirect Dental Restorations. Polymers 2021, 13, 808. [Google Scholar] [CrossRef]

- Zakir, M.; Al Kheraif, A.A.A.; Asif, M.; Wong, F.S.L.; Rehman, I.U. A comparison of the mechanical properties of a modified silorane based dental composite with those of commercially available composite material. Dent. Mater. 2013, 29, e53–e59. [Google Scholar] [CrossRef]

- ASTM E92–17; Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2003, 19, 3–20. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G.; Callister, R. Materials Science and Engineering, 9th ed.; John Wiley & Sons Inc. Publishing: New York, NY, USA, 2014. [Google Scholar]

- ISO 4049; Dentistry—Polymer-Based Restorative Materials. International Organization of Standarization: Geneva, Switzerland, 2019.

- ISO 6872:2015; Dentistry—Ceramic Materials. International Organization of Standarization: Geneva, Switzerland, 2015.

- Timoshenko, S.P. Strength of Materials, Vol. 1: Elementary Theory and Problems, 3rd ed.; Van Nostrand Reinhold, Inc. Publishing: Toronto, ON, Canada, 1955. [Google Scholar]

- Guinea, G.V.; Pastor, J.Y.; Planas, J. Stress Intensity factor, compliance and CMOD for a General Three-Point-Bend Beam. Int. J. Fract. 1988, 89, 103–116. [Google Scholar] [CrossRef]

- Información Básica las Técnicas Prostodóncicas Dentosoportadas de Straumann® Cares®; Institut Straumann AG: Basel, Switzerland, 2013.

- LavaTM Ultimate CAD/CAM Restorative Technical Product Profile; 3M ESPE: St. Paul, MN, USA; Available online: www.3m.com (accessed on 7 July 2022).

- Belli, R.; Wendler, M.; de Ligny, D.; Cicconi, M.R.; Petschelt, A.; Peterlik, H.; Lohbauer, U. Chairside CAD/CAM materials. Part 1: Measurement of elastic constants and microstructural characterization. Dent. Mater. 2017, 33, 84–98. [Google Scholar] [CrossRef] [PubMed]

- Della Bona, A.; Corazza, P.H.; Zhang, Y. Characterization of a polymer-infiltrated ceramic-network material. Dent. Mater. 2014, 30, 564–569. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goujat, A.; Abouelleil, H.; Colon, P.; Jeannin, C.; Pradelle, N.; Seux, D.; Grosgogeat, B. Mechanical properties and internal fit of 4 CAD-CAM blocks materials. J. Prosthet. Dent. 2018, 119, 384–389. [Google Scholar] [CrossRef]

- CERASMARTTM. GC Dental Product Technical Product Profile; GC Corporation: Tokyo, Japan; Available online: www.gcamerica.com (accessed on 7 July 2022).

- Lawn, B.R.; Lee, J.J.-W. Analysis of fracture and deformation modes in teeth subjected to occlusal loading. Acta Biomater. 2009, 5, 2213–2221. [Google Scholar] [CrossRef]

- Mahoney, E.; Holt, A.; Swain, M.V.; Kilpatrick, N. The hardness and modulus of elasticity of primary molar teeth: An ultra-micro-indentation study. J. Dent. 2000, 28, 589–594. [Google Scholar] [CrossRef]

- He, L.H.; Swain, M.V. Nanoindentation derived stress-strain properties of dental materials. Dent. Mater. 2007, 23, 814–821. [Google Scholar] [CrossRef]

- Park, S.; Quinn, J.B.; Romberg, E.; Arola, D. On the brittleness of enamel and selected dental materials. Dent. Mater. 2008, 24, 1477–1485. [Google Scholar] [CrossRef] [Green Version]

- Kinney, J.H.; Marshall, S.J.; Marshall, G.W. The mechanical properties of human dentin: A critical review and re-evaluation of the dental literature. Crit. Rev. Oral Biol. Med. 2003, 14, 13–29. [Google Scholar] [CrossRef]

- Shinno, Y.; Ishimoto, T.; Saito, M.; Uemura, R.; Arino, M.; Marumo, K.; Nakano, T.; Hayashi, M. Comprehensive analysis of how tubular occlusion and advanced glycation end-products diminish strength of aged dentin. Sci. Rep. 2016, 6, 19849. [Google Scholar] [CrossRef] [Green Version]

- Plotino, G.; Grande, N.M.; Bedini, R.; Pameijer, C.H.; Francesco, S. Flexural properties of endodontic posts and human root dentin. Dent. Mater. 2007, 23, 1129–1135. [Google Scholar] [CrossRef] [PubMed]

- Imbeni, V.; Nalla, R.K.; Bosi, C.; Kinney, J.H.; Ritchie, R.O. In vitro fracture toughness of human dentin. J. Biomed. Mater. Res. 2003, 66, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Mowafy, O.M.; Watts, D. Fracture toughness of human dentin. J. Dent. Res. 1986, 65, 677–681. [Google Scholar] [CrossRef] [PubMed]

| Material | Abbreviation | Manufacturer | Type |

|---|---|---|---|

| Vita Enamic® | VE | VITA Zahnfabrick, Germany | Polymer-infiltrated ceramic-network composed by 86 wt.%/75 vol.% porous ceramic network infiltrated by capillary action with 14 wt.%/25 vol.% polymer (UDMA, TEGDMA). |

| IPS Empress® CAD | EC | Ivoclar Vivadent AG, Liechtenstein | Leucite (35–45 vol.%) reinforced glass ceramic |

| Material | SiO2 | Al2O3 | Na2O | K2O | BaO | ZrO2 | CaO | Y2O3 | Other |

|---|---|---|---|---|---|---|---|---|---|

| VE | 61.47 | 21.47 | 7.97 | 7.54 | - | 0.62 | 0.35 | 0.25 | 0.53 |

| EC | 62.24 | 17.58 | 5.53 | 11.63 | 0.44 | 0.07 | 0.99 | 0.08 | 1.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palacios, T.; Tarancón, S.; Pastor, J.Y. On the Mechanical Properties of Hybrid Dental Materials for CAD/CAM Restorations. Polymers 2022, 14, 3252. https://doi.org/10.3390/polym14163252

Palacios T, Tarancón S, Pastor JY. On the Mechanical Properties of Hybrid Dental Materials for CAD/CAM Restorations. Polymers. 2022; 14(16):3252. https://doi.org/10.3390/polym14163252

Chicago/Turabian StylePalacios, Teresa, Sandra Tarancón, and José Ygnacio Pastor. 2022. "On the Mechanical Properties of Hybrid Dental Materials for CAD/CAM Restorations" Polymers 14, no. 16: 3252. https://doi.org/10.3390/polym14163252

APA StylePalacios, T., Tarancón, S., & Pastor, J. Y. (2022). On the Mechanical Properties of Hybrid Dental Materials for CAD/CAM Restorations. Polymers, 14(16), 3252. https://doi.org/10.3390/polym14163252