Numerical Simulation of Solids Conveying in Grooved Feed Sections of Single Screw Extruders

Abstract

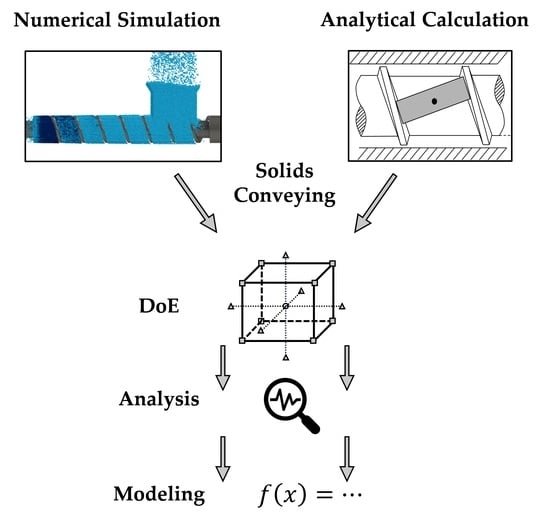

:1. Introduction

1.1. State of the Art and Historical Development of Treatment of Solids Conveying in Feed Sections of Single-Screw Extruders

1.1.1. Analytical Models

1.1.2. Numerical Investigation of Solids Conveying

2. Approach and Methods

2.1. Design of Experiments

- Length of feed section ;

- Barrel coefficient of friction ;

- Screw coefficient of friction ;

- Groove shape: rectangular;

- Groove width ;

- Groove depth , tapered towards the end of the feed section;

- Number of grooves was calculated, so that one third of the barrel surface was covered with grooves [24]:

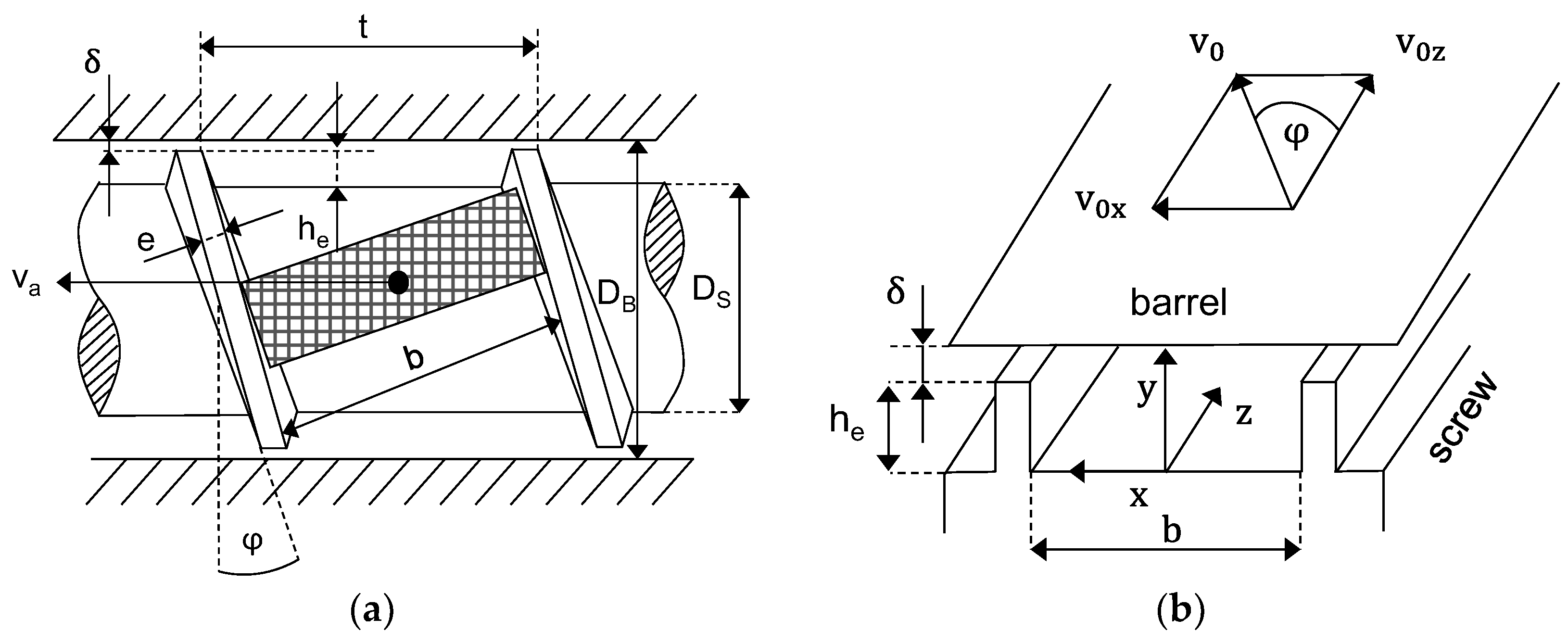

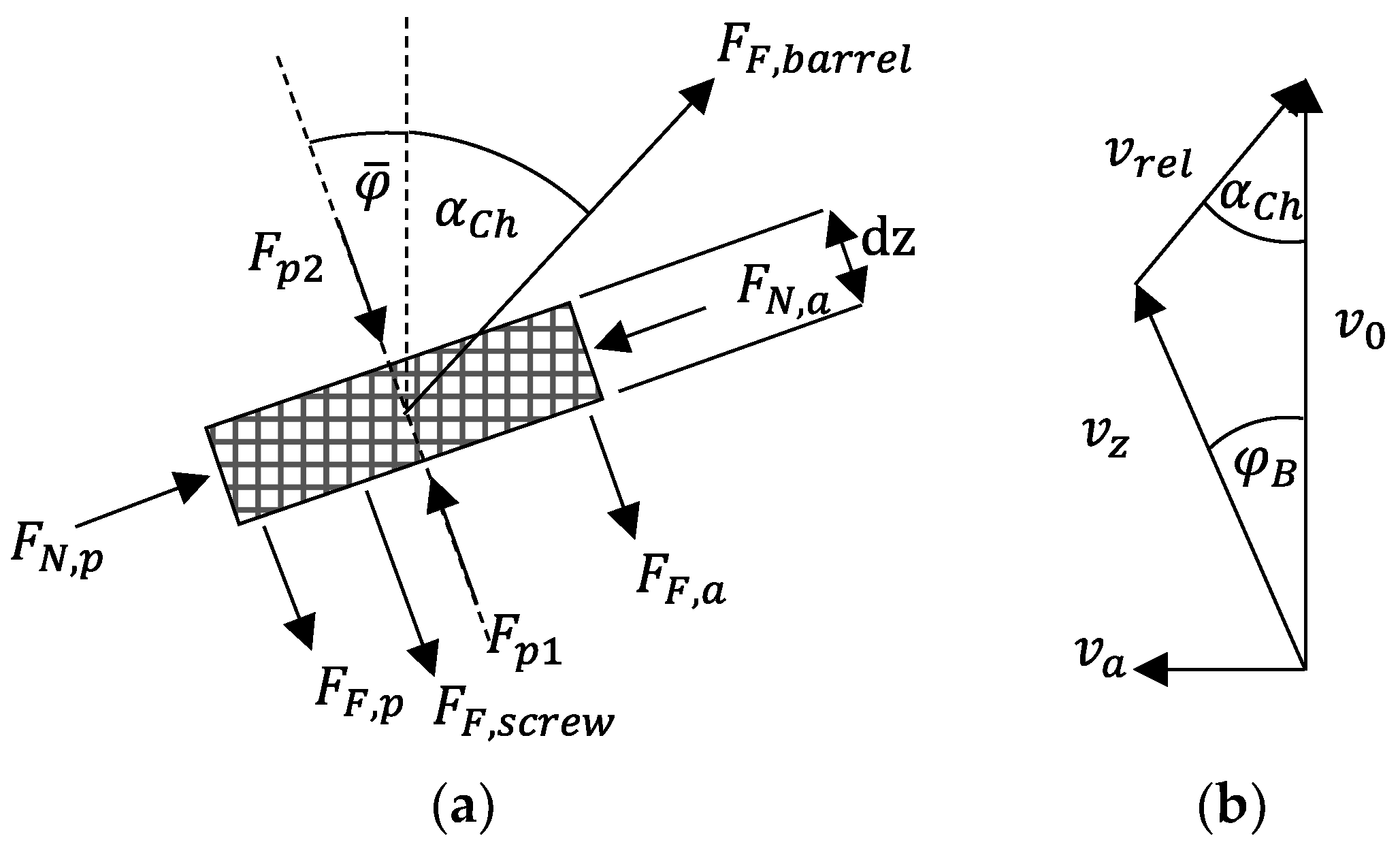

2.2. Mathematics of Analytical Calculation

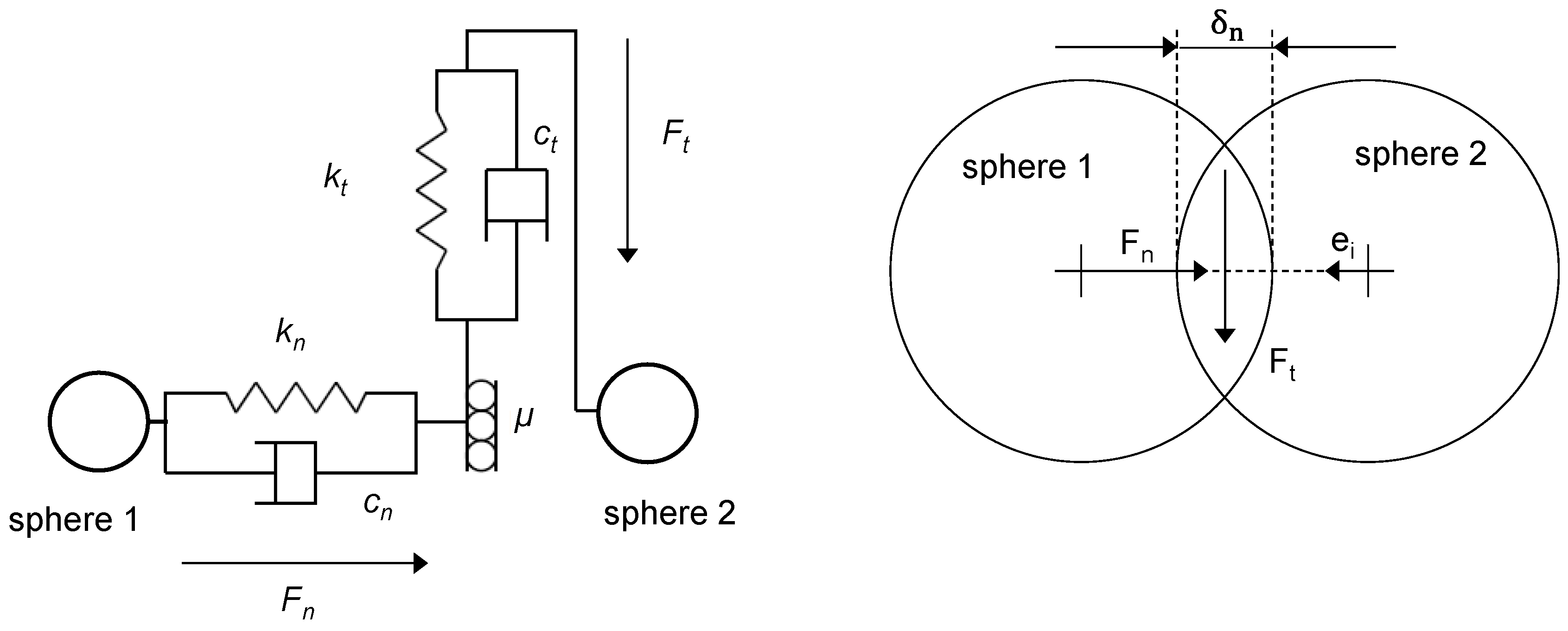

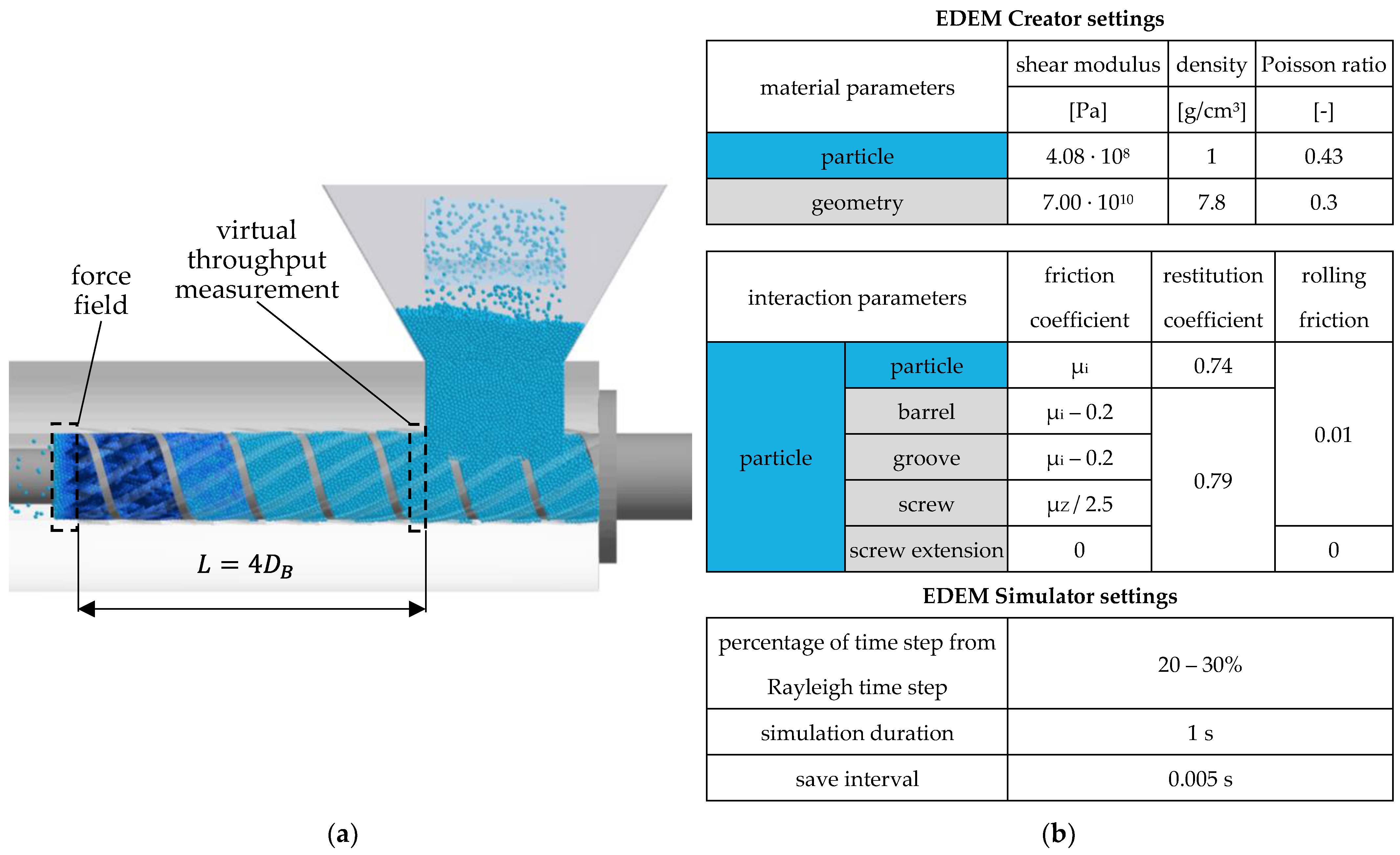

2.3. Numerical DEM Simulation Model

3. Results, Analysis and Discussion

3.1. Investigation of Assumptions: Backpressure Independence

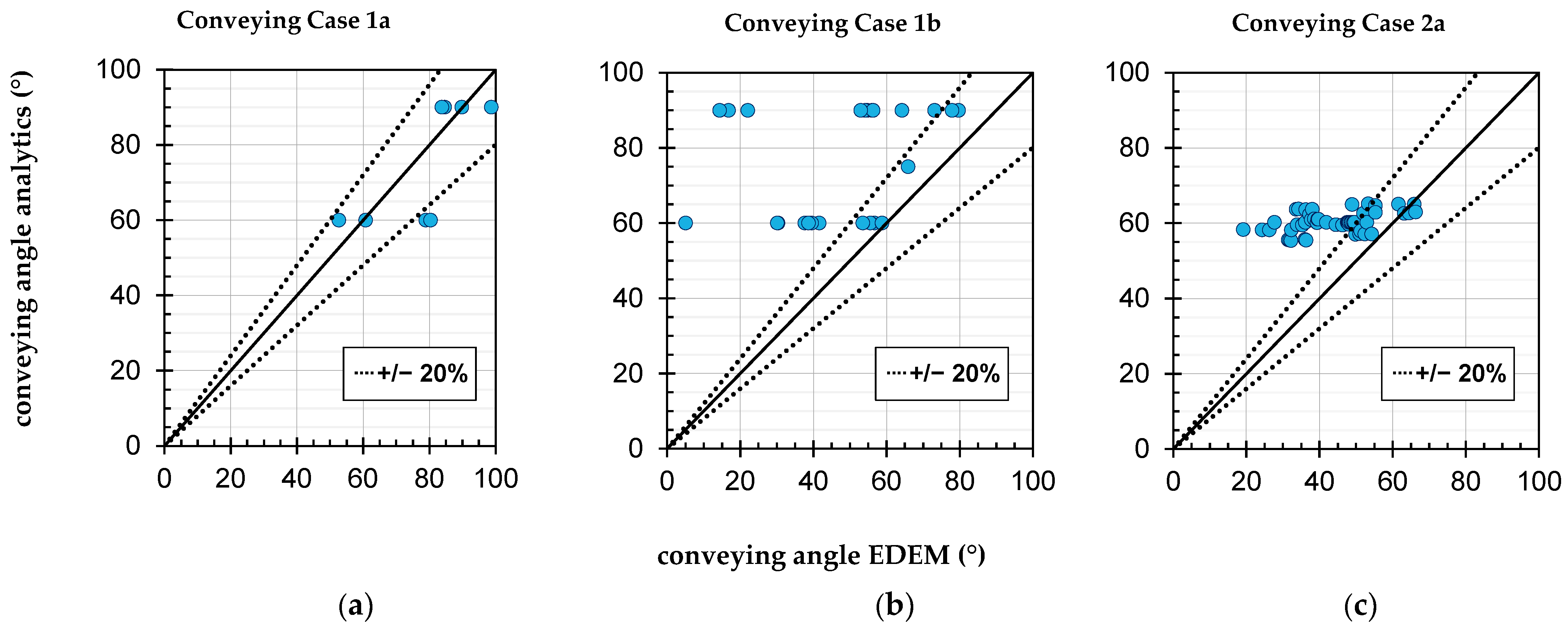

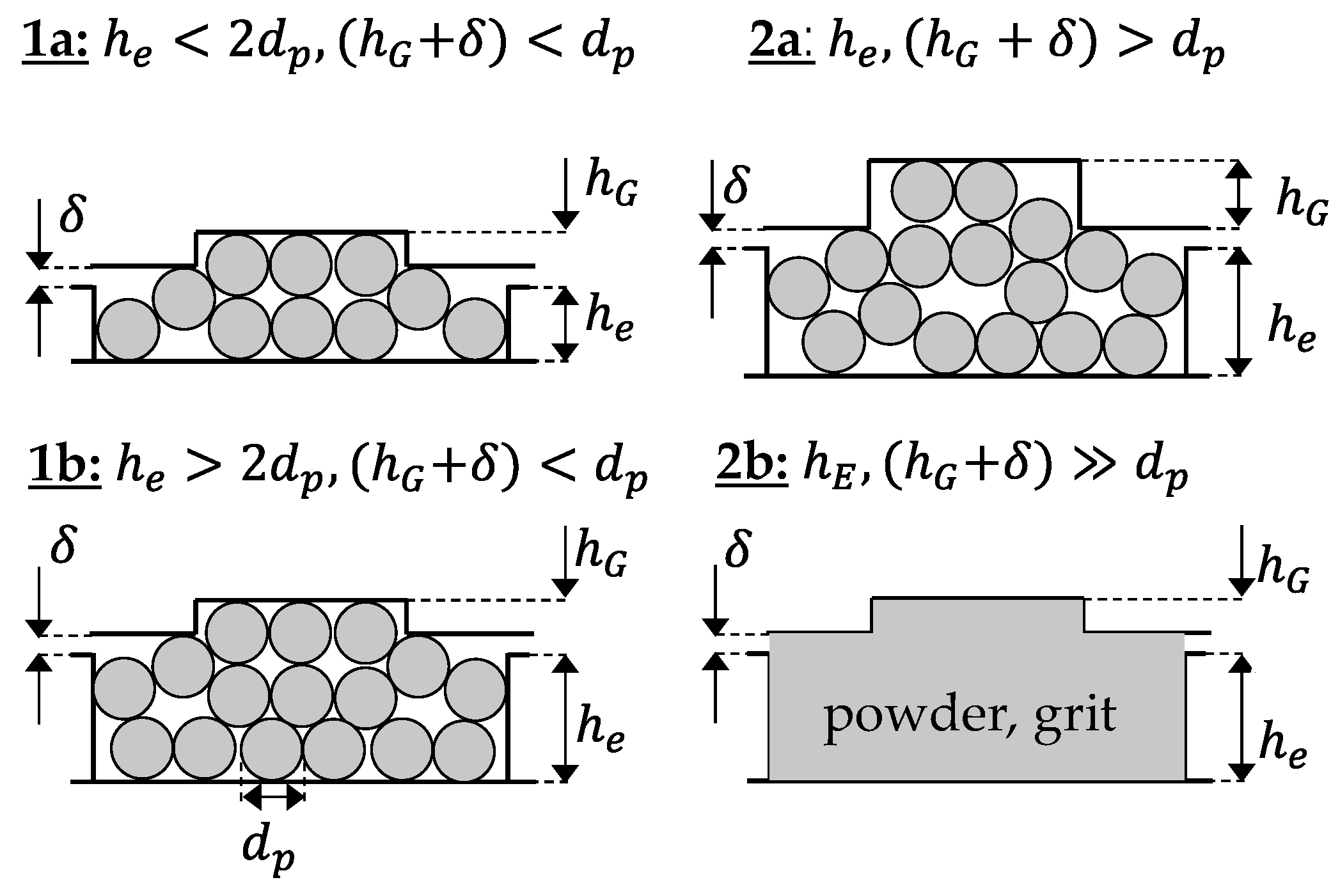

3.2. Investigation of Assumptions: Conveying Cases

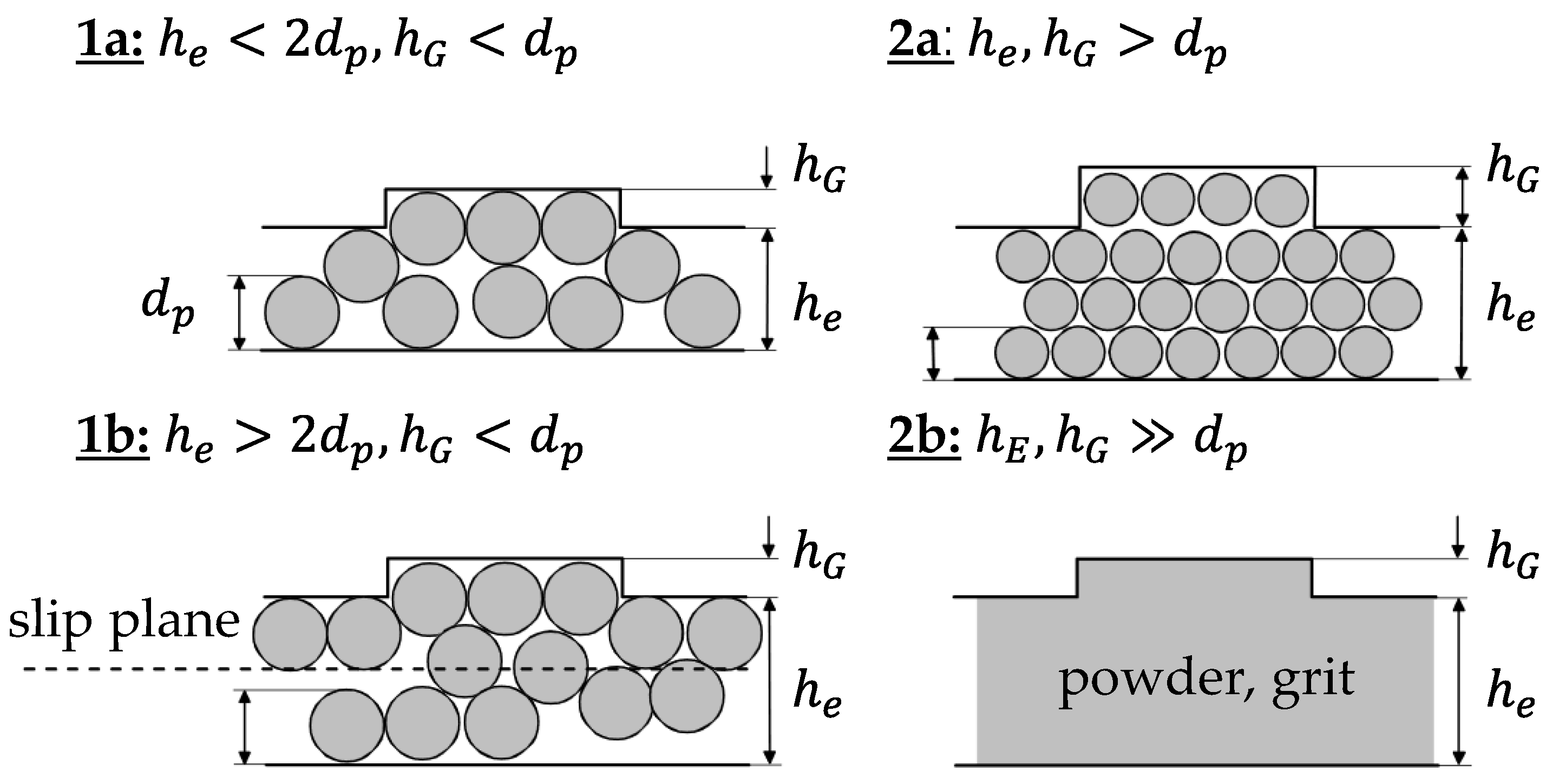

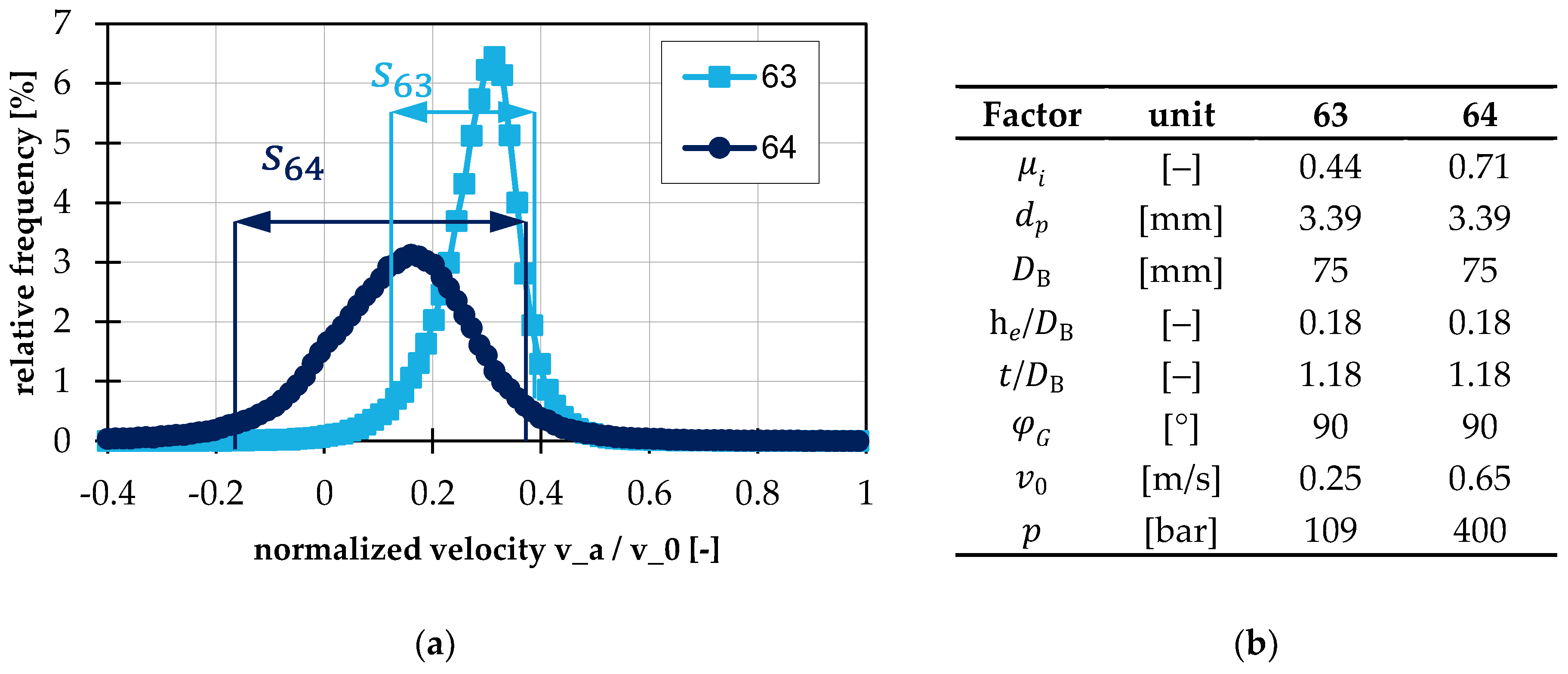

3.3. Investigation of Assumptions: Block Flow

3.4. Modeling of a Correction Factor for Conveying Angle in Case 2a

3.5. Adjustment of Classification of Conveying Cases

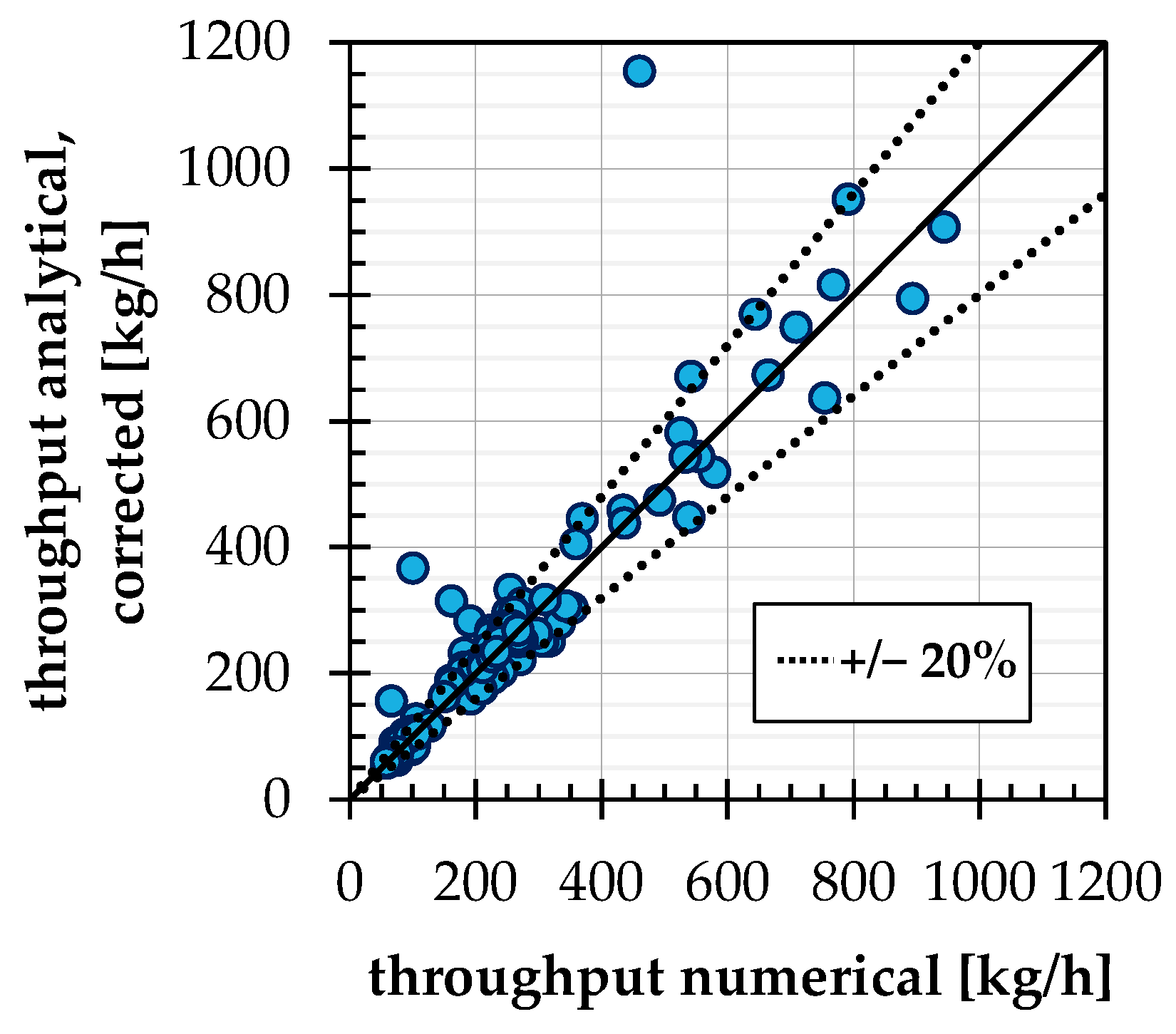

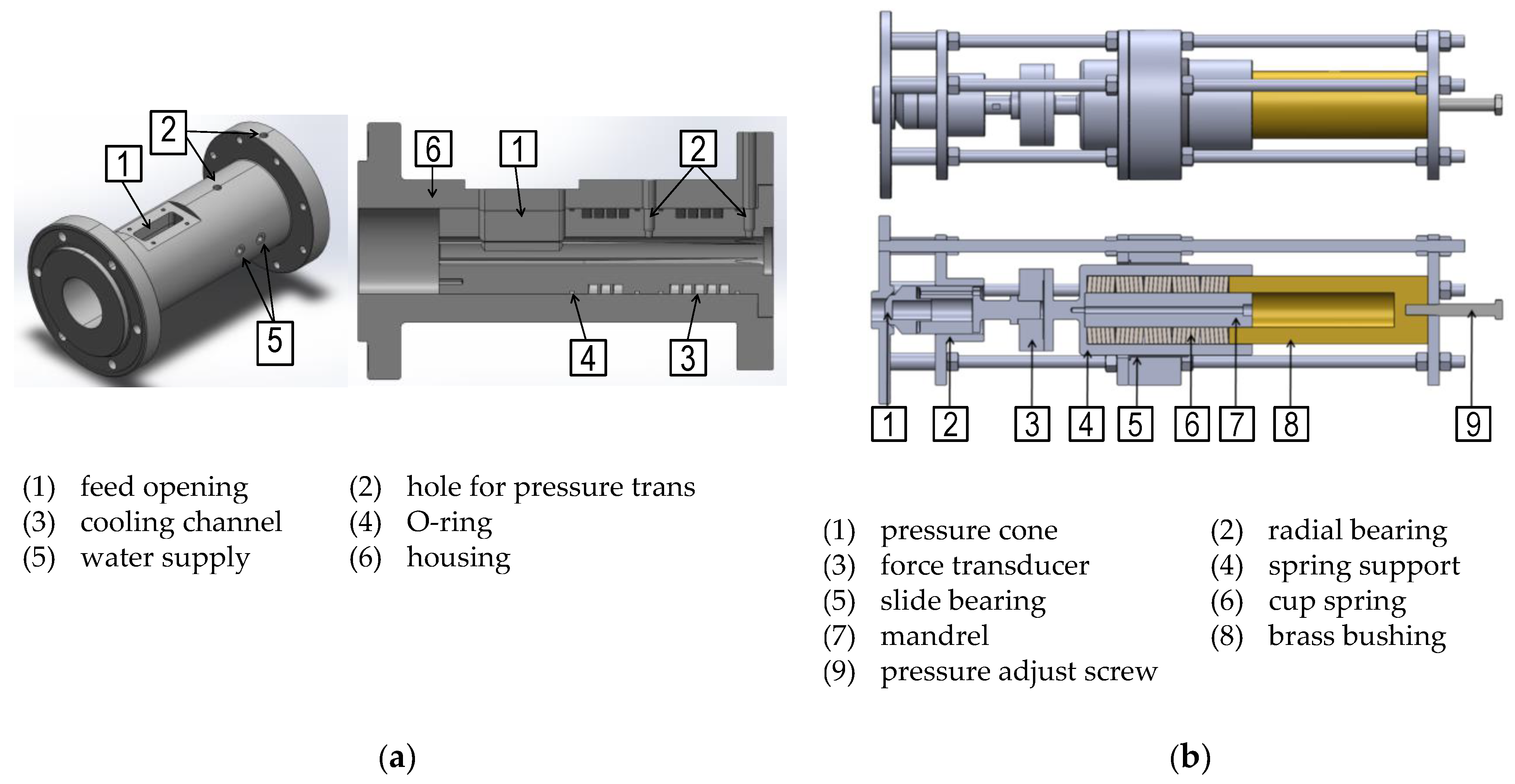

4. Summarizing Comparison of the Throughputs and Validation

- Screw speed: 70 rpm, 285 rpm and 500 rpm;

- Backpressure: 0 bar, 110 bar and 220 bar (LLDPE, PA6, PP);

- Backpressure: 0 bar, 7 bar and 14 bar (PS);

- Screw 1: ; ; ;

- Screw 2: ; ; ;

- Screw 3: ; ; .

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Nomenclature

| Character | Meaning |

|---|---|

| axial cross-sectional area of channel | |

| axial cross-sectional area of grooves | |

| width of grooves | |

| channel width | |

| damping constant in normal direction | |

| damping constant in tangential direction | |

| geometric variable for conveying angle calculation | |

| barrel diameter | |

| screw core diameter | |

| particle diameter | |

| unit vector of contact area of colliding particles | |

| geometric variable for conveying angle calculation | |

| flight width | |

| normal force vector of DEM collision | |

| tangential force vector of DEM collision | |

| resulting frictional force from barrel | |

| frictional force from screw | |

| frictional force from active flight | |

| frictional force from passive flight | |

| normal force from active flight | |

| normal force from passive flight | |

| normal force on particles | |

| tangential force on particles | |

| additional force for backpressure | |

| normal force from pressure | |

| normal force from pressure | |

| regression-based correction factor | |

| maximum shear modulus of DEM particles | |

| gravity vector | |

| depth of grooves | |

| channel depth | |

| moment of inertia | |

| number of flights | |

| spring constant in normal direction | |

| spring constant in tangential direction | |

| geometric variable for conveying angle calculation | |

| k | number of factors in DoE |

| pressure anisotropy coefficient on barrel | |

| pressure anisotropy coefficient on screw flights | |

| pressure anisotropy coefficient on screw root | |

| torque on DEM particle | |

| channel mass throughput | |

| groove mass throughput | |

| total mass throughput | |

| mass | |

| number of grooves | |

| number of particles (in force field) | |

| number of test points in DoE | |

| backpressure; reduction level of DoE | |

| minimum radius of DEM particles | |

| screw pitch; time | |

| Rayleigh time step | |

| average velocity of solids in grooves | |

| velocity vector of DEM particle | |

| peripheral speed | |

| peripheral speed in x-direction | |

| peripheral speed in z-direction | |

| axial velocity of solids in channel | |

| axial velocity | |

| maximum Poisson ratio of DEM particles | |

| relative velocity | |

| solid bed velocity in z-direction after iteration | |

| solid bed velocity in z-direction |

| Character | Meaning |

|---|---|

| conveying angle obtained from numerical simulation | |

| channel conveying angle | |

| groove conveying angle | |

| screw clearance; virtual overlap | |

| unknown additional force | |

| average barrel friction coefficient | |

| barrel coefficient of friction | |

| average internal coefficient of friction | |

| internal coefficient of friction | |

| screw coefficient of friction | |

| maximum Poisson’s ratio of DEM particles | |

| standard bulk density | |

| corrected bulk density | |

| minimum density of DEM particles | |

| helix angle in general | |

| helix angle at barrel | |

| groove angle | |

| mean helix angle | |

| helix angle at screw | |

| angular velocity of DEM particle |

Appendix B. Detailed Mathematics for Calculation of Conveying Angle

Appendix C

| Factor 1 | Factor 2 | Factor 3 | Factor 4 | Factor 5 | Factor 6 | Factor 7 | Factor 8 | |

|---|---|---|---|---|---|---|---|---|

| Meaning | Internal Coefficient of Friction | Particle Diameter | Barrel Diameter | Channel Depth | Screw Pitch | Grooves Angle | Peripheral Speed | Back-Pressure |

| Symbol | ||||||||

| Unit | (-) | (mm) | (mm) | (-) | (-) | (°) | (m/s) | (bar) |

| 1 | 0.44 | 1.61 | 45 | 0.12 | 0.82 | 60 | 0.65 | 401 |

| 0.71 | 1.61 | 45 | 0.12 | 0.82 | 60 | 0.25 | 109 | |

| 3 | 0.44 | 3.39 | 45 | 0.12 | 0.82 | 60 | 0.25 | 109 |

| 0.71 | 3.39 | 45 | 0.12 | 0.82 | 60 | 0.65 | 401 | |

| 0.44 | 1.61 | 75 | 0.12 | 0.82 | 60 | 0.25 | 401 | |

| 0.71 | 1.61 | 75 | 0.12 | 0.82 | 60 | 0.65 | 109 | |

| 7 | 0.44 | 3.39 | 75 | 0.12 | 0.82 | 60 | 0.65 | 109 |

| 8 | 0.71 | 3.39 | 75 | 0.12 | 0.82 | 60 | 0.25 | 401 |

| 9 | 0.44 | 1.61 | 45 | 0.18 | 0.82 | 60 | 0.25 | 401 |

| 10 | 0.71 | 1.61 | 45 | 0.18 | 0.82 | 60 | 0.65 | 109 |

| 0.44 | 3.39 | 45 | 0.18 | 0.82 | 60 | 0.65 | 109 | |

| 0.71 | 3.39 | 45 | 0.18 | 0.82 | 60 | 0.25 | 401 | |

| 0.44 | 1.61 | 75 | 0.18 | 0.82 | 60 | 0.65 | 401 | |

| 0.71 | 1.61 | 75 | 0.18 | 0.82 | 60 | 0.25 | 109 | |

| 15 | 0.44 | 3.39 | 75 | 0.18 | 0.82 | 60 | 0.25 | 109 |

| 0.71 | 3.39 | 75 | 0.18 | 0.82 | 60 | 0.65 | 401 | |

| 0.44 | 1.61 | 45 | 0.12 | 1.18 | 60 | 0.65 | 109 | |

| 18 | 0.71 | 1.61 | 45 | 0.12 | 1.18 | 60 | 0.25 | 401 |

| 19 | 0.44 | 3.39 | 45 | 0.12 | 1.18 | 60 | 0.25 | 401 |

| 20 | 0.71 | 3.39 | 45 | 0.12 | 1.18 | 60 | 0.65 | 109 |

| 21 | 0.44 | 1.61 | 75 | 0.12 | 1.18 | 60 | 0.25 | 109 |

| 22 | 0.71 | 1.61 | 75 | 0.12 | 1.18 | 60 | 0.65 | 401 |

| 23 | 0.44 | 3.39 | 75 | 0.12 | 1.18 | 60 | 0.65 | 401 |

| 24 | 0.71 | 3.39 | 75 | 0.12 | 1.18 | 60 | 0.25 | 109 |

| 25 | 0.44 | 1.61 | 45 | 0.18 | 1.18 | 60 | 0.25 | 109 |

| 26 | 0.71 | 1.61 | 45 | 0.18 | 1.18 | 60 | 0.65 | 401 |

| 27 | 0.44 | 3.39 | 45 | 0.18 | 1.18 | 60 | 0.65 | 401 |

| 28 | 0.71 | 3.39 | 45 | 0.18 | 1.18 | 60 | 0.25 | 109 |

| 29 | 0.44 | 1.61 | 75 | 0.18 | 1.18 | 60 | 0.65 | 109 |

| 30 | 0.71 | 1.61 | 75 | 0.18 | 1.18 | 60 | 0.25 | 401 |

| 31 | 0.44 | 3.39 | 75 | 0.18 | 1.18 | 60 | 0.25 | 401 |

| 32 | 0.71 | 3.39 | 75 | 0.18 | 1.18 | 60 | 0.65 | 109 |

| 33 | 0.44 | 1.61 | 45 | 0.12 | 0.82 | 90 | 0.65 | 109 |

| 34 | 0.71 | 1.61 | 45 | 0.12 | 0.82 | 90 | 0.25 | 401 |

| 35 | 0.44 | 3.39 | 45 | 0.12 | 0.82 | 90 | 0.25 | 401 |

| 36 | 0.71 | 3.39 | 45 | 0.12 | 0.82 | 90 | 0.65 | 109 |

| 37 | 0.44 | 1.61 | 75 | 0.12 | 0.82 | 90 | 0.25 | 109 |

| 38 | 0.71 | 1.61 | 75 | 0.12 | 0.82 | 90 | 0.65 | 401 |

| 39 | 0.44 | 3.39 | 75 | 0.12 | 0.82 | 90 | 0.65 | 401 |

| 40 | 0.71 | 3.39 | 75 | 0.12 | 0.82 | 90 | 0.25 | 109 |

| 41 | 0.44 | 1.61 | 45 | 0.18 | 0.82 | 90 | 0.25 | 109 |

| 42 | 0.71 | 1.61 | 45 | 0.18 | 0.82 | 90 | 0.65 | 401 |

| 43 | 0.44 | 3.39 | 45 | 0.18 | 0.82 | 90 | 0.65 | 401 |

| 44 | 0.71 | 3.39 | 45 | 0.18 | 0.82 | 90 | 0.25 | 109 |

| 45 | 0.44 | 1.61 | 75 | 0.18 | 0.82 | 90 | 0.65 | 109 |

| 46 | 0.71 | 1.61 | 75 | 0.18 | 0.82 | 90 | 0.25 | 401 |

| 47 | 0.44 | 3.39 | 75 | 0.18 | 0.82 | 90 | 0.25 | 401 |

| 48 | 0.71 | 3.39 | 75 | 0.18 | 0.82 | 90 | 0.65 | 109 |

| 49 | 0.44 | 1.61 | 45 | 0.12 | 1.18 | 90 | 0.65 | 401 |

| 50 | 0.71 | 1.61 | 45 | 0.12 | 1.18 | 90 | 0.25 | 109 |

| 51 | 0.44 | 3.39 | 45 | 0.12 | 1.18 | 90 | 0.25 | 109 |

| 52 | 0.71 | 3.39 | 45 | 0.12 | 1.18 | 90 | 0.65 | 401 |

| 53 | 0.44 | 1.61 | 75 | 0.12 | 1.18 | 90 | 0.25 | 401 |

| 54 | 0.71 | 1.61 | 75 | 0.12 | 1.18 | 90 | 0.65 | 109 |

| 55 | 0.44 | 3.39 | 75 | 0.12 | 1.18 | 90 | 0.65 | 109 |

| 56 | 0.71 | 3.39 | 75 | 0.12 | 1.18 | 90 | 0.25 | 401 |

| 57 | 0.44 | 1.61 | 45 | 0.18 | 1.18 | 90 | 0.25 | 401 |

| 58 | 0.71 | 1.61 | 45 | 0.18 | 1.18 | 90 | 0.65 | 109 |

| 59 | 0.44 | 3.39 | 45 | 0.18 | 1.18 | 90 | 0.65 | 109 |

| 60 | 0.71 | 3.39 | 45 | 0.18 | 1.18 | 90 | 0.25 | 401 |

| 61 | 0.44 | 1.61 | 75 | 0.18 | 1.18 | 90 | 0.65 | 401 |

| 62 | 0.71 | 1.61 | 75 | 0.18 | 1.18 | 90 | 0.25 | 109 |

| 63 | 0.44 | 3.39 | 75 | 0.18 | 1.18 | 90 | 0.25 | 109 |

| 64 | 0.71 | 3.39 | 75 | 0.18 | 1.18 | 90 | 0.65 | 401 |

| 65 | 0.35 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 66 | 0.8 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 67 | 0.58 | 1 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 68 | 0.58 | 4 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 69 | 0.58 | 2.5 | 35 | 0.15 | 1 | 75 | 0.45 | 255 |

| 70 | 0.58 | 2.5 | 85 | 0.15 | 1 | 75 | 0.45 | 255 |

| 71 | 0.58 | 2.5 | 60 | 0.1 | 1 | 75 | 0.45 | 255 |

| 72 | 0.58 | 2.5 | 60 | 0.2 | 1 | 75 | 0.45 | 255 |

| 73 | 0.58 | 2.5 | 60 | 0.15 | 0.7 | 75 | 0.45 | 255 |

| 74 | 0.58 | 2.5 | 60 | 0.15 | 1.3 | 75 | 0.45 | 255 |

| 75 | 0.58 | 2.5 | 60 | 0.15 | 1 | 50 | 0.45 | 255 |

| 76 | 0.58 | 2.5 | 60 | 0.15 | 1 | 100 | 0.45 | 255 |

| 77 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.11 | 255 |

| 78 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.79 | 255 |

| 79 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 10 |

| 80 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 500 |

| 81 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 82 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 83 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 84 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 85 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 86 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 87 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 88 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 89 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

| 90 | 0.58 | 2.5 | 60 | 0.15 | 1 | 75 | 0.45 | 255 |

Appendix D. Data Used for Analytical Throughput Calculation of Validation

| Factor 1 | Factor 2 | Factor 3 | Factor 4 | Factor 5 | |

|---|---|---|---|---|---|

| Meaning | Screw Friction Coefficient | Barrel Friction Coefficient | Internal Friction Coefficient | Standard Bulk Density | Average Pellet Diameter |

| Symbol | |||||

| Unit | (-) | (mm) | (mm) | (-) | (-) |

| PP | 0.112 | 0.28 | 0.5 | 540 | 4.55 |

| PA6 | 0.068 | 0.17 | 0.37 | 718.6 | 2.68 |

| LLDPE | 0.08 | 0.2 | 0.5 | 550 | 1.41 |

| PS small | 0.156 | 0.39 | 0.38 | 580 | 0.9921 |

| PS medium | 0.156 | 0.39 | 0.38 | 580 | 1.3622 |

| PS large | 0.156 | 0.39 | 0.38 | 580 | 2.8614 |

References

- White, J.L.; Potente, H. Screw Extrusion; Hanser: Munich, Germany, 2003; ISBN 3446196242. [Google Scholar]

- Darnell, W.H.; Mol, E.A.J. Solids Conveying in Extruders. SPE J. 1956, 12, 20–29. [Google Scholar]

- Schneider, K. der Fördervorgang in der Einzugszone Eines Extruders. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 1968. [Google Scholar]

- Ingen Housz, J.F. Druckverteilung im Feststoffbereich des Einschneckenextruders. Plastverarbeiter 1974, 25, 620–622. [Google Scholar]

- Tadmor, Z.; Broyer, E. Solids Conveying in Screw Extruders Part I: A Modified Isothermal Model. Polym. Eng. Sci. 1972, 12, 12–24. [Google Scholar] [CrossRef]

- Tadmor, Z.; Broyer, E. Solids conveying in screw extruders part II: Non isothermal model. Polym. Eng. Sci. 1972, 12, 378–386. [Google Scholar] [CrossRef]

- Hegele, R. Untersuchungen zur Verarbeitung Pulverförmiger Polyolefine auf Einschnecken-Extrudern. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 1972. [Google Scholar]

- Langecker, G.R. Untersuchungen zum Stoffverhalten von Kunststoffpulvern in der Einzugszone von Einschneckenmaschinen mit Genuteten Buchsen. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 1977. [Google Scholar]

- Hwang, C.-G.; McKelvey, J.M. Solid bed compaction and frictional drag during melting in a simulated plasticating extruder. Adv. Polym. Technol. 1989, 9, 227–251. [Google Scholar] [CrossRef]

- Hyun, K.S.; Spalding, M.A. A New Model for Solids Conveying in Single-Screw Plasticating Extruders. In SPE ANTEC Technical Papers; Society of Plastic Engineers: Toronto, ON, Canada, 1997. [Google Scholar]

- Potente, H.; Jungemann, J. Plasticizing Extruder Model—Linking the Pressure and Throughput Models. J. Polym. Eng. 2000, 20, 225–236. [Google Scholar] [CrossRef]

- Imhoff, A. Dreidimensionale Beschreibung der Vorgänge in Einem Einschneckenplastifizierextruder: Three-Dimensional Description of the Process in a Single-Screw Plasticating Extruder. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2004. [Google Scholar]

- Hennes, J.P. Ermittlung von Materialkennwerten von Kunststoffschüttgütern und Simulation der Vorgänge im Einzugsbereich von Konventionellen Einschneckenextrudern. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2000. [Google Scholar]

- Peiffer, H. Zum Förderproblem in der Genuteten Einzugszone von Einschneckenextrudern. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 1981. [Google Scholar]

- Rautenbach, R.; Peiffer, H. Durchsatz- und Drehmomentverhalten genuteter Einzugszonen von Einschneckenextrudern. Kunststoffe 1982, 72, 262–266. [Google Scholar]

- Goldacker, E. Untersuchung zur Inneren Reibung von Pulvern, Insbesondere im Hinblick auf die Förderung in Extrudern. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 1971. [Google Scholar]

- Menges, G.; Hegele, R.; Langecker, G.R. Theorie der Förderung im Einschneckenextruder, Vergleich Genutete und Glatte Einzugsbuchse; Plastverarbeiter: Heidelberg, Germany, 1972; Volume 23. [Google Scholar]

- Potente, H.; Schöppner, V. A Throughput Model for Grooved Bush Extruders. IPP 1995, 10, 289–295. [Google Scholar] [CrossRef]

- Potente, H.; Schöppner, V. Bulk Density of Plastic Pellets in a Screw Channel. IPP 1995, 10, 10–14. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Plastics—Determination of Apparent Density of Material That Can Be Poured from a Specified Funnel; ISO 60; International Organization for Standardization (ISO): Geneva, Switzerland, 1977. [Google Scholar]

- Miethlinger, J. Modellierung der Feststoffförderzone von Einschneckenextrudern unter besonderer Berücksichtigung von Wendelnutbuchsen. Kunststoffe 2003, 93, 49–53. [Google Scholar]

- Kaczmarek, D.; Wortberg, J. New Forced Feeding System for Regrind Extrusion. In SPE ANTEC Technical Papers; Society of Plastic Engineers: San Francisco, CA, USA, 2002. [Google Scholar]

- Michels, R. Verbesserung der Verarbeitungsbandbreite und der Leistungsfähigkeit von Einschneckenextrudern. Ph.D. Thesis, University Duisburg-Essen, Duisburg, Germany, 2005. [Google Scholar]

- Bornemann, M. Erweiterung der Modelltheoretischen Grundlagen zur Durchsatz- und Leistungsberechnung von Einschneckenplastifiziereinheiten. Ph.D. Thesis, Paderborn University, Paderborn, Germany, 2011. [Google Scholar]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Investigation of solids transport in a single-screw extruder using a 3-D discrete particle simulation. Polym. Eng. Sci. 2004, 44, 2203–2215. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Modelling the solids inflow and solids conveying of single-screw extruders using the discrete element method. Powder Technol. 2005, 153, 95–107. [Google Scholar] [CrossRef]

- Moysey, P.A.; Cloet, K.L.; Thompson, M.R. Studying the Effective Thermal Properties of Solids in Extrusion Machinery using a Discrete Particle Simulation Approach. IPP 2008, 23, 301–311. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Determining the collision properties of semi-crystalline and amorphous thermoplastics for DEM simulations of solids transport in an extruder. Chem. Eng. Sci. 2007, 62, 3699–3709. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Discrete particle simulations of solids compaction and conveying in a single-screw extruder. Polym. Eng. Sci. 2008, 48, 62–73. [Google Scholar] [CrossRef]

- Weddige, R.; Schöppner, V. Improving the Feeding Zone of Single-Screw Extruders at High Rotation Speed by Using the Discrete Element Method. In SPE ANTEC Technical Papers; Society of Plastic Engineers: Orlando, FL, USA, 2010. [Google Scholar]

- Leßmann, J.-S.; Weddige, R.; Schöppner, V.; Porsch, A. Modelling the Solids Throughput of Single Screw Smooth Barrel Extruders as a Function of the Feed Section Parameters. IPP 2012, 27, 469–477. [Google Scholar] [CrossRef]

- Trippe, J.; Schöppner, V. Modeling of Solid Conveying Pressure Throughput Behavior of Single Screw Smooth Barrel Extruders under Consideration of Backpressure and High Screw Speeds. IPP 2018, 33, 486–496. [Google Scholar] [CrossRef]

- Leßmann, J.-S.; Schöppner, V. Validation of Discrete Element Simulations in the Field of Solids Conveying in Single-Screw Extruders. In Proceedings of the AIP Conference, the 30th International Conference of the Polymer Processing Society—Conference Papers (PPS-30), Cleveland, OH, USA, 6–12 June 2014. AIP: 2015. [Google Scholar]

- Celik, O.; Bonten, C. Three-Dimensional Simulation of a Single-Screw Extruder’s Grooved Feed Section. In Proceedings of the AIP Conference, the Regional Conference, Graz, Austria, 21–25 September 2015. AIP: 2016. [Google Scholar]

- Thieleke, P.; Bonten, C. Enhanced Processing of Regrind as Recycling Material in Single-Screw Extruders. Polymers 2021, 13, 1540. [Google Scholar] [CrossRef] [PubMed]

- Anderson, M.J.; Whitcomb, P.J. RSM Simplified; Taylor and Francis Group: Boca Raton, FL, USA, 2005. [Google Scholar]

- Trippe, J. Erweiterung der Modellierung zur Durchsatz- und Leistungsberechnung von Feststoffförderprozessen in der Einschneckenextrusion. Ph.D. Thesis, Paderborn University, Paderborn, Germany, 2018. [Google Scholar]

- Brüning, F.; Schöppner, V. Calibration of a Contact Model for DEM Simulations of Grooved Feed Sections of Single Screw Extruders. In Proceedings of the 36th International Conference of the Polymer Processing Society (PPS-36), Montreal, QC, Canada, 26–29 September 2021. [Google Scholar]

- Schöppner, V. Simulation der Plastifiziereinheit von Einschneckenextrudern. Ph.D. Thesis, Paderborn University, Paderborn, Germamy, 1995. [Google Scholar]

- Gelnar, D.; Zegzulka, J. Discrete Element Method in the Design of Transport. In Systems: Verification and Validation of 3D Models; Springer International Publishing: Cham, Switzerland, 2019; ISBN 9783030057145. [Google Scholar]

- Leßmann, J.-S. Berechnung und Simulation von Feststoffförderprozessen in Einschneckenextrudern bis in den Hochgeschwindigkeitsbereich. Ph.D. Thesis, Paderborn University, Paderborn, Germangy, 2016. [Google Scholar]

- Potente, H. Der Nutbuchsenextruder muss umgedacht werden. Kunststoffe 1988, 78, 355–362. [Google Scholar]

- Ottens, T. Modellierung des Druck-Durchsatzverhaltens in Nutbuchsenextrudern auf Basis Numerischer Simulationen. Master’s Thesis, Paderborn University, Paderborn, Germany, 2021. [Google Scholar]

| Factor | Meaning | Unit | |||||

|---|---|---|---|---|---|---|---|

| inner coefficient of friction | - | 0.35 | 0.44 | 0.58 | 0.71 | 0.8 | |

| particle diameter | mm | 1 | 1.61 | 2.5 | 3.39 | 4 | |

| barrel diameter | mm | 35 | 45 | 60 | 75 | 85 | |

| channel depth | - | 0.1 | 0.12 | 0.15 | 0.18 | 0.2 | |

| screw pitch | - | 0.7 | 0.82 | 1 | 1.18 | 1.3 | |

| groove angle | ° | 50 | 60 | 75 | 90 | 100 | |

| peripheral speed | m/s | 0.11 | 0.25 | 0.45 | 0.65 | 0.79 | |

| backpressure | Bar | 10 | 110 | 255 | 400 | 500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brüning, F.; Schöppner, V. Numerical Simulation of Solids Conveying in Grooved Feed Sections of Single Screw Extruders. Polymers 2022, 14, 256. https://doi.org/10.3390/polym14020256

Brüning F, Schöppner V. Numerical Simulation of Solids Conveying in Grooved Feed Sections of Single Screw Extruders. Polymers. 2022; 14(2):256. https://doi.org/10.3390/polym14020256

Chicago/Turabian StyleBrüning, Florian, and Volker Schöppner. 2022. "Numerical Simulation of Solids Conveying in Grooved Feed Sections of Single Screw Extruders" Polymers 14, no. 2: 256. https://doi.org/10.3390/polym14020256

APA StyleBrüning, F., & Schöppner, V. (2022). Numerical Simulation of Solids Conveying in Grooved Feed Sections of Single Screw Extruders. Polymers, 14(2), 256. https://doi.org/10.3390/polym14020256