Functional Polymer and Packaging Technology for Bakery Products

Abstract

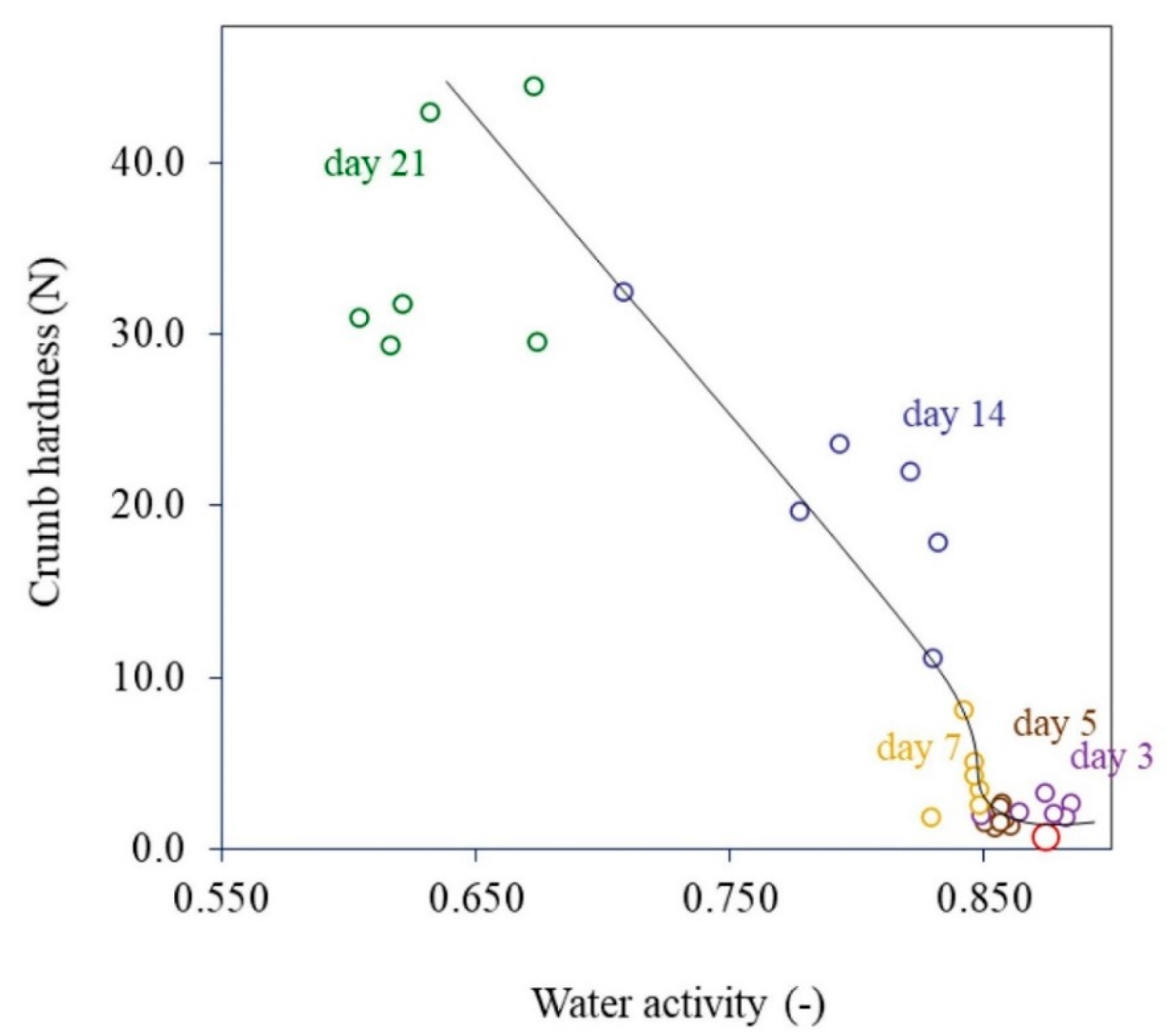

:1. Introduction

2. Bakery Deterioration Factors through Packaging System

2.1. Physico-Chemical and Chemical Deteriorations

2.2. Microbial Deteriorations

| Functional Packaging | Active Agents | Packaging Form | Type of Bakery | Remarkable Results | References |

|---|---|---|---|---|---|

| Non-volatile active compounds | Zinc oxide nanoparticles | Chitosan-carboxymethyl cellulose film | Preservative-free soft sliced wheat bread |

| [36] |

| Natamycin | Chitosan-natamycin vacuum packaged and spraying | Phyllo pastry |

| [37] | |

| Sodium propionate | Polypropylene-sodium propionate film | Bread |

| [38] | |

| Silver nanoparticles | Polyvinyl chloride film | Sliced Bread |

| [39] | |

| ε-poly-L-lysine (ε-PL) | Starch film | Bread |

| [40] | |

| ZnO nanoparticles | Gelatin- polyethylene film | Sponge cake |

| [41] | |

| TiO2 | Potato starch film | Sliced bread |

| [42] | |

| Chitosan | Chitosan-PLA film | Sliced bread |

| [43] | |

| Sulfur quantum dot | Alginate film | Bread |

| [44] | |

| Sorbate anion | Polypropylene bag | White bread |

| [45] | |

| Volatile active compounds | Cinnamaldehyde | Gliadin films | Sliced bread |

| [25] |

| Oregano essential oil | Nonwoven tissue/polypropylene-based sachet | Preservative-free sliced bread |

| [46] | |

| Apricot kernel essential oil | Chitosan film | Sliced bread |

| [47] | |

| Grapefruit seed extract/Chitosan | Poly(ε-caprolactone)/chitosan film | Preservative-free bread |

| [48] | |

| trans-cinnamaldehyde | PLA/PBAT film | Bread |

| [24] | |

| Eugenol and citral | Corn starch microcapsule sachet | Sliced bread |

| [49] | |

| Thymol | PLA/PBSA film | Preservative-free bread |

| [50] | |

| Sorbitol/Grapefruit seed extract | Corn starch-chitosan film | Bread |

| [51] | |

| Cymbopogon citratus essential oil | Cashew gum-gelatin film | Bread |

| [52] | |

| Carvacrol | PLA/PBAT film | Preservative-free bread |

| [53] | |

| Cinnamon oil | Natural rubber pressure-sensitive adhesive patch | Banana cake |

| [54] | |

| Piper betel Linn extract | Poly (vinyl alcohol) film | Sliced bread |

| [55] | |

| Cinnamaldehyde Limonene Eugenol | Fish gelatin-based nanofiber mat | Bread |

| [56] | |

| Thyme essential oil | Poly (3-hydroxybutyrate-co-4-hydroxybutyrate) film | White bread |

| [57] | |

| Schiff base | PLA film | Bread |

| [58] | |

| Functional paper and paperboard | PLA | Coated paperboard | - |

| [59] |

| Vanillin with dimethyl sulfoxide, ethyl alcohol, and chitosan | Coated paper | - |

| [60] | |

| Wax | Coated paper | Milk cake |

| [61] | |

| Cinnamon essential oil | Coated paper | - |

| [62] | |

| Ag/TiO2-SiO2, Ag/N-TiO2, or Au/TiO2 | Paper modification | “Pave” bread |

| [63] | |

| Chitosan | Coating paper | - |

| [64] | |

| TiO2 Ag-TiO2 Ag-TiO2-zeolite | Bleached paper | Bread |

| [65] | |

| Nano-carbon | Wrapping paper | Brownie cake |

| [66] | |

| Blending of alginate, carboxymethyl cellulose, carrageenan, and grapefruit seed extract | Coated paper | Mined fish cake |

| [67] | |

| Chitosan/Ag/TiO2 | Coated paper | Clarified butter |

| [68] | |

| Starch, NaCl, Aquaseal | Paper bag | Bread |

| [69] | |

| Geraniol | Paper sachet | Sliced bread |

| [70] | |

| Schiff base PLA | Kraft paper coating | Bread |

| [58] | |

| Edible and non-edible coating | Lactobacillus acidophilus | Edible starch/probiotic coating | Bread |

| [71] |

| Ag/TiO2 nanocomposite | HDPE film | White bread |

| [72] | |

| Potassium sorbate and citric acid | Potato starch, inverted sugar, sucrose coating solution | Mini panettones |

| [73] | |

| Triticale flour | Edible coating and spraying | Muffin |

| [74] | |

| Star anise essential oil and thymol | PP/SAEO/PET/TH/LDPE film | Preservative-free sliced wheat bread |

| [75] | |

| Garlic extract and Bread aroma | Coating on PE film | Preservative-free sliced pan loaf |

| [76] | |

| Lactic acid bacteria | Edible lactic acid bacteria coating | Wheat bread |

| [77] | |

| Okra mucilage | Edible okra mucilage gum surface coating | Biscuit |

| [78] | |

| Absorber/ Emitter | Iron-based oxygen absorber | Sachet (FreshPax®) | Cracker |

| [79] |

| Oxygen absorber and ethanol emitter | Sachet | Wheat bread |

| [80] | |

| Iron-based oxygen scavenger sachets | Sachet | Sliced wheat bread |

| [81] | |

| Ethanol emitter | Sachet | Ciabatta bread |

| [82] | |

| Oxygen absorber and ethanol emitter | Sachet | Chinese steamed bread |

| [83] | |

| Oxygen scavenger and ethanol emitter | Pouch | Sponge cake |

| [84] | |

| Oxygen absorber | Nylon/LLDPE/cast polypropylene film | Preservative-free Chinese pastry (kha-nom pia) |

| [85] | |

| Iron-based oxygen scavenger | Sachet | Preservative-free white bread |

| [86] | |

| Vacuum conditioning | Bag | Chinese steamed bread |

| [87] | |

| Iron based oxygen absorbers | Bag | Sourdough sliced bread |

| [88] | |

| Oxygen scavenging compound—pyrogallol | Film | - |

| [22] | |

| Ethanol emitter, Oxygen absorber Moisture absorber | Sachet | Refined wheat bread (RWF) and Whole wheat bread (WWF) |

| [89] | |

| Palladium-based oxygen scavenger | Film | Par-baked bun and toast bread |

| [90] | |

| Pyrogallic acid | LDPE/sodium carbonate film | Fish cake |

| [91] |

3. Functional Polymeric Plastic

3.1. Non-Volatile Active Ingredients

3.2. Volatile Active Ingredients

4. Functional Paper and Coating Technology

5. Edible Polymeric Coating in Bakery Products

6. Other Forms of Active Packaging Technology for Bakery Products

6.1. Oxygen Absorbers

6.2. Ethanol Emitters

7. Conclusions and Final Remarks

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Newswire, P. Baking Ingredients Market Worth $22.3 Billion by 2026—Exclusive Report by MarketsandMarkets™. PR Newswire US. 2021. Available online: http://www.prnewswire.com/news-releases/baking-ingredients-market-worth-22-3-billion-by-2026--exclusive-report-by-marketsandmarkets-301270475.html (accessed on 25 August 2021).

- Goryńska-Goldmann, E.; Gazdecki, M.; Rejman, K.; Łaba, S.; Kobus-Cisowska, J.; Szczepański, K. Magnitude, Causes and Scope for Reducing Food Losses in the Baking and Confectionery Industry—A Multi-Method Approach. Agriculture 2021, 11, 936. [Google Scholar] [CrossRef]

- Izabella, K.-K.; Justyna, R.-K.; Lucjan, K. Factors Influencing Quality and Shelf Life of Baking Products. J. Processing Energy Agric. 2014, 18, 1–7. [Google Scholar]

- Yildirim, S.; Röcker, B.; Pettersen, M.K.; Nilsen-Nygaard, J.; Ayhan, Z.; Rutkaite, R.; Radusin, T.; Suminska, P.; Marcos, B.; Coma, V. Active Packaging Applications for Food. Compr. Rev. Food Sci. Food Saf. 2017, 17, 165–199. [Google Scholar] [CrossRef] [PubMed]

- European Commission. EU Guidance to the Commission Regulation (EC) No 450/2009 on active and intelligent materials and articles intended to come into contact with food. Off. J. Eur. Union 2009, 38, 214–222. [Google Scholar]

- Garcia, M.V.; Copetti, M.V. Alternative methods for mould spoilage control in bread and bakery products. Int. Food Res. J. 2019, 26, 737–749. [Google Scholar]

- Jideani, V.A.; Vogt, K. Antimicrobial Packaging for Extending the Shelf Life of Bread—A Review. Crit. Rev. Food Sci. Nutr. 2013, 56, 1313–1324. [Google Scholar] [CrossRef]

- Kuorwel, K.K.; Cran, M.J.; Sonneveld, K.; Miltz, J.; Bigger, S.W. Essential Oils and Their Principal Constituents as Antimicrobial Agents for Synthetic Packaging Films. J. Food Sci. 2011, 76, R164–R177. [Google Scholar] [CrossRef]

- Bagamboula, C.; Uyttendaele, M.; Debevere, J. Inhibitory effect of thyme and basil essential oils, carvacrol, thymol, estragol, linalool and p-cymene towards Shigella sonnei and S. flexneri. Food Microbiol. 2004, 21, 33–42. [Google Scholar] [CrossRef]

- Nanditha, B.; Prabhasankar, P. Antioxidants in Bakery Products: A Review. Crit. Rev. Food Sci. Nutr. 2008, 49, 1–27. [Google Scholar] [CrossRef]

- Madhavi, D.L.; Deshpande, S.S.; Salunkhe, D.K. Food Antioxidants: Technological: Toxicological and Health Perspectives; Taylor & Francis Group: Boca Raton, FL, USA, 1996. [Google Scholar]

- Saura-Calixto, F. Antioxidant Dietary Fiber Product: A New Concept and a Potential Food Ingredient. J. Agric. Food Chem. 1998, 46, 4303–4306. [Google Scholar] [CrossRef]

- Someya, S.; Yoshiki, Y.; Okubo, K. Antioxidant compounds from bananas (Musa Cavendish). Food Chem. 2002, 79, 351–354. [Google Scholar] [CrossRef]

- Gavahian, M.; Chu, Y.-H.; Lorenzo, J.M.; Mousavi Khaneghah, A.; Barba, F.J. Essential oils as natural preservatives for bakery products: Understanding the mechanisms of action, recent findings, and applications. Crit. Rev. Food Sci. Nutr. 2020, 60, 310–321. [Google Scholar] [CrossRef] [PubMed]

- Kotsianis, I.; Giannou, V.; Tzia, C. Production and packaging of bakery products using MAP technology. Trends Food Sci. Technol. 2002, 13, 319–324. [Google Scholar] [CrossRef]

- Galic, K.; Ćurić, D.; Gabric, D. Shelf Life of Packaged Bakery Goods—A Review. Crit. Rev. Food Sci. Nutr. 2009, 49, 405–426. [Google Scholar] [CrossRef]

- Martins, I.E.; Shittu, T.A.; Onabanjo, O.O.; Adesina, A.D.; Soares, A.G.; Okolie, P.I.; Kupoluyi, A.O.; Ojo, O.A.; Obadina, A.O. Effect of packaging materials and storage conditions on the microbial quality of pearl millet sourdough bread. J. Food Sci. Technol. 2020, 58, 52–61. [Google Scholar] [CrossRef]

- Zhou, W.; Hui, Y.H. Bakery Products Sciences and Technology, 2nd ed.; Jonh Wiley & Sons, Ltd.: Chichester, UK, 2014. [Google Scholar]

- Ashokkumar, Y. Textbook of Bakery and Confectionery, 2nd ed.; PHI Learning: Delhi, India, 2018. [Google Scholar]

- Cauvain, S.P.; Young, L.S. Chemical and physical deterioration of bakery products. In Chemical Deterioration and Physical Instability of Food and Beverages; Woodhead Publishing Limited: Bucks, UK, 2010; pp. 381–412. [Google Scholar]

- Manley, D. Manley’s Technology of Biscuits, Crackers and Cookies, 4th ed.; Woodhead Publishing: Sawston, UK, 2011. [Google Scholar]

- Promsorn, J.; Harnkarnsujarit, N. Pyrogallol loaded thermoplastic cassava starch based films as bio-based oxygen scavengers. Ind. Crop. Prod. 2022, 186, 115226. [Google Scholar] [CrossRef]

- Troller, J.A.; Christian, J. Water Activity and Food; Academic Press: New York, NY, USA, 1978; pp. 372–381. [Google Scholar]

- Srisa, A.; Harnkarnsujarit, N. Antifungal films from trans-cinnamaldehyde incorporated poly(lactic acid) and poly(butylene adipate-co-terephthalate) for bread packaging. Food Chem. 2020, 333, 127537. [Google Scholar] [CrossRef]

- Balaguer, M.P.; Lopez-Carballo, G.; Catala, R.; Gavara, R.; Hernandez-Munoz, P. Antifungal properties of gliadin films incorporating cinnamaldehyde and application in active food packaging of bread and cheese spread foodstuffs. Int. J. Food Microbiol. 2013, 166, 369–377. [Google Scholar] [CrossRef]

- Bumbudsanpharoke, N.; Wongphan, P.; Promhuad, K.; Leelaphiwat, P.; Harnkarnsujarit, N. Morphology and permeability of bio-based poly(butylene adipate-co-terephthalate) (PBAT), poly(butylene succinate) (PBS) and linear low-density polyethylene (LLDPE) blend films control shelf-life of packaged bread. Food Control 2021, 132, 108541. [Google Scholar] [CrossRef]

- Licciardello, F. Packaging, blessing in disguise. Review on its diverse contribution to food sustainability. Trends Food Sci. Technol. 2017, 65, 32–39. [Google Scholar] [CrossRef]

- Saranraj, P.; Geetha, M. Microbial Spoilage of Bakery Products and Its Control by Preservatives. Int. J. Pharm. Biol. Arch. 2012, 3, 38–48. [Google Scholar]

- Pateras, I.M.C. Bread Spoilage and Staling. In Technology of Bread Making; Springer: Berlin/Heidelberg, Germany, 2007; pp. 275–298. [Google Scholar]

- Galanakis, C.M. Recovery of high added-value components from food wastes: Conventional, emerging technologies and commercialized applications. Trends Food Sci. Technol. 2012, 26, 68–87. [Google Scholar] [CrossRef]

- Bello, F.D.; Clarke, C.; Ryan, L.; Ulmer, H.; Schober, T.; Ström, K.; Sjögren, J.; van Sinderen, D.; Schnürer, J.; Arendt, E. Improvement of the quality and shelf life of wheat bread by fermentation with the antifungal strain Lactobacillus plantarum FST 1.7. J. Cereal Sci. 2007, 45, 309–318. [Google Scholar] [CrossRef]

- Needham, R.; Williams, J.; Beales, N.; Voysey, P.; Magan, N. Early detection and differentiation of spoilage of bakery products. Sens. Actuators B Chem. 2005, 106, 20–23. [Google Scholar] [CrossRef]

- Knight, R.A.; Menlove, E.M. Effect of the Bread-baking process on destruction of certain mold spores. J. Sci. Food Agric. 1961, 10, 653–660. [Google Scholar] [CrossRef]

- Degirmencioglu, N.; Göcmen, D.; Inkaya, A.N.; Aydin, E.; Guldas, M.; Gonenc, S. Influence of modified atmosphere packaging and potassium sorbate on microbiological characteristics of sliced bread. J. Food Sci. Technol. 2010, 48, 236–241. [Google Scholar] [CrossRef]

- Rodríguez, M.; Medina, L.M.; Jordano, R. Effect of modified atmosphere packaging on the shelf life of sliced wheat flour bread. Nahrung 2000, 44, 247–252. [Google Scholar] [CrossRef]

- Noshirvani, N.; Ghanbarzadeh, B.; Mokarram, R.R.; Hashemi, M. Novel active packaging based on carboxymethyl cellulose-chitosan-ZnO NPs nanocomposite for increasing the shelf life of bread. Food Packag. Shelf Life 2017, 11, 106–114. [Google Scholar] [CrossRef]

- Tsiraki, M.I.; El-Obeid, T.; Yehia, H.M.; Karam, L.; Savvaidis, I.N. Effects of Chitosan and Natamycin on Vacuum-Packaged Phyllo: A Pastry Product. J. Food Prot. 2018, 81, 1982–1987. [Google Scholar] [CrossRef]

- Thanakkasaranee, S.; Kim, D.; Seo, J. Preparation and characterization of polypropylene/sodium propionate (PP/SP) composite films for bread packaging application. Packag. Technol. Sci. 2018, 31, 221–231. [Google Scholar] [CrossRef]

- Braga, L.R.; Rangel, E.T.; Suarez, P.A.Z.; Machado, F. Simple synthesis of active films based on PVC incorporated with silver nanoparticles: Evaluation of the thermal, structural and antimicrobial properties. Food Packag. Shelf Life 2018, 15, 122–129. [Google Scholar] [CrossRef]

- Luz, C.; Calpe, J.; Saladino, F.; Luciano, F.B.; Fernandez-Franzón, M.; Mañes, J.; Meca, G. Antimicrobial packaging based on ɛ-polylysine bioactive film for the control of mycotoxigenic fungi in vitro and in bread. J. Food Process. Preserv. 2017, 42, e13370. [Google Scholar] [CrossRef] [PubMed]

- Sahraee, S.; Milani, J.M.; Ghanbarzadeh, B.; Hamishehkar, H. Development of emulsion films based on bovine gelatin-nano chitin-nano ZnO for cake packaging. Food Sci. Nutr. 2020, 8, 1303–1312. [Google Scholar] [CrossRef] [PubMed]

- Shulga, O.; Chorna, A.; Shulga, S. Antimicrobial biodegradable packaging for sliced bakery. Food Sci. Technol. 2021, 15, 71–78. [Google Scholar] [CrossRef]

- Kongkaoroptham, P.; Piroonpan, T.; Pasanphan, W. Chitosan nanoparticles based on their derivatives as antioxidant and antibacterial additives for active bioplastic packaging. Carbohydr. Polym. 2021, 257, 117610. [Google Scholar] [CrossRef]

- Riahi, Z.; Priyadarshi, R.; Rhim, J.-W.; Lotfali, E.; Bagheri, R.; Pircheraghi, G. Alginate-based multifunctional films incorporated with sulfur quantum dots for active packaging applications. Colloids Surf. B Biointerfaces 2022, 215, 112519. [Google Scholar] [CrossRef]

- Viscusi, G.; Bugatti, V.; Vittoria, V.; Gorrasi, G. Antimicrobial sorbate anchored to layered double hydroxide (LDH) nano-carrier employed as active coating on Polypropylene (PP) packaging: Application to bread stored at ambient temperature. Future Foods 2021, 4, 100063. [Google Scholar] [CrossRef]

- Passarinho, A.T.P.; Dias, N.F.; Camilloto, G.P.; Cruz, R.S.; Otoni, C.; Moraes, A.R.F.; Soares, N.D.F.F. Sliced Bread Preservation through Oregano Essential Oil-Containing Sachet. J. Food Process Eng. 2014, 37, 53–62. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Kumar, B.; Deeba, F.; Kulshreshtha, A.; Negi, Y.S. Chitosan films incorporated with Apricot (Prunus armeniaca) kernel essential oil as active food packaging material. Food Hydrocoll. 2018, 85, 158–166. [Google Scholar] [CrossRef]

- Wang, K.; Lim, P.N.; Tong, S.Y.; Thian, E.S. Development of grapefruit seed extract-loaded poly(ε-caprolactone)/chitosan films for antimicrobial food packaging. Food Packag. Shelf Life 2019, 22, 100396. [Google Scholar] [CrossRef]

- Ju, J.; Xie, Y.; Yu, H.; Guo, Y.; Cheng, Y.; Qian, H.; Yao, W. A novel method to prolong bread shelf life: Sachets containing essential oils components. LWT 2020, 131, 109744. [Google Scholar] [CrossRef]

- Suwanamornlert, P.; Kerddonfag, N.; Sane, A.; Chinsirikul, W.; Zhou, W.; Chonhenchob, V. Poly(lactic acid)/poly(butylene-succinate-co-adipate) (PLA/PBSA) blend films containing thymol as alternative to synthetic preservatives for active packaging of bread. Food Packag. Shelf Life 2020, 25, 100515. [Google Scholar] [CrossRef]

- Jha, P. Effect of plasticizer and antimicrobial agents on functional properties of bionanocomposite films based on corn starch-chitosan for food packaging applications. Int. J. Biol. Macromol. 2020, 160, 571–582. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, M.A.; Gonzaga, M.L.; Bastos, M.S.; Magalhães, H.C.; Benevides, S.D.; Furtado, R.F.; Zambelli, R.A.; Garruti, D.S. Packaging with cashew gum/gelatin/essential oil for bread: Release potential of the citral. Food Packag. Shelf Life 2019, 23, 100431. [Google Scholar] [CrossRef]

- Klinmalai, P.; Srisa, A.; Laorenza, Y.; Katekhong, W.; Harnkarnsujarit, N. Antifungal and plasticization effects of carvacrol in biodegradable poly(lactic acid) and poly(butylene adipate terephthalate) blend films for bakery packaging. LWT 2021, 152, 112356. [Google Scholar] [CrossRef]

- Songtipya, P.; Sengsuk, T.; Songtipya, L.; Prodpran, T.; Kalkornsurapranee, E. A novel natural rubber pressure sensitive adhesive patch amended with cinnamon oil for preserving bakery product. Food Packag. Shelf Life 2021, 29, 100729. [Google Scholar] [CrossRef]

- Bui, Q.T.P.; Nguyen, T.T.; Nguyen, L.T.T.; Kim, S.H.; Nguyen, H.N. Development of ecofriendly active food packaging materials based on blends of cross-linked poly (vinyl alcohol) and Piper betle Linn. leaf extract. J. Appl. Polym. Sci. 2021, 138, 50974. [Google Scholar] [CrossRef]

- Mahmood, K.; Kamilah, H.; Alias, A.K.; Ariffin, F.; Nafchi, A.M. Functionalization of electrospun fish gelatin mats with bioactive agents: Comparative effect on morphology, thermo-mechanical, antioxidant, antimicrobial properties, and bread shelf stability. Food Sci. Nutr. 2021, 10, 584–596. [Google Scholar] [CrossRef]

- Sharma, P.; Ahuja, A.; Izrayeel, A.M.D.; Samyn, P.; Rastogi, V.K. Physicochemical and thermal characterization of poly (3-hydroxybutyrate-co-4-hydroxybutyrate) films incorporating thyme essential oil for active packaging of white bread. Food Control 2021, 133, 108688. [Google Scholar] [CrossRef]

- Natesan, S.; Samuel, J.S.; Srinivasan, A.K. Design and development of Schiff’s base (SB)-modified polylactic acid (PLA) antimicrobial film for packaging applications. Polym. Bull. 2021, 79, 4627–4646. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Lee, J.-H.; Hong, S.-I. Increase in water resistance of paperboard by coating with poly(lactide). Packag. Technol. Sci. 2007, 20, 393–402. [Google Scholar] [CrossRef]

- Rakchoy, S.; Suppakul, P.; Jinkarn, T. Antimicrobial effects of vanillin coated solution for coating paperboard intended for packaging bakery products. Asian J. Food Agro-Ind. 2009, 2, 138–147. [Google Scholar]

- Landge, S.N.; Chavan, B.R.; Kulkarni, D.N.; Khedkar, C.D. Effect of packaging materials, storage period and temper-ature on acceptability of milk cake. J. Dairy. Foods Home Sci. 2009, 28, 20–25. [Google Scholar]

- Rodríguez, A.; Nerín, C.; Batlle, R. New Cinnamon-Based Active Paper Packaging against Rhizopusstolonifer Food Spoilage. J. Agric. Food Chem. 2008, 56, 6364–6369. [Google Scholar] [CrossRef] [PubMed]

- Peter, A.; Mihaly-Cozmuta, L.; Mihaly-Cozmuta, A.; Nicula, C.; Ziemkowska, W.; Basiak, D.; Danciu, V.; Vulpoi, A.; Baia, L.; Falup, A.; et al. Changes in the microbiological and chemical characteristics of white bread during storage in paper packages modified with Ag/TiO2–SiO2, Ag/N–TiO2 or Au/TiO2. Food Chem. 2016, 197, 790–798. [Google Scholar] [CrossRef]

- Brodnjak, U.V. Influence of ultrasonic treatment on properties of bio-based coated paper. Prog. Org. Coat. 2017, 103, 93–100. [Google Scholar] [CrossRef]

- Mihaly-Cozmuta, A.; Peter, A.; Craciun, G.; Falup, A.; Mihaly-Cozmuta, L.; Nicula, C.; Vulpoi, A.; Baia, M. Preparation and characterization of active cellulose-based papers modified with TiO2, Ag and zeolite nanocomposites for bread packaging application. Cellulose 2017, 24, 3911–3928. [Google Scholar] [CrossRef]

- Efiyanti, L.; Hastuti, N.; Indrawan, D.A. Potential Utilization of Nano Carbon Wrapping Paper from Bamboo for Packaging of Brownies Cake. In Proceedings of the 5th International Symposium on Innovative Bio-Production Indonesia, Bogor, Indonesia, 10 October 2018; Research Center for Biotechnology: Bogor, Indonesia, 2018. [Google Scholar]

- Shankar, S.; Rhim, J.-W. Antimicrobial wrapping paper coated with a ternary blend of carbohydrates (alginate, carboxymethyl cellulose, carrageenan) and grapefruit seed extract. Carbohydr. Polym. 2018, 196, 92–101. [Google Scholar] [CrossRef]

- Apjok, R.; Cozmuta, A.M.; Peter, A.; Cozmuta, L.M.; Nicula, C.; Baia, M.; Vulpoi, A. Active packaging based on cellulose-chitosan-Ag/TiO2 nanocomposite for storage of clarified butter. Cellulose 2019, 26, 1923–1946. [Google Scholar] [CrossRef]

- Mizielińska, M.; Kowalska, U.; Tarnowiecka-Kuca, A.; Dzięcioł, P.; Kozłowska, K.; Bartkowiak, A. The Influence of Multilayer, “Sandwich” Package on the Freshness of Bread after 72 h Storage. Coatings 2020, 10, 1175. [Google Scholar] [CrossRef]

- Petchwattana, N.; Naknaen, P.; Cha-Aim, K.; Suksri, C.; Sanetuntikul, J. Controlled release antimicrobial sachet prepared from poly(butylene succinate)/geraniol and ethylene vinyl alcohol coated paper for bread shelf-life extension application. Int. J. Biol. Macromol. 2021, 189, 251–261. [Google Scholar] [CrossRef] [PubMed]

- Altamirano-Fortoul, R.; Moreno-Terrazas, R.; Quezada-Gallo, A.; Rosell, C. Viability of some probiotic coatings in bread and its effect on the crust mechanical properties. Food Hydrocoll. 2012, 29, 166–174. [Google Scholar] [CrossRef]

- Cozmuta, A.M.; Peter, A.; Cozmuta, L.M.; Nicula, C.; Crisan, L.; Baia, L.; Turila, A. Active Packaging System Based on Ag/TiO2Nanocomposite Used for Extending the Shelf Life of Bread. Chemical and Microbiological Investigations. Packag. Technol. Sci. 2014, 28, 271–284. [Google Scholar] [CrossRef]

- Saraiva, L.E.F.; Naponucena, L.D.O.M.; Santos, V.D.S.; Silva, R.P.D.; de Souza, C.O.; Souza, I.E.G.L.; Mamede, M.E.D.O.; Druzian, J.I. Development and application of edible film of active potato starch to extend mini panettone shelf life. LWT 2016, 73, 311–319. [Google Scholar] [CrossRef]

- Bartolozzo, J.; Borneo, R.; Aguirre, A. Effect of triticale-based edible coating on muffin quality maintenance during storage. J. Food Meas. Charact. 2015, 10, 88–95. [Google Scholar] [CrossRef]

- Lee, J.; Park, M.A.; Yoon, C.S.; Na, J.H.; Han, J. Characterization and Preservation Performance of Multilayer Film with Insect Repellent and Antimicrobial Activities for Sliced Wheat Bread Packaging. J. Food Sci. 2019, 84, 3194–3203. [Google Scholar] [CrossRef]

- Heras-Mozos, R.; Muriel-Galet, V.; López-Carballo, G.; Catalá, R.; Hernandez-Munoz, P.; Gavara, R. Development and optimization of antifungal packaging for sliced pan loaf based on garlic as active agent and bread aroma as aroma corrector. Int. J. Food Microbiol. 2018, 290, 42–48. [Google Scholar] [CrossRef]

- Gregirchak, N.; Stabnikova, O.; Stabnikov, V. Application of Lactic Acid Bacteria for Coating of Wheat Bread to Protect it from Microbial Spoilage. Mater. Veg. 2020, 75, 223–229. [Google Scholar] [CrossRef]

- Senanayake, C.M.; Nayanakanthi, T.; Siranjiv, P. Development of an Edible Coating from Okra Mucilage to Preserve the Crispiness in Soft Dough Biscuits Upon Storage. Adv. Technol. 2021, 1, 307–320. [Google Scholar] [CrossRef]

- Berenzon, S.; Saguy, I.S. Oxygen Absorber for Externsion of Crackers Shelf-life. LWT-Food Sci. Technol. 1998, 31, 1–5. [Google Scholar] [CrossRef]

- Latou, E.; Mexis, S.; Badeka, A.; Kontominas, M. Shelf life extension of sliced wheat bread using either an ethanol emitter or an ethanol emitter combined with an oxygen absorber as alternatives to chemical preservatives. J. Cereal Sci. 2010, 52, 457–465. [Google Scholar] [CrossRef]

- Muizniece-Brasava, S.; Dukalska, L.; Murniece, I.; Dabina-Bicka, I.; Kozlinskis, E.; Sarvi, S.; Santars, R.; Silvjane, A. Active Packaging Influence on Shelf Life Extension of Sliced Wheat Bread. Int. J. Nutr. Food Eng. 2012, 6, 480–486. [Google Scholar]

- Hempel, A.W.; O’Sullivan, M.G.; Papkovsky, D.B.; Kerry, J.P. Use of smart packaging technologies for monitoring and extending the shelf-life quality of modified atmosphere packaged (MAP) bread: Application of intelligent oxygen sensors and active ethanol emitters. Eur. Food Res. Technol. 2013, 237, 117–124. [Google Scholar] [CrossRef]

- Sheng, Q.; Guo, X.-N.; Zhu, K.-X. The Effect of Active Packaging on Microbial Stability and Quality of Chinese Steamed Bread. Packag. Technol. Sci. 2015, 28, 775–787. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Tananuwong, K.; Kongpensook, V.; Tantratian, S.; Kokpol, S. Shelf life extension of sponge cake by active packaging as an alternative to direct addition of chemical preservatives. LWT 2016, 72, 166–174. [Google Scholar] [CrossRef]

- Chuaythong, C.; Rachtanapun, C. Effect of packaging film and oxygen absorber of shelf life extension of Chinese pastry (kha-nom pia). Ital. J. Food Sci. 2017, 30, 51–56. [Google Scholar]

- Upasen, S.; Wattanachai, P. Packaging to prolong shelf life of preservative-free white bread. Heliyon 2018, 4, e00802. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Li, X.; Ma, Z.; Liu, L.; Hu, X. Chinese steamed bread: Packaging conditions and starch retrogradation. Cereal Chem. 2018, 96, 95–103. [Google Scholar] [CrossRef] [Green Version]

- Kütahneci, E.; Ayhan, Z. Applications of different oxygen scavenging systems as an active packaging to improve freshness and shelf life of sliced bread. J. Consum. Prot. Food Saf. 2021, 16, 247–259. [Google Scholar] [CrossRef]

- Shashikumar, J.N.; Nidoni, U.; Ramachandra, C.T. Influence of active packaging materials on microbial characteristics of wheat flour bread during storage. Pharma Innov. J. 2022, 11, 531–537. [Google Scholar]

- Rüegg, N.; Röcker, B.; Yildirim, S. Application of palladium-based oxygen scavenger to extend the mould free shelf life of bakery products. Food Packag. Shelf Life 2021, 31, 100771. [Google Scholar] [CrossRef]

- Gaikwad, K.K.; Deshmukh, R.K.; Lee, Y.S. Natural phenolic compound coated oxygen scavenging active polyolefin film for preserving quality of fish cake. Biomass Convers. Biorefinery 2022, 1–10. [Google Scholar] [CrossRef]

- Charles, B.R.; Drew, S.V.; Thomas, K.D.; Marvin, H.R. Oxygen Detection System for a Ridig Container. WO2004/052644A2, 25 November 2004. [Google Scholar]

- Scott, M.W.; Terrence, L.P.; William, S.J.; Norman, J.L.; Jonh, F.C.; Tom, W. Absorbent Microwave Interactive Packaging. WO 2006/026345 A2(PCT/US2005/030231), 2006. [Google Scholar]

- Sirkku, R.J. Coated Recyclable Paper or Paperboard and Methods for Their Production. WO 2010/052571A2, 10 May 2010. [Google Scholar]

- Minna, A.; Gerhard, S. Multilayer Film. WO2012/016938A1, 2012. [Google Scholar]

- Carolina, L.D.D.B.A.; Alicia, G.L.M.J.; Abel, G.M.; Jose, V.V.E.; Simon, R.F. Antifungal Polymeric Multilayer Active Packaging with Inner Polymeric Coating Comprising Mustard Oil, Useful for Extending the Shelf Life of Bakery Products for Coeliacs. WO2021207864 (A1), 21 October 2021. [Google Scholar]

- Carolina, L.D.D.B.A.; Virginia, M.G.; Simon, R.F.; Abel, G.M.; Alicia, G.L.M.J. Active Antifungal Packaging, Polyolefin with a Water-Soluble Polymer Coating and Synergistic Mixture of Volatile Natural Components, Carvacrol and al-lyl-Isothiocyanate, Useful for Extending the Useful Life of Bakery Products. WO2021068089 (A1), 15 April 2022. [Google Scholar]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K.; Promsorn, J.; Harnkarnsujarit, N. Blown film extrusion of PBAT/TPS/ZnO nanocomposites for shelf-life extension of meat packaging. Colloids Surf. B Biointerfaces 2022, 214, 112472. [Google Scholar] [CrossRef] [PubMed]

- Wadaugsorn, K.; Panrong, T.; Wongphan, P.; Harnkarnsujarit, N. Plasticized hydroxypropyl cassava starch blended PBAT for improved clarity blown films: Morphology and properties. Ind. Crop. Prod. 2021, 176, 114311. [Google Scholar] [CrossRef]

- Wongphan, P.; Panrong, T.; Harnkarnsujarit, N. Effect of different modified starches on physical, morphological, thermomechanical, barrier and biodegradation properties of cassava starch and polybutylene adipate terephthalate blend film. Food Packag. Shelf Life 2022, 32, 100844. [Google Scholar] [CrossRef]

- Huntrakul, K.; Yoksan, R.; Sane, A.; Harnkarnsujarit, N. Effects of pea protein on properties of cassava starch edible films produced by blown-film extrusion for oil packaging. Food Packag. Shelf Life 2020, 24, 100480. [Google Scholar] [CrossRef]

- Phothisarattana, D.; Harnkarnsujarit, N. Migration, aggregations and thermal degradation behaviors of TiO2 and ZnO incorporated PBAT/TPS nanocomposite blown films. Food Packag. Shelf Life 2022, 33, 100901. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Alam, T.; Talwar, N. Recent advances in active packaging of agri-food products: A review. J. Postharvest Technol. 2019, 7, 33–62. [Google Scholar]

- Fasihi, H.; Fasihi, H.; Noshirvani, N.; Noshirvani, N.; Hashemi, M.; Hashemi, M.; Fazilati, M.; Fazilati, M.; Salavati, H.; Salavati, H.; et al. Antioxidant and antimicrobial properties of carbohydrate-based films enriched with cinnamon essential oil by Pickering emulsion method. Food Packag. Shelf Life 2019, 19, 147–154. [Google Scholar] [CrossRef]

- Tyagi, P.; Salem, K.S.; Hubbe, M.A.; Pal, L. Advances in barrier coatings and film technologies for achieving sustainable packaging of food products—A review. Trends Food Sci. Technol. 2021, 115, 461–485. [Google Scholar] [CrossRef]

- Regulation, E. Regulation (EC) No 853/2004 of the European Parliament and of the council on laying down specific hygience rules for on the hygiene of foodstuffs. Eur. Comm. 2004, 139, 139. [Google Scholar]

- Kouhi, M.; Prabhakaran, M.P.; Ramakrishna, S. Edible polymers: An insight into its application in food, biomedicine and cosmetics. Trends Food Sci. Technol. 2020, 103, 248–263. [Google Scholar] [CrossRef]

- Shit, S.C.; Shah, P.M. Edible Polymers: Challenges and Opportunities. J. Polym. 2014, 2014, 427259. [Google Scholar] [CrossRef]

- Ali, A.; Ahmed, S. Recent Advances in Edible Polymer Based Hydrogels as a Sustainable Alternative to Conventional Polymers. J. Agric. Food Chem. 2018, 66, 6940–6967. [Google Scholar] [CrossRef]

- McHugh, T.H. Protein-lipid interactions in edible films and coatings. Nahrung 2000, 44, 148–151. [Google Scholar] [CrossRef]

- Gough, C.R.; Rivera-Galletti, A.; Cowan, D.A.; La Cruz, D.S.-D.; Hu, X. Protein and Polysaccharide-Based Fiber Materials Generated from Ionic Liquids: A Review. Molecules 2020, 25, 3362. [Google Scholar] [CrossRef] [PubMed]

- Wongphan, P.; Khowthong, M.; Supatrawiporn, T.; Harnkarnsujarit, N. Novel edible starch films incorporating papain for meat tenderization. Food Packag. Shelf Life 2021, 31, 100787. [Google Scholar] [CrossRef]

- Kocira, A.; Kozłowicz, K.; Panasiewicz, K.; Staniak, M.; Szpunar-Krok, E.; Hortyńska, P. Polysaccharides as Edible Films and Coatings: Characteristics and Influence on Fruit and Vegetable Quality—A Review. Agronomy 2021, 11, 813. [Google Scholar] [CrossRef]

- BeMiller, J.N. Carbohydrate Chemistry for Food Scientists, 3rd ed.; Elsevier: Cambridge, MA, USA, 2018. [Google Scholar]

- Cichello, S.A. Oxygen absorbers in food preservation: A review. J. Food Sci. Technol. 2014, 52, 1889–1895. [Google Scholar] [CrossRef]

- Promsorn, J.; Harnkarnsujarit, N. Oxygen absorbing food packaging made by extrusion compounding of thermoplastic cassava starch with gallic acid. Food Control 2022, 142, 109273. [Google Scholar] [CrossRef]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K.; Promsorn, J.; Harnkarnsujarit, N. Biodegradable Poly(Butylene Adipate-Co-Terephthalate) and Thermoplastic Starch-Blended TiO2 Nanocomposite Blown Films as Functional Active Packaging of Fresh Fruit. Polymers 2021, 13, 4192. [Google Scholar] [CrossRef] [PubMed]

- De Pilli, T. Development of a vegetable oil and egg proteins edible film to replace preservatives and primary packaging of sweet baked goods. Food Control 2020, 114, 107273. [Google Scholar] [CrossRef]

- Dao, T.; Dantigny, P. Control of food spoilage fungi by ethanol. Food Control 2011, 22, 360–368. [Google Scholar] [CrossRef]

- Dantigny, P.; Guilmart, A.; Radoi, F.; Bensoussan, M.; Zwietering, M. Modelling the effect of ethanol on growth rate of food spoilage moulds. Int. J. Food Microbiol. 2005, 98, 261–269. [Google Scholar] [CrossRef]

- Kalathenos, P.; Russell, N.J. Ethanol as a food preservative. In Food Preservatives; Russell, N.J., Gould, G.W., Eds.; Springer: Berlin/Heidelberg, Germany, 2003; pp. 196–217. [Google Scholar]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

| Materials and Components | Packaging Form | Package Conversion Technology | Bakery | Key Technology | Results | References |

|---|---|---|---|---|---|---|

| Oxygen detection system | Rigid container with an oxygen detection system | Bakery products |

|

| [92] |

| Absorbent sheet | Absorbent structure compression | Bakery products |

|

| [93] |

| Coated paper or paperboard | Paper or paperboard is coated with a polymer emulsion in one or more coating | Bakery products |

|

| [94] |

| Multilayer film |

| Frozen food packaging Bakery product |

|

| [95] |

| Coated film | Multilayers include coating | Gluten-free bread |

|

| [96] |

| Film | Coating film | Sliced bread |

|

| [97] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

San, H.; Laorenza, Y.; Behzadfar, E.; Sonchaeng, U.; Wadaugsorn, K.; Sodsai, J.; Kaewpetch, T.; Promhuad, K.; Srisa, A.; Wongphan, P.; et al. Functional Polymer and Packaging Technology for Bakery Products. Polymers 2022, 14, 3793. https://doi.org/10.3390/polym14183793

San H, Laorenza Y, Behzadfar E, Sonchaeng U, Wadaugsorn K, Sodsai J, Kaewpetch T, Promhuad K, Srisa A, Wongphan P, et al. Functional Polymer and Packaging Technology for Bakery Products. Polymers. 2022; 14(18):3793. https://doi.org/10.3390/polym14183793

Chicago/Turabian StyleSan, Horman, Yeyen Laorenza, Ehsan Behzadfar, Uruchaya Sonchaeng, Kiattichai Wadaugsorn, Janenutch Sodsai, Thitiporn Kaewpetch, Khwanchat Promhuad, Atcharawan Srisa, Phanwipa Wongphan, and et al. 2022. "Functional Polymer and Packaging Technology for Bakery Products" Polymers 14, no. 18: 3793. https://doi.org/10.3390/polym14183793

APA StyleSan, H., Laorenza, Y., Behzadfar, E., Sonchaeng, U., Wadaugsorn, K., Sodsai, J., Kaewpetch, T., Promhuad, K., Srisa, A., Wongphan, P., & Harnkarnsujarit, N. (2022). Functional Polymer and Packaging Technology for Bakery Products. Polymers, 14(18), 3793. https://doi.org/10.3390/polym14183793