A Comparative Study on Bio-Based PU Foam Reinforced with Nanoparticles for EMI-Shielding Applications

Abstract

:1. Introduction

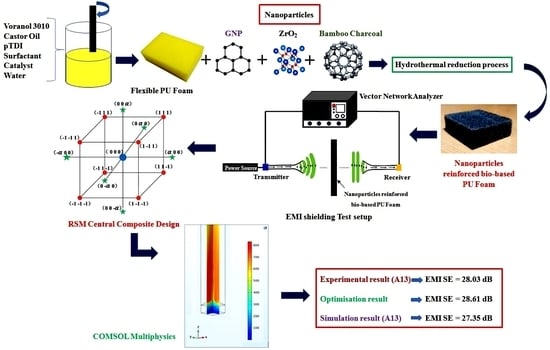

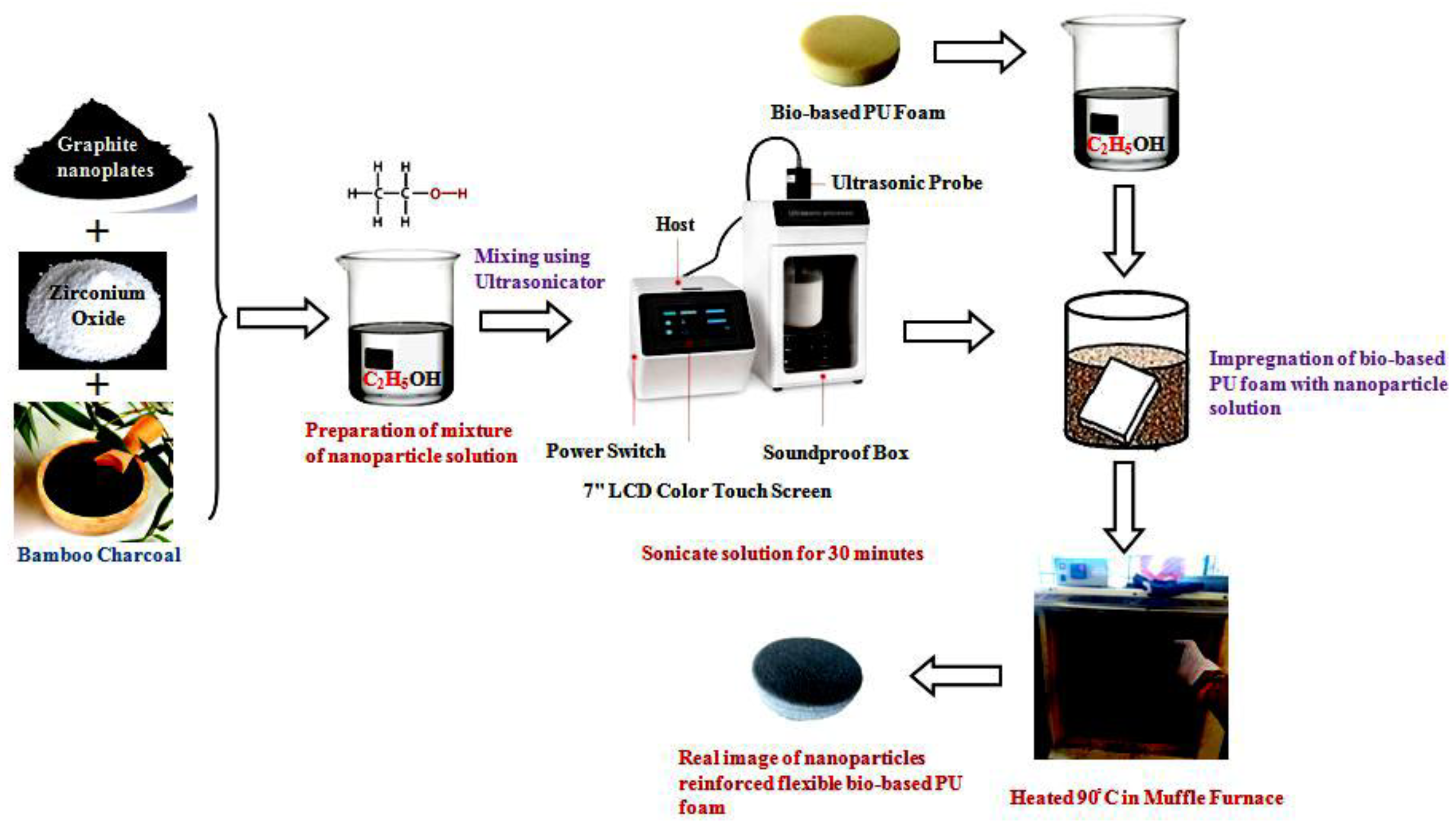

2. Materials and Methods

3. Results and Discussion

3.1. Field Emission Scanning Electron Microscope (FESEM)

3.2. Fourier-Transform Infrared Spectroscopy (FTIR) Characterization

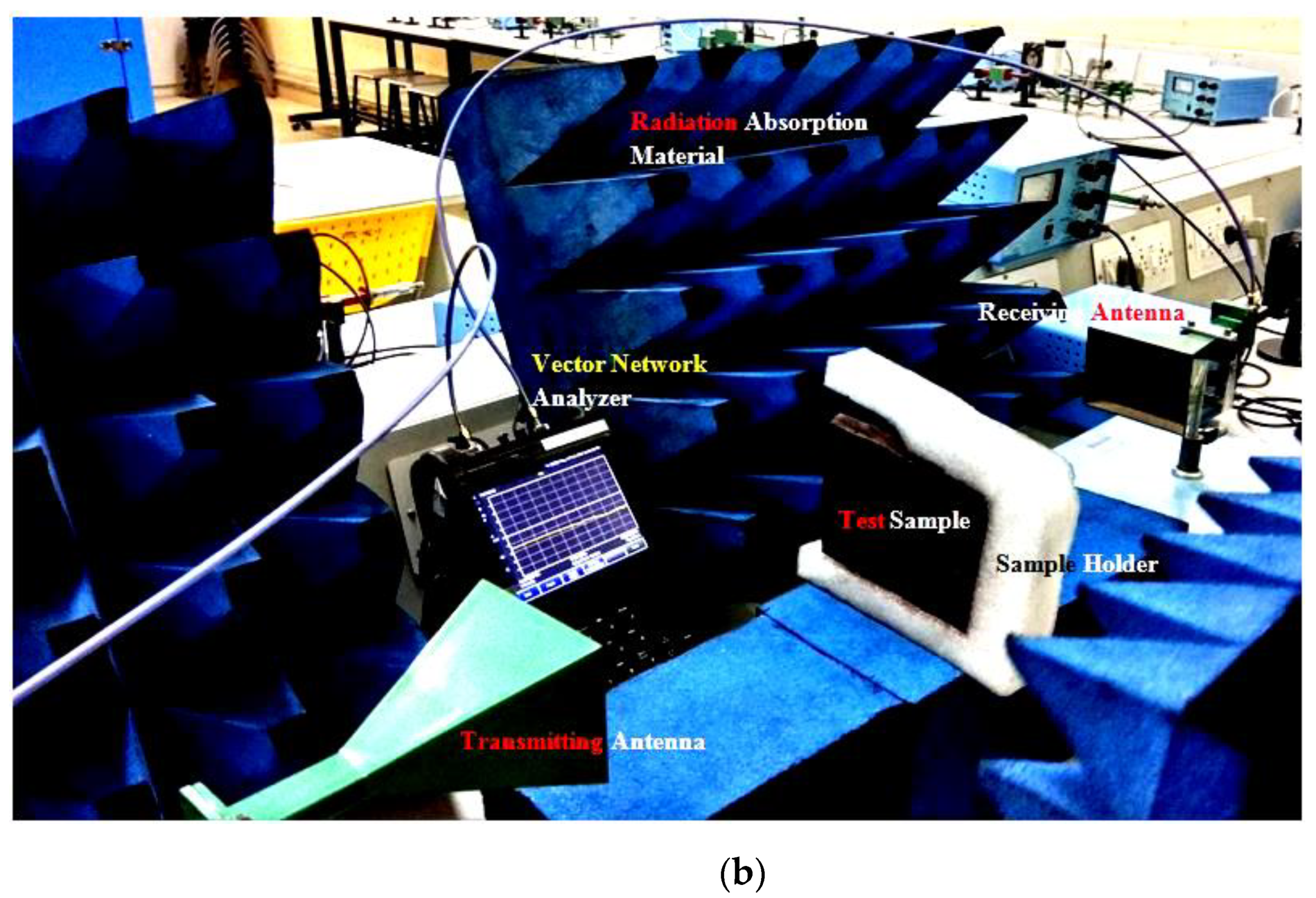

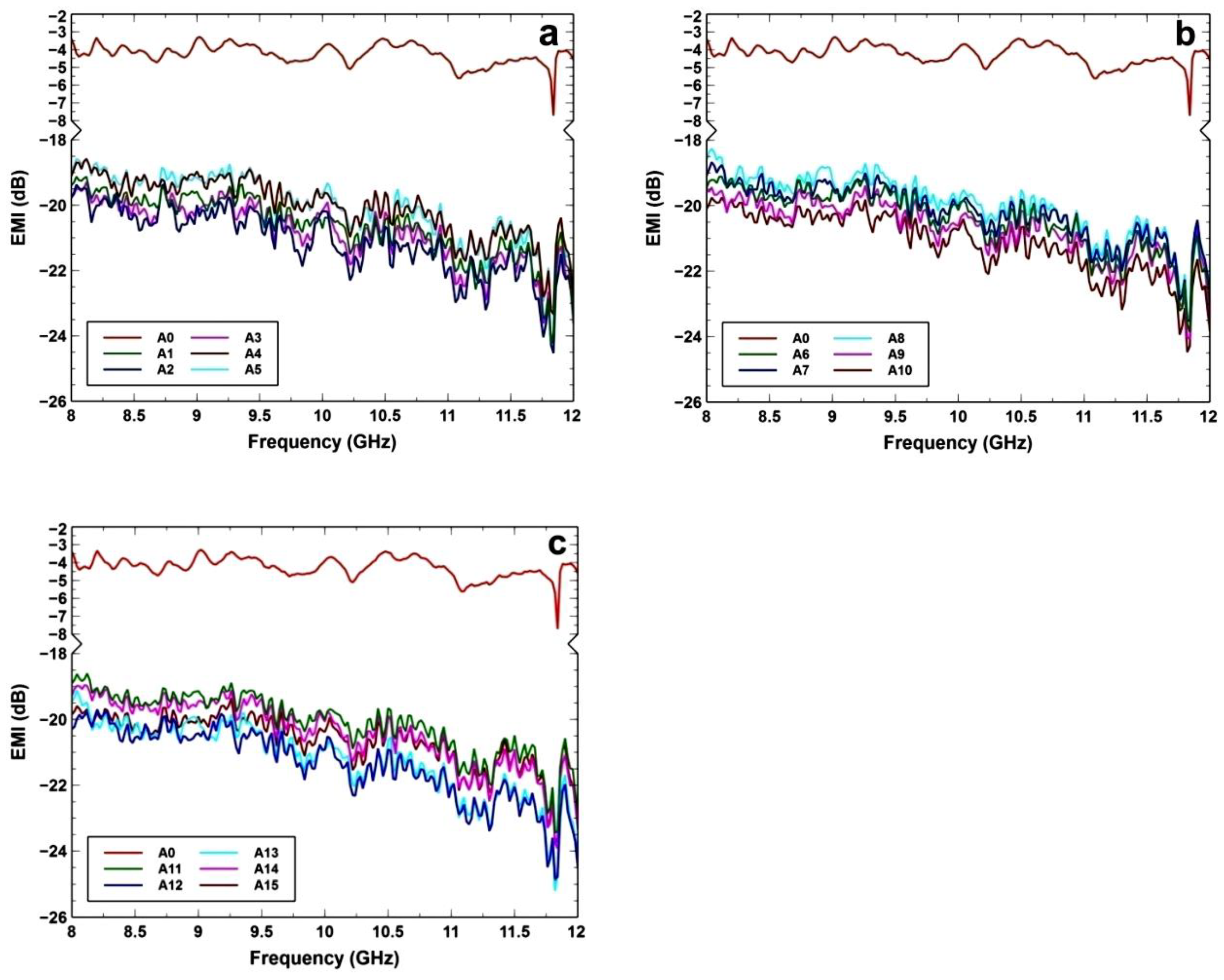

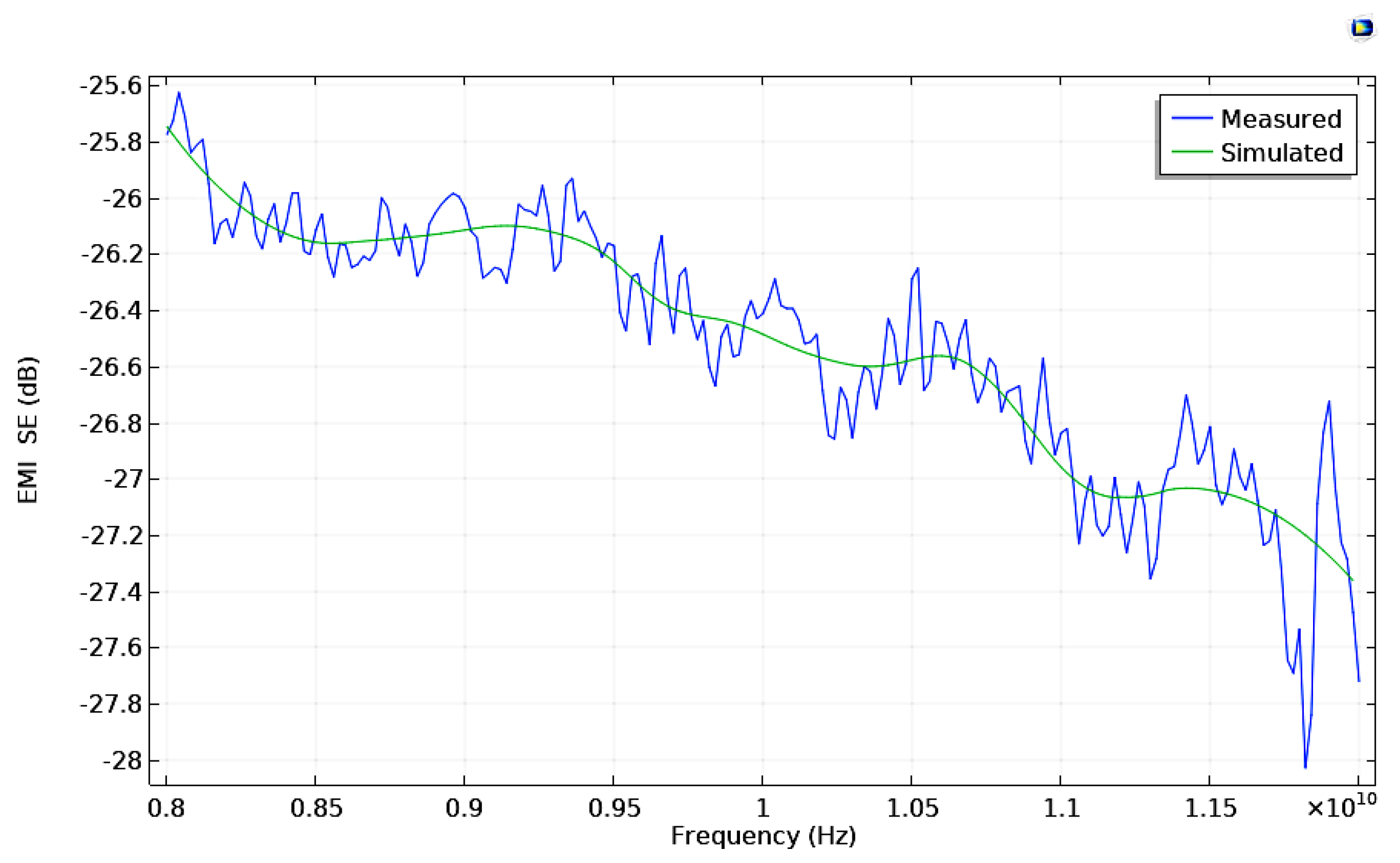

3.3. EMI SE Experimental Characterization

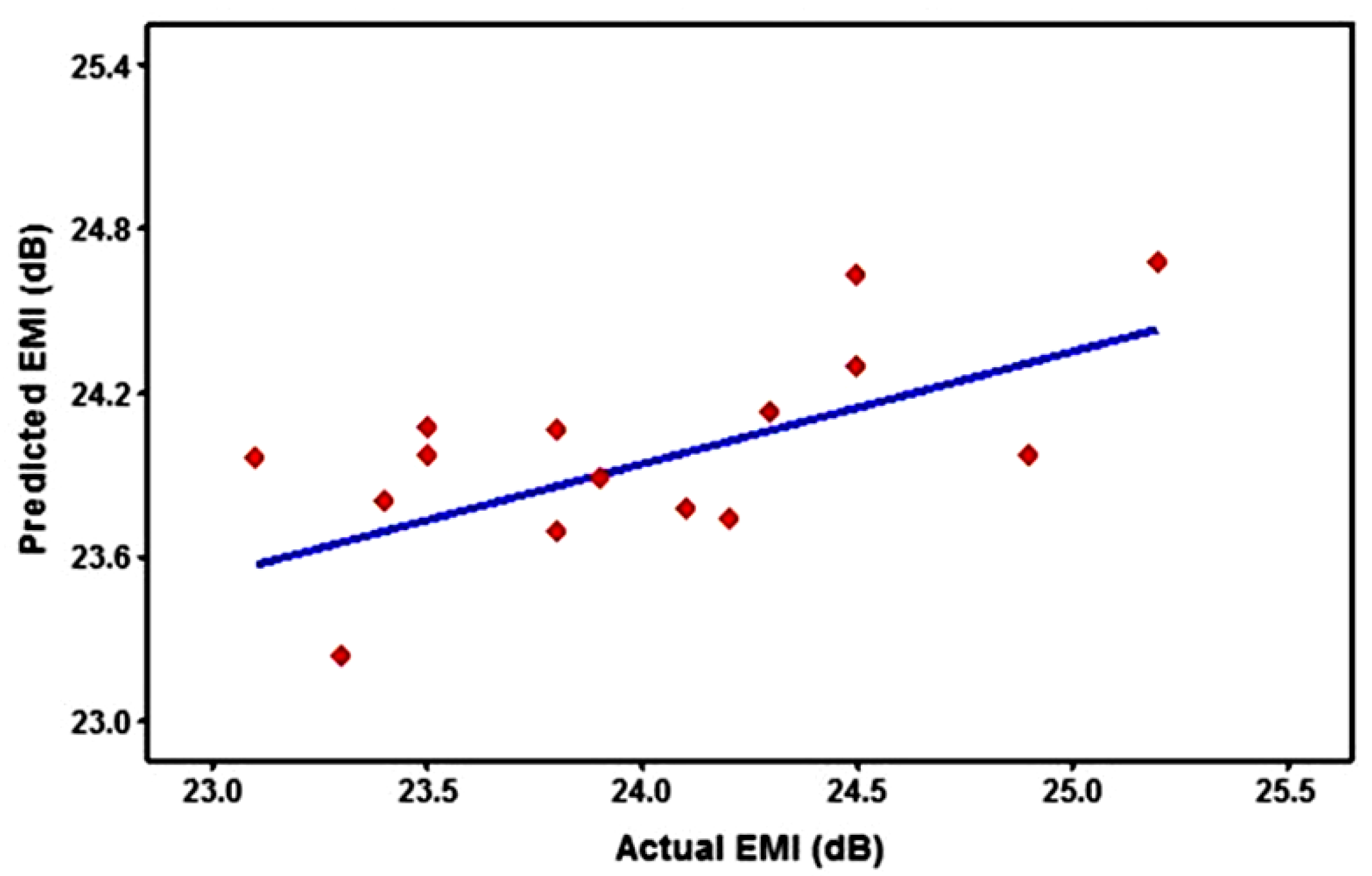

3.4. EMI SE Statistical Analysis

5.00 ∗ B ∗ C

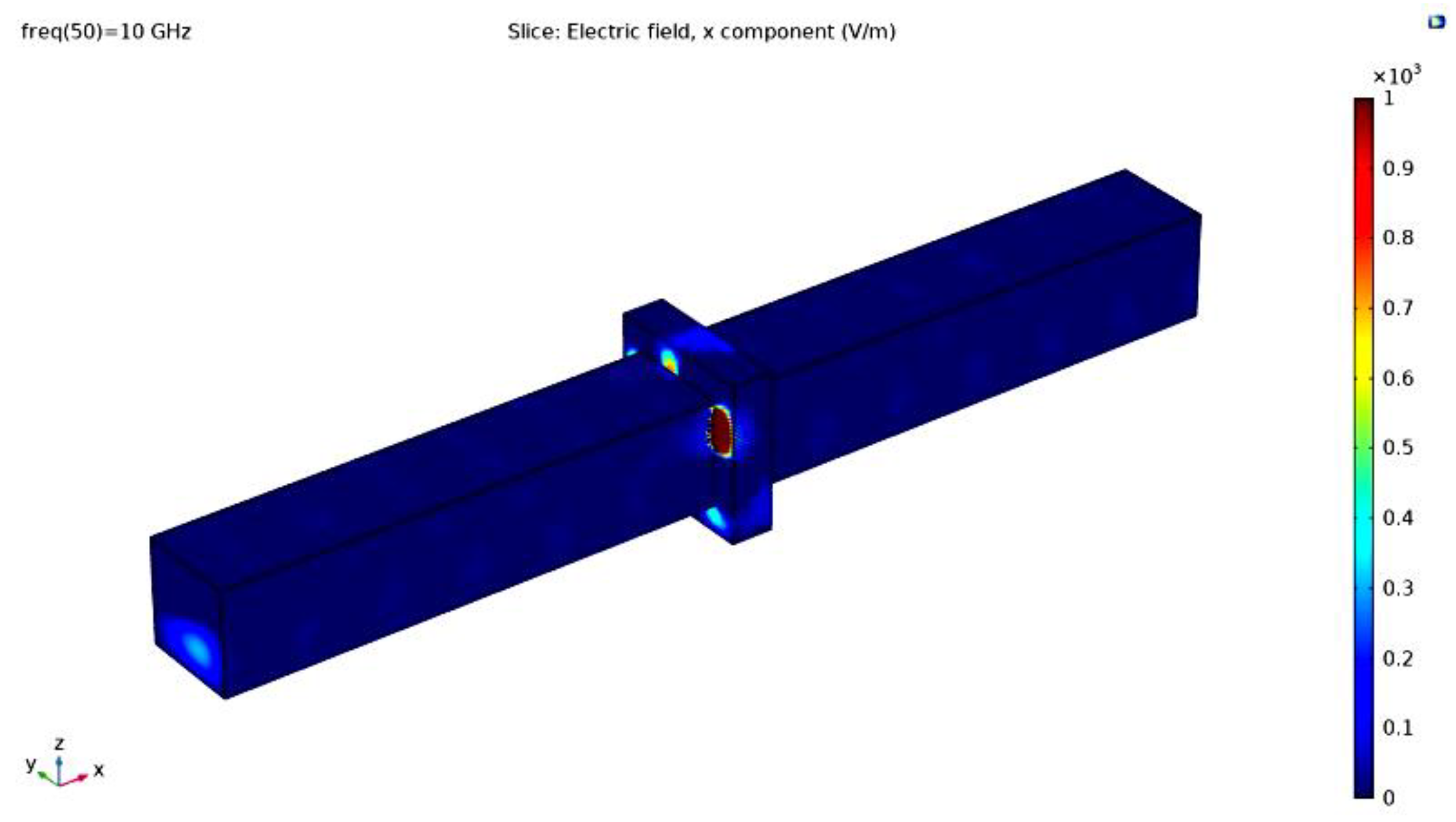

3.5. EMI SE Computational Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| EMI SE | Electromagnetic Interference Shielding Effectiveness |

| RSM | Response Surface Methodology |

| CCD | Central Composite Design |

| FESEM | Field Emission Scanning Electron Microscope |

| FTIR | Fourier-transform infrared spectroscopy |

| GNP | Graphite nanoplates |

| ZrO2 | Zirconium Oxide |

| BC | Bamboo Charcoal |

| wt.% | Weight Percentage |

| Eqs | Equation |

| CAD | Computer-Aided Design |

| RF | Radio Frequency |

References

- Brito, A. How Polyurethane Can Be Used in Today’s Manufacturing Industry. Reinf. Plast. 2020, 64, 268–270. [Google Scholar] [CrossRef]

- Das, A.; Mahanwar, P. A Brief Discussion on Advances in Polyurethane Applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials. 2018, 11, 1841. [Google Scholar] [CrossRef] [PubMed]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnama, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications–a review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Gurgel, D.; Bresolin, D.; Sayer, C.; Cardozo Filho, L.; Hermes de Araújo, P.H. Flexible Polyurethane Foams Produced from Industrial Residues and Castor Oil. Ind. Crops Prod. 2021, 164, 113377. [Google Scholar] [CrossRef]

- Anandan, K.; Rajendran, V. A Low-Temperature Synthesis and Characterization of Tetragonal-ZrO2 Nanoparticles via Simple Hydrothermal Process. J. Phys. Sci. 2013, 17, 179–184. [Google Scholar]

- Klemperer, C.J.v.; Maharaj, D. Composite Electromagnetic Interference Shielding Materials for Aerospace Applications. Compos. Struct. 2009, 91, 467–472. [Google Scholar] [CrossRef]

- Serrano, L.; Rincón, E.; García, A.; Rodríguez, J.; Briones, R. Bio-degradable polyurethane foams produced by liquefied polyol from wheat straw biomass. Polymers 2020, 12, 2646. [Google Scholar] [CrossRef]

- Zahedifar, P.; Due, L.P.; Billen, P. Multistage Chemical Recycling of Polyurethanes and Dicarbamates: A Glycolysis–Hydrolysis Demonstration. Sustainability 2021, 13, 3583. [Google Scholar] [CrossRef]

- Yang, W.; Dong, Q.; Liu, S.; Xie, H.; Liub, L.; Lib, J. Recycling and disposal methods for polyurethane foam wastes. Procedia Environ. Sci. 2012, 16, 167–175. [Google Scholar] [CrossRef]

- Gómez-Rojo, R.; Alameda, L.; Rodríguez, A.; Calderón, V.; Gutiérrez-González, S. Characterization of Polyurethane Foam Waste for Reuse in Eco-Efficient Building Materials. Polymers 2019, 11, 359. [Google Scholar] [CrossRef]

- Vinoth Kumar, S.; Subramanian, J.; Giridharan, A.; Gupta, M.; Adhikari, A.; Gayen, M. Processing and Characterization of Bio-based PU Foam Reinforced with Nano Particles. Mater. Today Proc. 2021, 46, 1077–1084. [Google Scholar] [CrossRef]

- Khanderay, J.C.; Khanderay, J.C. Vegetable Oil-Based Polyurethane Coatings: Recent Developments in India. Green Mater. 2017, 5, 109–122. [Google Scholar] [CrossRef]

- Ye, X.; Hu, J.; Li, B.; Hong, M.; Zhang, Y. Graphene Loaded with Nano-Cu as a Highly Efficient Foam Interface Material with Excellent Properties of Thermal-Electronic Conduction, Anti-Permeation and Electromagnetic Interference Shielding. Chem. Eng. J. 2019, 361, 1110–1120. [Google Scholar] [CrossRef]

- Selvaraj, V.K.; Subramanian, J.; Gupta, M.; Gayen, M.; Mailan Chinnapandi, L.B. An Experimental Investigation on Acoustical Properties of Organic PU Foam Reinforced with Nanoparticles Fabricated by Hydrothermal Reduction Technique to Emerging Applications. J. Inst. Eng. Ser. D 2020, 101, 271–284. [Google Scholar] [CrossRef]

- Wu, H.; Zhong, Y.; Tang, Y.; Huang, Y.; Liu, G.; Sun, W.; Xie, P.; Pan, D.; Liu, C.; Guo, Z. Precise Regulation of Weakly Negative Permittivity in CaCu3Ti4O12 Metacomposites by Synergistic Effects of Carbon Nanotubes and Grapheme. Adv. Compos. Hybrid. Mater. 2022, 5, 419–430. [Google Scholar] [CrossRef]

- Jung, W.K.; Ahn, S.H.; Won, M.S. Effect of Nanoparticles and Ion Implantation on the Electromagnetic Shielding of Glass-Epoxy Composites. J. Compos. Mater. 2006, 40, 175–188. [Google Scholar] [CrossRef]

- Qin, C.; Gong, H.; Sun, C.; Wu, X. Optical Properties of a Core/Shell/Shell Shape Metal-Insulator-Metal Composite Nanoparticle for Solar Energy Absorption. Eng. Sci. 2021, 17, 224–230. [Google Scholar] [CrossRef]

- Rokade, A.; Jadhav, Y.; Jathar, S.; Rahane, S.; Barma, S.; Rahane, G.; Thawarkar, S.; Vairale, P.; Punde, A.; Shah, S.; et al. Realization of Electrochemically Grown A-Fe2O3 Thin Films for Photoelectrochemical Water Splitting Application. Eng. Sci. 2021, 17, 242–255. [Google Scholar] [CrossRef]

- Saito, K.; Nakamura, J.; Natori, A. Ballistic Thermal Conductance of a Graphene Sheet. Phys. Rev. B-Condens. Matter Mater. Phys. 2007, 76, 115409. [Google Scholar] [CrossRef]

- MacHado, B.F.; Serp, P. Graphene-Based Materials for Catalysis. Catal. Sci. Technol. 2012, 2, 54–75. [Google Scholar] [CrossRef]

- Le, M.T.; Huang, S.C. Effect of Nano-Fillers on the Strength Reinforcement of Novel Hybrid Polymer Nanocomposites. Mater. Manuf. Process. 2016, 31, 1066–1072. [Google Scholar] [CrossRef]

- Eshed, M.; Pol, S.; Gedanken, A.; Balasubramanian, M. Zirconium Nanoparticles Prepared by the Reduction of Zirconium Oxide Using the RAPET Method. Beilstein J. Nanotechnol. 2011, 2, 198–203. [Google Scholar] [CrossRef] [PubMed]

- Mbayachi, V.B.; Ndayiragije, E.; Sammani, T.; Taj, S.; Mbuta, E.R.; Khan, A.U. Results in Chemistry Graphene synthesis, characterization and its applications: A review. Results Chem. 2021, 3, 100163. [Google Scholar] [CrossRef]

- Alam, S.; Nizam, U.; Maksudul, I.; Bipasha, F.A.; Hossain, S.S. Synthesis of graphene. Int. Nano. Lett. 2016, 6, 65–83. [Google Scholar] [CrossRef]

- Su, Y.; Cui, H.; Li, Q.; Gao, S.; Shang, J.K. Strong Adsorption of Phosphate by Amorphous Zirconium Oxide Nanoparticles. Water Res. 2013, 47, 5018–5026. [Google Scholar] [CrossRef] [PubMed]

- Sagadevan, S.; Podder, J.; Das, I. Hydrothermal Synthesis of Zirconium Oxide Nanoparticles and Its Characterization. J. Mater. Sci. Mater. Electron. 2016, 27, 5622–5627. [Google Scholar] [CrossRef]

- Ergun, G.; Sahin, Z.; Ataol, A.S. The Effects of Adding Various Ratios of Zirconium Oxide Nanoparticles to Poly(Methyl Methacrylate) on Physical and Mechanical Properties. J. Oral Sci. 2018, 60, 304–315. [Google Scholar] [CrossRef] [PubMed]

- Huang, P.H.; Jhan, J.W.; Cheng, Y.M.; Cheng, H.H. Effects of Carbonization Parameters of Moso-Bamboo-Based Porous Charcoal on Capturing Carbon Dioxide. Sci. World J. 2014, 9, 937867. [Google Scholar] [CrossRef]

- Tang, C.M.; Tian, Y.H.; Hsu, S.H. Poly(Vinyl Alcohol) Nanocomposites Reinforced with Bamboo Charcoal Nanoparticles: Mineralization Behavior and Characterization. Materials 2015, 8, 4895–4911. [Google Scholar] [CrossRef]

- Subramanian, J.; Vinoth Kumar, S.; Venkatachalam, G.; Gupta, M.; Singh, R. An Investigation of EMI Shielding Effectiveness of Organic Polyurethane Composite Reinforced with MWCNT-CuO-Bamboo Charcoal Nanoparticles. J. Electron. Mater. 2021, 50, 1282–1291. [Google Scholar] [CrossRef]

- Song, H.; Lim, S. Screen-Printing Process of Electromagnetic Interference (EMI) Shielding Materials on Mulberry Paper. Mater. Manuf. Process. 2020, 35, 1701–1706. [Google Scholar] [CrossRef]

- Nazir, A. A Review of Polyvinylidene Fluoride (PVDF), Polyurethane (PU), and Polyaniline (PANI) Composites-Based Materials for Electromagnetic Interference Shielding. J. Thermoplast. Compos. Mater. 2020, 1–21. [Google Scholar] [CrossRef]

- Muzaffar, A.; Ahamed, M.B.; Deshmukh, K.; Pasha, S.K.K. Dielectric Properties and Electromagnetic Interference Shielding Studies of Nickel Oxide and Tungsten Oxide Reinforced Polyvinylchloride Nanocomposites. Polym. Technol. Mater. 2020, 59, 1667–1678. [Google Scholar] [CrossRef]

- Sankaran, S.; Deshmukh, K.; Ahamed, M.B.; Sadasivuni, K.K.; Faisal, M.; Pasha, S.K.K. Electrical and Electromagnetic Interference (EMI) Shielding Properties of Hexagonal Boron Nitride Nanoparticles Reinforced Polyvinylidene Fluoride Nanocomposite Films. Polym. Technol. Mater. 2019, 58, 1191–1209. [Google Scholar] [CrossRef]

- Peng, H.; Wang, X.; Li, T.T.; Huang, S.Y.; Wu, L.; Lou, C.W.; Lin, J.H. Study on Preparation, Sound Absorption, and Electromagnetic Shielding Effectiveness of Rigid Foam Composites. J. Sandw. Struct. Mater. 2019, 21, 2512–2526. [Google Scholar] [CrossRef]

- Plyushch, A.; Macutkevic, J.; Kuzhir, P.; Banys, J.; Bychanok, D.Z.; Lambin, P.H.; Bistarelli, S.; Cataldo, A.; Micciulla, F.; Bellucci, S. Electromagnetic properties of graphene nanoplatelets/epoxy composites. Compos. Sci Technol. 2016, 128, 75–83. [Google Scholar] [CrossRef]

- Mondal, S.; Das, P.; Ganguly, S.; Ravindren, R.; Remanan, S.; Bhawal, P.; Das, T.K.; Das, N.C. Thermal-air ageing treatment on mechanical, electrical, and electromagnetic interference shielding properties of lightweight carbon nanotube based polymer nanocomposites. Compos. Part A 2018, 107, 447–460. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Tang, M.; Zhou, L.; Li, J.; Fan, X.; Shi, X.; Qin, J. Synergistic effect of carbon nanotube and graphene nanoplates on the mechanical, electrical and electromagnetic interference shielding properties of polymer composites and polymer composite foams. Chem. Eng. J. 2018, 353, 381–393. [Google Scholar] [CrossRef]

- Jiang, Q.; Liao, X.; Li, J.; Chen, J.; Wang, G.; Yi, J.; Yang, Q.; Li, G. Flexible Thermoplastic Polyurethane/Reduced Graphene Oxide Composite Foams for Electromagnetic Interference Shielding with High Absorption Characteristic. Compos. Part A 2019, 123, 310–319. [Google Scholar] [CrossRef]

- Yang, Y.; Gupta, M.C.; Dudley, K.L.; Lawrence, R.W. Novel Carbon Nanotube-Polystyrene Foam Composites for Electromagnetic Interference Shielding. Nano. Lett. 2005, 5, 2131–2134. [Google Scholar] [CrossRef] [PubMed]

- Basuli, U.; Chattopadhyay, S.; Nah, C.; Chak, T.K. Electrical Properties and Electromagnetic Interference Shielding Effectiveness of Multiwalled Carbon Nanotubes-Reinforced EMA Nanocomposites. Polym. Compos. 2012, 33, 897–903. [Google Scholar] [CrossRef]

- Cheng, H.C.; Chen, C.R.; Cheng, K.B.; Hsu, S.h. Ag/GNS Conductive Laminated Woven Fabrics for EMI Shielding Applications. Mater. Manuf. Process. 2021, 36, 1693–1700. [Google Scholar] [CrossRef]

- Kim, J.M.; Lee, Y.; Jang, M.G.; Han, C.; Kim, W.N. Electrical Conductivity and EMI Shielding Effectiveness of Polyurethane Foam–Conductive Filler Composites. J. Appl. Polym. Sci. 2017, 134, 1–9. [Google Scholar] [CrossRef]

- Rodríguez, F.M.; Meneses, M.G.; Chinè, B. Computational Analysis of Metal Foams for EMI Shielding Using Comsol Multiphysics. In Proceedings of theCOMSOL Conference, Cambridge, UK, 24–26 September 2019. [Google Scholar]

- Wang, L.B.; See, K.Y.; Ling, Y.; Koh, W.J. Study of Metal Foams for Architectural Electromagnetic Shielding. J. Mater. Civ. Eng. 2012, 24, 488–493. [Google Scholar] [CrossRef]

- Ameli, A.; Nofar, M.; Wang, S.; Park, C.B. Lightweight Polypropylene/Stainless-Steel Fiber Composite Foams with Low Percolation for Efficient Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2014, 6, 11091–11100. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Xu, C.; Yuan, Z.; Wei, Q. Synthesis of Bio-Based Polyurethane Foams with Liquefied Wheat Straw: Process Optimization. Biomass Bioenergy 2018, 111, 134–140. [Google Scholar] [CrossRef]

- Behera, S.K.; Meena, H.; Chakraborty, S.; Meikap, B.C. Application of Response Surface Methodology (RSM) for Optimization of Leaching Parameters for Ash Reduction from Low-Grade Coal. Int. J. Min. Sci. Technol. 2018, 28, 621–629. [Google Scholar] [CrossRef]

- Torğut, G. Fabrication, Characterization of Poly(MA-Co-NIPA)-Graphene Composites and Optimization the Dielectric Properties Using the Response Surface Method (RSM). Polym. Test. 2019, 76, 312–319. [Google Scholar] [CrossRef]

- Panda, S.S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Preparation, characterization, and properties of castor oil-based flexible polyurethane/Cloisite 30B nanocomposites foam. J. Compos. Mater. 2017, 52, 531–542. [Google Scholar] [CrossRef]

- Bregman, A.; Michielssen, E.; Taub, A. Comparison of Experimental and Modeled EMI Shielding Properties of Periodic Porous xGNP/PLA Composites. Polymers 2019, 11, 1233. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, S.H.; Oh, K.W. Bio-Based Polyurethane Foams with Castor Oil Based Multifunctional Polyols for Improved Compressive Properties. Polymers 2021, 13, 576. [Google Scholar] [CrossRef] [PubMed]

- Oraby, H.; Naeem, I.; Darwish, M.; Senna, M.H.; Tantawy, H.R. Effective electromagnetic interference shielding using foamy polyurethane composites. Polym. Compos. 2021, 42, 3077–3088. [Google Scholar] [CrossRef]

- Jeyanthi, S.; Nivedhitha, D.; Venkatachalam, G.; Singh, R.; Sangwan, G. An Experimental Investigation and Optimization of Electromagnetic Interference Shielding Effectiveness of Hybrid Epoxy Nanocomposites. J. Electron. Mater. 2022, 51, 3453–3465. [Google Scholar] [CrossRef]

- Hu, Z.; Ji, X.; Li, B.; Luo, Y. A self-assembled graphene/polyurethane sponge for excellent electromagnetic interference shielding performance. RSC Adv. 2019, 9, 25829–25835. [Google Scholar] [CrossRef]

- Liang, J.; Wang, Y.; Huang, Y.; Ma, Y.; Liu, Z.; Cai, J.; Zhang, C.; Gao, H.; Chen, Y. Electromagnetic interference shielding of graphene/epoxy composites. Carbon 2009, 47, 922–925. [Google Scholar] [CrossRef]

- Song, W.L.; Guan, X.T.; Fan, L.Z.; Cao, W.Q.; Wang, C.Y.; Zhao, Q.L.; Cao, M.S. Magnetic and conductive graphene papers toward thin layers of effective electromagnetic shielding. J. Mater. Chem. A 2015, 3, 2097–2107. [Google Scholar] [CrossRef]

- Song, W.L.; Fan, L.Z.; Cao, M.S.; Lu, M.M.; Wang, C.Y.; Wang, J.; Chen, T.T.; Li, Y.; Hou, Z.L.; Liu, J.; et al. Facile fabrication of ultrathin graphene papers for effective electromagnetic shielding. J. Mater. Chem. C 2014, 2, 5057–5064. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.B.; Yang, Y.; Wang, M.; Cao, A.; Yu, Z.Z. High-Performance Epoxy Nanocomposites Reinforced with Three-Dimensional Carbon Nanotube Sponge for Electromagnetic Interference Shielding. Adv. Funct. Mater. 2016, 26, 447–455. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.; Zheng, W. Ultrathin flexible graphene film: An excellent thermal conducting material with efficient EMI shielding. Adv. Funct. Mater. 2014, 24, 4542–4548. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, C.; Ma, C.; Ren, W.; Cheng, H.M. Lightweight and flexible graphene foam composites for high-performance electromagnetic interference shielding. Adv. Mater. 2013, 25, 1296–1300. [Google Scholar] [CrossRef] [PubMed]

| Components | Weight of Components in g |

|---|---|

| Voranol 3010 | 50 |

| Castor Oil (CO) | 50 |

| pTDI | 46.2 |

| Surfactant | 3.6 |

| Tin Catalyst | 1.0 |

| Amine Catalyst | 0.25 |

| Distilled Water | 0.9 |

| Nanoparticles | Density (g/cm3) | Melting Point (°C) | Particle Size (nm) |

|---|---|---|---|

| Graphite nanoplates (GNP) | 2.267 | 3650 | 5–10 |

| Zirconium Oxide (ZrO2) | 5.680 | 2715 | 20–50 |

| Bamboo Charcoal (BC) | 0.690 | 1200 | 20–50 |

| Specimen | Weight of PU Foam without Reinforcement (g) | Graphite Nanoplates (wt.%) | Zirconium Oxide (wt.%) | Bamboo Charcoal (wt.%) | Weight of PU Foam with Reinforcement | Weight Achieved after Reinforcement (%) | Density (g/cm3) | EMI (dB) | |

|---|---|---|---|---|---|---|---|---|---|

| Theoretical Value (g) | Actual Value (g) | ||||||||

| A0 | 4.217 | - | - | - | - | - | - | 0.015 | 7.71 |

| A1 | 4.137 | 0.4 | 0.4 | 2 | 15.337 | 16.128 | 94.84 | 0.056 | 24.3 |

| A2 | 4.281 | 0.2 | 0.4 | 2 | 14.681 | 15.552 | 94.07 | 0.054 | 24.5 |

| A3 | 4.358 | 0.2 | 0.4 | 1 | 10.758 | 12.069 | 87.81 | 0.042 | 24.2 |

| A4 | 4.330 | 0.4 | 0.4 | 1 | 11.530 | 12.960 | 87.60 | 0.045 | 23.3 |

| A5 | 4.284 | 0.4 | 0.2 | 2 | 14.684 | 15.552 | 94.09 | 0.054 | 23.1 |

| A6 | 4.343 | 0.4 | 0.2 | 1 | 10.743 | 11.808 | 90.09 | 0.041 | 23.8 |

| A7 | 4.305 | 0.2 | 0.2 | 1 | 9.905 | 11.369 | 85.22 | 0.040 | 23.5 |

| A8 | 4.325 | 0.2 | 0.2 | 2 | 13.925 | 15.264 | 90.38 | 0.053 | 23.5 |

| A9 | 4.116 | 0.5 | 0.3 | 1.5 | 13.316 | 14.688 | 89.70 | 0.051 | 24.1 |

| A10 | 4.260 | 0.1 | 0.3 | 1.5 | 11.860 | 12.384 | 95.58 | 0.043 | 24.5 |

| A11 | 4.366 | 0.3 | 0.5 | 1.5 | 13.566 | 14.400 | 93.85 | 0.050 | 23.4 |

| A12 | 4.304 | 0.3 | 0.1 | 1.5 | 11.904 | 12.960 | 91.13 | 0.045 | 24.9 |

| A13 | 4.353 | 0.3 | 0.3 | 2.5 | 16.753 | 16.953 | 98.81 | 0.058 | 25.2 |

| A14 | 4.365 | 0.3 | 0.3 | 0.5 | 8.765 | 10.025 | 85.62 | 0.035 | 23.9 |

| A15 | 4.267 | 0.3 | 0.3 | 1.5 | 12.667 | 12.960 | 97.69 | 0.045 | 23.8 |

| A16 | 4.267 | 0.3 | 0.3 | 1.5 | 12.667 | 12.960 | 97.69 | 0.045 | 23.8 |

| A17 | 4.267 | 0.3 | 0.3 | 1.5 | 12.667 | 12.960 | 97.69 | 0.045 | 23.8 |

| A18 | 4.267 | 0.3 | 0.3 | 1.5 | 12.667 | 12.960 | 97.69 | 0.045 | 23.8 |

| A19 | 4.267 | 0.3 | 0.3 | 1.5 | 12.667 | 12.960 | 97.69 | 0.045 | 23.8 |

| A20 | 4.267 | 0.3 | 0.3 | 1.5 | 12.667 | 12.960 | 97.69 | 0.045 | 23.8 |

| Specimen | Transmission Coefficient (T) (dB) | Absorption Coefficient (A) (dB) | Shielding Effectiveness Absorption (SEabs) (dB) | Total Electromagnetic Interference Shielding Effectiveness (EMI SETotal) (dB) |

|---|---|---|---|---|

| A0 | 7.34 ~ 59.57 | −9.07 ~ −78.82 | −6.28 ~ −4.91 | −8.66 ~ −17.75 |

| A1 | 364.81 ~ 590.49 | −366.54 ~ −609.74 | −23.24 ~ −14.87 | −25.62 ~ −27.71 |

| A2 | 372.49 ~ 600.25 | −374.22 ~ −619.5 | −23.33 ~ −14.94 | −25.71 ~ −27.78 |

| A3 | 372.49 ~ 585.64 | −374.22 ~ −604.89 | −23.33 ~ −14.83 | −25.71 ~ −27.68 |

| A4 | 345.96 ~ 542.89 | −347.69 ~ −562.14 | −23.01 ~ −14.50 | −25.39 ~ −27.35 |

| A5 | 345.96 ~ 533.61 | −347.69 ~ −552.86 | −23.01 ~ −14.43 | −25.39 ~ −27.27 |

| A6 | 364.81 ~ 566.44 | −366.54 ~ −585.69 | −23.24 ~ −14.69 | −25.62 ~ −27.53 |

| A7 | 349.69 ~ 552.25 | −351.42 ~ −571.5 | −23.06 ~ −14.58 | −25.44 ~ −27.42 |

| A8 | 334.89 ~ 552.25 | −336.62 ~ −571.5 | −22.87 ~ −14.58 | −25.25 ~ −27.42 |

| A9 | 376.36 ~ 580.81 | −378.09 ~ −600.06 | −23.38 ~ −14.80 | −25.76 ~ −27.64 |

| A10 | 392.04 ~ 600.25 | −393.77 ~ −619.5 | −23.55 ~ −14.94 | −25.93 ~ −27.78 |

| A11 | 345.96 ~ 547.56 | −347.69 ~ −566.81 | −23.01 ~ −14.54 | −25.39 ~ −27.38 |

| A12 | 388.09 ~ 620.01 | −389.82 ~ −639.26 | −23.51 ~ −15.08 | −25.89 ~ −27.92 |

| A13 | 364.81 ~ 635.04 | −366.54 ~ −654.29 | −23.24 ~ −15.18 | −25.62 ~ −28.03 |

| A14 | 357.21 ~ 571.21 | −358.94 ~ −590.46 | −23.15 ~ −14.72 | −25.53 ~ −27.57 |

| A15 | 372.49 ~ 566.44 | −374.22 ~ −585.69 | −23.33 ~ −14.69 | −25.71 ~ −27.53 |

| A16 | 372.49 ~ 566.44 | −374.22 ~ −585.69 | −23.33 ~ −14.69 | −25.71 ~ −27.53 |

| A17 | 372.49 ~ 566.44 | −374.22 ~ −585.69 | −23.33 ~ −14.69 | −25.71 ~ −27.53 |

| A18 | 372.49 ~ 566.44 | −374.22 ~ −585.69 | −23.33 ~ −14.69 | −25.71 ~ −27.53 |

| A19 | 372.49 ~ 566.44 | −374.22 ~ −585.69 | −23.33 ~ −14.69 | −25.71 ~ −27.53 |

| A20 | 372.49 ~ 566.44 | −374.22 ~ −585.69 | −23.33 ~ −14.69 | −25.71 ~ −27.53 |

| Specimen | Reflection Coefficient (R) (dB) | SE Reflection (SEref) (dB) |

|---|---|---|

| Free Air Medium | 2.73 ~ 20.25 | −2.38 ~ −12.84 |

| Code | Parameters | Levels | ||||

|---|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | ||

| A | Graphite nanoplates (wt.%) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 |

| B | Zirconium Oxide (wt.%) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 |

| C | Bamboo Charcoal (wt.%) | 0.5 | 1 | 1.5 | 2 | 2.5 |

| Source | DF | Sum of Squares | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 2.17432 | 0.241591 | 0.78 | 0.644 |

| Linear | 3 | 0.59970 | 0.199900 | 0.64 | 0.605 |

| A | 1 | 0.01921 | 0.019208 | 0.06 | 0.809 |

| B | 1 | 0.13300 | 0.132998 | 0.43 | 0.528 |

| C | 1 | 0.55625 | 0.556249 | 1.79 | 0.211 |

| Square | 3 | 0.63682 | 0.212273 | 0.68 | 0.583 |

| A * A | 1 | 0.18753 | 0.187532 | 0.60 | 0.456 |

| B * B | 1 | 0.06003 | 0.060032 | 0.19 | 0.670 |

| C * C | 1 | 0.55718 | 0.557175 | 1.79 | 0.211 |

| 2-Way Interaction | 3 | 0.62500 | 0.208333 | 0.67 | 0.590 |

| A * B | 1 | 0.12500 | 0.125000 | 0.40 | 0.541 |

| A * C | 1 | 0.00000 | 0.000000 | 0.00 | 1.000 |

| B * C | 1 | 0.50000 | 0.500000 | 1.60 | 0.234 |

| Error | 10 | 3.11568 | 0.311568 | ||

| Lack-of-Fit | 5 | 3.11568 | 0.623136 | * | * |

| Pure Error | 5 | 0.00000 | 0.000000 | ||

| Total | 19 | 5.29000 |

| Specimen | Real Value of EMI (dB) | Statistical Value of EMI (dB) | Residual | Error% |

|---|---|---|---|---|

| A1 | 24.3 | 24.1 | 0.2 | 0.69 |

| A2 | 24.5 | 24.6 | −0.1 | −0.56 |

| A3 | 24.2 | 23.7 | 0.5 | 1.88 |

| A4 | 23.3 | 23.2 | 0.1 | 0.27 |

| A5 | 23.1 | 23.9 | −0.8 | −3.73 |

| A6 | 23.8 | 24.0 | −0.2 | −1.12 |

| A7 | 23.5 | 24.0 | −0.5 | −2.44 |

| A8 | 23.5 | 23.9 | −0.4 | −2.00 |

| A9 | 24.1 | 23.7 | 0.4 | 1.32 |

| A10 | 24.5 | 24.2 | 0.3 | 0.83 |

| A11 | 23.4 | 23.8 | −0.4 | −1.74 |

| A12 | 24.9 | 23.9 | 1.0 | 3.72 |

| A13 | 25.2 | 24.6 | 0.6 | 2.04 |

| A14 | 23.9 | 23.8 | 0.1 | 0.02 |

| A15 | 23.8 | 23.6 | 0.2 | 0.44 |

| A16 | 23.8 | 23.6 | 0.2 | 0.44 |

| A17 | 23.8 | 23.6 | 0.2 | 0.44 |

| A18 | 23.8 | 23.6 | 0.2 | 0.44 |

| A19 | 23.8 | 23.6 | 0.2 | 0.44 |

| A20 | 23.8 | 23.6 | 0.2 | 0.44 |

| Solution | Graphite Nanoplates (wt.%) | Zirconium Oxide (wt.%) | Bamboo Charcoal (wt.%) | EMI SE FIT | Desirability |

|---|---|---|---|---|---|

| 1 | 0.1 | 0.5 | 2.5 | 28.61 | 1 |

| Matrix and Fillers Used | Dominant Mechanism | Frequency Range (GHz) | Thickness (mm) | EMI SE (dB) | Ref. |

|---|---|---|---|---|---|

| PU Foam/0.75 wt.% MWCNT/1.5 wt.% CuO/1.5 wt.% BC | Absorption | 8–12 | 20 | 22.6 | [31] |

| PU Foam/30 wt.% Gr | Absorption | 8–12 | 5 | 44 | [54] |

| Epoxy/1 wt.% MWCNT/5.5 wt.% BC/5.5 wt.% CuO | Absorption | 8–12 | 3 | 24.52 | [55] |

| PU Foam/18.7 wt.% GO | Absorption | 8–12 | 9 | 30–35 | [56] |

| Epoxy/Graphene | Absorption | 8.2–12.4 | 0.8 × 10−6–1.1 × 10−6 | 21 | [57] |

| Fe3O4/GN | Reflection | 8–12 | 0.2–0.25 | 21–24 | [58] |

| Fe3O4/RGO/PEI | Absorption | 8–12 | 2.5 | 14–18 | [59] |

| MWCNT/PC | Absorption | 8–12 | 1.85 | 25 | [60] |

| RGO films | Reflection | 8–12 | 0.0084 | 18–22 | [61] |

| CVD graphene/PDMS | Absorption | 8–12 | 1 | 20 | [62] |

| PU/0.3 wt.% GNP/0.3 wt.% ZrO2/2.5 wt.% BC | Absorption | 8–12 | 20 | 28.03 | Current research |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selvaraj, V.K.; Subramanian, J. A Comparative Study on Bio-Based PU Foam Reinforced with Nanoparticles for EMI-Shielding Applications. Polymers 2022, 14, 3344. https://doi.org/10.3390/polym14163344

Selvaraj VK, Subramanian J. A Comparative Study on Bio-Based PU Foam Reinforced with Nanoparticles for EMI-Shielding Applications. Polymers. 2022; 14(16):3344. https://doi.org/10.3390/polym14163344

Chicago/Turabian StyleSelvaraj, Vinoth Kumar, and Jeyanthi Subramanian. 2022. "A Comparative Study on Bio-Based PU Foam Reinforced with Nanoparticles for EMI-Shielding Applications" Polymers 14, no. 16: 3344. https://doi.org/10.3390/polym14163344

APA StyleSelvaraj, V. K., & Subramanian, J. (2022). A Comparative Study on Bio-Based PU Foam Reinforced with Nanoparticles for EMI-Shielding Applications. Polymers, 14(16), 3344. https://doi.org/10.3390/polym14163344