Synthesis of a Novel Hyperbranched Polyimide for Reinforcing Toughness and Insulating Properties of Bismaleimide Resin

Abstract

:1. Introduction

2. Experimental

2.1. Material

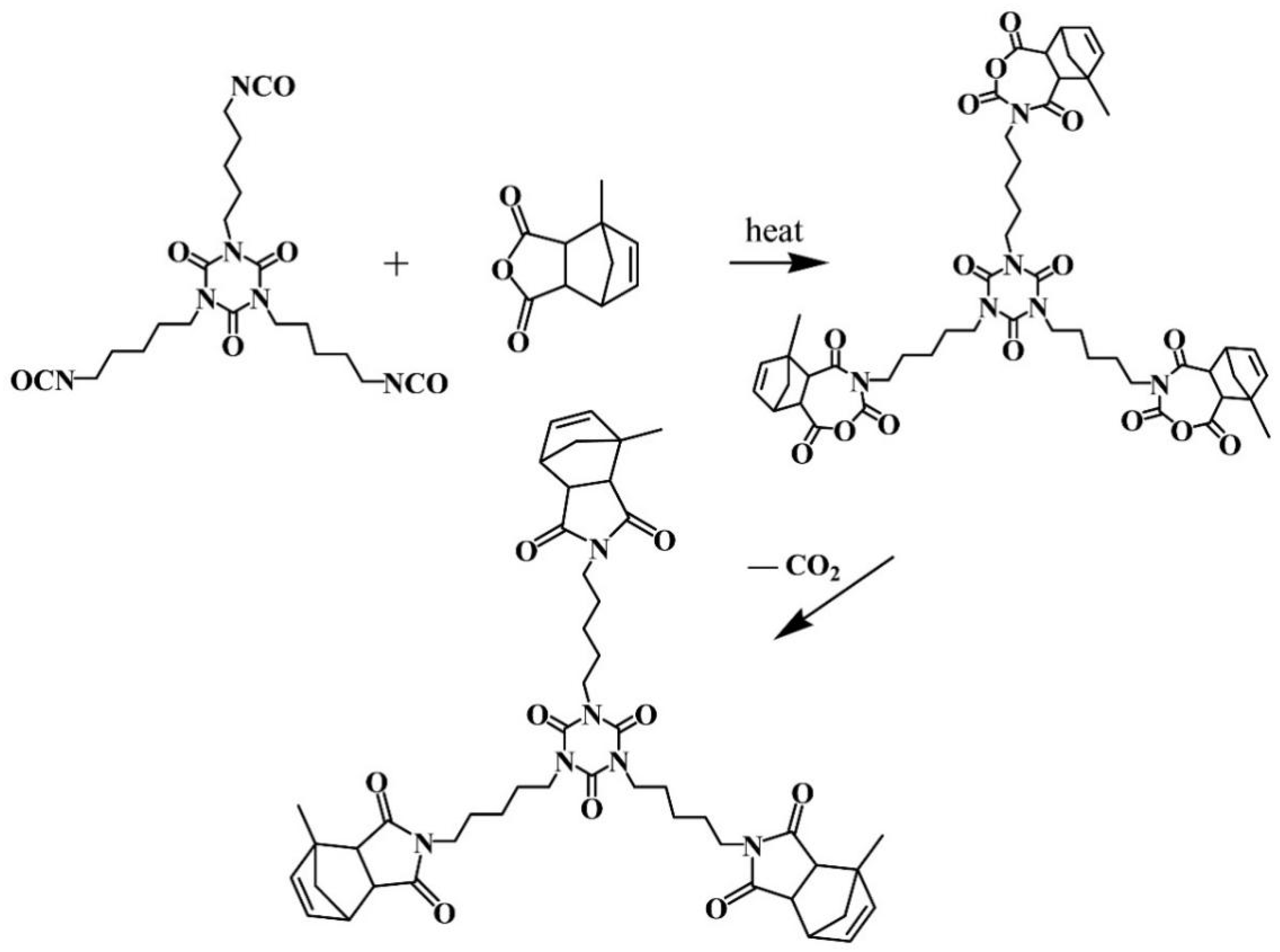

2.2. Preparation of Hyperbranched Polyimide and Cured Material

2.3. Instrumentation and Methods

3. Results and Discussion

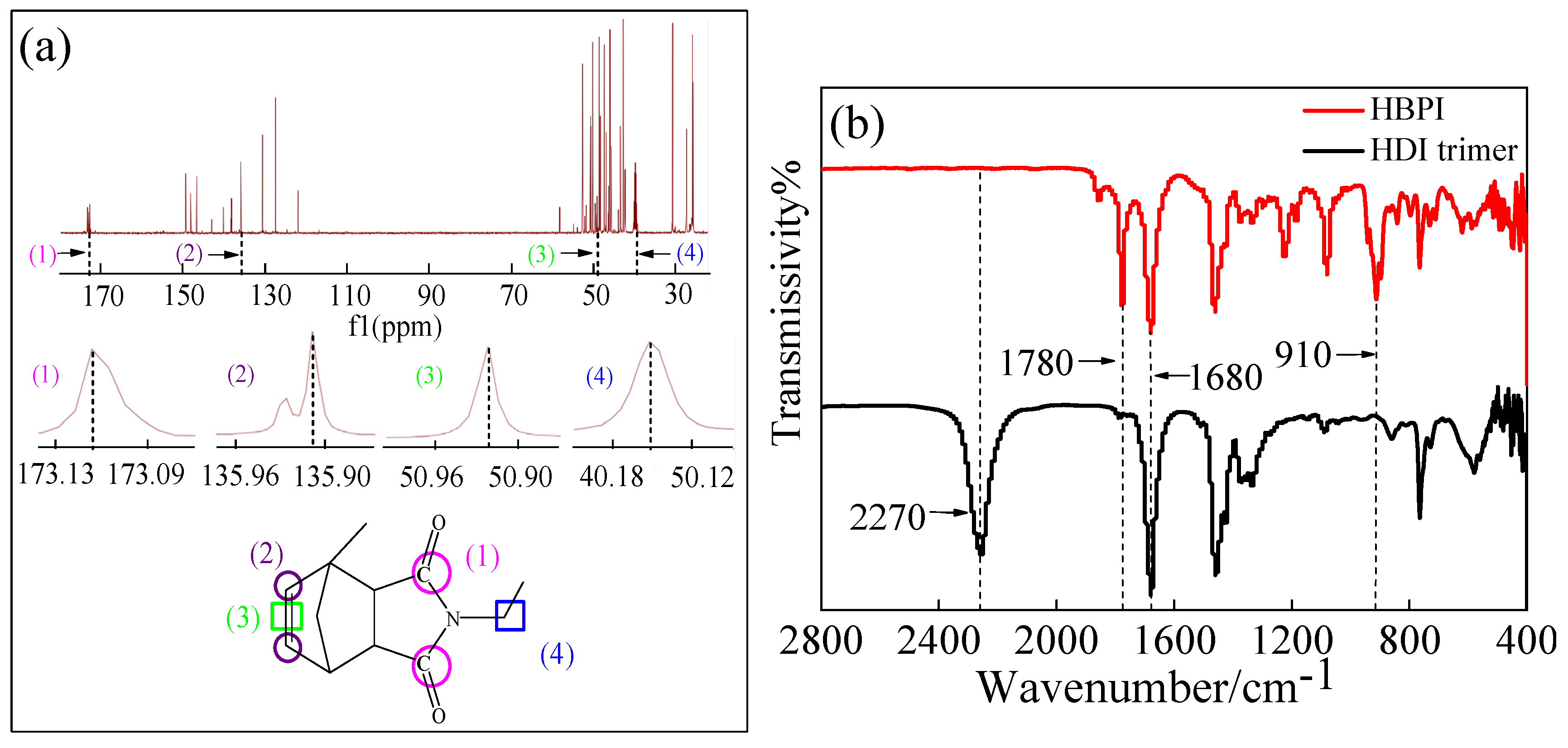

3.1. Characterization of HBPI

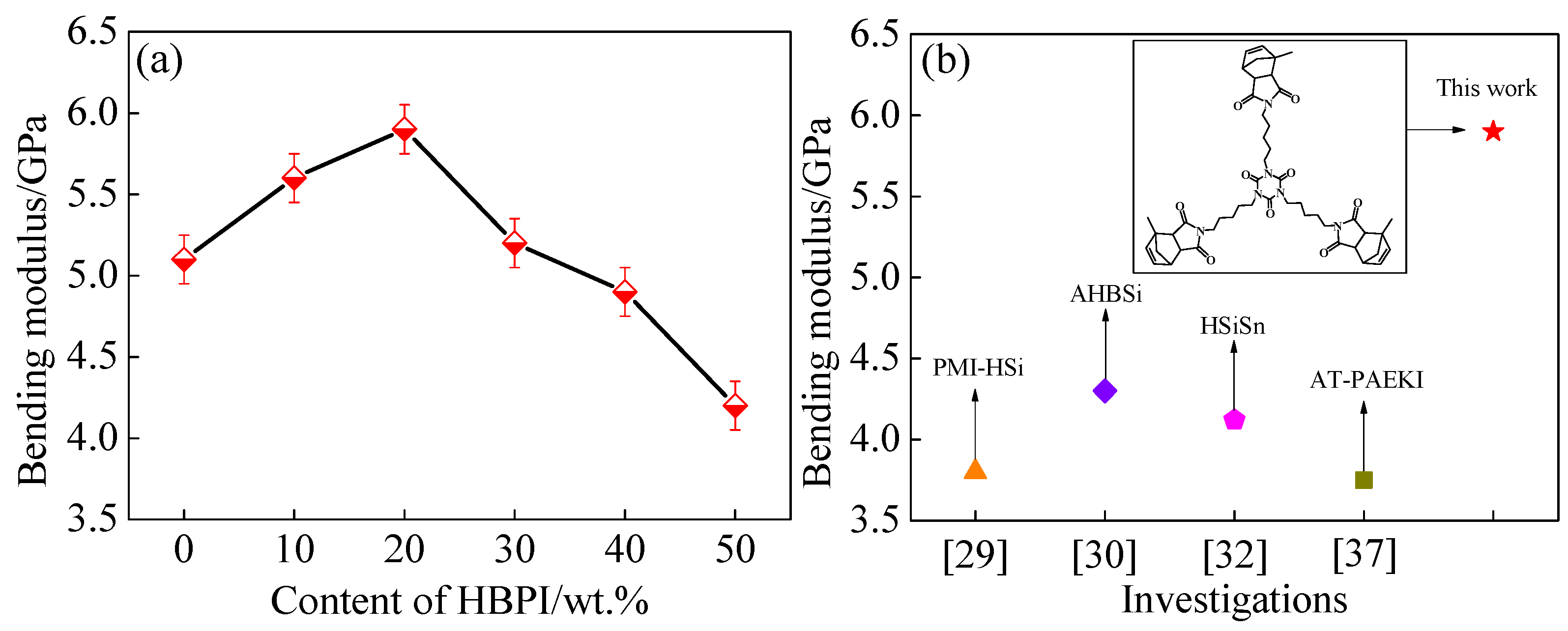

3.2. Mechanical Property of Cured Materials

3.3. Dynamic Thermomechanical Analysis

3.4. Microstructure of BMI Resin Modified with HBPI

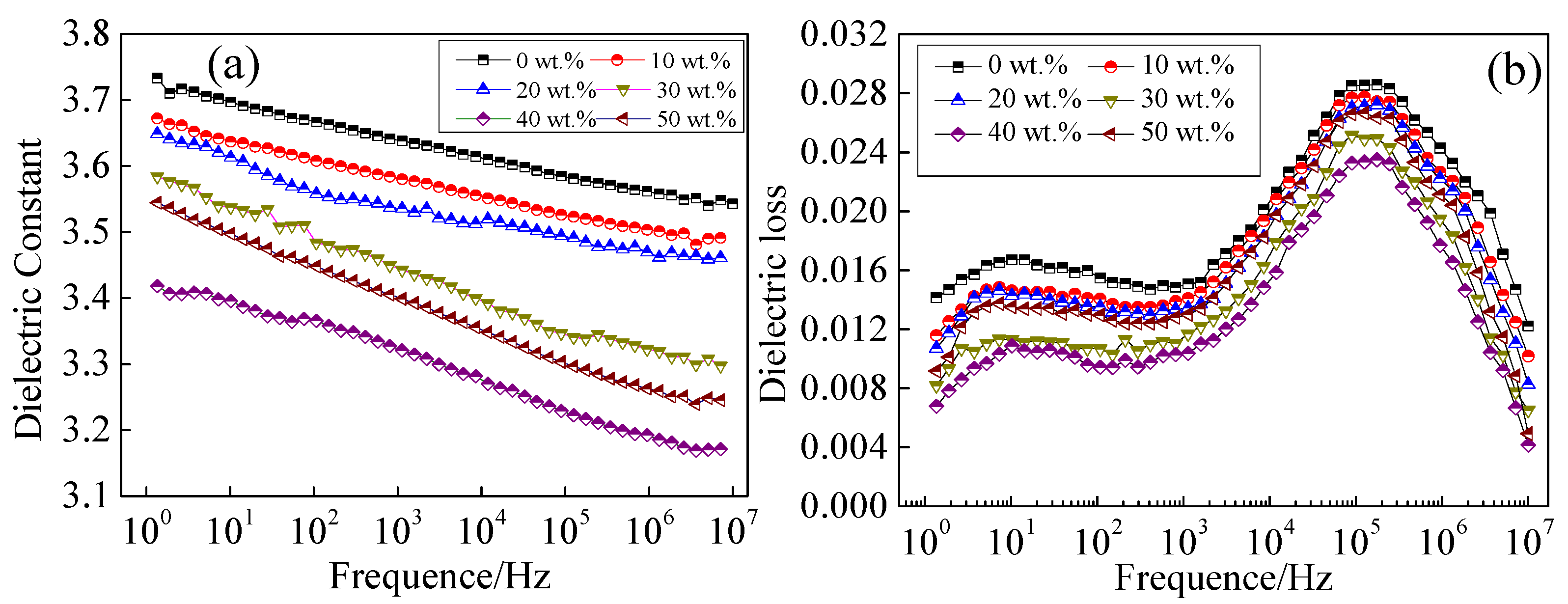

3.5. Insulating Performance of Cured Materials

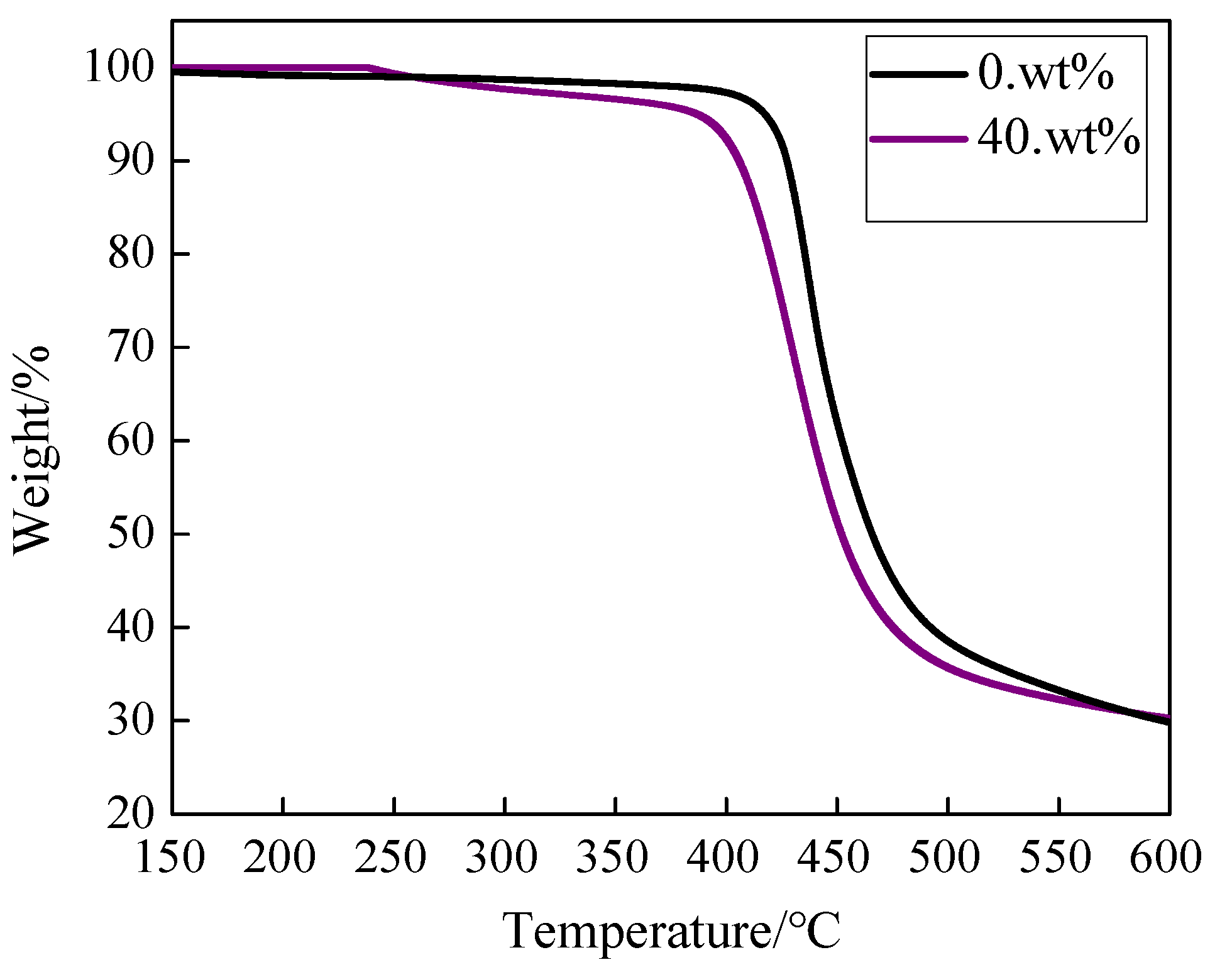

3.6. Thermal Property of Modified BMI Resin

4. Practical Implemention

5. Conclusions

- The structure of HBPI was successfully confirmed by FT-IR and NMR.

- The mechanical properties of the modified BMI were significantly improved. The impact strength reached 32 kJ/mm. The bending strength increased up to 88 MPa.

- The modulus was retained while the toughness and mechanical strength were improved.

- The enhanced insulating properties of modified BMI resin were obtained with a certain level of HBPI. The breakdown strength reaches 30 kV/mm when the content of HBPI is 30 wt.%.

- The heat resistance of modified BMI was still satisfactory and meet sthe need of insulating coatings and low dielectric laminates used in the high-frequency area.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Liu, X.; Yu, Y.F.; Li, S. Study on cure reaction of the blends of bismaleimide and dicyanate ester. Polymer 2006, 47, 3767–3773. [Google Scholar] [CrossRef]

- Ghose, S.; Watson, K.A.; Cano, R.J.; Britton, S.M.; Jensen, B.J.; Connell, J.W.; Herring, H.M.; Lineberry, Q.J. High temperature VARTM of phenylethynyl terminated imides. High Perform. Polym. 2009, 21, 653–672. [Google Scholar] [CrossRef] [Green Version]

- Iredale, R.J.; Ward, C.; Hamerton, I. Modern advances in bismaleimide resin technology: A 21st century perspective on the chemistry of addition polyimides. Prog. Polym. Sci. 2017, 69, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Yao, H.Y.; Fan, Z.; Cheng, H.L.; Guan, X.; Wang, C.; Sun, K.; Ouyang, J.Y. Recent Development of Thermoelectric Polymers and Composites. Macromol. Rapid Commun. 2018, 39, 1700727–1700749. [Google Scholar] [CrossRef]

- Vanaja, A.; Rao, R.M. Synthesis and characterization of epoxy-novolac/bismaleimide networks. Eur. Polym. J. 2002, 38, 187–193. [Google Scholar] [CrossRef]

- Guo, Z.S.; Du, S.Y.; Zhang, B.M.; Wu, Z.J. Cure characterization of a new bismaleimide resin using differential scanning calorimetry. Macromol. Sci. A Pure Appl. Chem. 2006, 43, 1687–1693. [Google Scholar] [CrossRef]

- Araya-Hermosilla, R.; Fortunato, G.; Pucci, A.; Raffa, P.; Polgar, L.; Broekhuis, A.A.; Pourhossein, P.; Lima, G.M.R.; Beljaars, M.; Picchioni, F. Thermally reversible rubber-toughened thermoset networks via Diels-Alder chemistry. Eur. Polym. J. 2016, 74, 229–240. [Google Scholar] [CrossRef]

- Yu, H.; Wang, L.H.; Wang, Z.G.; Han, X.Y.; Zhao, M.S. Alkyl-substituted carboxyl-containing polyaryletherketones and the crosslinking modifications with various bisphenols: Preparation and optical properties. Polymer 2010, 51, 3269–3276. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Q.; Gaize, D.U.; Gao, Y.; Jian, X.; Wang, J. Study on the bismaleimide resin blends system of poly (aryl ether)s/DABPA/BDM containing phthalazinone structure. Mater. China 2015, 34, 910–915. [Google Scholar]

- Ji, L.F.; Gu, A.J.; Liang, G.Z.; Yuan, L. Novel modification of bismaleimide–triazine resin by reactive hyperbranched polysiloxane. J. Mater. Sci. 2010, 45, 1859–1865. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Yan, H.X.; Liu, T.Y.; Niu, S. Nanosheets of MoS2 and reduced graphene oxide as hybrid fillers improved the mechanical and tribological properties of bismaleimide composites. Comp. Sci. Technol. 2016, 125, 47–54. [Google Scholar] [CrossRef]

- Tian, X.W.; Yang, Z.G. Effect of CTBN Concentration on Thermal and Morphological Properties of Binary Copolymers of o-Cresol Novolac Epoxy Resin and Bismaleimide. Polym. Technol. Eng. 2011, 50, 474–480. [Google Scholar] [CrossRef]

- Wang, D.Z.; Wang, X.; Liu, L.Z.; Qu, C.Y.; Liu, C.W.; Yang, H.D. Vinyl-terminated butadiene acrylonitrile improves the toughness, processing window, and thermal stability of bismaleimide resin. High Perform. Polym. 2017, 29, 1199–1208. [Google Scholar] [CrossRef]

- Shangguan, J.; Liao, G.; Liu, C.; Zhou, H.; Lu, D.; Jian, X. The preparation and properties of PPENK modified BMI resin. Polym. Mater. Sci. Eng. 2012, 28, 89–92. [Google Scholar]

- Jiang, H.L.; Liao, G.X.; Han, Y.J.; Jian, X.G. Research on BMI/DABPA blends modified with PPES-DA. Thermosetting Resin. 2010, 25, 30–34. [Google Scholar]

- Jin, J.Y.; Cui, J.; Tang, X.L.; Ding, Y.F.; Li, S.J.; Wang, J.C.; Zhao, Q.S.; Hua, X.Y.; Cai, X.Q. On polyetherimide modified bismaleimide resins, 1: Effect of the chemical backbone of polyetherimide. Macromol. Chem. Phys. 1999, 200, 1956–1960. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Li, P.; Chen, X.B. Studies of modified bismaleimide resins Part I The influence of resin composition on thermal and impact properties. J. Mater. Sci. 1998, 33, 5683–5687. [Google Scholar] [CrossRef]

- Liu, X.; Yu, Y.; Li, S. Viscoelastic phase separation in polyethersulfone modified bismaleimide resin. Eur. Polym. J. 2006, 42, 835–842. [Google Scholar] [CrossRef]

- Zeng, X.L.; Yu, S.H.; Sun, R.; Xu, J.B. Mechanical reinforcement while remaining electrical insulation of glass fibre/polymer composites using core–shell CNT@ SiO2 hybrids as fillers. Compos. Part A 2015, 73, 260–268. [Google Scholar] [CrossRef]

- Zhou, X.; Qiu, S.L.; Cai, W.; Liu, L.X.; Hou, Y.B.; Wang, W.; Song, L.; Wang, X.; Hu, Y. Construction of hierarchical MoS2@TiO2 structure for the high performance bimaleimide system with excellent fire safety and mechanical properties. Chem. Eng. J. 2019, 369, 451–462. [Google Scholar] [CrossRef]

- Wei, G.; Sue, H. Fracture Mechanisms in Preformed Polyphenylene Oxide Particle-Modified Bismaleimide Resins. J. Appl. Polym. Sci. 1999, 74, 2539–2545. [Google Scholar] [CrossRef]

- Hsieh, T.-T.; Tiu, C.; Simon, G.P. Miscibility and free volume behaviour of a number of polymer blends containing only thermotropic liquid crystalline polymers. Polymer 2000, 41, 4737–4742. [Google Scholar] [CrossRef]

- Kwak, S.Y.; Ahn, D.U. Processability of hyperbranched poly (ether ketone) s with different degrees of branching from viewpoints of molecular mobility and comparison with their linear analogue. Macromolecules 2000, 33, 7557–7563. [Google Scholar] [CrossRef]

- Zhang, D.H.; Liang, E.B.; Li, T.C.; Chen, S.F.; Chen, J.H.; Cheng, X.J.; Zhou, J.L.; Zhang, A.Q. The effect of molecular weight of hyperbranched epoxy resins with a silicone skeleton on performance. RSC Adv. 2013, 3, 9522–9529. [Google Scholar] [CrossRef]

- Zhao, Z.J.; He, B.R.; Tang, B.Z. ChemInform Abstract: Aggregation-Induced Emission of Siloles. Chem. Sci. 2015, 46, 5347–5365. [Google Scholar] [CrossRef] [Green Version]

- Frohlich, J.; Kautz, H.; Thomann, R.; Frey, H.; Mulhaupt, R. Reactive core/shell type hyperbranched blockcopolyethers as new liquid rubbers for epoxy toughening. Polymer 2004, 45, 2155–2164. [Google Scholar] [CrossRef]

- Hawker, C.J.; Chu, F.K.; Pomery, P.J.; Hill, D.J.T. Hyperbranched poly (ethylene glycol) s: A new class of ion-conducting materials. Macromolecules 1996, 29, 3831–3838. [Google Scholar] [CrossRef]

- Zhang, Y.D.; Wang, L.M.; Wada, T.; Sasabe, H. Synthesis and characterization of polymers containing in the chain backbone carbazoles substituted with two acceptor groups as nonlinear optical chromophores. Macromolecules 1996, 29, 1569–1573. [Google Scholar] [CrossRef]

- Jiang, Z.J.; Yuan, L.; Liang, G.Z.; Gu, A.J. Unique liquid multi-maleimide terminated branched polysiloxane and its flame retarding bismaleimide resin with outstanding thermal and mechanical properties. Polym. Degrad. Stab. 2015, 121, 30–41. [Google Scholar] [CrossRef]

- Sun, B.; Liang, G.Z.; Gu, A.J.; Yuan, L. High Performance Miscible Polyetherimide/Bismaleimide Resins with Simultaneously Improved Integrated Properties Based on a Novel Hyperbranched Polysiloxane Having a High Degree of Branching. Ind. Eng. Chem. Res. 2013, 52, 5054–5065. [Google Scholar] [CrossRef]

- Niu, S.; Yan, H.X.; Li, S.; Tang, C.; Chen, Z.Y.; Zhi, X.L.; Xu, P.L. A multifunctional silicon-containing hyperbranched epoxy: Controlled synthesis, toughening bismaleimide and fluorescent properties. J. Mater. Chem. C 2016, 4, 6881–6893. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Yuan, L.; Liang, G.Z.; Gu, A.J. New Bismaleimide Resin Toughened by In Situ Ring-Opening Polymer of Cyclic Butylene Terephthalate Oligomer with Unique Organotin Initiator. Ind. Eng. Chem. Res. 2015, 54, 5948–5958. [Google Scholar] [CrossRef]

- Shi, J.H.; Zhang, X.R.; Weng, L.; Sun, X.; Zhu, P.W.; Wang, Q.Y. High toughness and excellent electrical performance bismaleimide resin modified by hyperbranched unsaturated polyester of flexible aliphatic side chains. High Perform. Polym. 2021, 33, 695–703. [Google Scholar] [CrossRef]

- Peter, S.C.; Williams, J.; Farrissey, J.; James, S.R. The Formation of Polyimides from Anhydrides and Isocyanates. J. Appl. Polym. Sci. 1972, 16, 2983–2989. [Google Scholar]

- Yu, F.; Wang, K.; Liu, X.-Y.; Zhan, M.S. Preparation and properties of rigid polyimide foams derived from dianhydride and isocyanate. J. Appl. Polym. Sci. 2013, 127, 5075–5081. [Google Scholar] [CrossRef]

- Yang, J.P.; Chen, Z.K.; Yang, G.; Fu, S.Y.; Ye, L. Simultaneous improvements in the cryogenic tensile strength, ductility and impact strength of epoxy resins by a hyperbranched polymer. Polymer 2008, 49, 3168–3175. [Google Scholar] [CrossRef]

- Qin, H.; Mather, P.T.; Baek, J.B.; Tan, L.S. Modification of bisphenol-A based bismaleimide resin (BPA-BMI) with an allyl-terminated hyperbranched polyimide (AT-PAEKI). Polymer 2006, 47, 2813–2821. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, L.; Yu, Y.; Shi, J.; Zhang, X.; Gao, F.; Li, C.; Yang, Z.; Zhao, J. Synthesis of a Novel Hyperbranched Polyimide for Reinforcing Toughness and Insulating Properties of Bismaleimide Resin. Polymers 2022, 14, 4234. https://doi.org/10.3390/polym14194234

Yu L, Yu Y, Shi J, Zhang X, Gao F, Li C, Yang Z, Zhao J. Synthesis of a Novel Hyperbranched Polyimide for Reinforcing Toughness and Insulating Properties of Bismaleimide Resin. Polymers. 2022; 14(19):4234. https://doi.org/10.3390/polym14194234

Chicago/Turabian StyleYu, Lida, Yang Yu, Jiahao Shi, Xiaorui Zhang, Feng Gao, Chenhao Li, Zhou Yang, and Jingui Zhao. 2022. "Synthesis of a Novel Hyperbranched Polyimide for Reinforcing Toughness and Insulating Properties of Bismaleimide Resin" Polymers 14, no. 19: 4234. https://doi.org/10.3390/polym14194234