New Composite Materials Made from Rigid/Flexible Polyurethane Foams with Fir Sawdust: Acoustic and Thermal Behavior

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

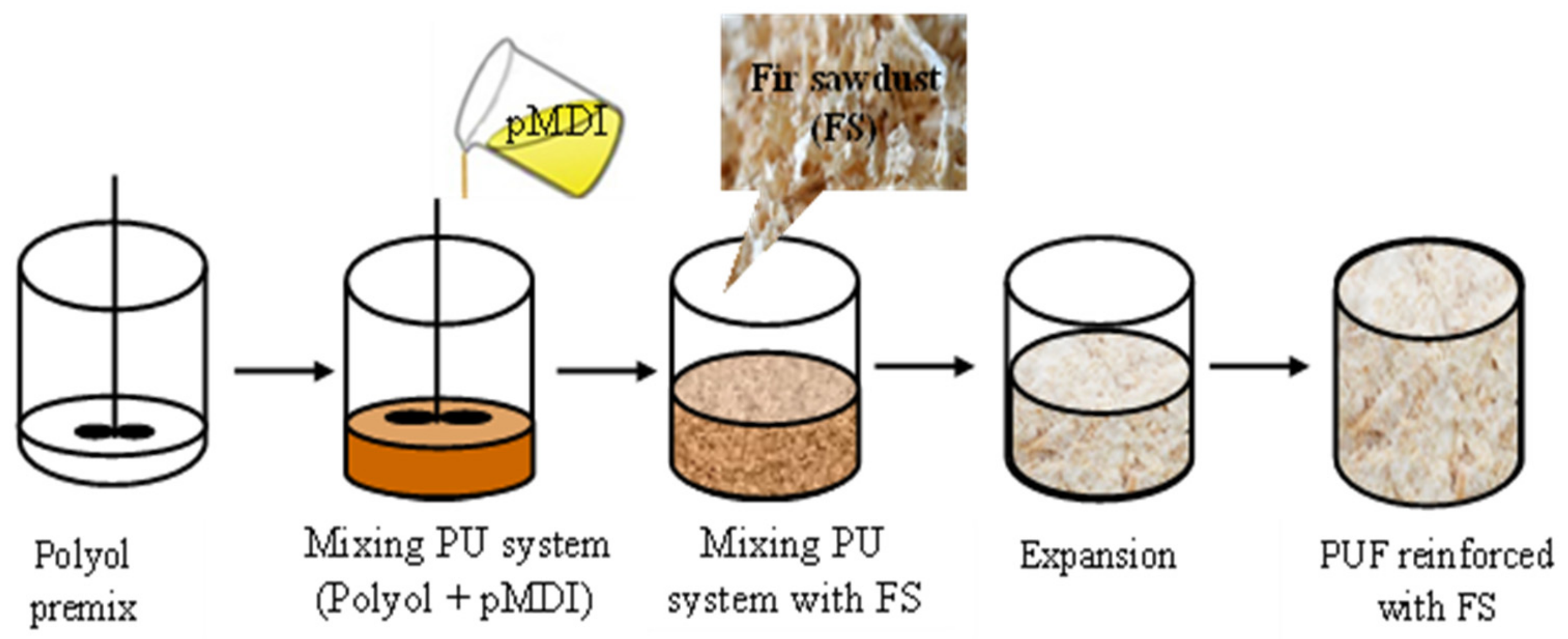

2.2. Preparation of the New Composite Materials

2.3. Morphological Analysis

2.4. Acoustical Properties

2.5. Thermal Conductivity

3. Results and Discussion

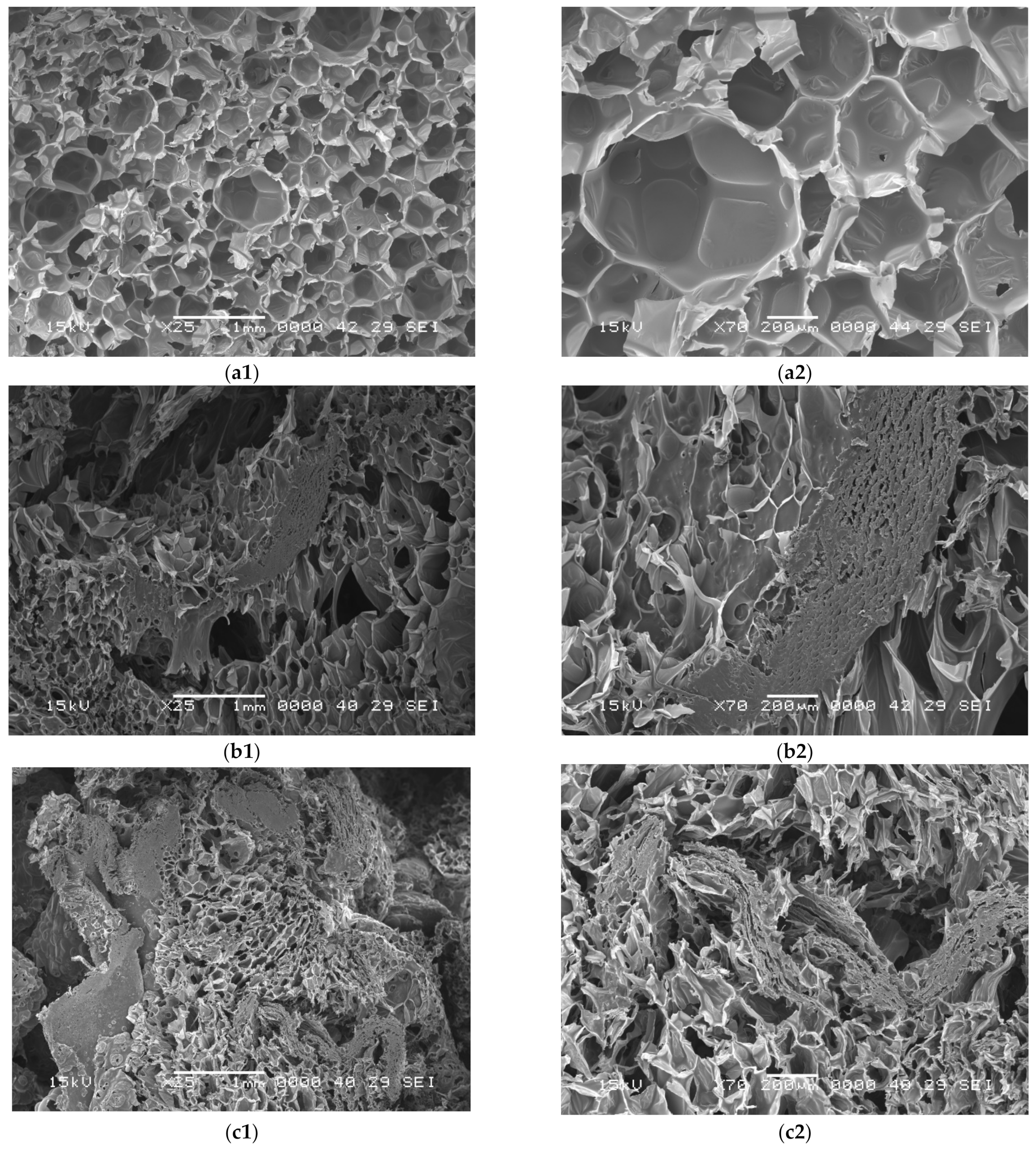

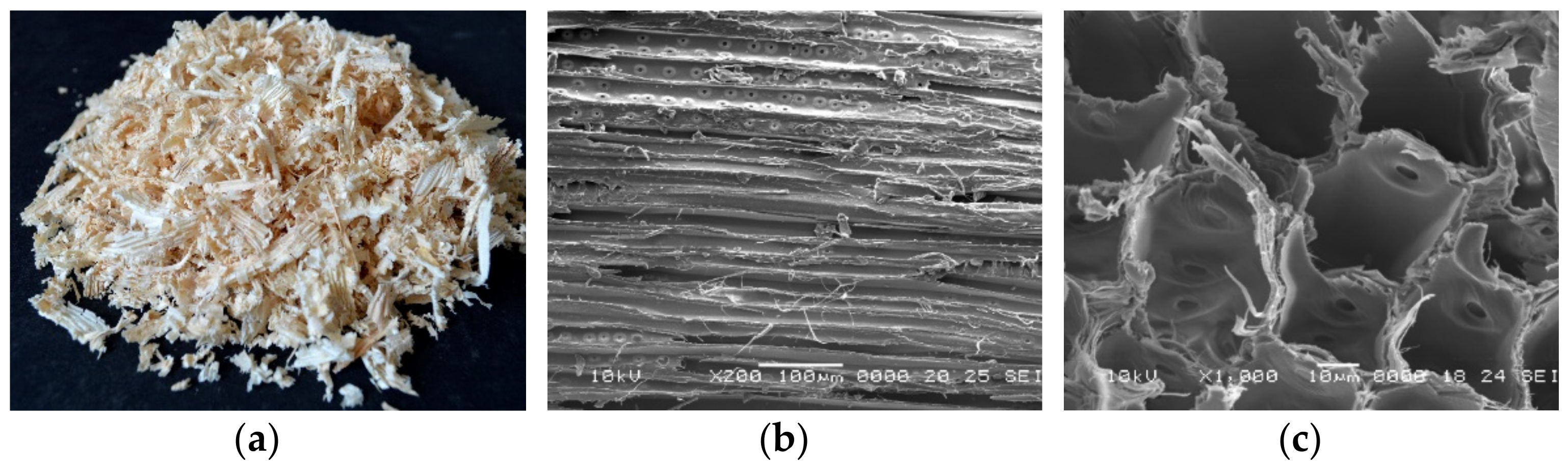

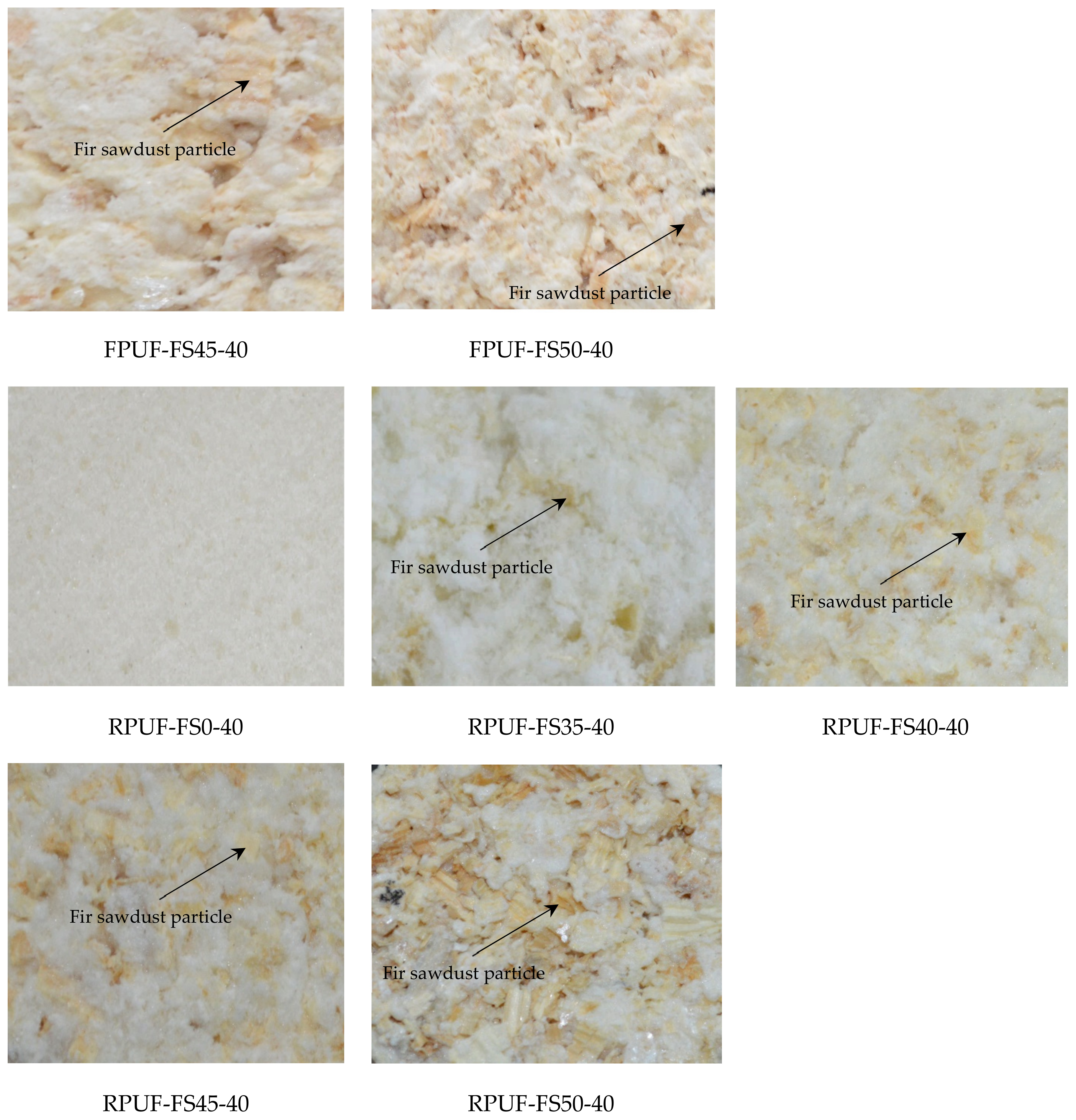

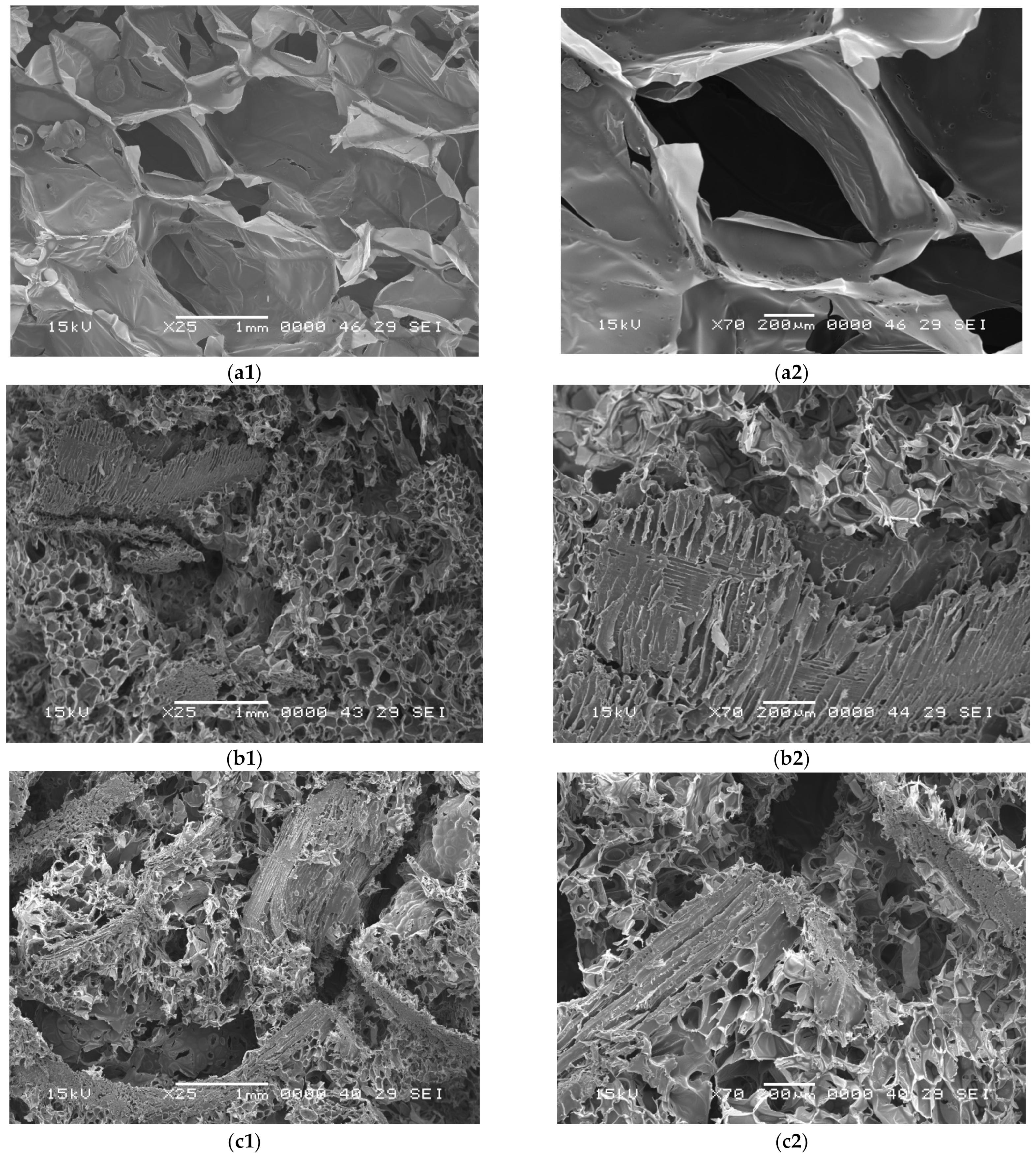

3.1. Morphological Characterization

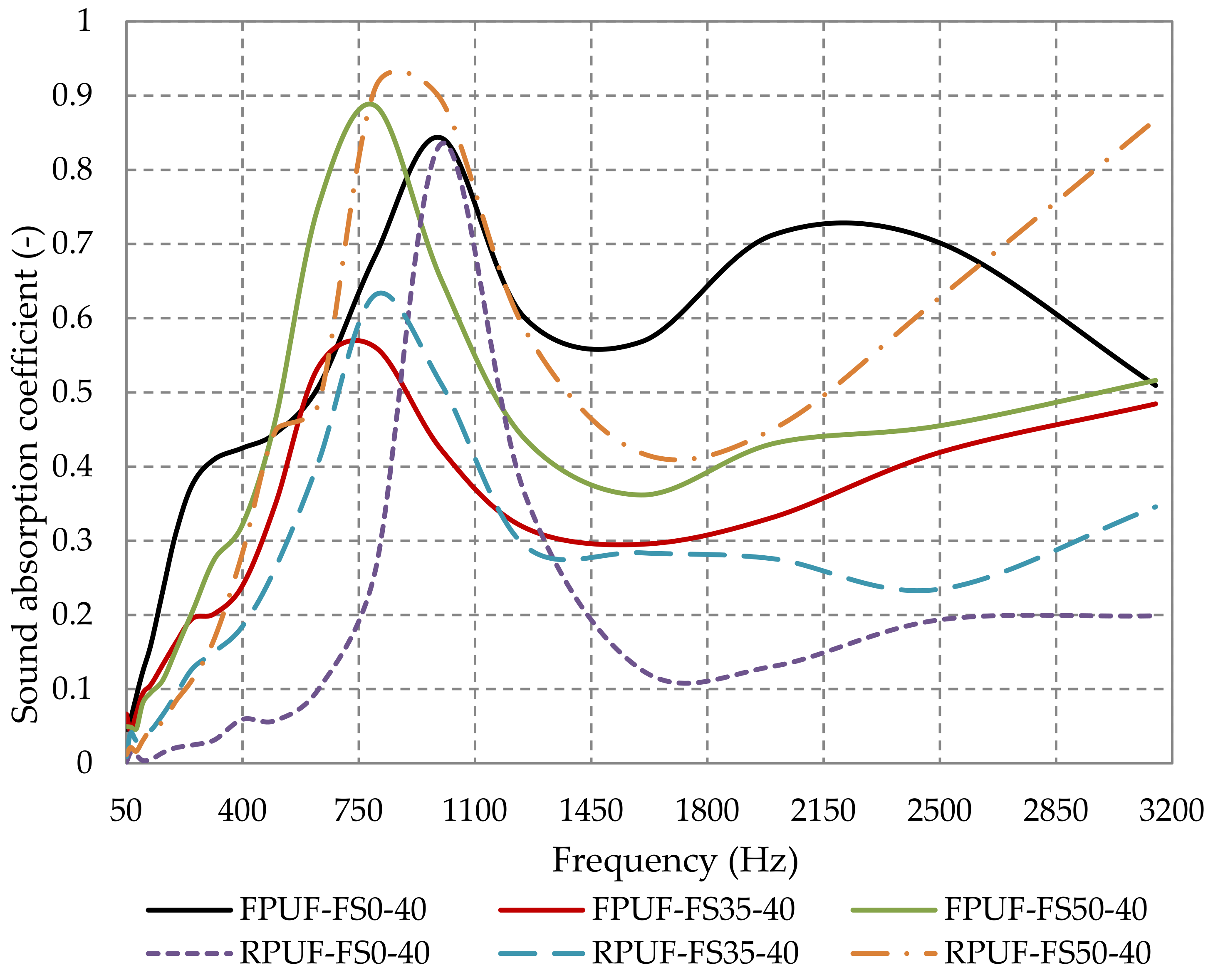

3.2. Sound Absorbtion Coefficients

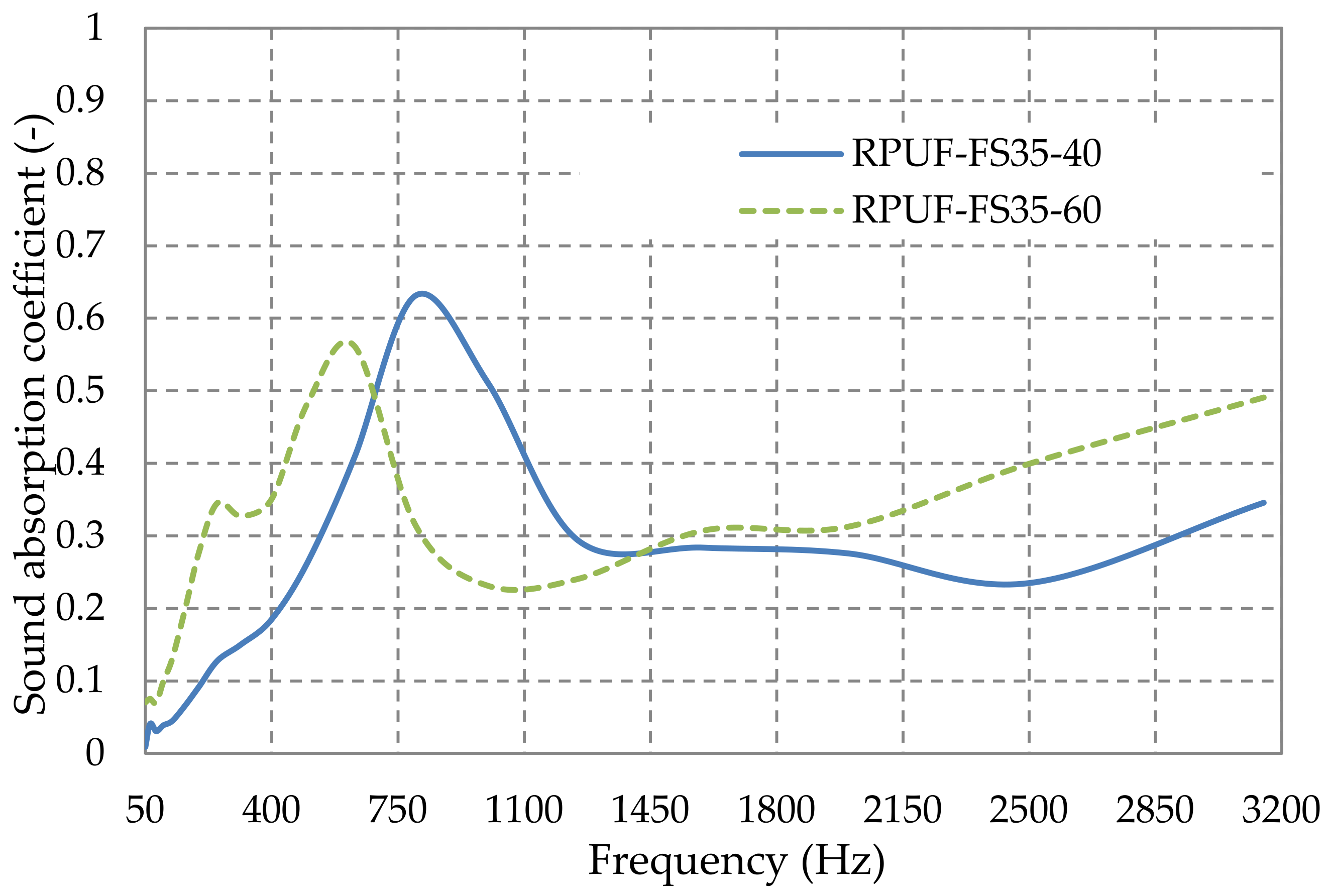

3.2.1. Influence of Material Thickness and Placement on Acoustic Properties

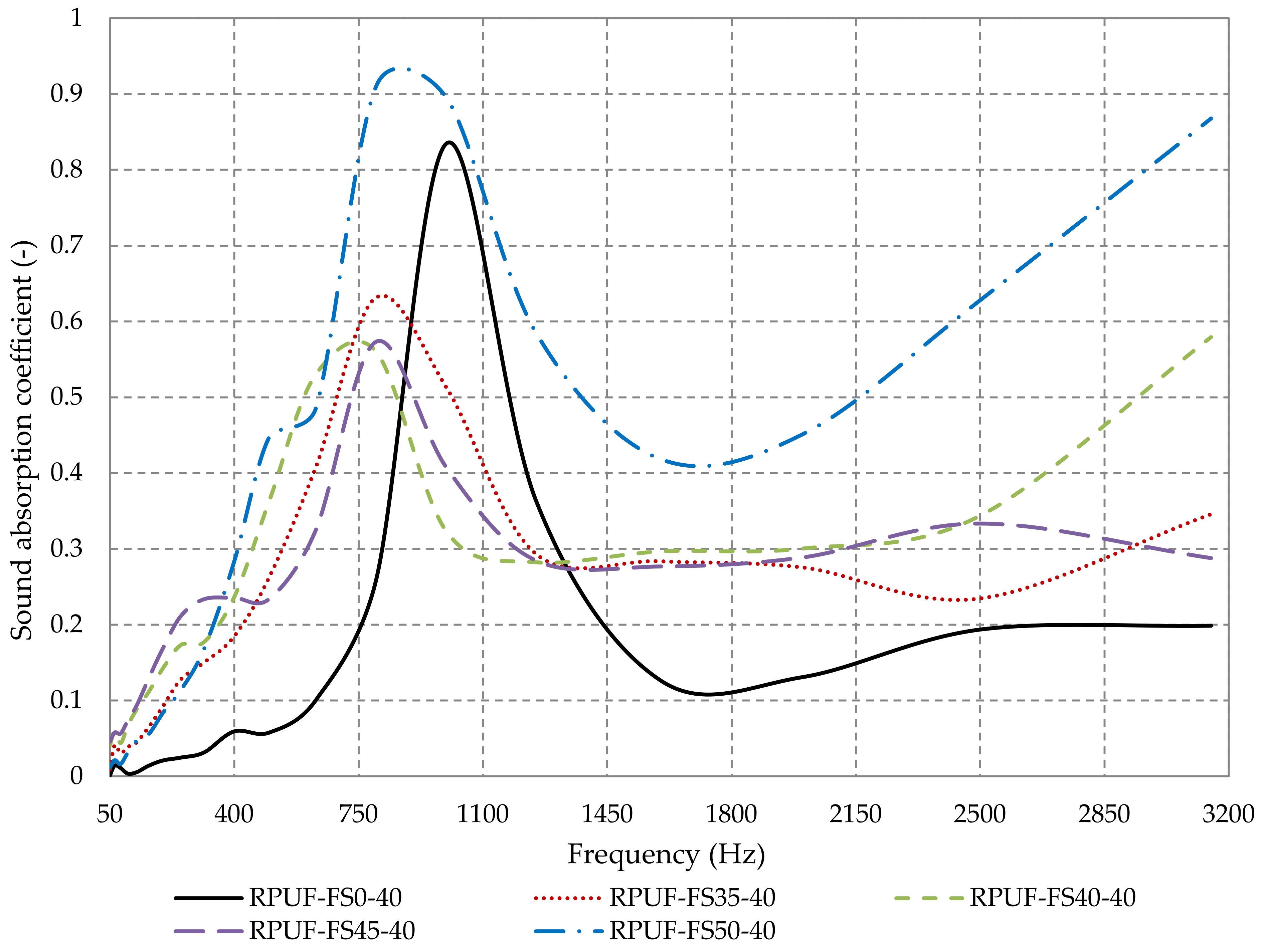

3.2.2. Influence of Sawdust Percentage on Sound Absorption Coefficient

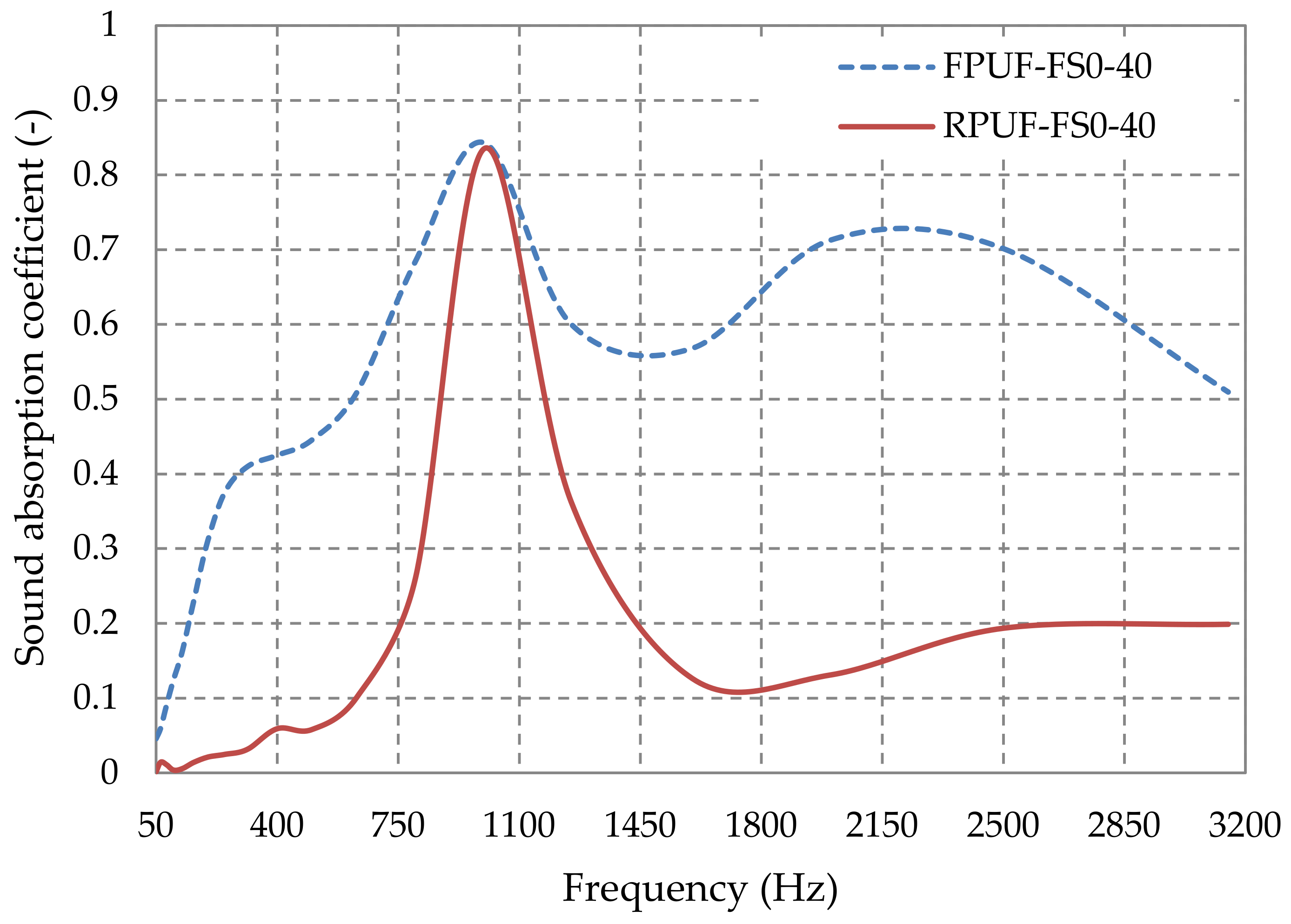

3.2.3. Influence of the Type of Polyurethane Foam on Sound Absorption Coefficient

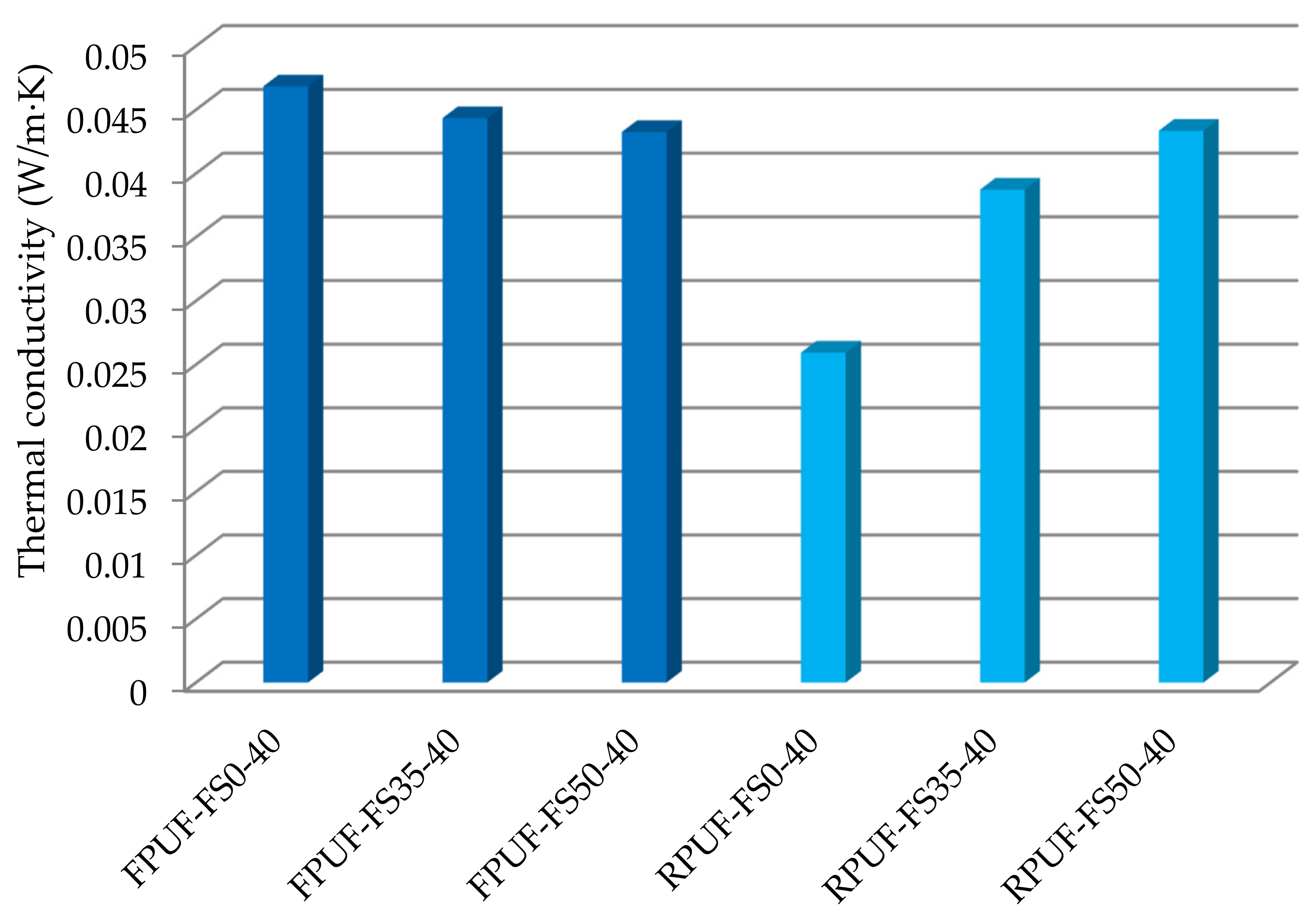

3.3. Thermal Conductivity

4. Conclusions

- -

- the morphological structure,

- -

- the percentage of sawdust in the matrix,

- -

- the type of the matrix,

- -

- the thickness of the plate,

- -

- the position of the material in the structure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kishore, S.; Sujithra, R.; Dhatreyi, B. A review on latest acoustic noise mitigation materials. Mater. Today Proc. 2021, 47, 4700–4707. [Google Scholar] [CrossRef]

- Lyu, L.; Zhang, D.; Tian, Y.; Zhou, X. Sound-absorption Performance and fractal dimension feature of kapok fibre/polycaprolactone composites. Coatings 2021, 11, 1000. [Google Scholar] [CrossRef]

- Bhingare, N.H.; Prakash, S.; Jatti, V.S. A review on natural and waste material composite as acoustic material. Polym. Test. 2019, 80, 106142. [Google Scholar] [CrossRef]

- Vahabi, H.; Jouyandeh, M.; Parpaite, T.; Saeb, M.R.; Ramakrishna, S. Coffee wastes as sustainable flame retardants for polymer materials. Coatings 2021, 11, 1021. [Google Scholar] [CrossRef]

- Tiuc, A.E.; Vasile, O.; Vermeşan, H.; Nemeş, O. The Use of mathematical models in determining acoustic absorption coefficient of new composite porous materials. Rom. J. Acoust. Vib. 2017, 14, 97–101. [Google Scholar]

- Pedroso, M.; de Brito, J.; Silvestre, J. Characterization of eco-efficient acoustic insulation materials (traditional and innovative). Constr. Build. Mater. 2017, 140, 221–228. [Google Scholar] [CrossRef]

- Peng, L.; Song, B.; Wang, J.; Wang, D. Mechanic and acoustic properties of the sound-absorbing material made from natural fiber and polyester. Adv. Mater. Sci. Eng. 2015, 2015, 274913. [Google Scholar] [CrossRef]

- Alrahman, L.A.; Raja, R.I.; Rahman, R.A. Experimental study on natural fibers for green acoustic absorption materials. Am. J. Appl. Sci. 2013, 10, 1307–1314. [Google Scholar] [CrossRef]

- Cuthbertson, D.; Berardi, U.; Briens, C.; Berruti, F. Biochar from residual biomass as a concrete filler for improved thermal and acoustic properties. Biomass Bioenergy 2019, 120, 77–83. [Google Scholar] [CrossRef]

- Mokhtari, C.; Harit, T.; Khiari, R.; Malek, F. Biobased Composites from jojoba oil and fibers from alfa stems: Elaboration and characterization. Ind. Crop. Prod. 2022, 176, 114294. [Google Scholar] [CrossRef]

- Alothman, O.Y.; Kian, L.K.; Saba, N.; Jawaid, M.; Khiari, R. Cellulose nanocrystal extracted from date palm fibre: Morphological, structural and thermal properties. Ind. Crop. Prod. 2021, 159, 113075. [Google Scholar] [CrossRef]

- Väisänen, T.; Das, O.; Tomppo, L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Demirel, S.; Tuna, B.E. Evaluation of the cyclic fatigue performance of polyurethane foam in different density and category. Polym. Test. 2019, 76, 146–153. [Google Scholar] [CrossRef]

- Yun, G.W.; Lee, J.H.; Kim, S.H. Flame Retardant and mechanical properties of expandable graphite/polyurethane foam composites containing iron phosphonate dopamine-coated cellulose. Polym. Compos. 2020, 41, 2816–2828. [Google Scholar] [CrossRef]

- Bedell, M.; Brown, M.; Kiziltas, A.; Mielewski, D.; Mukerjee, S.; Tabor, R. A case for closed-loop recycling of post-consumer PET for automotive foams. Waste Manag. 2018, 71, 97–108. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, S.H.; Oh, K.W. Bio-based polyurethane foams with castor oil based multifunctional polyols for improved compressive properties. Polymers 2021, 13, 576. [Google Scholar] [CrossRef]

- Yu, S.; Li, X.; Zhao, Y.; Zou, M. A Novel lightweight polyurethane composite for application on ultra-high-voltage insulator core filler. Polymers 2020, 12, 2737. [Google Scholar] [CrossRef]

- Wang, H.; Li, T.-T.; Ren, H.; Peng, H.; Huang, S.-Y.; Lin, Q.; Lin, J.-H.; Lou, C.-W. Expanded vermiculite-filled polyurethane foam-core bionic composites: Preparation and thermal, compression, and dynamic cushion properties. Polymers 2019, 11, 1028. [Google Scholar] [CrossRef]

- Lee, Y.J.; Park, C.K.; Kim, S.H. Fabrication of castor-oil/polycaprolactone based bio-polyurethane foam reinforced with nanocellulose. Polym. Compos. 2018, 39, 2004–2011. [Google Scholar] [CrossRef]

- Jonjaroen, V.; Ummartyotin, S.; Chittapun, S. Algal cellulose as a reinforcement in rigid polyurethane foam. Algal Res. 2020, 51, 102057. [Google Scholar] [CrossRef]

- Kaur, R.; Kumar, M. Addition of Anti-Flaming Agents in Castor Oil Based Rigid Polyurethane Foams: Studies on Mechanical and Flammable Behaviour. Mater. Res. Express 2020, 7, 015333. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R. Effect of Nano Filler on the Flammability of Bio-Based RPUF. Integr. Ferroelectr. 2019, 202, 20–28. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R.S. Flame Retardancy of Ceramic-based Rigid Polyurethane Foam Composites. J. Appl. Polym. Sci. 2019, 136, 48250. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R.S. Investigation on Flammability of Rigid Polyurethane Foam-mineral Fillers Composite. Fire Mater. 2019, 43, 917–927. [Google Scholar] [CrossRef]

- Doutres, O.; Atalla, N.; Dong, K. Effect of the microstructure closed pore content on the acoustic behavior of polyurethane foams. J. Appl. Phys. 2011, 110, 064901. [Google Scholar] [CrossRef]

- Soto, G.; Castro, A.; Vechiatti, N.; Iasi, F.; Armas, A.; Marcovich, N.E.; Mosiewicki, M.A. Biobased porous acoustical absorbers made from polyurethane and waste tire particles. Polym. Test. 2017, 57, 42–51. [Google Scholar] [CrossRef]

- Arenas, J.P.; Crocker, M.J. Recent trends in porous sound-absorbing materials. Sound Vib. 2010, 44, 12–18. [Google Scholar]

- Tan, S.; Abraham, T.; Ference, D.; Macosko, C.W. Rigid polyurethane foams from a soybean oil-based polyol. Polymer 2011, 52, 2840–2846. [Google Scholar] [CrossRef]

- Yang, C.; Fischer, L.; Maranda, S.; Worlitschek, J. Rigid polyurethane foams incorporated with phase change materials: A state-of-the-art review and future research pathways. Energy Build. 2015, 87, 25–36. [Google Scholar] [CrossRef]

- Zhang, W.; Lei, Y.; Li, X.; Shao, H.; Xu, W.; Li, D. A Facile, Environmentally and friendly flame-retardant: Synergistic flame retardant property of polyurethane rigid foam. Mater. Lett. 2020, 267, 127542. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, J.; Liu, L.; Zheng, H.; Dai, J.; Tang, L.-C.; Song, P. A highly fire-retardant rigid polyurethane foam capable of fire-warning. Compos. Commun. 2022, 29, 101046. [Google Scholar] [CrossRef]

- Bernardini, J.; Cinelli, P.; Anguillesi, I.; Coltelli, M.-B.; Lazzeri, A. Flexible polyurethane foams green production employing lignin or oxypropylated lignin. Eur. Polym. J. 2015, 64, 147–156. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R.S. PU Foam Derived from Renewable Sources: Perspective on Properties Enhancement: An Overview. Eur. Polym. J. 2017, 95, 255–274. [Google Scholar] [CrossRef]

- Kumar, M.; Kaur, R. Glass Fiber Reinforced Rigid Polyurethane Foam: Synthesis and Characterization. e-Polymers 2017, 17, 517–521. [Google Scholar] [CrossRef]

- Da Silva, V.R.; Mosiewicki, M.A.; Yoshida, M.I.; da Silva, M.C.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash i: Synthesis and physical chemical characterization. Polym. Test. 2013, 32, 438–445. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K. Rigid Polyurethane foams reinforced with industrial potato protein. Polym. Test. 2018, 68, 135–145. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Tiuc, A.E.; Nemes, O.; Vermeșan, H.; Gavrea, D.R.T.; Vasile, O. New sound absorbing materials obtained from waste rigid polyurethane foam. Mater. Plast. 2019, 56, 1021–1027. [Google Scholar] [CrossRef]

- Tiuc, A.E.; Nemeş, O.; Vermeşan, H.; Toma, A.C. New sound absorbent composite materials based on sawdust and polyurethane foam. Compos. Part B Eng. 2019, 165, 120–130. [Google Scholar] [CrossRef]

- Borlea, A.; Rusu, T.; Vasile, O. Using particles of recycled rubber when making some soundproofing materials. Mater. Plast. 2012, 49, 275–278. [Google Scholar]

- Tiuc, A.E.; Vermeşan, H.; Gabor, T.; Vasile, O. Improved sound absorption properties of polyurethane foam mixed with textile waste. Energy Procedia 2016, 85, 559–565. [Google Scholar] [CrossRef]

- Mohammadi, B.; Safaiyan, A.; Habibi, P.; Moradi, G. Evaluation of the acoustic performance of polyurethane foams embedded with rock wool fibers at low-frequency range; design and construction. Appl. Acoust. 2021, 182, 108223. [Google Scholar] [CrossRef]

- Kairytė, A.; Członka, S.; Boris, R.; Vėjelis, S. Evaluation of the performance of bio-based rigid polyurethane foam with high amounts of sunflower press cake particles. Materials 2021, 14, 5475. [Google Scholar] [CrossRef]

- Lima, D.C.; de Melo, R.R.; Pimenta, A.S.; Pedrosa, T.D.; de Souza, M.J.C.; de Souza, E.C. Physical–mechanical properties of wood panel composites produced with Qualea Sp. sawdust and recycled polypropylene. Environ. Sci. Pollut. Res. 2020, 27, 4858–4865. [Google Scholar] [CrossRef]

- Tiuc, A.E.; Rusu, T.; Nemeş, O. Obtaining Process Sound Absorbent Composite Material. International Classification C04B 26/26 (2006.01). Patent No. 129228 B1, 28 August 2015. [Google Scholar]

- EN 12085; Thermal Insulating Products for Building Applications—Determination of Linear Dimensions of Test Specimens. European Standardization Committee: Brussels, Belgium, 2013.

- EN 10534; Acoustics. Determination of Sound Absorption Coefficient and Impedance in Impedances Tubes Part 2: Transfer-Function Method. International Organization for Standardization (ISO): Geneva, Switzerland, 2002.

- EN 12667; Thermal Performance of Building Materials and Products. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods. Products of High and Medium Thermal Resistance. International Organization for Standardization (ISO): Geneva, Switzerland, 2001.

- Moradi, G.; Monazzam, M.; Ershad-Langroudi, A.; Parsimehr, H.; Keshavarz, S.T. Organoclay nanoparticles interaction in PU:PMMA IPN foams: Relationship between the cellular structure and damping-acoustical properties. Appl. Acoust. 2020, 164, 107295. [Google Scholar] [CrossRef]

- Pinto, S.C.; Marques, P.A.A.P.; Vicente, R.; Godinho, L.; Duarte, I. Hybrid structures made of polyurethane/graphene nanocomposite foams embedded within aluminum open-cell foam. Metals 2020, 10, 768. [Google Scholar] [CrossRef]

- Gu, R.; Sain, M.M.; Konar, S.K. A Feasibility study of polyurethane composite foam with added hardwood pulp. Ind. Crop. Prod. 2013, 42, 273–279. [Google Scholar] [CrossRef]

- Silva, M.C.; Takahashi, J.A.; Chaussy, D.; Belgacem, M.N.; Silva, G.G. Composites of rigid polyurethane foam and cellulose fiber residue. J. Appl. Polym. Sci. 2010, 117, 3665–3672. [Google Scholar] [CrossRef]

- Shan, C.W.; Idris, M.I.; Ghazali, M.I. Study of flexible polyurethane foams reinforced with coir fibres and tyre particles. Int. J. Appl. Phys. Math. 2012, 2, 123. [Google Scholar] [CrossRef]

- Park, S.J.; Cho, S.-H.; Seo, H.W.; Nam, J.-D.; Suhr, J. Natural cork agglomerate enabled mechanically robust rigid polyurethane foams with outstanding viscoelastic damping properties. Polymer 2021, 217, 123437. [Google Scholar] [CrossRef]

- Madaleno, L.; Pyrz, R.; Crosky, A.; Jensen, L.R.; Rauhe, J.C.M.; Dolomanova, V.; Timmons, A.M.M.V.D.B.; Pinto, J.J.C.; Norman, J. Processing and characterization of polyurethane nanocomposite foam reinforced with montmorillonite–carbon nanotube hybrids. Compos. A Appl. Sci. Manuf. 2013, 44, 1–7. [Google Scholar] [CrossRef]

- Uram, K.; Kurańska, M.; Andrzejewski, J.; Prociak, A. Rigid polyurethane foams modified with biochar. Materials 2021, 14, 5616. [Google Scholar] [CrossRef] [PubMed]

- Miedzińska, K.; Członka, S.; Strąkowska, A.; Strzelec, K. Biobased polyurethane composite foams reinforced with plum stones and silanized plum stones. Int. J. Mol. Sci. 2021, 22, 4757. [Google Scholar] [CrossRef] [PubMed]

- Gwon, J.G.; Kim, S.K.; Kim, J.H. Sound absorption behavior of flexible polyurethane foams with distinct cellular structures. Mater. Des. 2016, 89, 448–454. [Google Scholar] [CrossRef]

- Gayathri, R.; Vasanthakumari, R.; Padmanabhan, C. Sound Absorption, Thermal and mechanical behavior of polyurethane foam modified with nano silica, nano clay and crumb rubber fillers. Int. J. Sci. Eng. Res. 2013, 4, 301–308. [Google Scholar]

- Lee, J.; Kim, G.-H.; Ha, C.-S. Sound absorption properties of polyurethane/nanosilica nanocomposite foams. J. Appl. Polym. Sci. 2012, 123, 2384–2390. [Google Scholar] [CrossRef]

- Sung, C.H.; Lee, K.S.; Lee, K.S.; Oh, S.M.; Kim, J.H.; Kim, M.S.; Jeong, H.M. Sound damping of a PU foam nanocomposite. In Proceedings of the 2008 Third International Forum on Strategic Technologies, Novosibirsk, Russia, 23–29 June 2008; Instsitute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2008; pp. 181–185. [Google Scholar]

- Park, H.-M.; Mohanty, A.K.; Drzal, L.T.; Lee, E.; Mielewski, D.F.; Misra, M. Effect of sequential mixing and compounding conditions on cellulose acetate/layered silicate nanocomposites. J. Polym. Environ. 2006, 14, 27–35. [Google Scholar] [CrossRef]

- Doutres, O.; Atalla, N.; Dong, K. A Semi-phenomenological model to predict the acoustic behavior of fully and partially reticulated polyurethane foams. J. Appl. Phys. 2013, 113, 054901. [Google Scholar] [CrossRef]

- Mosanenzadeh, S.G.; Doutres, O.; Naguib, H.E.; Park, C.B.; Atalla, N. A Numerical scheme for investigating the effect of bimodal structure on acoustic behavior of polylactide foams. Appl. Acoust. 2015, 88, 75–83. [Google Scholar] [CrossRef]

- Prasetiyo, I.; Muqowi, E.; Putra, A.; Novenbrianty, M.; Desendra, G.; Adhika, D.R. Modelling sound absorption of tunable double layer woven fabrics. Appl. Acoust. 2020, 157, 107008. [Google Scholar] [CrossRef]

- El-Abbassi, F.E.; Assarar, M.; Ayad, R.; Bourmaud, A.; Baley, C. A Review on alfa fibre (Stipa tenacissima L.): From the plant architecture to the reinforcement of polymer composites. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105677. [Google Scholar] [CrossRef]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Tichy, M.; Muller, M. Factors affecting acoustic properties of natural-fiber-based materials and composites: A review. Textiles 2021, 1, 55–85. [Google Scholar] [CrossRef]

- Cherradi, Y.; Rosca, I.C.; Cerbu, C.; Kebir, H.; Guendouz, A.; Benyoucef, M. Acoustic properties for composite materials based on alfa and wood fibers. Appl. Acoust. 2021, 174, 107759. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Hu, Z.; Zhu, F.; Huang, Y. Correlation between the acoustic and porous cell morphology of polyurethane foam: Effect of interconnected porosity. Mater. Des. 2012, 41, 319–325. [Google Scholar] [CrossRef]

- Hong, Z.; Bo, L.; Guangsu, H.; Jia, H. A Novel composite sound absorber with recycled rubber particles. J. Sound Vib. 2007, 304, 400–406. [Google Scholar] [CrossRef]

- Verdejo, R.; Stämpfli, R.; Alvarez-Lainez, M.; Mourad, S.; Perez, M.A.R.; Brühwiler, P.; Shaffer, M. Enhanced acoustic damping in flexible polyurethane foams filled with carbon nanotubes. Compos. Sci. Technol. 2009, 69, 1564–1569. [Google Scholar] [CrossRef]

- Lind-Nordgren, E.; Göransson, P. Optimising open porous foam for acoustical and vibrational performance. J. Sound Vib. 2010, 329, 753–767. [Google Scholar] [CrossRef]

- Bahrambeygi, H.; Sabetzadeh, N.; Rabbi, A.; Nasouri, K.; Shoushtari, A.M.; Babaei, M.R. Nanofibers (PU and PAN) and nanoparticles (Nanoclay and MWNTs) simultaneous effects on polyurethane foam sound absorption. J. Polym. Res. 2013, 20, 72. [Google Scholar] [CrossRef]

- Liu, T.; Mao, L.; Liu, F.; Jiang, W.; He, Z.; Fang, P. Preparation, structure, and properties of flexible polyurethane foams filled with fumed silica. Wuhan Univ. J. Nat. Sci. 2011, 16, 29–32. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M.R. Dynamic mechanical properties of sugar palm/glass fiber reinforced thermoplastic polyurethane hybrid composites. Polym. Compos. 2019, 40, 1329–1334. [Google Scholar] [CrossRef]

- Koruk, H.; Koc, B.; Genc, G. Acoustic and mechanical properties of biofibers and their composites. In Advances in Bio-Based Fiber; Rangappa, S.M., Puttegowda, M., Parameswaranpillai, J., Siengchin, S., Gorbatyuk, S., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 407–446. [Google Scholar]

- Zhang, H.; Fang, W.-Z.; Li, Y.-M.; Tao, W.-Q. Experimental study of the thermal conductivity of polyurethane foams. Appl. Therm. Eng. 2017, 115, 528–538. [Google Scholar] [CrossRef]

- De Avila Delucis, R.; Magalhaes, W.L.E.; Petzhold, C.L.; Amico, S.C. Forest-based resources as fillers in biobased polyurethane foams. J. Appl. Polym. Sci. 2018, 135, 45684. [Google Scholar] [CrossRef]

- Khaleel, M.; Soykan, U.; Çetin, S. Influences of turkey feather fiber loading on significant characteristics of rigid polyurethane foam: Thermal degradation, heat insulation, acoustic performance, air permeability and cellular structure. Constr. Build. Mater. 2021, 308, 125014. [Google Scholar] [CrossRef]

- Zou, S.; Li, H.; Wang, S.; Jiang, R.; Zou, J.; Zhang, X.; Liu, L.; Zhang, G. Experimental research on an innovative sawdust biomass-based insulation material for buildings. J. Clean. Prod. 2020, 260, 121029. [Google Scholar] [CrossRef]

- Tiuc, A.E.; Moga, L. Improvement of acoustic and thermal comfort by turning waste into composite materials. Rom. J. Acoust. Vib. 2013, 10, 77–82. [Google Scholar]

| Sample No. | Code | Fir Sawdust (wt%) | Binder Type | Thickness (mm) | Apparent Density (g/cm3) |

|---|---|---|---|---|---|

| 1 | FPUF-FS0-40 | 0 | Flexible polyurethane foam | 40 | 0.026 |

| 2 | FPUF-FS0-60 | 0 | 60 | 0.026 | |

| 3 | FPUF-FS35-40 | 35 | 40 | 0.075 | |

| 4 | FPUF-FS35-60 | 35 | 60 | 0.075 | |

| 5 | FPUF-FS40-40 | 40 | 40 | 0.094 | |

| 6 | FPUF-FS40-60 | 40 | 60 | 0.094 | |

| 7 | FPUF-FS45-40 | 45 | 40 | 0.108 | |

| 8 | FPUF-FS50-40 | 50 | 40 | 0.116 | |

| 9 | RPUF-FS0-40 | 0 | Rigid polyurethane foam | 40 | 0.034 |

| 10 | RPUF-FS0-60 | 0 | 60 | 0.034 | |

| 11 | RPUF-FS35-40 | 35 | 40 | 0.089 | |

| 12 | RPUF-FS35-60 | 35 | 60 | 0.089 | |

| 13 | RPUF-FS40-40 | 40 | 40 | 0.102 | |

| 14 | RPUF-FS40-60 | 40 | 60 | 0.102 | |

| 15 | RPUF-FS45-40 | 45 | 40 | 0.117 | |

| 16 | RPUF-FS50-40 | 50 | 40 | 0.125 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiuc, A.-E.; Borlea, S.I.; Nemeș, O.; Vermeșan, H.; Vasile, O.; Popa, F.; Pințoi, R. New Composite Materials Made from Rigid/Flexible Polyurethane Foams with Fir Sawdust: Acoustic and Thermal Behavior. Polymers 2022, 14, 3643. https://doi.org/10.3390/polym14173643

Tiuc A-E, Borlea SI, Nemeș O, Vermeșan H, Vasile O, Popa F, Pințoi R. New Composite Materials Made from Rigid/Flexible Polyurethane Foams with Fir Sawdust: Acoustic and Thermal Behavior. Polymers. 2022; 14(17):3643. https://doi.org/10.3390/polym14173643

Chicago/Turabian StyleTiuc, Ancuța-Elena, Simona Ioana Borlea (Mureșan), Ovidiu Nemeș, Horațiu Vermeșan, Ovidiu Vasile, Florin Popa, and Ramona Pințoi. 2022. "New Composite Materials Made from Rigid/Flexible Polyurethane Foams with Fir Sawdust: Acoustic and Thermal Behavior" Polymers 14, no. 17: 3643. https://doi.org/10.3390/polym14173643

APA StyleTiuc, A.-E., Borlea, S. I., Nemeș, O., Vermeșan, H., Vasile, O., Popa, F., & Pințoi, R. (2022). New Composite Materials Made from Rigid/Flexible Polyurethane Foams with Fir Sawdust: Acoustic and Thermal Behavior. Polymers, 14(17), 3643. https://doi.org/10.3390/polym14173643