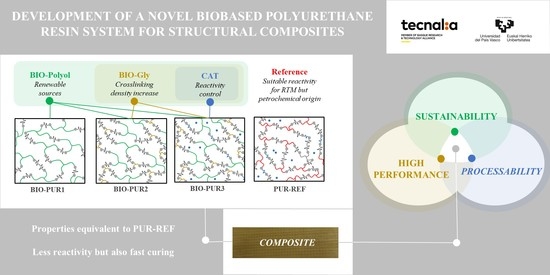

Development of a Novel Biobased Polyurethane Resin System for Structural Composites

Abstract

:1. Introduction

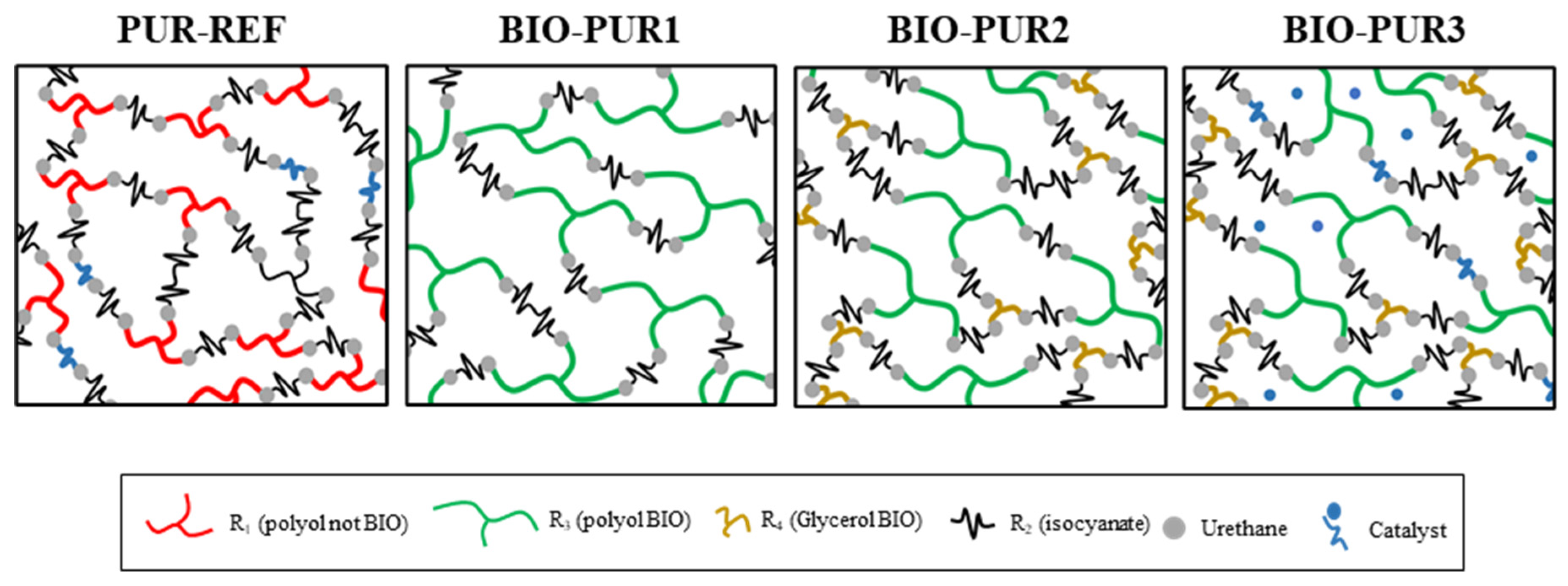

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Rheological Characterisation

2.2.2. Differential Scanning Calorimetry (DSC)

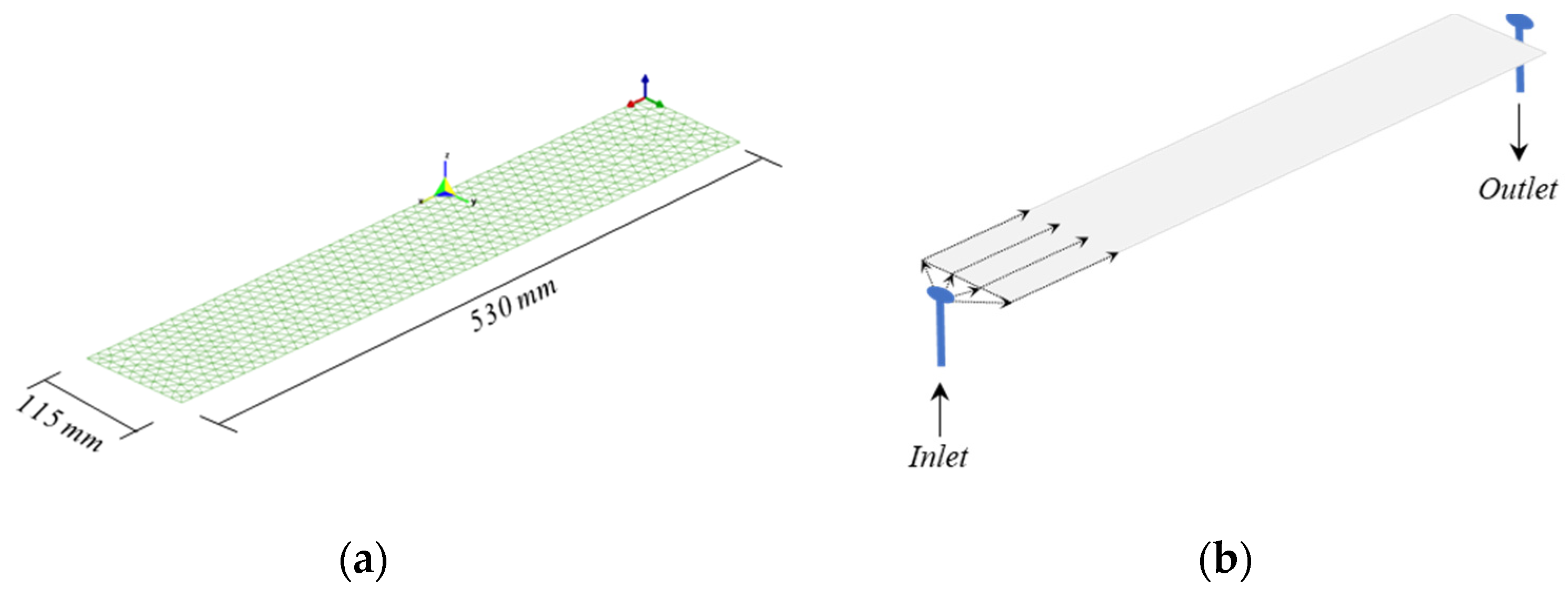

2.2.3. RTM Process Simulation

2.2.4. Dynamic Mechanical Analysis (DMA)

2.2.5. Mechanical Properties

2.2.6. Density

2.2.7. Fibre and Void Volume Fraction

3. Results and Discussion

3.1. Rheological Characterisation

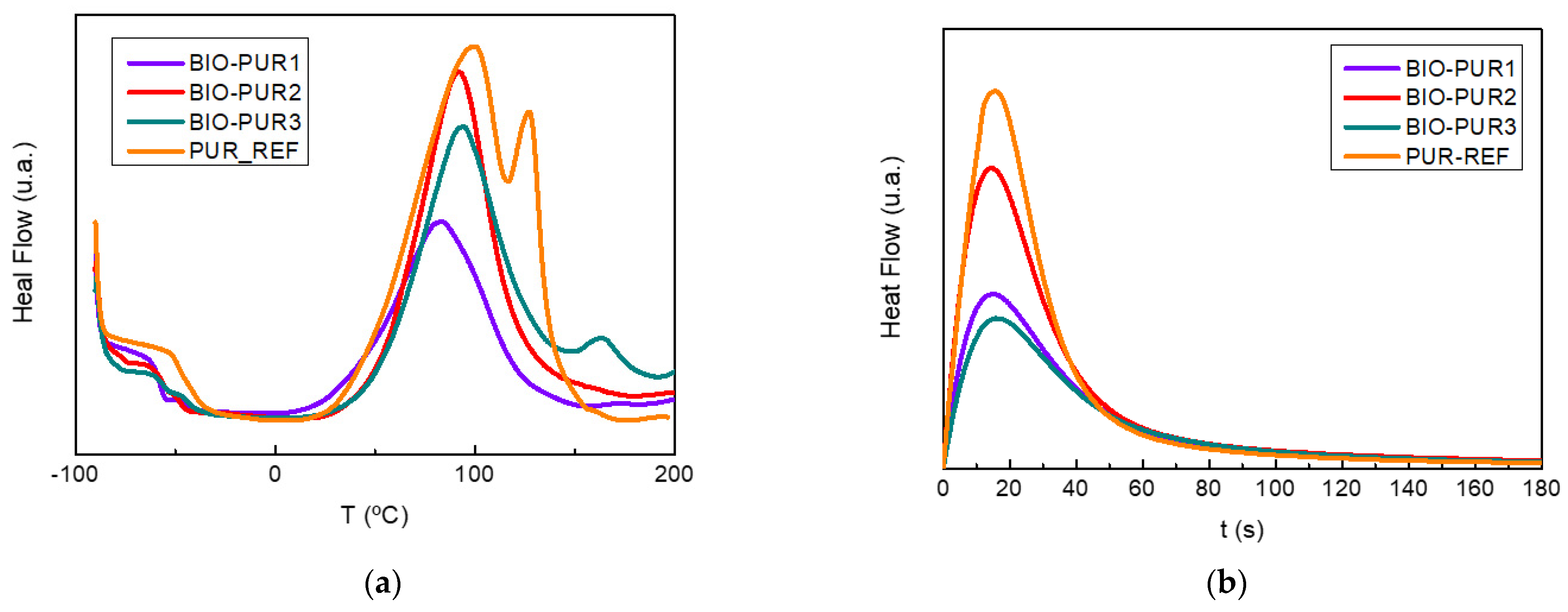

3.2. Differential Scanning Calorimetry

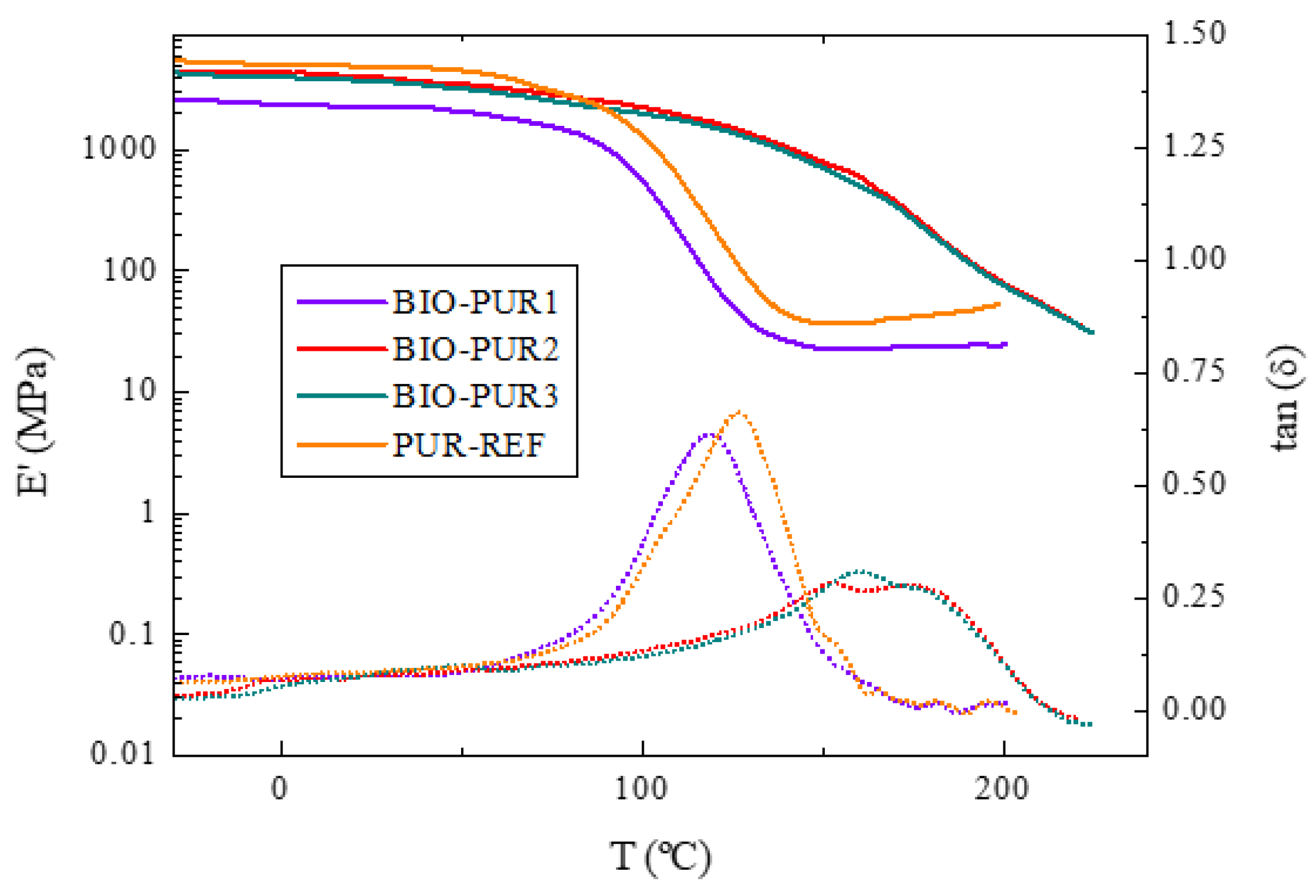

3.3. Dynamical Mechanical Analysis

3.4. Mechanical Properties

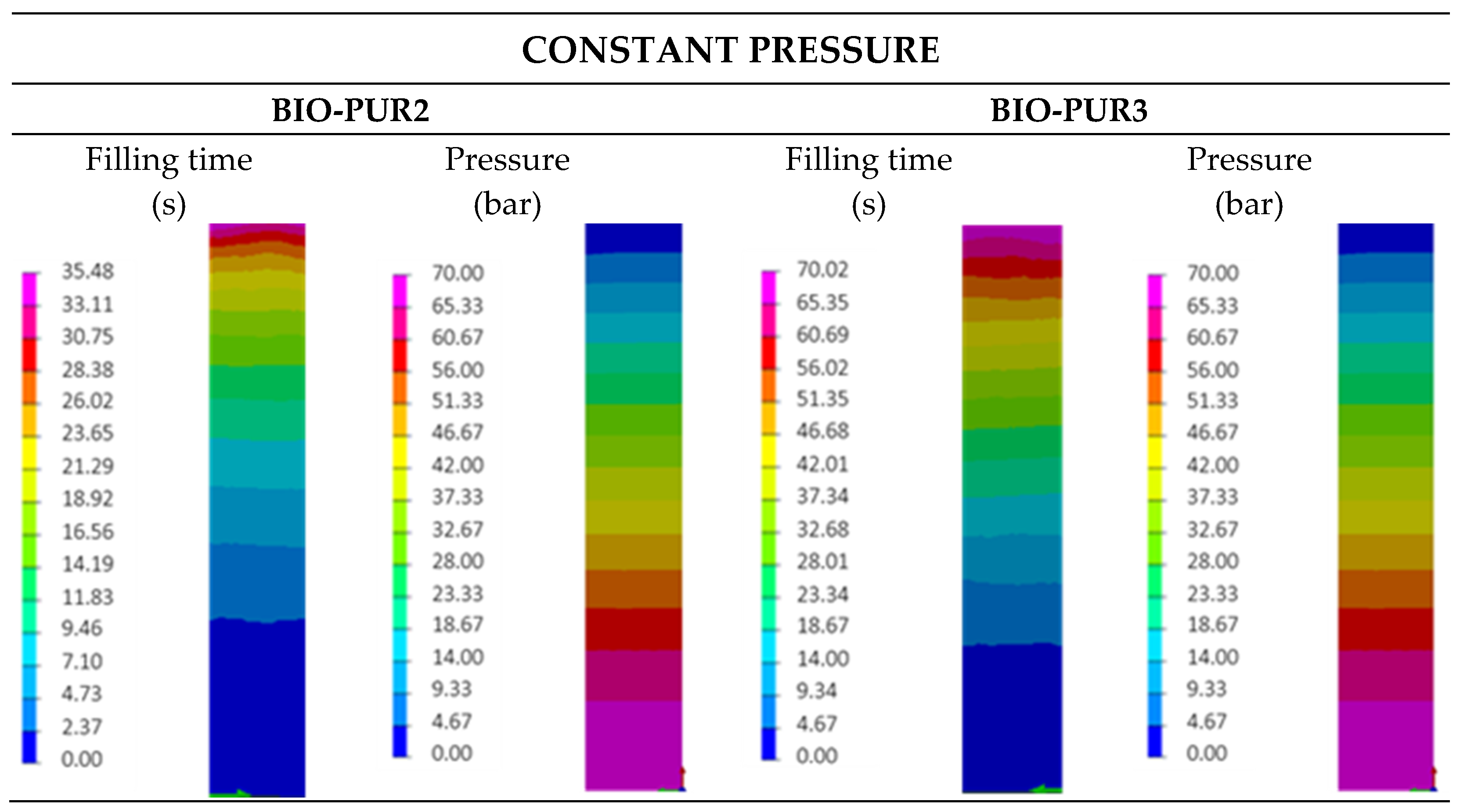

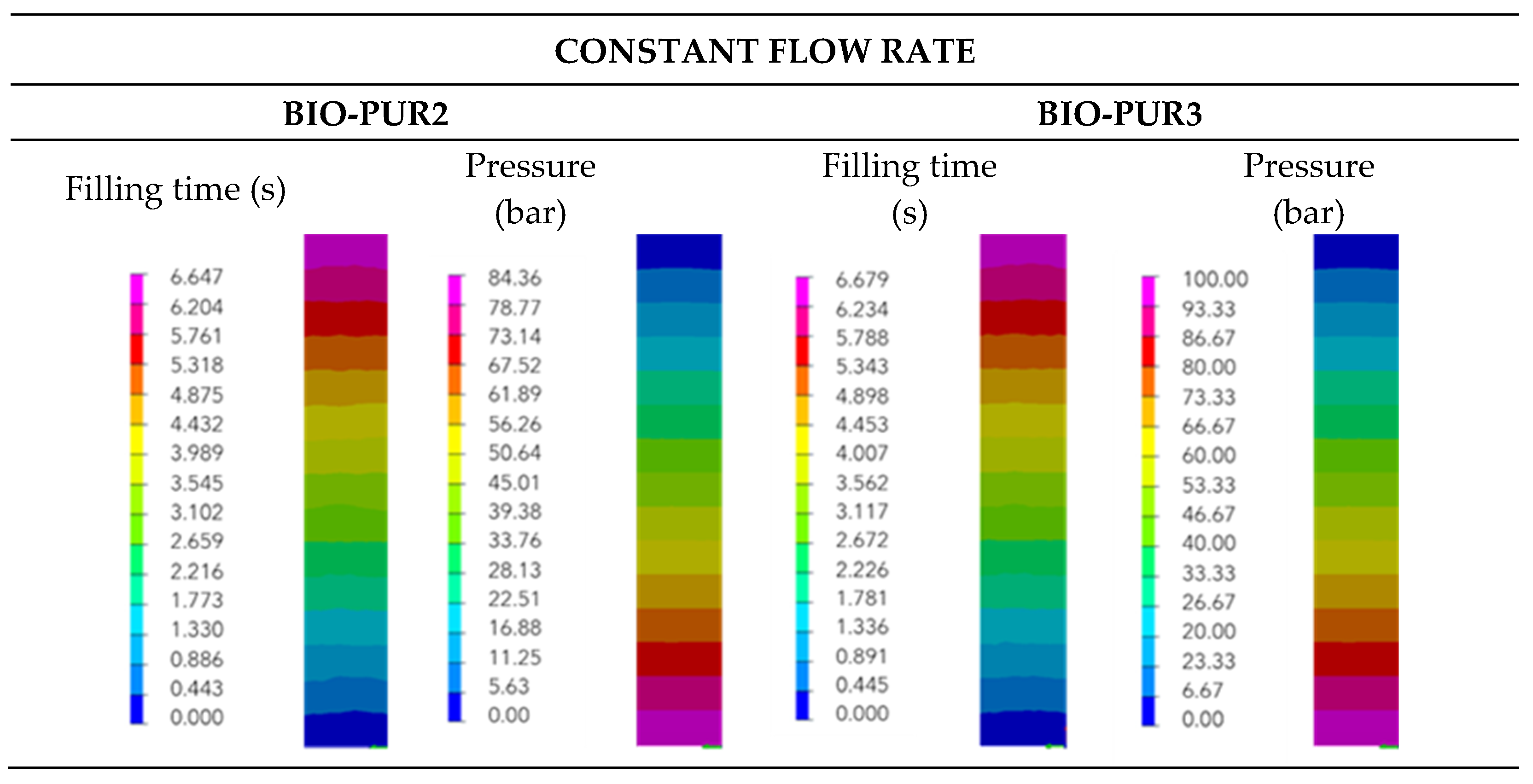

3.5. Modelling and Process Simulation

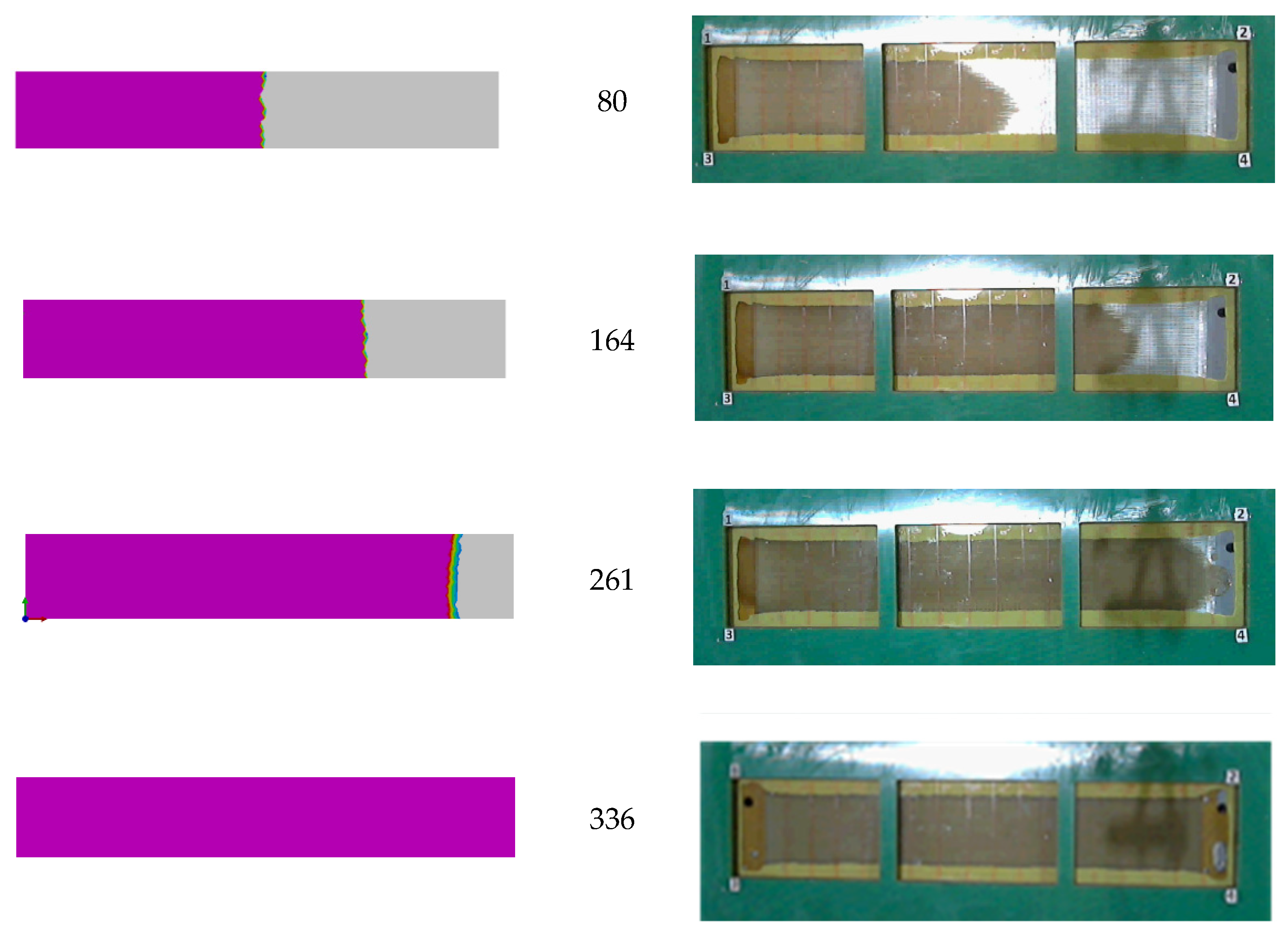

3.6. Composites Manufacturing, Testing, and Validation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gardiner, G. The Rise of HP-RTM. CompositesWorld. 2015. Available online: https://www.compositesworld.com/articles/hp-rtm-on-the-rise (accessed on 20 October 2022).

- Bareis, D.; Heberer, D.; Connolly, M. Advances in Urethane Composites: Resins With Tunable Reaction Times. In Proceedings of the COMPOSITES, Fort Lauderdale, FL, USA, 2–4 February 2011. [Google Scholar]

- Mason, H. SGL Carbon Produces Composite Leaf Springs for Ford Transit. CompositesWorld. 2019. Available online: https://www.compositesworld.com/news/sgl-carbon-produces-composite-leaf-springs-for-ford-transit (accessed on 20 October 2022).

- Albrecht, P.; Becher, J.; Wiemand, M.; Hindahl, J. Optimizing Leaf Springs via Enhanced Composite Solutions. JEC Compos. Mag. 2019, N°128, 24–26. Available online: https://www.nxtbook.fr/newpress/jeccomposites/jcm1905_128/index.php?startid=24&qs=Optimizing+Leaf+Springs+via+Enhanced+Composite+Solutions.#/p/24 (accessed on 26 October 2022).

- Kreiling, S.; Fetscher, F. Progress with Polyurethane Matrix Resin Technology: High-Speed Resin Transfer Molding Processes and Application Examples. In Proceedings of the SPE ACCE, Novi, MI, USA, 11–13 September 2013. [Google Scholar]

- Wood, K. Composite Leaf Springs: Saving Weight in Production. CompositesWorld. 2014. Available online: https://www.compositesworld.com/articles/composite-leaf-springs-saving-weight-in-production-suspension-systems (accessed on 20 October 2022).

- Acuña, P.; Zhang, J.; Yin, G.Z.; Liu, X.Q.; Wang, D.Y. Bio-Based Rigid Polyurethane Foam from Castor Oil with Excellent Flame Retardancy and High Insulation Capacity via Cooperation with Carbon-Based Materials. J. Mater. Sci. 2021, 56, 2684–2701. [Google Scholar] [CrossRef]

- Bobade, S.K.; Paluvai, N.R.; Mohanty, S.; Nayak, S.K. Bio-Based Thermosetting Resins for Future Generation: A Review. Polym. Plast. Technol. Eng. 2016, 55, 1863–1896. [Google Scholar] [CrossRef]

- Calvo-Correas, T.; Gabilondo, N.; Alonso-Varona, A.; Palomares, T.; Corcuera, M.A.; Eceiza, A. Shape-Memory Properties of Crosslinked Biobased Polyurethanes. Eur. Polym. J. 2016, 78, 253–263. [Google Scholar] [CrossRef]

- Chundawat, T.S.; Verma, N.; Vaya, D. Development in Synthesis and Coating Applications of Polyurethane. J. Chil. Chem. Soc. 2021, 66, 5142–5148. [Google Scholar] [CrossRef]

- Wendels, S.; Avérous, L. Biobased Polyurethanes for Biomedical Applications. Bioact. Mater. 2021, 6, 1083–1106. [Google Scholar] [CrossRef]

- Tenorio-Alfonso, A.; Sánchez, M.C.; Franco, J.M. A Review of the Sustainable Approaches in the Production of Bio-Based Polyurethanes and Their Applications in the Adhesive Field. J. Polym. Environ. 2020, 28, 749–774. [Google Scholar] [CrossRef] [Green Version]

- Meiorin, C.; Calvo-Correas, T.; Mosiewicki, M.A.; Aranguren, M.I.; Corcuera, M.A.; Eceiza, A. Comparative Effects of Two Different Crosslinkers on the Properties of Vegetable Oil-Based Polyurethanes. J. Appl. Polym. Sci. 2020, 137, 48741. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, M.; Yu, R.; Huang, J.; Dong, X.; Zhang, R.; Zhu, J. Bio-Based Shape Memory Polyurethanes (Bio-SMPUs) with Short Side Chains in the Soft Segment. J. Mater. Chem. A 2014, 2, 11490–11498. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, R.; Guo, B.; Ma, P.X. Dopamine-Incorporated Dual Bioactive Electroactive Shape Memory Polyurethane Elastomers with Physiological Shape Recovery Temperature, High Stretchability, and Enhanced C2C12 Myogenic Differentiation. ACS Appl. Mater. Interfaces 2017, 9, 29595–29611. [Google Scholar] [CrossRef]

- Gurunathan, T.; Nayak, S.K. The Influence of Reactive Organoclay on a Biorenewable Castor Oil-Based Polyurethane Prepolymers Toughened Polylactide Nanocomposites. Polym. Adv. Technol. 2016, 27, 1484–1493. [Google Scholar] [CrossRef]

- Gama, N.V.; Soares, B.; Freire, C.S.R.; Silva, R.; Neto, C.P.; Barros-Timmons, A.; Ferreira, A. Bio-Based Polyurethane Foams toward Applications beyond Thermal Insulation. Mater. Des. 2015, 76, 77–85. [Google Scholar] [CrossRef]

- Kurańska, M.; Cabulis, U.; Auguścik, M.; Prociak, A.; Ryszkowska, J.; Kirpluks, M. Bio-Based Polyurethane-Polyisocyanurate Composites with an Intumescent Flame Retardant. Polym. Degrad. Stab. 2016, 127, 11–19. [Google Scholar] [CrossRef]

- Peyrton, J.; Avérous, L. Structure-Properties Relationships of Cellular Materials from Biobased Polyurethane Foams. Mater. Sci. Eng. R Rep. 2021, 145, 100608. [Google Scholar] [CrossRef]

- Coman, A.E.; Peyrton, J.; Hubca, G.; Sarbu, A.; Gabor, A.R.; Nicolae, C.A.; Iordache, T.V.; Averous, L. Synthesis and Characterization of Renewable Polyurethane Foams Using Different Biobased Polyols from Olive Oil. Eur. Polym. J. 2021, 149, 110363. [Google Scholar] [CrossRef]

- Pan, X.; Webster, D.C. New Biobased High Functionality Polyols and Their Use in Polyurethane Coatings. ChemSusChem 2012, 5, 419–429. [Google Scholar] [CrossRef]

- Patil, C.K.; Rajput, S.D.; Marathe, R.J.; Kulkarni, R.D.; Phadnis, H.; Sohn, D.; Mahulikar, P.P.; Gite, V.V. Synthesis of Bio-Based Polyurethane Coatings from Vegetable Oil and Dicarboxylic Acids. Prog. Org. Coat. 2017, 106, 87–95. [Google Scholar] [CrossRef]

- Noreen, A.; Zia, K.M.; Zuber, M.; Tabasum, S.; Zahoor, A.F. Bio-Based Polyurethane: An Efficient and Environment Friendly Coating Systems: A Review. Prog. Org. Coat. 2016, 91, 25–32. [Google Scholar] [CrossRef]

- Garrison, T.F.; Kessler, M.R.; Larock, R.C. Effects of Unsaturation and Different Ring-Opening Methods on the Properties of Vegetable Oil-Based Polyurethane Coatings. Polymer 2014, 55, 1004–1011. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, S.; Mohanty, S.; Nayak, S.K. Biobased Polyurethane Adhesive over Petroleum Based Adhesive: Use of Renewable Resource. J. Macromol. Sci. Part A Pure Appl. Chem. 2018, 55, 36–48. [Google Scholar] [CrossRef]

- Gadhave, R.V.; Mahanwar, P.A.; Gadekar, P.T. Bio-Renewable Sources for Synthesis of Eco-Friendly Polyurethane Adhesives—Review. Open J. Polym. Chem. 2017, 7, 57–75. [Google Scholar] [CrossRef]

- Ertaş, M.; Fidan, M.S.; Alma, M.H. Preparation and Characterization of Biodegradable Rigid Polyurethane Foams from the Liquefied Eucalyptus and Pine Woods. Wood Res. 2014, 59, 97–108. [Google Scholar]

- Kong, X.; Liu, G.; Curtis, J.M. Novel Polyurethane Produced from Canola Oil Based Poly(Ether Ester) Polyols: Synthesis, Characterization and Properties. Eur. Polym. J. 2012, 48, 2097–2106. [Google Scholar] [CrossRef]

- Pawlik, H.; Prociak, A. Influence of Palm Oil-Based Polyol on the Properties of Flexible Polyurethane Foams. J. Polym. Environ. 2012, 20, 438–445. [Google Scholar] [CrossRef]

- Prociak, A.; Malewska, E.; Kurańska, M.; Bąk, S.; Budny, P. Flexible Polyurethane Foams Synthesized with Palm Oil-Based Bio-Polyols Obtained with the Use of Different Oxirane Ring Opener. Ind. Crops Prod. 2018, 115, 69–77. [Google Scholar] [CrossRef]

- Das, B.; Konwar, U.; Mandal, M.; Karak, N. Sunflower Oil Based Biodegradable Hyperbranched Polyurethane as a Thin Film Material. Ind. Crops Prod. 2013, 44, 396–404. [Google Scholar] [CrossRef]

- Datta, J.; Głowińska, E. Effect of Hydroxylated Soybean Oil and Bio-Based Propanediol on the Structure and Thermal Properties of Synthesized Bio-Polyurethanes. Ind. Crops Prod. 2014, 61, 84–91. [Google Scholar] [CrossRef]

- Pantone, V.; Laurenza, A.G.; Annese, C.; Comparelli, R.; Fracassi, F.; Fini, P.; Nacci, A.; Russo, A.; Fusco, C.; D’Accolti, L. Preparation and Characterization of Soybean Oil-Based Polyurethanes for Digital Doming Applications. Materials 2017, 10, 848. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, S.H.; Oh, K.W. Bio-Based Polyurethane Foams with Castor Oil Based Multifunctional Polyols for Improved Compressive Properties. Polymers 2021, 13, 576. [Google Scholar] [CrossRef]

- Calvo-Correas, T.; Mosiewicki, M.A.; Corcuera, M.A.; Eceiza, A.; Aranguren, M.I. Linseed Oil-Based Polyurethane Rigid Foams: Synthesis and Characterization. J. Renew. Mater. 2015, 3, 3–13. [Google Scholar] [CrossRef]

- Calvo-Correas, T.; Martin, M.D.; Retegi, A.; Gabilondo, N.; Corcuera, M.A.; Eceiza, A. Synthesis and Characterization of Polyurethanes with High Renewable Carbon Content and Tailored Properties. ACS Sustain. Chem. Eng. 2016, 4, 5684–5692. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, M.; Chen, J.; Jiang, Z.; Ma, Y. Synthesis and Properties of Polyurethane Elastomers Based on Renewable Castor Oil Polyols. J. Appl. Polym. Sci. 2019, 136, 47309. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Hu, L.; Zhou, Y. Synthesis of Rigid Polyurethane Foams with Castor Oil-Based Flame Retardant Polyols. Ind. Crops Prod. 2014, 52, 380–388. [Google Scholar] [CrossRef]

- Ionescu, M.; Radojčić, D.; Wan, X.; Shrestha, M.L.; Petrović, Z.S.; Upshaw, T.A. Highly Functional Polyols from Castor Oil for Rigid Polyurethanes. Eur. Polym. J. 2016, 84, 736–749. [Google Scholar] [CrossRef] [Green Version]

- Echeverria-Altuna, O.; Ollo, O.; Larraza, I.; Harismendy, I.; Eceiza, A. Effect of the biobased polyols chemical structure in high performance thermoset polyurethane properties. Polym. Under Rev. 2022, 42, 809–819. [Google Scholar]

- Tan, A.C.W.; Polo-Cambronell, B.J.; Provaggi, E.; Ardila-Suárez, C.; Ramirez-Caballero, G.E.; Baldovino-Medrano, V.G.; Kalaskar, D.M. Design and Development of Low Cost Polyurethane Biopolymer Based on Castor Oil and Glycerol for Biomedical Applications. Biopolymers 2018, 109, e23078. [Google Scholar] [CrossRef] [Green Version]

- Morales-Cerrada, R.; Tavernier, R.; Caillol, S. Fully Bio-Based Thermosetting Polyurethanes from Bio-Based Polyols and Isocyanates. Polymers 2021, 13, 1255. [Google Scholar] [CrossRef]

- Hejna, A.; Kirpluks, M.; Kosmela, P.; Cabulis, U.; Haponiuk, J.; Piszczyk, Ł. The Influence of Crude Glycerol and Castor Oil-Based Polyol on the Structure and Performance of Rigid Polyurethane-Polyisocyanurate Foams. Ind. Crops Prod. 2017, 95, 113–125. [Google Scholar] [CrossRef]

- Tan, H.W.; Abdul Aziz, A.R.; Aroua, M.K. Glycerol Production and Its Applications as a Raw Material: A Review. Renew. Sustain. Energy Rev. 2013, 27, 118–127. [Google Scholar] [CrossRef]

- Echeverria-Altuna, O.; Ollo, O.; Calvo-Correas, T.; Harismendy, I.; Eceiza, A. Effect of the Catalyst System on the Reactivity of a Polyurethane Resin System for RTM Manufacturing of Structural Composites. Express Polym. Lett. 2022, 16, 234–247. [Google Scholar] [CrossRef]

- Kim, T.H.; Kim, M.; Lee, W.; Kim, H.-G.; Lim, C.-S.; Seo, B. Synthesis and Characterization of a Polyurethane Phase Separated to Nano Size in an Epoxy Polymer. Coatings 2019, 9, 319. [Google Scholar] [CrossRef] [Green Version]

- Garate, G.; Harismendy, I.; Echeverria-Altuna, O.; Estévez, J. A Dynamic Data Driven Application System for Real-Time Simulation of Resin Transfer Moulding Processes. Int. J. Mater. Form. 2022, 15, 28. [Google Scholar] [CrossRef]

- Kamal, M.R.; Sourour, S. Kinetics and Thermal Characterization of Thermoset Cure. Polym. Eng. Sci. 1973, 13, 59–64. [Google Scholar] [CrossRef]

- Chern, C.S.; Poehlein, G.W. A Kinetic Model for Curing Reactions of Epoxides with Amines. Polym. Eng. Sci. 1987, 27, 788–795. [Google Scholar] [CrossRef]

- Castro, J.M.; Macosko, C.W.; Perry, S.J. Viscosity Changes during Urethane Polymerization with Phase Separation. Polym. Commun. 1984, 25, 82–87. [Google Scholar]

| System | Components Ratio (Pbw) | ||||||

|---|---|---|---|---|---|---|---|

| Part A | Part B | Renewable Content (%) | |||||

| Polyol | Glycerol | BDDE | Isocyanate | LiCl | DAS | ||

| PUR-REF | 100 | - | 7 | 181 | 3 | 12 | 4 |

| BIO-PUR1 | 100 | - | - | 117 | - | - | 37 |

| BIO-PUR2 | 100 | 22 | - | 233 | - | - | 29 |

| BIO-PUR3 | 100 | 22 | 7 | 267 | 2 | 9 | 27 |

| System | Tg | E’ (25 °C) |

|---|---|---|

| °C | GPa | |

| PUR-REF | 124 | 3.4 |

| BIO-PUR1 | 119 | 2.3 |

| BIO-PUR2 | 161 | 3.2 |

| BIO-PUR3 | 167 | 3.0 |

| Systems | Flexural Strength | Flexural Modulus | Flexural Strain |

|---|---|---|---|

| MPa | GPa | % | |

| PUR-REF | 139.0 ± 1.6 | 3.3 ± 0.1 | 6.6 ± 0.2 |

| BIO-PUR1 | 92.8 ± 4.3 | 2.2 ± 0.1 | 6.6 ± 0.7 |

| BIO-PUR2 | 124.2 ± 2.3 | 2.9 ± 0.1 | 6.9 ± 0.3 |

| BIO-PUR3 | 127.6 ± 0.9 | 3.0 ± 0.1 | 6.5 ± 0.1 |

| BIO-PUR3 | ||

|---|---|---|

| Method | Properties | Value |

| Mechanical properties | Flexural strength (MPa) | 1009 ± 61 |

| Flexural modulus (GPa) | 36.8 ± 1.0 | |

| Flexural strain (%) | 2.8 ± 0.2 | |

| ILLS (MPa) | 65 ± 2 | |

| DMA | Tg (℃) | 138 |

| Liquid displacement method | Matrix density at 25 ℃ (ρm) (g cm−3) | 1.21 |

| Burn-off method | Void content (Vv) (%) | −0.28 ± 0.96 |

| Fibre volume content (Vf) (%) | 48.2 ± 0.9 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Echeverria-Altuna, O.; Ollo, O.; Larraza, I.; Elizetxea, C.; Harismendy, I.; Eceiza, A. Development of a Novel Biobased Polyurethane Resin System for Structural Composites. Polymers 2022, 14, 4553. https://doi.org/10.3390/polym14214553

Echeverria-Altuna O, Ollo O, Larraza I, Elizetxea C, Harismendy I, Eceiza A. Development of a Novel Biobased Polyurethane Resin System for Structural Composites. Polymers. 2022; 14(21):4553. https://doi.org/10.3390/polym14214553

Chicago/Turabian StyleEcheverria-Altuna, Oihane, Olatz Ollo, Izaskun Larraza, Cristina Elizetxea, Isabel Harismendy, and Arantxa Eceiza. 2022. "Development of a Novel Biobased Polyurethane Resin System for Structural Composites" Polymers 14, no. 21: 4553. https://doi.org/10.3390/polym14214553

APA StyleEcheverria-Altuna, O., Ollo, O., Larraza, I., Elizetxea, C., Harismendy, I., & Eceiza, A. (2022). Development of a Novel Biobased Polyurethane Resin System for Structural Composites. Polymers, 14(21), 4553. https://doi.org/10.3390/polym14214553