Oriented Tapes of Incompatible Polymers Using a Novel Multiplication Co-Extrusion Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

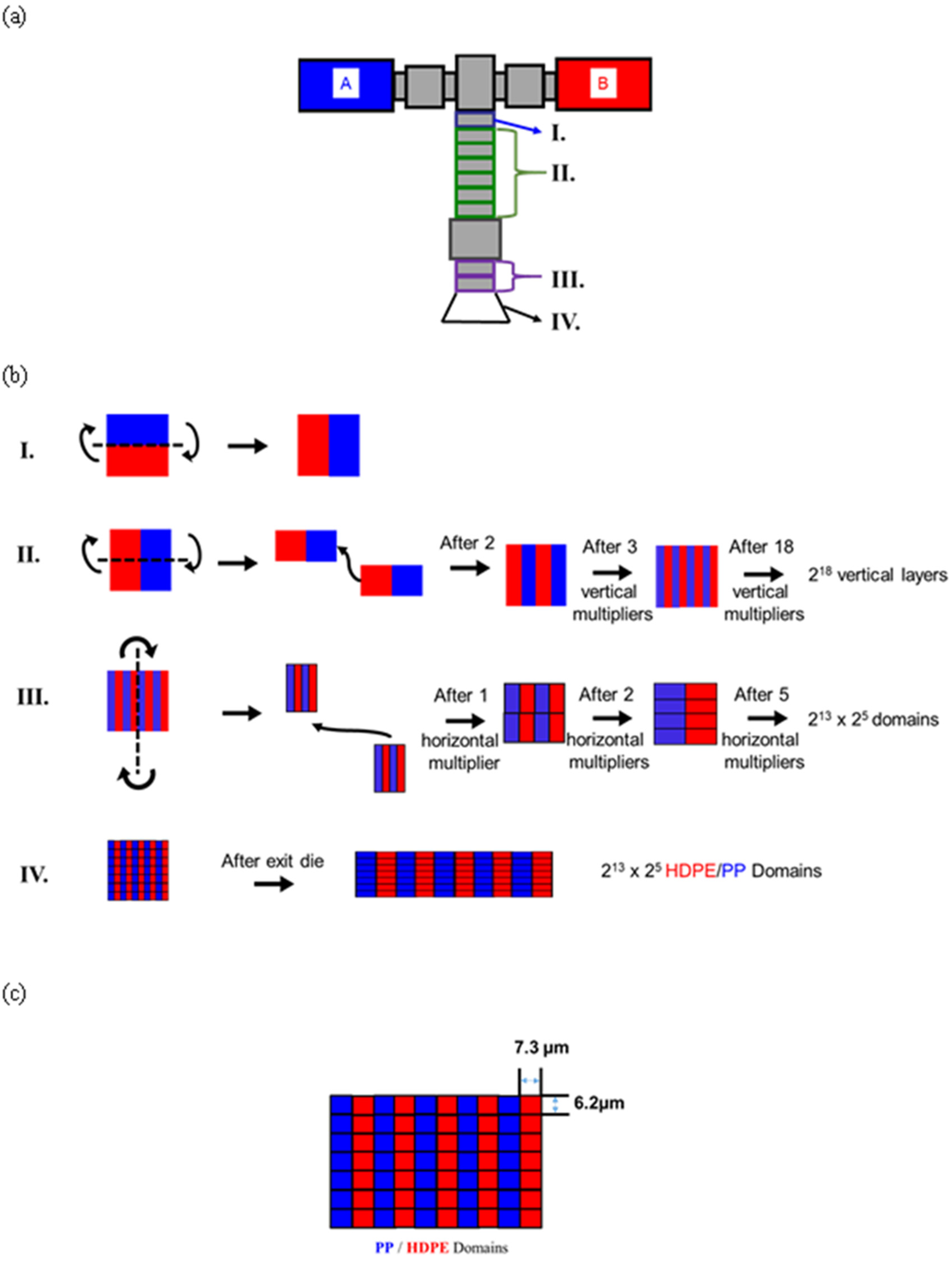

2.2. Co-Extrusion of Tapes

2.3. High-Temperature Orientation of Tapes

2.4. Tensile Measurements

2.5. Structural Characterization

3. Results

3.1. Characterization and Properties of Unoriented Tapes

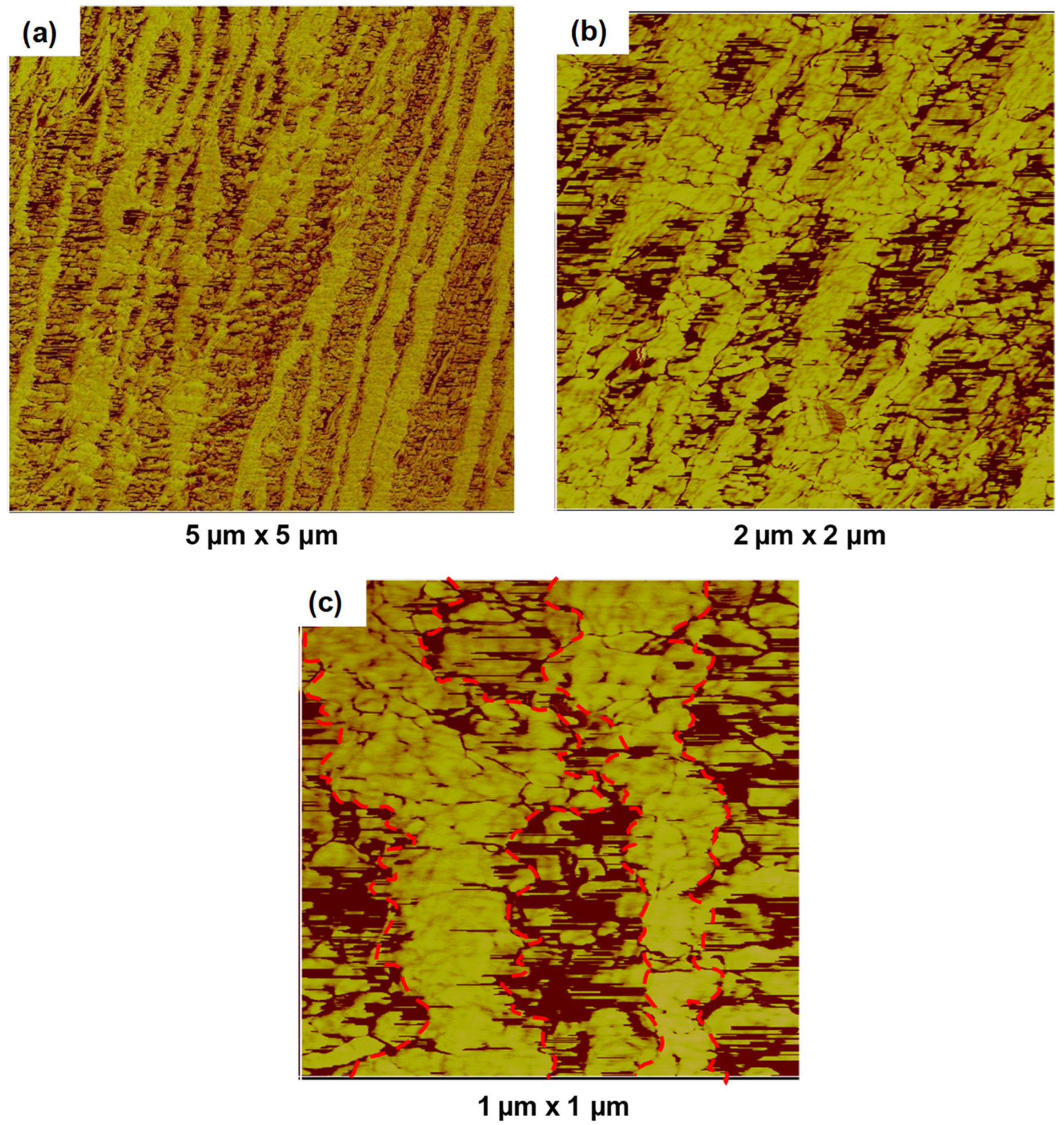

3.1.1. Morphology

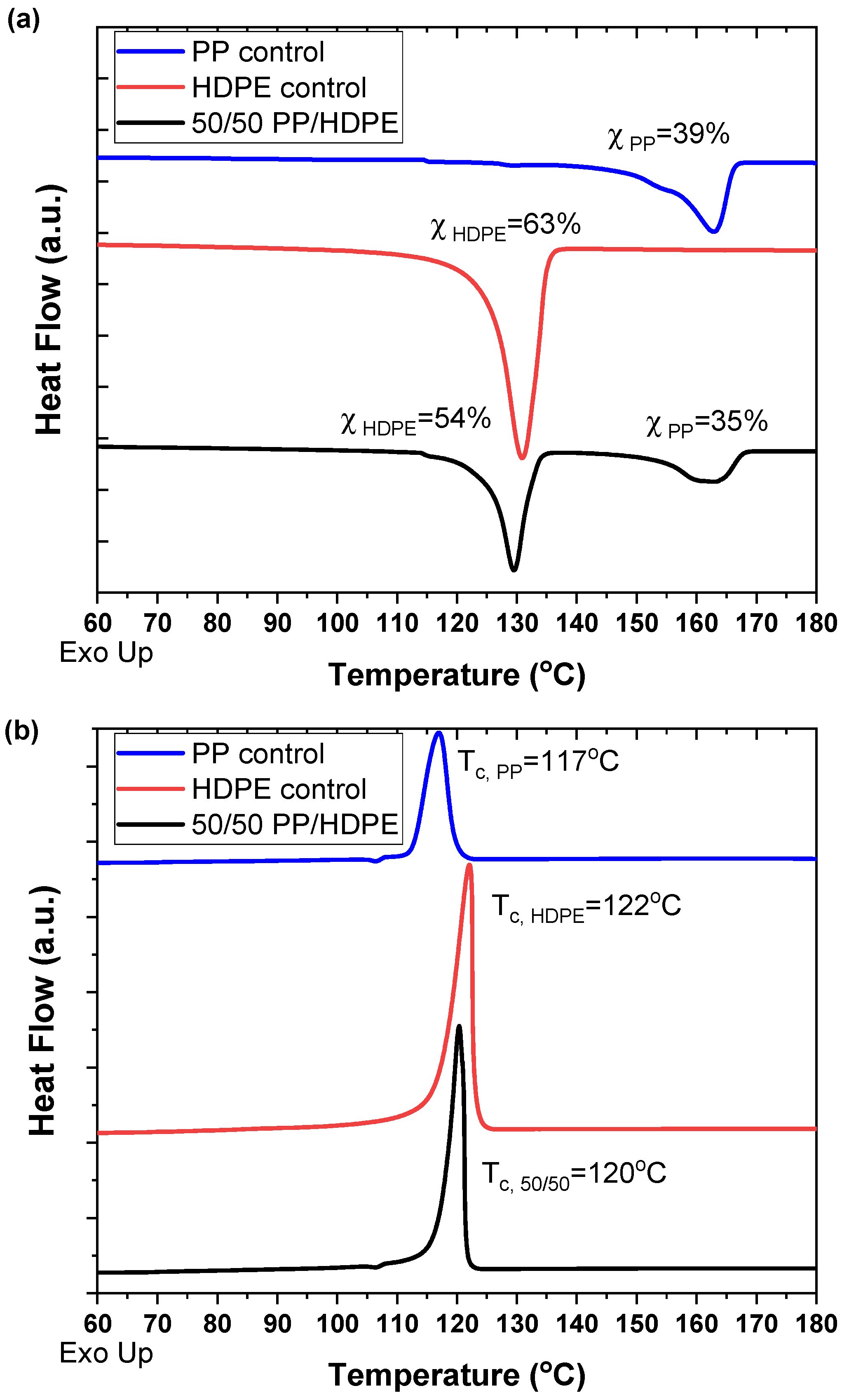

3.1.2. DSC and WAXD Characterization

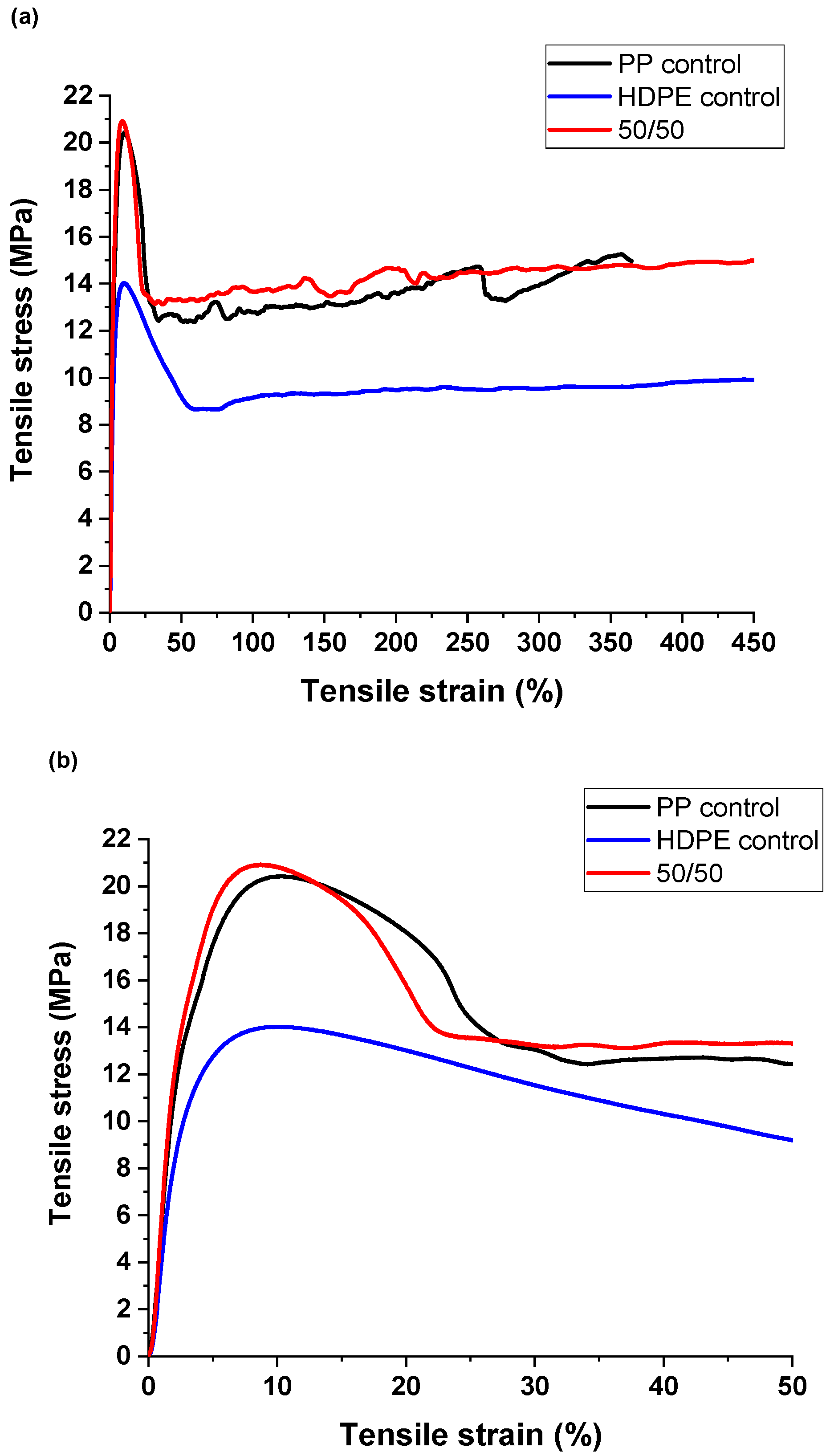

3.1.3. Mechanical Properties of the Unoriented Tape

3.2. Orientation of Tapes

3.2.1. Mechanical Behavior during Orientation

3.2.2. Mechanical Behavior of Oriented Tapes at Room Temperature

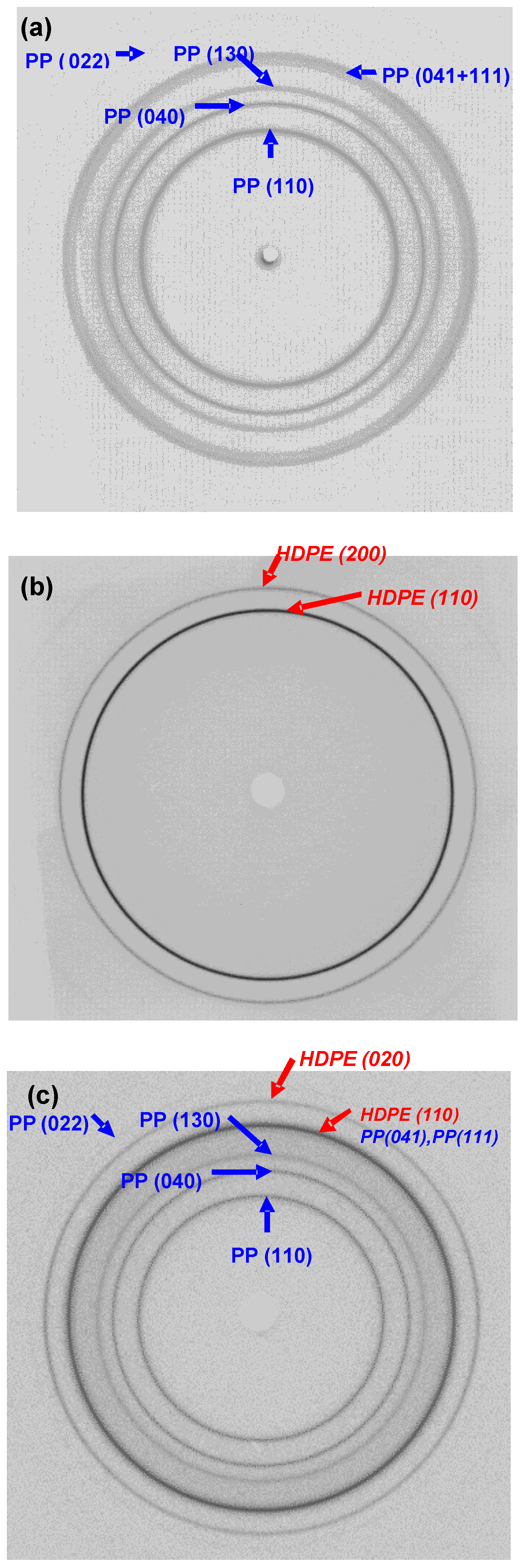

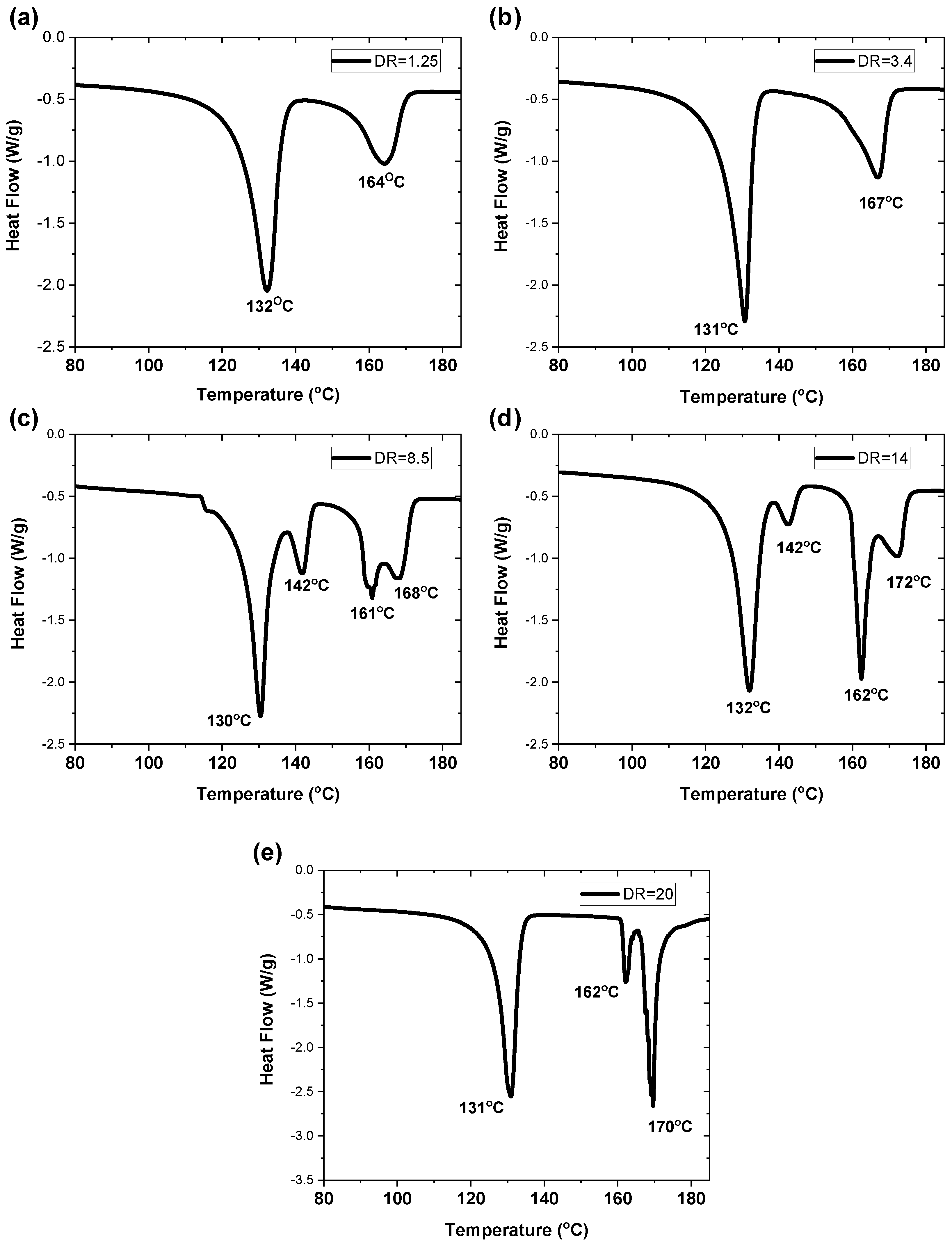

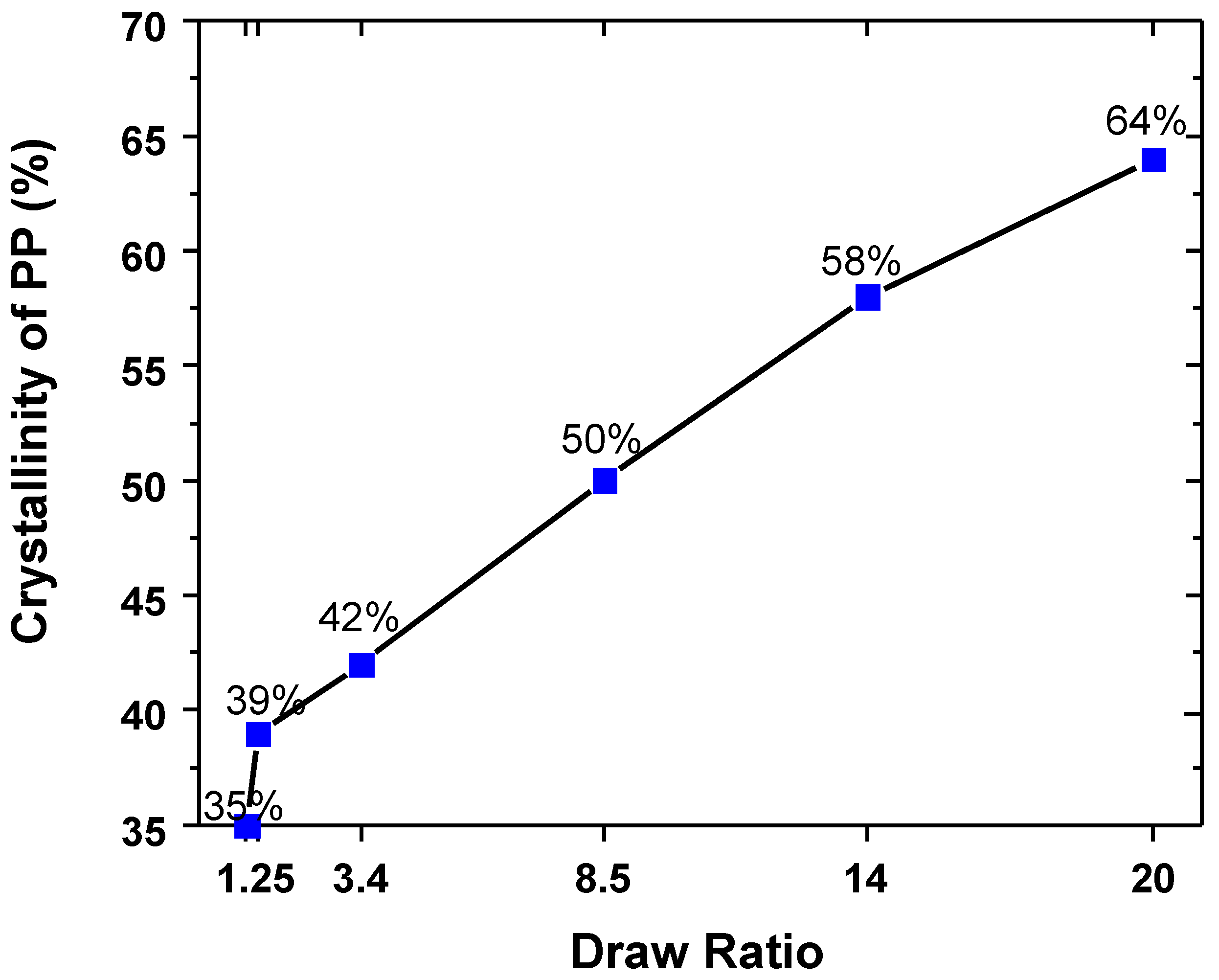

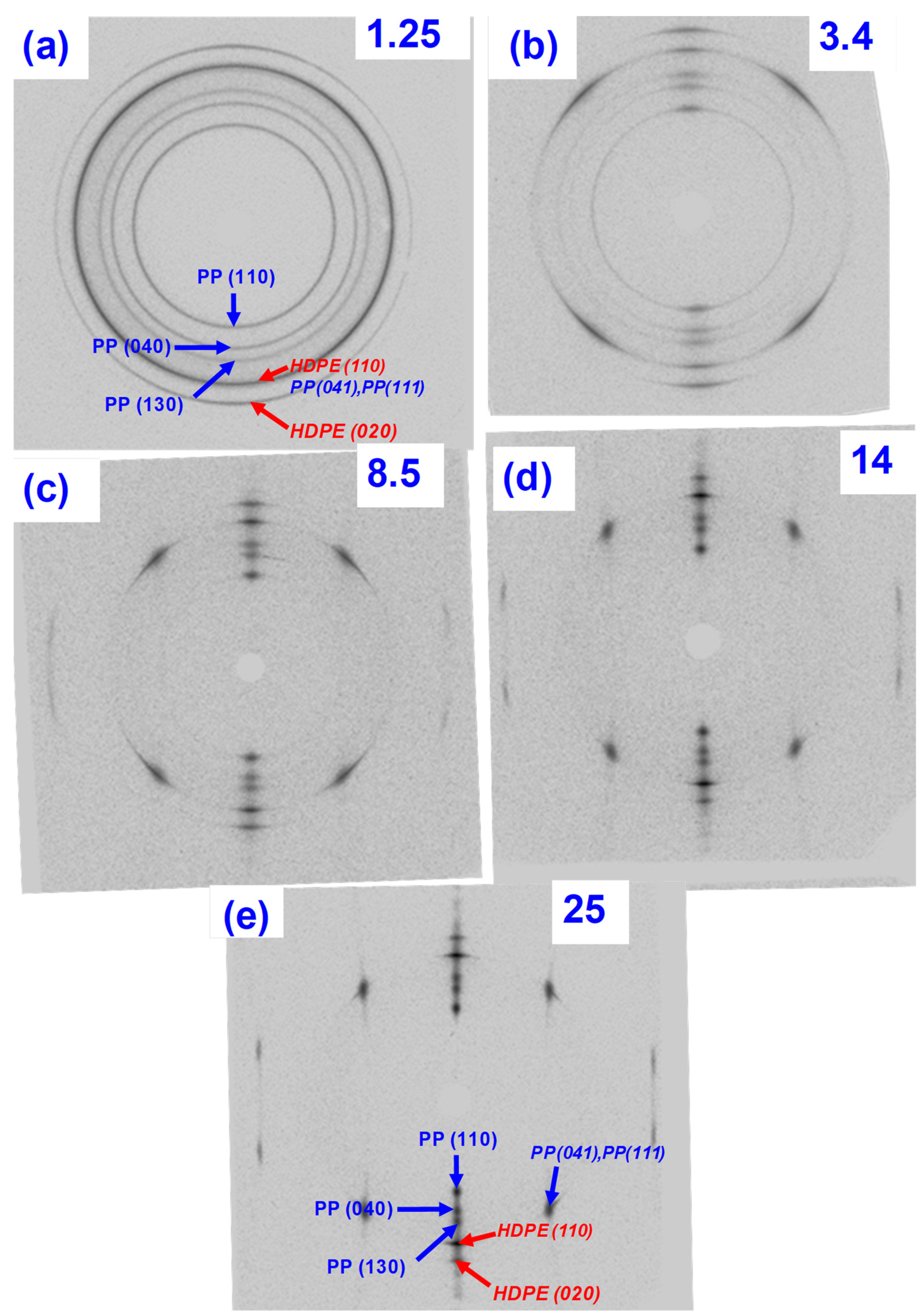

3.2.3. Structural Characterization of Oriented Tapes

4. Discussion

Comparison to Other Materials

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gallagher, G.A.; Jakeways, R.; Ward, I.M. The Structure and Properties of Drawn Blends of Polyethylene and Polypropylene. J. Appl. Polym. Sci. 1991, 43, 1399–1409. [Google Scholar] [CrossRef]

- Schimidt, P.; Baldrian, J.; Scudla, J.; Dydal, J.; Raab, M.; Eichhorn, K.-J. Structural transformation of polyethylene phase in oriented polyethylene/polypropylene blends: A hierarchical structure approach. Polymer 2001, 42, 5321–5326. [Google Scholar] [CrossRef]

- Lotz, B.; Wittmann, J.C. The Molecular Origin of Lamellar Branching in the α (Monoclinic) Form of Isotactic Polypropylene. J. Polym. Sci. B Polym. Phys. 1986, 24, 1541–1558. [Google Scholar] [CrossRef]

- Lotz, B.; Wittmann, J.C. Polyethylene-Isotactic Polypropylene Epitaxy: Analysis of the Diffraction Patterns of Oriented Biphasic Blends. J. Polym. Sci. B Polym. Phys. 1987, 25, 1079–1087. [Google Scholar] [CrossRef]

- Wittmann, J.C.; Lotz, B. Epitaxial Crystallization of Polymers on Organic and Polymeric Substrates. Prog. Polym. Sci. 1990, 15, 909–948. [Google Scholar] [CrossRef]

- Bartczak, Z.; Galeski, A.; Pracella, M. Spherulite nucleation in blends of isotactic polypropylene with high-density polyethylene. Polymer 1986, 27, 537. [Google Scholar] [CrossRef]

- Polaskova, M.; Cermak, R.; Sedlacek, T.; Kalus, J.; Obadal, M.; Saha, P. Extrusion of polyethylene/polypropylene blends with microfibrillar-phase morphology. Polym. Compos. 2009, 31, 1427–1433. [Google Scholar] [CrossRef]

- Wang, J.; Langhe, D.; Pointing, M.; Wnek, G.E.; Korley, L.T.J.; Baer, E. Manufacturing of polymer continuous nanofibers using a novel co-extrusion and multiplication technique. Polymer 2014, 55, 673–685. [Google Scholar] [CrossRef]

- Wang, J.; Olah, A.; Baer, E. Continuous micro-/nano-fiber composites of polyamide 6/polyethylene oxide with tunable mechanical properties using a novel co-extrusion technique. Polymer 2016, 82, 166–171. [Google Scholar] [CrossRef]

- Wang, J.; Ayyar, R.; Olah, A.; Baer, E. Processing-structure-property relationships of novel fibrous filters produced by a melt-process. J. Mater. Sci. 2015, 51, 188–203. [Google Scholar] [CrossRef]

- Wang, X.; Lin, J.; Viswanath, V.; Olah, A.; Baer, E. Alkaline Battery Separators with High Electrolyte Absorption from Forced Assembly Coextruded Composite Tapes. Ind. Eng. Chem. Res. 2020, 59, 5227–5237. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Grimme, C.; Olah, A.; Baer, E.; Wnek, G.E. Fabrication of Surlyn ionomer fibers using a novel coextrusion approach and mechanical property characterization. J. Appl. Polym. Sci. 2019, 136, 48046. [Google Scholar] [CrossRef]

- Rahman, A.; Lee, P.W.; Wang, X.; Zhang, C.; Pokorski, J.K.; Baer, E. Polyolefin Microfiber Based Antibacterial Fibrous Membrane by Forced Assembly Coextrusion. Macromol. Mater. Eng. 2016, 302, 1600304. [Google Scholar] [CrossRef]

- Jordan, A.M.; Kim, K.; Soetrisno, D.; Hannah, J.; Bates, F.S.; Jaffer, S.; Lhost, O.; Macosko, C.W. Role of Crystallization on Polyolefin Interfaces: An Improved Outlook for Polyolefin Blends. Macromolecules 2018, 51, 2506–2516. [Google Scholar] [CrossRef]

- Bashir, Z.; Odell, J.A.; Keller, A. Stiff and strong polyethylene with shish kebab morphology by continuous melt extrusion. J. Mater. Sci. 1986, 21, 3993–4002. [Google Scholar] [CrossRef]

- Mi, D.; Xia, C.; Jin, M.; Wang, F.; Shen, K.; Zhang, J. Quantification of the Effect of Shish-Kebab Structure on the Mechanical Properties of Polypropylene Samples by Controlling Shear Layer Thickness. Macromolecules 2016, 49, 4571–4578. [Google Scholar] [CrossRef]

- Li, J.-X.; Wu, J.; Chan, C.-M. Thermoplastic nanocomposites. Polymer Comm. 2000, 41, 6935–6937. [Google Scholar] [CrossRef]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.-M.; Reynolds, C.T.; Govaert, L.E.; Peijs, T. The effect of temperature and strain rate on the mechanical properties of highly oriented polypropylene tapes and all-polypropylene composites. Compos. Sci. Technol. 2007, 67, 2061–2070. [Google Scholar] [CrossRef]

| Orientation Temperature (°C) | Modulus (2% Secant) (MPa) | Yield Stress (MPa) | Work-Hardening Slope (MPa) | Fracture Initiation (Draw Ratio) | |

|---|---|---|---|---|---|

| 50/50 PP/HDPE | 110 °C | 77 ± 12 | 7.7 ± 1.2 | 0.3 | 20.5 ± 1.0 |

| 130 °C | 48 ± 5 | 2.8 ± 0.5 | 0.2 | 25.5 ± 0.5 | |

| PP | 110 °C | 147 ± 14 | 9.1 ± 1.4 | 0.3 | 12 ± 1 |

| 130 °C | 89 ± 8 | 4.1 ± 0.3 | 0.2 | 29 ± 2 | |

| HDPE | 110 °C | 41 ± 4 | 5.9 ± 0.4 | 0.1 | 8 ± 1 |

| 130 °C | - | - | - | - |

| Draw Ratio | Modulus (GPa) | Tensile Strength (MPa) | Strain at Break (%) |

|---|---|---|---|

| 1.25 | 0.9 ± 0.1 | 29 ± 1 | 1400 ± 70 |

| 1.6 | 1.0 ± 0.1 | 41 ± 2 | 930 ± 100 |

| 3.4 | 2.8 ± 0.3 | 180 ± 2 | 220 ± 65 |

| 8.5 | 3.5 ± 0.2 | 240 ± 38 | 13 ± 2 |

| 14 | 5.5 ± 0.6 | 320 ± 29 | 10 ± 1 |

| 20 | 6.6 ± 0.7 | 410 ± 80 | 10 ± 2 |

| 25 | 9.8 ± 0.9 | 540 ± 140 | 10 ± 3 |

| Materials | Modulus (GPa) | Tensile Strength (MPa) | Strain at Break (%) |

|---|---|---|---|

| LDPE/PP Tape (DR = 22) [8] | 6.1 ± 0.3 | 370 ± 56 | --- |

| PA6/PEO Tape (DR = 6) [9] | 4.2 ± 0.1 | 240 ± 51 | 8 ± 1 |

| Commercial Floss [9] | 0.5 ± 0.3 | 170 ± 3 | 42 |

| PP/HDPE (25/75) [17] | 3.5 | 60 | --- |

| All PP Composites [18] | 3.8 | 190 | --- |

| Commercial PP Strapping | 2.2 ± 1.1 | 300 ± 8 | 50 ± 17 |

| 50/50 PP/HDPE Tape (DR = 25) (This Work) | 9.8 ± 0.9 | 540 ± 140 | 10 ± 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Price, E.J.; Wnek, G.E.; Olah, A.; Baer, E. Oriented Tapes of Incompatible Polymers Using a Novel Multiplication Co-Extrusion Process. Polymers 2022, 14, 3872. https://doi.org/10.3390/polym14183872

Wang X, Price EJ, Wnek GE, Olah A, Baer E. Oriented Tapes of Incompatible Polymers Using a Novel Multiplication Co-Extrusion Process. Polymers. 2022; 14(18):3872. https://doi.org/10.3390/polym14183872

Chicago/Turabian StyleWang, Xinting, Erik J. Price, Gary E. Wnek, Andrew Olah, and Eric Baer. 2022. "Oriented Tapes of Incompatible Polymers Using a Novel Multiplication Co-Extrusion Process" Polymers 14, no. 18: 3872. https://doi.org/10.3390/polym14183872