Mechanical Properties, Critical Length, and Interfacial Strength of Seven-Islands-Sedge Fibers (Cyperus malaccensis) for Possible Epoxy Matrix Reinforcement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

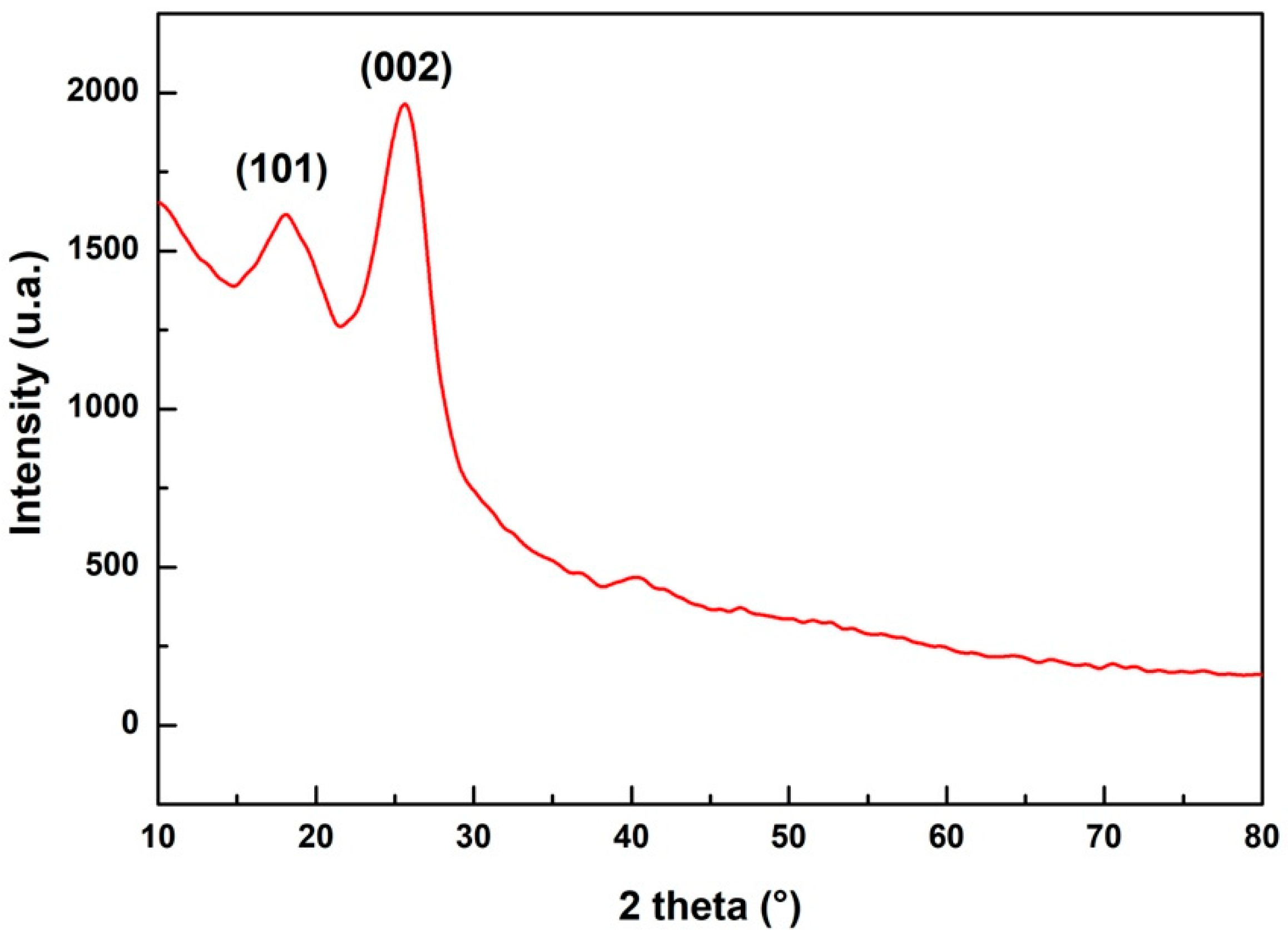

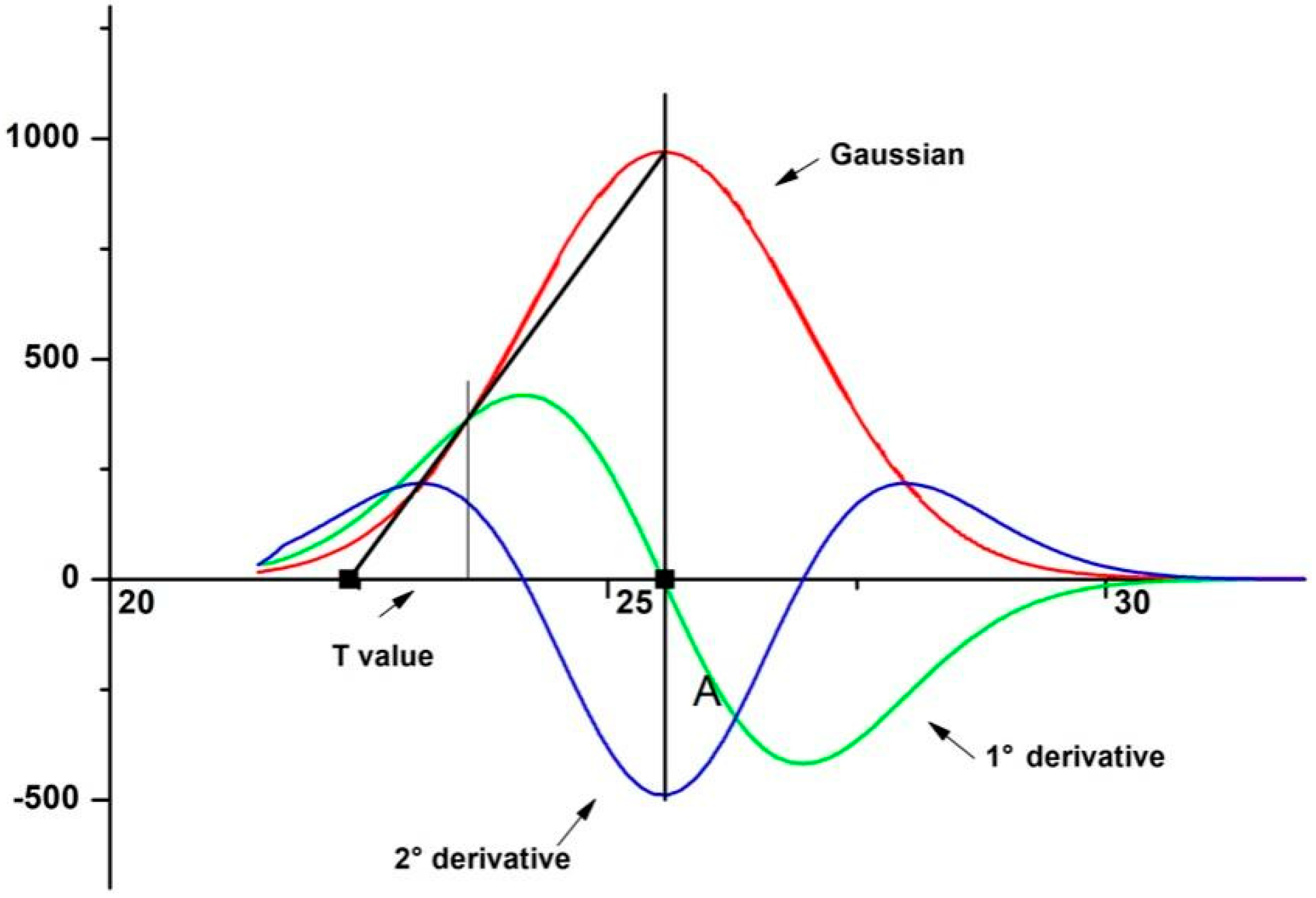

2.2. X-ray Diffraction (XRD)

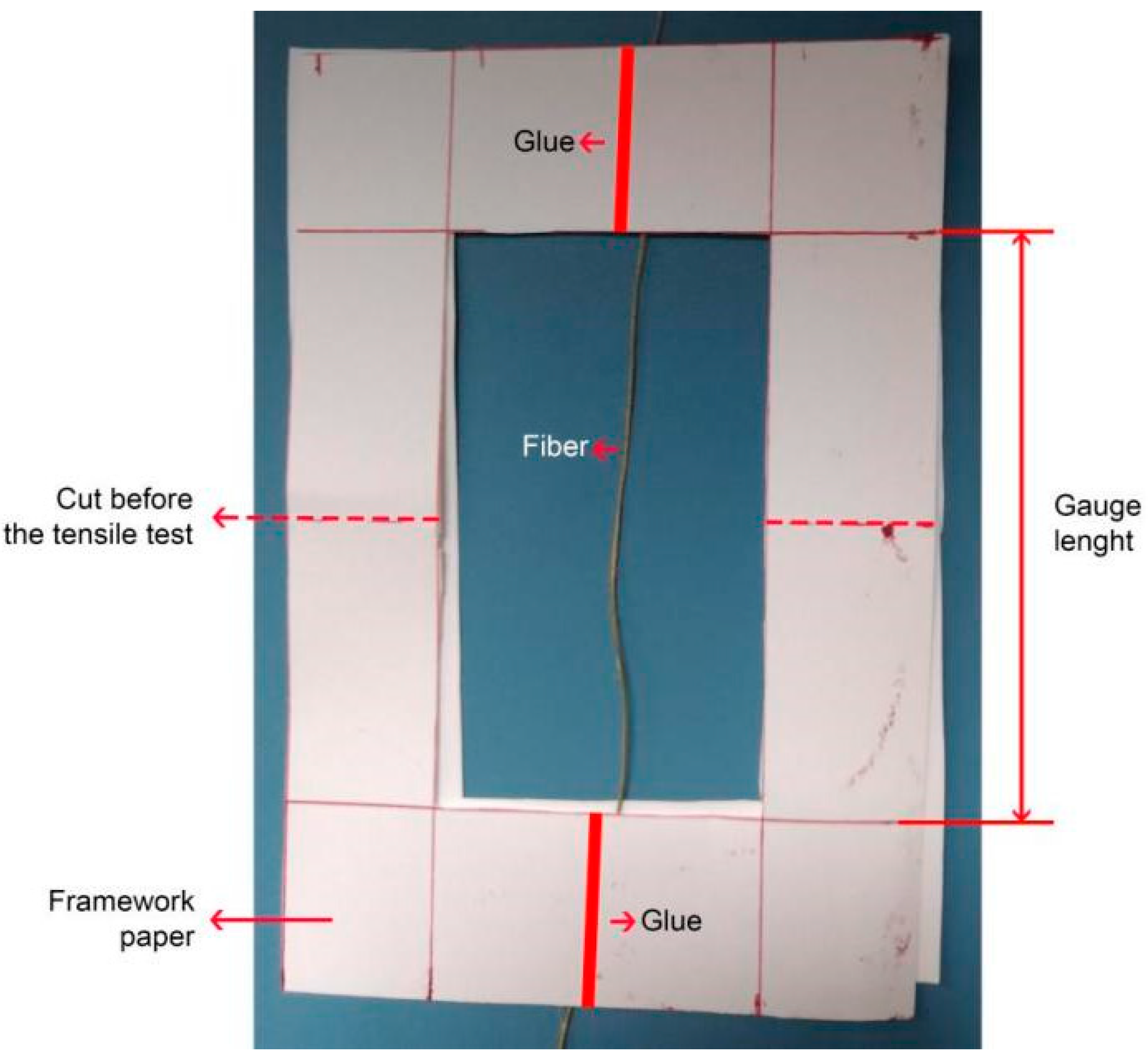

2.3. Tensile Tests

2.4. Pullout Tests

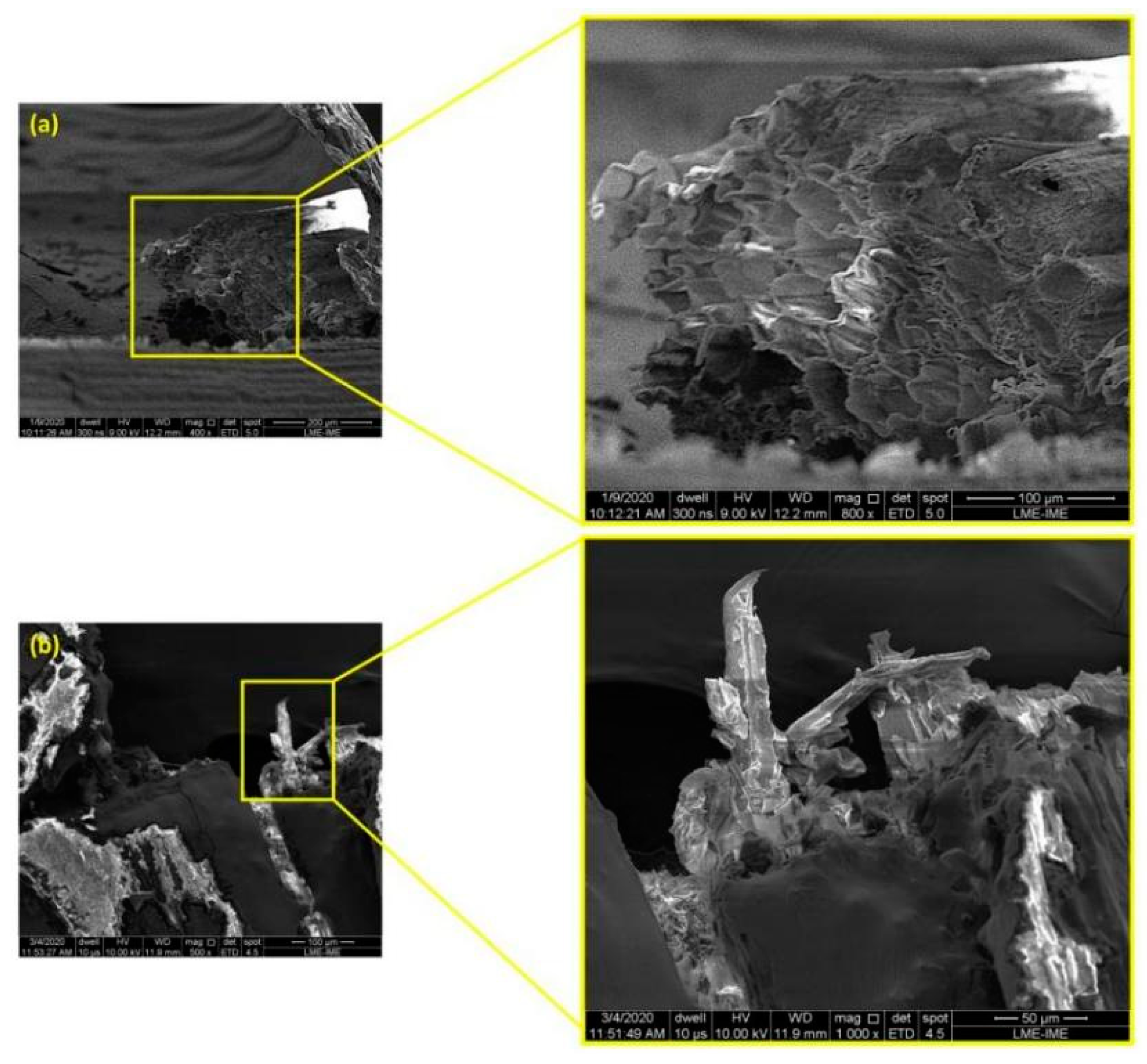

2.5. Scanning Electron Microscopy (SEM)

3. Results and Discussion

3.1. XRD Results

3.2. Tensile Tests Results

3.3. Microstructural Analysis

3.4. Fiber Diameter and Mechanical Properties Correlation

3.5. Pullout Results (Interfacial Strength)

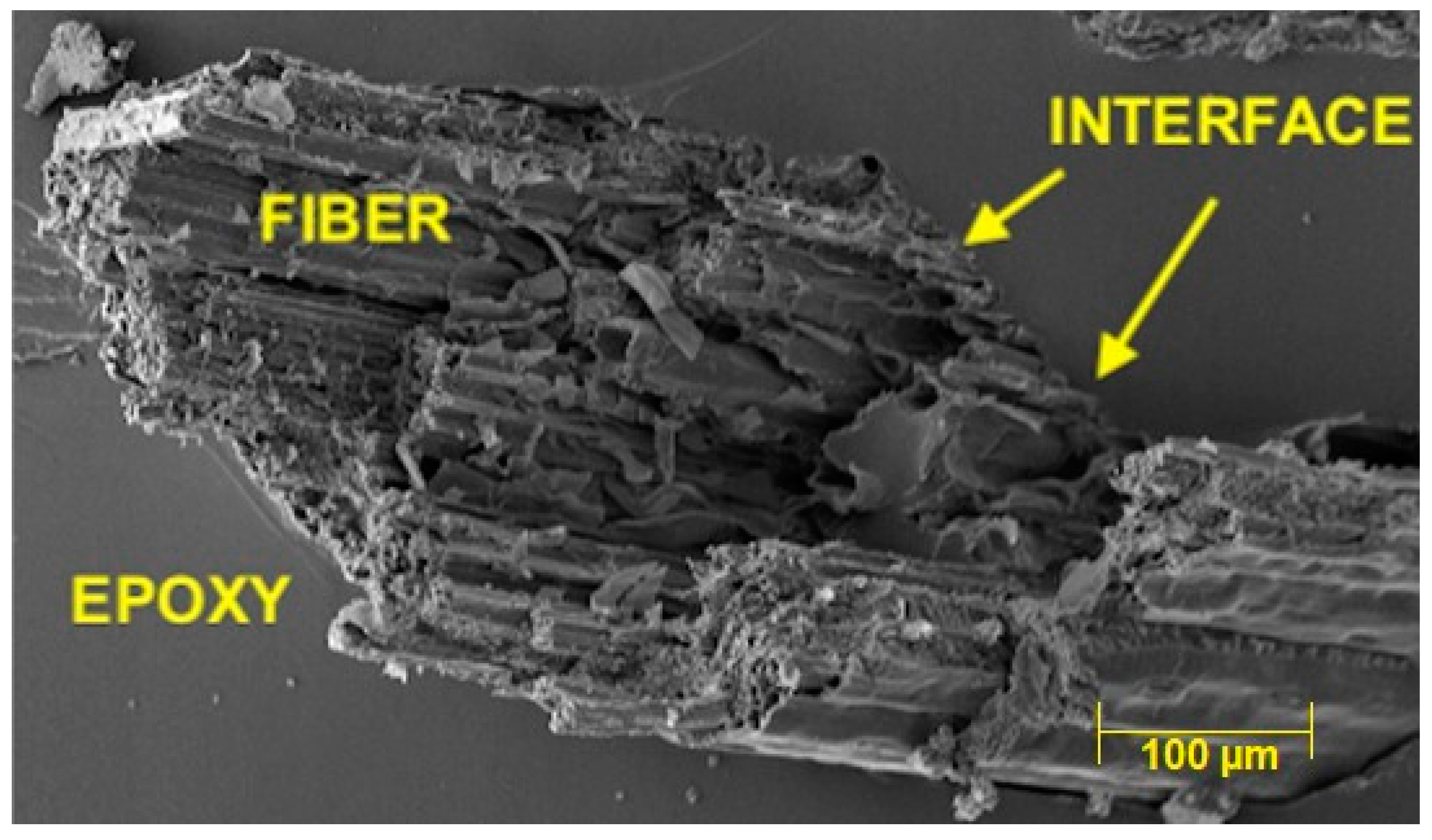

3.6. Interfacial Observation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural Fiber–Reinforced Composites: A Review on Material, Manufacturing, and Machinability. J. Thermoplast. Compos. Mater. 2021, 34, 238–284. [Google Scholar] [CrossRef]

- Rajak, D.; Pagar, D.; Menezes, P.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Kicińska-Jakubowska, A.; Bogacz, E.; Zimniewska, M. Review of Natural Fibers. Part I—Vegetable Fibers. J. Nat. Fibers 2012, 9, 150–167. [Google Scholar] [CrossRef]

- Mansour, M.M.A.; EL-Hefny, M.; Salem, M.Z.M.; Ali, H.M. The Biofungicide Activity of Some Plant Essential Oils for the Cleaner Production of Model Linen Fibers Similar to Those Used in Ancient Egyptian Mummification. Processes 2020, 8, 79. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. State of the Art on Tribological Behavior of Polymer Matrix Composites Reinforced with Natural Fibers in the Green Materials World. Eng. Sci. Technol. Int. J. 2016, 19, 717–736. [Google Scholar] [CrossRef]

- Singh, A.S.; Halder, S.; Kumar, A.; Chen, P. Tannic Acid Functionalization of Bamboo Micron Fibes: Its Capability to Toughen Epoxy Based Biocomposites. Mater. Chem. Phys. 2020, 243, 122112. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural Fiber Reinforced Polylactic Acid Composites: A Review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Jeyapragash, R.; Srinivasan, V.; Sathiyamurthy, S. Mechanical Properties of Natural Fiber/Particulate Reinforced Epoxy Composites—A Review of the Literature. Mater. Today Proc. 2020, 22, 1223–1227. [Google Scholar] [CrossRef]

- Barhoum, A.; García-Betancourt, M.L.; Jeevanandam, J.; Hussien, E.A.; Mekkawy, S.A.; Mostafa, M.; Omran, M.M.; Abdalla, M.S.; Bechelany, M. Review on Natural, Incidental, Bioinspired, and Engineered Nanomaterials: History, Definitions, Classifications, Synthesis, Properties, Market, Toxicities, Risks, and Regulations. Nanomaterials 2022, 12, 177. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Sapuan, S.M. Natural Fiber Reinforced Polymer Composites in Industrial Applications: Feasibility of Date Palm Fibers for Sustainable Automotive Industry. J. Clean. Prod. 2014, 66, 347–354. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, Biodegradable Polymers and Biocomposites: An Overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable Composites Based on Lignocellulosic Fibers—An Overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; da Silva, I.L.A.; da Costa, L.L. Natural Lignocellulosic Fibers as Engineering Materials—An Overview. Metall. Mater. Trans. A 2011, 42, 2963–2974. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Processing and Characterization of Natural Cellulose Fibers/Thermoset Polymer Composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Issam, A.M.; Ahmad Shakri, M.T.; Suriani, R.; Awang, A.Y. Conventional Agro-Composites from Chemically Modified Fibres. Ind. Crops Prod. 2007, 26, 315–323. [Google Scholar] [CrossRef]

- Hiroce, R.; Benatti Júnior, R.; Feitosa, C.T. Estudos Nutricionais Em Junco: Adubação e Calagem. Bragantia 1988, 47, 313–323. [Google Scholar] [CrossRef]

- Shioya, M.; Myoga, A.; Kitagawa, A.; Tokunaga, Y.; Hayashi, H.; Kogo, Y.; Shimada, H.; Satake, S. Analysis of Deflection and Dynamic Plant Characteristics of Cyperus Malaccensis Lam. Plant Prod. Sci. 2019, 22, 242–249. [Google Scholar] [CrossRef] [Green Version]

- Karamchand, K.S.; Sridhar, K.R.; Bhat, R. Diversity of Fungi Associated with Estuarine Sedge Cyperus Malaccensis Lam. J. Agric. Technol. 2009, 5, 111–127. [Google Scholar]

- Neuba, L.M.; Junio, R.F.P.; Ribeiro, M.P.; Souza, A.T.; Lima, E.S.; Garcia Filho, F.C.; Figueiredo, A.B.-H.; da Silva Figueiredo, A.B.-H.; Braga, F.O.; Azevedo, A.R.G.; et al. Promising Mechanical, Thermal, and Ballistic Properties of Novel Epoxy Composites Reinforced with Cyperus Malaccensis Sedge Fiber. Polymers 2020, 12, 1776. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, S.N.; Margem, F.M.; de Oliveira Braga, F.; da Luz, F.S.; Simonassi, N.T. Weibull Analysis of the Tensile Strength Dependence with Fiber Diameter of Giant Bamboo. J. Mater. Res. Technol. 2017, 6, 317–322. [Google Scholar] [CrossRef]

- Marchi, B.Z.; Oliveira, M.S.; Bezerra, W.B.A.; Souza, T.G.; Candido, V.S.; Silva, A.C.R.; Monteiro, S.N. Ubim Fiber (Geonoma baulifera): A Less Known Brazilian Amazon Natural Fiber for Engineering Applications. Sustainability 2021, 13, 421. [Google Scholar] [CrossRef]

- Souza, A.T.; Neuba, L.M.; Junio, R.F.P.; Carvalho, M.T.; Candido, V.S.; Figueiredo, A.B.-H.S.; Monteiro, S.N.; Nascimento, L.F.C.; Silva, A.C.R. Ballistic Properties and Izod Impact Resistance of Novel Epoxy Composites Reinforced with Caranan Fiber (Mauritiella armata). Polymers 2022, 14, 3348. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Cave, I.D. Theory of X-Ray Measurement of Microfibril Angle in Wood. Wood Sci. Technol. 1997, 31, 143–152. [Google Scholar] [CrossRef]

- Donaldson, L. Microfibril Angle: Measurement, Variation and Relationships—A Review. IAWA J. 2008, 29, 345–386. [Google Scholar] [CrossRef]

- Wang, W.Q.; Sardans, J.; Wang, C.; Zeng, C.S.; Tong, C.; Asensio, D.; Peñuelas, J. Ecological Stoichiometry of C, N, and P of Invasive Phragmites Australis and Native Cyperus Malaccensis Species in the Minjiang River Tidal Estuarine Wetlands of China. Plant Ecol. 2015, 216, 809–822. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Nunes, L.F.; Oliveira, M.S.; de Veiga Junior, V.F.; Filho, F.D.C.G.; Pinheiro, M.A.; Candido, V.S.; Monteiro, S.N. Guaruman Fiber: Another Possible Reinforcement in Composites. J. Mater. Res. Technol. 2020, 9, 622–628. [Google Scholar] [CrossRef]

- ASTM-D2101; American Society for Testing and Materials. Standard Test Method for Tensile Properties of Single Man-Made Textile Fibers Taken from Yarns and Tows. ASTM International: West Conshohocken, PA, USA, 1995; pp. 1–10.

- Jha, K.; Kataria, R.; Verma, J.; Pradhan, S. Potential Biodegradable Matrices and Fiber Treatment for Green Composites: A Review. AIMS Mater. Sci. 2019, 6, 119–138. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile Properties of Fibre-Reinforced Metals: Copper/Tungsten and Copper/Molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Saravanakumar, S.S.; Kumaravel, A.; Nagarajan, T.; Moorthy, I.G. Investigation of Physico-Chemical Properties of Alkali-Treated Prosopis Juliflora Fibers. Int. J. Polym. Anal. Charact. 2014, 19, 309–317. [Google Scholar] [CrossRef]

- Boudjellal, A.; Trache, D.; Khimeche, K.; Hafsaoui, S.L.; Razali, M.S. Preparation and Characterization of Graphene Oxide-Based Natural Hybrids Containing Alfa Fibers or Microcrystalline Cellulose. J. Nat. Fibers 2021, 1–12. [Google Scholar] [CrossRef]

- Okafor, C.E.; Kebodi, L.C.; Ihueze, C.C.; Rangappa, S.M.; Siengchin, S.; Okonkwo, U.C. Development of Dioscorea Alata Stem Fibers as Eco-Friendly Reinforcement for Composite Materials. J. King Saud Univ. Eng. Sci. 2022. [Google Scholar] [CrossRef]

- Pradhan, S.; Prakash, V.; Acharya, S.K. Influence of Chemical Modification on Structural, Morphological, Thermal, and Weathering Behavior of Eulaliopsis Binata Fiber and Its Composites. J. Nat. Fibers 2022, 1–15. [Google Scholar] [CrossRef]

- Manivel, S.; Pannirselvam, N.; Gopinath, R.; Sathishkumar, T.P. Influence of Alkali Treatment on Physicochemical, Thermal and Mechanical Properties of Hibiscus Vitifolius Fibers. J. Nat. Fibers 2022, 1–14. [Google Scholar] [CrossRef]

- Jena, P.K.; Mohanty, J.R.; Nayak, S. Effect of Surface Modification of Vetiver Fibers on Their Physical and Thermal Properties. J. Nat. Fibers 2022, 19, 25–36. [Google Scholar] [CrossRef]

- Kayambu, A.; Ramasubbu, R. Physical Chemical and Surface Morphological Characterization of Areca Catechu Fiber. J. Nat. Fibers 2022, 1–14. [Google Scholar] [CrossRef]

- Arruda Filho, A.B.; Dantas, C.L.D.E.R.; Lima, P.R.L.; Fontes, C.M.A. Autoclave Treatment of Sisal Fiber and Its Effect on Fiber Properties and on the Pull-out Behavior from Cementitious Matrix. J. Nat. Fibers 2022, 1–14. [Google Scholar] [CrossRef]

- Ju, Z.; Zhan, T.; Brosse, N.; Wei, Y.; Zhang, H.; Cui, J.; Lu, X. Interfacial Properties of Windmill Palm (Trachycarpus Fortunei) Fiber Reinforced Laminated Veneer Lumber (LVL) Composites under High Voltage Electrostatic Field (HVEF). Ind. Crops Prod. 2022, 180, 114795. [Google Scholar] [CrossRef]

- Mayandi, K.; Rajini, N.; Pitchipoo, P.; Jappes, J.T.W.; Rajulu, A.V. Extraction and Characterization of New Natural Lignocellulosic Fiber Cyperus Pangorei. Int. J. Polym. Anal. Charact. 2016, 21, 175–183. [Google Scholar] [CrossRef]

- Vijay, D.; Singaravelu, D.L.; Vinod, A.; Raj, I.D.F.P.; Sanjay, M.R.; Siengchin, S. Characterization of Novel Natural Fiber from Saccharum Bengalense Grass (Sarkanda). J. Nat. Fibers 2020, 17, 1739–1747. [Google Scholar] [CrossRef]

- Kumar, P.S.S.; Allamraju, K.V. A Review of Natural Fiber Composites [Jute, Sisal, Kenaf]. Mater. Today Proc. 2019, 18, 2556–2562. [Google Scholar] [CrossRef]

- Cunha, J.S.C.; Nascimento, L.F.C.; Luz, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Monteiro, S.N. Titica vine Fiber (Heteropsis flexuosa): A hidden Amazon Fiber with Potential Application as Reinforcement in Polymer Matrix Composites. J. Compos. Sci. 2022, 6, 251. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O.F.M.; Silva, F.A.; Filho, R.D.T. The Effect of Fiber Morphoogy on the Tensile Strength of Natural Fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites Reinforced with Cellulose Based Fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Tagawa, T.; Miyata, T. Size Effect on Tensile Strength of Carbon Fibers. Mater. Sci. Eng. A 1997, 238, 336–342. [Google Scholar] [CrossRef]

- Loganathan, T.M.; Sultan, M.T.H.; Jawaid, M.; Ahsan, Q.; Naveen, J.; Shah, A.U.M.; Talib, A.R.A.; Basri, A.A. Physical, Nechanical, and Morphological Properties of Hybrid Cyrtostachys renda/Kenaf Fiber Reinforced with Multi-Walled Carbon Nanotubes (MWCNT)-Phenolic Composites. Polymers 2021, 13, 3448. [Google Scholar] [CrossRef]

- Mahdi, E.; Ochoa, D.R.H.; Vaziri, A.; Dean, A.; Kucukvar, M. Khalasa Date Palm Leaf Fiber as a Potential Reinforcement for Polymeric Composite Materials. Compos. Struct. 2021, 256, 113501. [Google Scholar] [CrossRef]

- ASTM D 3379-75; American Society for Testing and Materials. Standard Test Method for Tensile Strength and Young’s Modulus for High-Modulus Single-Filament Materials. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–10.

- da Luz, F.S.; Ramos, F.J.H.T.V.; Nascimento, L.F.C.; da Silva Figueiredo, A.B.-H.; Monteiro, S.N. Critical Length and Interfacial Strength of PALF and Coir Fiber Incorporated in Epoxy Resin Matrix. J. Mater. Res. Technol. 2018, 7, 528–534. [Google Scholar] [CrossRef]

- Nirmal, U.; Singh, N.; Hashim, J.; Lau, S.T.W.; Jamil, N. On the Effect of Different Polymer Matrix and Fibre Treatment on Single Fibre Pullout Test Using Betelnut Fibres. Mater. Des. 2011, 32, 2717–2726. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Pereira, A.C.; Filho, F.C.G.; Luz, F.S.; Braga, F.O.; Nascimento, L.F.C.; Lima, E.P.; Demosthenes, L.C.C.; Monteiro, S.N. Fique Fiber-Reinforced Epoxy Composite for Ballistic Armor Against 7.62 mm Ammunition. Green Mater. Eng. 2019, 193–199. [Google Scholar] [CrossRef]

- Han, X.; Chen, T.; Zhao, Y.; Gao, J.; Sang, Y.; Xiong, H.; Chen, Z. Relationship Between the Microstructure and Performance of Graphene/Polyethylene Composites Investigated by Positron Annihilation Lifetime Spectroscopy. Nanomaterials 2021, 11, 2990. [Google Scholar] [CrossRef]

- Han, X.; Geo, J.; Chen, Z.; Tang, X.; Zhao, Y.; Chen, T. Correlation Between Microstructure and Properties of Graphene Oxide/Waterborne Polyurethene Composites Investigated by Positron Annihilation Spectroscopy. R. Soc. Chem. Adv. 2020, 10, 32436–32442. [Google Scholar] [CrossRef]

- Monteiro, S.N.; D’Almeida, J.D. Pullout Testing in Lignocellulosic Fibers—An Analysis of Methodology. Rev. Matér. 2006, 11, 189–196. [Google Scholar] [CrossRef] [Green Version]

| Mean Diameter (mm) | Tensile Strength (MPa) | Statistical Deviation (MPa) | Weibull Modulus (β) | Characteristic Stress. θ (MPa) | Precision Adjustment (R²) |

|---|---|---|---|---|---|

| 0.23 | 163.48 | 84.88 | 2.07 | 189.40 | 0.97 |

| 0.36 | 81.73 | 14.28 | 6.68 | 87.26 | 0.88 |

| 0.48 | 66.02 | 47.83 | 1.47 | 76.67 | 0.92 |

| 0.61 | 32.35 | 28.27 | 0.46 | 46.94 | 0.76 |

| 0.74 | 61.83 | 33.12 | 1.99 | 71.33 | 0.97 |

| 0.86 | 40.74 | 20.66 | 2.13 | 47.35 | 0.75 |

| Fiber | Tensile Strength (MPa) | References |

|---|---|---|

| Sedge | 75 | PW * |

| Saccharum Bengalense | 33 | [44] |

| Jute | 393–773 | [45] |

| Sisal | 511–635 | [45] |

| Kenaf | 930 | [45] |

| Piassava | 133 | [46] |

| Coir | 106–270 | [46] |

| Flax | 1035 | [47] |

| Curaua | 543 | [46] |

| Carbon | 2500–5600 | [48] |

| E-glass | 2000–3500 | [47] |

| Aramid | 3000–3150 | [47] |

| Variation Causes | Sum of Squares | DF | Average Square | F (Calculated) | Fcritical (Tabulated) |

|---|---|---|---|---|---|

| Among the groups | 53,478.08 | 5 | 10,695.62 | 7.86 | 2.62 |

| Inside the groups | 32,641.36 | 24 | 1360.06 | ||

| Total | 86,119.44 | 29 |

| Diameter Interval | 1° | 2° | 3° | 4° | 5° | 6° |

|---|---|---|---|---|---|---|

| 1° | 0 | 78.67 | 88.89 | 124.72 | 110.72 | 119.65 |

| 2° | 78.67 | 0 | 10.32 | 46.05 | 32.10 | 40.97 |

| 3° | 88.89 | 10.32 | 0 | 35.72 | 21.77 | 30.65 |

| 4° | 124.72 | 46.05 | 35.72 | 0 | 13.95 | 5.07 |

| 5° | 110.72 | 32.10 | 21.77 | 13.95 | 0 | 8.88 |

| 6° | 119.65 | 40.97 | 30.65 | 5.07 | 8.88 | 0 |

| Diameter Intervals (mm) | Maximum Elongation (%) | Tensile Modulus of Elasticity (GPa) |

|---|---|---|

| 0.23 | 4.08 | 4.36 |

| 0.36 | 3.56 | 2.96 |

| 0.48 | 4.22 | 1.92 |

| 0.61 | 2.79 | 1.79 |

| 0.74 | 4.07 | 1.77 |

| 0.86 | 4.49 | 0.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neuba, L.d.M.; Junio, R.F.P.; Souza, A.T.; Ribeiro, M.P.; da Silveira, P.H.P.M.; da Silva, T.T.; Pereira, A.C.; Monteiro, S.N. Mechanical Properties, Critical Length, and Interfacial Strength of Seven-Islands-Sedge Fibers (Cyperus malaccensis) for Possible Epoxy Matrix Reinforcement. Polymers 2022, 14, 3807. https://doi.org/10.3390/polym14183807

Neuba LdM, Junio RFP, Souza AT, Ribeiro MP, da Silveira PHPM, da Silva TT, Pereira AC, Monteiro SN. Mechanical Properties, Critical Length, and Interfacial Strength of Seven-Islands-Sedge Fibers (Cyperus malaccensis) for Possible Epoxy Matrix Reinforcement. Polymers. 2022; 14(18):3807. https://doi.org/10.3390/polym14183807

Chicago/Turabian StyleNeuba, Lucas de Mendonça, Raí Felipe Pereira Junio, Andressa Teixeira Souza, Matheus Pereira Ribeiro, Pedro Henrique Poubel Mendonça da Silveira, Thuane Teixeira da Silva, Artur Camposo Pereira, and Sergio Neves Monteiro. 2022. "Mechanical Properties, Critical Length, and Interfacial Strength of Seven-Islands-Sedge Fibers (Cyperus malaccensis) for Possible Epoxy Matrix Reinforcement" Polymers 14, no. 18: 3807. https://doi.org/10.3390/polym14183807

APA StyleNeuba, L. d. M., Junio, R. F. P., Souza, A. T., Ribeiro, M. P., da Silveira, P. H. P. M., da Silva, T. T., Pereira, A. C., & Monteiro, S. N. (2022). Mechanical Properties, Critical Length, and Interfacial Strength of Seven-Islands-Sedge Fibers (Cyperus malaccensis) for Possible Epoxy Matrix Reinforcement. Polymers, 14(18), 3807. https://doi.org/10.3390/polym14183807