Dual X-ray- and Neutron-Shielding Properties of Gd2O3/NR Composites with Autonomous Self-Healing Capabilities

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Chemicals

2.2. Sample Preparation

2.3. Characterization

2.3.1. Neutron-Shielding Properties

2.3.2. X-ray-Shielding Properties

2.3.3. Mechanical Properties

2.3.4. Density Measurement

2.3.5. Morphological Studies

3. Results and Discussion

3.1. Density

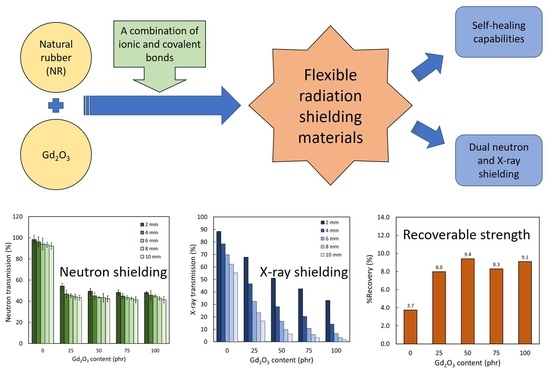

3.2. Neutron-Shielding Properties

3.3. X-ray-Shielding Properties

3.4. Comparative Neutron- and X-ray-Shielding Properties between Current and Other Similar Materials

3.5. Mechanical Properties

3.6. Self-Healing Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pradhan, P.; Costa, L.; Rybski, D.; Lucht, W.; Kropp, J.P. A systematic study of sustainable development goal (SDG) interactions. Earth’s Future 2017, 5, 1169–1179. [Google Scholar] [CrossRef] [Green Version]

- Courbet, G.; Gallardo, K.; Vigani, G.; Brunel-Muguet, S.; Trouverie, J.; Salon, C.; Ourry, A. Disentangling the complexity and diversity of crosstalk between sulfur and other mineral nutrients in cultivated plants. J. Exp. Bot. 2019, 70, 4183–4196. [Google Scholar] [CrossRef] [PubMed]

- Saenboonruang, K.; Phonchanthuek, E.; Prasandee, K. Soil-to-plant transfer factors of natural radionuclides (226Ra and 40K) in selected Thai medicinal plants. J. Environ. Radioact. 2018, 184–185, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Jassens, K.; Dik, J.; Cottee, M.; Susini, J. Photon-based techniques for nondestructive subsurface analysis of painted cultural heritage artifacts. Acc. Chem. Res. 2010, 43, 814–825. [Google Scholar] [CrossRef]

- Kut, C.; Chaichana, K.; Xi, J.; Raza, S.M.; Ye, X.; McVeigh, E.R.; Rodriguez, F.J.; Quinones-Hinojosa, A.; Li, X. Detection of human brain cancer infiltration ex vivo and in vivo using quantitative optical coherence tomography. Sci. Transl. Med. 2015, 7, 292ra100. [Google Scholar] [CrossRef] [Green Version]

- Taylor, C.W.; Kirby, A.M. Cardiac side-effects from breast cancer radiotherapy. Clin. Oncol. 2015, 27, 621–629. [Google Scholar] [CrossRef]

- Lekshmi, S.; Singh, D.N.; Baghini, M.S. A critical review of soil moisture measurement. Measurement 2014, 54, 92–105. [Google Scholar]

- Parejo Calvo, W.A.; Duarte, C.L.; Machado, L.D.B.; Manzoli, J.E.; Geraldo, A.B.C.; Kodama, Y.; Silva, L.G.A.; Pino, E.S.; Somessari, E.S.R.; Silveira, C.G.; et al. Electron beam accelerators—trends in radiation processing technology for industrial and environmental applications in Latin America and the Caribbean. Radiat. Phys. Chem. 2012, 81, 1276–1281. [Google Scholar] [CrossRef]

- Leuraud, K.; Richardson, D.B.; Cardis, E.; Daniels, R.D.; Gillies, M.; O’Hagan, J.A.; Hamra, G.B.; Haylock, R.; Laurier, D.; Moissonnier, M.; et al. Ionising radiation and risk of death from leukaemia and lymphoma in radiation-monitored workers (INWORKS): An international cohort study. Lancet Haematol. 2015, 2, e276–e281. [Google Scholar] [CrossRef] [Green Version]

- Yeung, A.W.K. The “As Low As Reasonably Achievable” (ALARA) principle: A brief historical overview and a bibliometric analysis of the most cited publications. Radioprotection 2019, 54, 103–109. [Google Scholar] [CrossRef]

- Ninyong, K.; Wimolmala, E.; Sombatsompop, N.; Saenboonruang, K. Potential use of NR and wood/NR composites as thermal neutron shielding materials. Polym. Test. 2017, 59, 336–343. [Google Scholar] [CrossRef]

- Kumar, A. Gamma ray shielding properties of PbO-Li2O-B2O3 glasses. Radiat. Phys. Chem. 2017, 136, 50–53. [Google Scholar] [CrossRef]

- Poltabtim, W.; Wimolmala, E.; Saenboonruang, K. Properties of lead-free gamma-ray shielding materials from metal oxide/EPDM rubber composites. Radiat. Phys. Chem. 2018, 153, 1–9. [Google Scholar] [CrossRef]

- Thumwong, A.; Chinnawet, M.; Intarasena, P.; Rattanapongs, C.; Tokonami, S.; Ishikawa, T.; Saenboonruang, K. A comparative study on X-ray shielding and mechanical properties of natural rubber latex nanocomposites containing Bi2O3 or BaSO4: Experimental and numerical determination. Polymers 2022, 14, 3654. [Google Scholar] [CrossRef]

- Singh, V.P.; Ali, A.M.; Badiger, N.M.; Al-Khayatt, A.M. Monte Carlo simulation of gamma ray shielding parameters of concretes. Nucl. Eng. Des. 2013, 265, 1071–1077. [Google Scholar] [CrossRef]

- Hu, G.; Shi, G.; Hu, H.; Yang, Q.; Yu, B.; Sun, W. Development of gradient composite shielding material for shielding neutrons and gamma rays. Nucl. Eng. Technol. 2020, 52, 2387–2393. [Google Scholar] [CrossRef]

- Tekin, H.O.; Altunsoy, E.E.; Kavaz, E.; Sayyed, M.I.; Agar, O.; Kamislioglu, M. Photon and neutron shielding performance of boron phosphate glasses for diagnostic radiology facilities. Results Phys. 2019, 12, 1457–1464. [Google Scholar] [CrossRef]

- Tiamduantawan, P.; Wimolmala, E.; Meesat, R.; Saenboonruang, K. Effects of Sm2O3 and Gd2O3 in poly (vinyl alcohol) hydrogels for potential use as self-healing thermal neutron shielding materials. Radiat. Phys. Chem. 2020, 172, 108818. [Google Scholar] [CrossRef]

- Kaewnuam, E.; Wantana, N.; Tanusilp, S.; Kurosaki, K.; Limkitjaroenporn, P.; Kaewkhao, J. The influence of Gd2O3 on shielding, thermal and luminescence properties of WO3-Gd2O3-B2O3 glass for radiation shielding and detection material. Radiat. Phys. Chem. 2022, 190, 109805. [Google Scholar] [CrossRef]

- Gwaily, S.E.; Badawy, M.M.; Hassan, H.H.; Madani, M. Natural rubber composites as thermal neutron radiation shields: I. B4C/NR composites. Polym. Test. 2002, 21, 129–133. [Google Scholar] [CrossRef]

- Ozdemir, T.; Akbay, I.K.; Uzun, H.; Reyhancan, I.A. Neutron shielding of EPDM rubber with boric acid: Mechanical, thermal properties and neutron absorption tests. Prog. Nucl. Energy 2016, 89, 102–109. [Google Scholar] [CrossRef]

- El-Khatib, A.M.; Doma, A.S.; Badawi, M.S.; Abu-Rayan, A.E.; Aly, N.S.; Alzahrani, J.S.; Abbas, M.I. Conductive natural and waste rubbers composites-loaded with lead powder as environmental flexible gamma radiation shielding material. Mater. Res. Express 2020, 7, 105309. [Google Scholar] [CrossRef]

- Xu, C.; Cao, L.; Lin, B.; Liang, X.; Chen, Y. Design of self-healing supramolecular rubbers by introducing ionic cross-links into natural rubber via a controlled vulcanization. ACS Appl. Mater. Interfaces 2016, 8, 17728–17737. [Google Scholar] [CrossRef]

- Xu, C.; Cao, L.; Huang, X.; Chen, Y.; Lin, B.; Fu, L. Self-healing natural rubber with tailorable mechanical properties based on ionic supramolecular hybrid network. ACS Appl. Mater. Interfaces 2017, 9, 29363–29373. [Google Scholar] [CrossRef] [PubMed]

- Norhazariah, S.; Azura, A.R.; Sivakumar, R.; Azahari, B. Effect of different preparation methods on crosslink density and mechanical properties of Carrageenan filled natural rubber (NR) latex films. Procedia Chem. 2016, 19, 986–992. [Google Scholar] [CrossRef] [Green Version]

- Boden, J.; Bowen, C.R.; Buchard, A.; Davidson, M.G.; Norris, C. Understanding the effects of cross-linking density on the self-healing performance of epoxidized natural rubber and natural rubber. ACS Omega 2022, 7, 15098–15105. [Google Scholar] [CrossRef]

- Gerward, L.; Guilbert, N.; Bjorn Jensen, K.; Levring, H. X-ray absorption in matter. Reengineering XCOM. Radiat. Phys. Chem. 2001, 60, 23–24. [Google Scholar] [CrossRef]

- Tiamduangtawan, P.; Kamkaew, C.; Kuntonwatchara, S.; Wimolmala, E.; Saenboonruang, K. Comparative mechanical, self-healing, and gamma attenuation properties of PVA hydrogels containing either nano- or micro-sized Bi2O3 for use as gamma-shielding materials. Radiat. Phys. Chem. 2020, 177, 109164. [Google Scholar] [CrossRef]

- Kires, M. Archimedes’ principle in action. Phys. Educ. 2007, 42, 484. [Google Scholar] [CrossRef] [Green Version]

- Moonart, U.; Utara, S. Effect of surface treatments and filler loading on the properties of hemp fiber/natural rubber composites. Cellulose 2019, 26, 7271–7295. [Google Scholar] [CrossRef]

- Sears, V.F. Neutron scattering lengths and cross sections. Neutron News 1992, 3, 26–37. [Google Scholar] [CrossRef]

- Piotrowski, T. Neutron shielding evaluation of concretes and mortars: A review. Const. Build Mater. 2021, 277, 122238. [Google Scholar] [CrossRef]

- Celli, M.; Grazzi, F.; Zoppi, M. A new ceramic material for shielding pulsed neutron scattering instruments. Nucl. Instrum. Methods Phys. Res. A. 2006, 565, 861–863. [Google Scholar] [CrossRef]

- Xu, Z.G.; Jiang, L.T.; Zhang, Q.; Qiao, J.; Gong, D.; Wu, G.H. The design of a novel neutron shielding B4C/Al composite containing Gd. Mater. Des. 2016, 111, 375–381. [Google Scholar] [CrossRef]

- Manohara, S.R.; Hanagodimath, S.M.; Thind, K.S.; Gerward, L. On the effective atomic number and electron density: A comprehensive set of formulas for all types of materials and energies above 1 keV. Nucl. Instrum. Methods Phys. Res. Sec. B 2008, 266, 3906–3912. [Google Scholar] [CrossRef]

- Singh, V.P.; Badiger, N.M. Study of mass attenuation coefficients, effectiv1e atomic numbers and electron densities of carbon steel and stainless steels. Radioprotection 2013, 48, 431–443. [Google Scholar] [CrossRef] [Green Version]

- Aghaz, A.; Faghihi, R.; Mortazavi, S.M.J.; Haghparast, A.; Mehdizadeh, S.; Sina, S. Radiation attenuation properties of shields containing micro and nano WO3 in diagnostic X-ray energy range. Int. J. Radiat. Res. 2016, 14, 127–131. [Google Scholar] [CrossRef] [Green Version]

- Chantler, C.T. Detailed tabulation of atomic form factors, photoelectric absorption and scattering cross section, and mass attenuation coefficients in the vicinity of absorption edges in the soft X-ray (Z=30–36, Z=60–89, E=0.1 keV–10 keV), addressing convergence issues of earlier work. J. Phys. Chem. Ref. Data 2000, 29, 597. [Google Scholar]

- McCaffrey, J.P.; Shen, H.; Downton, B.; Mainegra-Hing, E. Radiation attenuation by lead and nonlead materials used in radiation shielding garments. Med. Phys. 2007, 34, 530–537. [Google Scholar] [CrossRef] [Green Version]

- Ozdemir, T.; Gungor, A.; Reyhancan, I.A. Flexible neutron shielding composite material of EPDM rubber with boron trioxide: Mechanical, thermal investigations and neutron shielding tests. Radiat. Phys. Chem. 2017, 131, 7–12. [Google Scholar] [CrossRef]

- Intom, S.; Kalkornsurapranee, E.; Johns, J.; Kaewjaeng, S.; Kothan, S.; Hongtong, W.; Chaiphaksa, W.; Kaewkhao, J. Mechanical and radiation shielding properties of flexible material based on natural rubber/ Bi2O3 composites. Radiat. Phys. Chem. 2020, 172, 108772. [Google Scholar] [CrossRef]

- Kong, S.M.; Mariatti, M.; Busfield, J.J.C. Effects of types of fillers and filler loading on the properties of silicone rubber composites. J. Reinf. Plast. Compos. 2011, 30, 1087–1096. [Google Scholar] [CrossRef]

- Frohlich, J.; Niedermeier, W.; Luginsland, H.D. The effect of filler–filler and filler–elastomer interaction on rubber reinforcement. Compos. Part A Appl. Sci. Manuf. 2005, 36, 449–460. [Google Scholar] [CrossRef]

- Sambhudevan, S.; Shankar, B.; Appukuttan, S.; Joseph, K. Evaluation of kinetics and transport mechanism of solvents through natural rubber composites containing organically modified gadolinium oxide. Plast. Rubber Compos. 2016, 45, 216–223. [Google Scholar] [CrossRef]

- Fan, R.L.; Zhang, Y.; Li, F.; Zhang, Y.X.; Sun, K.; Fan, Y.Z. Effect of high-temperature curing on the crosslink structures and dynamic mechanical properties of gum and N330-filled natural rubber vulcanizates. Polym. Test. 2001, 20, 925–936. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Liu, R.; Liang, Z.; Yang, J.; Zhang, R.; Zhou, Z.; Nie, Y. Design of self-healing rubber by introducing ionic interaction to construct a network composed of ionic and covalent cross-linking. Ind. Eng. Chem. Res. 2019, 58, 14848–14858. [Google Scholar] [CrossRef]

- Zhao, M.; Chen, H.; Yuan, J.; Wu, Y.; Li, S.; Liu, R. The study of ionic and entanglements self-healing behavior of zinc dimethacrylate enhanced natural rubber and natural rubber/butyl rubber composite. J. Appl. Polym. Sci. 2022, 139, 52048. [Google Scholar] [CrossRef]

- Wu, M.; Yang, L.; Shen, Q.; Zheng, Z.; Xu, C. Endeavour to balance mechanical properties and self-healing of nature rubber by increasing covalent crosslinks via a controlled vulcanization. Eur. Polym. J. 2011, 161, 110823. [Google Scholar] [CrossRef]

- Peymanfar, R.; Selseleh-Zakerin, E.; Ahmadi, A.; Saeidi, A.; Tavassoli, S.H. Preparation of self-healing hydrogel toward improving electromagnetic interference shielding and energy efficiency. Sci. Rep. 2021, 11, 16161. [Google Scholar] [CrossRef]

- Park, J.; Kim, M.; Choi, S.; Sun, J. Self-healable soft shield for γ-ray radiation based on polyacrylamide hydrogel composites. Sci. Rep. 2020, 10, 21689. [Google Scholar] [CrossRef]

| Chemical | Content (phr) | Role | Supplier |

|---|---|---|---|

| Natural rubber (NR: STR 5CV) | 100 | Main matrix | Hybrid Post Co., Ltd. (Bangkok, Thailand) |

| Zinc dimethacrylate (ZDMA) | 40 | Accelerator | Shanghai Ruizheng Chemical Technology Co., Ltd. (Shanghai, China) |

| Dicumyl peroxide (DCP) | 1 | Curing agent | Shanghai Ruizheng Chemical Technology Co., Ltd. (Shanghai, China) |

| Gadolinium oxide (Gd2O3) | 0, 25, 50, 75, and 100 | Radiation-protective filler | Shanghai Ruizheng Chemical Technology Co., Ltd. (Shanghai, China) |

| Gd2O3 Content (phr) | Experimental Density (g/cm3) | Theoretical Density (g/cm3) | Difference (%) |

|---|---|---|---|

| 0 (Control) | 0.99 ± 0.01 | 0.95 | 4.0 |

| 25 | 1.19 ± 0.01 | 1.15 | 3.4 |

| 50 | 1.35 ± 0.01 | 1.33 | 1.5 |

| 75 | 1.49 ± 0.01 | 1.51 | 1.3 |

| 100 | 1.60 ± 0.01 | 1.68 | 5.0 |

| Main Matrix | Filler | Filler Content | Half-Value Layer (mm) | Reference | |

|---|---|---|---|---|---|

| Neutrons | X-rays | ||||

| NR | Gd2O3 | 50 phr | 2.0 | 2.1 (60 kV)/3.6 (100 kV) | This work |

| NR | Gd2O3 | 75 phr | 1.9 | 1.6 (60 kV)/2.7 (100 kV) | This work |

| NR | B2O3 | 80 phr | 3.2 | – | [11] |

| PVA | Sm2O3 | 10.5 wt% | 4.2 | – | [18] |

| PVA | Gd2O3 | 10.5 wt% | 3.6 | – | [18] |

| EPDM | B2O3 | 42.6 phr | 3.7 | – | [40] |

| NR | Bi2O3 | 50 phr | – | 6.0 (60 kV) | [14] |

| NR | BaSO4 | 50 phr | – | 6.0 (60 kV) | [14] |

| NR | Bi2O3 | 40 phr | – | ~3.5 (120 kV) | [41] |

| NR | Bi2O3 | 80 phr | – | ~3.0 (120 kV) | [41] |

| Gd2O3 Content (phr) | Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) |

|---|---|---|---|

| 0 (Control) | 8.29 ± 0.83 | 555 ± 53 | 38 ± 1 |

| 25 | 5.02 ± 0.79 | 387 ± 33 | 41 ± 1 |

| 50 | 4.07 ± 0.14 | 515 ± 10 | 45 ± 1 |

| 75 | 4.08 ± 0.77 | 463 ± 16 | 46 ± 1 |

| 100 | 3.34 ± 0.26 | 411 ± 9 | 50 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poltabtim, W.; Thumwong, A.; Wimolmala, E.; Rattanapongs, C.; Tokonami, S.; Ishikawa, T.; Saenboonruang, K. Dual X-ray- and Neutron-Shielding Properties of Gd2O3/NR Composites with Autonomous Self-Healing Capabilities. Polymers 2022, 14, 4481. https://doi.org/10.3390/polym14214481

Poltabtim W, Thumwong A, Wimolmala E, Rattanapongs C, Tokonami S, Ishikawa T, Saenboonruang K. Dual X-ray- and Neutron-Shielding Properties of Gd2O3/NR Composites with Autonomous Self-Healing Capabilities. Polymers. 2022; 14(21):4481. https://doi.org/10.3390/polym14214481

Chicago/Turabian StylePoltabtim, Worawat, Arkarapol Thumwong, Ekachai Wimolmala, Chanis Rattanapongs, Shinji Tokonami, Tetsuo Ishikawa, and Kiadtisak Saenboonruang. 2022. "Dual X-ray- and Neutron-Shielding Properties of Gd2O3/NR Composites with Autonomous Self-Healing Capabilities" Polymers 14, no. 21: 4481. https://doi.org/10.3390/polym14214481

APA StylePoltabtim, W., Thumwong, A., Wimolmala, E., Rattanapongs, C., Tokonami, S., Ishikawa, T., & Saenboonruang, K. (2022). Dual X-ray- and Neutron-Shielding Properties of Gd2O3/NR Composites with Autonomous Self-Healing Capabilities. Polymers, 14(21), 4481. https://doi.org/10.3390/polym14214481