Sustainable Reuse of Waste Tire Textile Fibers (WTTF) as Reinforcements

Abstract

:1. Introduction

2. Soil Composite

3. Reinforced Concrete

4. Asphalt Mixture

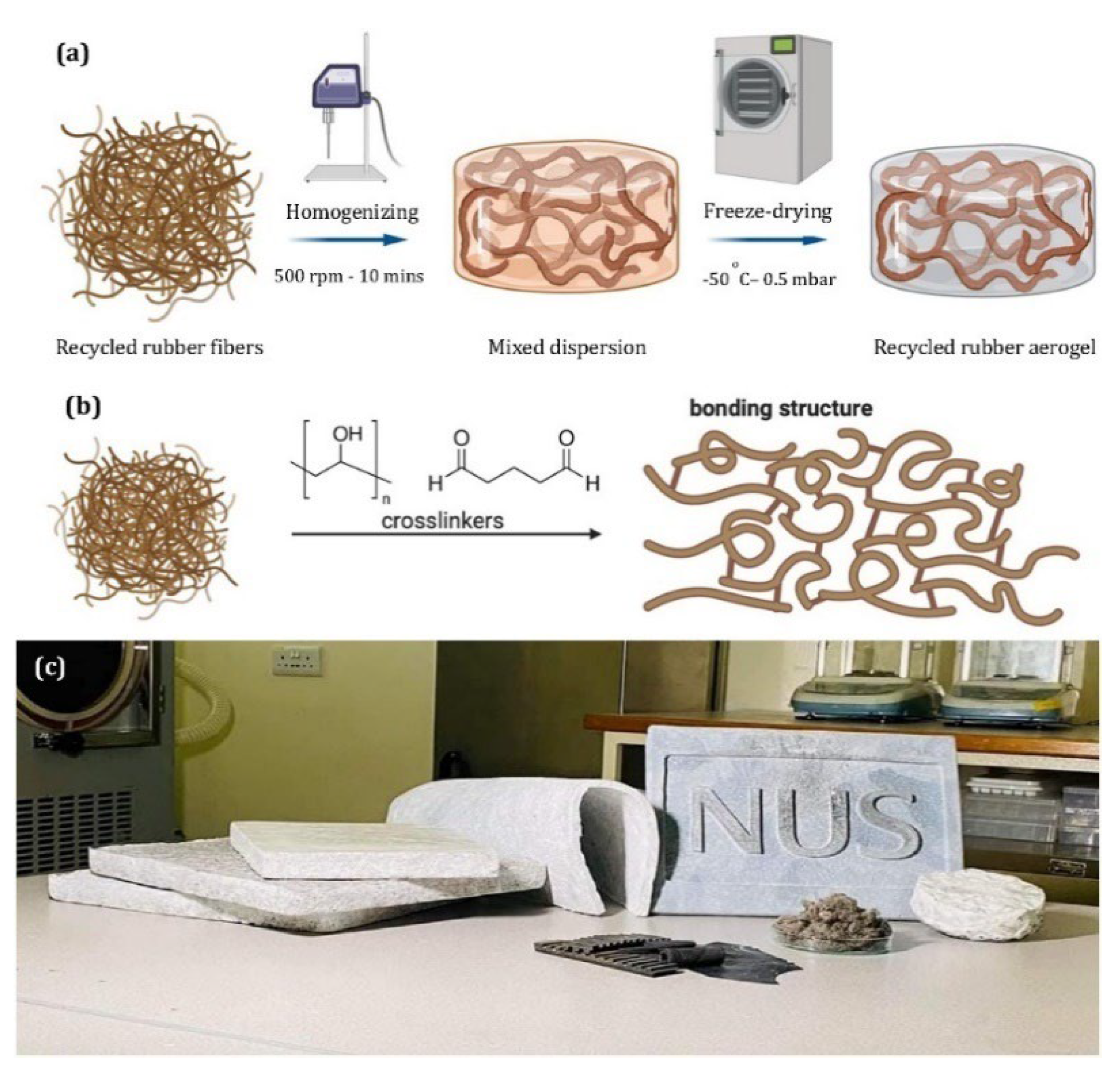

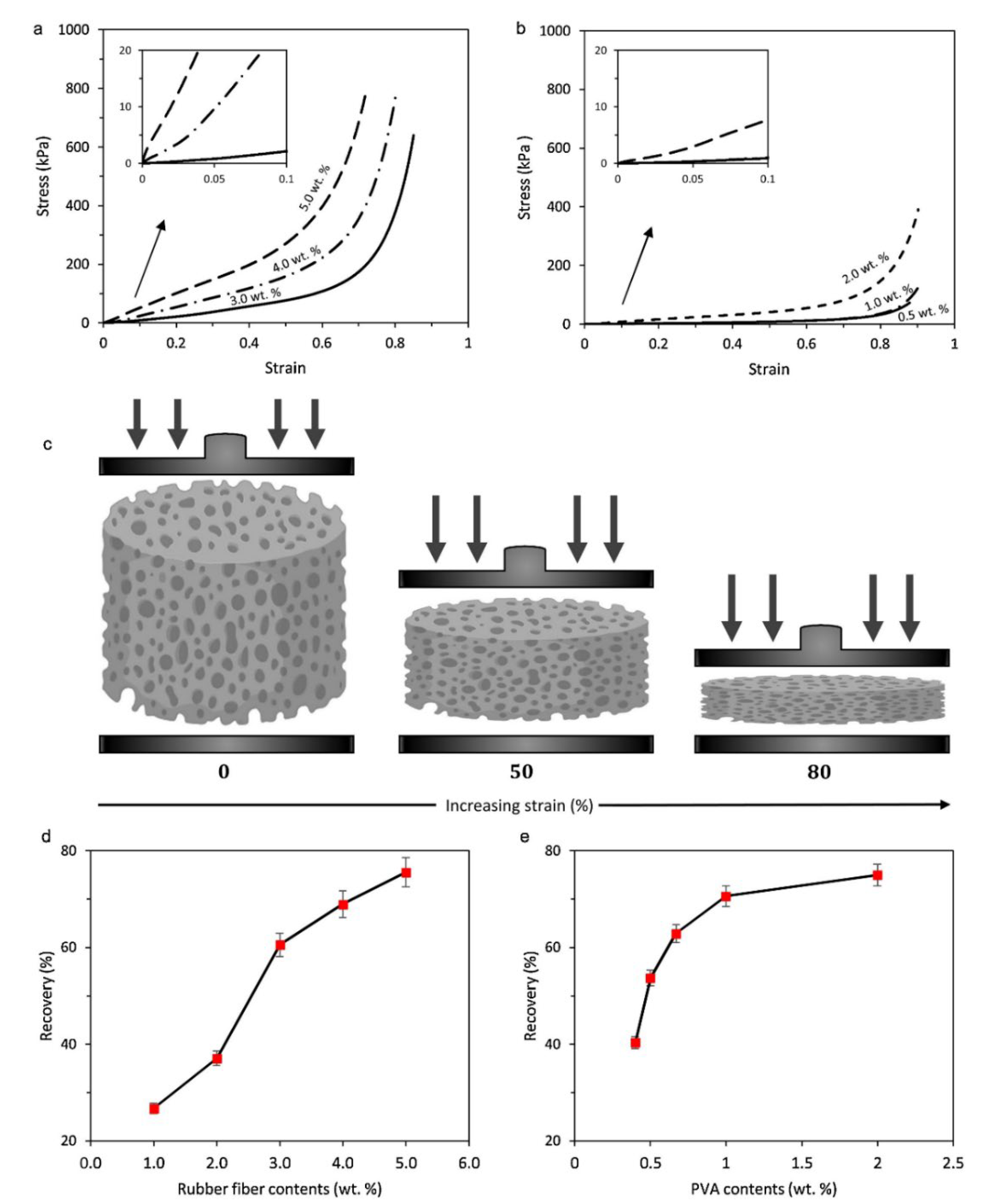

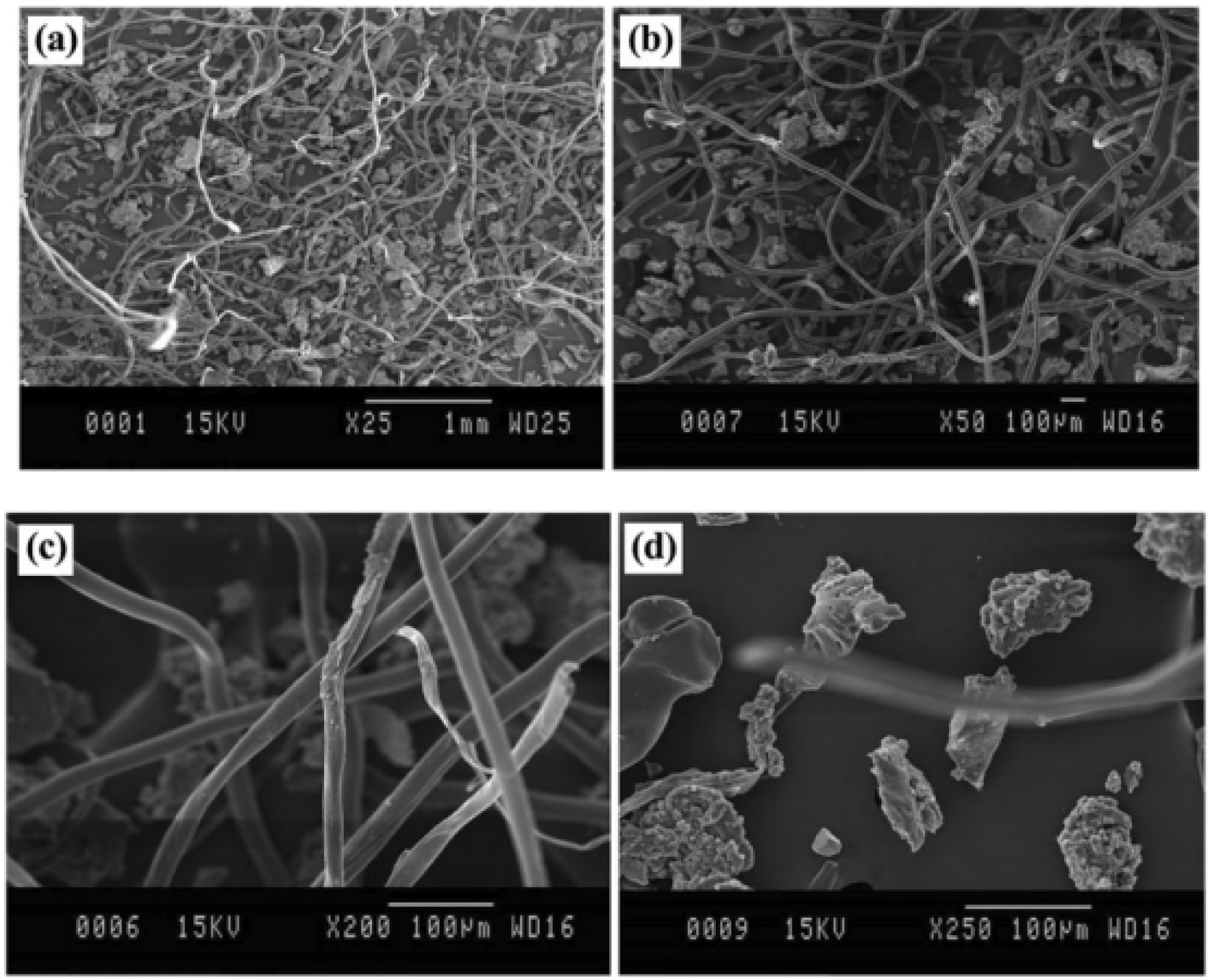

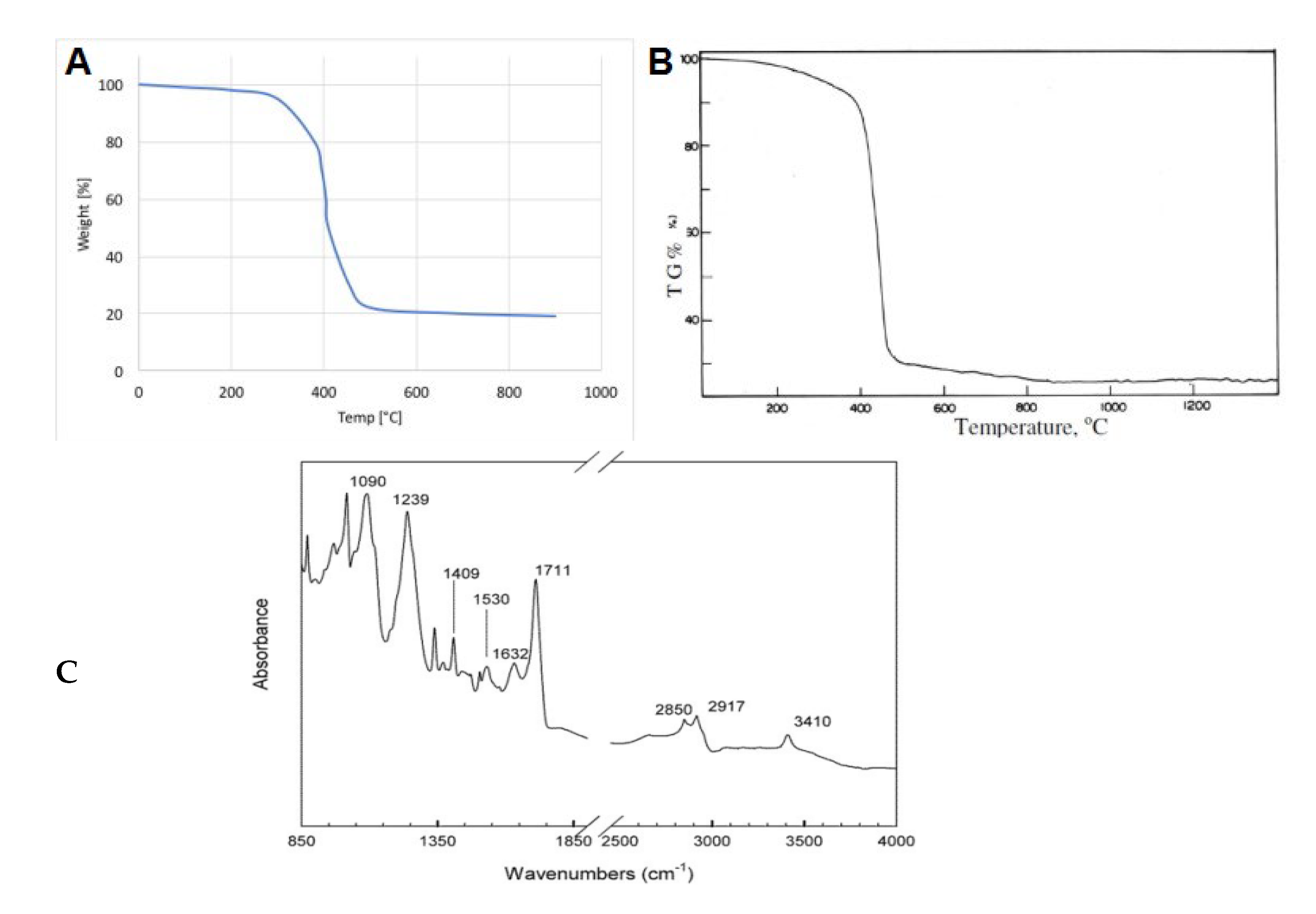

5. Rubber Aerogel

6. Blending with Polymers

7. Conclusions

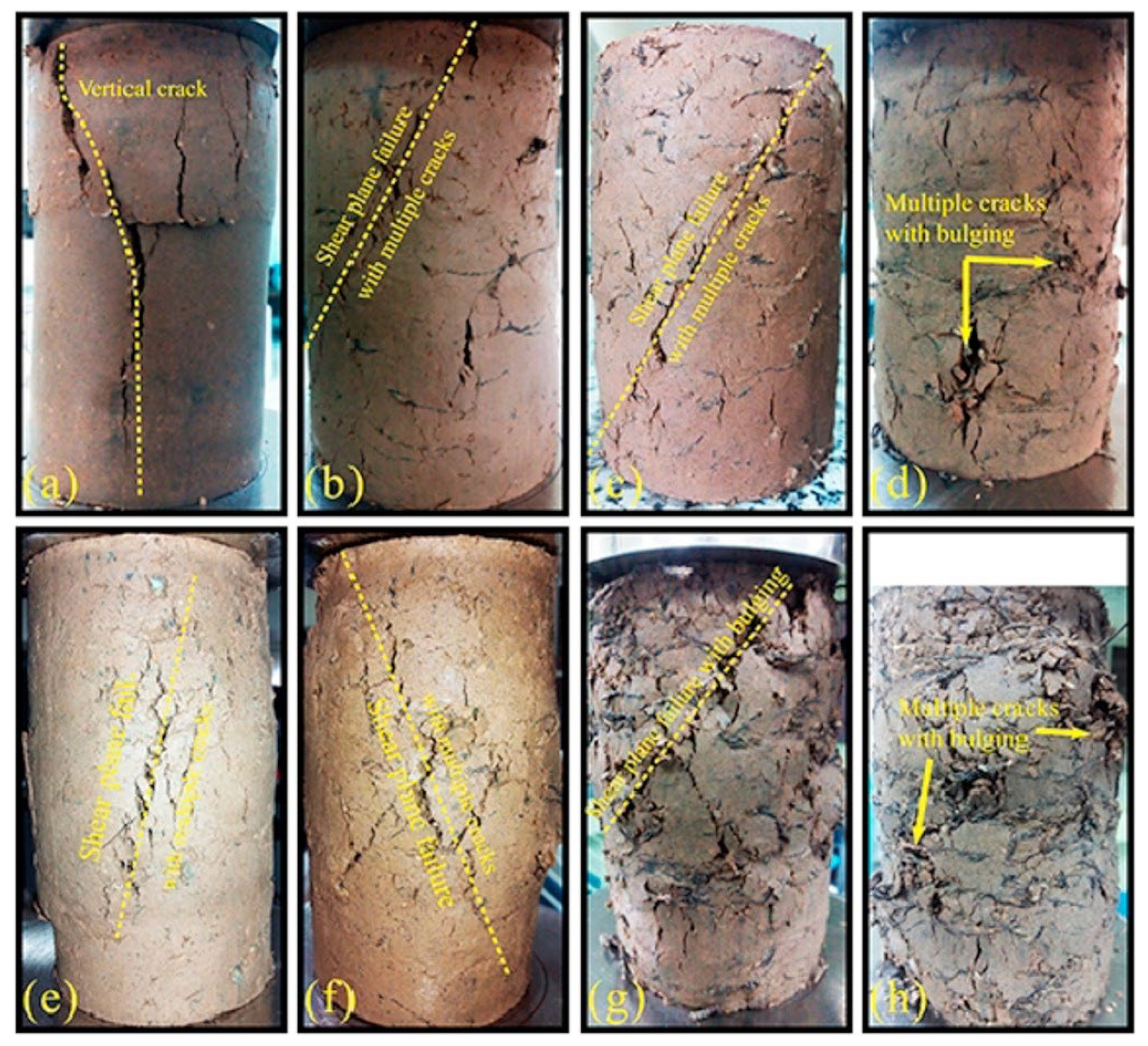

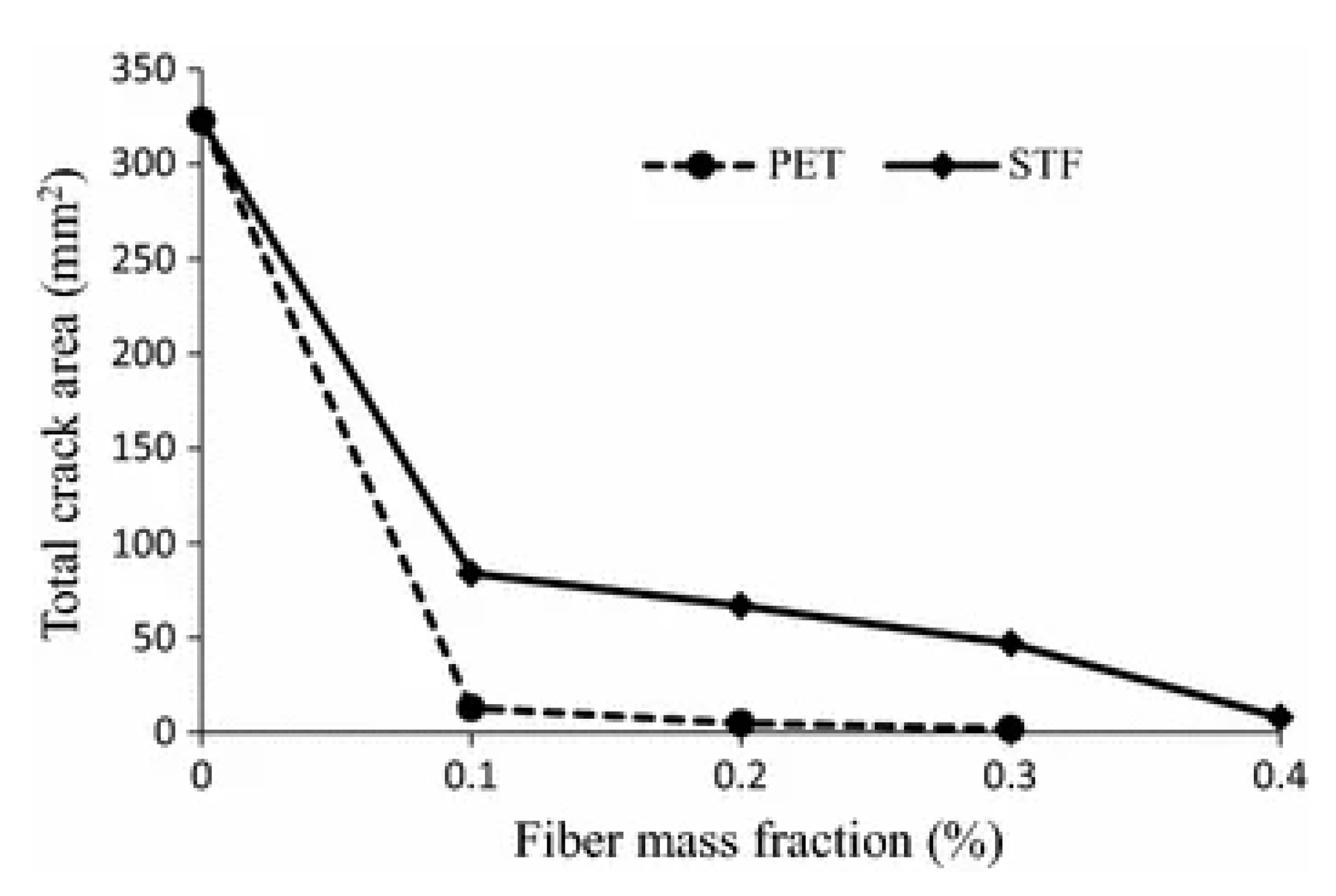

- Introduction of WTTF as soil reinforcement contributes to increase the load-bearing capacity of expansive soils while decreasing their swelling. The presence of WTTF in expansive subgrade results in the reduction of permanent deformation under repeated loadings and lower volumetric shrinkage strain.

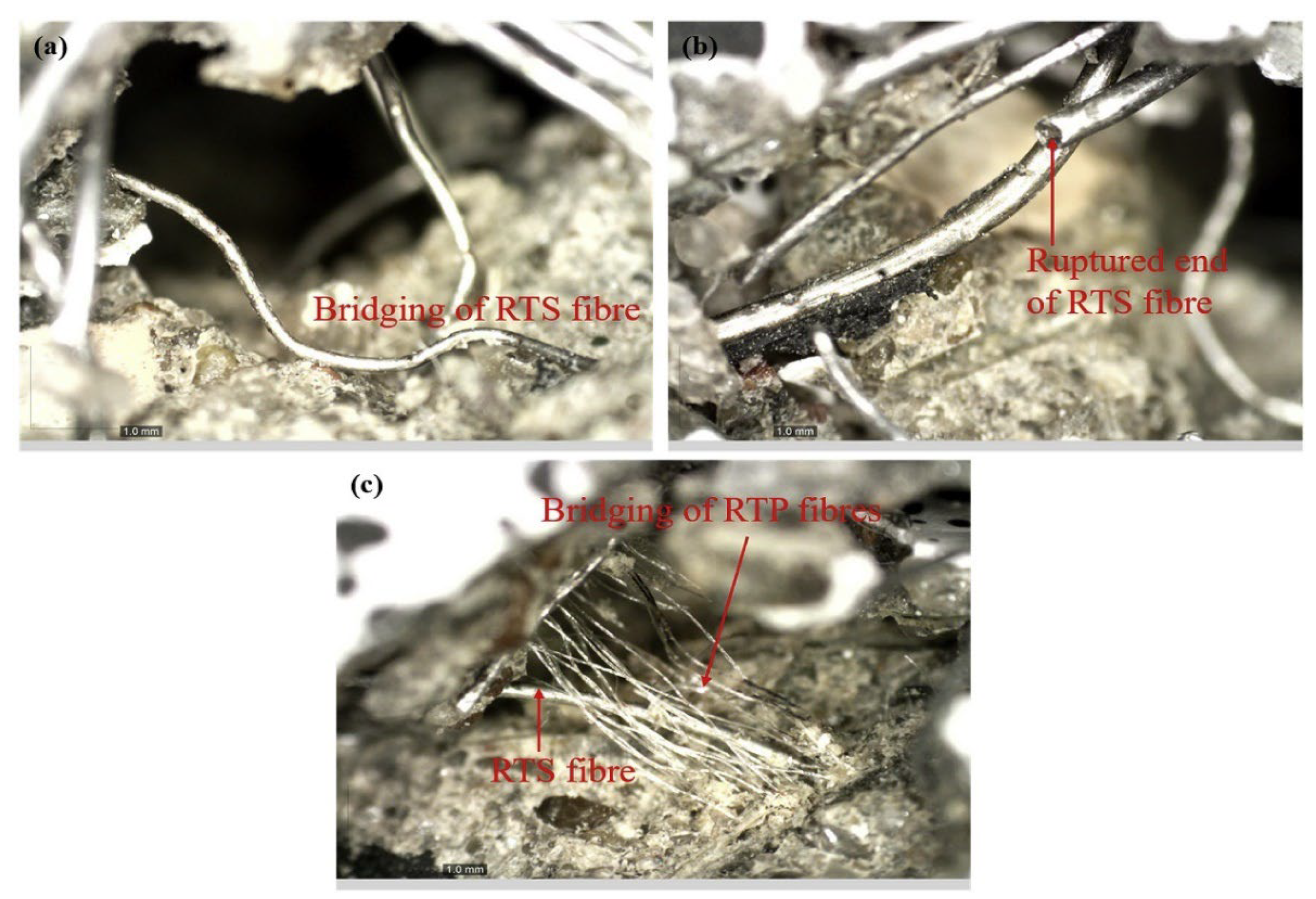

- Inclusion of WTTF in concrete composites can minimize plastic shrinkage cracking due to the fibers bridging effect across the cracks, preventing their growth. The fiber bridging effect of WTTF can be enhanced by its hybridization with steel fibers to increase the compressive strength of concrete composites.

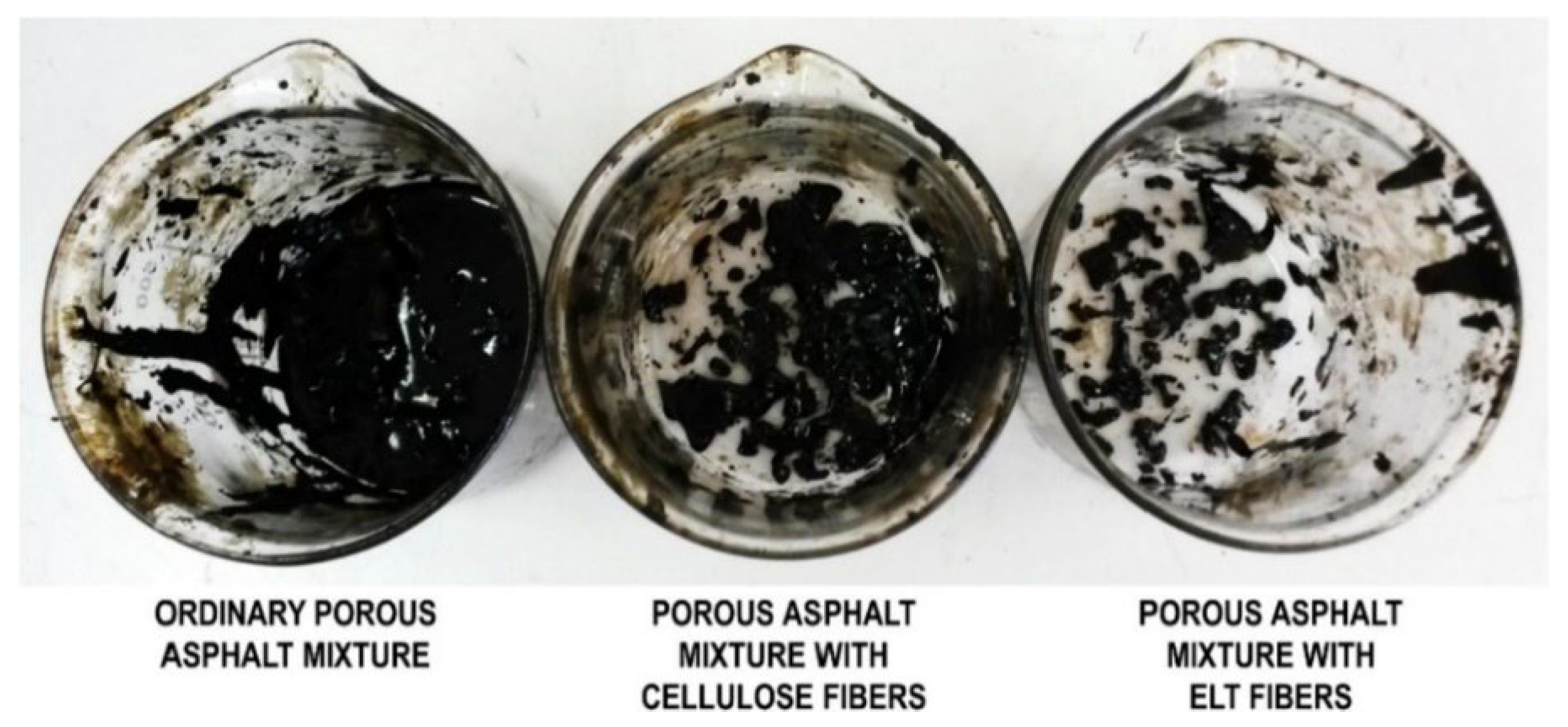

- WTTF have high potential to increase the toughness and fracture resistance of HMA, as well as serving as stabilizers to hinder drain down of the asphalt binder (porous asphalt and SMA mixtures).

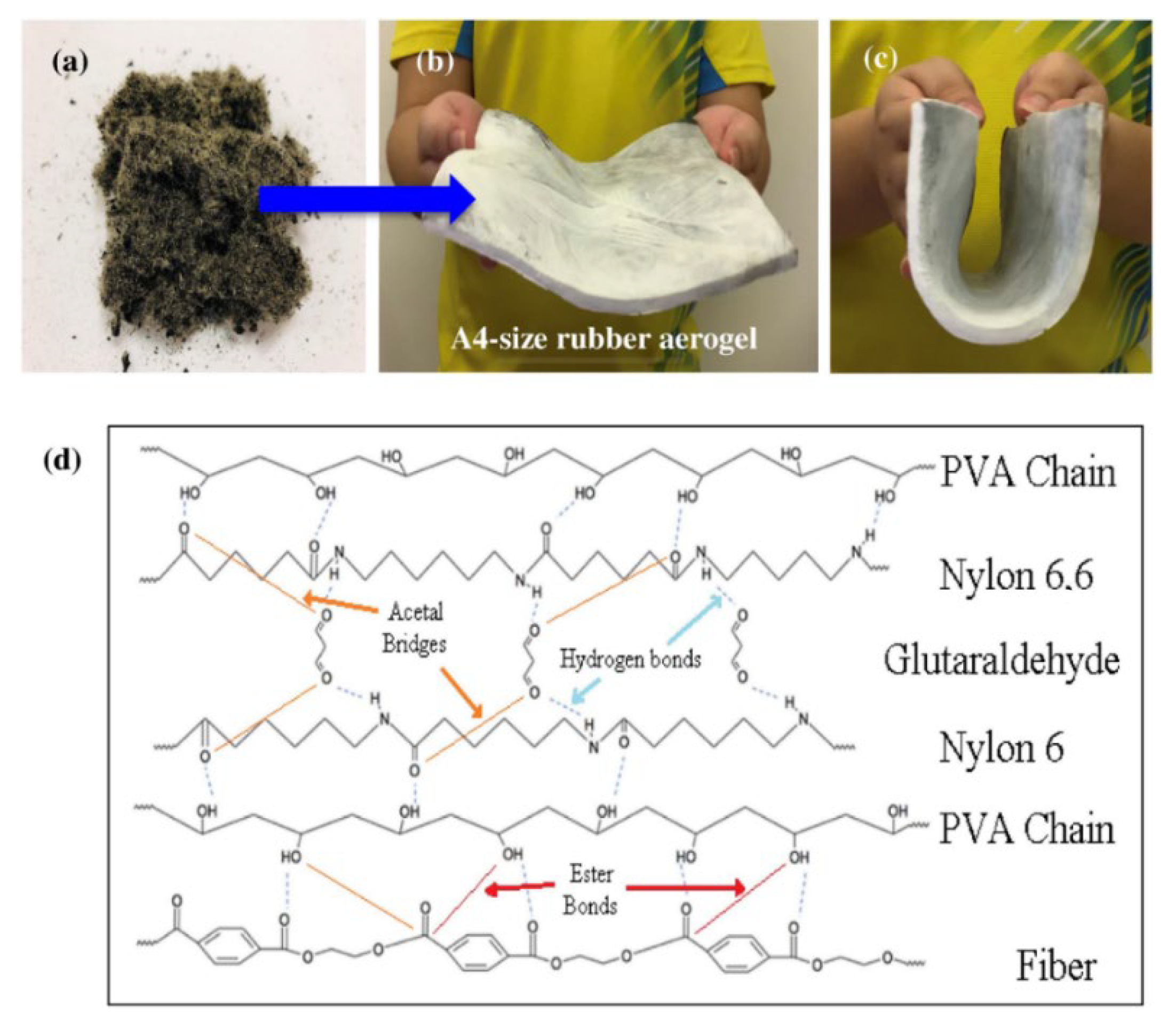

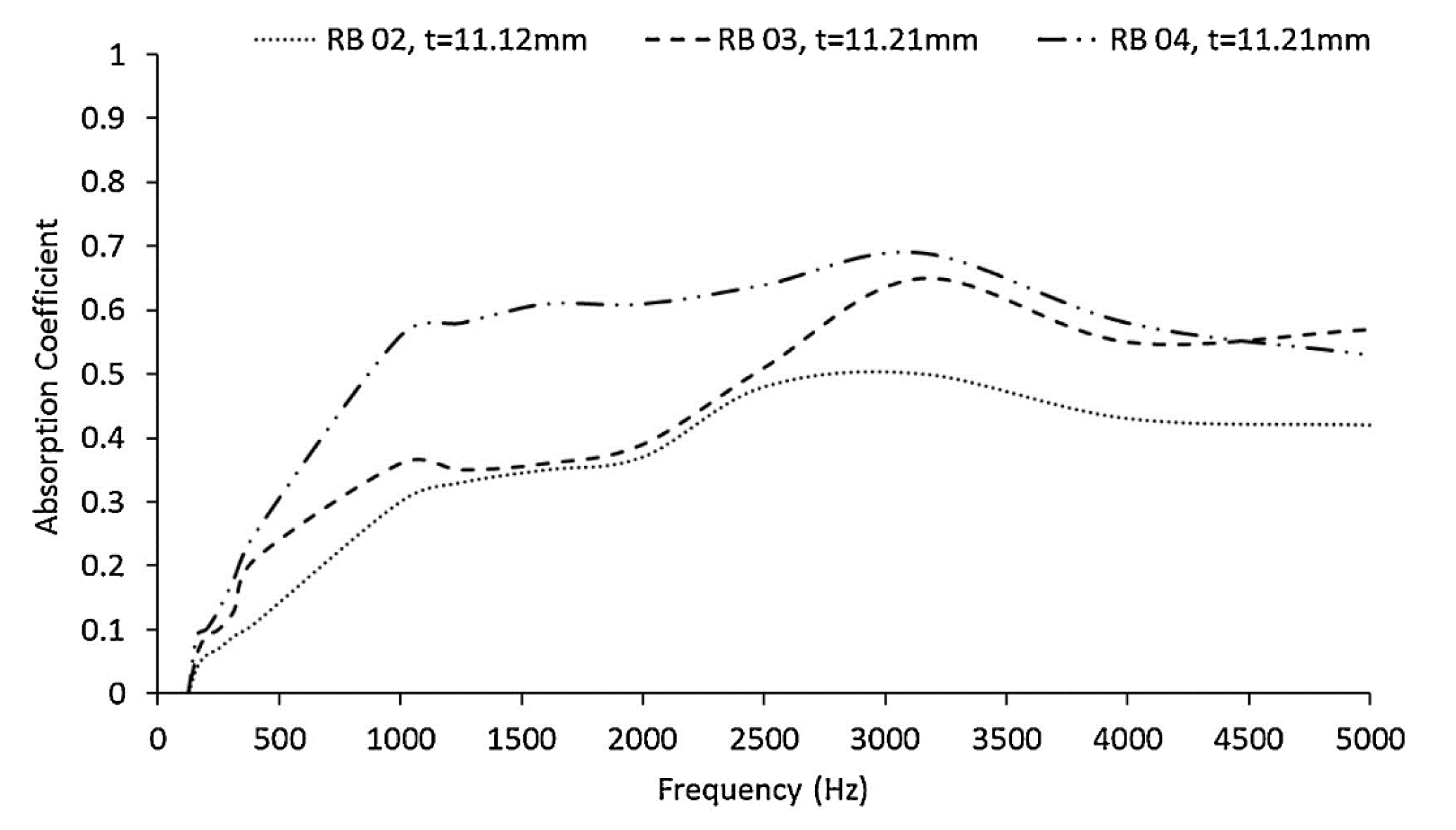

- Tire-derived textile fibers are potential candidates to produce ultralight and highly porous aerogels with strong mechanical performance (to be bent and folded without failure) through simple, cost-effective and time-saving fabrication methods showing great acoustic performance (sound insulation) and oil absorption capacity competitive with commercial sorbents.

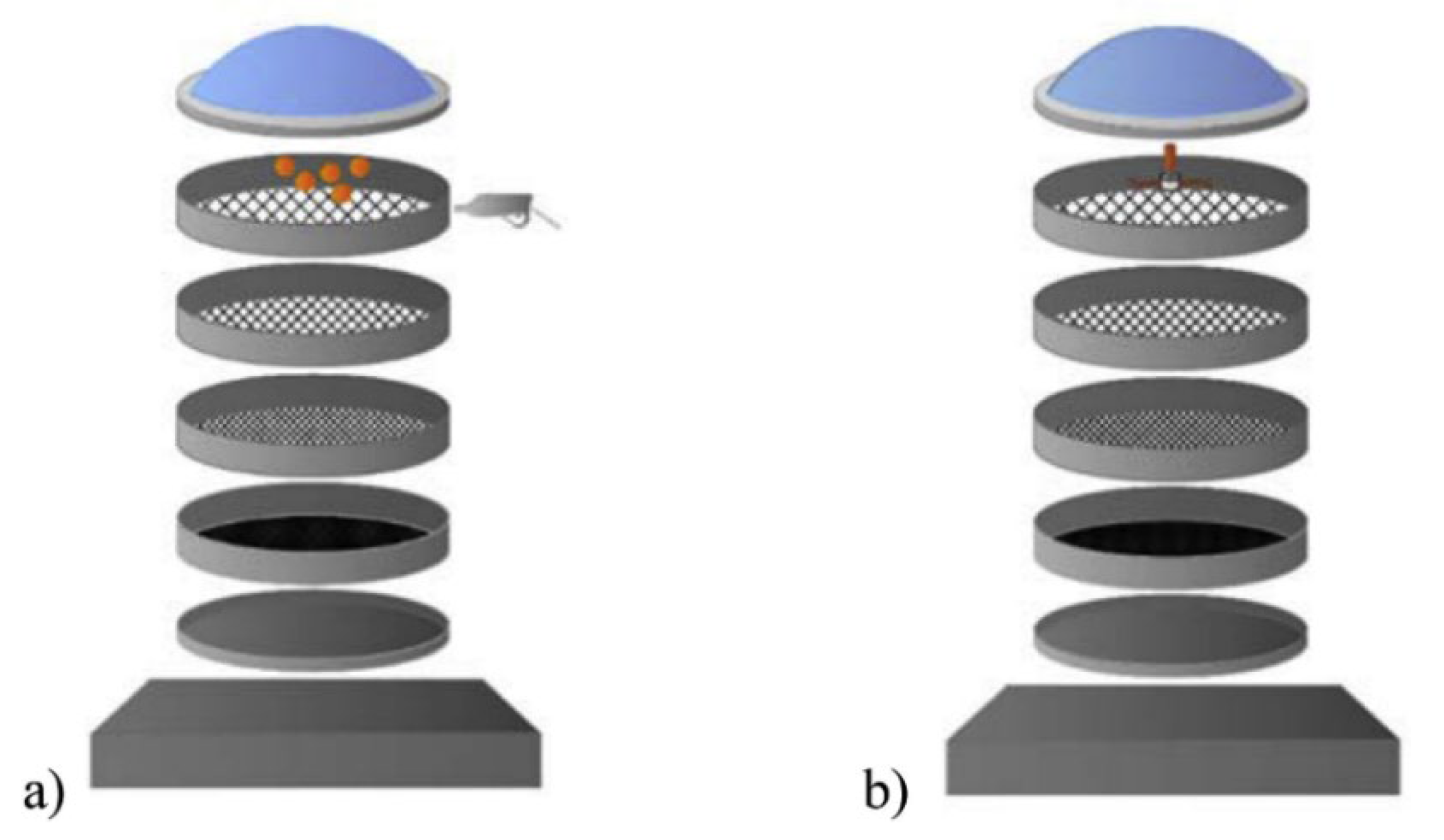

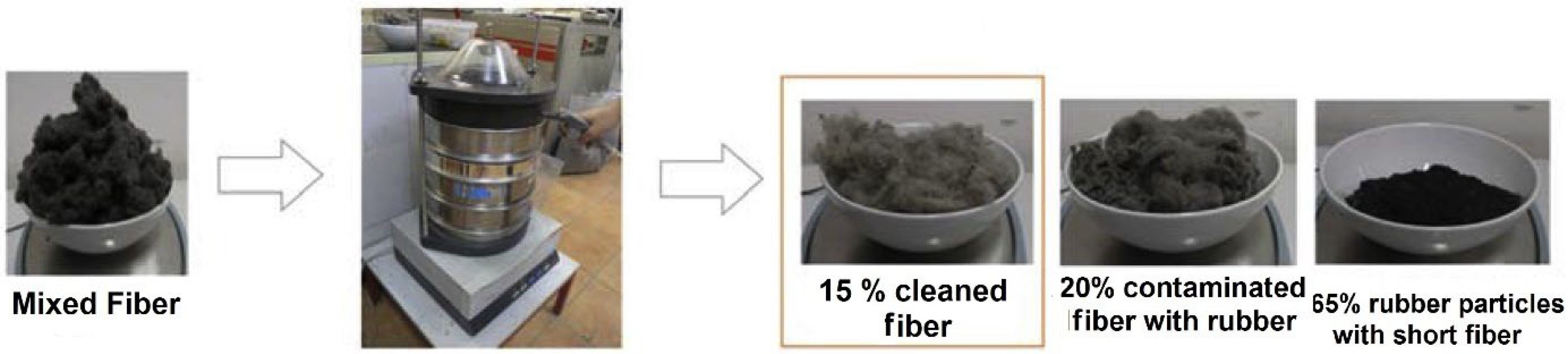

- A fiber cleaning step is highly recommended for melt blending of WTTF with polymers to avoid difficult processing (increasing viscosity) and poor mechanical properties (low compatibility). Recent progress in processing WTTF-reinforced polymer composites reported a substantial increase in impact strength by the introduction of surface-coated fillers to postpone failure due to the presence of a thick and soft interphase surrounding the rubber particles and fibers, resulting in more energy being dissipated before complete failure.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sahajwalla, V.; Zaharia, M.; Rahman, M.; Khanna, R.; Saha-Chaudhury, N.; O’Kane, P.; Dicker, J.; Skidmore, C.; Knights, D. Recycling rubber tyres and waste plastics in EAF steelmaking. Steel Res. Int. 2011, 82, 566–572. [Google Scholar] [CrossRef]

- Ramarad, S.; Khalid, M.; Ratnam, C.; Chuah, A.L.; Rashmi, W. Waste tire rubber in polymer blends: A review on the evolution, properties and future. Prog. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- Archibong, F.N.; Sanusi, O.M.; Médéric, P.; Hocine, N.A. An overview on the recycling of waste ground tyre rubbers in thermoplastic matrices: Effect of added fillers. Resour. Conserv. Recycl. 2021, 175, 105894–105906. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, Y.; Wang, D.; Yan, M.; Zhang, J.; Zhang, P.; Ding, T.; Chen, L.; Chen, C. Current technologies for plastic waste treatment: A review. J. Clean. Prod. 2021, 282, 124523. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.; Xue, C. Advanced progress in recycling municipal and construction solid wastes for manufacturing sustainable construction materials. Resour. Conserv. Recycl. X 2020, 6, 100036. [Google Scholar] [CrossRef]

- United States Tire Manufacturers Association. US Scrap Tire Management Summary; U. T. M. Association: Washington, DC, USA, 2018. [Google Scholar]

- Canadian Association of Tire Recycling Agencies. CATRA Annual Report; Canadian Association of Tire Recycling Agencies: Toronto, ON, Canada, 2017. [Google Scholar]

- European Tyre and Rubber Manufacturers Association. End-of-life Tyre Report Europe; European Tyre and Rubber Manufacturers Association: Brussels, Belgium, 2015. [Google Scholar]

- Mountjoy, E.; Hasthanayake, D.; Freeman, T. Stocks & Fate of End of Life Tyres-2013–2014 Study; Hyder Consulting Pty Ltd.: Melbourne, Australia, 2015. [Google Scholar]

- Landi, D.; Gigli, S.; Germani, M.; Marconi, M. Investigating the feasibility of a reuse scenario for textile fibres recovered from end-of-life tyres. Waste Manag. 2018, 75, 187–204. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Waste Rubber Recycling: A Review on the Evolution and Properties of Thermoplastic Elastomers. Materials 2020, 13, 782. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Chen, K.; Tong, L. On the pyrolysis kinetics of scrap automotive tires. J. Hazard. Mater. 2001, 84, 43–55. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Recycling waste tires into ground tire rubber (GTR)/rubber compounds: A review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Forrest, M.J. Recycling and Re-Use of Waste Rubber, 2nd ed.; De Gruyter: Berlin, Germany, 2019. [Google Scholar]

- Yerezhep, D.; Tychengulova, A.; Sokolov, D.; Aldiyarov, A. A multifaceted approach for cryogenic waste tire recycling. Polymers 2021, 13, 2494. [Google Scholar] [CrossRef]

- Awolusi, T.F.; Oke, O.L.; Atoyebi, O.D.; Akinkurolere, O.O.; Sojobi, A.O. Waste tires steel fiber in concrete: A review. Innov. Infrastruct. Solut. 2021, 6, 1–12. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of landfill wastes (tyres, plastics and glass) in construction–A review on global waste generation, performance, application and future opportunities. Resour. Conserv. Recycl. 2021, 173, 105745. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mészáros, L.; Bárány, T. Ground tyre rubber (GTR) in thermoplastics, thermosets, and rubbers. J. Mater. Sci. 2013, 48, 1–38. [Google Scholar] [CrossRef]

- Levendis, Y.A.; Atal, A.; Carlson, J.; Dunayevskiy, Y.; Vouros, P. Comparative study on the combustion and emissions of waste tire crumb and pulverized coal. Environ. Sci. Technol. 1996, 30, 2742–2754. [Google Scholar] [CrossRef]

- Williams, P.T. Pyrolysis of waste tyres: A review. Waste Manag. 2013, 33, 1714–1728. [Google Scholar] [CrossRef]

- Sathiskumar, C.; Karthikeyan, S. Recycling of waste tires and its energy storage application of by-products–a review. Sustain. Mater. Technol. 2019, 22, 00125–00130. [Google Scholar] [CrossRef]

- Tang, L.; Huang, H. An investigation of sulfur distribution during thermal plasma pyrolysis of used tires. J. Anal. Appl. Pyrolysis 2004, 72, 35–40. [Google Scholar] [CrossRef]

- Medina, N.F.; Garcia, R.; Hajirasouliha, I.; Pilakoutas, K.; Guadagnini, M.; Raffoul, S. Composites with recycled rubber aggregates: Properties and opportunities in construction. Constr. Build. Mater. 2018, 188, 884–897. [Google Scholar] [CrossRef]

- Zanchet, A.; Carli, L.; Giovanela, M.; Brandalise, R.; Crespo, J. Use of styrene butadiene rubber industrial waste devulcanized by microwave in rubber composites for automotive application. Mater. Des. 2012, 39, 437–443. [Google Scholar] [CrossRef]

- Siddika, A.; al Mamun, M.A.; Alyousef, R.; Amran, Y.M.; Aslani, F.; Alabduljabbar, H. Properties and utilizations of waste tire rubber in concrete: A review. Constr. Build. Mater. 2019, 224, 711–731. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.; Hassan, N.; Haloul, M.; Modibbo, S. Influence of crumb rubber size particles on moisture damage and strength of the hot mix asphalt. Mater. Today Proc. 2021, 42, 2387–2391. [Google Scholar] [CrossRef]

- Milad, A.; Ahmeda, A.G.; Taib, A.M.; Rahmad, S.; Solla, M.; Yusoff, N.I.M. A review of the feasibility of using crumb rubber derived from end-of-life tire as asphalt binder modifier. J. Rubber Res. 2020, 23, 203–216. [Google Scholar] [CrossRef]

- Alfayez, S.A.; Suleiman, A.R.; Nehdi, M.L. Recycling tire rubber in asphalt pavements: State of the art. Sustainability 2020, 12, 9076. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M. Reuse of deconstructed tires as anti-reflective cracking mat systems in asphalt pavements. Constr. Build. Mater. 2014, 53, 182–189. [Google Scholar] [CrossRef]

- Naseem, A.; Mumtaz, W.; de Backer, H. Stabilization of expansive soil using tire rubber powder and cement kiln dust. Soil. Mech. Found. Eng. 2019, 56, 54–58. [Google Scholar] [CrossRef]

- Fernández, A.; Barriocanal, C.; Alvarez, R. Pyrolysis of a waste from the grinding of scrap tyres. J. Hazard. Mater. 2012, 203, 236–243. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, J.; Das, A.; Sinha, T.; Saha, P.; Kim, J.K. Grinding of Waste Rubber. In Grinding of Waste Rubber: Royal Society of Chemistry; Kim, K.J., Saha, P., Thomas, S., Haponiuk, J.T., Aswathi, M.K., Eds.; Royal Society of Chemistry (RSC): London, UK, 2018; pp. 1–23. [Google Scholar] [CrossRef]

- Thai, Q.B.; Le-Cao, K.; Nguyen, P.T.; Le, P.K.; Phan-Thien, N.; Duong, H.M. Fabrication and optimization of multifunctional nanoporous aerogels using recycled textile fibers from car tire wastes for oil-spill cleaning, heat-insulating and sound absorbing applications. Colloids Surf. Physicochem. Eng. Asp. 2021, 628, 127363–127378. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Nadal-Gisbert, A.V.; Crespo-Amorós, J.E.; Parres-García, F. A novel sound absorber with recycled fibers coming from end of life tires (ELTs). Appl. Acoust. 2012, 73, 402–408. [Google Scholar] [CrossRef]

- Medina, N.F.; Medina, D.F.; Hernández-Olivares, F.; Navacerrada, M. Mechanical and thermal properties of concrete incorporating rubber and fibres from tyre recycling. Constr. Build. Mater. 2017, 144, 563–573. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Value-added reuse of scrap tire polymeric fibers in cement-based structural applications. J. Clean. Prod. 2019, 231, 543–555. [Google Scholar] [CrossRef]

- Abbaspour, M.; Aflaki, E.; Nejad, F.M. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2019, 207, 1059–1071. [Google Scholar] [CrossRef]

- Chen, M.; Zhong, H.; Zhang, M. Flexural fatigue behaviour of recycled tyre polymer fibre reinforced concrete. Cem. Concr. Compos. 2020, 105, 103441–103483. [Google Scholar] [CrossRef]

- Baričević, A.; Rukavina, M.J.; Pezer, M.; Štirmer, N. Influence of recycled tire polymer fibers on concrete properties. Cem. Concr. Compos. 2018, 91, 29–41. [Google Scholar] [CrossRef]

- Narani, S.; Abbaspour, M.; Hosseini, S.M.M.; Aflaki, E.; Nejad, F.M. Sustainable reuse of Waste Tire Textile Fibers (WTTFs) as reinforcement materials for expansive soils: With a special focus on landfill liners/covers. J. Clean. Prod. 2020, 247, 119151. [Google Scholar] [CrossRef]

- Bekhiti, M.; Trouzine, H.; Rabehi, M. Influence of waste tire rubber fibers on swelling behavior, unconfined compressive strength and ductility of cement stabilized bentonite clay soil. Constr. Build. Mater. 2019, 208, 304–313. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Durability performance of polymeric scrap tire fibers and its reinforced cement mortar. Mater. Struct. 2017, 50, 1–10. [Google Scholar] [CrossRef]

- Moghaddamzadeh, S.; Rodrigue, D. The effect of polyester recycled tire fibers mixed with ground tire rubber on polyethylene composites. Part I: Morphological analysis. Prog. Rubber Plast. Recycl. 2018, 34, 200–220. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Phase morphology, mechanical, and thermal properties of fiber-reinforced thermoplastic elastomer: Effects of blend composition and compatibilization. J. Reinf. Plast. Compos. 2022, 41, 267–283. [Google Scholar] [CrossRef]

- Acevedo, B.; Fernández, A.; Barriocanal, C. Identification of polymers in waste tyre reinforcing fibre by thermal analysis and pyrolysis. J. Anal. Appl. Pyrolysis 2015, 111, 224–232. [Google Scholar] [CrossRef] [Green Version]

- Wong, S.; Sui, G.; Yue, C.; Mai, Y.-W. Characterization of microstructures and toughening behavior of fiber-containing toughened nylon 6, 6. J. Mater. Sci. 2002, 37, 2659–2667. [Google Scholar] [CrossRef]

- Abbaspour, M.; Narani, S.; Aflaki, E.; Nejad, F.M.; Hosseini, S.M.M. Strength and swelling properties of a waste tire textile fiber-reinforced expansive soil. Geosynth. Int. 2020, 27, 476–489. [Google Scholar] [CrossRef]

- Putman, B.J.; Amirkhanian, S.N. Utilization of waste fibers in stone matrix asphalt mixtures. Resour. Conserv. Recycl. 2004, 42, 265–274. [Google Scholar] [CrossRef]

- Bockstal, L.; Berchem, T.; Schmetz, Q.; Richel, A. Devulcanisation and reclaiming of tires and rubber by physical and chemical processes: A review. J. Clean. Prod. 2019, 236, 117574. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Olgun, C.G.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 1–16. [Google Scholar] [CrossRef]

- Kianimehr, M.; Shourijeh, P.T.; Binesh, S.M.; Mohammadinia, A.; Arulrajah, A. Utilization of recycled concrete aggregates for light-stabilization of clay soils. Constr. Build. Mater. 2019, 227, 116792. [Google Scholar] [CrossRef]

- Phanikumar, B.; Shankar, M.U. Studies on hydraulic conductivity of fly ash-stabilised expansive clay liners. Geotech. Geol. Eng. 2016, 34, 449–462. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Karabash, Z.; Mustafa, W.S. Stabilising a clay using tyre buffings and lime. Road Mater. Pavement Des. 2014, 15, 872–891. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, H.; El-Korchi, T.; Zhang, G.; Tao, M. Experimental feasibility study of geopolymer as the next-generation soil stabilizer. Constr. Build. Mater. 2013, 47, 1468–1478. [Google Scholar] [CrossRef]

- Khemissa, M.; Mahamedi, A. Cement and lime mixture stabilization of an expansive overconsolidated clay. Appl. Clay Sci. 2014, 95, 104–110. [Google Scholar] [CrossRef]

- Tyagi, A.; Soni, D. Effects of Granulated Ground Blast Furnace Slag and Fly Ash on Stabilization of Soil. Agnihotri, A., Reddy, K., Bansal, A., Eds.; Springer: Singapore, 2019; pp. 79–90. [Google Scholar] [CrossRef]

- Thyagaraj, T.; Soujanya, D. Polypropylene fiber reinforced bentonite for waste containment barriers. Appl. Clay Sci. 2017, 142, 153–162. [Google Scholar] [CrossRef]

- Chaduvula, U.; Viswanadham, B.; Kodikara, J. A study on desiccation cracking behavior of polyester fiber-reinforced expansive clay. Appl. Clay Sci. 2017, 142, 163–172. [Google Scholar] [CrossRef]

- Yao, X.; Huang, G.; Wang, M.; Dong, X. Mechanical properties and microstructure of PVA fiber reinforced cemented soil. KSCE J. Civ. Eng. 2021, 25, 482–491. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Mohamed, M.; Arulrajah, A.; Horpibulsuk, S.; Anggraini, V. Practical approach to predict the shear strength of fibre-reinforced clay. Geosynth. Int. 2018, 25, 50–66. [Google Scholar] [CrossRef]

- Rabab’ah, S.; al Hattamleh, O.; Aldeeky, H.; Alfoul, B.A. Effect of glass fiber on the properties of expansive soil and its utilization as subgrade reinforcement in pavement applications. Case Stud. Constr. Mater. 2021, 14, 00485–00496. [Google Scholar] [CrossRef]

- Bao, X.; Huang, Y.; Jin, Z.; Xiao, X.; Tang, W.; Cui, H.; Chen, X. Experimental investigation on mechanical properties of clay soil reinforced with carbon fiber. Constr. Build. Mater. 2021, 280, 122517. [Google Scholar] [CrossRef]

- Ghadakpour, M.; Choobbasti, A.J.; Kutanaei, S.S. Investigation of the Kenaf fiber hybrid length on the properties of the cement-treated sandy soil. Transp. Geotech. 2020, 22, 100301. [Google Scholar] [CrossRef]

- Karatai, T.R.; Kaluli, J.W.; Kabubo, C.; Thiong’o, G. Soil stabilization using rice husk ash and natural lime as an alternative to cutting and filling in road construction. J. Constr. Eng. Manag. 2017, 143, 04016127. [Google Scholar] [CrossRef]

- Syed, M.; GuhaRay, A. Effect of natural fiber reinforcement on strength response of alkali activated binder treated expansive soil: Experimental investigation and reliability analysis. Constr. Build. Mater. 2021, 273, 121743. [Google Scholar] [CrossRef]

- Dang, L.C.; Fatahi, B.; Khabbaz, H. Behaviour of expansive soils stabilized with hydrated lime and bagasse fibres. Procedia Eng. 2016, 143, 658–665. [Google Scholar] [CrossRef]

- Kafodya, I.; Okonta, F. Effects of natural fiber inclusions and pre-compression on the strength properties of lime-fly ash stabilised soil. Constr. Build. Mater. 2018, 170, 737–746. [Google Scholar] [CrossRef]

- Yixian, W.; Panpan, G.; Shengbiao, S.; Haiping, Y.; Binxiang, Y. Study on strength influence mechanism of fiber-reinforced expansive soil using jute. Geotech. Geol. Eng. 2016, 34, 1079–1088. [Google Scholar] [CrossRef]

- Yoon, Y.W.; Heo, S.B.; Kim, K.S. Geotechnical performance of waste tires for soil reinforcement from chamber tests. Geotext. Geomembr. 2008, 26, 100–107. [Google Scholar] [CrossRef]

- Valipour, M.; Shourijeh, P.T.; Mohammadinia, A. Application of recycled tire polymer fibers and glass fibers for clay reinforcement. Transp. Geotech. 2021, 27, 100474. [Google Scholar] [CrossRef]

- Olgun, M. Effects of polypropylene fiber inclusion on the strength and volume change characteristics of cement-fly ash stabilized clay soil. Geosynth. Int. 2013, 20, 263–275. [Google Scholar] [CrossRef]

- Wang, Y.-X.; Guo, P.-P.; Ren, W.-X.; Yuan, B.-X.; Yuan, H.-P.; Zhao, Y.-L.; Shan, S.-B.; Cao, P. Laboratory investigation on strength characteristics of expansive soil treated with jute fiber reinforcement. Int. J. Geomech. 2017, 17, 04017101. [Google Scholar] [CrossRef]

- Tabakouei, A.R.; Narani, S.; Abbaspour, M.; Aflaki, E.; Siddiqua, S. Coupled specimen and fiber dimensions influence measurement on the properties of fiber-reinforced soil. Measurement 2022, 188, 110556. [Google Scholar] [CrossRef]

- Narani, S.; Abbaspour, M.; Hosseini, S.M.M.; Nejad, F.M. Long-term dynamic behavior of a sandy subgrade reinforced by Waste Tire Textile Fibers (WTTFs). Transp. Geotech. 2020, 24, 100375. [Google Scholar] [CrossRef]

- Abbaspour, M.; Narani, S.S.; Aflaki, E.; Nejad, F.M. Behavior of a subgrade soil reinforced by waste tire textile fibers under static and cyclic loading. J. Mater. Civ. Eng. 2020, 32, 04020208. [Google Scholar] [CrossRef]

- Abbaspour, M.; Narani, S.S.; Aflaki, E.; Nejad, F.M. Dynamic characteristics of a sandy subgrade reinforced by waste tire textile fibres. Int. J. Pavement Eng. 2020, 23, 2293–2308. [Google Scholar] [CrossRef]

- Mohammadifar, L.; Miraki, H.; Rahmani, A.; Jahandari, S.; Mehdizadeh, B.; Rasekh, H.; Samadi, P.; Samali, B. Properties of Lime-Cement Concrete Containing Various Amounts of Waste Tire Powder under Different Ground Moisture Conditions. Polymers 2022, 14, 482. [Google Scholar] [CrossRef]

- Angelin, A.F.; da Silva, F.M.; Barbosa, L.A.; Lintz, R.C.; de Carvalho, M.A.; Franco, R.A.S. Voids identification in rubberized mortar digital images using K-Means and Watershed algorithms. J. Clean. Prod. 2017, 164, 455–464. [Google Scholar] [CrossRef]

- Onuaguluchi, O. Effects of surface pre-coating and silica fume on crumb rubber-cement matrix interface and cement mortar properties. J. Clean. Prod. 2015, 104, 339–345. [Google Scholar] [CrossRef]

- Mucsi, G.; Szenczi, Á.; Nagy, S. Fiber reinforced geopolymer from synergetic utilization of fly ash and waste tire. J. Clean. Prod. 2018, 178, 429–440. [Google Scholar] [CrossRef]

- Song, W.; Yin, J. Hybrid effect evaluation of steel fiber and carbon fiber on the performance of the fiber reinforced concrete. Materials 2016, 9, 704. [Google Scholar] [CrossRef]

- Zhao, Q.; Yu, J.; Geng, G.; Jiang, J.; Liu, X. Effect of fiber types on creep behavior of concrete. Constr. Build. Mater. 2016, 105, 416–422. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Mechanical durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. J. Clean. Prod. 2019, 234, 1351–1364. [Google Scholar] [CrossRef]

- Yuan, T.-F.; Lee, J.-Y.; Min, K.-H.; Yoon, Y.-S. Experimental Investigation on Mechanical Properties of Hybrid Steel and Polyethylene Fiber-Reinforced No-Slump High-Strength Concrete. Int. J. Polym. Sci. 2019, 2019, 4737384. [Google Scholar] [CrossRef]

- Banthia, N.; Onuaguluchi, O. Recycling Scrap Tire-Derived Fibers in Concrete. Trans. Indian Natl. Acad. Eng. 2022, 7, 207–217. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, Y.; Li, J. Performance Investigation and Cost–Benefit Analysis of Recycled Tire Polymer Fiber-Reinforced Cemented Paste Backfill. Polymers 2022, 14, 708. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Pacheco-Torres, R.; Cerro-Prada, E.; Escolano, F.; Varela, F. Fatigue performance of waste rubber concrete for rigid road pavements. Constr. Build. Mater. 2018, 176, 539–548. [Google Scholar] [CrossRef]

- Serdar, M.; Baričević, A.; Rukavina, M.J.; Pezer, M.; Bjegović, D.; Štirmer, N. Shrinkage behaviour of fibre reinforced concrete with recycled tyre polymer fibres. Int. J. Polym. Sci. 2015, 215, 145918. [Google Scholar] [CrossRef]

- Chen, M.; Zhong, H.; Chen, L.; Zhang, Y.; Zhang, M. Engineering properties and sustainability assessment of recycled fibre reinforced rubberised cementitious composite. J. Clean. Prod. 2021, 278, 123996–124010. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Walraven, J.C. High performance fiber reinforced concrete: Progress in knowledge and design codes. Mater. Struct. 2009, 42, 1247–1260. [Google Scholar] [CrossRef]

- Ríos, J.D.; Cifuentes, H.; Yu, R.C.; Ruiz, G. Probabilistic flexural fatigue in plain and fiber-reinforced concrete. Materials 2017, 10, 767. [Google Scholar] [CrossRef]

- Pais, J.C.; Santos, C.R.; Presti, D.L. Application of textile fibres from tire recycling in asphalt mixtures. Road Mater. Pavement Des. 2021, 23, 1–22. [Google Scholar] [CrossRef]

- Jin, D.; Ge, D.; Zhou, X.; You, Z. Asphalt Mixture with Scrap Tire Rubber and Nylon Fiber from Waste Tires: Laboratory Performance and Preliminary ME Design Analysis. Buildings 2022, 12, 160. [Google Scholar] [CrossRef]

- Ling, S.; Yu, F.; Sun, D.; Sun, G.; Xu, L. A comprehensive review of tire-pavement noise: Generation mechanism, measurement methods, and quiet asphalt pavement. J. Clean. Prod. 2021, 287, 125056. [Google Scholar] [CrossRef]

- Wong, C.C.; Wong, W.-G. Effect of crumb rubber modifiers on high temperature susceptibility of wearing course mixtures. Constr. Build. Mater. 2007, 21, 1741–1745. [Google Scholar] [CrossRef]

- Valdés-Vidal, G.; Calabi-Floody, A.; Duarte-Nass, C.; Mignolet, C.; Díaz, C. Development of a New Additive Based on Textile Fibers of End-of-Life Tires (ELT) for Sustainable Asphalt Mixtures with Improved Mechanical Properties. Polymers 2022, 14, 3250. [Google Scholar] [CrossRef] [PubMed]

- Landi, D.; Marconi, M.; Bocci, E.; Germani, M. Comparative life cycle assessment of standard, cellulose-reinforced and end of life tires fiber-reinforced hot mix asphalt mixtures. J. Clean. Prod. 2020, 248, 119295. [Google Scholar] [CrossRef]

- Bocci, E.; Prosperi, E. Recycling of reclaimed fibers from end-of-life tires in hot mix asphalt. J. Traffic Transp. Eng. 2020, 7, 678–687. [Google Scholar] [CrossRef]

- Moreno, F.; Rubio, M.; Martinez-Echevarria, M. Analysis of digestion time and the crumb rubber percentage in dry-process crumb rubber modified hot bituminous mixes. Constr. Build. Mater. 2011, 25, 2323–2334. [Google Scholar] [CrossRef]

- Chen, H.; Xu, Q. Experimental study of fibers in stabilizing and reinforcing asphalt binder. Fuel 2010, 89, 1616–1622. [Google Scholar] [CrossRef]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Schiavoni, S.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sust. Energ. Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Thai, Q.B.; Chong, R.O.; Nguyen, P.T.; Le, D.K.; Le, P.K.; Phan-Thien, N.; Duong, H.M. Recycling of waste tire fibers into advanced aerogels for thermal insulation and sound absorption applications. J. Environ. Chem. Eng. 2020, 8, 104279. [Google Scholar] [CrossRef]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous materials for sound absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Gesser, H.; Goswami, P. Aerogels and related porous materials. Chem. Rev. 1989, 89, 765–788. [Google Scholar] [CrossRef]

- Thai, Q.B.; Siang, T.E.; Le, D.K.; Shah, W.A.; Phan-Thien, N.; Duong, H.M. Advanced fabrication and multi-properties of rubber aerogels from car tire waste. Colloids Surf. Physicochem. Eng. Asp. 2019, 577, 702–708. [Google Scholar] [CrossRef]

- Nguyen, S.T.; Feng, J.; Ng, S.K.; Wong, J.P.; Tan, V.B.; Duong, H.M. Advanced thermal insulation and absorption properties of recycled cellulose aerogels. Colloids Surf. Physicochem. Eng. Asp. 2014, 445, 128–134. [Google Scholar] [CrossRef]

- Cao, L.; Si, Y.; Wu, Y.; Wang, X.; Yu, J.; Ding, B. Ultralight, superelastic and bendable lashing-structured nanofibrous aerogels for effective sound absorption. Nanoscale 2019, 11, 2289–2298. [Google Scholar] [CrossRef] [PubMed]

- Sorour, M.H.; Hani, H.A.; Al-Bazedi, G.A.; El-Rafei, A. Hydrophobic silica aerogels for oil spills clean-up, synthesis, characterization and preliminary performance evaluation. J. Porous Mater. 2016, 23, 1401–1409. [Google Scholar] [CrossRef]

- Wang, D.; McLaughlin, E.; Pfeffer, R.; Lin, Y. Adsorption of oils from pure liquid and oil–water emulsion on hydrophobic silica aerogels. Sep. Purif. Technol. 2012, 99, 28–35. [Google Scholar] [CrossRef]

- Thai, Q.B.; Le, D.K.; Do, N.H.; Le, P.K.; Phan-Thien, N.; Wee, C.Y.; Duong, H.M. Advanced aerogels from waste tire fibers for oil spill-cleaning applications. J. Environ. Chem. Eng. 2020, 8, 104016. [Google Scholar] [CrossRef]

- Dorcheh, A.S.; Abbasi, M. Silica aerogel, synthesis, properties and characterization. J. Mater. Process. Technol. 2008, 199, 10–26. [Google Scholar] [CrossRef]

- Thai, Q.B.; Nguyen, S.T.; Ho, D.K.; Tran, T.D.; Huynh, D.M.; Do, N.H.; Luu, T.P.; Le, P.K.; Le, D.K.; Phan-Thien, N. Cellulose-based aerogels from sugarcane bagasse for oil spill-cleaning and heat insulation applications. Carbohydr. Polym. 2020, 228, 115365–115371. [Google Scholar] [CrossRef]

- Shi, M.; Tang, C.; Yang, X.; Zhou, J.; Jia, F.; Han, Y.; Li, Z. Superhydrophobic silica aerogels reinforced with polyacrylonitrile fibers for adsorbing oil from water and oil mixtures. RSC Adv. 2017, 7, 4039–4045. [Google Scholar] [CrossRef]

- Chang, C.; Zhang, L. Cellulose-based hydrogels: Present status and application prospects. Carbohydr. Polym. 2011, 84, 40–53. [Google Scholar] [CrossRef]

- Shi, J.; Jiang, K.; Ren, D.; Zou, H.; Wang, Y.; Lv, X.; Zhang, L. Structure and performance of reclaimed rubber obtained by different methods. J. Appl. Polym. Sci. 2013, 129, 999–1007. [Google Scholar] [CrossRef]

- Sakai, K.; Kobayashi, Y.; Saito, T.; Isogai, A. Partitioned airs at microscale and nanoscale: Thermal diffusivity in ultrahigh porosity solids of nanocellulose. Sci. Rep. 2016, 6, 1–7. [Google Scholar] [CrossRef]

- Pham, D.; Phan-Thien, N. On the optimal bounds for the effective conductivity of isotropic quasi-symmetric multiphase media. J. Appl. Math. Phys. 1997, 48, 744–759. [Google Scholar] [CrossRef]

- Xie, X.; Li, D.; Tsai, T.-H.; Liu, J.; Braun, P.V.; Cahill, D.G. Thermal conductivity, heat capacity, and elastic constants of water-soluble polymers and polymer blends. Macromolecules 2016, 49, 972–978. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Rodrigue, D. Mechanical, rheological, morphological and water absorption properties of maleated polyethylene/hemp composites: Effect of ground tire rubber addition. Compos. B. Eng 2013, 51, 337–344. [Google Scholar] [CrossRef]

- Ghasemzadeh-Barvarz, M.; Duchesne, C.; Rodrigue, D. Mechanical, water absorption, and aging properties of polypropylene/flax/glass fiber hybrid composites. J. Compos. Mater. 2015, 49, 3781–3798. [Google Scholar] [CrossRef]

- Lokesh, P.; Kumari, T.S.; Gopi, R.; Loganathan, G.B. A study on mechanical properties of bamboo fiber reinforced polymer composite. Mater. Today Proc. 2020, 22, 897–903. [Google Scholar] [CrossRef]

- Sever, K.; Sarikanat, M.; Seki, Y.; Erkan, G.; Erdoğan, Ü.H.; Erden, S. Surface treatments of jute fabric: The influence of surface characteristics on jute fabrics and mechanical properties of jute/polyester composites. Ind. Crop. Prod. 2012, 35, 22–30. [Google Scholar] [CrossRef]

- Fávaro, S.L.; Lopes, M.S.; Neto, A.G.V.d.; de Santana, R.R.; Radovanovic, E. Chemical, morphological, and mechanical analysis of rice husk/post-consumer polyethylene composites. Compos. Part A Appl. Sci. 2010, 41, 154–160. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Correlo, V.M.; Mano, J.F.; Reis, R.L. Novel cork–polymer composites reinforced with short natural coconut fibres: Effect of fibre loading and coupling agent addition. Compos. Sci. Technol. 2013, 78, 56–62. [Google Scholar] [CrossRef]

- Saha, A.; Kumar, S.; Kumar, A. Influence of pineapple leaf particulate on mechanical, thermal and biodegradation characteristics of pineapple leaf fiber reinforced polymer composite. J. Polym. Res. 2021, 28, 1–23. [Google Scholar] [CrossRef]

- Chimeni, D.Y.; Toupe, J.L.; Dubois, C.; Rodrigue, D. Effect of hemp surface modification on the morphological and tensile properties of linear medium density polyethylene (LMDPE) composites. Compos. Interfaces 2016, 23, 405–421. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Mahmud, S.; Hasan, K.; Jahid, M.; Mohiuddin, K.; Zhang, R.; Zhu, J. Comprehensive review on plant fiber-reinforced polymeric biocomposites. J. Mater. Sci. 2021, 56, 7231–7264. [Google Scholar] [CrossRef]

- DiBenedetto, A. Tailoring of interfaces in glass fiber reinforced polymer composites: A review. Mater. Sci. Eng. A 2001, 302, 74–82. [Google Scholar] [CrossRef]

- Zhang, X.X.; Lu, C.H.; Liang, M. Preparation of rubber composites from ground tire rubber reinforced with waste-tire fiber through mechanical milling. J. Appl. Polym. Sci. 2007, 103, 4087–4094. [Google Scholar] [CrossRef]

- Marconi, M.; Landi, D.; Meo, I.; Germani, M. Reuse of tires textile fibers in plastic compounds: Is this scenario environmentally sustainable? Procedia Cirp 2018, 69, 944–949. [Google Scholar] [CrossRef]

- Anthony, W.S. Separation of Crumb and Fiber in Tire Recycling Operations. In ASAE Annual Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2005. [Google Scholar]

- Fazli, A.; Rodrigue, D. Effect of ground tire rubber (GTR) particle size and content on the morphological and mechanical properties of recycled high-density polyethylene (rHDPE)/GTR blends. Recycling 2021, 6, 44. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Thermoplastic elastomers based on recycled high-density polyethylene/ground tire rubber/ethylene vinyl acetate: Effect of ground tire rubber regeneration on morphological and mechanical properties. J. Thermoplast. Compos. Mater. 2022, 35, 08927057221095388. [Google Scholar] [CrossRef]

- Moghaddamzadeh, S.; Rodrigue, D. The effect of polyester recycled tire fibers mixed with ground tire rubber on polyethylene composites. Part II: Physico-mechanical analysis. Prog. Rubber Plast. Recycl. 2018, 34, 128–142. [Google Scholar] [CrossRef]

- Ferreira, C.T.; Perez, C.A.; Hirayama, D.; Saron, C. Recycling of polyamide (PA) from scrap tires as composites and blends. J. Environ. Chem. Eng. 2013, 1, 762–767. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Thermoplastic Elastomer based on Recycled HDPE/Ground Tire Rubber Interfacially Modified with an Elastomer: Effect of Mixing Sequence and Elastomer Type/Content. Polym. Plast. Technol. Eng. 2022, 61, 1021–1038. [Google Scholar] [CrossRef]

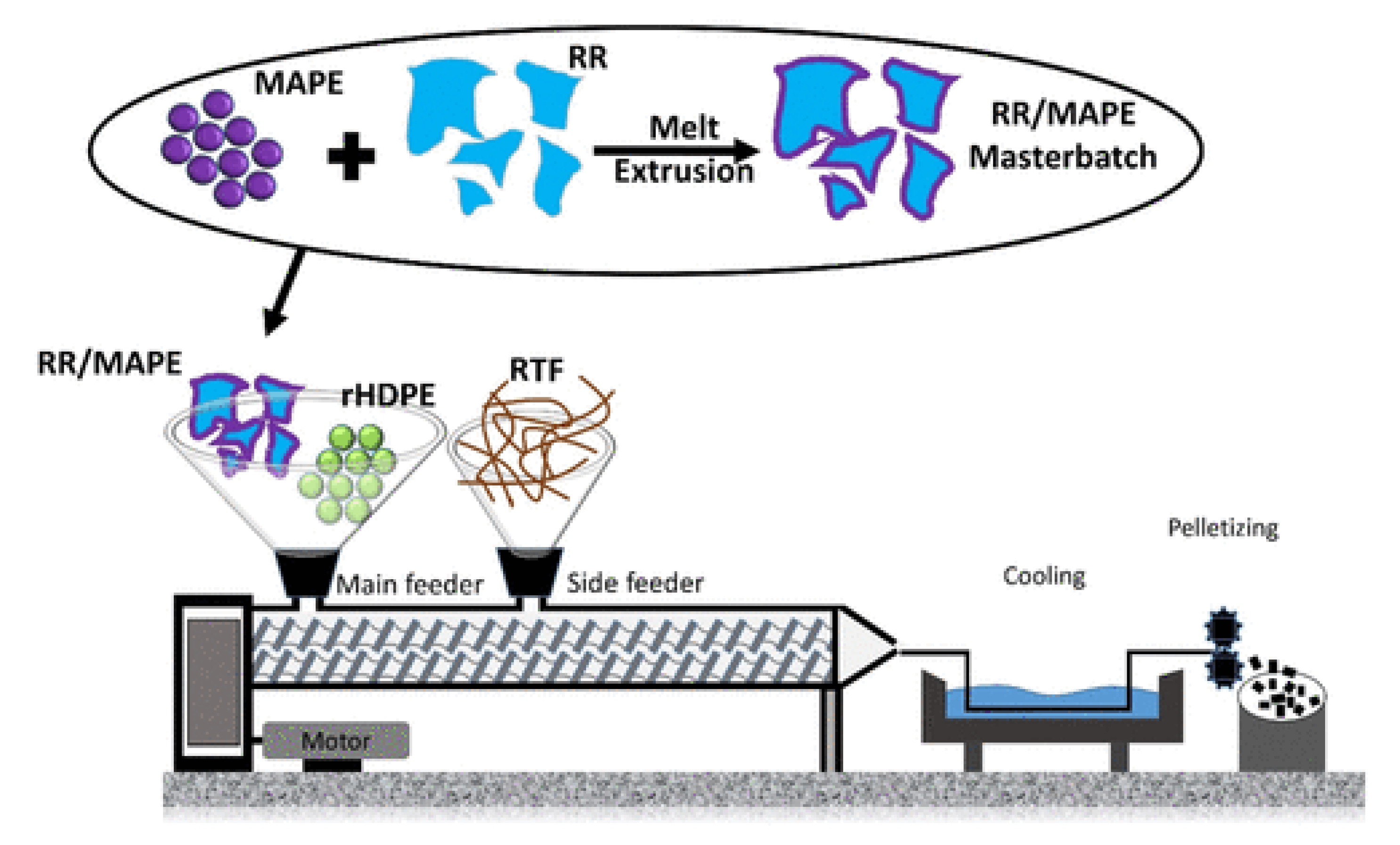

- Fazli, A.; Stevanovic, T.; Rodrigue, D. Recycled HDPE/Natural Fiber Composites Modified with Waste Tire Rubber: A Comparison between Injection and Compression Molding. Polymers 2022, 14, 3197. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Morphological and Mechanical Properties of Thermoplastic Elastomers Based on Recycled High Density Polyethylene and Recycled Natural Rubber. Int. Polym. Proc. 2021, 36, 156–164. [Google Scholar] [CrossRef]

- Simon-Stőger, L.; Varga, C. PE-contaminated industrial waste ground tire rubber: How to transform a handicapped resource to a valuable one. Waste Manag. 2021, 119, 111–121. [Google Scholar] [CrossRef]

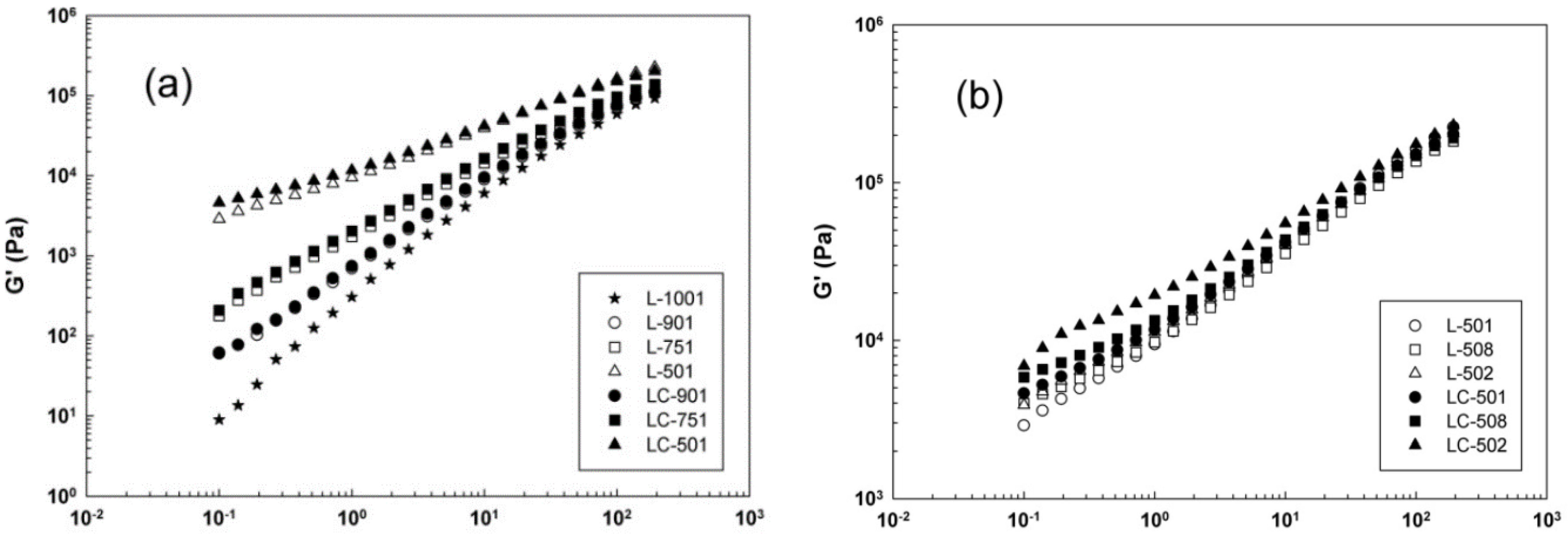

- Moghaddamzadeh, S.; Rodrigue, D. Rheological characterization of polyethylene/polyester recycled tire fibers/ground tire rubber composites. J. Appl. Polym. Sci. 2018, 135, 46563–46571. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L.; Vimal, V. Interfacial Studies of Natural Fiber-Reinforced Particulate Thermoplastic Composites and Their Mechanical Properties. J. Nat. Fibers 2020, 19, 2299–2326. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Bainier, J.; Rodrigue, D. Mechanical and morphological properties of flax fiber reinforced high density polyethylene/recycled rubber composites. Int. Polym. Proc. 2012, 27, 196–204. [Google Scholar] [CrossRef]

| Type of Tire | Rubber/Elastomers | Carbon Black | Metal | Textile | Zinc Oxide | Others |

|---|---|---|---|---|---|---|

| Passenger Car | 47 | 21.5 | 16.5 | 5.5 | 1 | 8.5 |

| Lorry | 45 | 22 | 23 | 3 | 2 | 5 |

| Off Road | 47 | 22 | 12 | 10 | 2 | 7 |

| Property | Unit | Testing Method | Values | |

|---|---|---|---|---|

| General | Most Frequent | |||

| Fiber type | – | – | Yarned | – |

| Equivalent diameter | mm | ASTM D885M-10A e1 (2014) | 0.030–1.50 | 0.80 |

| Length | mm | ASTM D885M-10A e1 (2014) | 0–70 | 20–40 |

| Tensile strength | MPa | ASTM D885M-10A e1 (2014) | 300–2000 | 600 |

| Twist S (Folded) | T/10 cm | ASTM D885M-10A e1 (2014) | 30–50 | 39 |

| Elongation at break | % | ASTM D885M-10A e1 (2014) | 18–25 | 22 |

| Elastic modulus | GPa | ASTM D885M-10A e1 (2014) | 2–7.5 | 2.7 |

| Hot air shrinkage (at 177 °C × 2 min × 143 g) | % | ASTM D5591-04 (2016) | 3–5 | 4.5 |

| Linear density | Denier | ASTM D885M-10A e1 (2014) | 840–1890 | 1260 |

| Melting point | °C | ASTM D885M-10A e1 (2014) | 250–260 | 256 |

| Water absorption | % | ASTM D885M-10A e1 (2014) | 5–13 | 9.5 |

| Element | Symbols | Content (%) |

|---|---|---|

| Carbon | C | 62.3 |

| Oxygen | O | 23.9 |

| Sodium | Na | 4.75 |

| Zinc | Zn | 2.91 |

| Sulfur | S | 2.19 |

| Aluminum | Al | 1.83 |

| Silicon | Si | 1.38 |

| Magnesium | Mg | 0.72 |

| Property | Asphalt with Cellulose Fibers | Asphalt with ELT Fibers |

|---|---|---|

| Bitumen (%) | 5.4 | 5.4 |

| Filler (%) | 6 | 6 |

| Indirect tensile module (MPa) | 4482 | 5212 |

| Indirect tensile strength (MPa) | 1.37 | 1.38 |

| Number of cycles to failure | 3085 | 4785 |

| Sample | Tensile Strength (MPa) | Young’s Modulus (MPa) | Tensile Strain at Break (%) | Flexural Modulus (MPa) |

|---|---|---|---|---|

| rHDPE | 19.0 (0.3) | 427.1 (14.9) | 949.2 (26.4) | 594.4 (11.3) |

| HR35 | 13.0 (0.3) | 191.2 (4.3) | 38.1 (4.8) | 384.1 (3.5) |

| HR50 | 9.2 (0.3) | 152.3 (3.2) | 44.2 (7.2) | 281.8 (5.4) |

| HR65 | 7.7 (0.1) | 99.3 (4.2) | 56.7 (5.3) | 189.4 (3.8) |

| HR80 | 4.7 (0.4) | 32.5 (5.4) | 77.9 (8.6) | 103.6 (4.7) |

| HR15F | 9.5 (0.1) | 246.5 (6.1) | 30.2 (6.1) | 405.6 (2.1) |

| HR30F | 9.2 (0.3) | 170.5 (6.6) | 36.4 (4.9) | 308.5 (3.8) |

| HR45F | 7.4 (0.2) | 109.3 (4.7) | 45.3 (6.4) | 202.7 (3.5) |

| HR60F | 4.9 (0.1) | 45.8 (5.2) | 65.2 (5.7) | 134.7 (2.9) |

| HR15F * | 13.2 (0.2) | 277.3 (4.9) | 64.5 (8.2) | 437.9 (3.4) |

| HR30F * | 12.1 (0.2) | 212.2 (5.3) | 87.6 (7.9) | 384.6 (4.5) |

| HR45F * | 9.8 (0.1) | 126.5 (3.6) | 138.2 (7.6) | 262.5 (4.2) |

| HR60F * | 8.8 (0.4) | 80.9 (4.5) | 172.3 (8.3) | 182.7 (5.1) |

| Rx: RR wt.% (x) blended with rHDPE (wt.%). RxF: RR wt.% (x) blended with 20 wt.% of FF (F) and rHDPE (wt.%). RyF *: RR/MPAE wt.% (y) blended with 20 wt.% of FF (F) and rHDPE (wt.%). | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fazli, A.; Rodrigue, D. Sustainable Reuse of Waste Tire Textile Fibers (WTTF) as Reinforcements. Polymers 2022, 14, 3933. https://doi.org/10.3390/polym14193933

Fazli A, Rodrigue D. Sustainable Reuse of Waste Tire Textile Fibers (WTTF) as Reinforcements. Polymers. 2022; 14(19):3933. https://doi.org/10.3390/polym14193933

Chicago/Turabian StyleFazli, Ali, and Denis Rodrigue. 2022. "Sustainable Reuse of Waste Tire Textile Fibers (WTTF) as Reinforcements" Polymers 14, no. 19: 3933. https://doi.org/10.3390/polym14193933

APA StyleFazli, A., & Rodrigue, D. (2022). Sustainable Reuse of Waste Tire Textile Fibers (WTTF) as Reinforcements. Polymers, 14(19), 3933. https://doi.org/10.3390/polym14193933