Effect of Trap Regulation on Vacuum DC Surface Flashover Characteristics of Nano-ZnO/PI Film

Abstract

:1. Introduction

2. Experimental Preparation

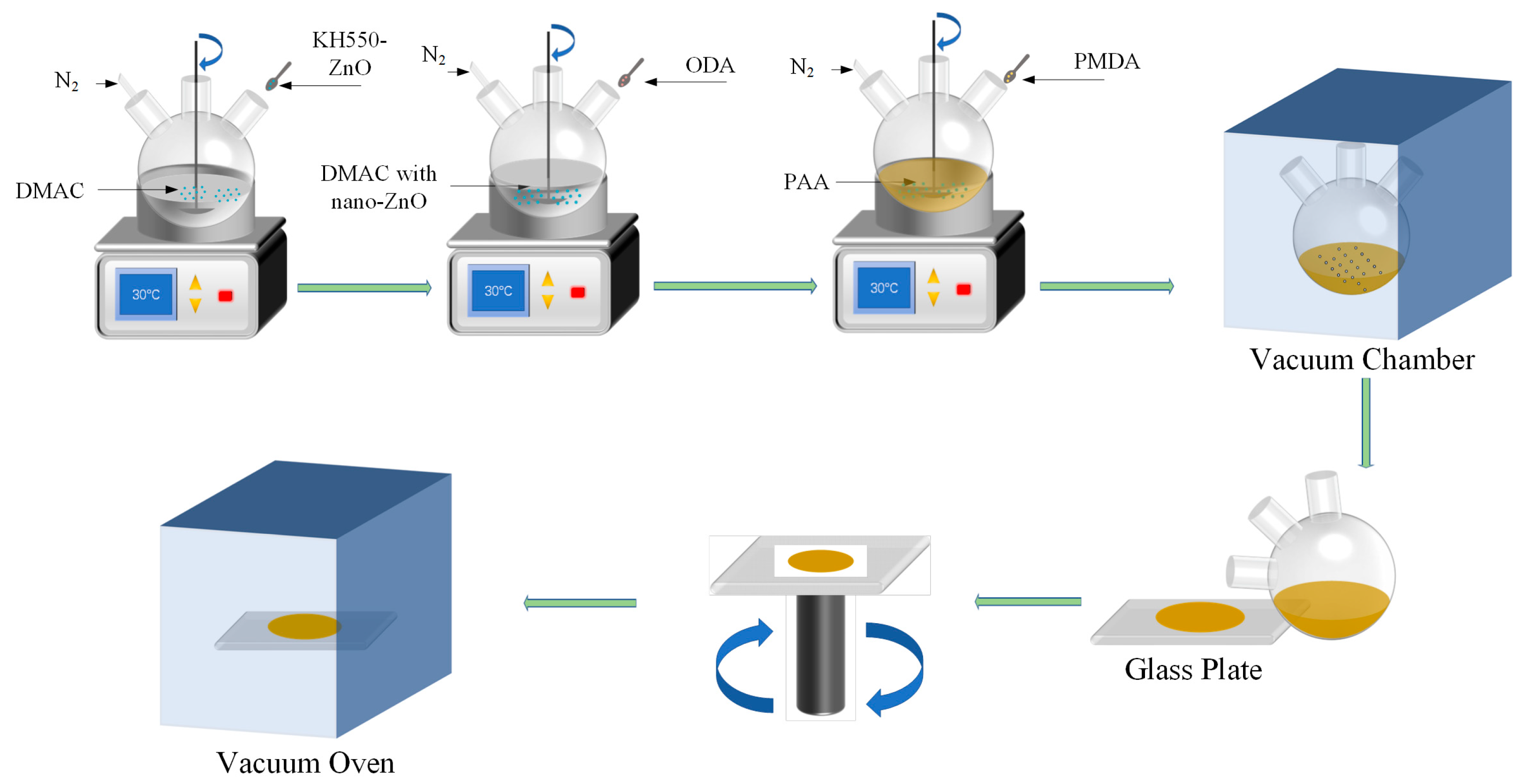

2.1. Preparation Technology of PI Nanocomposite Film

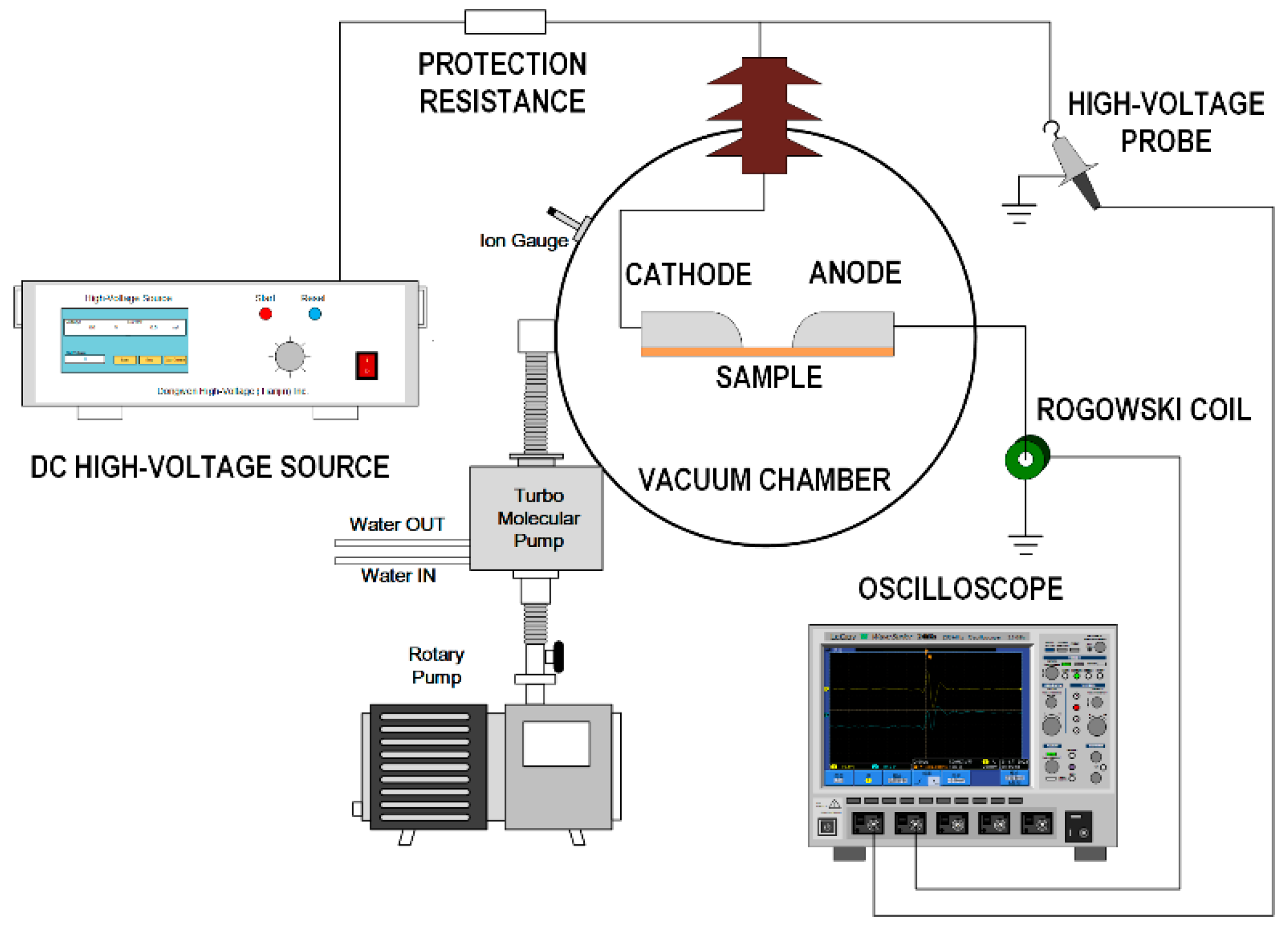

2.2. Vacuum DC Surface Flashover Characteristic Measurement System

2.3. Surface Trap Distribution Measurement System

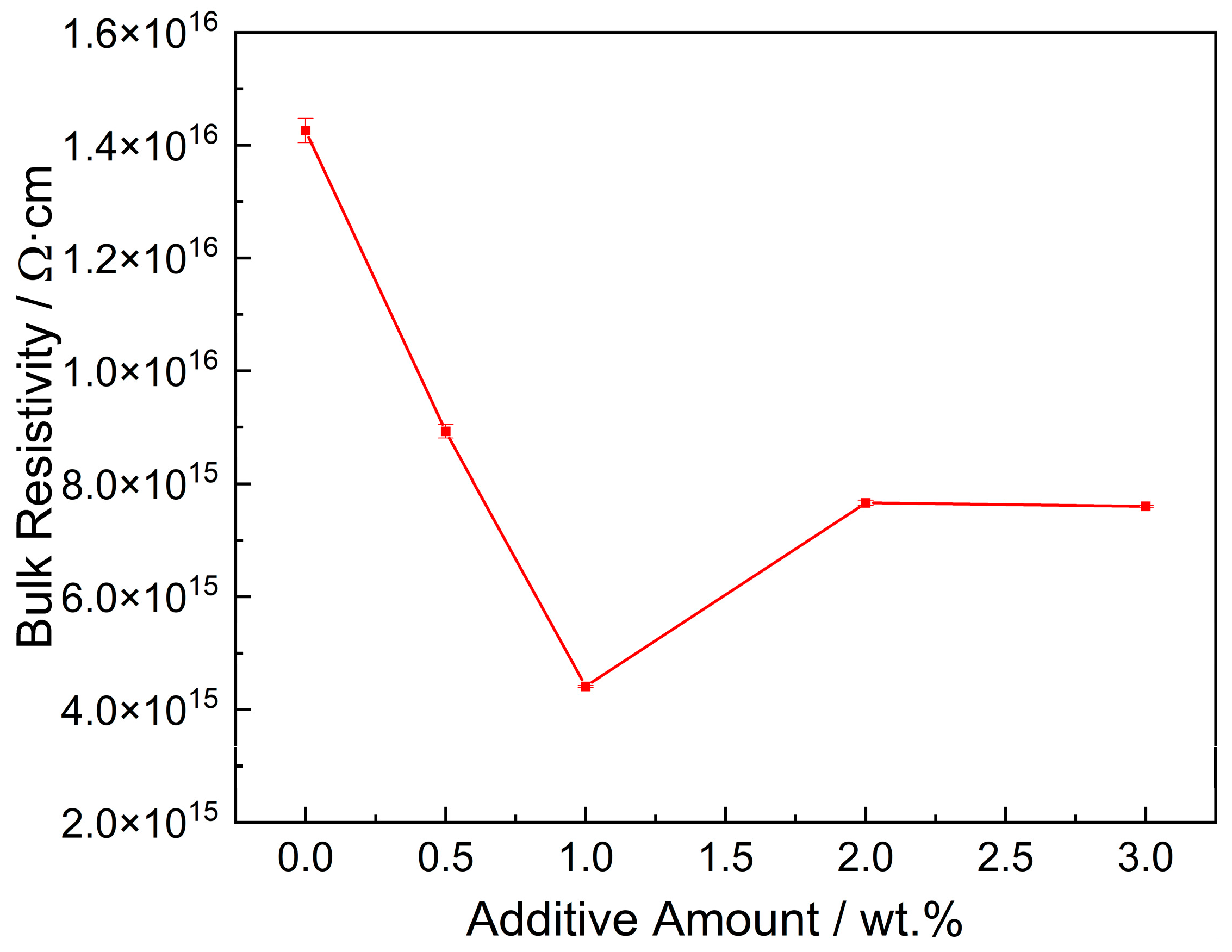

2.4. Bulk Resistivity Measurement

3. Experimental Results and Analysis

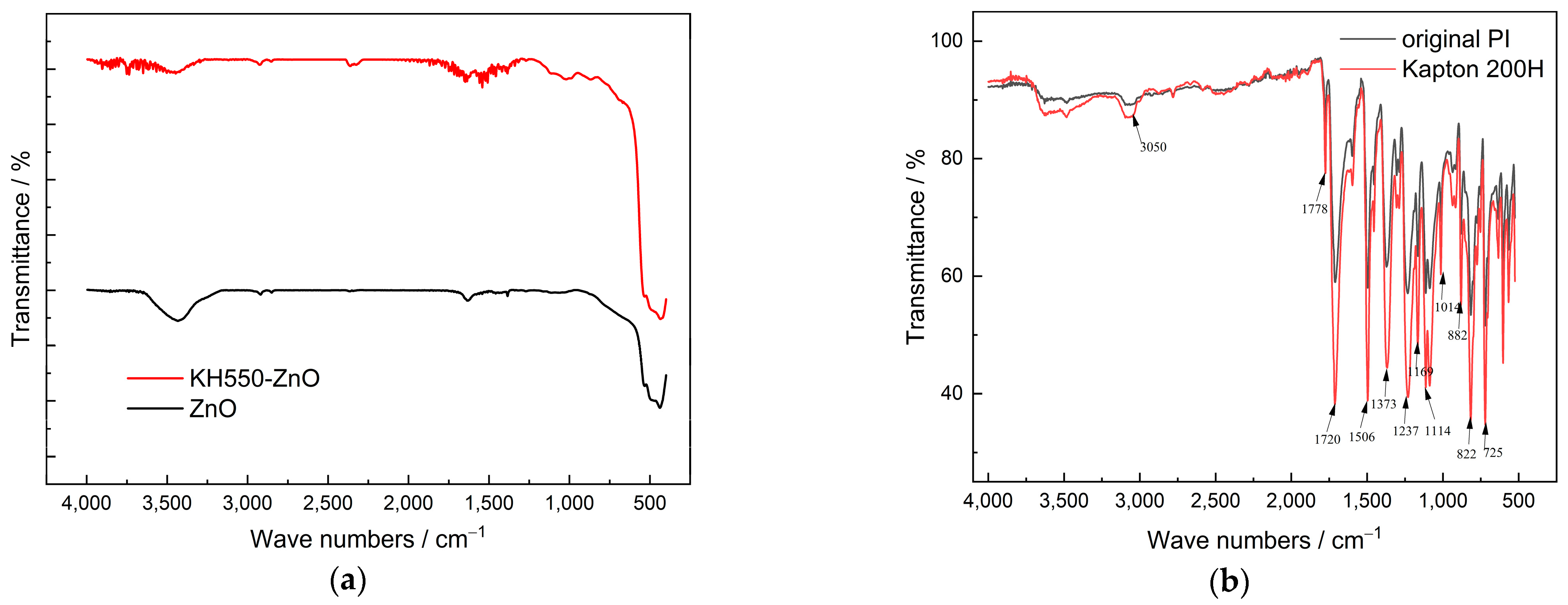

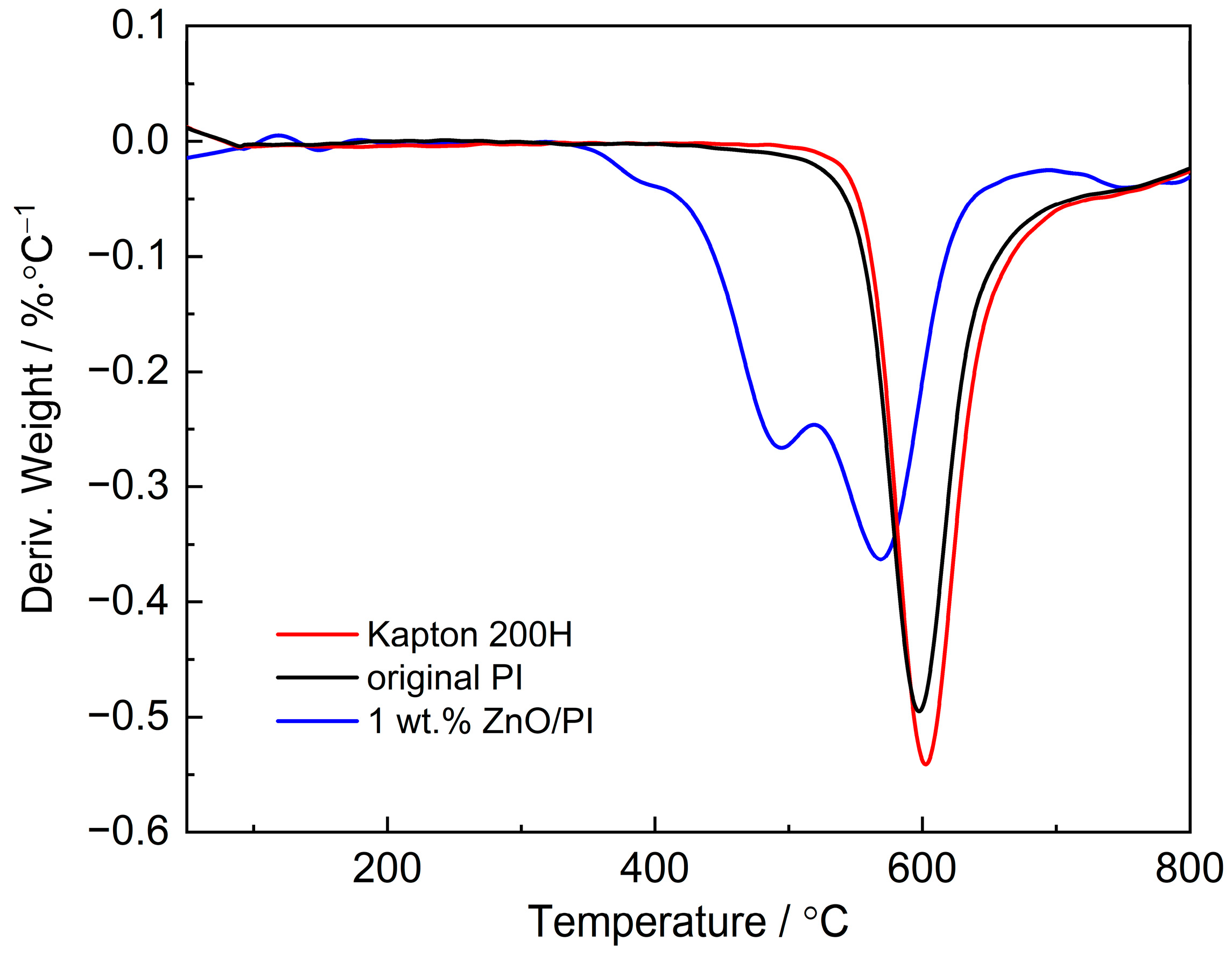

3.1. Performance Characterization of ZnO/PI Films

3.2. Vacuum DC Surface Flashover Characteristics of ZnO/PI Composite Films

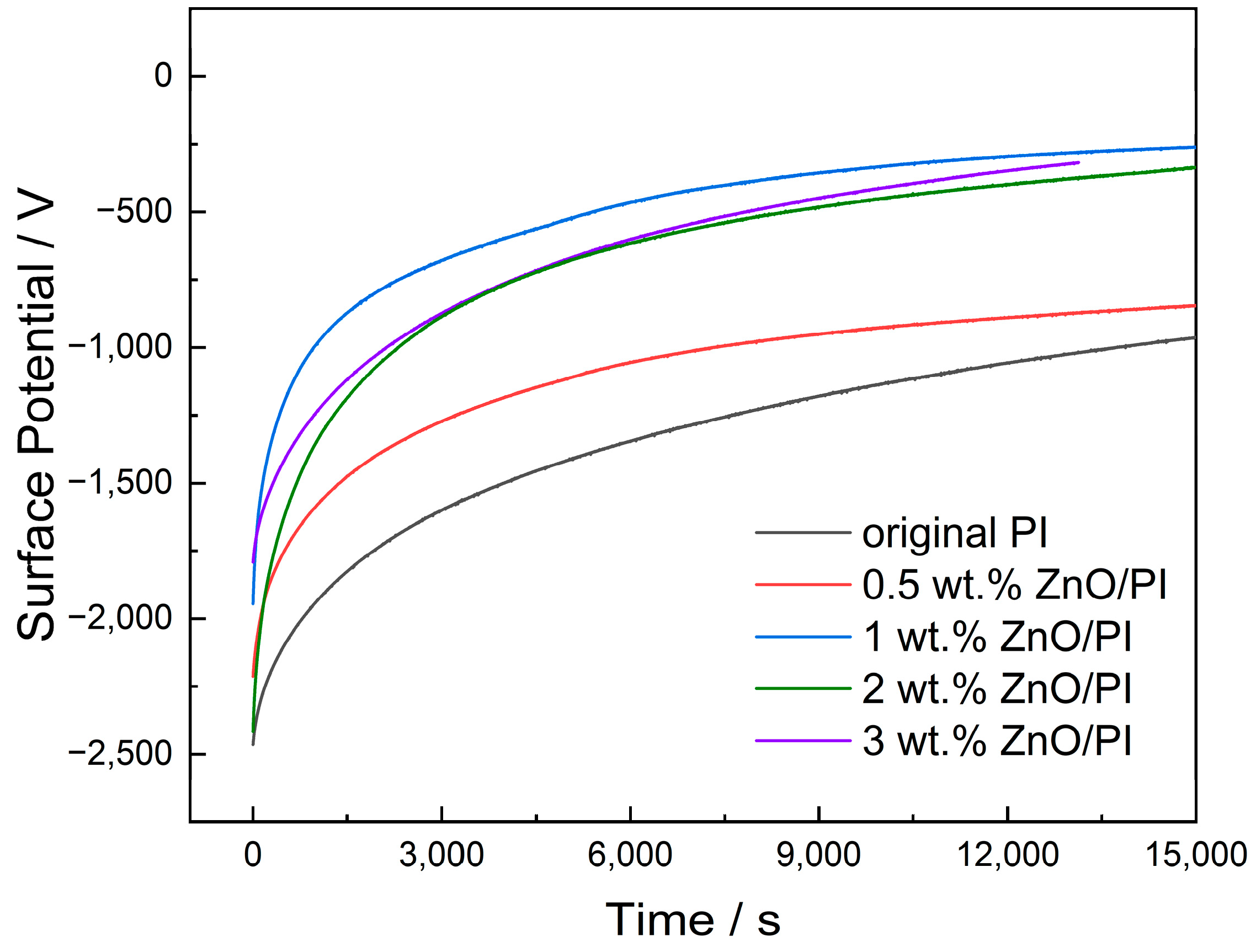

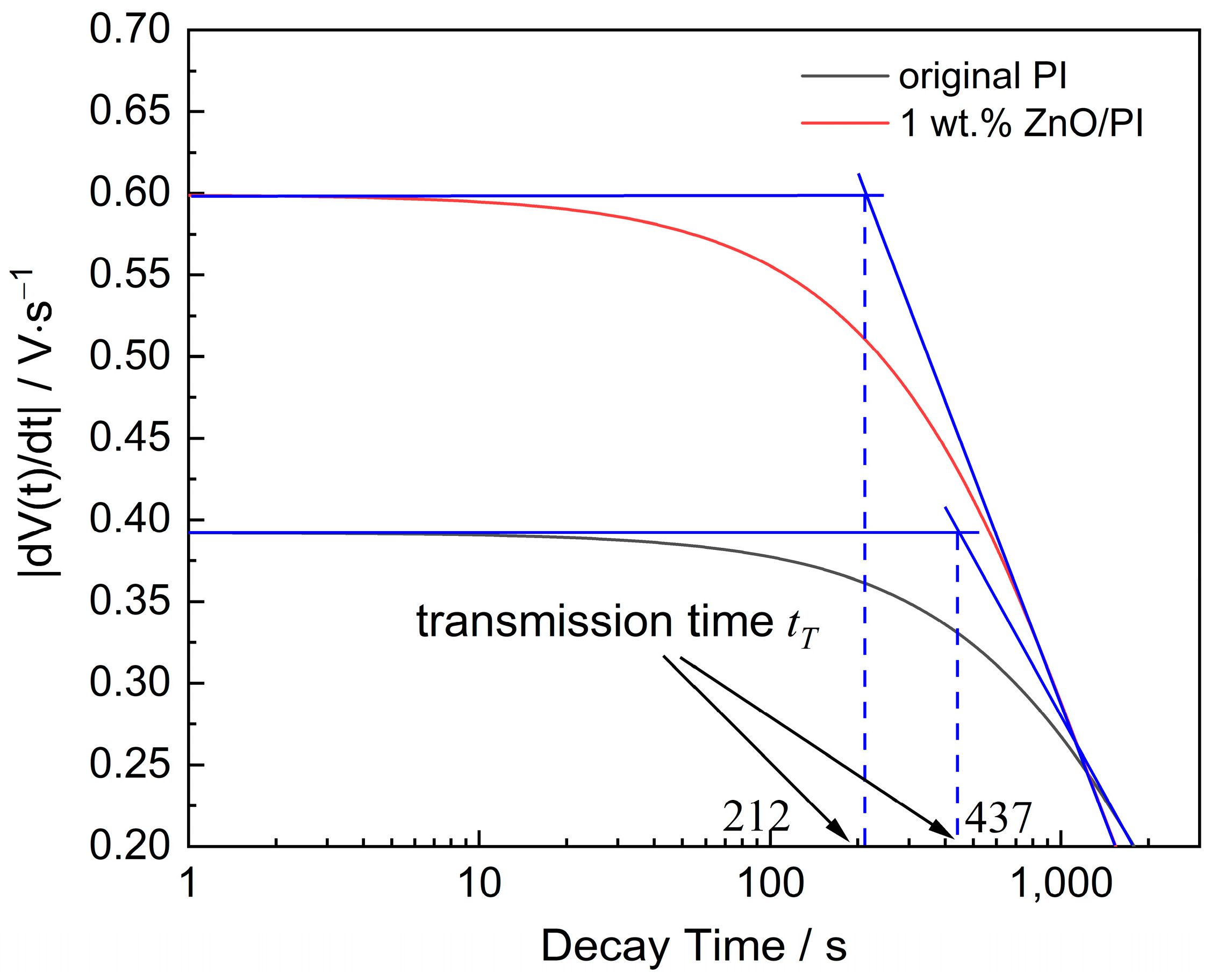

3.3. Surface Potential Decay Characteristic of Nano-ZnO/PI Films

4. Discussion

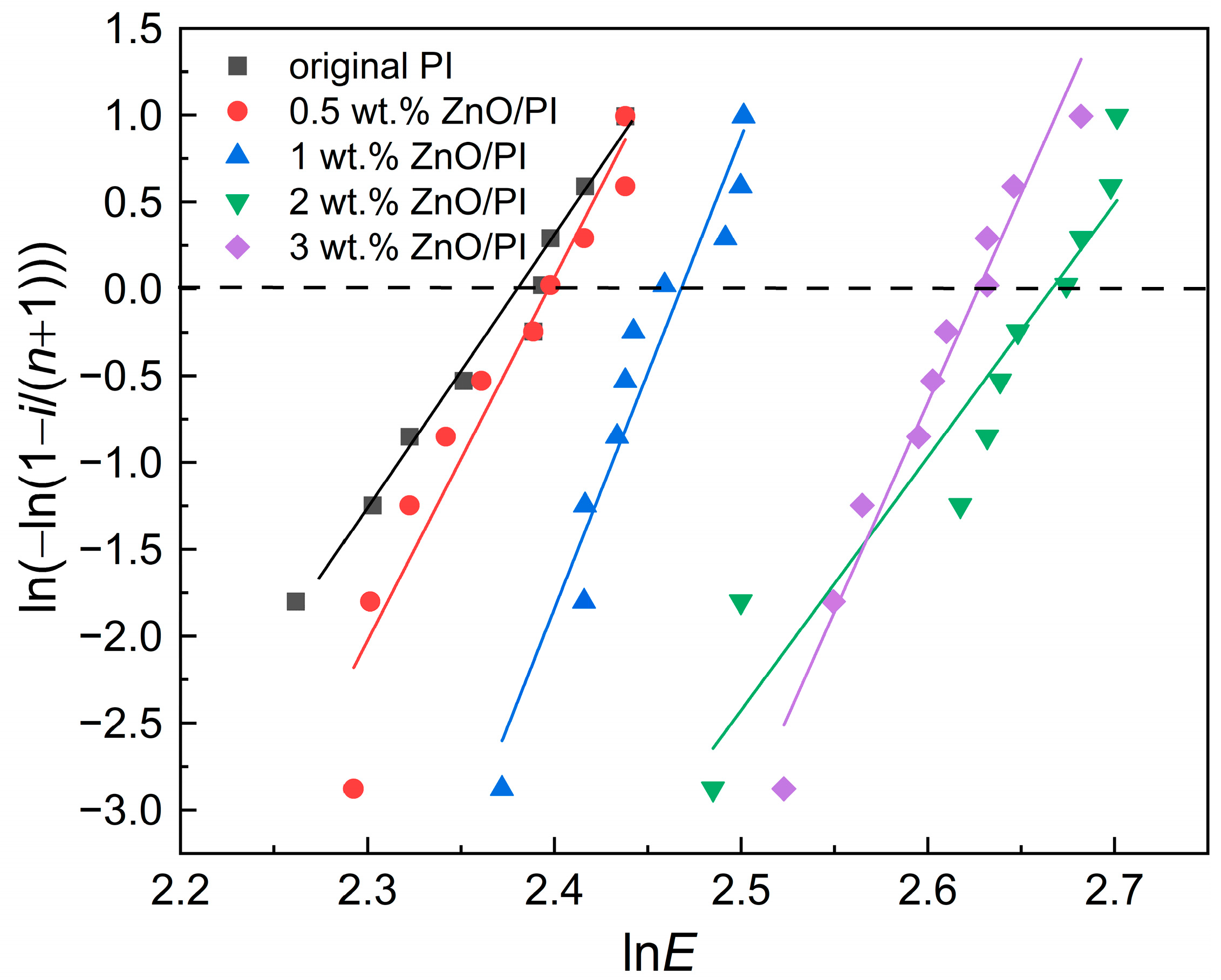

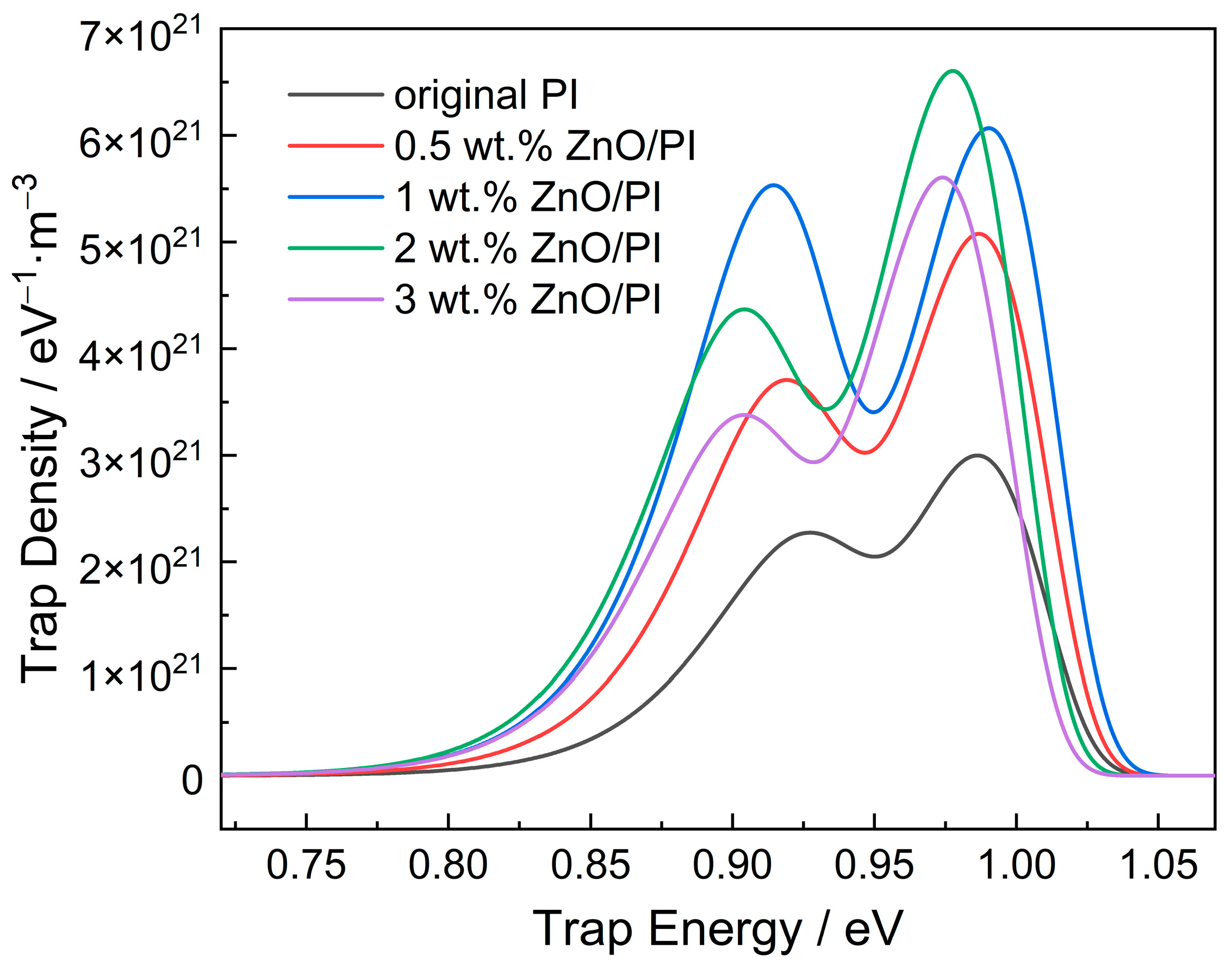

4.1. Surface Trap Distribution of Nano-ZnO/PI Films

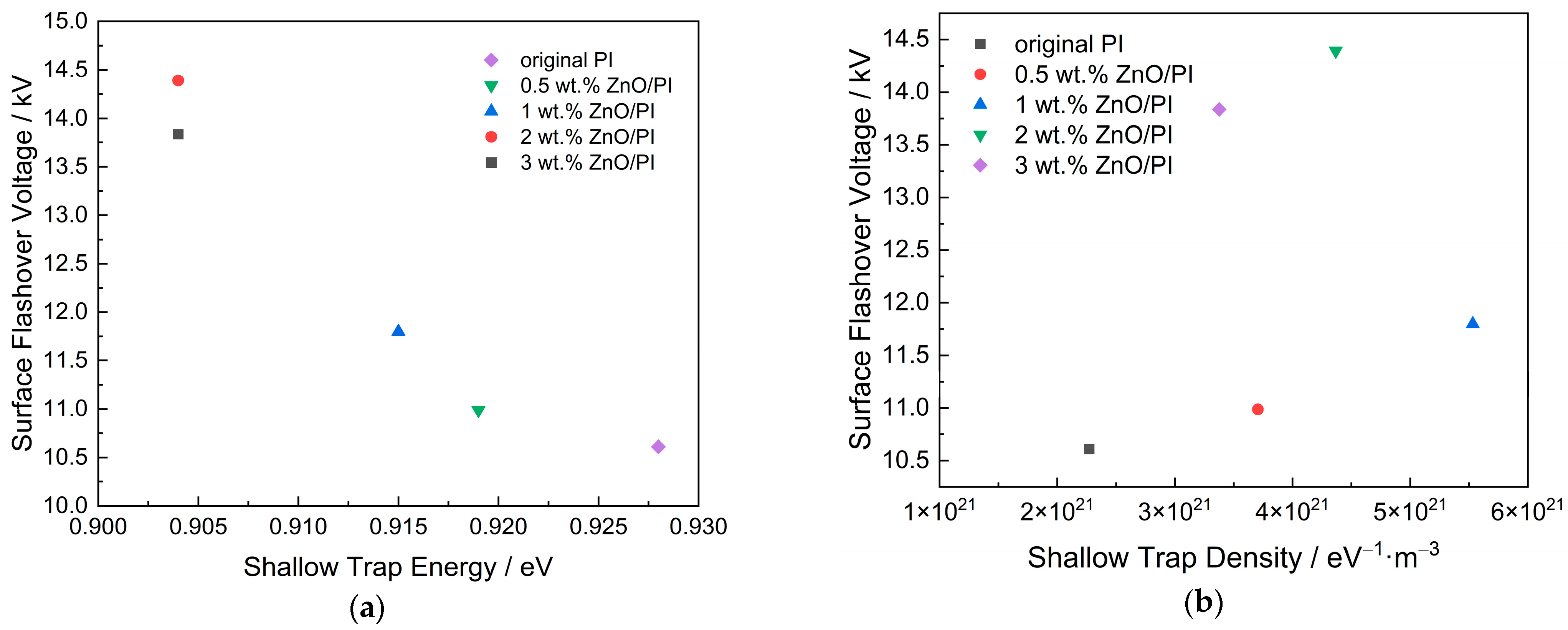

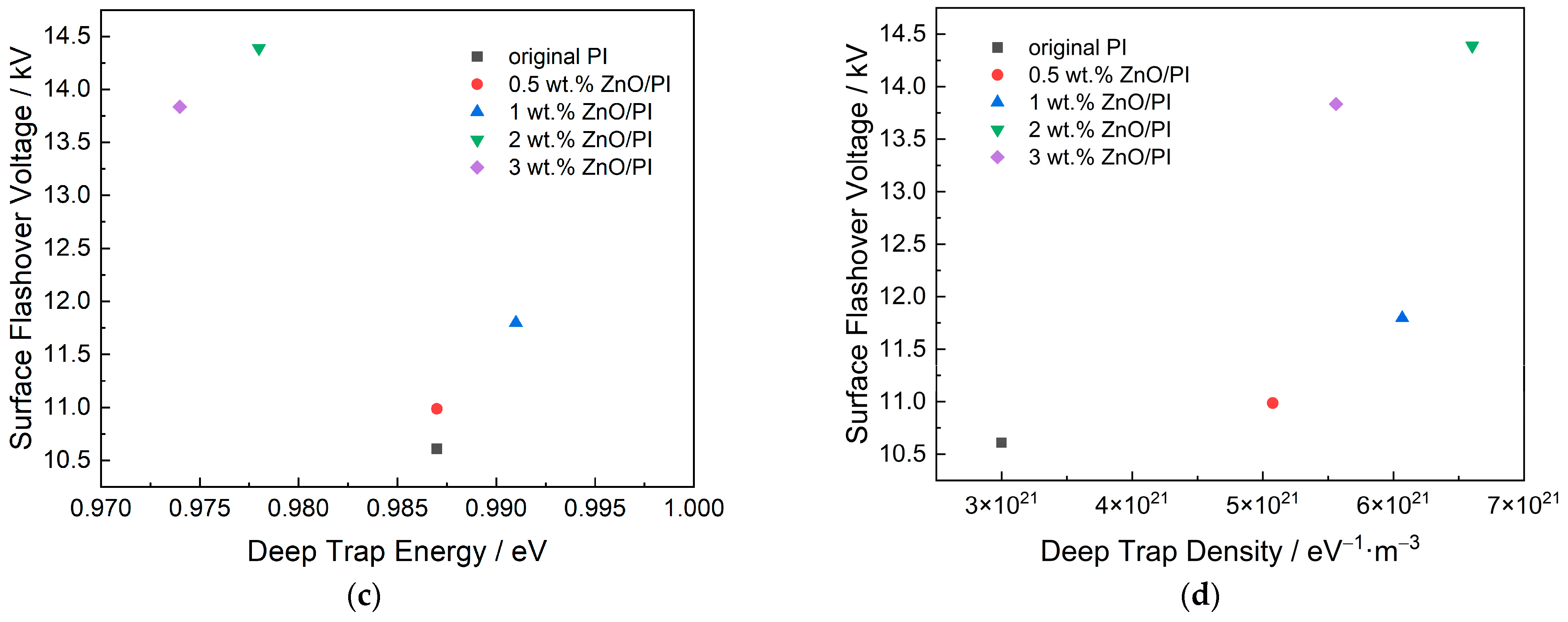

4.2. Relationship between Trap Distribution and DC Surface Flashover Voltage

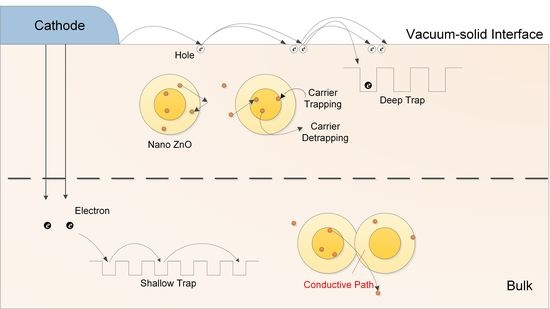

4.3. The Regulation Mechanism of Trap Distribution on the Surface Flashover Development

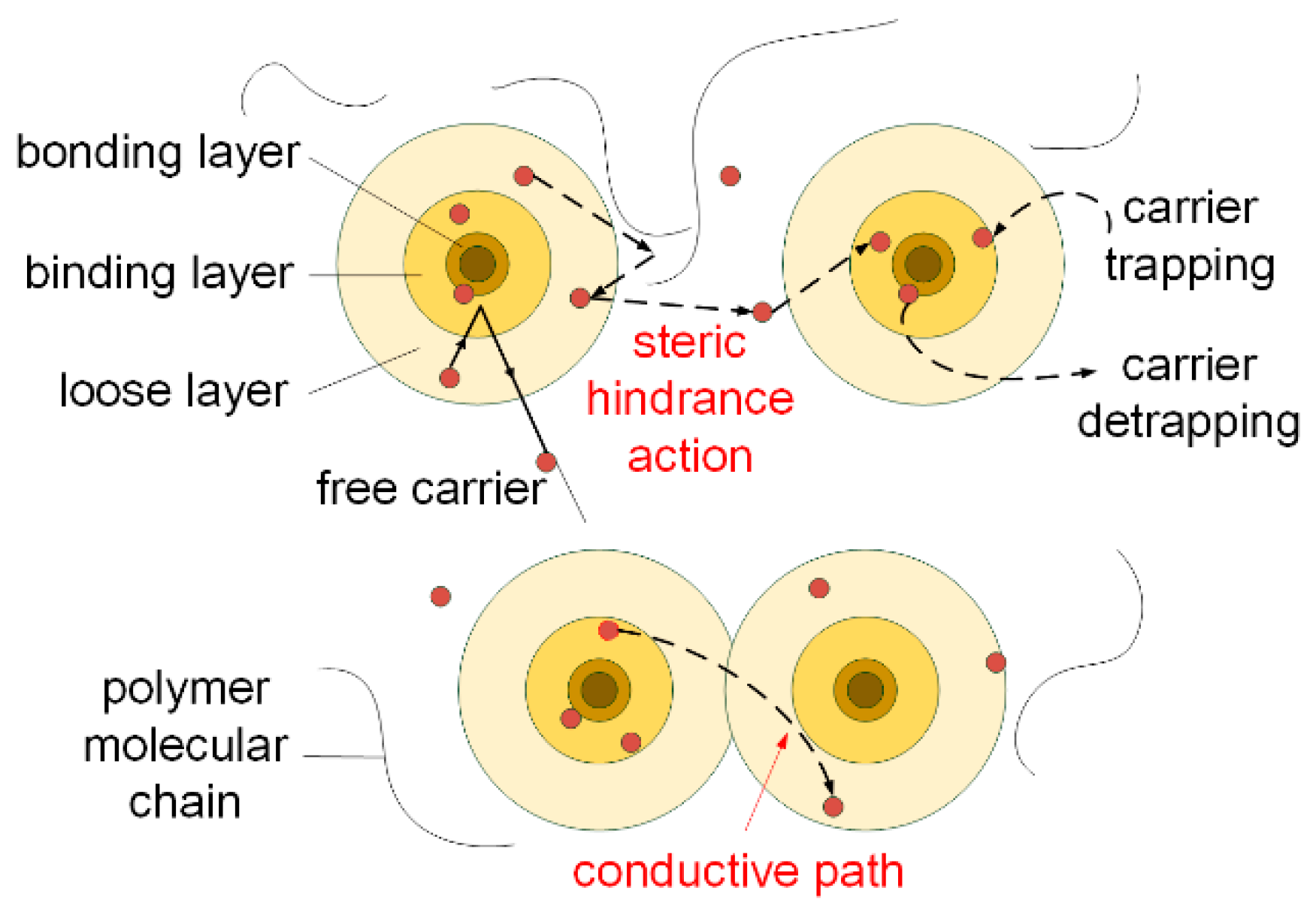

4.3.1. Effects of Nanoparticles on the Trap Distribution of Composite Film

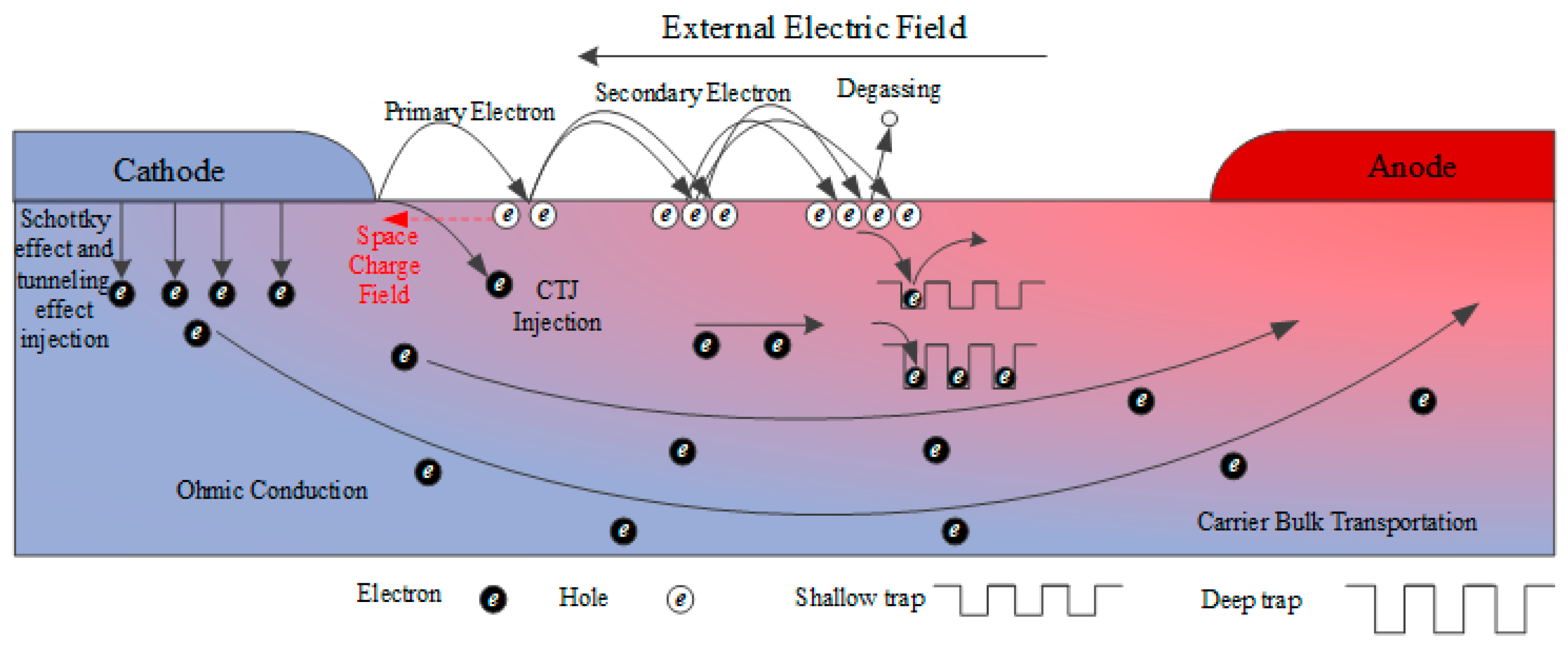

4.3.2. Influence of Trap Distribution on Surface Flashover Development

5. Conclusions

- (1)

- The nano additive can influence the surface trap distribution of the nano-ZnO/PI film and thus affect the surface charge transport. With the increase in the amount of nano-ZnO, the deep trap energy of ZnO/PI film varies slightly, whereas the shallow trap energy decreases slightly. Moreover, both shallow and deep trap density show a trend of first increasing and then decreasing, and carrier mobility increases continuously.

- (2)

- The vacuum DC surface flashover voltage of the nano-ZnO/PI composite film clearly increases. The flashover voltage continues to rise with the increase in the amount of ZnO and reaches a peak for 2 wt.% ZnO/PI, and then the flashover voltage decreases slightly with the further increase in additive amount. Comparative analysis of the trap distribution and flashover voltage mainly concludes that the increases in shallow and deep trap density both contribute to the rising of flashover voltage.

- (3)

- The regulation effect of trap distribution on the vacuum DC surface flashover development was analyzed using a bilayer model. The results of the bilayer model indicate that on the vacuum–solid surface of the nanocomposite film, deep traps dominate. The increase in the deep trap density can effectively suppress the multiplication of secondary electrons. Moreover, in the inner surface of the dielectric, shallow traps dominate. The decreased shallow trap energy and increased trap density improve the dissipation speed of the surface charge, which is beneficial to the increase in the flashover voltage.

- (4)

- The trap distribution characteristics of the nano-ZnO/PI composite film exhibit an obvious effect on the improvement in the flashover voltage. Therefore, in future studies, it is necessary to verify its effectiveness under extreme space environments such as high-energy electron radiation and high–low temperature cyclic aging.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abdel-Aziz, Y.A.; Abd EI-Hameed, A.M.; Ismail, M.I.; Ahmed, A.; Elifiky, D.; Gregorio, A. Effects of space plasma on an oxide coating of spacecraft’s surface materials. Adv. Space Res. 2021, 68, 1601–1612. [Google Scholar] [CrossRef]

- Polsak, A.W.; Delacourt, B.; Disa, N.; Semprimoschnig, C.O.A. Material charging investigations for solar orbiter. IEEE Trans. Plasma Sci. 2019, 47, 3746–3751. [Google Scholar] [CrossRef]

- Cooper, R.; Ferguson, D.; Engelhart, D.P.; Hoffmann, R. Effects of radiation damage on polyimide resistivity. J. Spacecraft Rockets 2017, 54, 343–348. [Google Scholar] [CrossRef]

- Song, B.P.; Zhou, R.D.; Yang, X.; Zhang, S.; Yang, N.; Fang, J.Y.; Song, F.L.; Zhang, G.J. Surface electrostatic discharge of charged typical space materials induced by strong electromagnetic interference. J. Phys. D-Appl. Phys. 2021, 54, 275002. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Safian, M.T.; Rashid, M.; Parveen, T.; Umar, K.; Ibrahim, M.N.M. Chapter One-Introduction of Smart Polymer Nanocomposites. In Smart Polymer Nanocomposites: Biomedical and Environmental Applications; Elsevier Inc.: Cambridge, MA, USA, 2021; pp. 1–25. [Google Scholar]

- Li, S.T. Improvement of surface flashover in vacuum. High Volt. 2020, 5, 122–133. [Google Scholar] [CrossRef]

- Xing, Z.; Chen, W.; Li, Z.; Xue, N.; Li, F.; Dai, X.; Guo, S.; Cui, H. Study on high frequency surface discharge characteristics of SiO2 modified polyimide film. Polymers 2021, 13, 4387. [Google Scholar] [CrossRef]

- Anderson, R.A.; Brainard, J.P. Mechanism of pulsed surface flashover involving electron-stimulated desorption. J. Appl. Phys. 1980, 51, 1414–1421. [Google Scholar] [CrossRef]

- Su, G.Q.; Wang, Y.B.; Guo, B.H.; Song, B.P.; Mu, H.B.; Zhang, G.J. Experimental investigation of surface charge accumulation behaviors on PTFE insulator under DC and impulse voltage in vacuum. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3347–3356. [Google Scholar] [CrossRef]

- Blaise, G.; Legressus, C. Charging and flashover induced by surface polarization relaxation process. J. Appl. Phys. 1991, 69, 6334–6339. [Google Scholar] [CrossRef]

- Kuffel, E.; Grzybowski, S.; Ugarte, R.B. Flashover across polyethylene and tetrafluoroethylene surfaces in vacuum under direct, alternating and surge voltages of various waveshapes. J. Phys. D-Appl. Phys. 1972, 5, 575–579. [Google Scholar] [CrossRef]

- Yamamoto, O.; Hara, T.; Nakae, T.; Hayashi, M.; Ueno, I. Effects of spark conditioning, insulator angle and length on surface flashover in vacuum. IEEE Trans. Electr. Insul. 1989, 24, 991–994. [Google Scholar] [CrossRef]

- Wang, W.W.; Li, S.T.; Min, D.M. Enhanced flashover strength in polyethylene nanodielectrics by secondary electron emission modification. AIP ADV 2016, 6, 045022. [Google Scholar] [CrossRef]

- Yamamoto, O.; Takuma, T.; Fukuda, M.; Nagata, S.; Sonoda, T. Improving withstand voltage by roughening the surface of an insulating spacer used in vacuum. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 550–556. [Google Scholar] [CrossRef]

- Tu, Y.; Yi, C.; Wang, S.; Qin, S.; Yuan, Z.; Fan, L. Effect of temperature on polyimide dc flashover characteristics in different vacuum degrees. J. Phys. D-Appl. Phys. 2019, 52, 305201. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, S.; Li, Z.; Pan, S.; Fan, W.; Min, D.; Li, S. Radiation electron trajectory modulated DC surface flashover of polyimide in vacuum. J. Phys. D-Appl. Phys. 2022, 55, 205201. [Google Scholar] [CrossRef]

- Neuber, A.A.; Butcher, M.; Krompholz, H.; Hatfield, L.L.; Kristiansen, M. The role of outgassing in surface flashover under vacuum. IEEE Trans. Plasma Sci. 2000, 28, 1593–1598. [Google Scholar] [CrossRef]

- Guan, H.; Chen, X.; Du, H.; Jiang, T.; Paramance, A.; Zhou, H. Surface potential decay and DC surface flashover characteristics of DBD plasma-treated silicone rubber. Nanotechnology 2020, 31, 424005. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Yin, J.; Chen, M.; Song, M.; Su, B.; Lei, Q. Effect of nano-TiO2 on the polarization process of polyimide/TiO2 composites. Mater. Lett. 2013, 96, 113–116. [Google Scholar] [CrossRef]

- Yang, X.; Sun, G.; Zhou, R.; Huang, K.; Li, W.; Wang, C.; Dong, J.; Song, B.; Zhang, G. Ultralow secondary electron emission and improved vacuum surface insulation of polyimide with scalable nanocomposite coating. Appl. Surf. Sci. 2022, 592, 153221. [Google Scholar] [CrossRef]

- Bhutta, M.S.; Akram, S.; Meng, P.; Castellon, J.; Agnel, S.; Li, H.; Guo, Y.; Rasool, G.; Hussain, S.; Nazir, M.T. Steady-state conduction current performance for multilayer polyimide/SiO2 films. Polymers 2021, 13, 640. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, R.; Liu, R.; Ping, A.; Wang, Z.; Liu, J.; Zhang, S.; Liu, Y. DC surface flashover characteristics of polyimide containing polyhedral oligomeric silsesquioxane (POSS) in the main chains under vacuum. Polymers 2022, 14, 2453. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y. Controllable aggregation structure preparation and films properties study for polyimide based on PMDA-ODA. Ph.D. Thesis, College of Polymer Science and Engineering, Sichuan University, Chengdu, China, 2007. [Google Scholar]

- Han, Y.S.; Li, S.T.; Min, D.M. Trap energy distribution in polymeric insulating materials through surface potential decay method. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 639–648. [Google Scholar] [CrossRef]

- Rychkov, A.; Kuznetsov, A.; Gulyakova, A.; Rychkov, D. Surface potential decay of corona charged polyethylene films: Influence of deep surface traps. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1933–1937. [Google Scholar] [CrossRef]

- Simmons, J.G.; Tam, M.C. Theory of isothermal currents and the direct determination of trap parameters in semiconductors and insulators containing arbitrary trap distributions. Phys. Rev. B 1973, 7, 3706–3713. [Google Scholar] [CrossRef]

- Chen, G.; Xu, Z. Charge trapping and detrapping in polymeric materials. J. Appl. Phys. 2009, 106, 637–644. [Google Scholar] [CrossRef]

- Lewis, T.J. Interfaces are the dominant feature of dielectrics at the nanometric level. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 739–753. [Google Scholar] [CrossRef]

- Tanaka, T.; Kozako, M.; Fuse, N.; Ohki, Y. Proposal of a multi-core model for polymer nanocomposite Dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 669–681. [Google Scholar] [CrossRef]

| Material | CAS | Company | Purity |

|---|---|---|---|

| Silane coupling agent (KH550) | 919-30-2 | Aladdin Inc. (Shanghai, China) | 99% |

| Anhydrous ethanol | 64-17-5 | Aladdin Inc. (Shanghai, China) | moisture content ≤0.3% |

| Nano ZnO | 1314-13-2 | ZHONGKEJINYAN Inc. (Beijing, China) | 99.98% |

| N,N-Dimethylacetamide | 127-19-5 | Aladdin Inc. (Shanghai, China) | ≥99.8% |

| Pyromellitic dianhydride | 89-32-7 | Aladdin Inc. (Shanghai, China) | 99% |

| 4,4′-Diaminodiphenyl ether | 101-80-4 | Aladdin Inc. (Shanghai, China) | 99% |

| Parameter | Original PI | 0.5 wt.% ZnO/PI | 1 wt.% ZnO/PI | 2 wt.% ZnO/PI | 3 wt.% ZnO/PI |

|---|---|---|---|---|---|

| β | 14.842 | 20.898 | 27.138 | 14.575 | 24.076 |

| α | 10.610 | 10.988 | 11.797 | 14.390 | 13.836 |

| error | 1.106 | 1.259 | 1.258 | 1.343 | 1.185 |

| Samples | Shallow Trap Energy/eV | Shallow Trap Density/eV−1‧m−3 | Deep Trap Energy/eV | Deep Trap Density/eV−1‧m−3 |

|---|---|---|---|---|

| original PI | 0.928 | 2.273 × 1021 | 0.987 | 2.998 × 1021 |

| 0.5 wt% ZnO/PI | 0.919 | 3.706 × 1021 | 0.987 | 5.076 × 1021 |

| 1 wt% ZnO/PI | 0.915 | 5.532 × 1021 | 0.991 | 6.067 × 1021 |

| 2 wt% ZnO/PI | 0.904 | 4.368 × 1021 | 0.978 | 6.603 × 1021 |

| 3 wt% ZnO/PI | 0.904 | 3.378 × 1021 | 0.974 | 5.604 × 1021 |

| Sample | Transmission Time tT/s | Thickness d/μm | Mobility μ/m2·(V·s)−1 |

|---|---|---|---|

| Original PI | 437 | 58 | 3.12 × 10−15 |

| 0.5 wt.% PI/ZnO | 344 | 52 | 3.55 × 10−15 |

| 1 wt.% PI/ZnO | 212 | 50 | 6.06 × 10−15 |

| 2 wt.% PI/ZnO | 283 | 67 | 6.56 × 10−15 |

| 3 wt.% PI/ZnO | 209 | 58 | 8.98 × 10−15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Zhang, B.; Li, T.; Du, Y.; Cao, W.; Yang, H. Effect of Trap Regulation on Vacuum DC Surface Flashover Characteristics of Nano-ZnO/PI Film. Polymers 2022, 14, 3605. https://doi.org/10.3390/polym14173605

Wu J, Zhang B, Li T, Du Y, Cao W, Yang H. Effect of Trap Regulation on Vacuum DC Surface Flashover Characteristics of Nano-ZnO/PI Film. Polymers. 2022; 14(17):3605. https://doi.org/10.3390/polym14173605

Chicago/Turabian StyleWu, Jiang, Bo Zhang, Tianjiao Li, Yan Du, Wen Cao, and Hao Yang. 2022. "Effect of Trap Regulation on Vacuum DC Surface Flashover Characteristics of Nano-ZnO/PI Film" Polymers 14, no. 17: 3605. https://doi.org/10.3390/polym14173605