Mechanical Response of Carbon Composite Octet Truss Structures Produced via Axial Lattice Extrusion

Abstract

:1. Introduction

2. Materials and Methods

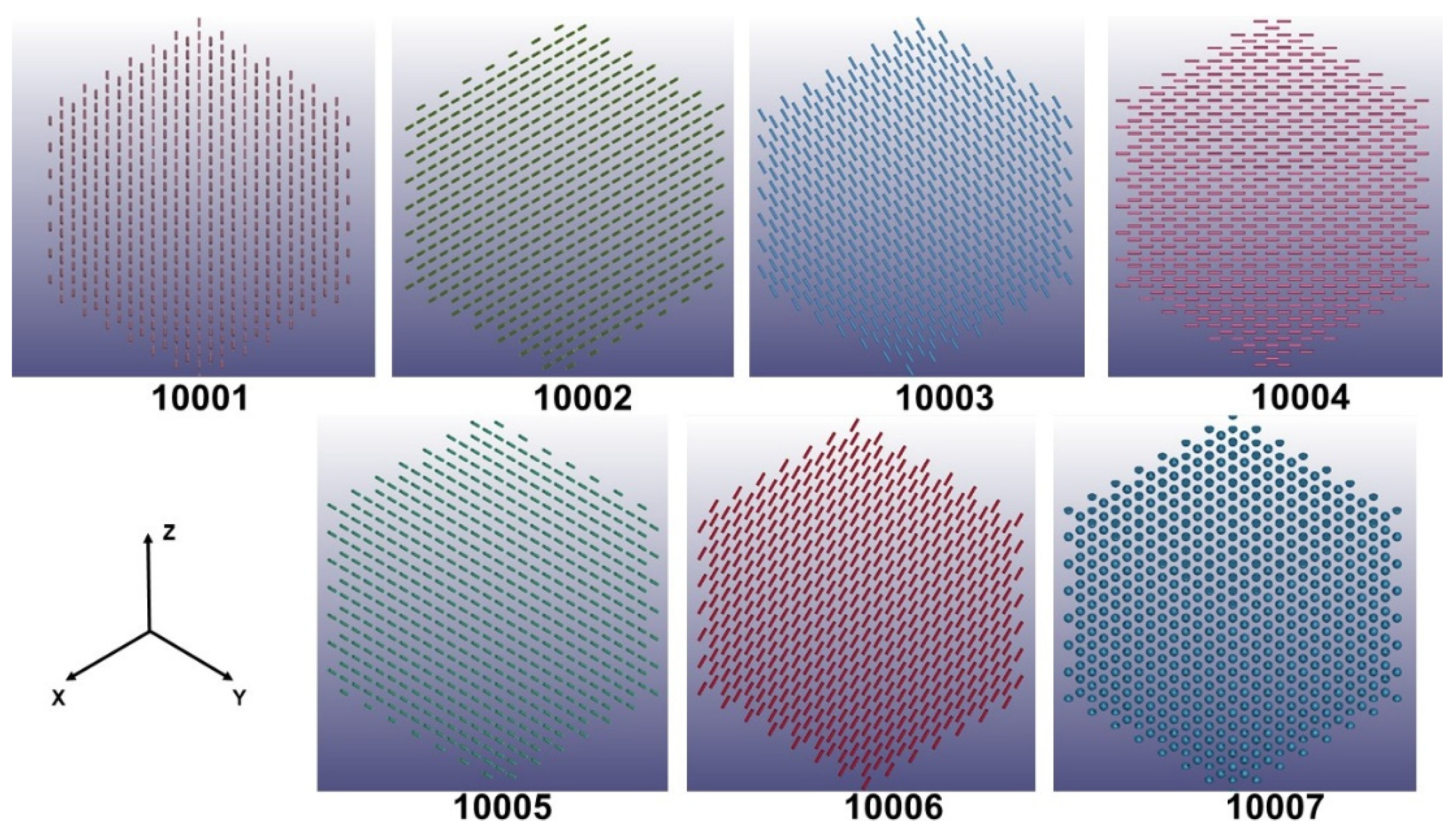

2.1. Numerical Simulation

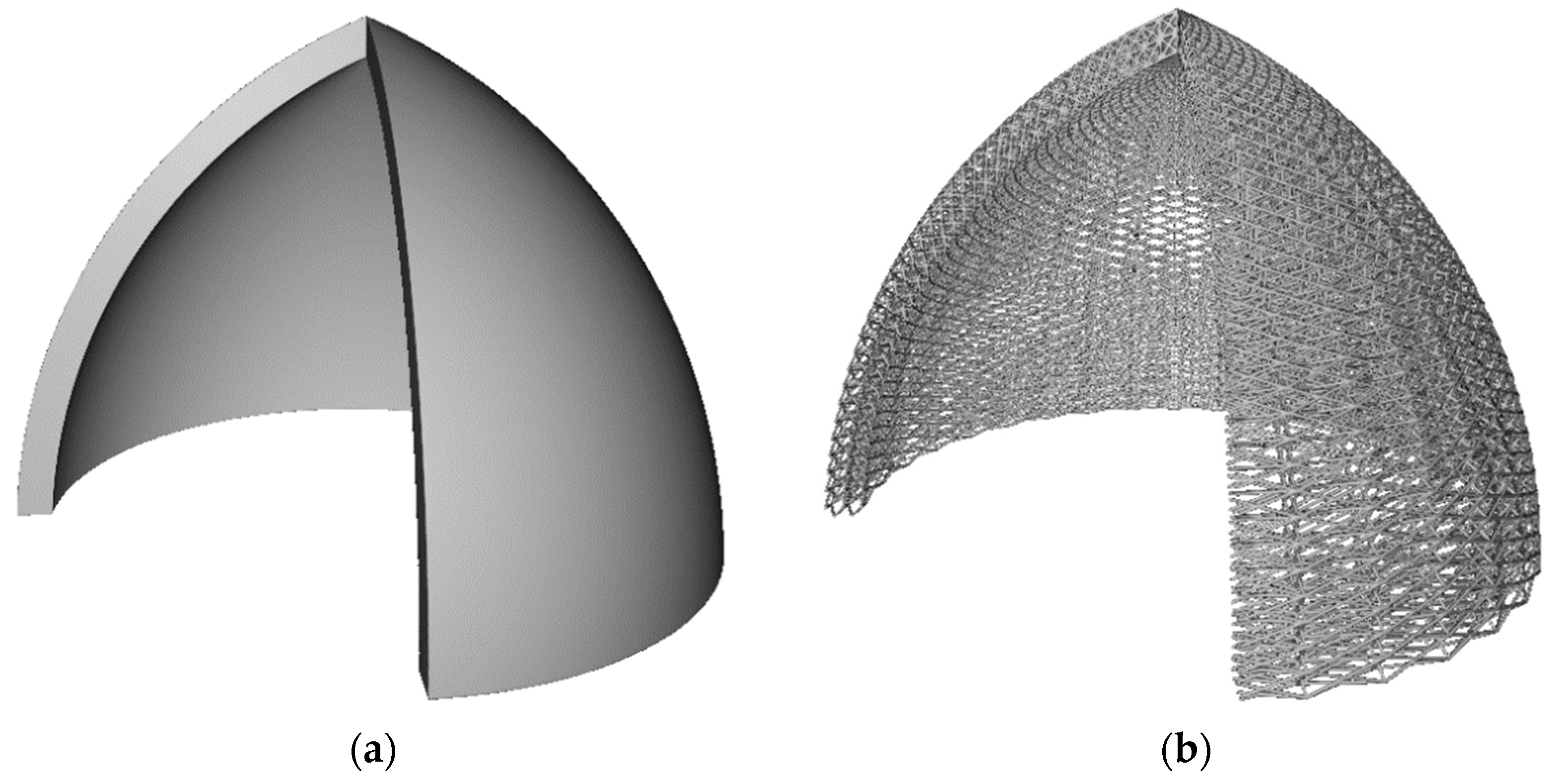

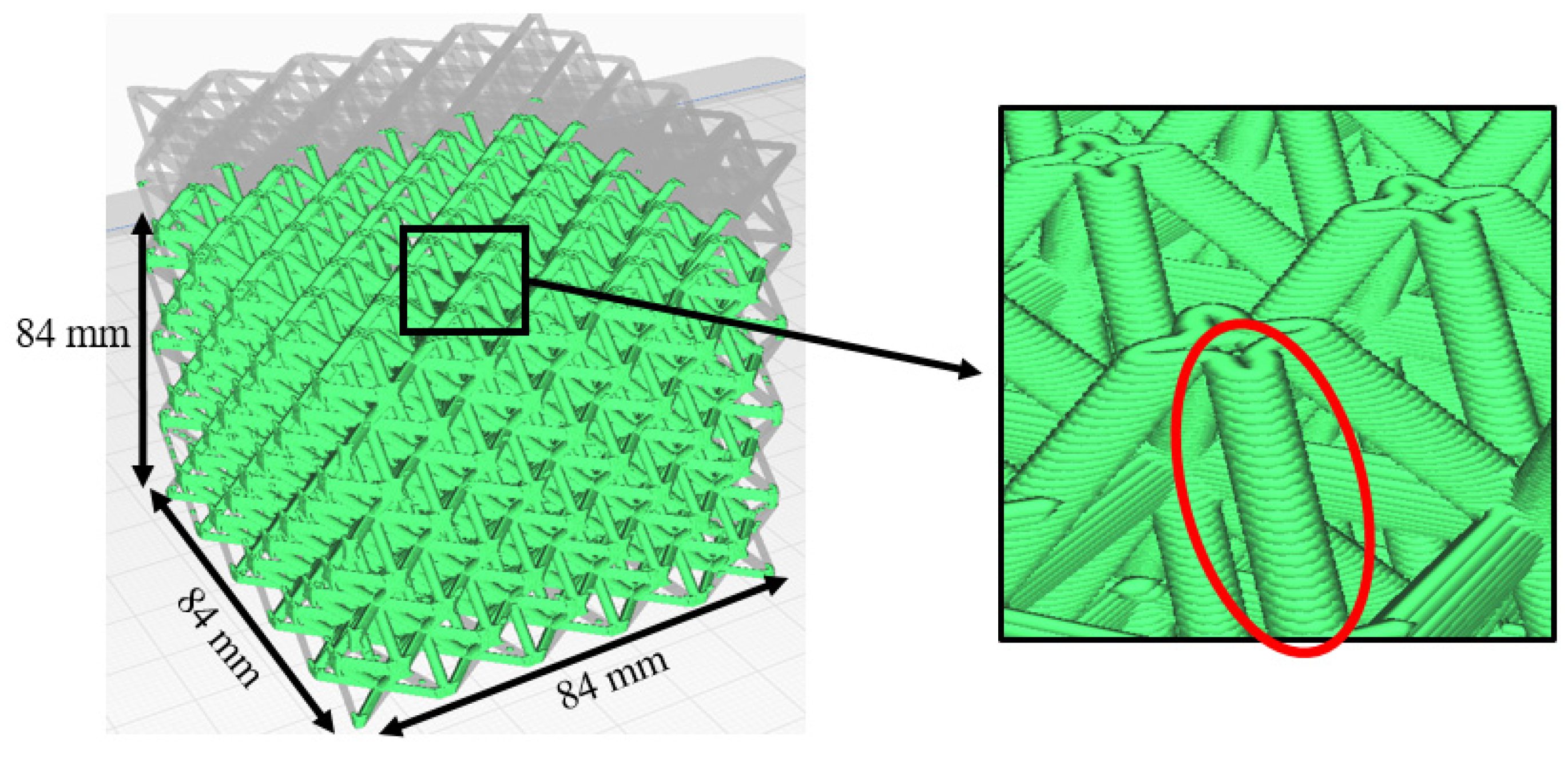

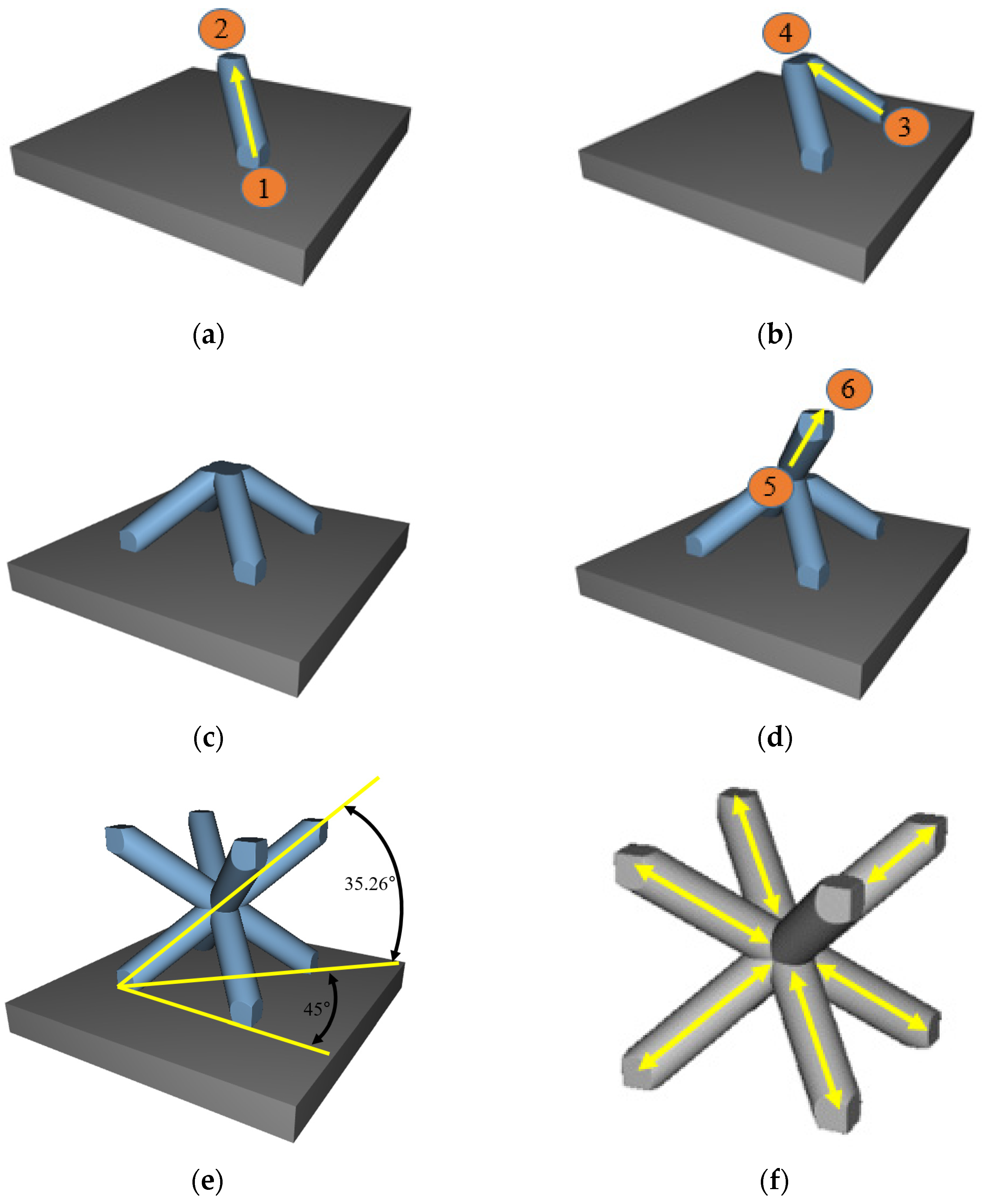

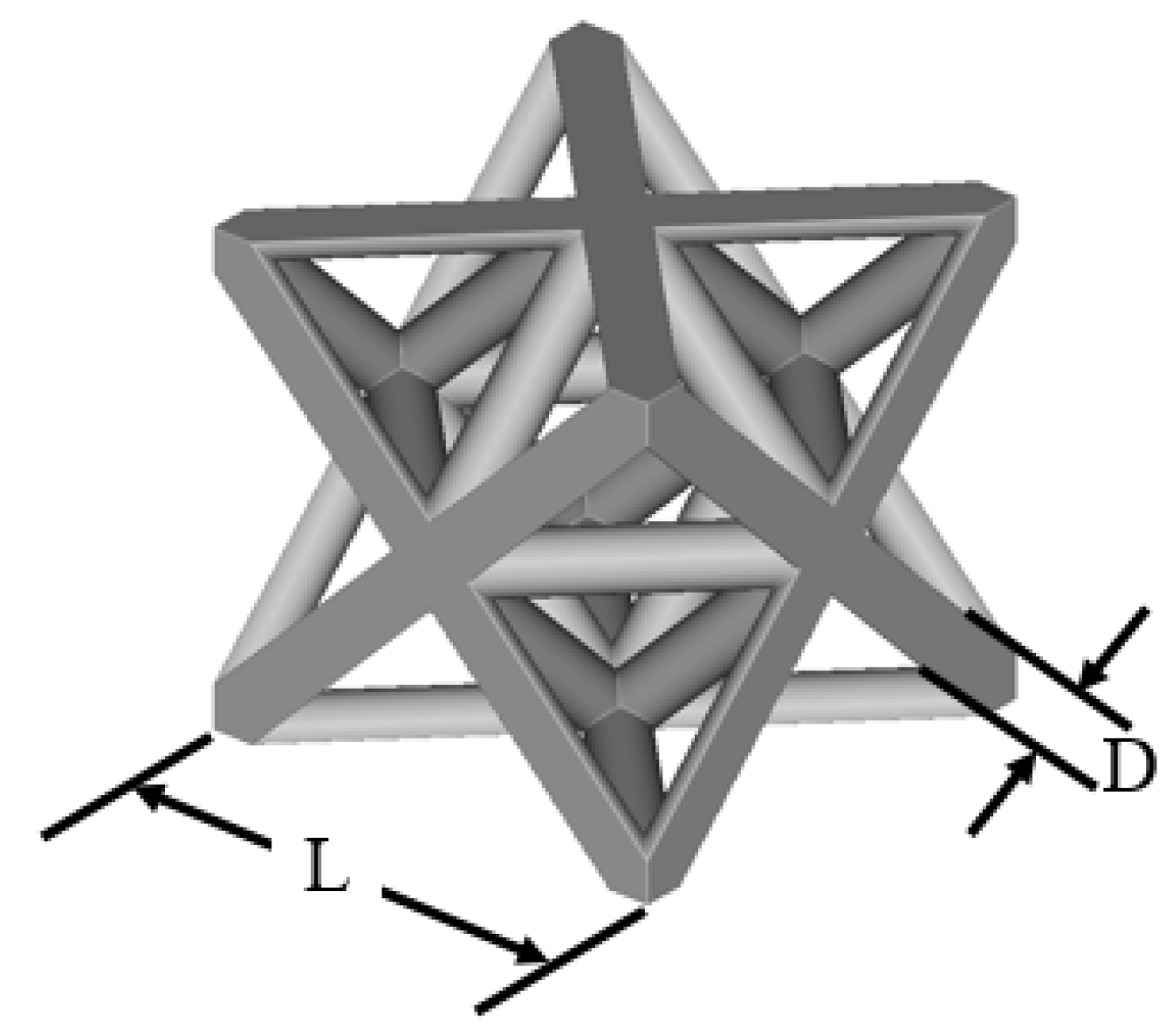

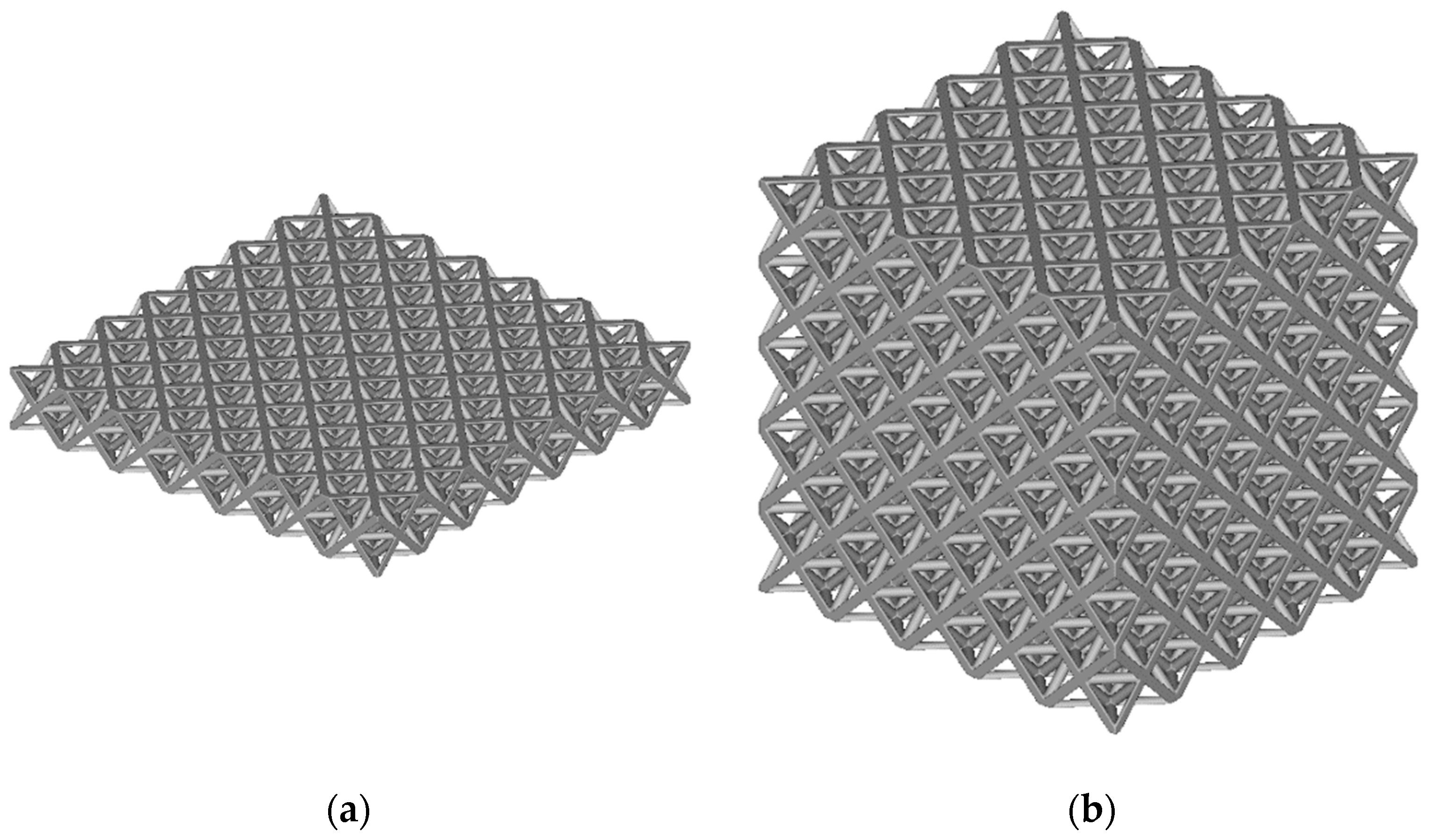

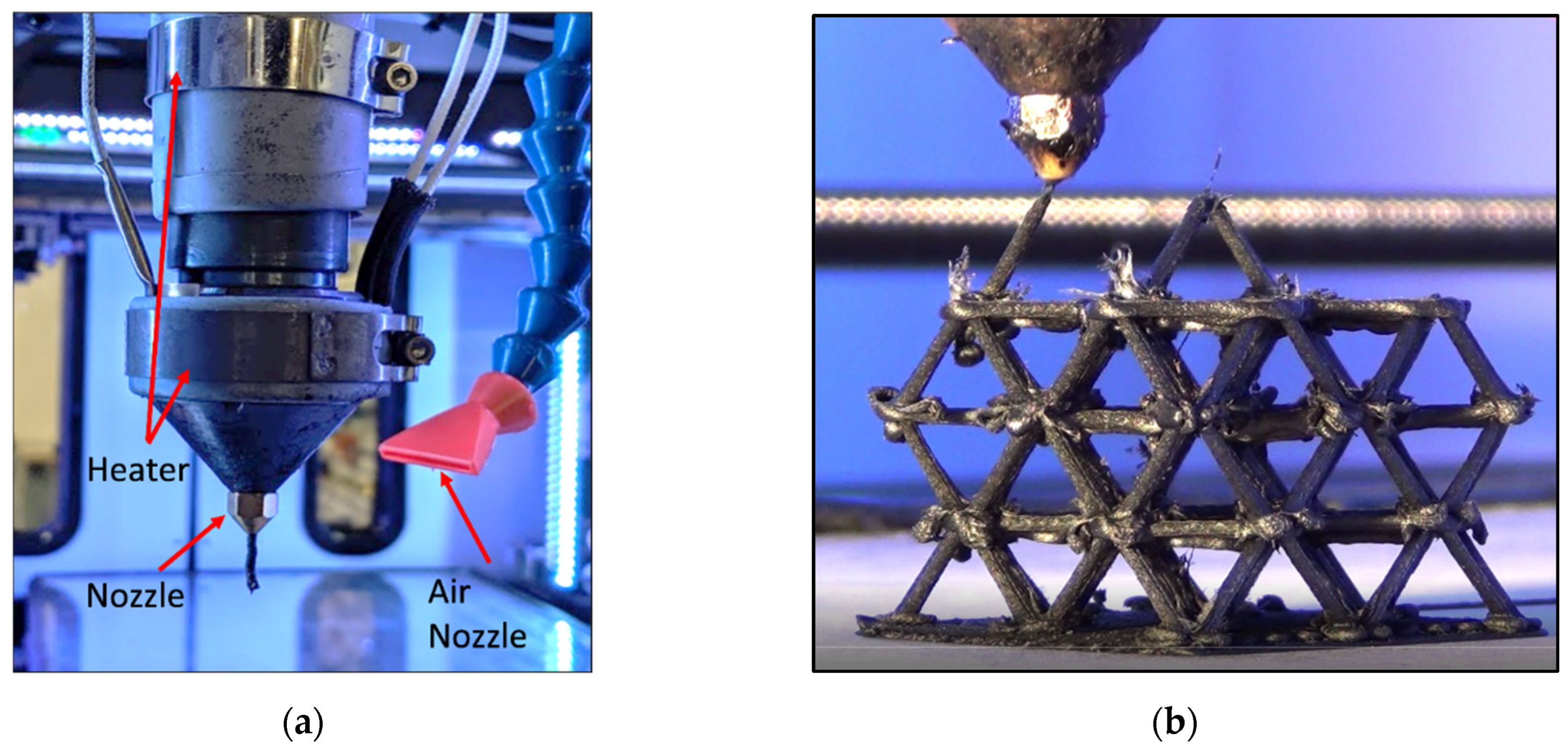

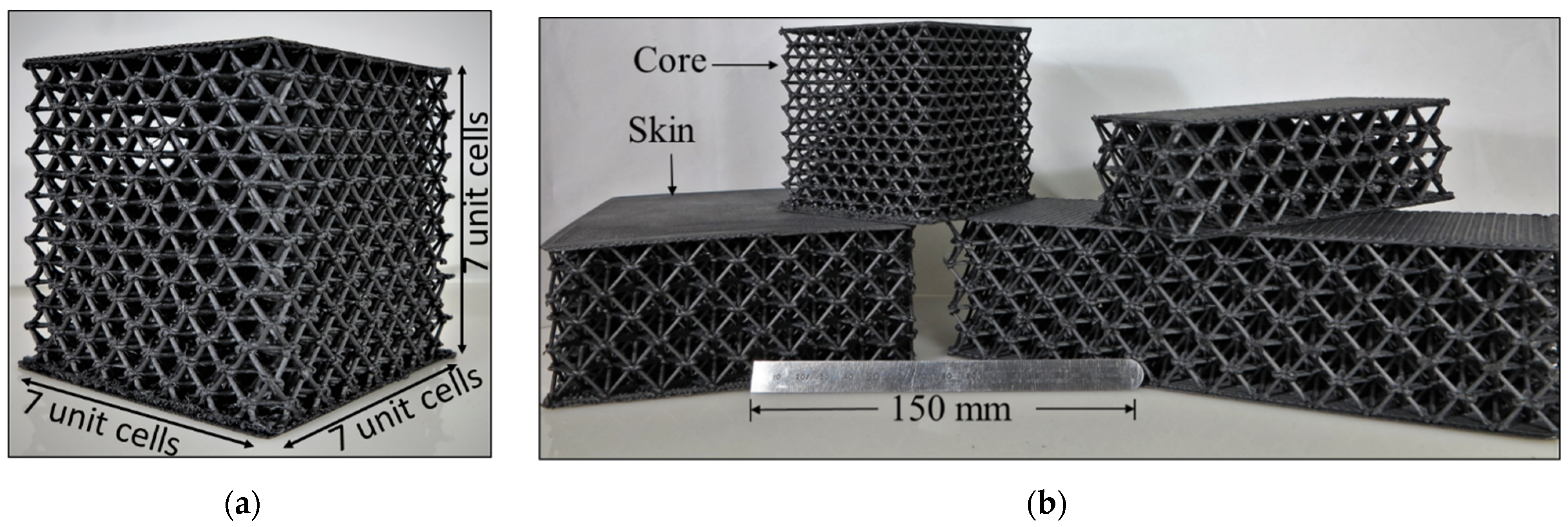

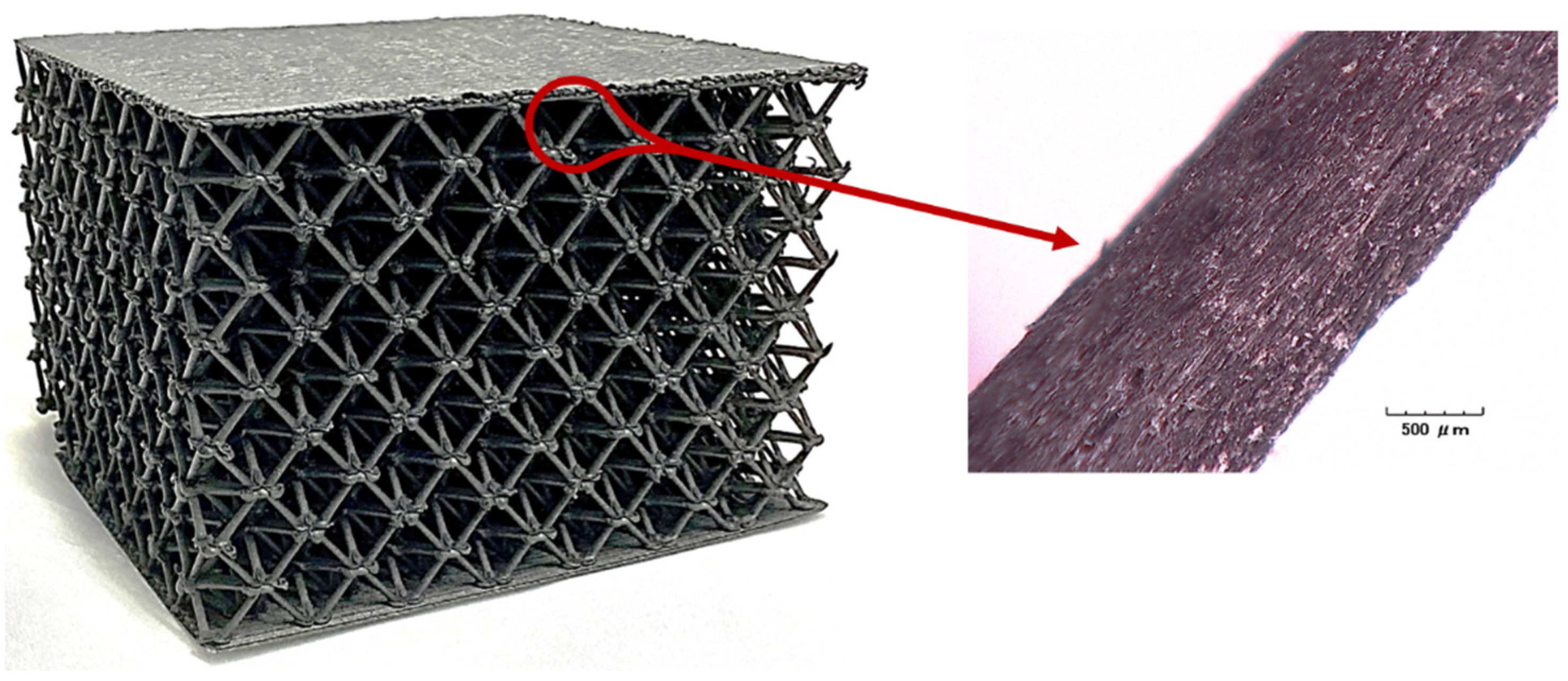

2.2. Component Fabrication

2.3. Mechanical Testing

3. Results

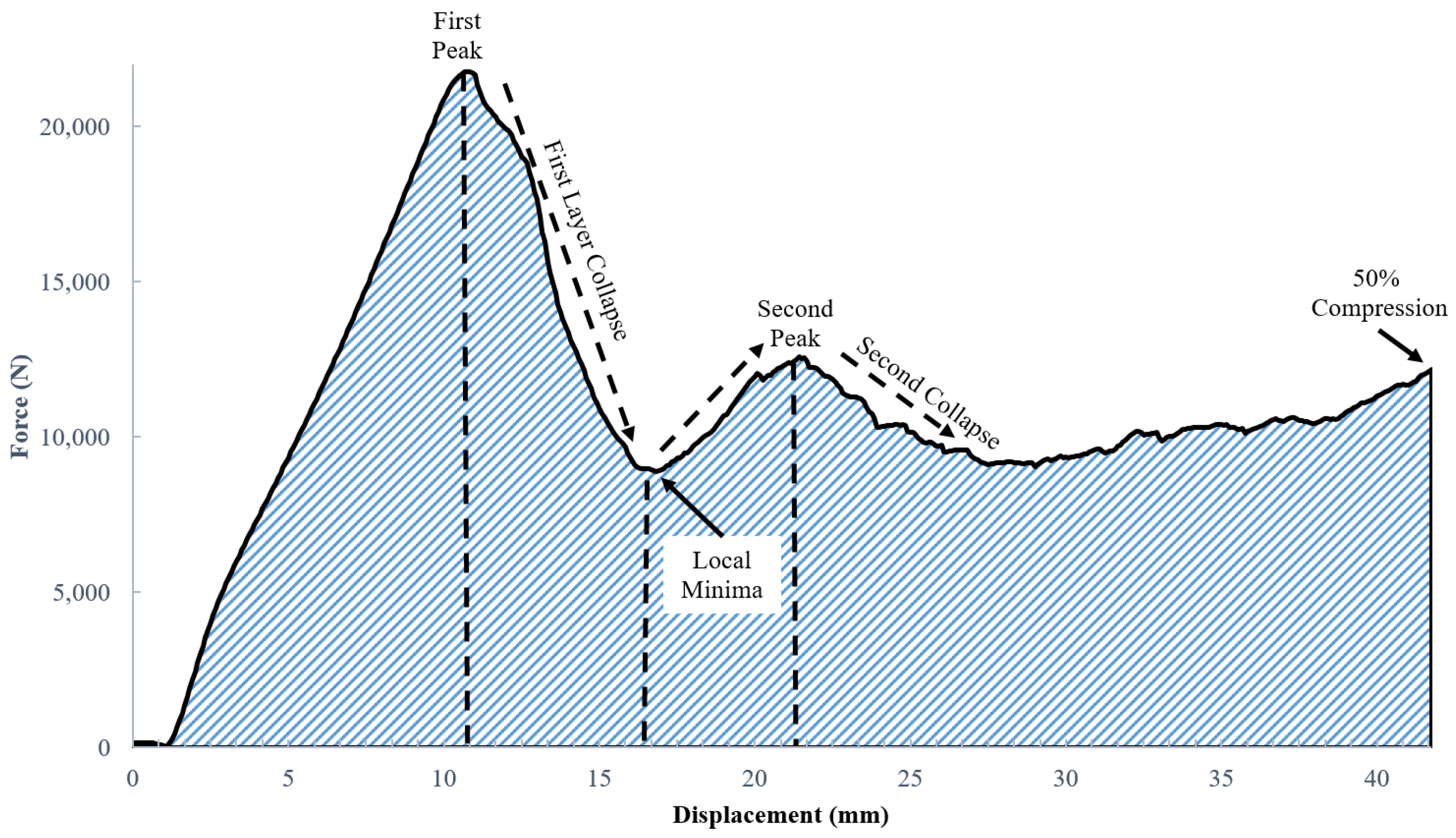

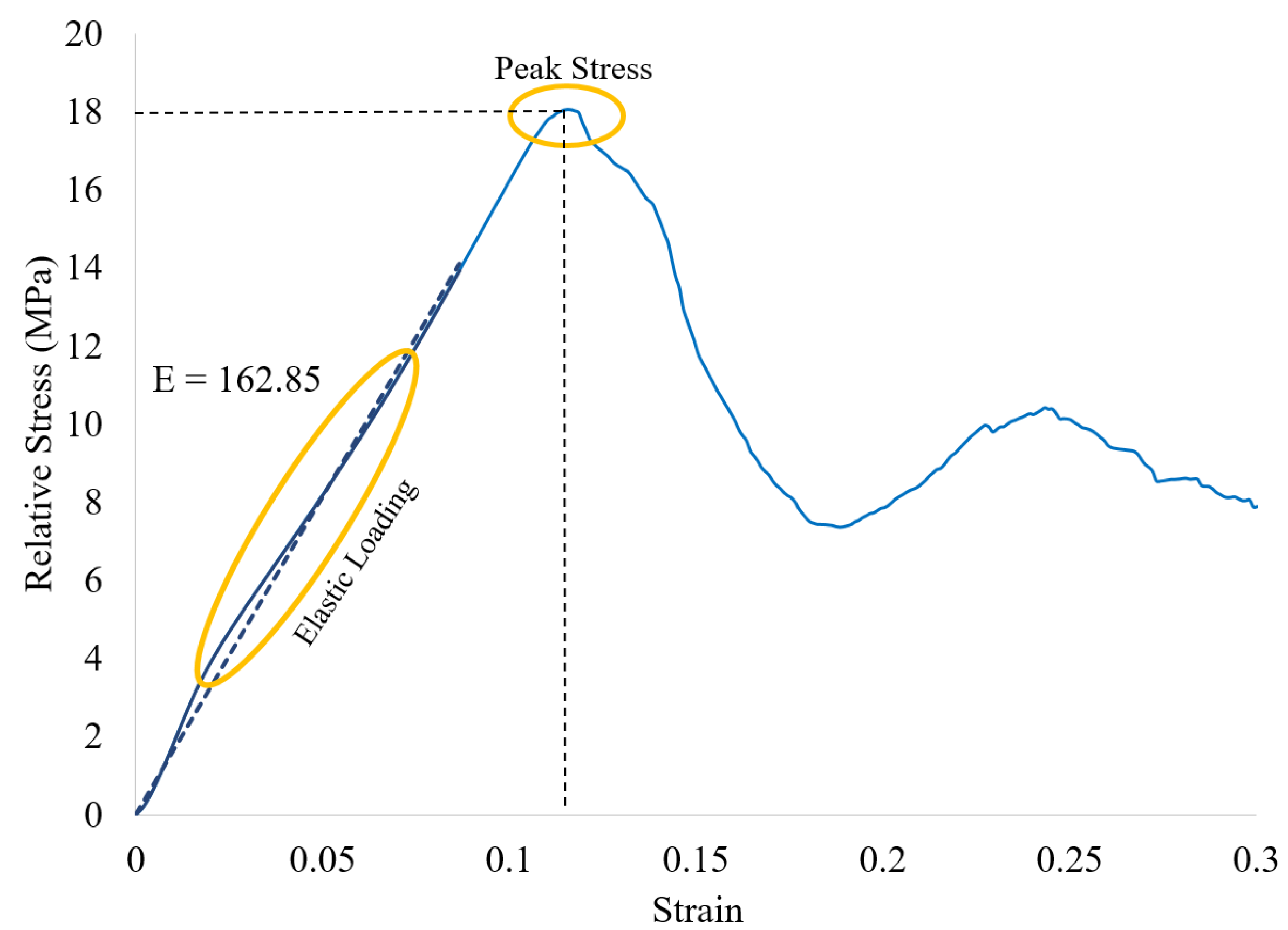

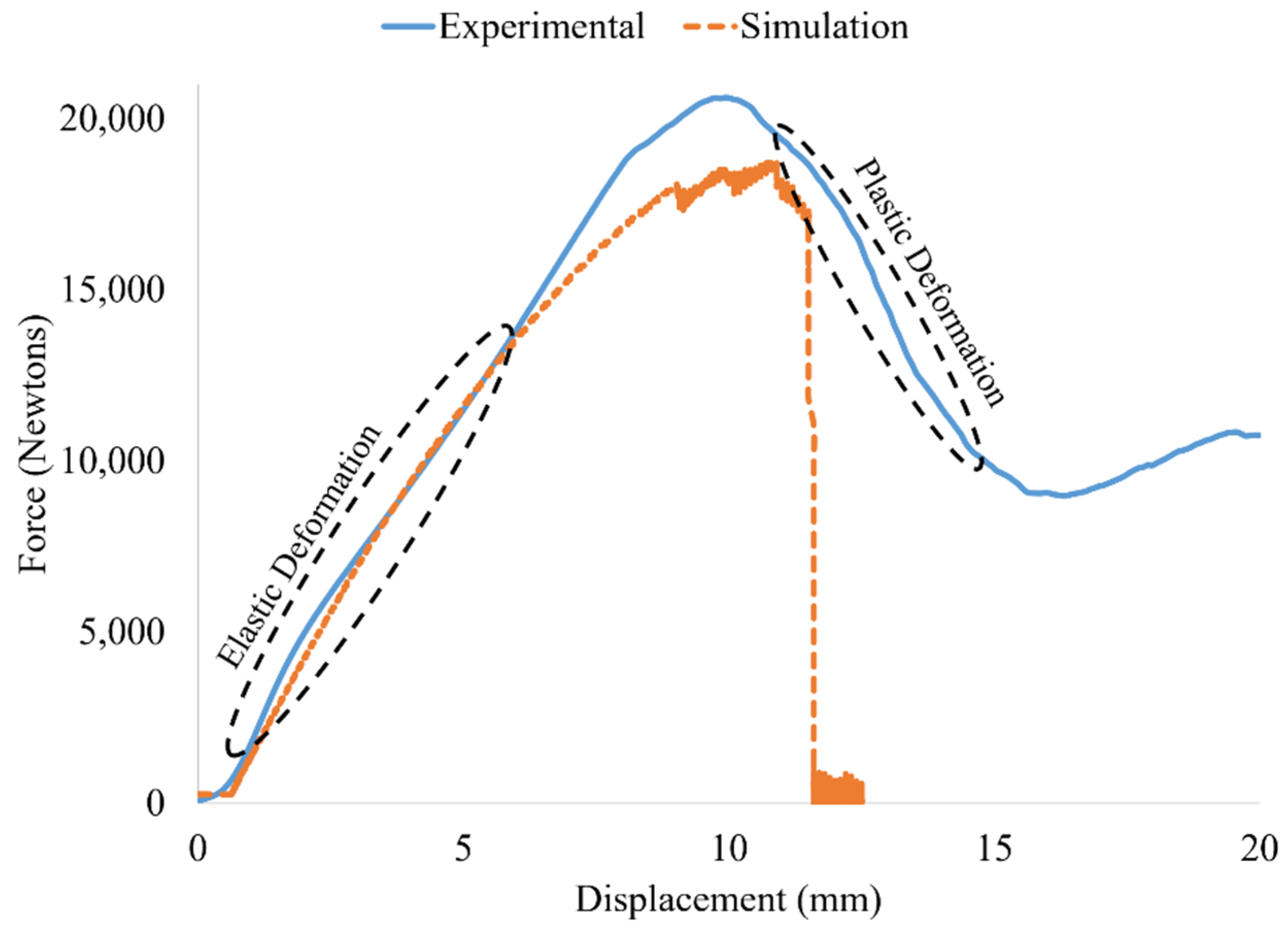

3.1. Mechanical Test Results

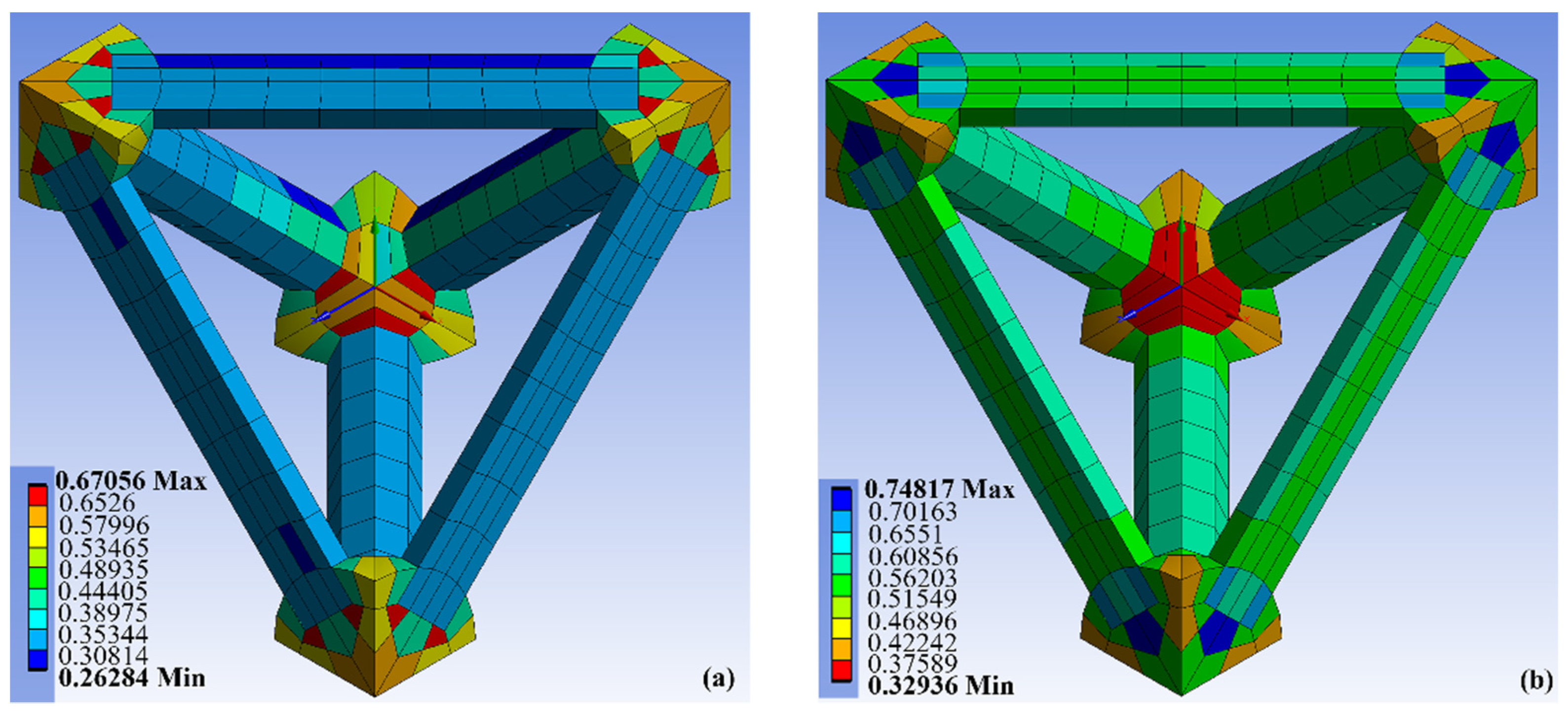

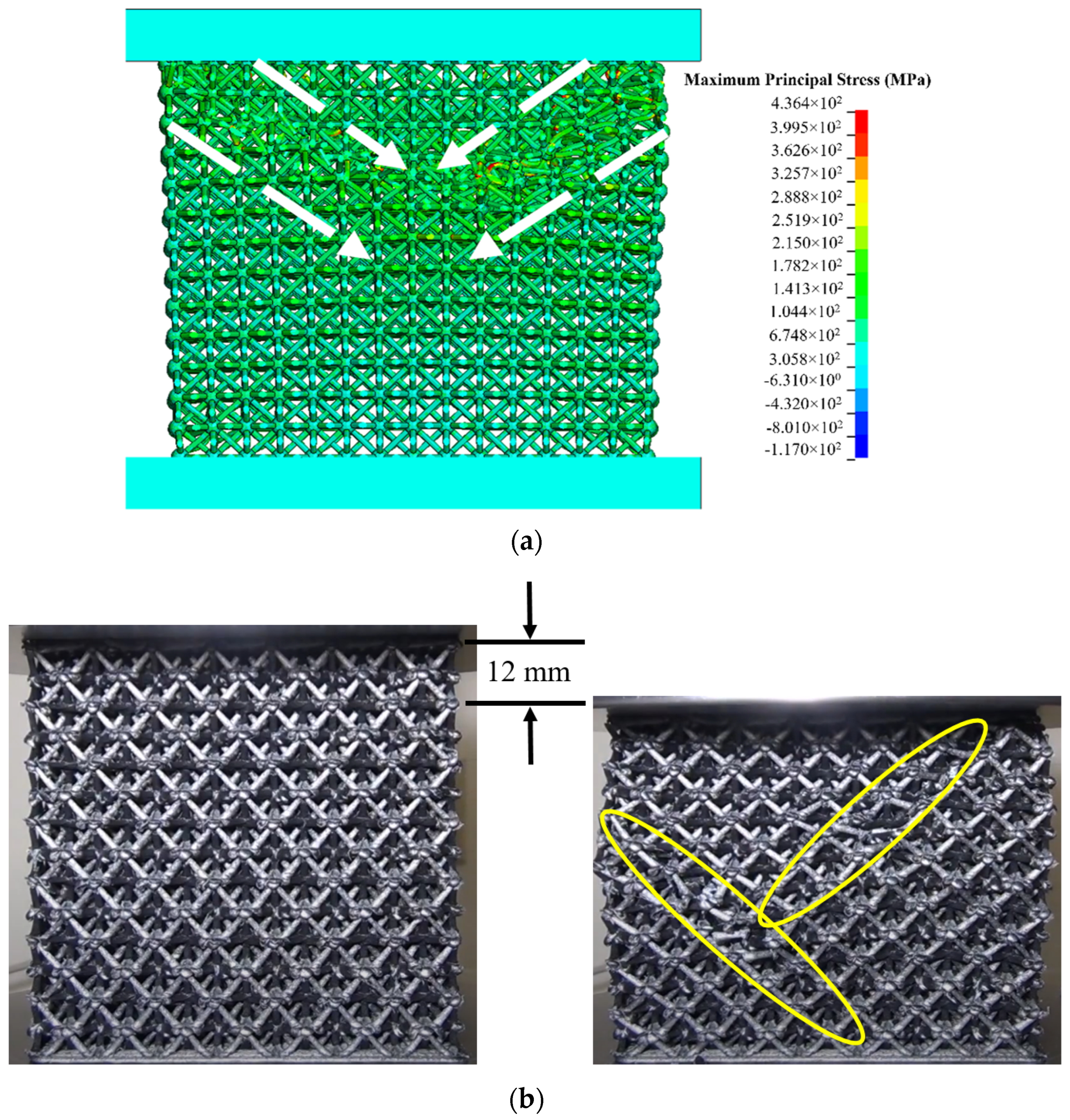

3.2. FEA Simulation Results

4. Discussion

5. Conclusions and Future Recommendations

- Modifications to the ALE print strategy will be studied to increase node bond strength via printing of additional material and/or modifications to nozzle temperature and speed at the nodes to enhance polymer entanglement.

- Contact interfaces between the platens and all beams will need to be defined in order to improve accuracy beyond the yield stress point.

- Future studies should focus on studying behavior of lattices at different relative density values by increasing or decreasing the length parameter (L) value of the the lattice unit cell.

- Future tests should assess properties in those different loading conditions.

- Future research should explore properties of each unit cell type in order to gain insight into the loading conditions that each unit cell type are best suited for. In applications involving multiple loading conditions, blends of different lattice unit cell types within a single structure may ultimately be the ideal approach.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, L.J.; Krishnadas Nair, C.G. Current trends of additive manufacturing in the aerospace industry. In Advances in 3D Printing & Additive Manufacturing Technologies; Springer: Singapore, 2017; pp. 39–54. [Google Scholar]

- Mahmoud, D.; Elbestawi, M.A. Lattice structures and functionally graded materials applications in additive manufacturing of orthopedic implants: A review. J. Manuf. Mater. Process. 2017, 1, 13. [Google Scholar] [CrossRef]

- Baich, L.; Manogharan, G. Study of infill print parameters on mechanical strength and production cost-time of 3D printed ABS parts. In 2014 International Solid Freeform Fabrication Symposium; The University of Texas at Austin: Austin, TX, USA, 2014. [Google Scholar]

- Jenett, B.; Cameron, C.; Tourlomousis, F.; Rubio, A.P.; Ochalek, M.; Gershenfeld, N. Discretely assembled mechanical metamaterials. Sci. Adv. 2020, 6, eabc9943. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Wu, Y.; Gao, X.; Wu, H.; Nutt, S.; Yin, S. Design of composite lattice materials combined with fabrication approaches. J. Compos. Mater. 2019, 53, 393–404. [Google Scholar] [CrossRef]

- Dong, L.; Wadley, H. Mechanical properties of carbon fiber composite octet-truss lattice structures. Compos. Sci. Technol. 2015, 119, 26–33. [Google Scholar] [CrossRef]

- Dar, U.A.; Mian, H.H.; Abid, M.; Topa, A.; Sheikh, M.Z.; Bilal, M. Experimental and numerical investigation of compressive behavior of lattice structures manufactured through projection micro stereolithography. Mater. Today Commun. 2020, 25, 101563. [Google Scholar] [CrossRef]

- Ge, Q.; Li, Z.; Wang, Z.; Kowsari, K.; Zhang, W.; He, X.; Zhou, J.; Fang, N.X. Projection micro stereolithography based 3D printing and its applications. Int. J. Extrem. Manuf. 2020, 2, 022004. [Google Scholar] [CrossRef]

- Spadaccini, C.M. Ultrastrong, Ductile Ceramic Lattices Span an Order of Magnitude in Size. Matter 2019, 1, 1445–1446. [Google Scholar] [CrossRef]

- Li, B.; Shen, C. Solid Stress-Distribution-Oriented Design and Topology Optimization of 3D-Printed Heterogeneous Lattice Structures with Light Weight and High Specific Rigidity. Polymers 2022, 14, 2807. [Google Scholar] [CrossRef]

- Kozior, T.; Kundera, C. Viscoelastic properties of cell structures manufactured using a photo-curable additive technology—PJM. Polymers 2021, 13, 1895. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, A.; Wegener, K. Polymer powders for selective laser sintering (SLS). In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2015; Volume 1664, p. 160009. [Google Scholar]

- Cobian, L.; Rueda-Ruiz, M.; Fernandez-Blazquez, J.P.; Martinez, V.; Galvez, F.; Karayagiz, F.; Lück, T.; Segurado, J.; Monclus, M.A. Micromechanical characterization of the material response in a PA12-SLS fabricated lattice structure and its correlation with bulk behavior. Polym. Test. 2022, 110, 107556. [Google Scholar] [CrossRef]

- Jin, X.; Li, G.X.; Zhang, M. Optimal design of three-dimensional non-uniform nylon lattice structures for selective laser sintering manufacturing. Adv. Mech. Eng. 2018, 10, 1687814018790833. [Google Scholar] [CrossRef]

- Li, Z.H.; Nie, Y.F.; Liu, B.; Kuai, Z.Z.; Zhao, M.; Liu, F. Mechanical properties of AlSi10Mg lattice structures fabricated by selective laser melting. Mater. Des. 2020, 192, 108709. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Tran, P.; Harris, J.; Liu, Q.; Lu, G.; Ruan, D.; Faruque, O.; Brandt, M. The effect of topology on the quasi-static and dynamic behaviour of SLM AlSi10Mg lattice structures. Int. J. Adv. Manuf. Technol. 2022, 118, 4085–4104. [Google Scholar] [CrossRef]

- Xiao, L.; Song, W. Additively-manufactured functionally graded Ti-6Al-4V lattice structures with high strength under static and dynamic loading: Experiments. Int. J. Impact Eng. 2018, 111, 255–272. [Google Scholar] [CrossRef]

- Jin, N.; Yan, Z.; Wang, Y.; Cheng, H.; Zhang, H. Effects of heat treatment on microstructure and mechanical properties of selective laser melted Ti-6Al-4V lattice materials. Int. J. Mech. Sci. 2021, 190, 106042. [Google Scholar] [CrossRef]

- Post, B.K.; Chesser, P.C.; Lind, R.F.; Sallas, M.R.; Love, L.J. Feasibility of Using Big Area Additive Manufacturing to Directly Manufacture Boat Molds; No. ORNL/TM-2017/709; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2018.

- Naboni, R.; Breseghello, L.; Kunic, A. Multi-scale design and fabrication of the Trabeculae Pavilion. Addit. Manuf. 2019, 27, 305–317. [Google Scholar] [CrossRef]

- Gao, X.; Qi, S.; Kuang, X.; Su, Y.; Li, J.; Wang, D. Fused filament fabrication of polymer materials: A review of interlayer bond. Addit. Manuf. 2021, 37, 101658. [Google Scholar] [CrossRef]

- Gilmer, E.L.; Anderegg, D.; Gardner, J.M.; Sauti, G.; Siochi, E.J.; McKnight, S.H.; Dillard, D.A.; McIlroy, C.; Bortner, M.J. Temperature, diffusion, and stress modeling in filament extrusion additive manufacturing of polyetherimide: An examination of the influence of processing parameters and importance of modeling assumptions. Addit. Manuf. 2021, 48, 102412. [Google Scholar] [CrossRef]

- Abusabir, A.; Khan, M.A.; Asif, M.; Khan, K.A. Effect of Architected Structural Members on the Viscoelastic Response of 3D Printed Simple Cubic Lattice Structures. Polymers 2022, 14, 618. [Google Scholar] [CrossRef]

- Basurto-Vázquez, O.; Sánchez-Rodríguez, E.P.; McShane, G.J.; Medina, D.I. Load distribution on PET-G 3D prints of honeycomb cellular structures under compression load. Polymers 2021, 13, 1983. [Google Scholar] [CrossRef]

- Lin, Z.H.; Pan, J.H.; Li, H.Y. Mechanical Strength of Triply Periodic Minimal Surface Lattices Subjected to Three-Point Bending. Polymers 2022, 14, 2885. [Google Scholar] [CrossRef] [PubMed]

- Cuan-Urquizo, E.; Álvarez-Trejo, A.; Robles Gil, A.; Tejada-Ortigoza, V.; Camposeco-Negrete, C.; Uribe-Lam, E.; Treviño-Quintanilla, C.D. Effective stiffness of fused deposition modeling infill lattice patterns made of PLA-wood material. Polymers 2022, 14, 337. [Google Scholar] [CrossRef] [PubMed]

- Della Ripa, M.; Paolino, D.S.; Amorese, A.; Tridello, A. Numerical modelling of the mechanical response of lattice structures produced through AM. Procedia Struct. Integr. 2021, 33, 714–723. [Google Scholar] [CrossRef]

- Bouwhuis, B.; Bele, E.; Hibbard, G. Edge effects in compression testing periodic cellular metal sandwich cores. J. Mater. Sci. 2008, 43, 3267–3273. [Google Scholar] [CrossRef]

- Boursier Niutta, C.; Ciardiello, R.; Tridello, A. Experimental and Numerical Investigation of a Lattice Structure for Energy Absorption: Application to the Design of an Automotive Crash Absorber. Polymers 2022, 14, 1116. [Google Scholar] [CrossRef]

- Mrazova, M. Advanced composite materials of the future in aerospace industry. Incas Bull. 2013, 5, 139. [Google Scholar]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Hashimoto, M.; Okabe, T.; Sasayama, T.; Matsutani, H.; Nishikawa, M. Prediction of tensile strength of discontinuous carbon fiber/polypropylene composite with fiber orientation distribution. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1791–1799. [Google Scholar] [CrossRef]

- Mahajan, C.; Cormier, D. 3D Printing of Carbon Fiber Composites With Preferentially Aligned Fibers. In Proceedings of the 2015 Industrial and Systems Engineering Research Conference, Nashville, TN, USA, 30 May–2 June 2015. [Google Scholar]

- Poddar, P. Additive Manufacturing of Carbon Fiber Reinforced Polymer Lattice Structures. Ph.D. Dissertation, Rochester Institute of Technology, Rochester, NY, USA, 2022. [Google Scholar]

- Mueller, S.; Im, S.; Gurevich, S.; Teibrich, A.; Pfisterer, L.; Guimbretière, F.; Baudisch, P. WirePrint: 3D printed previews for fast prototyping. In Proceedings of the 27th Annual ACM Symposium on User Interface Software and Technology, Honolulu, HI, USA, 5–8 October 2014; pp. 273–280. [Google Scholar]

- Peng, H.; Wu, R.; Marschner, S.; Guimbretière, F. On-the-fly print: Incremental printing while modelling. In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems, San Jose, CA, USA, 7–12 May 2016; pp. 887–896. [Google Scholar]

- Liu, S.; Li, Y.; Li, N. A novel free-hanging 3D printing method for continuous carbon fiber reinforced thermoplastic lattice truss core structures. Mater. Des. 2018, 137, 235–244. [Google Scholar] [CrossRef]

- Ansys Training Center. Available online: https://www.ansys.com/training-center (accessed on 9 August 2022).

- Hill, R. A theory of the yielding and plastic flow of anisotropic metals. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1948, 193, 281–297. [Google Scholar]

- Abdelhamid, M. Effective Mechanical Properties of 3D Structural Metamaterials. M.S. Thesis, York University, Toronto, ON, Canada, 2017. [Google Scholar]

- Duan, S.; Liu, F.; Pettersson, T.; Creighton, C.; Asp, L.E. Determination of transverse and shear moduli of single carbon fibres. Carbon 2020, 158, 772–782. [Google Scholar] [CrossRef]

- Xu, B.; Yin, S.; Wang, Y.; Li, H.; Zhang, B.; Ritchie, R.O. Long-fiber reinforced thermoplastic composite lattice strutures: Fabrication and compressive properties. Compos. Part A Appl. Sci. Manuf. 2017, 97, 41–50. [Google Scholar] [CrossRef]

- Schneider, C.; Velea, M.N.; Kazemahvazi, S.; Zenkert, D. Compression properties of novel thermoplastic carbon fibre and poly-ethylene terephthalate fibre composite lattice structures. Mater. Des. 2015, 65, 1110–1120. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Units and Value |

|---|---|

| Element Order | Linear |

| Element Size | 0.75 mm |

| Transition | Fast |

| Span Angle Center | Coarse |

| Initial Seed Size | Assembly |

| Bounding Box Diagonal | 10.825 mm |

| Average Surface Area | 0.59879 mm2 |

| Minimum Edge Length | 0.1829 mm |

| Error Limits | Aggressive Mechanical |

| Target Quality | Default (0.05) |

| Smoothing | Medium |

| Rigid Body Behavior | Dimensionally Reduced |

| Parameter and LS-Dyna Keyword Code | Value and Units |

|---|---|

| Yield strength in axial direction of truss (mat_sigx) | 89 MPa |

| R mat_P1 (ktruss) | 3543 |

| R mat_P2 (ntruss) | 0.8 |

| R mat_P1_2 (knode) | 716 |

| R mat_P2_2 (nnode) | 0.8 |

| Young’s modulus in axial direction (R mat_Ea) | 11.8 GPa |

| Young’s modulus in transverse direction (R mat_Eb and Ec) | 6 GPa |

| Shear modulus in axial direction (R mat_Rxy) | 3 GPa |

| Shear modulus in transverse direction (R mat_Szx and Txy) | 6 GPa |

| Material density | 1.8 × 10−9 Mg/m3 |

| Poisson’s ratio axial direction | 0.4 |

| Poisson’s ratio transverse direction | 0.015 |

| Reference Work | Matrix Material | Manufacturing Method | σR (MPa) | Er (MPa) |

|---|---|---|---|---|

| Xu et al. [42] | Carbon-PP | Reversible assembly | 0.12 | 3.7 |

| Schneider et al. [43] | Carbon-PET | Fold-cut | 1.90 | 80.0 |

| Liu et al. [37] | CFRP-PLA | ALE | 1.24 | 27.7 |

| Present Work | CFRP-ABS | ALE | 17.40 | 162.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poddar, P.; Olles, M.; Cormier, D. Mechanical Response of Carbon Composite Octet Truss Structures Produced via Axial Lattice Extrusion. Polymers 2022, 14, 3553. https://doi.org/10.3390/polym14173553

Poddar P, Olles M, Cormier D. Mechanical Response of Carbon Composite Octet Truss Structures Produced via Axial Lattice Extrusion. Polymers. 2022; 14(17):3553. https://doi.org/10.3390/polym14173553

Chicago/Turabian StylePoddar, Pritam, Mark Olles, and Denis Cormier. 2022. "Mechanical Response of Carbon Composite Octet Truss Structures Produced via Axial Lattice Extrusion" Polymers 14, no. 17: 3553. https://doi.org/10.3390/polym14173553

APA StylePoddar, P., Olles, M., & Cormier, D. (2022). Mechanical Response of Carbon Composite Octet Truss Structures Produced via Axial Lattice Extrusion. Polymers, 14(17), 3553. https://doi.org/10.3390/polym14173553