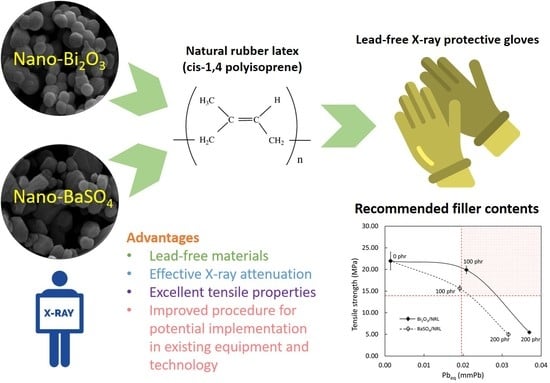

A Comparative Study on X-ray Shielding and Mechanical Properties of Natural Rubber Latex Nanocomposites Containing Bi2O3 or BaSO4: Experimental and Numerical Determination

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Chemicals

2.2. Preparation of SVNRL Mixture

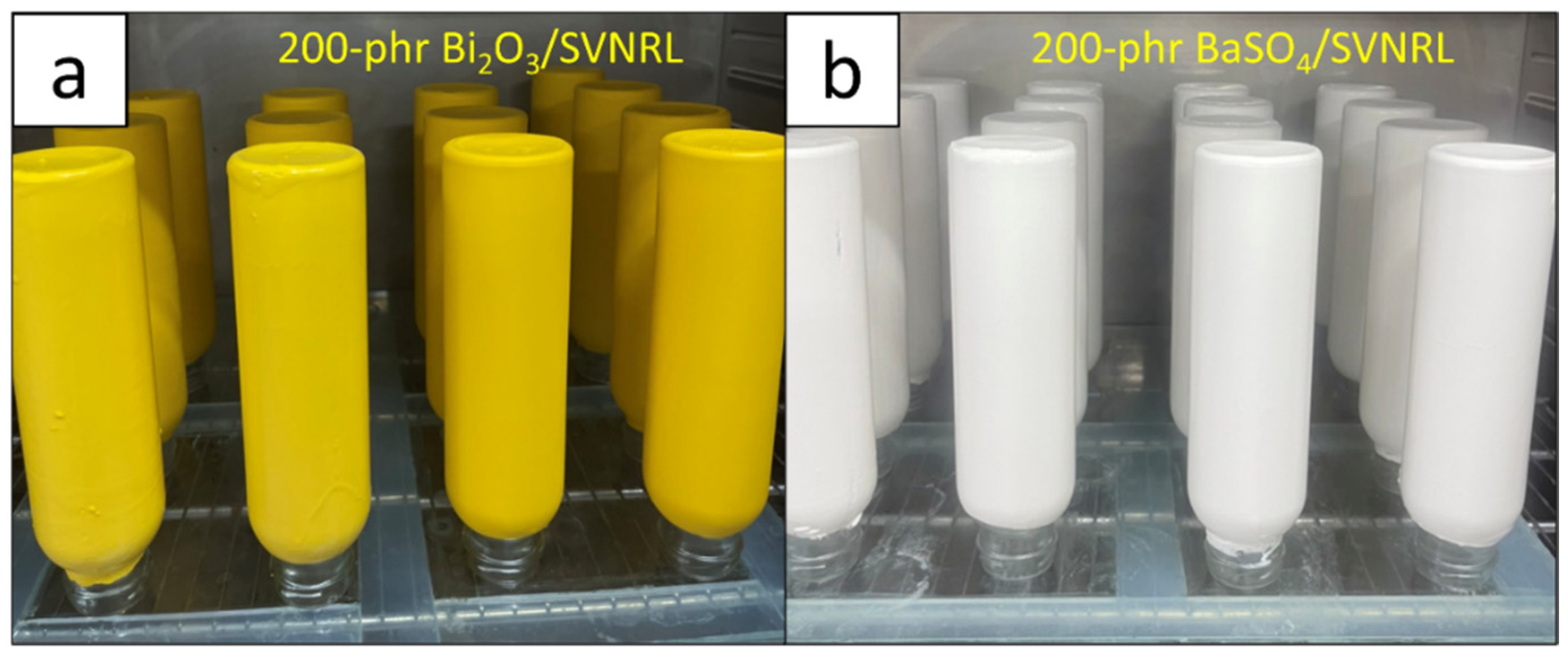

2.3. Preparation of Nano-Bi2O3/SVNRL and Nano-BaSO4/SVNRL Gloves

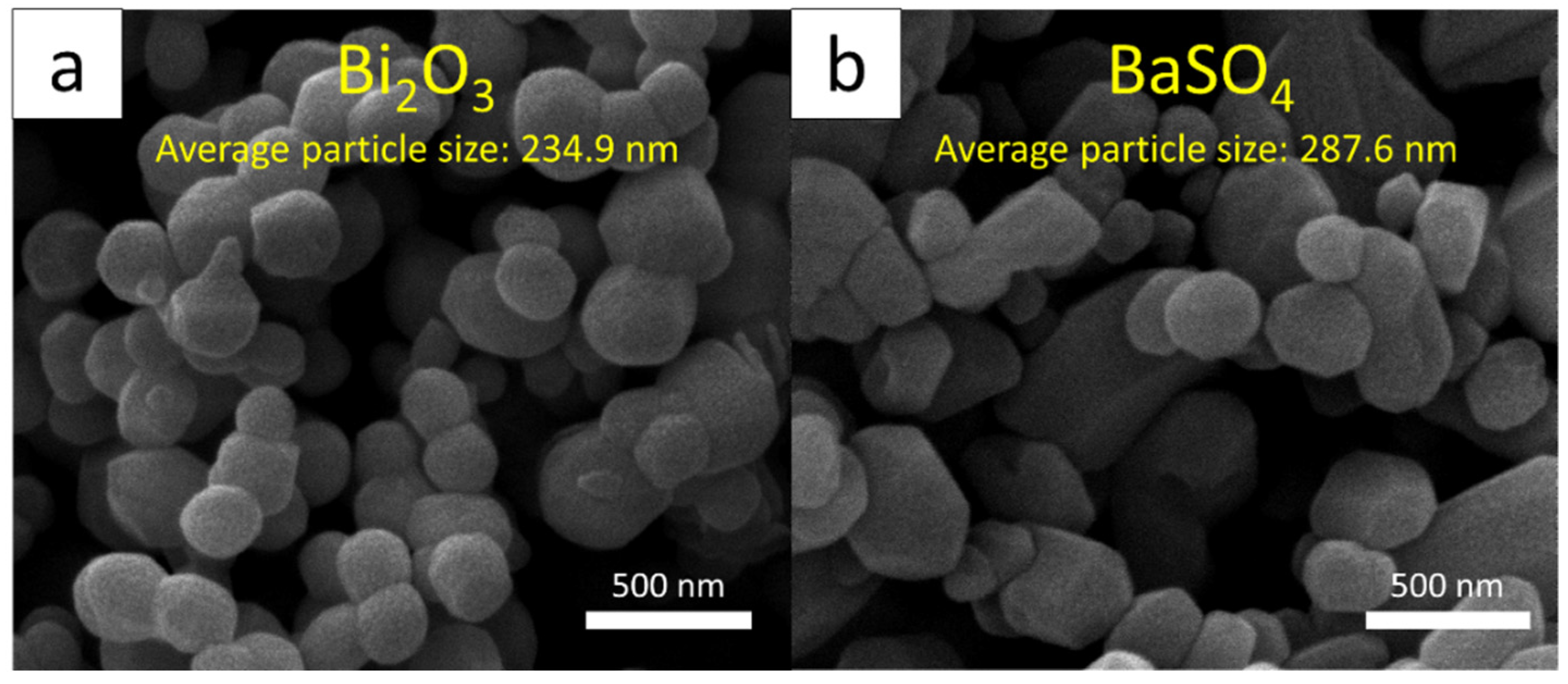

2.4. Characterization

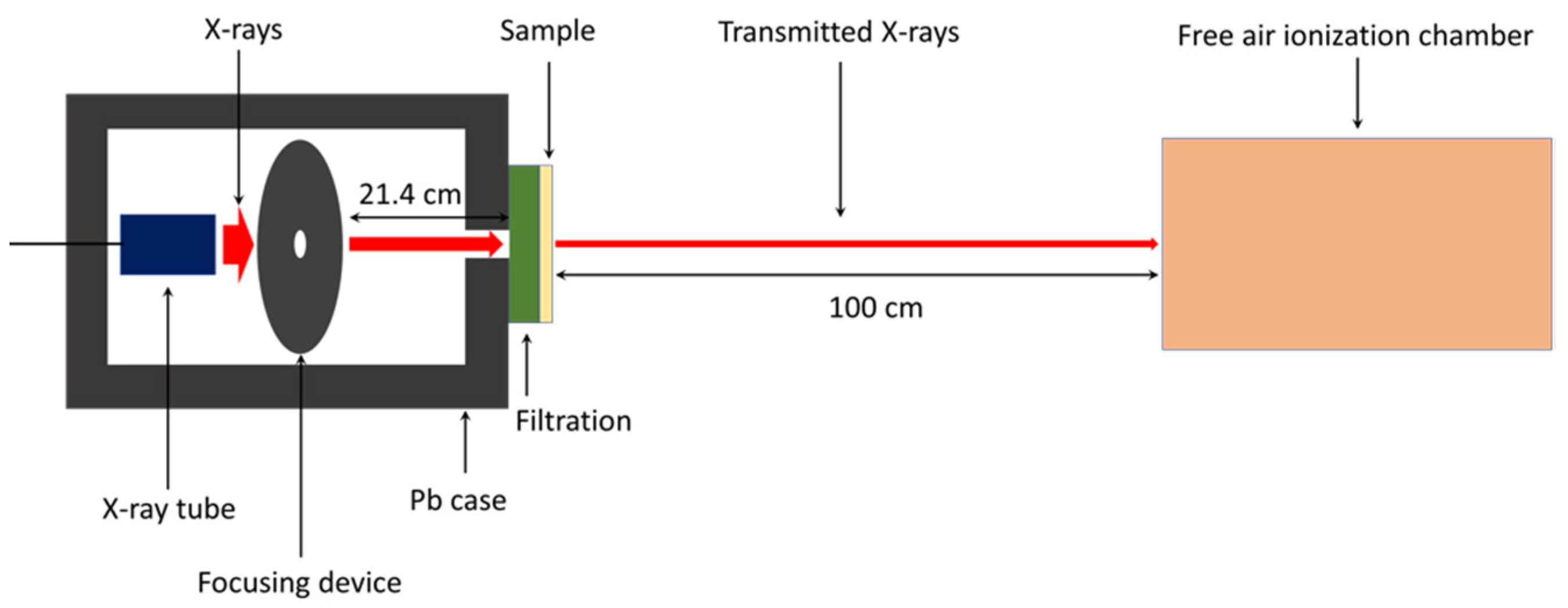

2.4.1. X-ray Shielding Properties

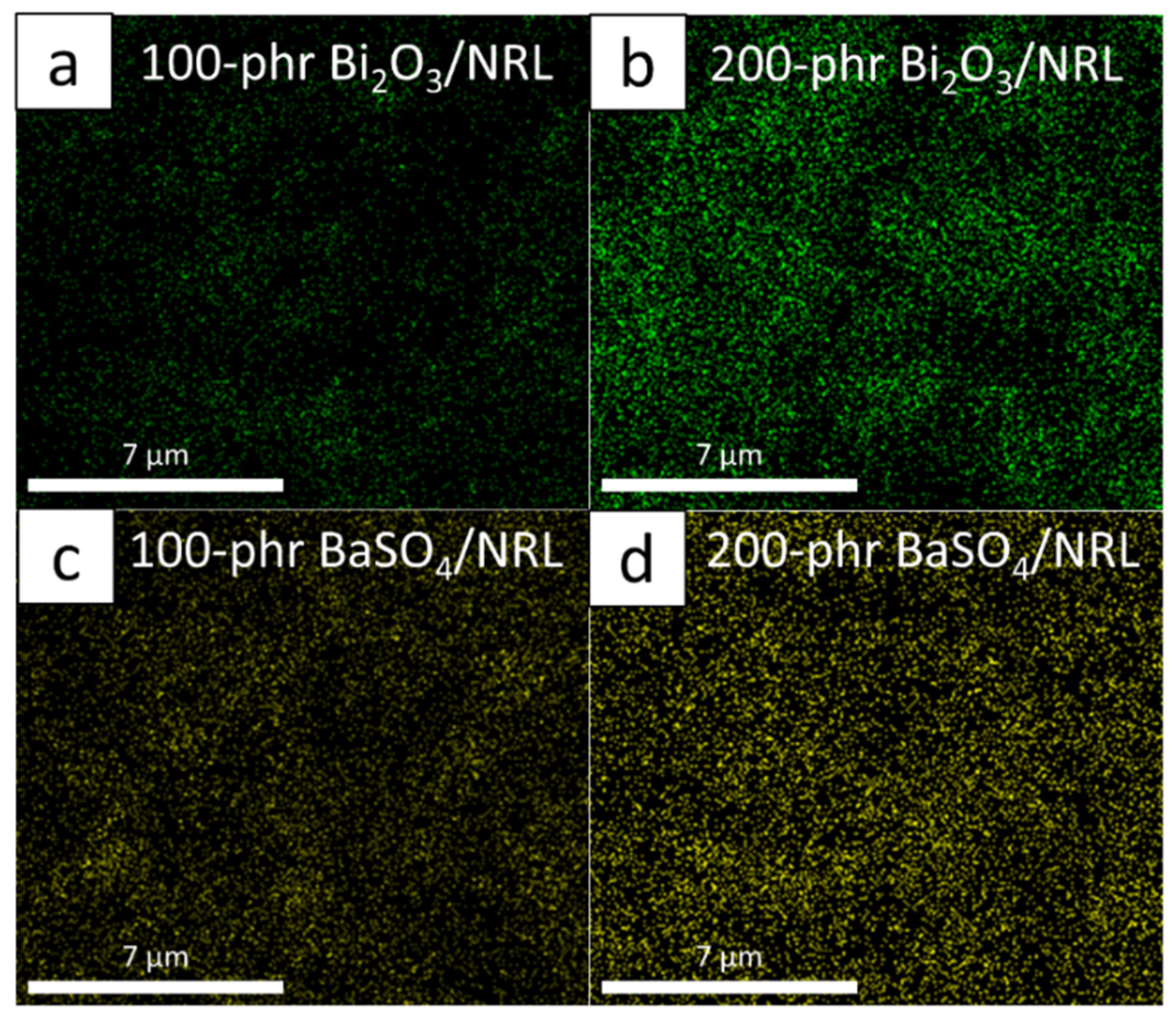

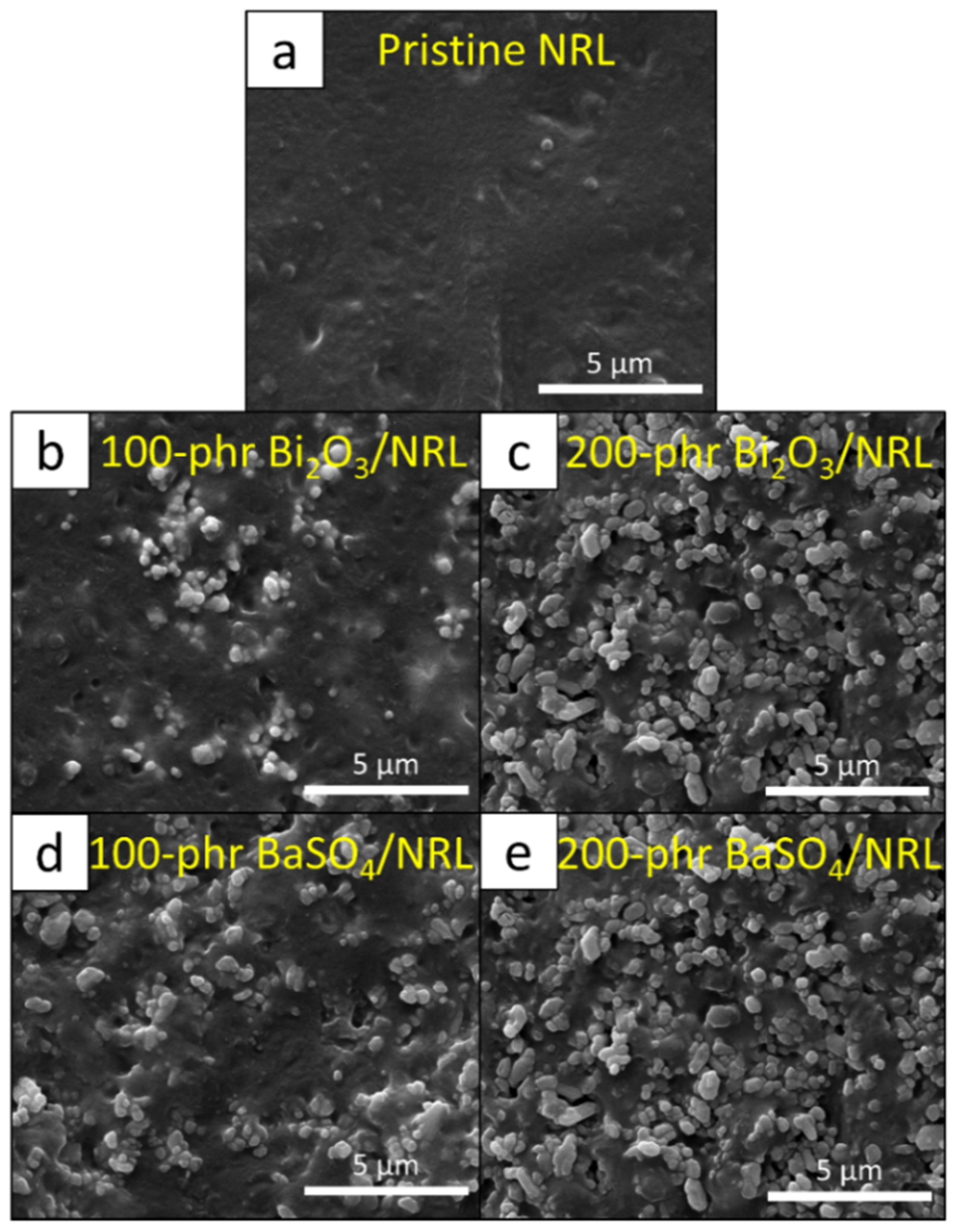

2.4.2. Morphology and Density Measurement

2.4.3. Mechanical Properties

2.5. Determination of Recommended Filler Content for Medical X-ray Protective Gloves

3. Results and Discussion

3.1. Density

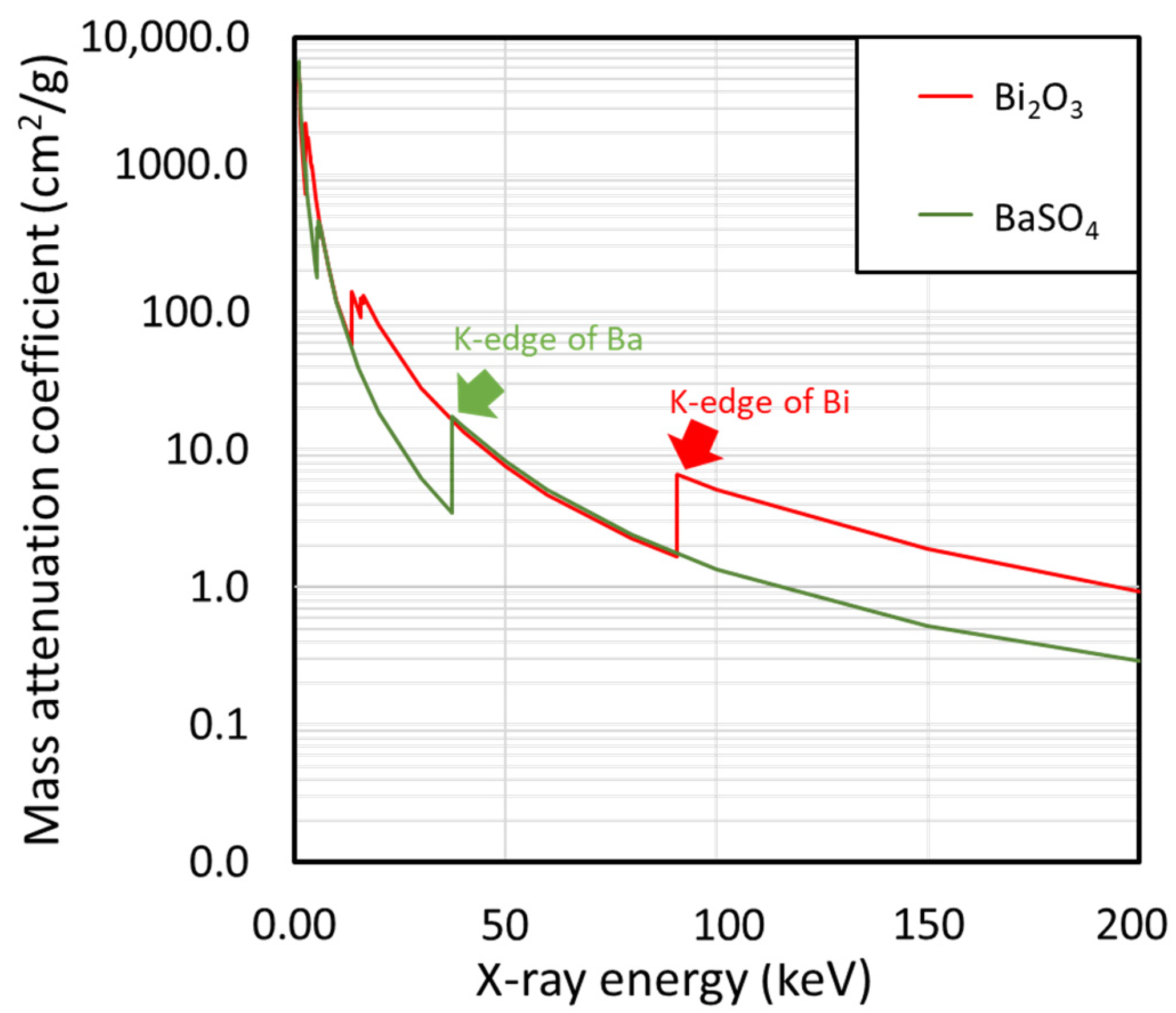

3.2. X-ray Shielding Properties

3.3. Mechanical Properties

3.4. Determination of Recommended Filler Content

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Saenboonruang, K.; Phonchanthuek, E.; Pransandee, K. Soil-to-plant transfer factors of natural radionuclides (226Ra and 40K) in selected Thai medicinal plants. J. Environ. Radioact. 2018, 184–185, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Timothy Oyedotun, T.D. X-ray fluorescence (XRF) in the investigation of the composition of earth materials: A review and an overview. Geol. Ecol. Landsc. 2018, 2, 148–154. [Google Scholar] [CrossRef]

- Kumar, A.; Lingfa, P. Sodium bentonite and kaolin clays: Comparative study on their FT-IR, XRF, and XRD. Mater. Today Proc. 2020, 22, 737–742. [Google Scholar] [CrossRef]

- Afshar, P.; Heidarian, S.; Naderkhani, F.; Oikonomou, A.; Plataniotis, K.N.; Mohammadi, A. COVID-CAPS: A capsule network-based framework for identification of COVID-19 cases from X-ray images. Pattern Recognit. Lett. 2020, 138, 638–643. [Google Scholar] [CrossRef] [PubMed]

- Withers, P.J.; Bouman, C.; Carmignato, S.; Cnudde, V.; Grimaldi, D.; Hagen, C.K.; Maire, E.; Manley, M.; Plessis, A.D.; Stock, S.R. X-ray computed tomography. Nat. Rev. Methods Primers 2021, 1, 18. [Google Scholar] [CrossRef]

- Lu, L.; Sun, M.; Lu, Q.; Wu, T.; Huang, B. High energy X-ray radiation sensitive scintillating materials for medical imaging, cancer diagnosis and therapy. Nano Energy 2021, 79, 105437. [Google Scholar] [CrossRef]

- Zheng, L.; Zhu, R.; Chen, L.; Fu, Q.; Li, J.; Chen, C.; Song, J.; Yang, H. X-ray sensitive high-Z metal nanocrystals for cancer imaging and therapy. Nano Res. 2021, 14, 3744–3755. [Google Scholar] [CrossRef]

- De Prados, M.; Fulladosa, E.; Gou, P.; Munoz, I.; Garcia-Perez, J.V.; Benedito, J. Non-destructive determination of fat content in green hams using ultrasound and X-rays. Meat Sci. 2015, 104, 37–43. [Google Scholar] [CrossRef]

- Bartley, K.; Metayer, C.; Selvin, S.; Ducore, J.; Buffler, P. Diagnostic X-rays and risk of childhood leukaemia. Int. J. Epidemiol. 2010, 39, 1628–1637. [Google Scholar] [CrossRef]

- Claus, E.B.; Calvocoressi, L.; Bondy, M.L.; Schildkraut, J.M.; Wiemels, J.L.; Wrensch, M. Dental X-rays and risk of meningioma. Cancer 2012, 118, 4530–4537. [Google Scholar] [CrossRef] [Green Version]

- Memon, A.; Godward, S.; Williams, D.; Siddique, I.; Al-Saleh, K. Dental X-rays and the risk of thyroid cancer: A case-control study. Acta Oncol. 2010, 49, 447–453. [Google Scholar] [CrossRef] [PubMed]

- Gislason-Lee, A.J. Patient X-ray exposure and ALARA in the neonatal intensive care unit: Global patterns. Pediatr. Neonatol. 2021, 62, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Tzounis, L.; Debnath, S.; Rooj, S.; Fischer, D.; Mader, E.; Das, A.; Stamm, M.; Heinrich, G. High performance natural rubber composites with a hierarchical reinforcement structure of carbon nanotube modified natural fibers. Mater. Des. 2014, 58, 1–11. [Google Scholar] [CrossRef]

- Kaewsakul, W.; Sahakaro, K.; Dierkes, W.K.; Noordermeer, J.W.M. Optimization of mixing conditions for silica-reinforced natural rubber tire tread compounds. Rubb. Chem. Technol. 2012, 85, 277–294. [Google Scholar] [CrossRef]

- Prasertsri, S.; Rattanasom, N. Mechanical and damping properties of silica/natural rubber composites prepared from latex system. Polym. Test. 2011, 30, 515–526. [Google Scholar] [CrossRef]

- Sareena, C.; Sreejith, M.P.; Ramesan, M.T.; Purushothaman, E. Biodegradation behaviour of natural rubber composites reinforced with natural resource fillers – monitoring by soil burial test. J. Reinf. Plast. Compos. 2013, 33, 412–429. [Google Scholar] [CrossRef]

- Abraham, E.; Elbi, P.A.; Deepa, B.; Jyotishkumar, P.; Pothen, L.A.; Narine, S.S.; Thomas, S. X-ray diffraction and biodegradation analysis of green composites of natural rubber/nanocellulose. Polym. Degrad. Stab. 2012, 97, 2378–2387. [Google Scholar] [CrossRef]

- Thumwong, A.; Jitsuna, D.; Saenboonruang, K. Comparative X-ray shielding properties of single-layered and multi-layered Bi2O3/NR composites: Simulation and numerical Studies. Polymers 2022, 14, 1788. [Google Scholar] [CrossRef]

- Liao, Y.C.; Xu, D.G.; Zhang, P.C. Preparation and characterization of Bi2O3/XNBR flexible films for attenuating gamma rays. Nucl. Sci. Tech. 2018, 29, 99. [Google Scholar] [CrossRef]

- Al-Ghamdi, H.; Hemily, H.M.; Saleh, I.H.; Ghataas, Z.F.; Abdel-Halim, A.A.; Sayyed, M.I.; Yasmin, S.; Almuqrin, A.H.; Elsafi, M. Impact of WO3-nanoparticles on silicone rubber for radiation protection efficiency. Materials 2022, 15, 5706. [Google Scholar] [CrossRef]

- Plangpleng, N.; Charoenphun, P.; Polpanich, D.; Sakulkaew, K.; Buasuwan, N.; Onjun, O.; Chuamsaamarkkee, K. Flexible gamma ray shielding based on natural Rubber/BaSO4 nanocomposites. Radiat. Phys. Chem. 2022, 199, 110311. [Google Scholar] [CrossRef]

- Sanpo, N.; Tharajak, J.; Kanthang, P. Determination of radiation attenuation coefficients of rubber containing barite. Appl. Mech. Mater. 2017, 866, 204–207. [Google Scholar]

- El-Khatib, A.M.; Doma, A.S.; Abu-Rayan, A.E.; Aly, N.S.; Abbas, M.I. Novel composites made of natural and waste rubber loaded with lead nanoparticles for gamma radiation shielding. Surf. Innov. 2022, 10, 312–328. [Google Scholar] [CrossRef]

- Kalkornsuranee, E.; Intom, S.; Lehman, N.; Johns, J.; Kothan, S.; Sengloyluan, K.; Chaiphaksa, W.; Kaewkhao, J. Mechanical and gamma radiation shielding properties of natural rubber composites: Effects of bismuth oxide (Bi2O3) and lead oxide (PbO). Mater. Res. Innov. 2022, 26, 8–15. [Google Scholar] [CrossRef]

- Poltabtim, W.; Wimolmala, E.; Markpin, T.; Sombatsompop, N.; Rosarpitak, V.; Saenboonruang, K. X-ray shielding, mechanical, physical, and water absorption properties of wood/PVC composites containing bismuth oxide. Polymers 2021, 13, 2212. [Google Scholar] [CrossRef]

- Konruang, S.; Srisook, A.; Buaphet, P.; Tayeh, F.; Naebpetch, W. Preparation of lead-free X-ray shielding materials based on natural rubber/barium sulfate composites. ASEAN J. Sci. Technol. Rep. 2022, 25, 59–66. [Google Scholar] [CrossRef]

- Kuempel, E.D.; Geraci, C.L.; Schulte, P.A. Risk assessment approaches and research needs for nanomaterials: An examination of data and information from current studies. In Nanotechnology—Toxicological Issues and Environmental Safety and Environmental Safety; NATO Science for Peace and Security Series; Springer: Dordrecht, The Netherlands, 2007. [Google Scholar]

- Thumwong, A.; Wimolmala, E.; Markpin, T.; Sombatsompop, N.; Saenboonruang, K. Enhanced X-ray shielding properties of NRL gloves with nano-Bi2O3 and their mechanical properties under aging conditions. Radiat. Phys. Chem. 2021, 186, 109530. [Google Scholar] [CrossRef]

- Ramirez Cadavid, D.A.; Layman, R.R.; Nishino, T.; Slutzky, J.L.; Li, Z.; Cornish, K. Guayule natural rubber latex and Bi2O3 films for X-ray attenuating medical gloves. Materials 2022, 15, 1184. [Google Scholar] [CrossRef]

- Sheikh, S.H.; Yin, X.; Ansarifar, A.; Yendall, K. The potential of kaolin as a reinforcing filler for rubber composites with new sulfur cure systems. J. Reinf. Plast. Compos. 2017, 36, 1132–1145. [Google Scholar] [CrossRef]

- Poltabtim, W.; Toyen, D.; Saenboonruang, K. Theoretical determination of high-energy photon attenuation and recommended protective filler contents for flexible and enhanced dimensionally stable wood/NR and NR composites. Polymers 2021, 13, 869. [Google Scholar] [CrossRef]

- Mesbahi, A.; Ghiasi, H. Shielding properties of the ordinary concrete loaded with micro- and nano-particles against neutron and gamma radiations. Radiat. Phys. Chem. 2018, 136, 27–31. [Google Scholar] [CrossRef] [PubMed]

- Shik, N.A.; Gholamzadeh, L. X-ray shielding performance of the EPVC composites with micro- or nanoparticles of WO3, PbO or Bi2O3. Appl. Radiat. Isot. 2018, 139, 61–65. [Google Scholar] [CrossRef] [PubMed]

- Saenboonruang, K.; Poltabtim, W.; Thumwong, A.; Pianpanit, T.; Rattanapongs, C. Rare-earth oxides as alternative high-energy photon protective fillers in HDPE composites: Theoretical aspects. Polymers 2021, 13, 1930. [Google Scholar] [CrossRef]

- Kires, M. Archimedes’ principle in action. Phys. Educ. 2007, 42, 484. [Google Scholar] [CrossRef]

- Pianpanit, T.; Saenboonruang, K. High-energy photon attenuation properties of lead-free and self-healing poly (vinyl alcohol) (PVA) hydrogels: Numerical determination and simulation. Gels 2022, 8, 197. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Chen, X.; Zhou, Y.; Chen, D.; Zhang, L. Impact of photoelectric effect on X-ray density logging and its correction. Appl. Radiat. Isot. 2020, 156, 108785. [Google Scholar] [CrossRef]

- Atak, H.; Shikhaliev, P.M. Photon counting x-ray imaging with K-edge filtered x-rays: A simulation study. Med. Phys. 2016, 43, 1385–1400. [Google Scholar] [CrossRef]

- Noor Azman, N.Z.; Siddiqui, S.A.; Low, I.M. Characterisation of micro-sized and nano-sized tungsten oxide-epoxy composites for radiation shielding of diagnostic X-rays. Mater. Sci. Eng. C 2013, 33, 4952–4957. [Google Scholar] [CrossRef]

- Poludniowski, G.G.; Evans, P.M. Calculation of x-ray spectra emerging from an x-ray tube. Part I. Electron penetration characteristics in x-ray targets. Med. Phys. 2007, 34, 2164–2174. [Google Scholar] [CrossRef]

- Poludniowski, G.G. Calculation of x-ray spectra emerging from an x-ray tube. Part II. X-ray production and filtration in x-ray targets. Med. Phys. 2007, 34, 2175–2186. [Google Scholar] [CrossRef]

- Abdolahzadeh, T.; Morshedian, J.; Ahmadi, S. Preparation and characterization of nano WO3/Bi2O3/GO and BaSO4/GO dispersed HDPE composites for X-ray shielding application. Polyolefins J. 2022, 9, 73–83. [Google Scholar]

- Amestoy, H.; Diego, P.; Meaurio, E.; Muñoz, J.; Sarasua, J.-R. Crystallization behavior and mechanical properties of poly(ε-caprolactone) reinforced with barium sulfate submicron particles. Materials 2021, 14, 2368. [Google Scholar] [CrossRef] [PubMed]

- Gaballah, M.; Issa, S.A.M.; Saddeek, Y.B.; Elsaman, R.; Susoy, G.; Erguzel, T.T.; Alharbi, T.; Tekin, H.O. Mechanical and nuclear radiation shielding properties of different boro-tellurite glasses: A comprehensive investigation on large Bi2O3 concentration. Phys. Scr. 2020, 95, 085701. [Google Scholar] [CrossRef]

- Leblanc, J.L. Rubber–filler interactions and rheological properties in filled compounds. Prog. Polym. Sci. 2002, 27, 627–687. [Google Scholar] [CrossRef]

- Brechet, Y.; Cavaille, J.Y.; Chabert, E.; Chazeau, L.; Dendievel, R.; Flandin, L.; Gauthier, C. Polymer based nanocomposites: Effect of filler-filler and filler-matrix interactions. Adv. Eng. Mater. 2001, 3, 571–577. [Google Scholar] [CrossRef]

- Kilic, G.; El Agawany, F.I.; Ilik, B.O.; Mahmoud, K.A.; Ilik, E.; Rammah, Y.S. Ta2O5 reinforced Bi2O3–TeO2–ZnO glasses: Fabrication, physical, structural characterization, and radiation shielding efficacy. Opt. Mater. 2021, 112, 110757. [Google Scholar] [CrossRef]

- Hegazy, H.H.; Al-Buriahi, M.S.; Alresheedi, F.; El-Agawany, F.I.; Sriwunkum, C.; Neffati, R.; Rammah, Y.S. Nuclear shielding properties of B2O3–Bi2O3–SrO glasses modified with Nd2O3: Theoretical and simulation studies. Ceram. Int. 2021, 47, 2772–2780. [Google Scholar] [CrossRef]

- Rammah, Y.S.; El-Agawany, F.I.; Gamal, A.; Olarinoye, I.O.; Ahmed, E.M.; Abouhaswa, A.S. Responsibility of Bi2O3 Content in Photon, Alpha, Proton, Fast and Thermal Neutron Shielding Capacity and Elastic Moduli of ZnO/B2O3/Bi2O3 Glasses. J. Inorg. Organomet. Polym. 2021, 31, 3505–3524. [Google Scholar] [CrossRef]

- Tasnim, A.; Sahadath, M.H.; Khan, M.N.I. Development of high-density radiation shielding materials containing BaSO4 and investigation of the gamma-ray attenuation properties. Radiat. Phys. Chem. 2021, 189, 109772. [Google Scholar] [CrossRef]

| Chemical | Content (phr) | Role |

|---|---|---|

| 50% w/w nano-Bi2O3 or nano-BaSO4 | 0, 100, and 200 | X-ray protective filler |

| 10% w/w potassium hydroxide (KOH) | 0.2 | Stabilizer |

| 10% w/w Teric 16A16 | 0.02 | Stabilizer |

| 50% w/w sulfur (S) | 0.8 | Crosslinking agent |

| 50% w/w zinc diethyl dithiocarbamate (ZDEC) | 0.4 | Accelerator |

| 50% w/w zinc-2-mercaptobenzthiazole (ZMBT) | 0.4 | Accelerator |

| 50% w/w titanium dioxide | 1.0 | Pigment |

| 50% w/w wingstay-L | 1.0 | Antioxidant |

| 50% w/w zinc oxide (ZnO) | 1.0 | Activator |

| Distilled water (H2O) | 170.5 | Solvent |

| Sample | Filler Content (phr) | Density (g/cm3) |

|---|---|---|

| Pristine SVNRL | 0 | 0.93 ± 0.01 |

| Nano-Bi2O3/SVNRL | 100 | 1.67 ± 0.02 |

| 200 | 1.95 ± 0.01 | |

| Nano-BaSO4/SVNRL | 100 | 1.44 ± 0.01 |

| 200 | 1.71 ± 0.02 |

| Properties | X-Ray Supplied Voltage | Pristine SVNRL | Bi2O3/SVNRL | BaSO4/SVNRL | ||

|---|---|---|---|---|---|---|

| 100 phr | 200 phr | 100 phr | 200 phr | |||

| µ (cm−1) | 60 kV | 0.24 ± 0.01 | 6.19 ± 0.20 | 9.36 ± 0.38 | 5.23 ± 0.12 | 8.23 ± 0.13 |

| 100 kV | 0.18 ± 0.01 | 2.17 ± 0.07 | 3.38 ± 0.13 | 1.75 ± 0.01 | 2.67 ± 0.06 | |

| µm (cm2/g) | 60 kV | 0.26 ± 0.01 | 3.71 ± 0.12 | 4.80 ± 0.19 | 3.63 ± 0.08 | 4.81 ± 0.07 |

| 100 kV | 0.19 ± 0.01 | 1.30 ± 0.04 | 1.74 ± 0.07 | 1.21 ± 0.01 | 1.56 ± 0.04 | |

| HVL (cm) | 60 kV | 2.87 ± 0.01 | 0.11 ± 0.01 | 0.07 ± 0.01 | 0.13 ± 0.01 | 0.08 ± 0.01 |

| 100 kV | 3.84 ± 0.09 | 0.32 ± 0.01 | 0.20 ± 0.01 | 0.40 ± 0.01 | 0.26 ± 0.01 | |

| Pbeq (mm Pb) | 60 kV | 0.0010 ± 0.0001 | 0.0245 ± 0.0008 | 0.0371 ± 0.0015 | 0.0207 ± 0.0005 | 0.0326 ± 0.0005 |

| 100 kV | 0.0017 ± 0.0001 | 0.0209 ± 0.0006 | 0.0326 ± 0.0012 | 0.0168 ± 0.0001 | 0.0257 ± 0.0006 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thumwong, A.; Chinnawet, M.; Intarasena, P.; Rattanapongs, C.; Tokonami, S.; Ishikawa, T.; Saenboonruang, K. A Comparative Study on X-ray Shielding and Mechanical Properties of Natural Rubber Latex Nanocomposites Containing Bi2O3 or BaSO4: Experimental and Numerical Determination. Polymers 2022, 14, 3654. https://doi.org/10.3390/polym14173654

Thumwong A, Chinnawet M, Intarasena P, Rattanapongs C, Tokonami S, Ishikawa T, Saenboonruang K. A Comparative Study on X-ray Shielding and Mechanical Properties of Natural Rubber Latex Nanocomposites Containing Bi2O3 or BaSO4: Experimental and Numerical Determination. Polymers. 2022; 14(17):3654. https://doi.org/10.3390/polym14173654

Chicago/Turabian StyleThumwong, Arkarapol, Manchusa Chinnawet, Preawpraw Intarasena, Chanis Rattanapongs, Shinji Tokonami, Tetsuo Ishikawa, and Kiadtisak Saenboonruang. 2022. "A Comparative Study on X-ray Shielding and Mechanical Properties of Natural Rubber Latex Nanocomposites Containing Bi2O3 or BaSO4: Experimental and Numerical Determination" Polymers 14, no. 17: 3654. https://doi.org/10.3390/polym14173654

APA StyleThumwong, A., Chinnawet, M., Intarasena, P., Rattanapongs, C., Tokonami, S., Ishikawa, T., & Saenboonruang, K. (2022). A Comparative Study on X-ray Shielding and Mechanical Properties of Natural Rubber Latex Nanocomposites Containing Bi2O3 or BaSO4: Experimental and Numerical Determination. Polymers, 14(17), 3654. https://doi.org/10.3390/polym14173654