A Methodology to Obtain the Accurate RVEs by a Multiscale Numerical Simulation of the 3D Braiding Process

Abstract

:1. Introduction

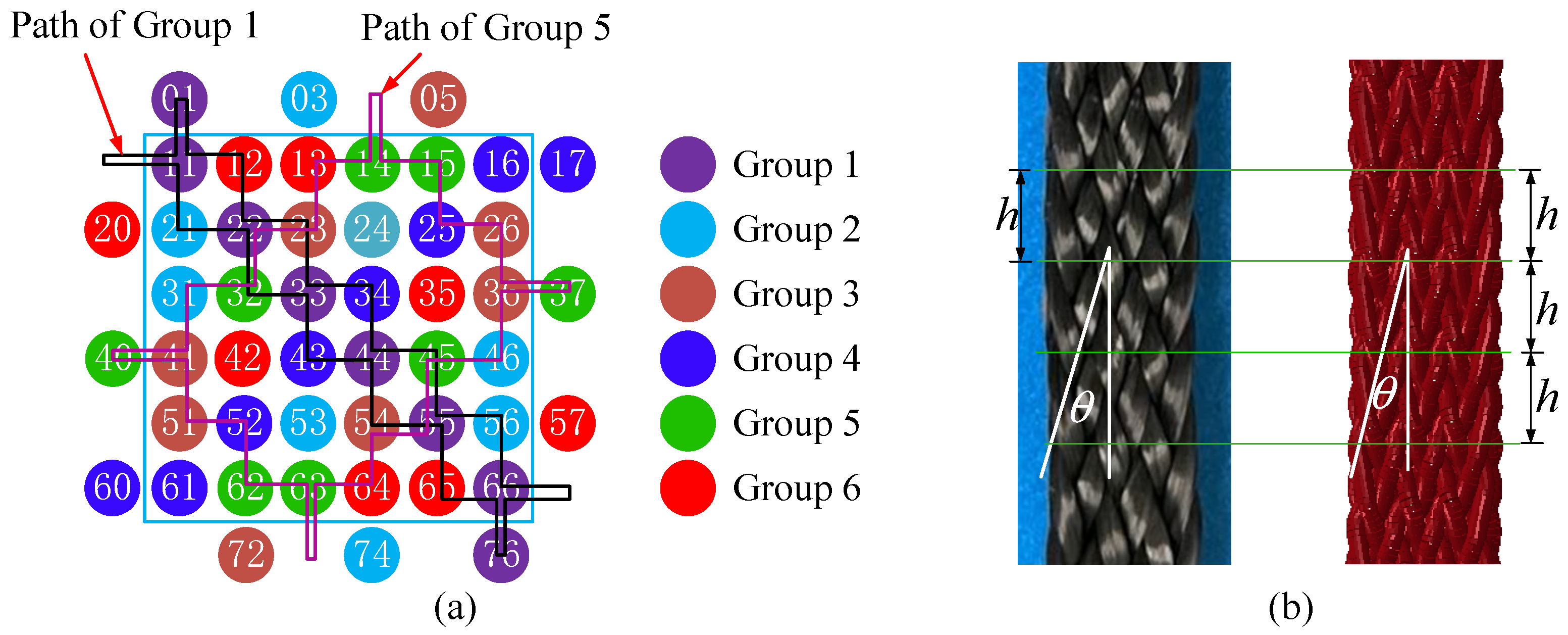

2. Three-Dimensional Four-Directional Braiding Process

3. Modeling Approach Using the FEA Method

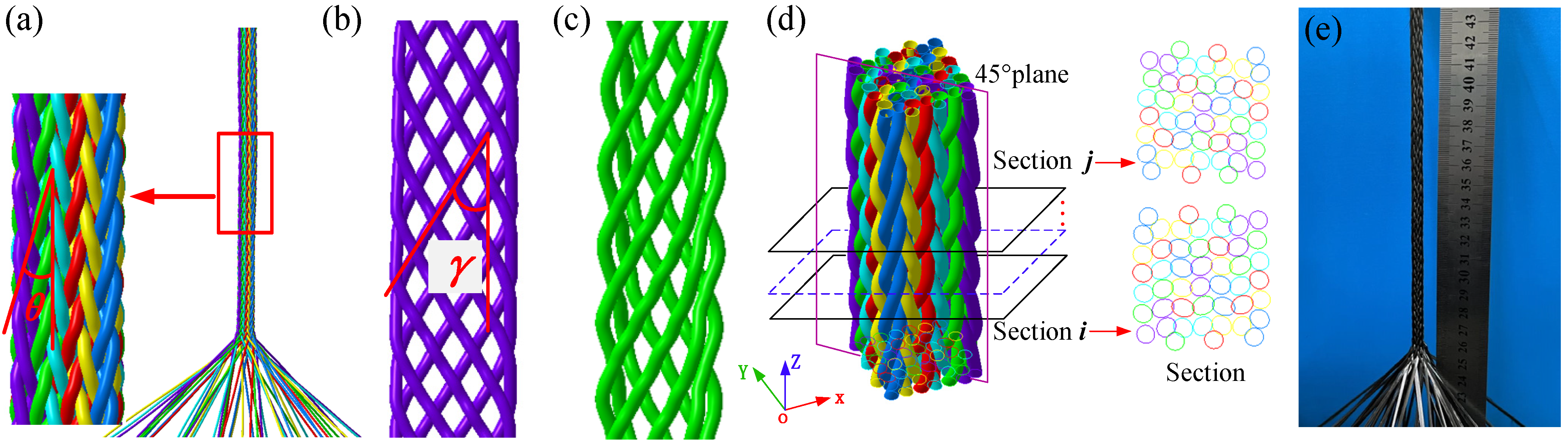

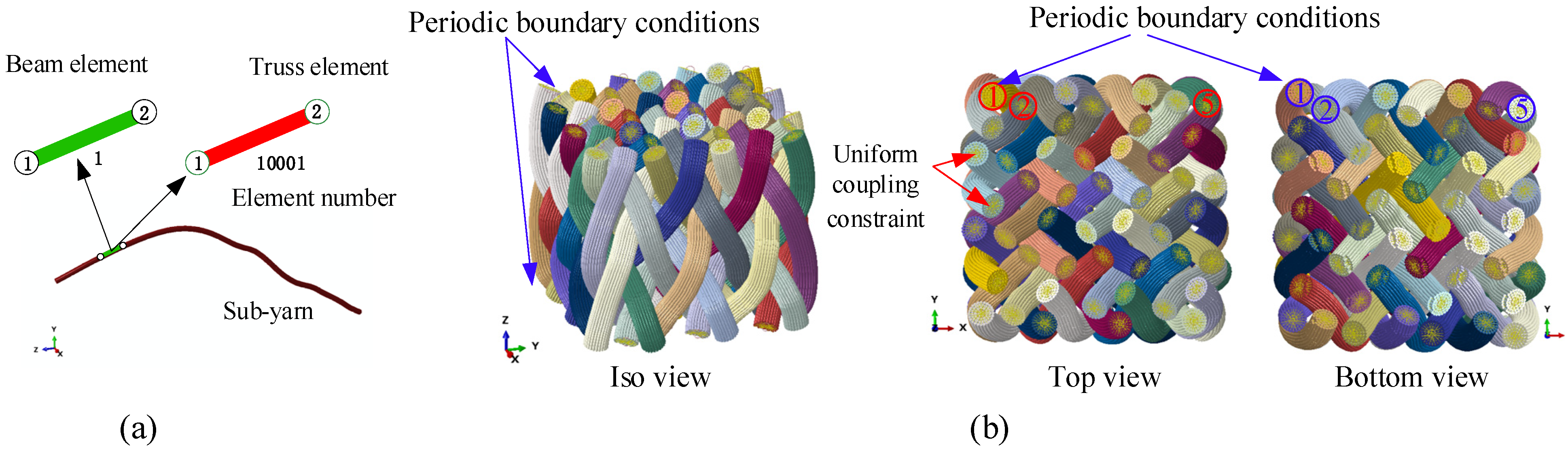

- Simulation of the 3D4D braiding process on the macroscale: The braiding process was simulated according to Section 2, during which the yarns were discretized as T3D2 truss elements. The parametric model was generated using a Python script and solved by the Abaqus software (Figure 3a). Yarns were interweaved to achieve the preform.

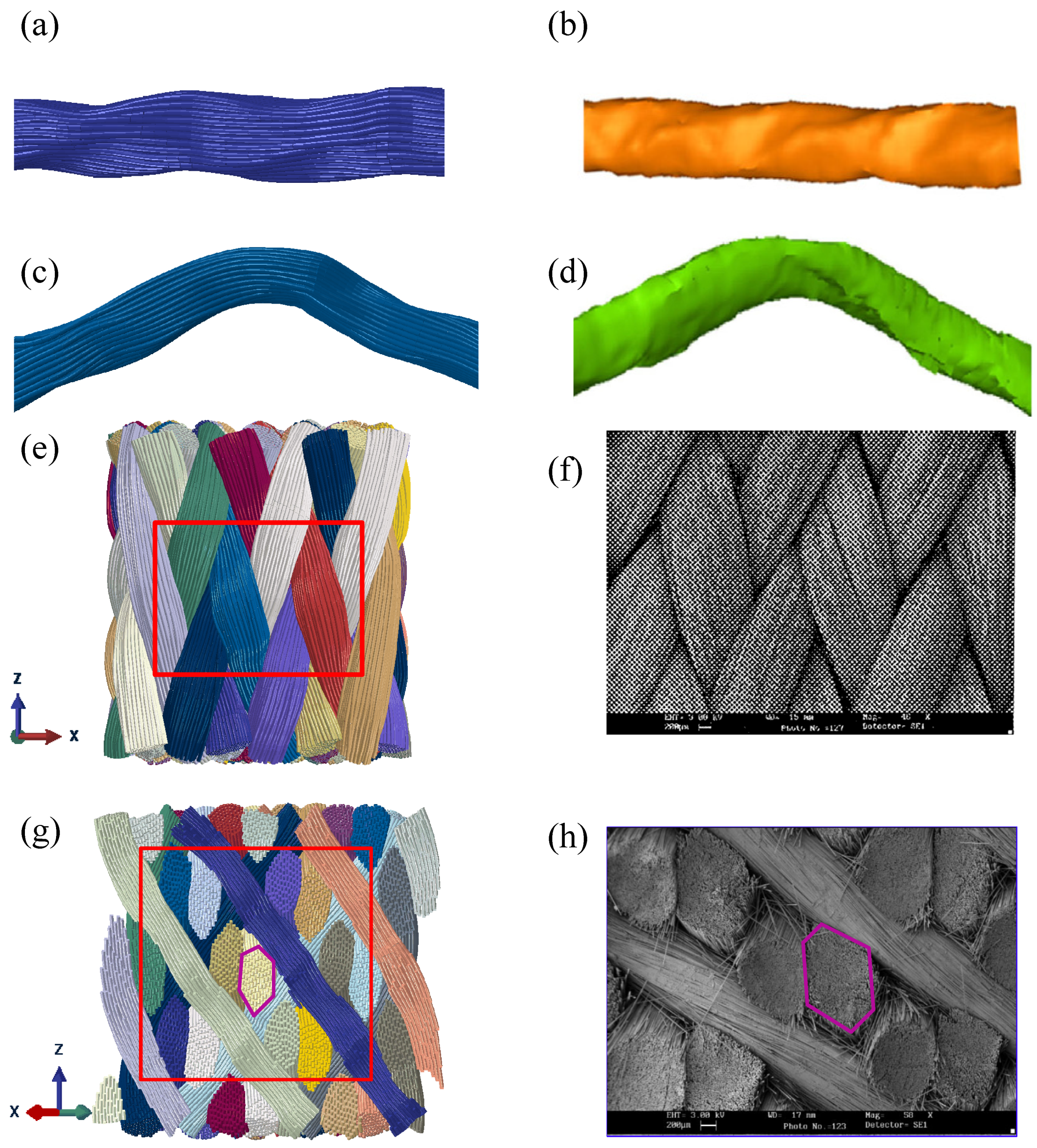

- Sub-yarn discretization: The yarns in the two pitches of the preform at the stable braiding stage (Figure 3b) were divided into several bundles of sub-yarns according to the center curve of the yarns achieved in Step I, as shown in Figure 3c. A Python script was written to automate the model generation and the assignment of boundary conditions.

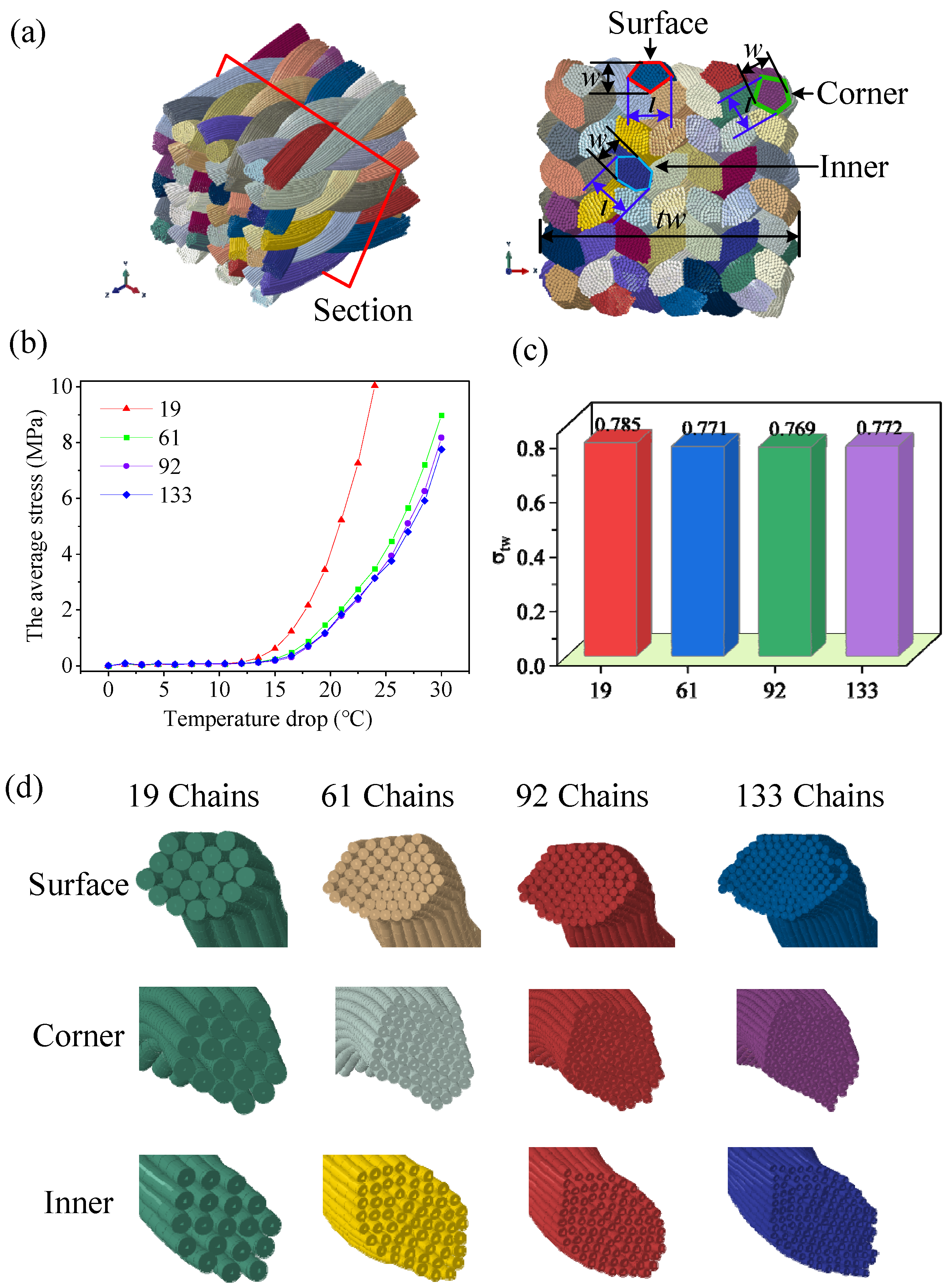

- Sub-yarn deforming simulation on the mesoscale: The contraction process was accomplished by imposing the temperature drop load with an appropriate thermal expansion coefficient (Figure 3d). The sub-yarns were represented by the hybrid elements consisting of the truss and beam element with coinciding nodes. Then, the yarn section changed from a circle to a realistic shape as the average stress of all sub-yarns reached the tension stress of the carrier retraction.

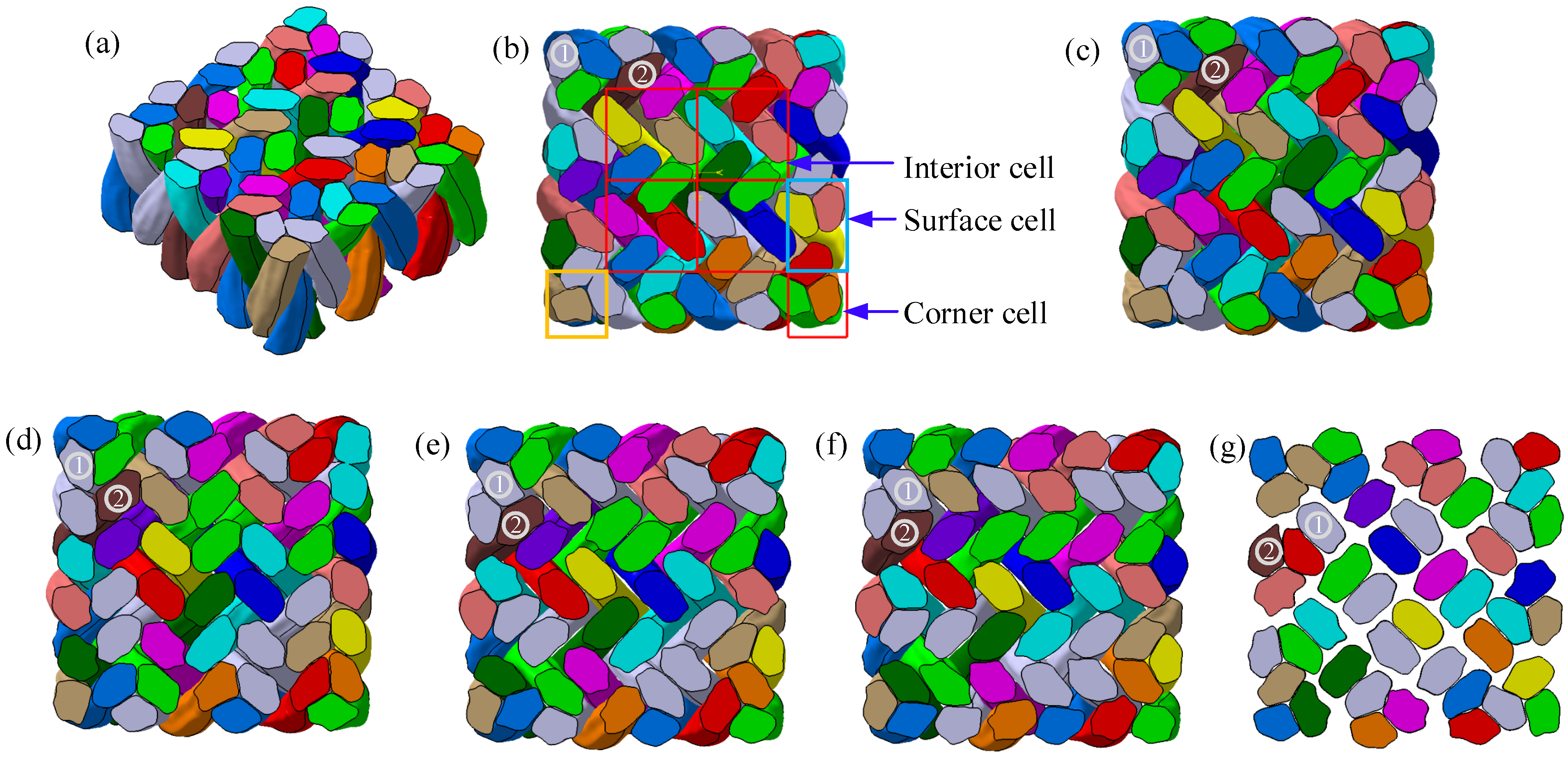

- Mesostructure reconstruction: Since the FEA analyses require yarns with a solid geometry rather than fibers, the chains of sub-yarns must be converted to solid geometry. Another Python script was written to extract the section shapes of different yarns and reconstruct the accurate yarn structure (Figure 3e). Eventually, three RVEs were generated: interior cell, surface cell, and corner cell (Figure 3f–g).

3.1. Simulation of the 3D4D Braiding Process on the Macroscale

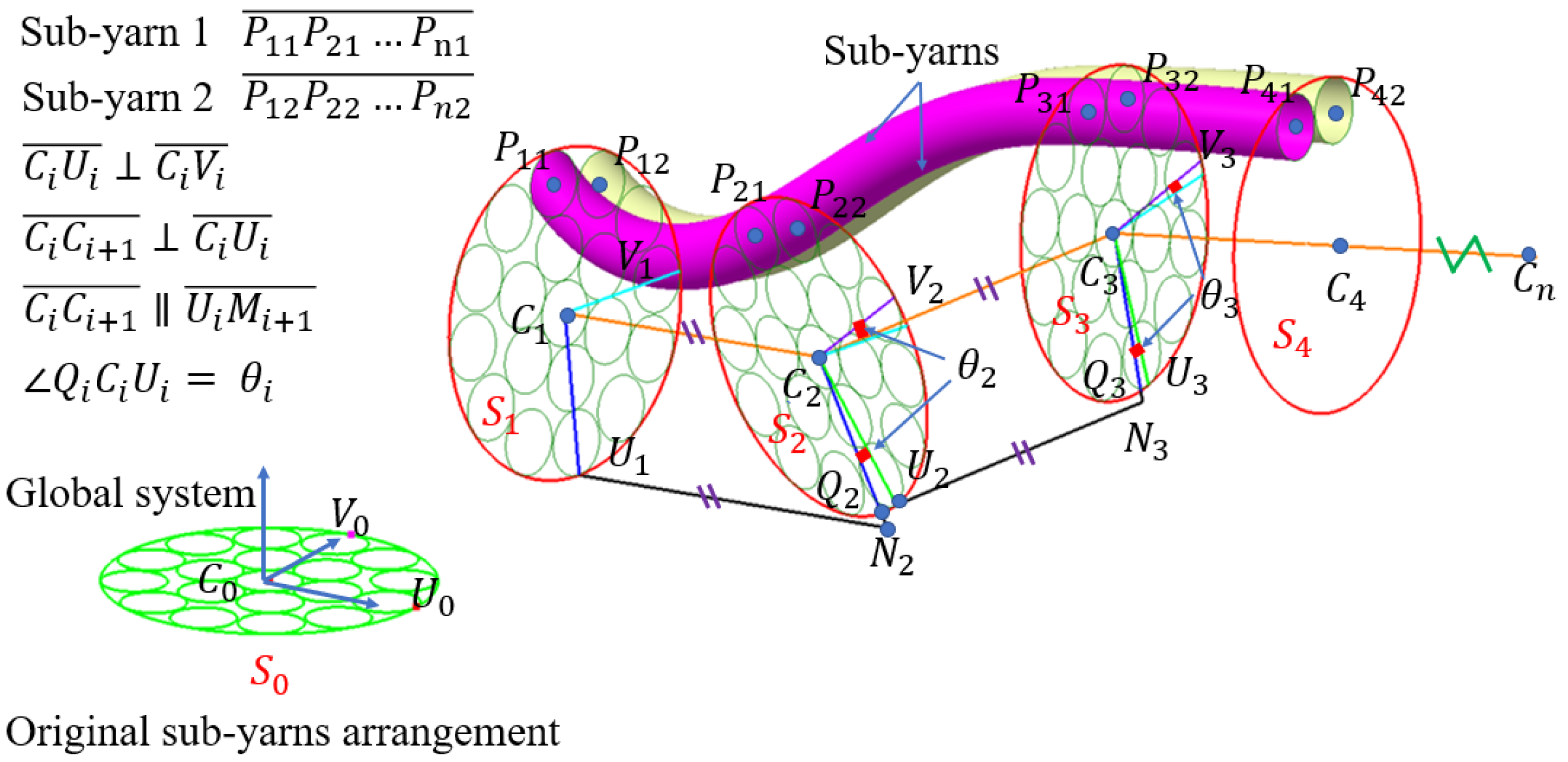

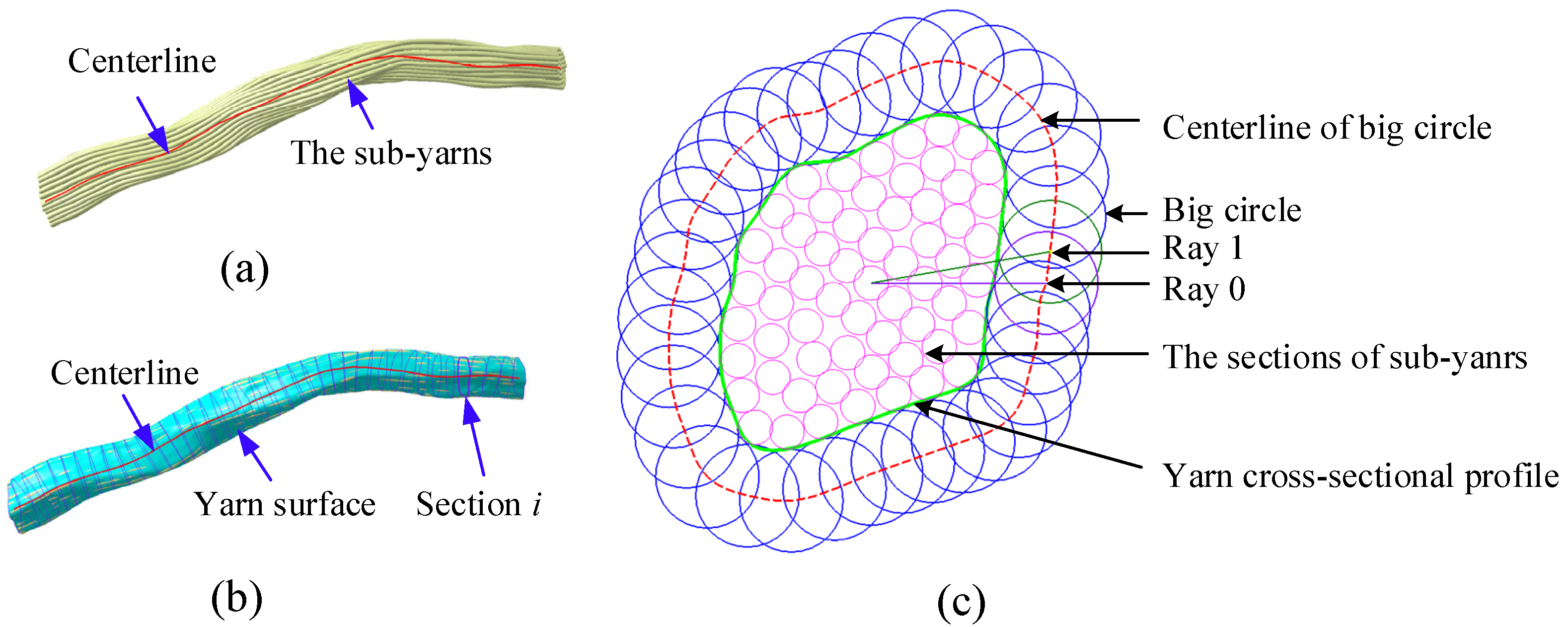

3.2. Sub-Yarn Discretization

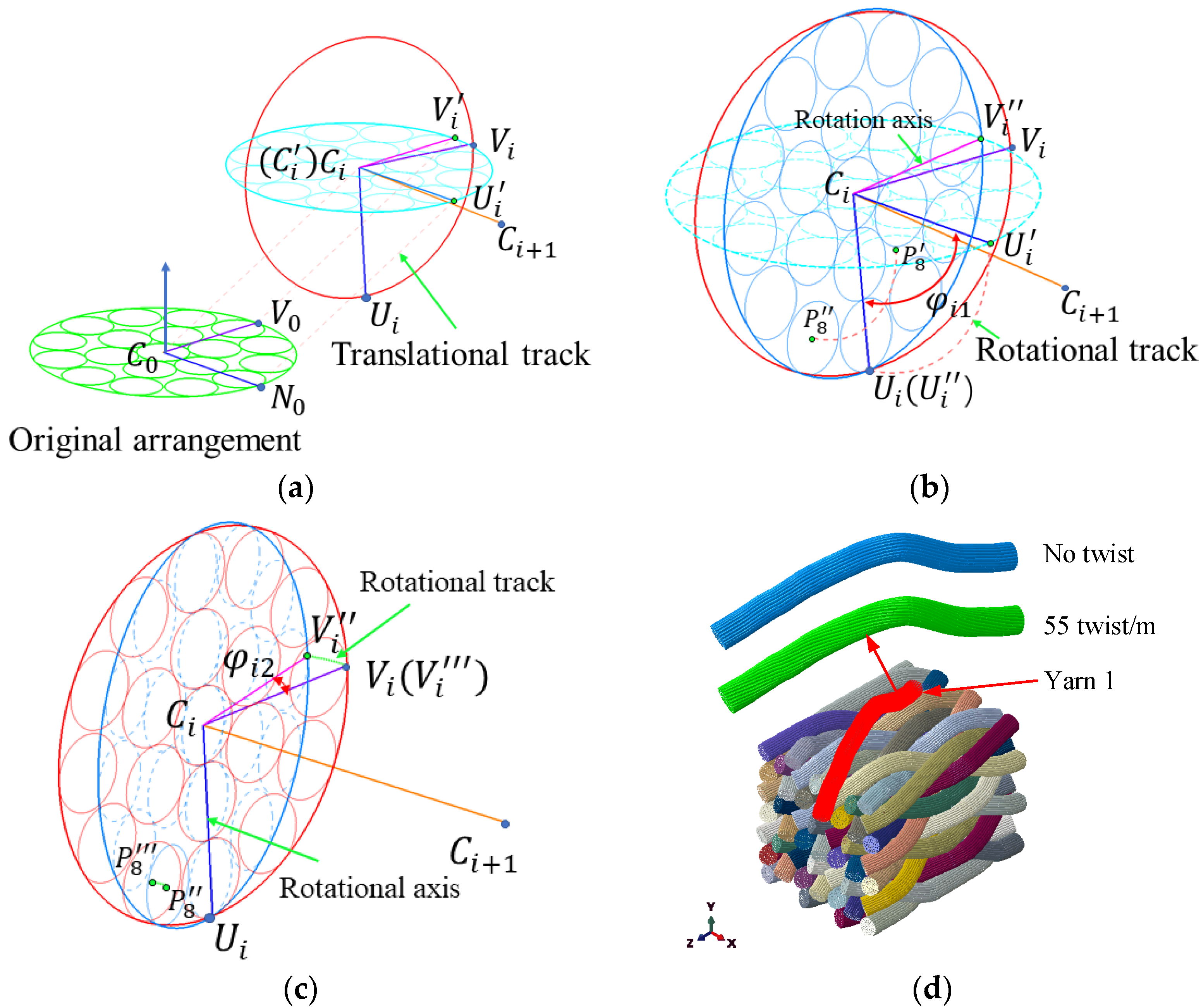

- The translational transformation was conducted to ensure that points and coincide, as shown in Figure 7a. The coordinates of points and are denoted as and , respectively. The vector is denoted as . The translation matrix is as follows:

- The rotational transformation was deployed to ensure that points and coincide. The rotation axis is determined by the cross product of vectors and , as shown in Figure 7b. The unit vector of the rotation direction and the rotation angle are calculated as follows:The rotation matrix is presented in Equation (8), where and . The blue lines (Figure 7b) are sub-yarns after rotation.

- Taking the vector as the axis, the angle between and is rotated so that point coincides with point and the corresponding rotation matrix is obtained, as illustrated in Figure 7c. After the three transformations, points , , and coincide at points , , and , respectively.

3.3. Sub-Yarn Deformation on the Mesoscale

3.4. Mesostructure Reconstruction

- The evenly distributed rays are drawn along the circumferential direction, with the center of the section as the starting point, as shown in Figure 10c. The center of the big circle moves outward from the center in steps of 0.001 mm on the ray until it does not intersect all sub-yarn sections. The big circle’s radius is set as 3–5 times the fiber radius to achieve a smooth and precise profile.

- The centers of all big circles are connected to form a curve. Then, the curve is offset by the radius of the big circle inward to obtain a curve that surrounds all fibers, that is, the cross-sectional profile of the yarn.

- All the cross-sectional profiles are joined to a multi-section surface, as shown in Figure 10b. These procedures are implemented with user-written Python scripts to obtain the coordinate sub-yarn nodes from the FEA result and generate realistic yarn geometry in Catia software.

4. Parametric Study

4.1. Geometrical Convergence

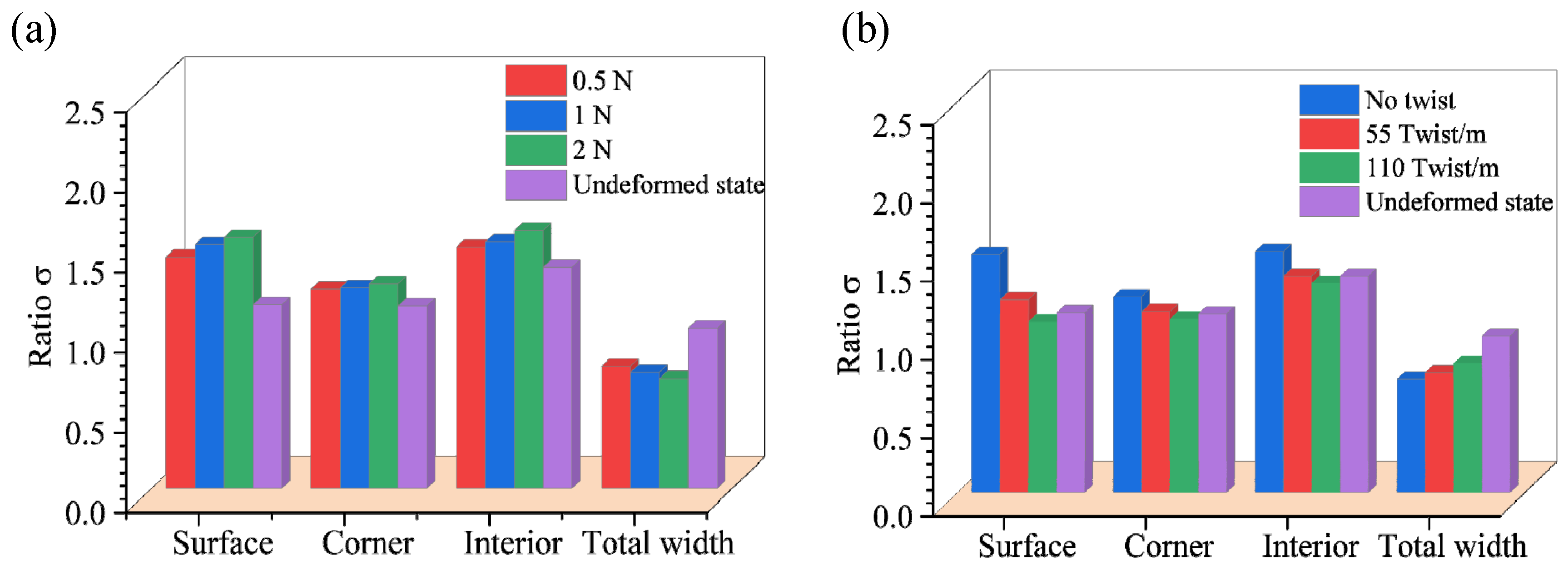

4.2. The Bending Stiffness

4.3. The Tension Force of Carriers and the Twisting of Yarns

5. Application

6. Conclusions

- (1)

- The braiding angle decreases as the height of the braiding point increases and vice versa for pitch length.

- (2)

- To achieve a realistic interior cell, surface cell, and corner cell, a temperature drop simulation with hybrid elements was conducted to make the yarn cross-section deformable. The simulation result shows good agreement with the experiment.

- (3)

- The parametric study shows that the use of 92 sub-yarns represents the cross-sectional deformation well. A smaller bending stiffness leads to a larger total width variation, resulting in a higher yarn volume fraction at the same tension force. The yarn deformation degree is positively related to the tension force of carriers. Finally, the twisted yarn has a higher resistance to cross-sectional deformation than the straight yarn.

- (4)

- The simulation methodology presented here is a versatile tool that can study the relationship between the different braiding processes and the mesostructure of the preform.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, Y.; Min, J.; Teng, H.; Lin, J.; Hu, J.; Xu, N. Flexural Performance of Steel–FRP Composites for Automotive Applications. Automot. Innov. 2020, 3, 280–295. [Google Scholar] [CrossRef]

- Bilisik, K. Three-Dimensional Braiding for Composites: A Review. Text. Res. J. 2013, 83, 1414–1436. [Google Scholar] [CrossRef]

- Kyosev, Y. (Ed.) Advances in Braiding Technology: Specialized Techniques and Applications; Woodhead Publishing Series in Textiles; Woodhead Publishing: Oxford, UK, 2016; ISBN 978-0-08-100926-0. [Google Scholar]

- Gu, Q.; Quan, Z.; Yu, J.; Yan, J.; Sun, B.; Xu, G. Structural Modeling and Mechanical Characterizing of Three-Dimensional Four-Step Braided Composites: A Review. Compos. Struct. 2019, 207, 119–128. [Google Scholar] [CrossRef]

- Hill, R. Elastic Properties of Reinforced Solids: Some Theoretical Principles. J. Mech. Phys. Solids 1963, 11, 357–372. [Google Scholar] [CrossRef]

- Wang, Y.Q. On the Topological Yarn Structure of 3-D Rectangular and Tubular Braided Preforms. Compos. Sci. Technol. 1994, 51, 575–586. [Google Scholar] [CrossRef]

- Chen, L.; Tao, X.; Choy, C. A Structural Analysis of Three-Dimensional Braids. J. China Text. Univ. 1997, 14, 8–13. [Google Scholar]

- Zhang, C.; Xu, X.; Chen, K. Application of Three Unit-Cells Models on Mechanical Analysis of 3D Five-Directional and Full Five-Directional Braided Composites. Appl. Compos. Mater. 2013, 20, 803–825. [Google Scholar] [CrossRef]

- Byun, J.-H.; Chou, T.-W. Process-Microstructure Relationships of 2-Step and 4-Step Braided Composites. Compos. Sci. Technol. 1996, 56, 235–251. [Google Scholar] [CrossRef]

- Mendoza, A.; Schneider, J.; Parra, E.; Roux, S. Measuring Yarn Deformations Induced by the Manufacturing Process of Woven Composites. Compos. Part A Appl. Sci. Manuf. 2019, 120, 127–139. [Google Scholar] [CrossRef] [Green Version]

- Blacklock, M.; Shaw, J.H.; Zok, F.W.; Cox, B.N. Virtual Specimens for Analyzing Strain Distributions in Textile Ceramic Composites. Compos. Part A Appl. Sci. Manuf. 2016, 85, 40–51. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Zhang, D.; Sun, J.; Yu, S.; Dai, Y.; Zhang, Z.; Sun, J.; Li, G.; Qian, K. Refine Reconstruction and Verification of Meso-Scale Modeling of Three-Dimensional Five-Directional Braided Composites from X-Ray Computed Tomography Data. Compos. Struct. 2020, 245, 112347. [Google Scholar] [CrossRef]

- Fang, G.; Chen, C.; Yuan, S.; Meng, S.; Liang, J. Micro-Tomography Based Geometry Modeling of Three-Dimensional Braided Composites. Appl. Compos. Mater. 2018, 25, 469–483. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, X. Digital-Element Simulation of Textile Processes. Compos. Sci. Technol. 2001, 61, 311–319. [Google Scholar] [CrossRef]

- Zhou, G.; Sun, X.; Wang, Y. Multi-Chain Digital Element Analysis in Textile Mechanics. Compos. Sci. Technol. 2004, 64, 239–244. [Google Scholar] [CrossRef]

- Ewert, A.; Drach, B.; Vasylevskyi, K.; Tsukrov, I. Predicting the Overall Response of an Orthogonal 3D Woven Composite Using Simulated and Tomography-Derived Geometry. Compos. Struct. 2020, 243, 112–169. [Google Scholar] [CrossRef]

- Huang, L.; Wang, Y.; Miao, Y.; Swenson, D.; Ma, Y.; Yen, C.-F. Dynamic Relaxation Approach with Periodic Boundary Conditions in Determining the 3-D Woven Textile Micro-Geometry. Compos. Struct. 2013, 106, 417–425. [Google Scholar] [CrossRef]

- Razavi, S.; Iannucci, L. Simulation of the Braiding Process in LS-DYNA®. In Proceedings of the 15th International LS-DYNA® User Conference, Detroit, MI, USA, 10–12 June 2018; 1004. [Google Scholar]

- Mahadik, Y.; Hallett, S.R. Finite Element Modelling of Tow Geometry in 3D Woven Fabrics. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1192–1200. [Google Scholar] [CrossRef] [Green Version]

- Green, S.D.; Matveev, M.Y.; Long, A.C.; Ivanov, D.; Hallett, S.R. Mechanical Modelling of 3D Woven Composites Considering Realistic Unit Cell Geometry. Compos. Struct. 2014, 118, 284–293. [Google Scholar] [CrossRef] [Green Version]

- Green, S.D.; Long, A.C.; El Said, B.S.F.; Hallett, S.R. Numerical Modelling of 3D Woven Preform Deformations. Compos. Struct. 2014, 108, 747–756. [Google Scholar] [CrossRef] [Green Version]

- Daelemans, L.; Faes, J.; Allaoui, S.; Hivet, G.; Dierick, M.; Van Hoorebeke, L.; Van Paepegem, W. Finite Element Simulation of the Woven Geometry and Mechanical Behaviour of a 3D Woven Dry Fabric under Tensile and Shear Loading Using the Digital Element Method. Compos. Sci. Technol. 2016, 137, 177–187. [Google Scholar] [CrossRef]

- Hans, T.; Cichosz, J.; Brand, M.; Hinterhölzl, R. Finite Element Simulation of the Braiding Process for Arbitrary Mandrel Shapes. Compos. Part A Appl. Sci. Manuf. 2015, 77, 124–132. [Google Scholar] [CrossRef]

- Ghaedsharaf, M.; Brunel, J.-E.; Lebel, L.L. Fiber-Level Numerical Simulation of Biaxial Braids for Mesoscopic Morphology Prediction Validated by X-Ray Computed Tomography Scan. Compos. Part B Eng. 2021, 218, 108938. [Google Scholar] [CrossRef]

- Ghaedsharaf, M.; Brunel, J.-E.; Laberge Lebel, L. Multiscale Numerical Simulation of the Forming Process of Biaxial Braids during Thermoplastic Braid-Trusion: Predicting 3D and Internal Geometry and Fiber Orientation Distribution. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106637. [Google Scholar] [CrossRef]

- Yang, Z.; Jiao, Y.; Xie, J.; Chen, L.; Jiao, W.; Li, X.; Zhu, M. Modeling of 3D Woven Fibre Structures by Numerical Simulation of the Weaving Process. Compos. Sci. Technol. 2021, 206, 108679. [Google Scholar] [CrossRef]

- Mengsteab, P.Y.; Freeman, J.; Barajaa, M.A.; Nair, L.S.; Laurencin, C.T. Ligament Regenerative Engineering: Braiding Scalable and Tunable Bioengineered Ligaments Using a Bench-Top Braiding Machine. Regen. Eng. Transl. Med. 2021, 7, 524–532. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Miao, Y.; Swenson, D.; Cheeseman, B.A.; Yen, C.-F.; LaMattina, B. Digital Element Approach for Simulating Impact and Penetration of Textiles. Int. J. Impact Eng. 2010, 37, 552–560. [Google Scholar] [CrossRef]

- Abaqus-6.14. Theory Manual. Available online: http://130.149.89.49:2080/v6.14/ (accessed on 10 July 2022).

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental Algorithms for Scientific Computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef] [Green Version]

- Yu, X.-W.; Wang, H.; Wang, Z.-W. Analysis of Yarn Fiber Volume Fraction in Textile Composites Using Scanning Electron Microscopy and X-Ray Micro-Computed Tomography. J. Reinf. Plast. Compos. 2019, 38, 199–210. [Google Scholar] [CrossRef]

- Daelemans, L.; Tomme, B.; Caglar, B.; Michaud, V.; Van Stappen, J.; Cnudde, V.; Boone, M.; Van Paepegem, W. Kinematic and Mechanical Response of Dry Woven Fabrics in Through-Thickness Compression: Virtual Fiber Modeling with Mesh Overlay Technique and Experimental Validation. Compos. Sci. Technol. 2021, 207, 108706. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Mazloomi, M.S. A New Analytical Model for Calculation of Stiffness of Three-Dimensional Four-Directional Braided Composites. Compos. Struct. 2012, 94, 1005–1015. [Google Scholar] [CrossRef]

- Chao, Z.; Xu, X. Finite element analysis of 3D braided composites based on three unit-cells models. Compos. Struct. 2013, 98, 130–142. [Google Scholar] [CrossRef]

- Naik, N.K.; Kuchibhotla, R. Analytical Study of Strength and Failure Behaviour of Plain Weave Fabric Composites Made of Twisted Yarns. Compos. Part A Appl. Sci. Manuf. 2002, 33, 697–708. [Google Scholar] [CrossRef]

- Hao, W.; Liu, Y.; Huang, X.; Liu, Y.; Zhu, J. A Unit-Cell Model for Predicting the Elastic Constants of 3D Four Directional Cylindrical Braided Composite Shafts. Appl. Compos. Mater. 2018, 25, 619–633. [Google Scholar] [CrossRef]

- Hao, W.; Huang, Z.; Zhang, L.; Zhao, G.; Luo, Y. Study on the Torsion Behavior of 3-D Braided Composite Shafts. Compos. Struct. 2019, 229, 111384. [Google Scholar] [CrossRef]

| Take-up distance of the preform in one machine cycle |

| Distance between every two adjacent carriers D |

| The tension force of carrier F |

| The braiding interweaving height H |

| Density (g/cm3) | 1.8 |

| Number of fibers per yarn | 12,000 |

| Modulus of elasticity (GPa) | 230 |

| Coefficient of friction among yarns | 0.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Wang, H.; Chen, Y.; Wang, Y. A Methodology to Obtain the Accurate RVEs by a Multiscale Numerical Simulation of the 3D Braiding Process. Polymers 2022, 14, 4210. https://doi.org/10.3390/polym14194210

Zhou W, Wang H, Chen Y, Wang Y. A Methodology to Obtain the Accurate RVEs by a Multiscale Numerical Simulation of the 3D Braiding Process. Polymers. 2022; 14(19):4210. https://doi.org/10.3390/polym14194210

Chicago/Turabian StyleZhou, Wei, Hui Wang, Yizhe Chen, and Yaoyao Wang. 2022. "A Methodology to Obtain the Accurate RVEs by a Multiscale Numerical Simulation of the 3D Braiding Process" Polymers 14, no. 19: 4210. https://doi.org/10.3390/polym14194210