Evaluation of Fatigue Life of Recycled Opaque PET from Household Milk Bottle Wastes

Abstract

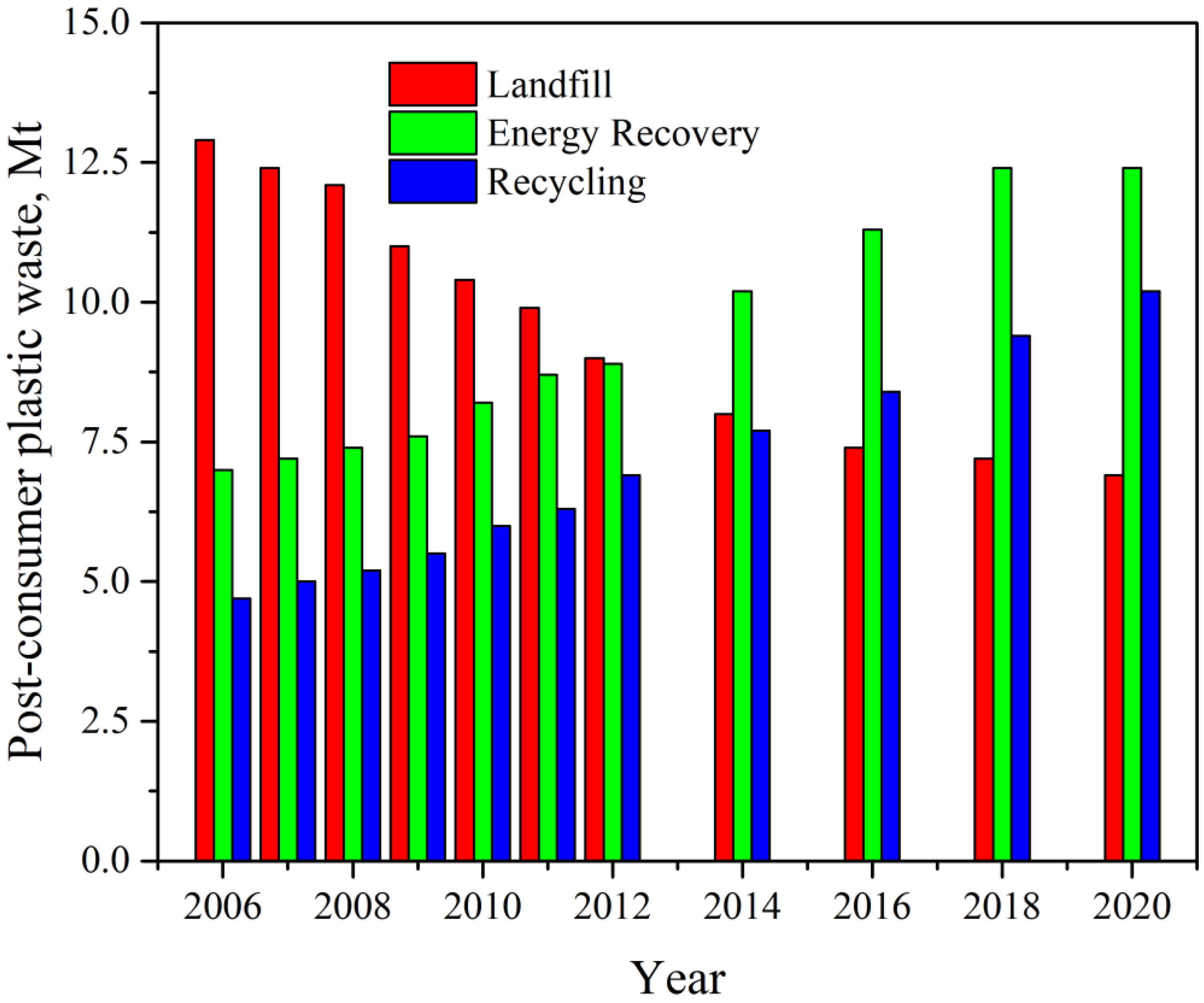

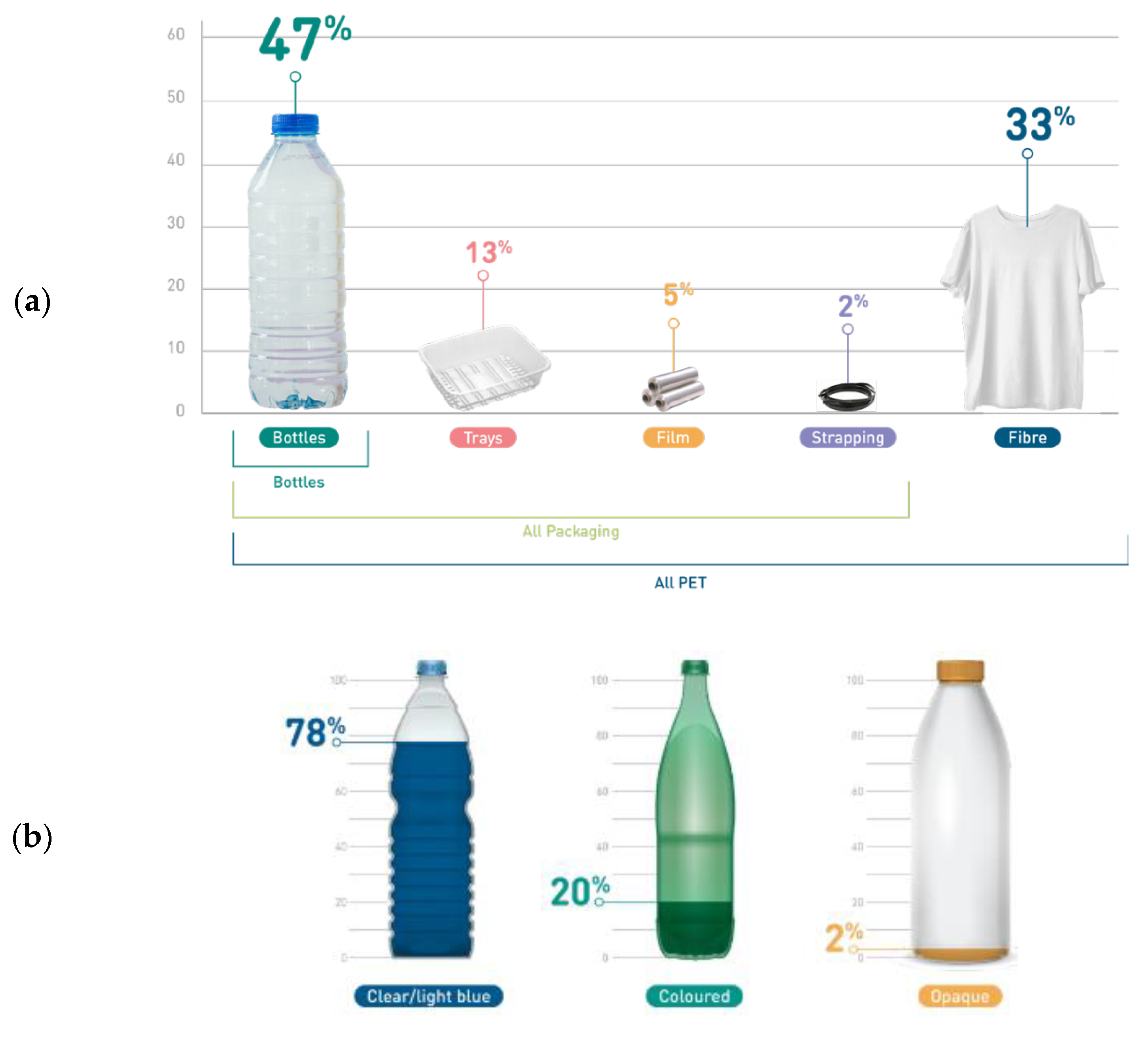

:1. Introduction

2. Materials and Methods

2.1. Materials

- F-r-OPET are the specimens injected directly from flakes;

- r-OPET-hom are made by processing the flakes via extrusion in filament followed by a pelletizing step. An extruder with L/D = 25 (IQAP-LAP E30/25, Masies de Roda, Spain) was employed with four heating zones along the profile of the screw. The temperature profile was set to 175 (hopper zone)/195/225/245 °C (die zone) and a screw rotation speed of 50 rpm. The process was performed in a N2-controlled atmosphere to minimize thermo-oxidative degradation. The r-OPET-hom filament obtained was quenched in room temperature water bath, dried, and then cut into pellets. Then, this material was recrystallized in an oven at 120 °C for 4 h to increase the crystallinity up to 20–30 %. This step results in homogenizing the recycled material. Then, the pellets were injection moulded [27].

- REx-r-OPET are obtained by processing the previous pellets by reactive extrusion with the addition of a styrene-acrylic multi-functional epoxide oligomer commercially available by BASF (Ludwigshafen, Germany) under the brand name Joncryl ADR-4400. The reactive extrusion of REx-r-OPET was performed using a corotating twin-screw extruder with L/D = 36 (KNETER-25X24D, Collin GmbH, Maitenbeth, Germany). As a reactive (chain extender) reagent, a multifunctional epoxide agent with an epoxy equivalent weight of 485 g.mol−1 and functionality of 14 was added (1 wt%). The temperature profile of the extruder was set to 175 (hopper zone)/215/230/235/240/245/245 °C (die zone), and the screw speed was 40 rpm, leading to residence times of 4.1 min. The process was performed in vacuum to avoid further degradation. Then, the REx-r-OPET product was water-cooled, dried, and pelletized, after which the acquired material was once again recrystallized at 120 °C for 4 h. This step was done by Centre Català del Plàstic—Universitat Politècnica de Catalunya Barcelona Tech (EEBE-UPC)-ePLASCOM Research Group, Barcelona, Spain. The process of reactive extrusion is described in Candal et al. [27];

- v-PET is a virgin PET supplied by Novapet (Zaragoza, Spain). Contrary to recycled opaque PET, virgin PET does not contain TiO2 particles.

2.2. Methods

2.2.1. Tensile Test

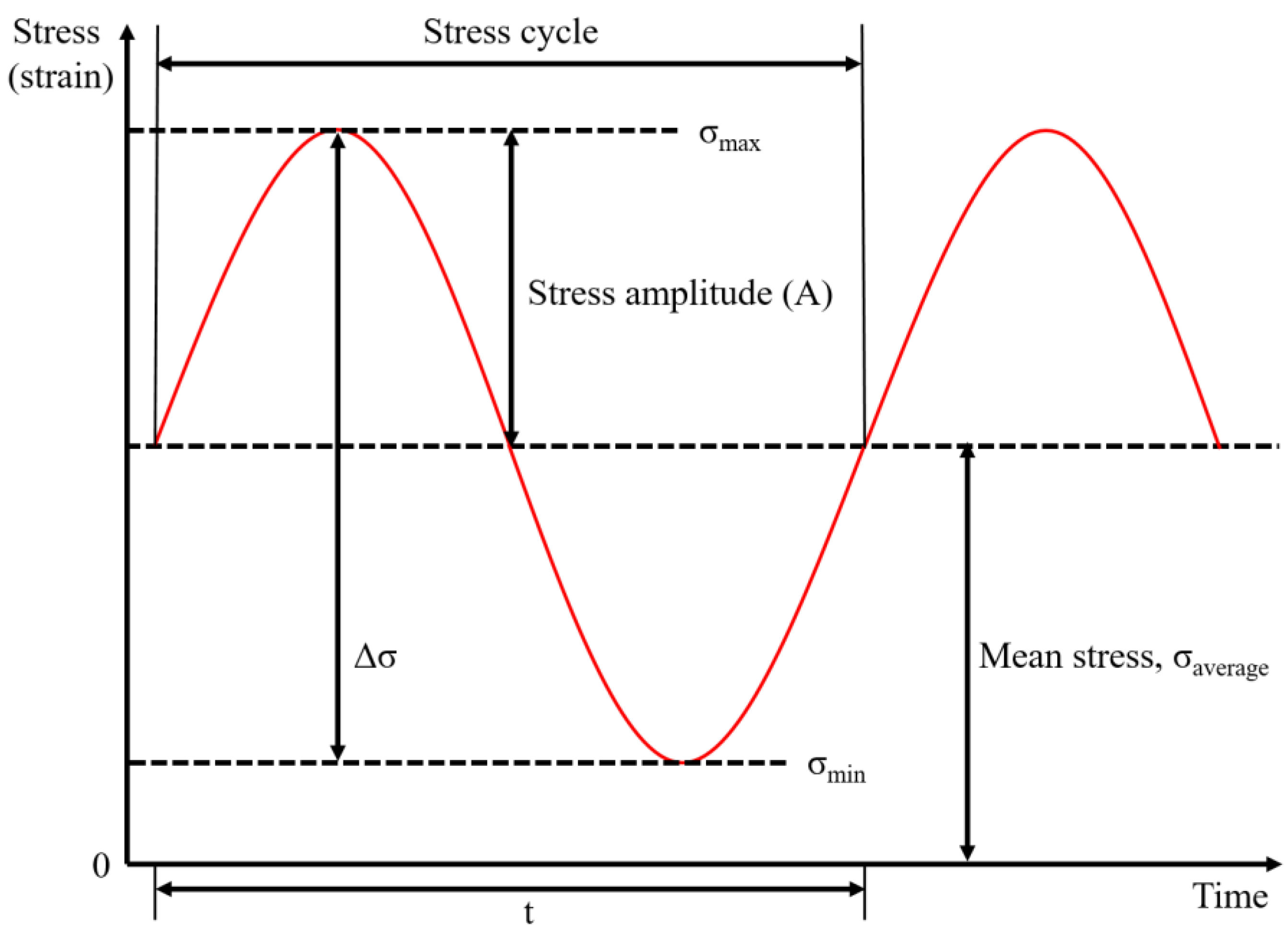

2.2.2. Fatigue Test

2.2.3. Digital Image Correlation

2.2.4. Backscattered Scanning Electron Microscopy

3. Results and Discussion

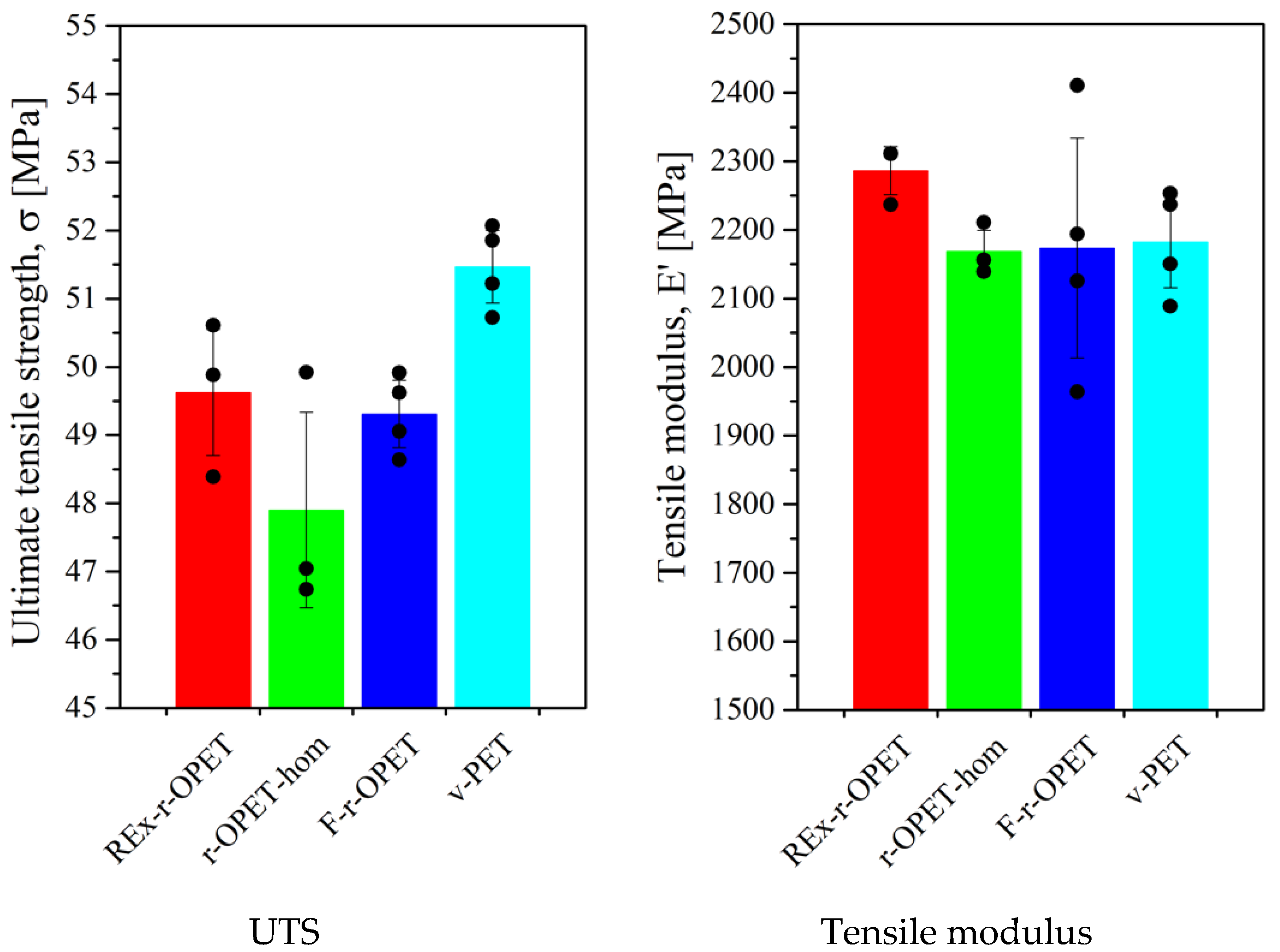

3.1. Tensile Properties

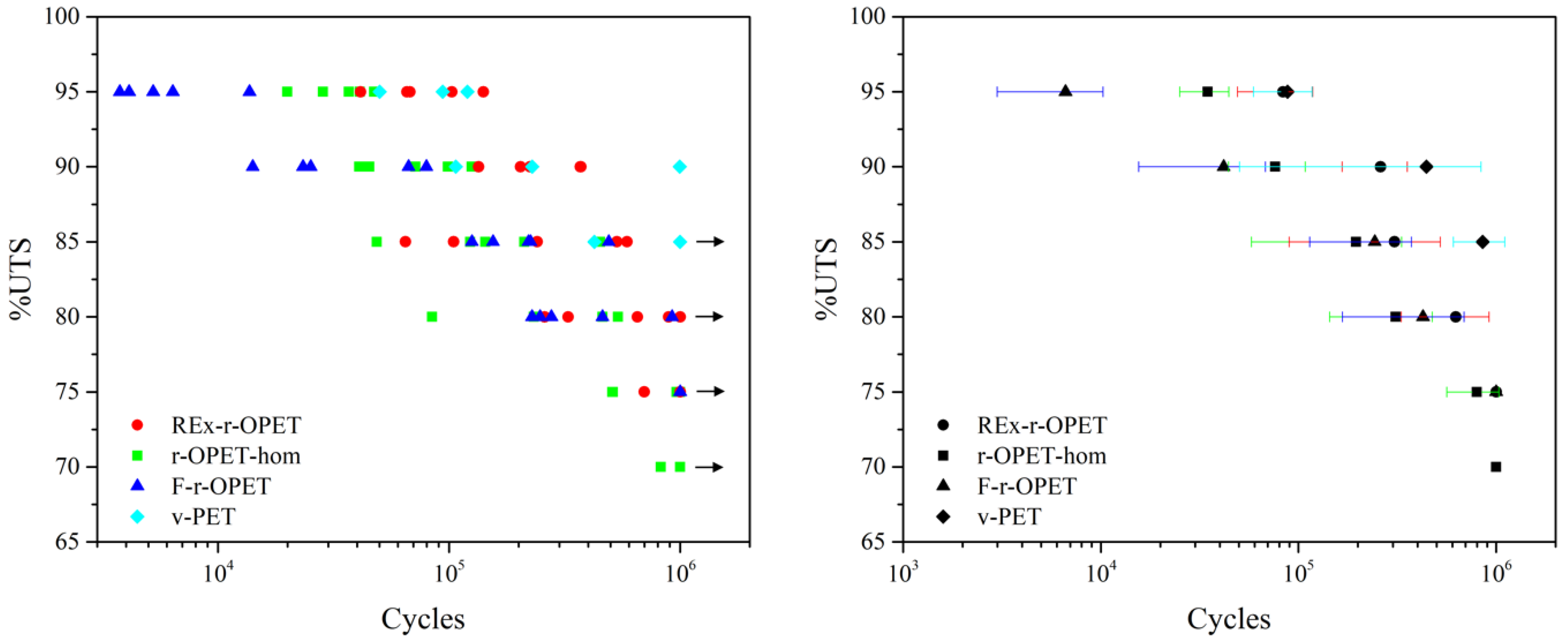

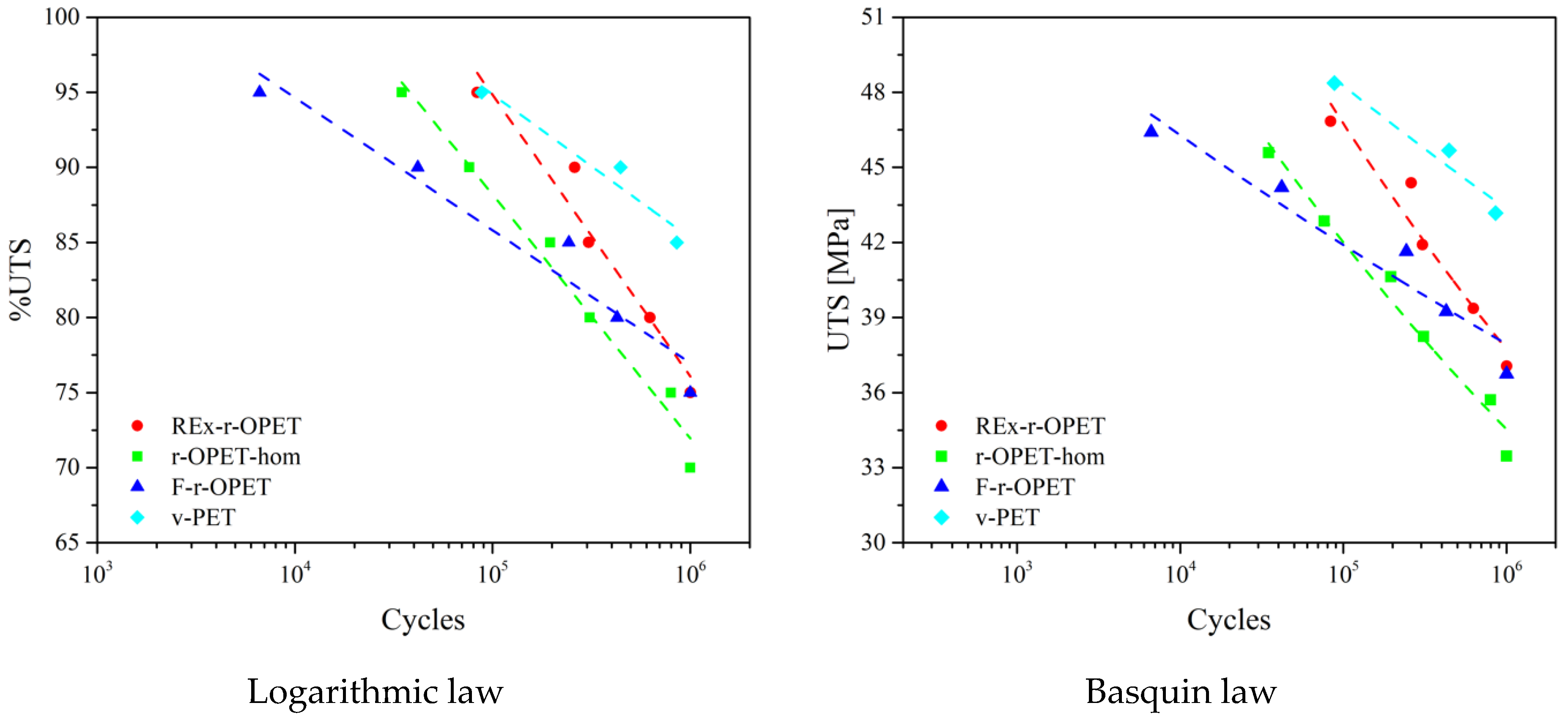

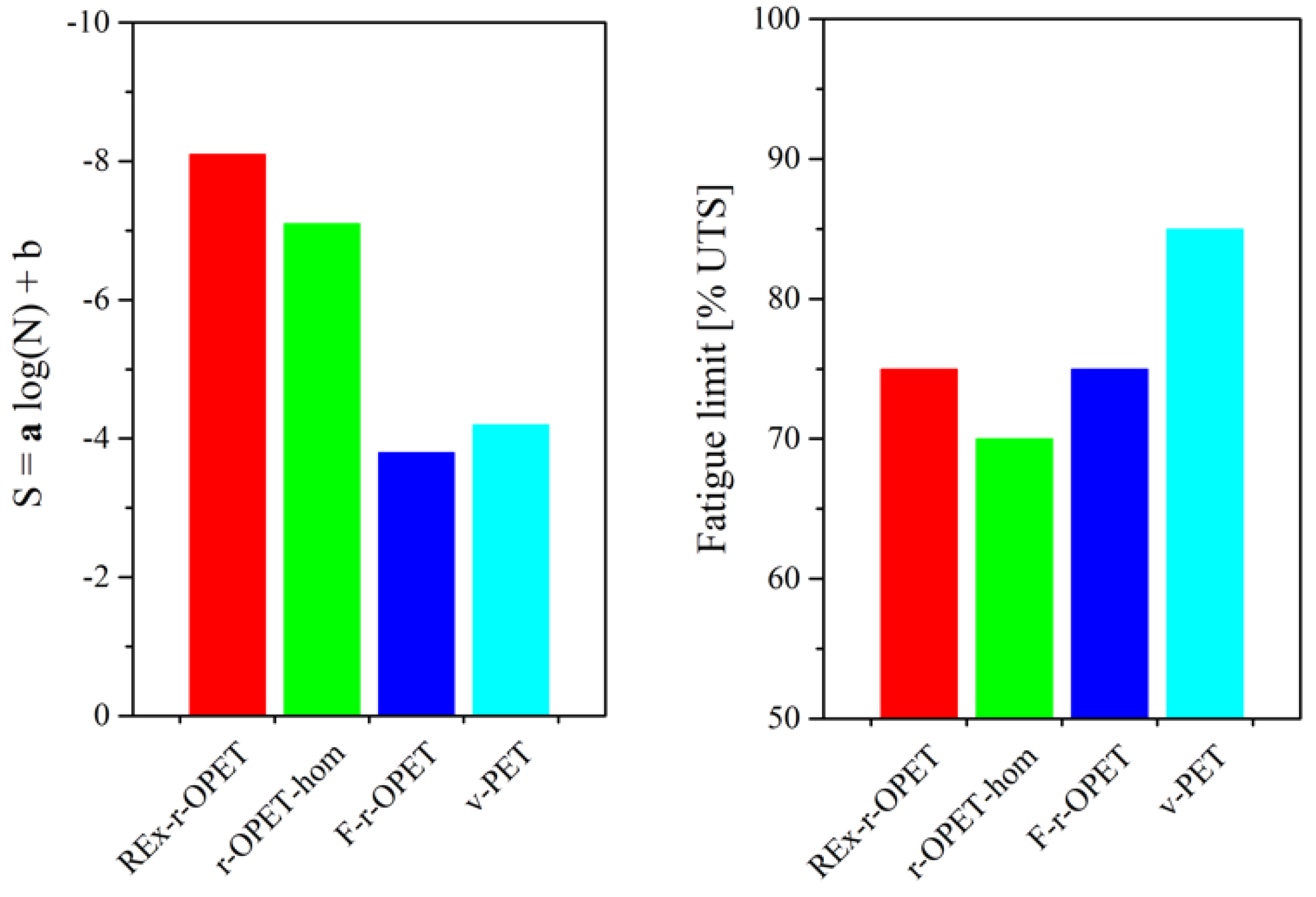

3.2. Fatigue Properties

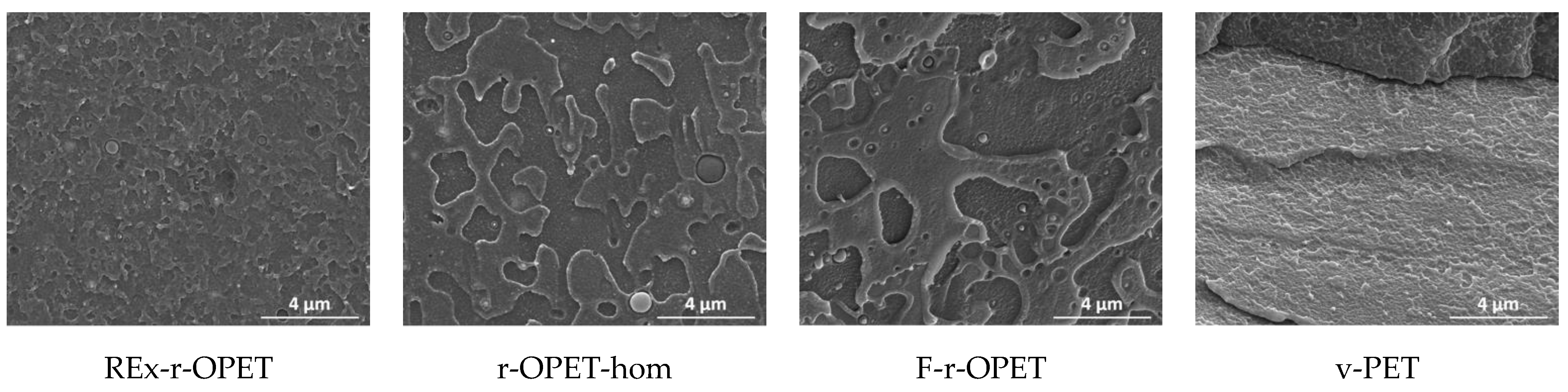

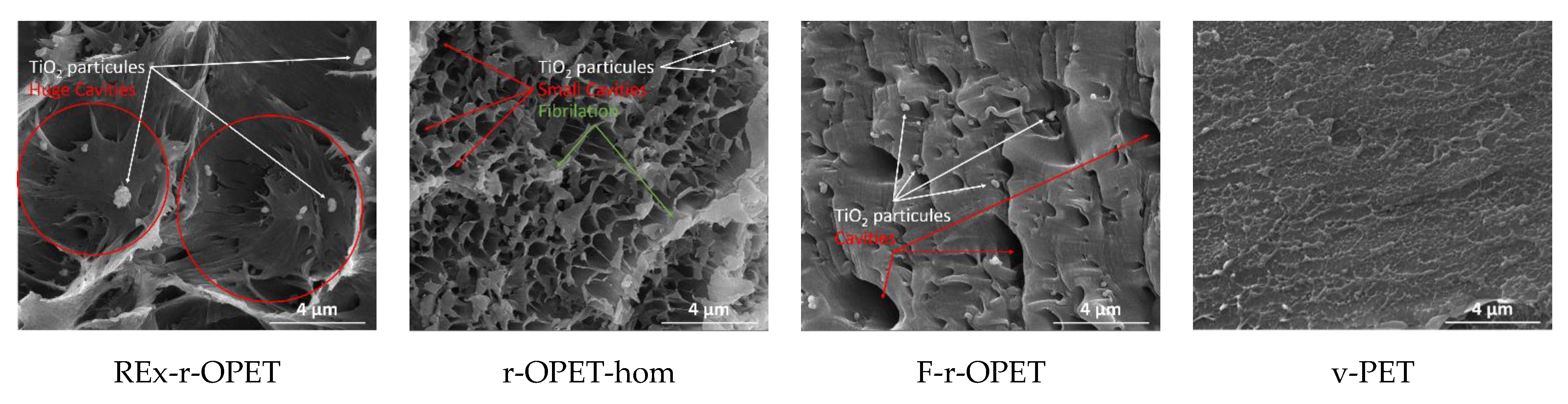

3.3. Fractography in Failure Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Plastics Europe. Plastics—The Facts an Analysis of European Plastics Production, Demand and Waste Data; Plastics Europe: Brussels, Belgium, 2021. [Google Scholar]

- Abelvik-Lawson, H. Why is There so Much Plastic in the Ocean? Greenpeace, Canonbury Villas: London, UK, 2020. [Google Scholar]

- Lonca, G.; Lesage, P.; Majeau-Bettez, G.; Bernard, S.; Margni, M. Assessing scaling effects of circular economy strategies: A case study on plastic bottle closed-loop recycling in the USA PET market. Resour. Conserv. Recycl. 2020, 162, 105013. [Google Scholar] [CrossRef]

- Meys, R.; Frick, F.; Westhues, S.; Sternberg, A.; Klankermayer, J.; Bardow, A. Towards a circular economy for plastic packaging wastes—The environmental potential of chemical recycling. Resour. Conserv. Recycl. 2020, 162, 105010. [Google Scholar] [CrossRef]

- Nisticò, R. Polyethylene terephthalate (PET) in the packaging industry. Polym. Test. 2020, 90, 106707. [Google Scholar] [CrossRef]

- Provin, A.P.; de Aguiar Dutra, A.R.; de Sousa e Silva Gouveia, I.C.A.; Cubas, A.L.V. Circular economy for fashion industry: Use of waste from the food industry for the production of biotextiles. Technol. Forecast. Soc. Chang. 2021, 169, 120858. [Google Scholar] [CrossRef]

- Welle, F. Twenty years of PET bottle to bottle recycling—An overview. Resour. Conserv. Recycl. 2011, 55, 865–875. [Google Scholar] [CrossRef]

- Karaman, A.D.; Ozer, B.; Pascall, M.A.; Alvarez, V. Recent Advances in Dairy Packaging. Food Rev. Int. 2015, 31, 295–318. [Google Scholar] [CrossRef]

- Mestdagh, F.; De Meulenaer, B.; De Clippeleer, J.; Devlieghere, F.; Huyghebaert, A. Protective Influence of Several Packaging Materials on Light Oxidation of Milk. J. Dairy Sci. 2005, 88, 499–510. [Google Scholar] [CrossRef]

- Tramis, O.; Garnier, C.; Yus, C.; Irusta, S.; Chabert, F. Enhancement of the fatigue life of recycled PP by incorporation of recycled opaque PET collected from household milk bottle wastes. Waste Manag. 2021, 125, 49–57. [Google Scholar] [CrossRef]

- Matxinandiarena, E.; Múgica, A.; Zubitur, M.; Yus, C.; Sebastián, V.; Irusta, S.; Loaeza, A.D.; Santana, O.; Maspoch, M.L.; Puig, C.; et al. The Effect of Titanium Dioxide Surface Modification on the Dispersion, Morphology, and Mechanical Properties of Recycled PP/PET/TiO2 PBNANOs. Polymers 2019, 11, 1692. [Google Scholar] [CrossRef]

- Grant, A.; Lahme, V.; Connock, T.; Lugal, L. How Circular is PET? A report on the circularity of PET bottles, using Europe as a case study; Zero Waste Europe: Brussels, Belgium, 2022. [Google Scholar]

- Cotrep. The Impact of the Increase in White Opaque PET on the Recycling of PET Packaging; Cotrep: Paris, France, 2013. [Google Scholar]

- Cotrep. Impact of the Increase in Opaque PET Packaging on the Recycling of Coloured PET Packaging; Cotrep: Paris, France, 2015. [Google Scholar]

- Wu, H.; Lv, S.; He, Y.; Qu, J.-P. The study of the thermomechanical degradation and mechanical properties of PET recycled by industrial-scale elongational processing. Polym. Test. 2019, 77, 105882. [Google Scholar] [CrossRef]

- Ügdüler, S.; Van Geem, K.M.; Denolf, R.; Roosen, M.; Mys, N.; Ragaert, K.; De Meester, S. Towards closed-loop recycling of multilayer and coloured PET plastic waste by alkaline hydrolysis. Green Chem. 2020, 22, 5376–5394. [Google Scholar] [CrossRef]

- Spychaj, T. Chemical recycling of PET: Methods and products. In Handbook of Thermoplastic Polyesters: Homopolymers, Copolymers, Blends, and Composites; Fakirov, S., Ed.; Wiley-VCH Verlag: Weinheim, Germany, 2002; pp. 1252–1290. [Google Scholar]

- Schijve, J. Fatigue of structures and materials in the 20th century and the state of the art. Int. J. Fatigue 2003, 25, 679–702. [Google Scholar] [CrossRef]

- Lesser, A.J. Fatigue Behavior of Polymers. In Encyclopedia of Polymer Science and Technology; American Cancer Society: New York, NY, USA, 2002. [Google Scholar]

- Lesser, A.J. Changes in mechanical behavior during fatigue of semicrystalline thermoplastics. J. Appl. Polym. Sci. 1995, 58, 869–879. [Google Scholar] [CrossRef]

- Janssen, R.P.M.; Govaert, L.E.; Meijer, H.E.H. An Analytical Method to Predict Fatigue Life of Thermoplastics in Uniaxial Loading: Sensitivity to Wave Type, Frequency, and Stress Amplitude. Macromolecules 2008, 41, 2531–2540. [Google Scholar] [CrossRef]

- Mellott, S.R.; Fatemi, A. Fatigue behavior and modeling of thermoplastics including temperature and mean stress effects. Polym. Eng. Sci. 2013, 54, 725–738. [Google Scholar] [CrossRef]

- Elamri, A.; Lallam, A.; Harzallah, O.; Bencheikh, L. Mechanical characterization of melt spun fibers from recycled and virgin PET blends. J. Mater. Sci. 2007, 42, 8271–8278. [Google Scholar] [CrossRef]

- Sauer, J.A.; Richardson, G.C. Fatigue of polymers. Int. J. Fract. 1980, 16, 499–532. [Google Scholar] [CrossRef]

- Kim, Y.J.; You, H.; Kim, S.J.; Yun, G.J. Effects of porosity on the fatigue life of polyamide 12 considering crack initiation and propagation. Adv. Compos. Mater. 2020, 29, 399–421. [Google Scholar] [CrossRef]

- Khan, Z. Fracture Surface Analysis in HDPE Pipe Material Fatigued at Different Temperatures and Loading Frequencies. J. Mater. Eng. Perform. 2011, 21, 1468–1473. [Google Scholar] [CrossRef]

- Candal, M.V.; Safari, M.; Fernández, M.; Otaegi, I.; Múgica, A.; Zubitur, M.; Gerrica-Echevarria, G.; Sebastián, V.; Irusta, S.; Loaeza, D.; et al. Structure and Properties of Reactively Extruded Opaque Post-Consumer Recycled PET. Polymers 2021, 13, 3531. [Google Scholar] [CrossRef]

- Basquin, O.H. The exponential law of endurance tests. In Proceedings of the American Society for Testing and Materials; ASTM International: West Conshocken, PA, USA, 1910; pp. 625–630. [Google Scholar]

- Raffa, P.; Coltelli, M.-B.; Savi, S.; Bianchi, S.; Castelvetro, V. Chain extension and branching of poly(ethylene terephthalate) (PET) with di- and multifunctional epoxy or isocyanate additives: An experimental and modelling study. React. Funct. Polym. 2012, 72, 50–60. [Google Scholar] [CrossRef]

- Duarte, I.S.; Tavares, A.A.; Lima, P.S.; Andrade, D.L.; Carvalho, L.H.; Canedo, E.L.; Silva, S.M. Chain extension of virgin and recycled poly(ethylene terephthalate): Effect of processing conditions and reprocessing. Polym. Degrad. Stab. 2016, 124, 26–34. [Google Scholar] [CrossRef]

- Tavares, A.A.; Silva, D.F.; Lima, P.S.; Andrade, D.L.; Silva, S.M.; Canedo, E.L. Chain extension of virgin and recycled polyethylene terephthalate. Polym. Test. 2016, 50, 26–32. [Google Scholar] [CrossRef]

- Cerpentier, R.R.J.; van Vliet, T.; Pastukhow, V.; van Drongelen, M.; Boerakker, M.J.; Tervoort, T.A.; Govaert, L.E. Fatigue-crack propagation of high-density polyethylene homopolymers: Influence of molecular weight distribution and temperature. Macromolecules 2021, 54, 11508–11521. [Google Scholar] [CrossRef]

| Sample | UTS (MPa) | Tensile Modulus (MPa) | ||

|---|---|---|---|---|

| REx-r-OPET | 49.6 | ±0.9 | 2286 | ±35 |

| r-OPET-hom | 47.9 | ±1.4 | 2169 | ±31 |

| F-r-OPET | 49.3 | ±0.5 | 2173 | ±160 |

| v-PET | 51.5 | ±0.5 | 2182 | ±67 |

| Sample | Logarithmic Law | Basquin Law |

|---|---|---|

| REx-r-OPET | S = −8.1 log(N) + 189, R2 = 0.95 | σα = 140.8(Nr)−0.096, R2 = 0.94 |

| r-OPET-hom | S = −7.1 log(N) + 169, R2 = 0.98 | σα = 114.0(Nr)−0.087, R2 = 0.97 |

| F-r-OPET | S = −3.8 log(N) + 130, R2 = 0.94 | σα = 70.0(Nr)−0.045, R2 = 0.93 |

| v-PET | S = −4.2 log(N) + 143, R2 = 0.94 | σα = 83.2(Nr)−0.047, R2 = 0.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korycki, A.; Garnier, C.; Irusta, S.; Chabert, F. Evaluation of Fatigue Life of Recycled Opaque PET from Household Milk Bottle Wastes. Polymers 2022, 14, 3466. https://doi.org/10.3390/polym14173466

Korycki A, Garnier C, Irusta S, Chabert F. Evaluation of Fatigue Life of Recycled Opaque PET from Household Milk Bottle Wastes. Polymers. 2022; 14(17):3466. https://doi.org/10.3390/polym14173466

Chicago/Turabian StyleKorycki, Adrian, Christian Garnier, Silvia Irusta, and France Chabert. 2022. "Evaluation of Fatigue Life of Recycled Opaque PET from Household Milk Bottle Wastes" Polymers 14, no. 17: 3466. https://doi.org/10.3390/polym14173466

APA StyleKorycki, A., Garnier, C., Irusta, S., & Chabert, F. (2022). Evaluation of Fatigue Life of Recycled Opaque PET from Household Milk Bottle Wastes. Polymers, 14(17), 3466. https://doi.org/10.3390/polym14173466