Mechanical Properties of 3D-Printed PEEK/HA Composite Filaments

Abstract

:1. Introduction

2. Materials and Methods

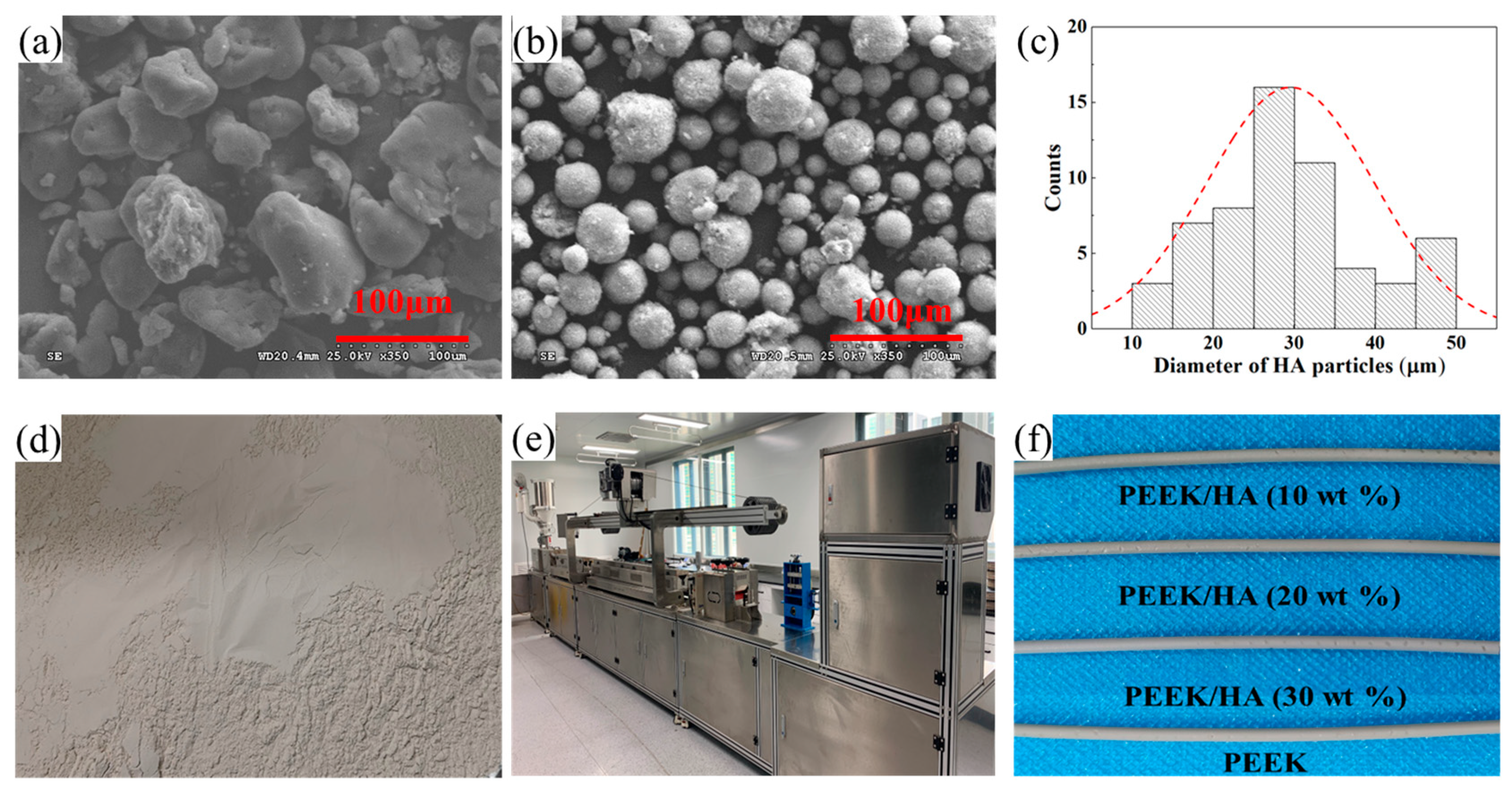

2.1. Fabrication of PEEK/HA Composite Filament

2.2. Mechanical Testing of Composite Filaments

2.3. Analysis of Mechanical Properties

3. Results and Discussion

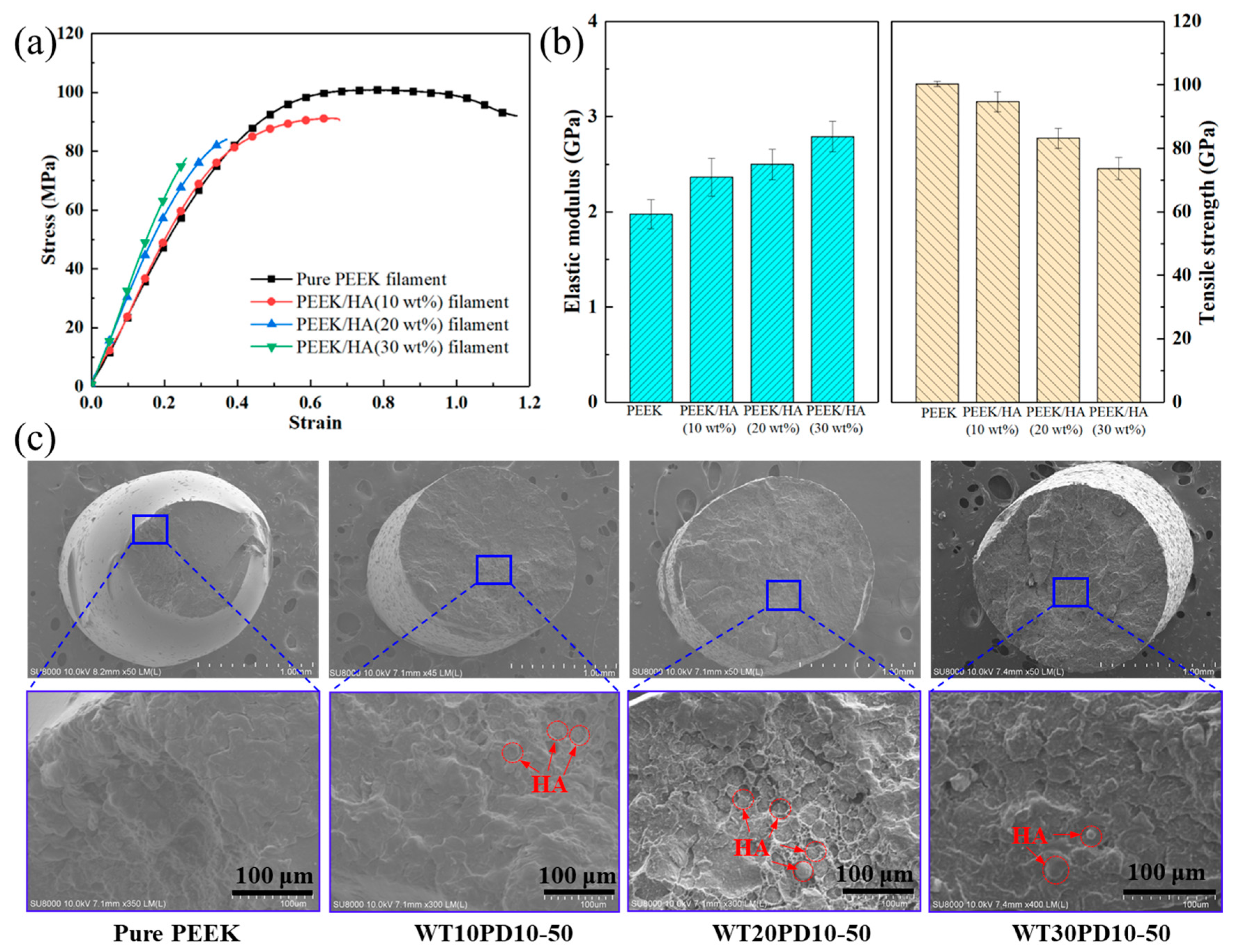

3.1. Tensile Properties of the Composite Filaments

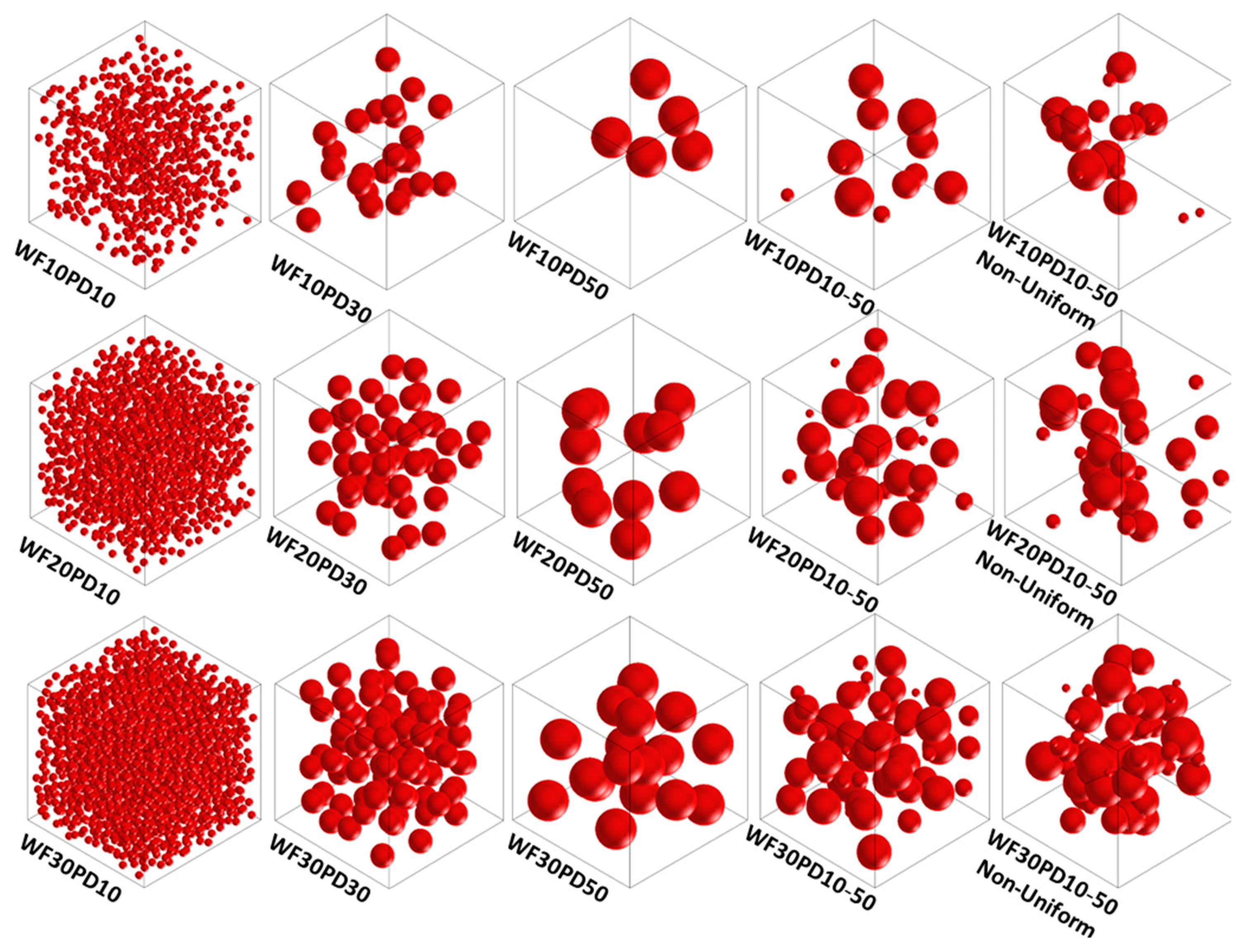

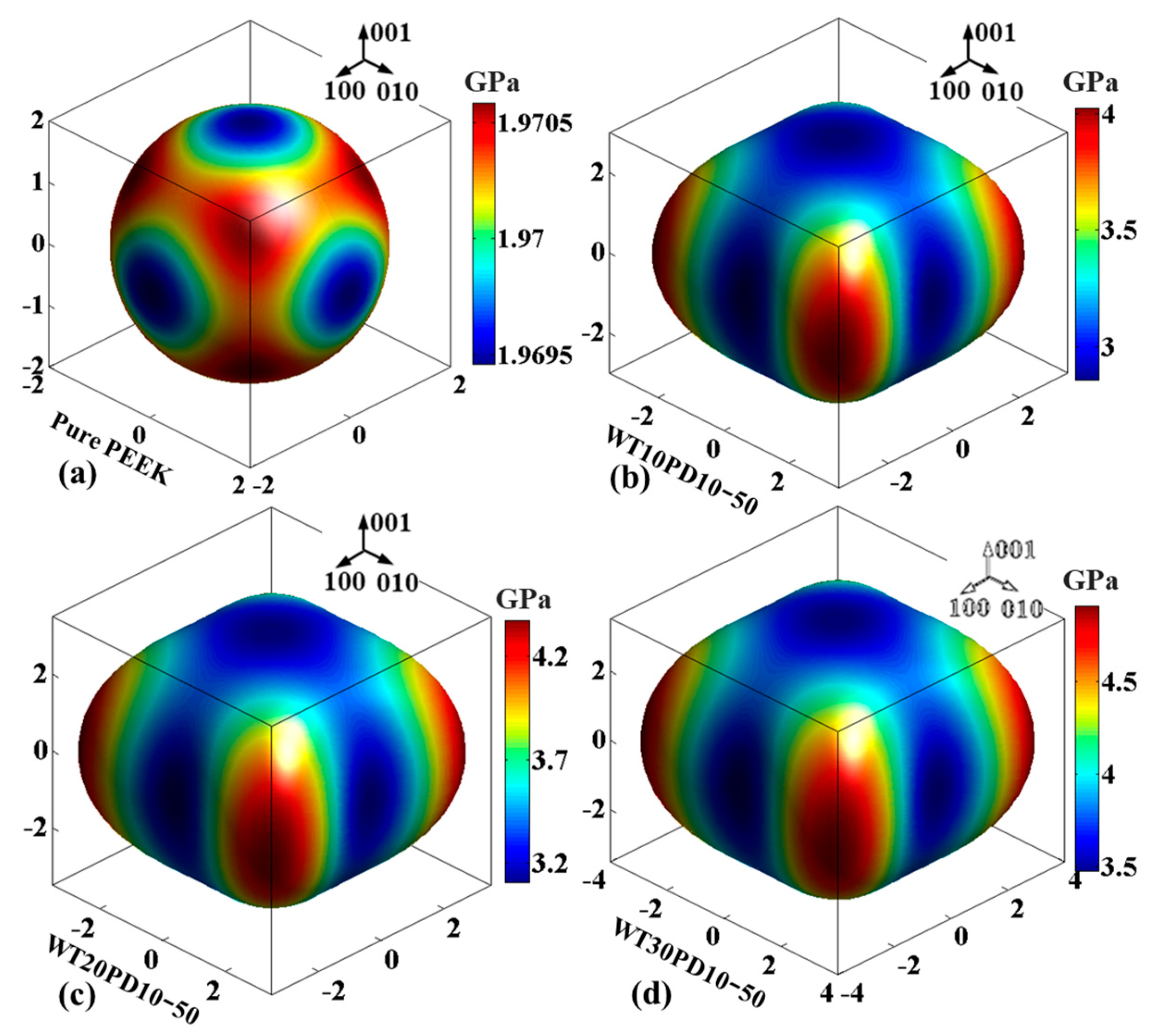

3.2. Influence Analysis of Mechanical Properties

4. Conclusions

- (1)

- The PEEK/HA composite filaments used for fused deposition modeling were fabricated. With an increase in HA content from 10 wt% to 30 wt%, the elastic modulus of the composite increased from 2.36 GPa to 2.79 GPa, while the tensile strength decreased from 95 MPa to 74 MPa, and the fracture elongation decreased from 63% to 23%, exhibiting brittle fracture failure under uniaxial tensile testing.

- (2)

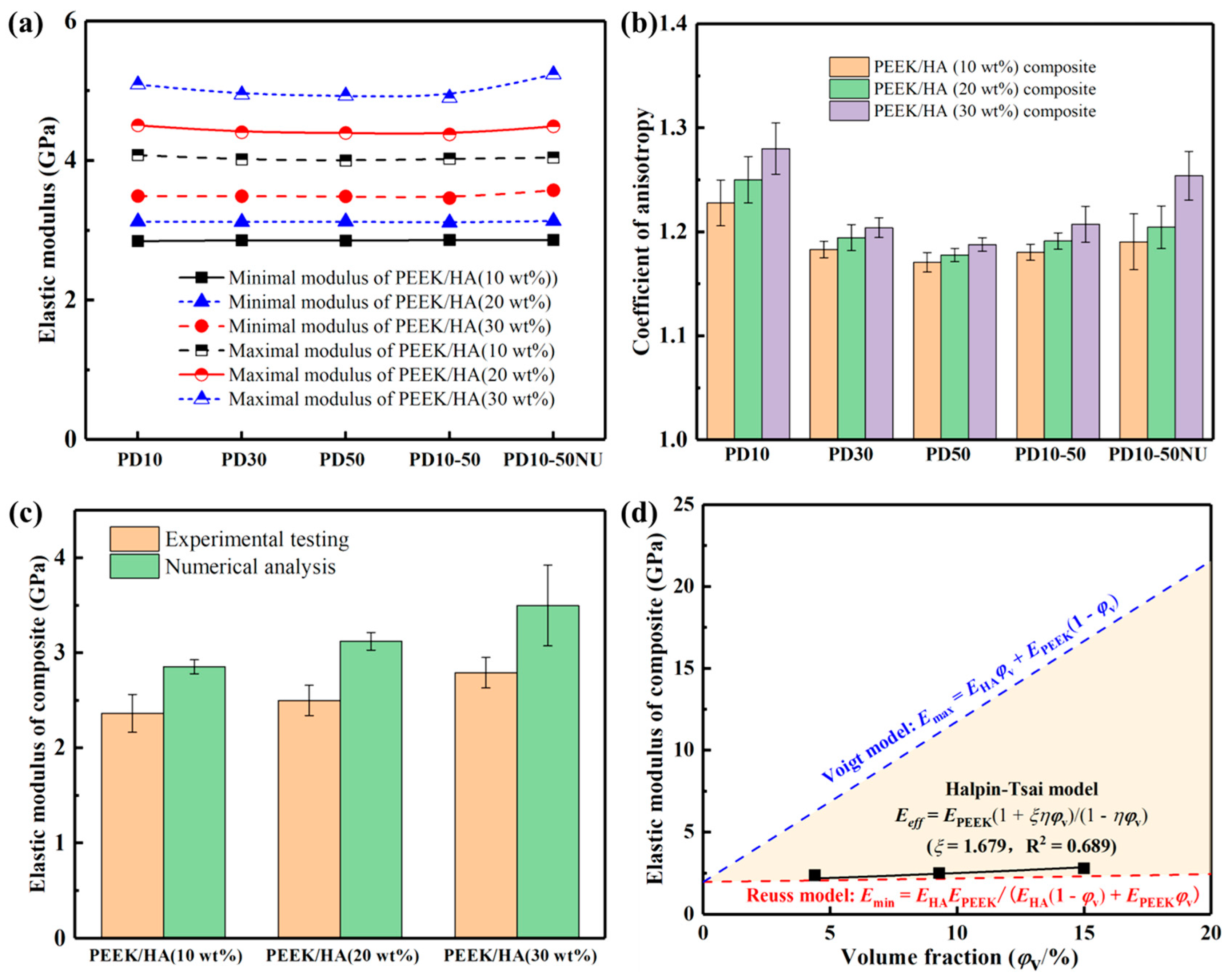

- The influence of particle diameter and dispersity on the elastic modulus of PEEK/HA composite was estimated using finite element analysis. When HA particles were uniformly distributed, the elastic modulus was less affected by the change in particle diameter. However, the modulus and anisotropic coefficient increased with the increase in HA content and particle clustering. Therefore, during the preparation process of the PEEK/HA composite, it is necessary to ensure the uniformity of particle size and dispersion uniformity as far as possible, so as to ensure the stability of its mechanical properties.

- (3)

- The mathematical relationship between the elastic modulus of a composite and the volume fraction of HA content was established on the basis of the Halpin–Tsai model and experimental data. The empirical parameter ξ was equal to 1.679 within the setting range of volume fraction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, J.F.; Wang, L.; Yang, C.C.; Wang, L.; Cao, Y.; He, J.K.; Li, D.C. Custom design and biomechanical analysis of 3D-printed PEEK rib prostheses. Biomech. Model Mechanobiol. 2018, 17, 1083–1092. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, C.; Kang, J.; Yang, C.; Zheng, J.; Su, Y.; Dong, E.; Liu, Y.; Yao, S.; Shi, C.; Pang, H.; et al. Additive manufactured polyether-ether-ketone implants for orthopaedic applications: A narrative review. Biomater. Transl. 2022, 3, 116–133. [Google Scholar] [PubMed]

- Toth, J.M.; Wang, M.; Estes, B.T.; Scifert, J.L.; Seim, H.B.; Turner, A.S. Polyetheretherketone as a biomaterial for spinal applications. Biomaterials 2006, 27, 324–334. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- O’Reilly, E.B.; Barnett, S.; Madden, C.; Welch, B.; Mickey, B.; Rozen, S. Computed-tomography modeled polyether ether ketone (PEEK) implants in revision cranioplasty. J. Plast. Reconstr. Aesthet. Surg. 2015, 68, 329–338. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Zhang, J.; Zheng, J.; Wang, L.; Li, D.; Liu, S. 3D-printed PEEK implant for mandibular defects repair—A new method. J. Mech. Behav. Biomed. Mater. 2021, 116, 104335. [Google Scholar] [CrossRef]

- Ma, R.; Tang, T.T. Current Strategies to Improve the Bioactivity of PEEK. Int. J. Mol. Sci. 2014, 15, 5426–5445. [Google Scholar] [CrossRef] [Green Version]

- Buck, E.; Li, H.; Cerruti, M. Surface Modification Strategies to Improve the Osseointegration of Poly(etheretherketone) and Its Composites. Macromol. Biosci. 2020, 20, e1900271. [Google Scholar] [CrossRef]

- Johansson, P.; Barkarmo, S.; Hawthan, M.; Peruzzi, N.; Kjellin, P.; Wennerberg, A. Biomechanical, histological, and computed X-ray tomographic analyses of hydroxyapatite coated PEEK implants in an extended healing model in rabbit. J. Biomed. Mater. Res. A 2018, 106, 1440–1447. [Google Scholar] [CrossRef]

- Das, T.K.; Ganguly, S.; Bhawal, P.; Mondal, S.; Das, N.C. A facile green synthesis of silver nanoparticle-decorated hydroxyapatite for efficient catalytic activity towards 4-nitrophenol reduction. Res. Chem. Intermed. 2018, 44, 1189–1208. [Google Scholar] [CrossRef]

- Das, T.K.; Bhawal, P.; Ganguly, S.; Mondal, S.; Remanan, S.; Ghosh, S.; Das, N.C. Synthesis of hydroxyapatite nanorods and its use as a nanoreinforcement block for ethylene methacrylate copolymer matrix. Polym. Bull. 2019, 76, 3621–3642. [Google Scholar] [CrossRef]

- Ma, H.; Suonan, A.; Zhou, J.; Yuan, Q.; Liu, L.; Zhao, X.; Lou, X.; Yang, C.; Li, D.; Zhang, Y.-g. PEEK (Polyether-ether-ketone) and its composite materials in orthopedic implantation. Arab. J. Chem. 2021, 14, 102977. [Google Scholar] [CrossRef]

- Zheng, J.; Dong, E.; Kang, J.; Sun, C.; Liu, C.; Wang, L.; Li, D. Effects of Raster Angle and Material Components on Mechanical Properties of Polyether-Ether-Ketone/Calcium Silicate Scaffolds. Polymers 2021, 13, 2547. [Google Scholar] [CrossRef] [PubMed]

- Manzoor, F.; Golbang, A.; Jindal, S.; Dixon, D.; McIlhagger, A.; Harkin-Jones, E.; Crawford, D.; Mancuso, E. 3D printed PEEK/HA composites for bone tissue engineering applications: Effect of material formulation on mechanical performance and bioactive potential. J. Mech. Behav. Biomed. Mater. 2021, 121, 104601. [Google Scholar] [CrossRef] [PubMed]

- Geng, Y.M.; Ren, D.N.; Li, S.Y.; Li, Z.Y.; Shen, X.Q.; Yuan, Y.Y. Hydroxyapatite-incorporation improves bone formation on endosseous PEEK implant in canine tibia. J. Appl. Biomater. Funct. Mater. 2020, 18, 1–9. [Google Scholar] [CrossRef]

- Zheng, J.; Kang, J.; Sun, C.; Yang, C.; Wang, L.; Li, D. Effects of printing path and material components on mechanical properties of 3D-printed polyether-ether-ketone/hydroxyapatite composites. J. Mech. Behav. Biomed. Mater. 2021, 118, 104475. [Google Scholar] [CrossRef] [PubMed]

- Rodzen, K.; Sharma, P.K.; McIlhagger, A.; Mokhtari, M.; Dave, F.; Tormey, D.; Sherlock, R.; Meenan, B.J.; Boyd, A. The Direct 3D Printing of Functional PEEK/Hydroxyapatite Composites via a Fused Filament Fabrication Approach. Polymers 2021, 13, 545. [Google Scholar] [CrossRef]

- Kang, J.; Dong, E.; Li, D.; Dong, S.; Zhang, C.; Wang, L. Anisotropy characteristics of microstructures for bone substitutes and porous implants with application of additive manufacturing in orthopaedic. Mater. Des. 2020, 191, 108608. [Google Scholar] [CrossRef]

- Rezwan, K.; Chen, Q.Z.; Blaker, J.J.; Boccaccini, A.R. Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering. Biomaterials 2006, 27, 3413–3431. [Google Scholar] [CrossRef]

- Liao, C.; Li, Y.; Tjong, S.C. Polyetheretherketone and Its Composites for Bone Replacement and Regeneration. Polymers 2020, 12, 2858. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Meenan, B.J.; McClorey, C.; Akay, M. Thermal analysis studies of poly(etheretherketone)/hydroxyapatite biocomposite mixtures. J. Mater. Sci. Mater. Med. 2000, 11, 481–489. [Google Scholar]

- Ma, S.M.; Zhuang, X.C.; Wang, X.M. 3D micromechanical simulation of the mechanical behavior of an in-situ Al3Ti/A356 composite. Compos. Part B Eng. 2019, 176, 107115. [Google Scholar] [CrossRef]

- Ma, S.M.; Zhuang, X.C.; Wang, X.M. Particle distribution-dependent micromechanical simulation on mechanical properties and damage behaviors of particle reinforced metal matrix composites. J. Mater. Sci. 2021, 56, 6780–6798. [Google Scholar] [CrossRef]

- Tseng, J.-W.; Liu, C.-Y.; Yen, Y.-K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.-J.; Wang, A.-B. Screw extrusion-based additive manufacturing of PEEK. Mater. Des. 2018, 140, 209–221. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Xu, G.; Mai, Y.-W. On the elastic modulus of hybrid particle/short-fiber/polymer composites. Compos. Part B Eng. 2002, 33, 291–299. [Google Scholar] [CrossRef]

- Raju, B.; Hiremath, S.R.; Mahapatra, D.R. A review of micromechanics based models for effective elastic properties of reinforced polymer matrix composites. Compos. Struct. 2018, 204, 607–619. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, J.; Zheng, J.; Hui, Y.; Li, D. Mechanical Properties of 3D-Printed PEEK/HA Composite Filaments. Polymers 2022, 14, 4293. https://doi.org/10.3390/polym14204293

Kang J, Zheng J, Hui Y, Li D. Mechanical Properties of 3D-Printed PEEK/HA Composite Filaments. Polymers. 2022; 14(20):4293. https://doi.org/10.3390/polym14204293

Chicago/Turabian StyleKang, Jianfeng, Jibao Zheng, Yijun Hui, and Dichen Li. 2022. "Mechanical Properties of 3D-Printed PEEK/HA Composite Filaments" Polymers 14, no. 20: 4293. https://doi.org/10.3390/polym14204293

APA StyleKang, J., Zheng, J., Hui, Y., & Li, D. (2022). Mechanical Properties of 3D-Printed PEEK/HA Composite Filaments. Polymers, 14(20), 4293. https://doi.org/10.3390/polym14204293