Effect of Accelerated Aging on Bamboo Fiber Lunch Box and Correlation with Soil Burial Degradation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods of Accelerated Aging

- The damp–heat treatment method referred to the national standard GB/T 22894-2008 “Paper and board-Accelerated ageing-Moist heat treatment at 80 °C and 65% relative humidity” [25]. The test temperature and humidity were adjusted as follows: temperature 98 °C ± 2 °C, humidity 95% ± 5% relative humidity. After 12, 24, 36, 48, and 60 h, the samples were taken, baked at 103 °C until they were absolutely dry, and placed under 0% humidity for 1 week.

- The freeze–thaw cycle method referred to Ref. [26], and some of the test parameters were modified in this study to suit the lunch box material. First, the lunch box specimens were immersed in water at 20 °C for 3 h, then placed in a constant-temperature water bath at 98 °C for 3 h, followed by in an environment of −20 °C for 20 h, and finally heated in an oven at 60 °C for 3 h. The aforementioned steps were one cycle. After 1, 3, 5, 7, and 9 cycles, the samples were taken, baked at 103 °C until they were absolutely dry, and placed under 0% humidity for 1 week.

- Artificial weathering cycle method referred to the national standard GB/T 16422.3-2014 “Plastic-Methods of exposure to laboratory light sources-Part 3: Fluorescent UV lamps” [27]. The lunch box specimens were put in an ultraviolet (UV) weathering test machine (IX-2130A, Guangdong Aisirui Instrument Technology Co., Ltd., Dongguan, China) equipped with two UVA-340 lamps (H358, Q-Lab Corporation, Westlake, OH, USA). A cycle was set for 8 h of UV light and 4 h of constant-temperature water bath heating at 60 °C. After 3, 7, 11, 15, and 19 cycles, the samples were taken, baked at 103 °C until they were absolutely dry, and placed under 0% humidity for 1 week.

2.3. Soil Burial Degradation

2.4. Mechanical Properties

2.5. Dynamic Thermomechanical Properties

2.6. Chemical Group

2.7. Relative Crystallinity

3. Results and Discussion

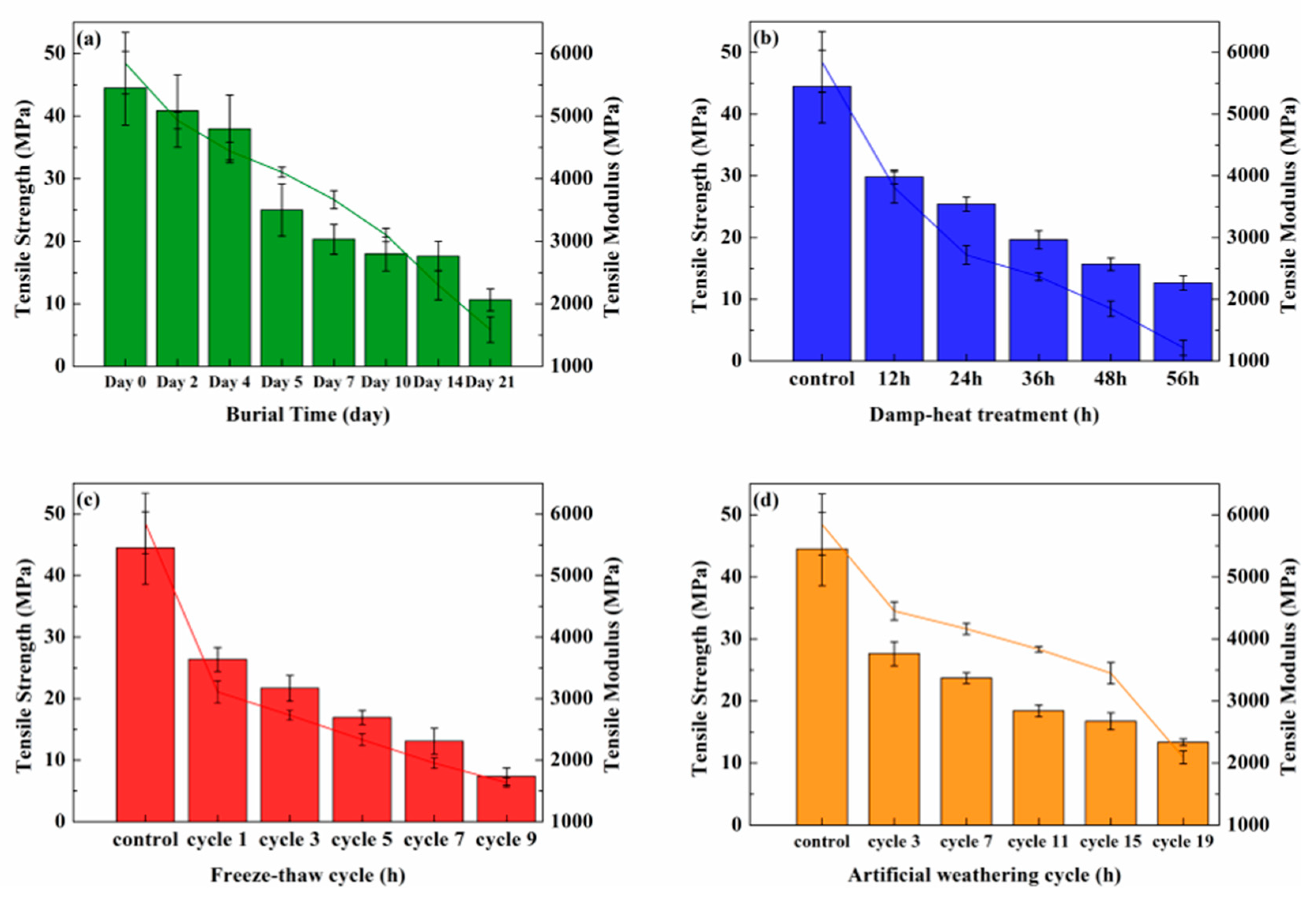

3.1. Mechanical Properties

3.2. Dynamic Thermomechanical Properties

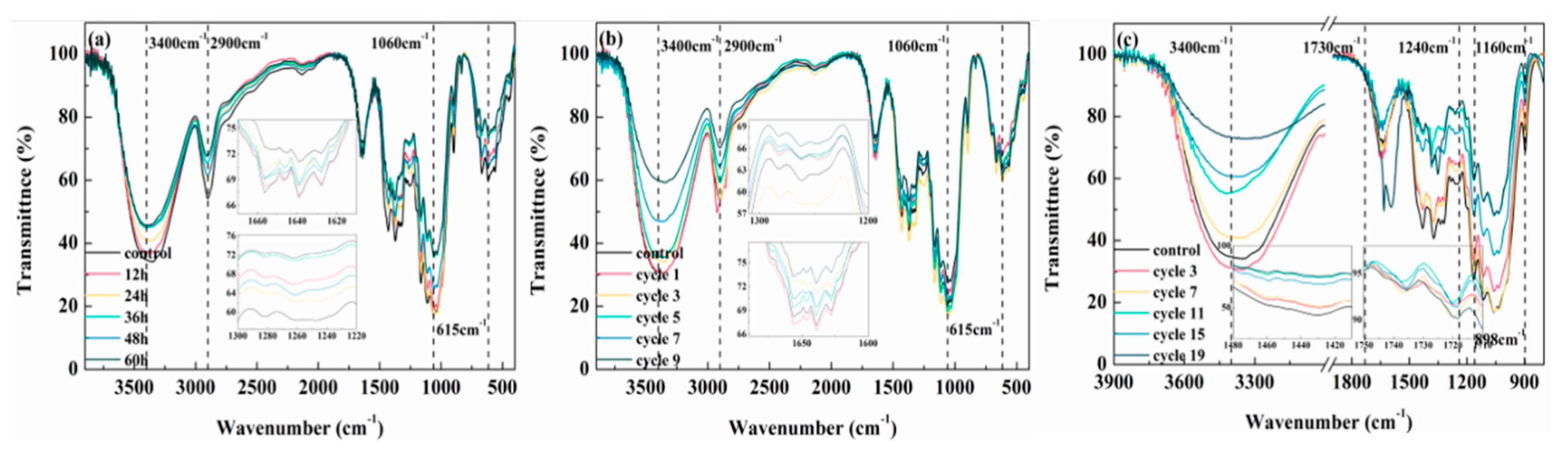

3.3. Fourier Transform Infrared Spectroscopy

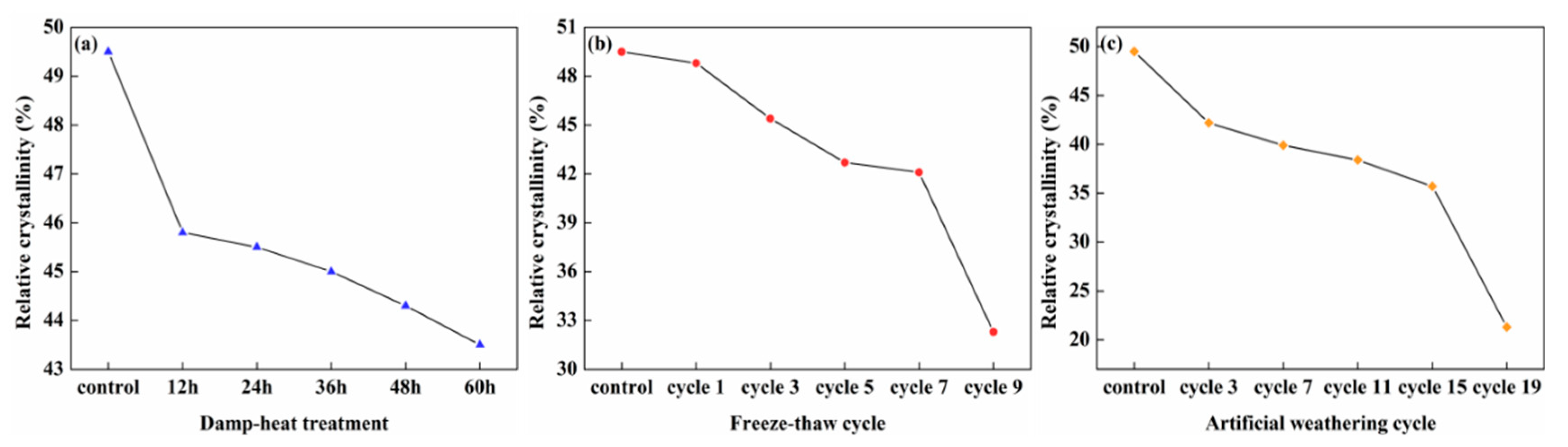

3.4. Relative Crystallinity

3.5. Comparison of Accelerated Aging Test Results

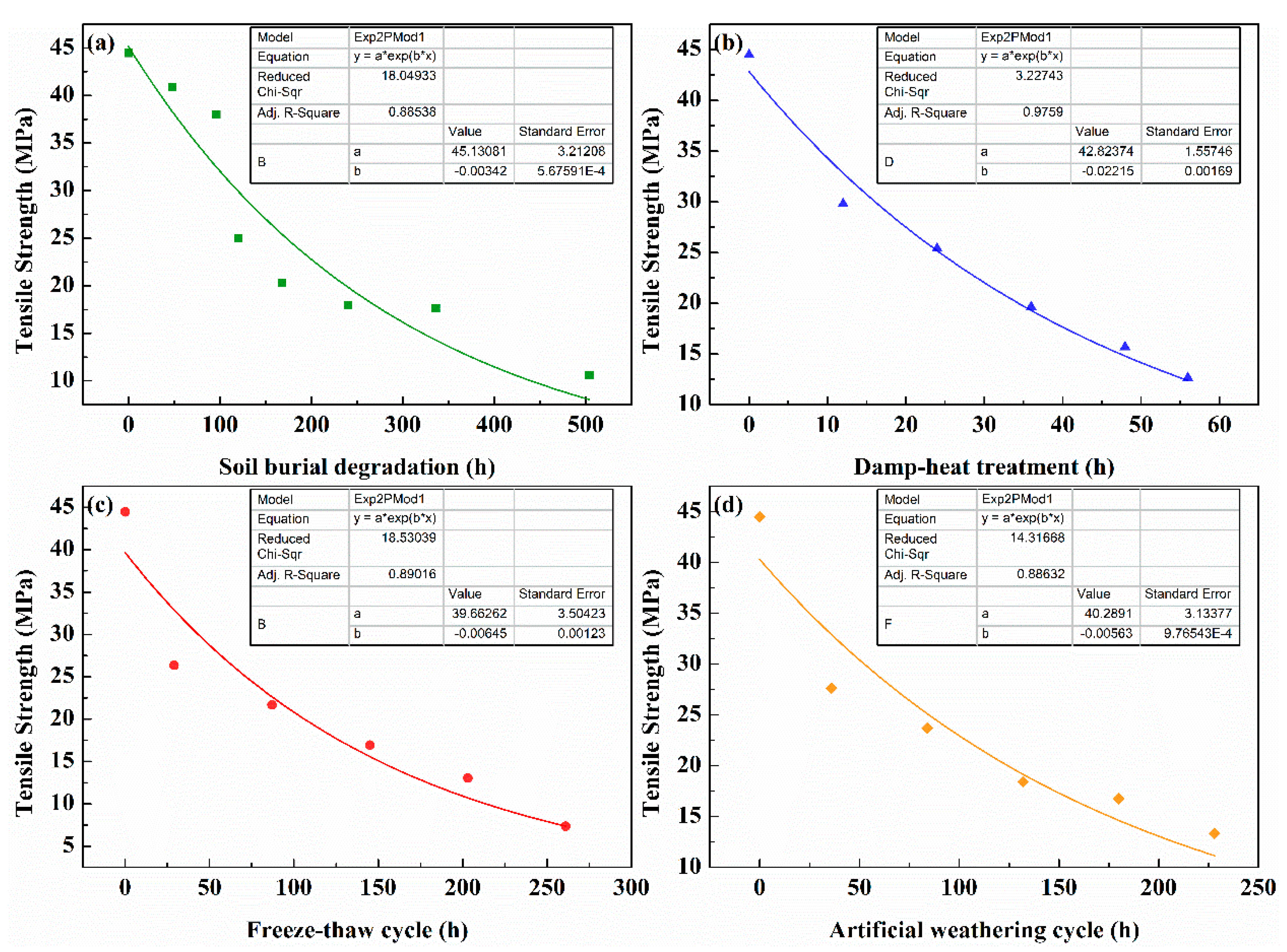

3.5.1. Comparison of Correlation Analysis of Tensile Strength of Lunch Boxes after Accelerated Aging

3.5.2. Correlation Analysis of Accelerated Aging and Soil Burial Degradation

4. Conclusions

- Freeze–thaw cycle had the most severe effects, with the greatest impact on lunch box performance degradation. It showed 7.4 MPa strength and 32.3% relative crystallinity at 9 cycles, a significant decrease in cellulose and hemicellulose content. The strength and crystallinity of damp–heat treatment were 12.6 MPa and 43.5% after 56 h. The lignin of the lunch box under artificial weathering cycle underwent massive decomposition, and the strength and relative crystallinity were 13.4 MPa and 21.5% after 19 cycles.

- When establishing the correlation between accelerated ageing and soil burial degradation, the tensile modulus is not as significant as the tensile strength. The damp–heat treatment was used to estimate the decay law of soil burial degradation tensile strength of the bamboo fiber lunch boxes and was more stable and reliable than the SAF fluctuation of freeze–thaw cycle and artificial weathering cycle. Additionally, the generalized calculation of the aging acceleration factor based on aging time was restricted. In the study of accelerated aging of meal boxes, acceleration factors, such as irradiation, can be used as a reference for prediction, and these merit further investigation in the future.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Souza Machado, A.A.; Kloas, W.; Zarfl, C.; Hempel, S.; Rillig, M.C. Microplastics as an emerging threat to terrestrial ecosystems. Glob. Chang. Biol. 2018, 24, 1405–1416. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pabortsava, K.; Lampitt, R.S. High concentrations of plastic hidden beneath the surface of the Atlantic Ocean. Nat. Commun. 2020, 11, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Van Cauwenberghe, L.; Devriese, L.; Galgani, F.; Robbens, J.; Janssen, C.R. Microplastics in sediments: A review of techniques, occurrence and effects. Mar. Environ. Res. 2015, 111, 5–17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, Y.; Shan, Y.; Guan, D.; Liang, X.; Cai, Y.; Liu, J.; Xie, W.; Xue, J.; Ma, Z.; Yang, Z. Sharing tableware reduces waste generation, emissions and water consumption in China’s takeaway packaging waste dilemma. Nat. Food 2020, 1, 552–561. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, T.; Piché-Choquette, S.; Wang, G.; Li, J. Microplastic Pollution in China, an Invisible Threat Exacerbated by Food Delivery Services. Bull. Environ. Contam. Toxicol. 2021, 107, 778–785. [Google Scholar] [CrossRef]

- Gautam, A.M.; Caetano, N. Study, design and analysis of sustainable alternatives to plastic takeaway cutlery and crockery. Energy Procedia 2017, 136, 507–512. [Google Scholar] [CrossRef]

- Dybka-Stępień, K.; Antolak, H.; Kmiotek, M.; Piechota, D.; Koziróg, A. Disposable Food Packaging and Serving Materials—Trends and Biodegradability. Polymers 2021, 13, 3606. [Google Scholar] [CrossRef]

- Iewkittayakorn, J.; Khunthongkaew, P.; Wongnoipla, Y.; Kaewtatip, K.; Suybangdum, P.; Sopajarn, A. Biodegradable plates made of pineapple leaf pulp with biocoatings to improve water resistance. J. Mater. Res. Technol. 2020, 9, 5056–5066. [Google Scholar] [CrossRef]

- Semple, K.E.; Zhou, C.; Rojas, O.J.; Nkeuwa, W.N.; Dai, C. Moulded pulp fibers for disposable food packaging: A state-of-the-art review. Food Packag. Shelf Life 2022, 33, 100908. [Google Scholar] [CrossRef]

- Ferreira, D.C.; Molina, G.; Pelissari, F.M. Biodegradable trays based on cassava starch blended with agroindustrial residues. Compos. Part B Eng. 2020, 183, 107682. [Google Scholar] [CrossRef]

- Liu, C.; Luan, P.; Li, Q.; Cheng, Z.; Sun, X.; Cao, D.; Zhu, H. Biodegradable, hygienic, and compostable tableware from hybrid sugarcane and bamboo fibers as plastic alternative. Matter 2020, 3, 2066–2079. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, G.; Chen, F.; Chen, X.; Wei, X. Degradation Characteristics of Environment-Friendly Bamboo Fiber Lunch Box Buried in the Soil. Forests 2022, 13, 1008. [Google Scholar] [CrossRef]

- Buxoo, S.; Jeetah, P. Feasibility of producing biodegradable disposable paper cup from pineapple peels, orange peels and Mauritian hemp leaves with beeswax coating. SN Appl. Sci. 2020, 2, 1–15. [Google Scholar] [CrossRef]

- Célino, A.; Fréour, S.; Jacquemin, F.; Casari, P. The hygroscopic behavior of plant fibers: A review. Front. Chem. 2014, 1, 43. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zabler, S.; Paris, O.; Burgert, I.; Fratzl, P. Moisture changes in the plant cell wall force cellulose crystallites to deform. J. Struct. Biol. 2010, 171, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, H.; Sujan, K.C.; Matsuo-Ueda, M.; Yoshida, M.; Chen, S. Microscopic mechanism of contraction of tension wood G-fiber due to boiling. Cellulose 2022, 29, 7935–7954. [Google Scholar] [CrossRef]

- Tian, Z.; Xiao, S.L.; Wang, Q.L. Effects of temperature, humidity and Ultraviolet aging on properties of pulp molding materials. Packag. Eng. 2019, 40, 8. (In Chinese) [Google Scholar]

- Berry, T.M.; Ambaw, A.; Defraeye, T.; Coetzee, C.; Opara, U.L. Moisture adsorption in palletised corrugated fibreboard cartons under shipping conditions: A CFD modelling approach. Food Bioprod. Process. 2019, 114, 43–59. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Effects of the accelerated freeze-thaw cycling on physical and mechanical properties of wood flour-recycled thermoplastic composites. Polym. Compos. 2010, 31, 185–194. [Google Scholar] [CrossRef]

- Muhamad, I.I.; Zahan, K.A.; Pa’e, N.; Salehudin, M.H.; Khairuddin, N.; Marsin, A.M.; Salleh, E. Accelerated testing methodology for long-term life prediction of cellulose-based polymeric composite materials. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publisher: Sawston, UK, 2019; pp. 149–171. [Google Scholar]

- Plota, A.; Masek, A. Lifetime prediction methods for degradable polymeric materials—A short review. Materials 2020, 13, 4507. [Google Scholar] [CrossRef]

- Giv, A.N.; Fu, Q.; Yan, L.; Kasal, B. Durability and life prediction of fiber-reinforced polymer composites. In Composite Materials; Elsevier: Amsterdam, The Netherlands, 2021; pp. 179–203. [Google Scholar]

- Gao, C.G.; Zhou, C.W. Environmental Factor Equivalent Accelerated Aging Test Method for Composites. Eng. Plast. Appl. 2020, 48, 6. (In Chinese) [Google Scholar]

- Sun, Y.; Wang, D.X.; Liu, Y.P.; Li, H. Correlation of accelerated aging and natural aging of glass fiber reinforced bromide epoxy vinyl ester composites. Acta Mater. Compos. Sin. 2014, 31, 916–924. (In Chinese) [Google Scholar]

- GB/T 22894-2008; Paper and Board-Accelerated Ageing-Moist Heat Treatment at 80 °C and 65% Relative Humidity. National Standards of P. R. China: Beijing, China, 2009. Available online: https://ishare.iask.sina.com.cn/f/f48ZJQ48l1.html (accessed on 1 September 2009).

- Zhou, X.; Huang, S.; Su, G.; Yu, Y.; Chen, L. Freeze-thaw cycles weathering degrading properties of bamboo flour-polypropylene foamed composites. Trans. Chin. Soc. Agric. Eng. 2014, 30, 285–292. [Google Scholar]

- GB/T 16422.3-2014; Plastic-Methods of Exposure to Laboratory Light Sources-Part 3: Fluorescent UV Lamps. National Standards of P. R. China: Beijing, China, 2014. Available online: https://max.book118.com/html/2015/0312/8047001027000015.shtm (accessed on 1 December 2014).

- GB/T 19275-2003; Evaluation of the Potential Biodegradation and Disintegration Ability of Materials under the Action of Specific Microorganisms. National Standards of P. R. China: Beijing, China, 2003. Available online: https://max.book118.com/html/2018/0427/163421514.shtm (accessed on 2 February 2004).

- GB/T 1040.3-2006; Plastic-Determination of Tensile Properties-Part 3: Test Conditions for Films and Sheets. National Standards of P. R. China: Beijing, China, 2007. Available online: https://max.book118.com/html/2020/0601/8061045061002114.shtm (accessed on 1 February 2007).

- Lionetto, F.; Del Sole, R.; Cannoletta, D.; Vasapollo, G.; Maffezzoli, A. Monitoring wood degradation during weathering by cellulose crystallinity. Materials 2012, 5, 1910–1922. [Google Scholar] [CrossRef]

- Chen, X.; Deng, L.; Wei, X.; Li, M.; Wang, G.; Chen, F. Measuring the damping performance of gradient-structured bamboo using the resonance method. Forests 2021, 12, 1654. [Google Scholar] [CrossRef]

- Wei, X.; Yuan, J.; Wang, G.; Chen, F.; Chen, X.; Jiang, H.; Smith, L.M.; Deng, J. Effect of chemical composition and cell structure on water vapor sorption behavior of parenchyma cells and fiber cells in moso bamboo (Phyllostachys edulis). Ind. Crops Prod. 2022, 178, 114652. [Google Scholar] [CrossRef]

- Wohlert, M.; Benselfelt, T.; Wågberg, L.; Furó, I.; Berglund, L.A.; Wohlert, J. Cellulose and the role of hydrogen bonds: Not in charge of everything. Cellulose 2021, 29, 1–23. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Ragauskas, A.J. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos. Part B 2020, 200, 108254. [Google Scholar] [CrossRef]

- Gong, X.; Zhao, S.; Chen, L. Properties of accelerated weathering of tea stalk/polypropylene composites. Trans. Chin. Soc. Agric. Eng. 2015, 31, 308–314. [Google Scholar]

- Bao, L.R.; Yee, A.F.; Lee, C.Y.C. Moisture absorption and hygrothermal aging in a bismaleimide resin. Polymer 2001, 42, 7327–7333. [Google Scholar] [CrossRef]

- Kim, Y.S.; Lee, K.H.; Kim, J.S. Weathering characteristics of bamboo (Phyllostachys puberscence) exposed to outdoors for one year. J. Wood Sci. 2016, 62, 332–338. [Google Scholar] [CrossRef] [Green Version]

- Rao, F.; Li, X.; Li, N.; Li, L.; Liu, Q.; Wang, J.; Chen, Y. Photodegradation and Photostability of Bamboo: Recent Advances. ACS Omega 2022, 7, 24041–24047. [Google Scholar] [CrossRef] [PubMed]

- Tanpichai, S.; Witayakran, S.; Srimarut, Y.; Woraprayote, W.; Malila, Y. Porosity, density and mechanical properties of the paper of steam exploded bamboo microfibers controlled by nanofibrillated cellulose. J. Mater. Res. Technol. 2019, 8, 3612–3622. [Google Scholar] [CrossRef]

- Zhang, W.G.; Wang, Z.; Jin, C.D. Experimental investigation of dynamic viscoelasticity of Bamboo with different ages. Appl. Mech. Mater. 2014, 651, 236–240. [Google Scholar] [CrossRef]

- Chen, X.; Chen, F.; Wang, G.; Ma, X.; Wang, J.; Deng, J. Eco-friendly, disposable bamboo fiber dishware: Static and dynamic mechanical properties and creep behavior. Ind. Crops Prod. 2022, 187, 115305. [Google Scholar] [CrossRef]

- Lyu, J.; Peng, H.; Cao, J.; Jiang, J.; Zhao, R.; Gao, Y. Application of dynamic mechanical analysis in wood science research. J. For. Eng. 2018, 3, 1–11. [Google Scholar]

- Skurydin, Y.G.; Skurydina, E.M. Digital differential spectrometry in the assessment of the structural characteristics of wood and wooden composite materials. IOP Conf. Ser. Earth Environ. Sci. 2021, 806, 012030. [Google Scholar] [CrossRef]

- Startsev, O.V.; Makhonkov, A.; Erofeev, V.; Gudojnikov, S. Impact of moisture content on dynamic mechanical properties and transition temperatures of wood. Wood Mater. Sci. Eng. 2017, 12, 55–62. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Fei, B.; Xu, X.; Lian, C.P.; Chen, H. The mechanical properties and thermal conductivity of bamboo with freeze–thaw treatment. J. Wood Sci. 2021, 67, 1–9. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, D.; Huang, X.; Song, L.; Gu, W.; Liang, X.; Li, Y.; Xu, B. Effect of high-temperature saturated steam treatment on the physical, chemical, and mechanical properties of moso bamboo. J. Wood Sci. 2020, 66, 52. [Google Scholar] [CrossRef]

- Li, X.; Peng, H.; Niu, S.; Liu, X.; Li, Y. Effect of High-Temperature Hydrothermal Treatment on Chemical, Mechanical, Physical, and Surface Properties of Moso Bamboo. Forests 2022, 13, 712. [Google Scholar] [CrossRef]

- Wang, X.Q.; Ren, H.Q. Surface deterioration of moso bamboo (Phyllostachys pubescens) induced by exposure to artificial sunlight. J. Wood Sci. 2009, 55, 47–52. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Ma, H.X.; Qi, Y.; Zhu, R.X.; Li, X.W.; Yu, W.J.; Rao, F. Study of the long-term degradation behavior of bamboo scrimber under natural weathering. NPJ Mater. Degrad. 2022, 6, 1–10. [Google Scholar] [CrossRef]

- Ying, L.; Wang, Y.; Liu, X.; Zhuang, Q.; Han, Z. Correlation between accelerated aging and natural aging of PBO fiber. J. Solid Rocket. Technol. 2013, 1, 6. (In Chinese) [Google Scholar]

| Descriptive Statistics | ||||||

| Mean | Std. Deviation | N | ||||

| Soil burial degradation | Strength | 26.8488 | 12.54872 | 8 | ||

| Modulus | 3747.6625 | 1394.17945 | 8 | |||

| Damp–heat treatment | Strength | 24.6033 | 11.57316 | 6 | ||

| Modulus | 2968.0350 | 1657.44982 | 6 | |||

| Freeze–thaw cycle | Strength | 21.6417 | 12.98841 | 6 | ||

| Modulus | 2933.4467 | 1521.02674 | 6 | |||

| Artificial weathering cycle | Strength | 24.0417 | 11.22202 | 6 | ||

| Modulus | 3972.1533 | 1232.36292 | 6 | |||

| Correlations | ||||||

| Soil burial degradation | Damp–heat treatment | Freeze–thaw cycle | Artificial weathering cycle | |||

| Soil burial degradation | Pearson Correlation | Strength | 1 | 0.920 ** | 0.894 * | 0.876 * |

| Modulus | 1 | 0.983 ** | 0.936 ** | 0.980 ** | ||

| Sig.(2-tailed) | Strength | 0.009 | 0.016 | 0.022 | ||

| Modulus | 0.000 | 0.006 | 0.001 | |||

| Sums of Squares and Cross-products | Strength | 1102.293 | 605.105 | 660.240 | 558.926 | |

| Modulus | 13,606,154.39 | 7,871,195.294 | 6,879,026.470 | 5,833,421.266 | ||

| Covariance | Strength | 157.470 | 121.021 | 132.048 | 111.785 | |

| Modulus | 1,943,736.341 | 1,574,239.059 | 1,375,805.294 | 1,166,684.253 | ||

| N | Strength | 8 | 6 | 6 | 6 | |

| Modulus | 8 | 6 | 6 | 6 | ||

| Damp–heat treatment | Pearson Correlation | Strength | 0.920 ** | 1 | 0.997 ** | 0.994 ** |

| Modulus | 0.983 ** | 1 | 0.977 ** | 0.950 ** | ||

| Sig.(2-tailed) | Strength | 0.009 | 0.000 | 0.000 | ||

| Modulus | 0.000 | 0.001 | 0.004 | |||

| Sums of Squares and Cross-products | Strength | 605.105 | 669.691 | 749.011 | 645.206 | |

| Modulus | 7,871,195.294 | 13,735,699.58 | 12,314,439.88 | 9,704,258.728 | ||

| Covariance | Strength | 121.021 | 133.938 | 149.802 | 129.041 | |

| Modulus | 1,574,239.059 | 2,747,139.916 | 2,462,887.976 | 1,940,851.746 | ||

| N | Strength | 6 | 6 | 6 | 6 | |

| Modulus | 6 | 6 | 6 | 6 | ||

| Freeze–thaw cycle | Pearson Correlation | Strength | 0.894 * | 0.997 ** | 1 | 0.995 ** |

| Modulus | 0.936 ** | 0.977 ** | 1 | 0.911 * | ||

| Sig.(2-tailed) | Strength | 0.016 | 0.000 | 0.000 | ||

| Modulus | 0.006 | 0.001 | 0.012 | |||

| Sums of Squares and Cross-products | Strength | 660.240 | 749.011 | 843.493 | 725.250 | |

| Modulus | 6,879,026.470 | 12,314,439.88 | 11,567,611.77 | 8,539,016.058 | ||

| Covariance | Strength | 132.048 | 149.802 | 168.699 | 145.050 | |

| Modulus | 1,375,805.294 | 2,462,887.976 | 2,313,522.353 | 1,707,803.212 | ||

| N | Strength | 6 | 6 | 6 | 6 | |

| Modulus | 6 | 6 | 6 | 6 | ||

| Artificial weathering cycle | Pearson Correlation | Strength | 0.876 * | 0.994 ** | 0.995 ** | 1 |

| Modulus | 0.980 ** | 0.950 ** | 0.911 ** | 1 | ||

| Sig.(2-tailed) | Strength | 0.022 | 0.000 | 0.000 | ||

| Modulus | 0.001 | 0.004 | 0.012 | |||

| Sums of Squares and Cross-products | Strength | 558.926 | 645.206 | 725.250 | 629.668 | |

| Modulus | 5,833,421.266 | 9,704,258.728 | 8,539,016.058 | 7,593,591.892 | ||

| Covariance | Strength | 111.785 | 129.041 | 145.050 | 125.934 | |

| Modulus | 1,166,684.253 | 1,940,851.746 | 1,707,803.212 | 1,518,718.378 | ||

| N | Strength | 6 | 6 | 6 | 6 | |

| Modulus | 6 | 6 | 6 | 6 | ||

| Fitted Objects | Fitting Type | Mean Square | Df | R2 | F | Sig.F | |

|---|---|---|---|---|---|---|---|

| Soil degradation | Strength | Linear | 874.166 | 1 | 0.793 | 22.992 | 0.003 |

| 38.021 | 6 | ||||||

| Exponential | 1.567 | 1 | 0.900 | 53.714 | 0.000 | ||

| 0.029 | 6 | ||||||

| Modulus | Linear | 12,904,038.14 | 1 | 0.948 | 110.273 | 0.000 | |

| 117,019.374 | 6 | ||||||

| Exponential | 1.278 | 1 | 0.997 | 2150.041 | 0.000 | ||

| 0.001 | 6 | ||||||

| Damp–heat treatment | Strength | Linear | 623.422 | 1 | 0.931 | 53.896 | 0.002 |

| 11.567 | 4 | ||||||

| Exponential | 1.027 | 1 | 0.988 | 331.036 | 0.000 | ||

| 0.003 | 4 | ||||||

| Modulus | Linear | 12,499,537.15 | 1 | 0.910 | 40.446 | 0.003 | |

| 309,040.606 | 4 | ||||||

| Exponential | 1.460 | 1 | 0.970 | 128.712 | 0.000 | ||

| 0.011 | 4 | ||||||

| Freeze–thaw cycle | Strength | Linear | 707.240 | 1 | 0.838 | 20.762 | 0.010 |

| 34.063 | 4 | ||||||

| Exponential | 1.806 | 1 | 0.950 | 76.528 | 0.001 | ||

| 0.024 | 4 | ||||||

| Modulus | Linear | 7,966,935.369 | 1 | 0.689 | 8.850 | 0.041 | |

| 900,169.100 | 4 | ||||||

| Exponential | 0.840 | 1 | 0.844 | 21.571 | 0.010 | ||

| 0.039 | 4 | ||||||

| Artificial weathering cycle | Strength | Linear | 515.231 | 1 | 0.818 | 18.003 | 0.013 |

| 28.609 | 4 | ||||||

| Exponential | 0.845 | 1 | 0.931 | 53.719 | 0.002 | ||

| 0.016 | 4 | ||||||

| Modulus | Linear | 6,861,510.934 | 1 | 0.904 | 37.490 | 0.004 | |

| 183,020.239 | 4 | ||||||

| Exponential | 0.509 | 1 | 0.874 | 27.665 | 0.006 | ||

| 0.018 | 4 |

| Tensile Strength /MPa | Aging Time/h | SAF | |||||

|---|---|---|---|---|---|---|---|

| Soil Degradation | Damp–Heat Treatment | Freeze–Thaw Cycle | Artificial Weathering Cycle | Damp–Heat Treatment | Freeze–Thaw Cycle | Artificial Weathering Cycle | |

| 30 | 119.4 | 16.1 | 43.3 | 52.4 | 7.4 | 2.7 | 2.3 |

| 25 | 172.7 | 24.3 | 71.6 | 84.7 | 7.1 | 2.4 | 2.0 |

| 20 | 237.9 | 34.4 | 106.2 | 124.4 | 6.9 | 2.2 | 1.9 |

| 15 | 322.1 | 47.4 | 150.7 | 175.5 | 6.8 | 2.1 | 1.8 |

| 10 | 440.6 | 65.6 | 213.6 | 247.5 | 6.7 | 2.0 | 1.7 |

| 5 | 643.3 | 96.9 | 321.1 | 370.6 | 6.6 | 2.0 | 1.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Wang, G.; Chen, F.; Deng, J.; Chen, X. Effect of Accelerated Aging on Bamboo Fiber Lunch Box and Correlation with Soil Burial Degradation. Polymers 2022, 14, 4220. https://doi.org/10.3390/polym14194220

Jiang H, Wang G, Chen F, Deng J, Chen X. Effect of Accelerated Aging on Bamboo Fiber Lunch Box and Correlation with Soil Burial Degradation. Polymers. 2022; 14(19):4220. https://doi.org/10.3390/polym14194220

Chicago/Turabian StyleJiang, Huan, Ge Wang, Fuming Chen, Jianchao Deng, and Xiaoyi Chen. 2022. "Effect of Accelerated Aging on Bamboo Fiber Lunch Box and Correlation with Soil Burial Degradation" Polymers 14, no. 19: 4220. https://doi.org/10.3390/polym14194220

APA StyleJiang, H., Wang, G., Chen, F., Deng, J., & Chen, X. (2022). Effect of Accelerated Aging on Bamboo Fiber Lunch Box and Correlation with Soil Burial Degradation. Polymers, 14(19), 4220. https://doi.org/10.3390/polym14194220