A Critical Review on Hygrothermal and Sound Absorption Behavior of Natural-Fiber-Reinforced Polymer Composites

Abstract

1. Introduction

2. Hygrothermal Behavior of Polymer Composites

2.1. Carbon Nanofibers Hybridized with Natural Fibers

2.2. Palm and Hemp Fibers

2.3. Wood Fiber

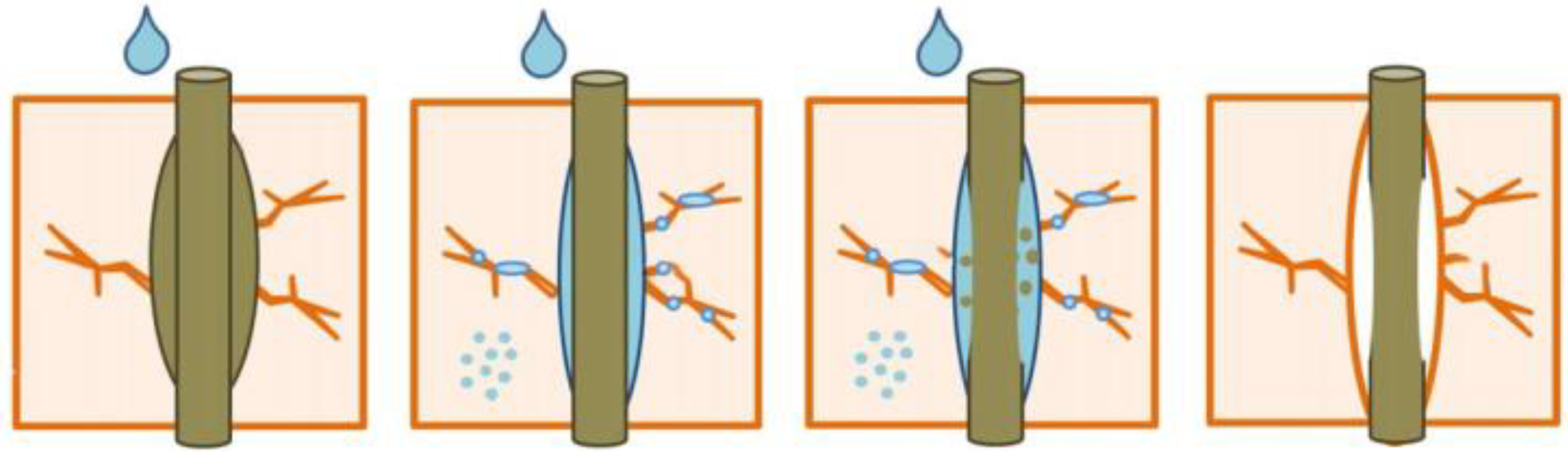

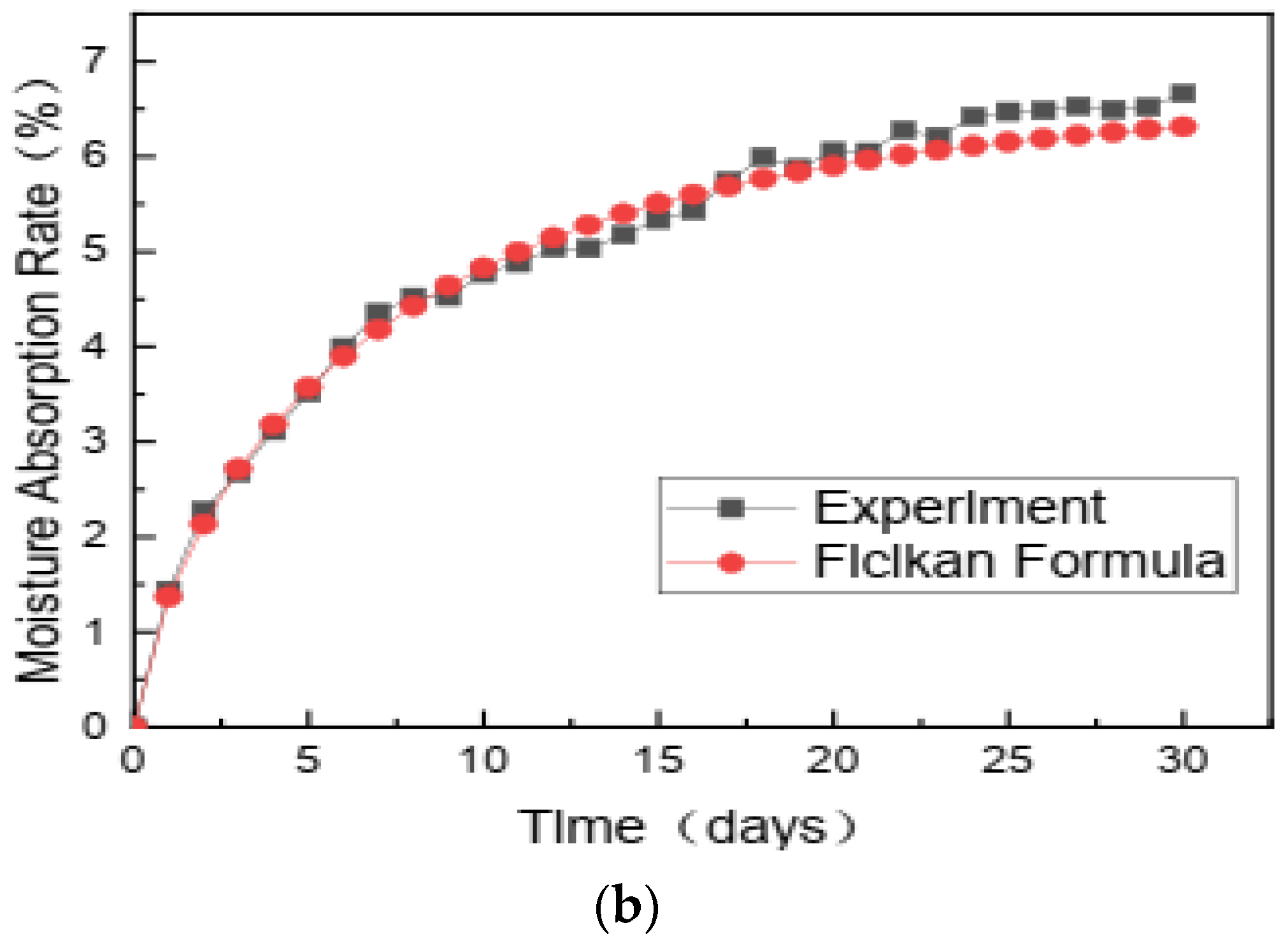

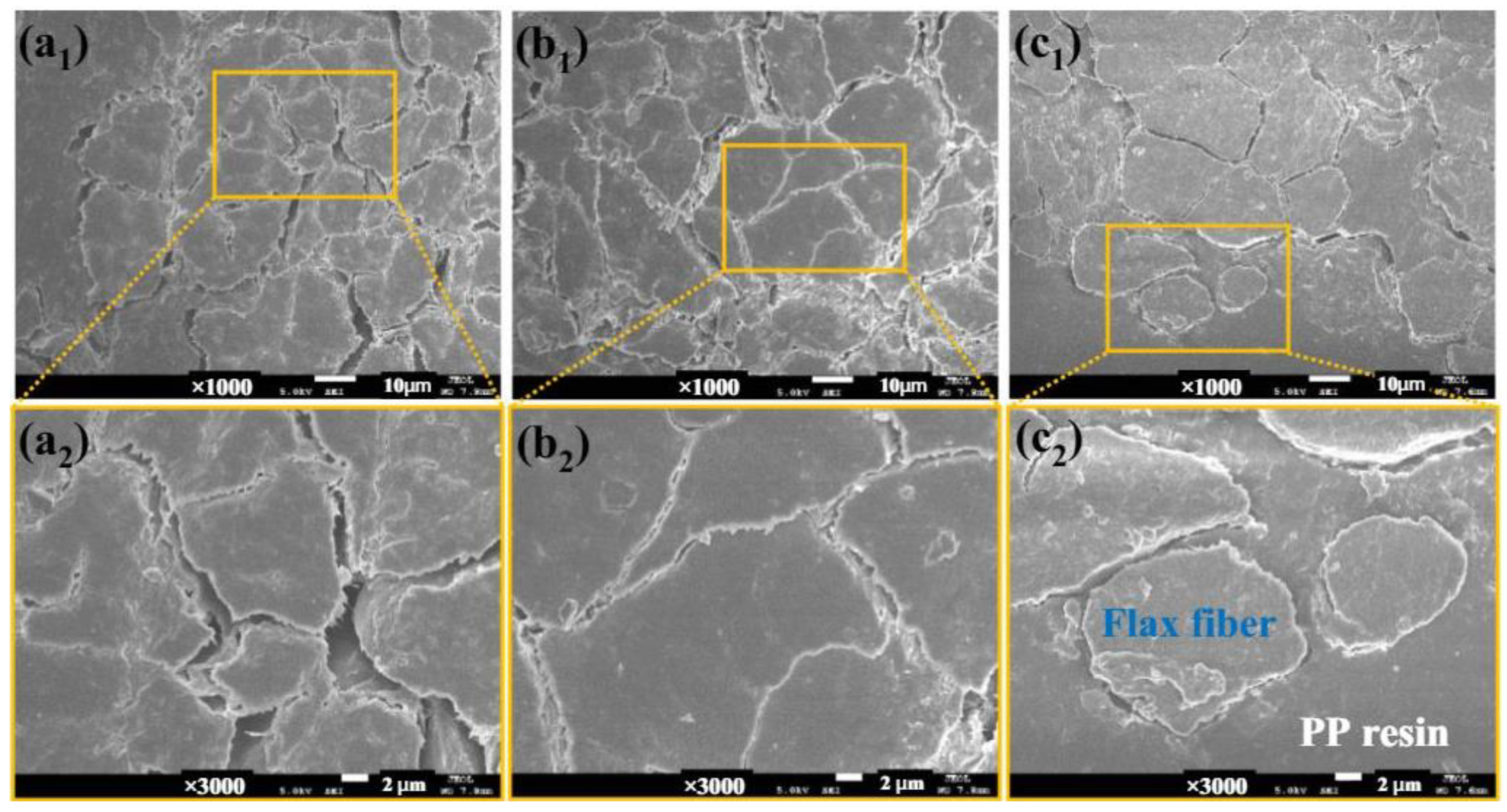

2.4. Flax-Fiber-Based Composites

2.5. Mycelium-Based Composites

2.6. Coconut Fiber

2.7. Jute-Fiber-Based Composites

2.8. Rice-Husk-Based Composites

2.9. Agave-Fiber-Based Composites

2.10. Silk- and Ramie-Fiber-Based Composites

2.11. Luffa Cylindrica Fiber-Based Composites

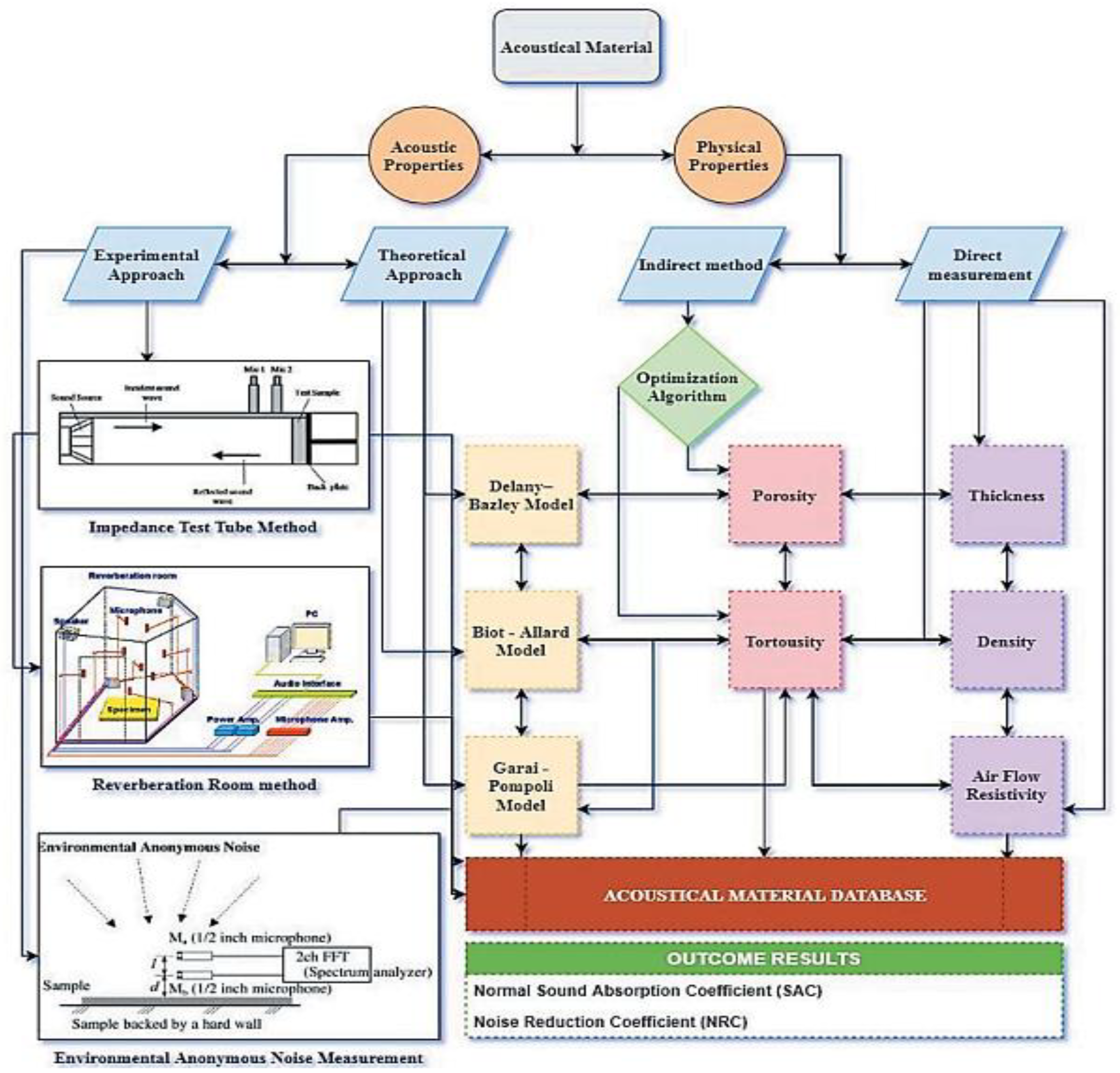

3. Sound Absorption Behavior of Polymer Composites

3.1. Yucca-Gloriosa-Based Composites

3.2. Oil Palm Trunk

3.3. Sugarcane-Bagasse-Based Composites

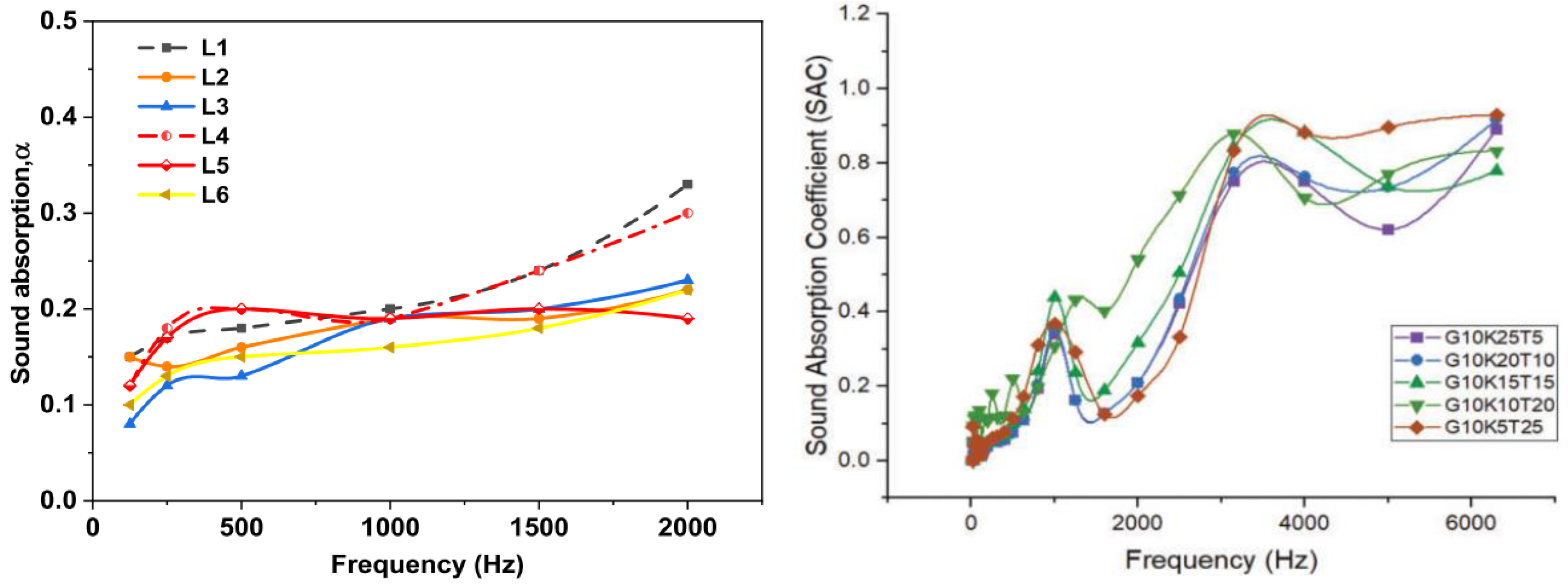

3.4. Kenaf with Waste Tea Leaf Fiber Composites

3.5. Sisal and Palm Fibers-Based Composites

3.6. Jute and Luffa Fiber-Based Composites

3.7. Coconut Coir and Oil Palm Fruit Bunches, with Pineapple Leaf

3.8. Finger Millet Straw and Darbha, with Ripe Bulrush Fibers

4. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- United Nations and Department of Economic and Social Affairs. Energy Statistics Pocketbook 2020; United Nations and Department of Economic and Social Affairs: New York, NY, USA, 2020. [Google Scholar]

- Bachchan, A.A.; Das, P.P.; Chaudhary, V. Effect of moisture absorption on the properties of natural fiber reinforced polymer composites: A review. Mater. Today Proc. 2021, 49, 3403–3408. [Google Scholar] [CrossRef]

- Sands, P. United Nations Framework Convention on Climate Change; General Assembly: New York, NY, USA, 1992. [Google Scholar]

- Al-Maharma, A.Y.; Al-Huniti, N. Critical Review of the Parameters Affecting the Effectiveness of Moisture Absorption Treatments Used for Natural Composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Kyoto Protocol to the United Nations Framework Convention on Climate Change. 1997. Available online: http://unfccc.int/resource/docs/cop3/07a01.pdf (accessed on 4 August 2022).

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Energy, E.; Eurostat. Energy Statistics—Quantities. Eur. Comm. Database 2020. Available online: https://ec.europa.eu/eurostat/en/web/main/data/database (accessed on 6 August 2022).

- Eurostat. Energy Consumption and Use by Households. Eur. Comm. Database 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_consumption_in_households (accessed on 6 August 2022).

- Berger, J.; Mazuroski, W.; Mendes, N.; Guernouti, S.; Woloszyn, M. 2D whole-building hygrothermal simulation analysis based on a PGD reduced order model. Energy Build. 2016, 112, 49–61. [Google Scholar] [CrossRef]

- Steeman, H.J.; Janssens, A.; Carmeliet, J.; Paepe, M.D. Modelling indoor air and hygrothermal wall interaction in building simulation: Comparison between CFD and a well-mixed zonal model. Build. Environ. 2009, 12, 572–583. [Google Scholar] [CrossRef]

- Rahim, M.; Le, A.T.; Douzane, O.; Promis, G.; Langlet, T. Numerical investigation of the effect of non-isotherme sorption characteristics on hygrothermal behavior of two bio-based building walls. J. Build. Eng. 2016, 7, 263–272. [Google Scholar] [CrossRef]

- Seng, B.; Lorente, S.; Magniont, C. Scale analysis of heat and moisture transfer through bio-based materials—Application to hemp concrete. Energy Build. 2017, 155, 546–558. [Google Scholar] [CrossRef]

- Deepa, C.; Rajeshkumar, L.; Ramesh, M. Preparation, synthesis, properties and characterization of graphene-based 2D nano-materials for biosensors and bioelectronics. J. Mater. Res. Technol. 2022, 19, 2657–2694. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Bhoopathi, R. Carbon substrates: A review on fabrication, properties and applications. Carbon Lett. 2021, 31, 557–580. [Google Scholar] [CrossRef]

- Promis, G.; Douzane, O.; Le, A.T.; Langlet, T. Moisture hysteresis influence on mass transfer through bio-based building materials in dynamic state. Energy Build. 2018, 166, 450–459. [Google Scholar] [CrossRef]

- Alioua, T.; Agoudjil, B.; Chennouf, N.; Boudenne, A.; Benzarti, K. Investigation on heat and moisture transfer in bio-based building wall with consideration of the hysteresis effect. Build. Environ. 2019, 163, 106333. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.R.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Text. 2020, 51, 5518S–5542S. [Google Scholar] [CrossRef]

- Khoukhi, M. The combined effect of heat and moisture transfer dependent thermal conductivity of polystyrene insulation material: Impact on building energy performance. Energy Build. 2018, 169, 228–235. [Google Scholar] [CrossRef]

- Delgado, J.M.P.Q.; Barreira, E.; Ramos, N.M.M.; de Freitas, V.P. Hygrothermal Numerical Simulation Tools Applied to Building Physics; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Bai, B.; Xu, T.; Nie, Q.; Li, P. Temperature-driven migration of heavy metal Pb2+ along with moisture movement in unsaturated soils. Int. J. Heat Mass Transf. 2020, 153, 119573. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Deepa, C.; Selvan, M.T.; Kushvaha, V.; Asrofi, M. Impact of Silane Treatment on Characterization of Ipomoea Staphylina Plant Fiber Reinforced Epoxy Composites. J. Nat. Fibers 2021, 1–12. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Balaji, D. Influence of Process Parameters on the Properties of Additively Manufactured Fiber-Reinforced Polymer Composite Materials: A Review. J. Mater. Eng. Perform. 2021, 30, 4792–4807. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Rajeshkumar, L.; Selvan, M.T.; Balaji, D. Influence of fiber surface treatment on the tribological properties of Calotropis gigantea plant fiber reinforced polymer composites. Polym. Compos. 2021, 42, 4308–4317. [Google Scholar] [CrossRef]

- Vidhyashankar, R.; Vinze, R.; Nagarathinam, S.; Natrajan, V.K. Modelling spatial variations in thermal comfort in indoor open-plan spaces using a whole-building simulation tool. J. Build. Eng. 2021, 46, 103727. [Google Scholar] [CrossRef]

- Benzaama, M.; Rajaoarisoa, L.; Ajib, B.; Lecoeuche, S. A data-driven methodology to predict thermal behavior of residential buildings using piecewise linear models. J. Build. Eng. 2020, 32, 101523. [Google Scholar] [CrossRef]

- Marquis-Favre, C.; Premat, E.; Aubrée, D.; Vallet, M. Noise and its effects—A review on qualitative aspects of sound. Part I: Notions and acoustic ratings. Acta Acust. United Acust. 2005, 91, 613–625. [Google Scholar]

- Ramesh, M.; Kumar, L.R. Bioadhesives. In Green Adhesives; Inamuddin, R., Boddula, M.I., Ahamed and Asiri, A.M., Eds.; Wiley: Hoboken, NJ, USA, 2020; pp. 145–164. [Google Scholar] [CrossRef]

- Marquis-Favre, C.; Premat, E.; Aubrée, D. Noise and its effects—A review on qualitative aspects of sound. Part II: Noise and annoyance. Acta Acust. United Acust. 2005, 91, 626–642. [Google Scholar]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous materials for sound absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Na, Y.; Lancaster, J.; Casali, J.; Cho, G. Sound Absorption Coefficients of Micro-fiber Fabrics by Reverberation Room Method. Text. Res. J. 2007, 77, 330–335. [Google Scholar] [CrossRef]

- Yang, T.; Xiong, X.; Mishra, R.; Novák, J.; Militký, J. Acoustic evaluation of Struto nonwovens and their relationship with thermal properties. Text. Res. J. 2016, 88, 426–437. [Google Scholar] [CrossRef]

- Papadopoulos, A. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Sahayaraj, A.F.; Muthukrishnan, M.; Ramesh, M.; Rajeshkumar, L. Effect of hybridization on properties of tamarind (Tamarindus indica L.) seed nano-powder incorporated jute-hemp fibers reinforced epoxy composites. Polym. Compos. 2021, 42, 6611–6620. [Google Scholar] [CrossRef]

- Deepa, C.; Rajeshkumar, L.; Ramesh, M. Thermal Properties of Kenaf Fiber-Based Hybrid Composites. In Natural Fiber-Reinforced Composites: Thermal Properties and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2021; pp. 167–182. [Google Scholar] [CrossRef]

- Zhu, X.; Kim, B.-J.; Wang, Q.; Wu, Q. Recent Advances in the Sound Insulation Properties of Bio-based Materials. BioResources 2013, 9, 1764–1786. [Google Scholar] [CrossRef]

- Devarajan, B.; LakshmiNarasimhan, R.; Venkateswaran, B.; Rangappa, S.M.; Siengchin, S. Additive manufacturing of jute fiber reinforced polymer composites: A concise review of material forms and methods. Polym. Compos. 2022, 43, 6735. [Google Scholar] [CrossRef]

- Arenas, J.P.; Crocker, M.J. Recent trends in porous sound-absorbing materials. Sound Vib. 2010, 44, 12–18. [Google Scholar]

- Ramesh, M. Aerogels for Insulation Applications. Mater. Res. Found 2021, 98, 57–76. [Google Scholar] [CrossRef]

- Kumar, T.S.; Kumar, S.S.; Kumar, L.R. Jute fibers, their composites and applications. In Plant Fibers, Their Composites, and Applications; Woodhead Publishing: Sawston, UK, 2022; pp. 253–282. [Google Scholar] [CrossRef]

- Priyadharshini, M.; Balaji, D.; Bhuvaneswari, V.; Rajeshkumar, L.; Sanjay, M.R.; Siengchin, S. Fiber Reinforced Composite Manufacturing With the Aid of Artificial Intelligence—A State-of-the-Art Review. Arch. Comput. Methods Eng. 2022, 1–14. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, W.; Wan, B.; Meng, Z.; Han, B. Hygrothermal ageing behavior and mechanism of carbon nanofibers modified flax fiber-reinforced epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2020, 140, 106142. [Google Scholar] [CrossRef]

- Zouaoui, Y.; Benmahiddine, F.; Yahia, A.; Belarbi, R. Hygrothermal and Mechanical Behaviors of Fiber Mortar: Comparative Study between Palm and Hemp Fibers. Energies 2021, 14, 7110. [Google Scholar] [CrossRef]

- Sala, B.; Gabrion, X.; Trivaudey, F.; Guicheret-Retel, V.; Placet, V. Influence of the stress level and hygrothermal conditions on the creep/recovery behaviour of high-grade flax and hemp fibre reinforced GreenPoxy matrix composites. Compos. Part A Appl. Sci. Manuf. 2020, 141, 106204. [Google Scholar] [CrossRef]

- Asli, M.; Sassine, E.; Brachelet, F.; Antczak, E. Hygrothermal behavior of wood fiber insulation, numerical and experimental approach. Heat Mass Transf. 2021, 57, 1069–1085. [Google Scholar] [CrossRef]

- Balaji, D.; Ranga, J.; Bhuvaneswari, V.; Arulmurugan, B.; Rajeshkumar, L.; Manimohan, M.P.; Devi, G.R.; Ramya, G.; Masi, C. Additive Manufacturing for Aerospace from Inception to Certification. J. Nanomater. 2022, 2022, 7226852. [Google Scholar] [CrossRef]

- Ramesh, M.; Balaji, D.; Rajeshkumar, L.; Bhuvaneswari, V. Manufacturing methods of elastomer blends and composites. In Elastomer Blends and Composites; Elsevier: Amsterdam, The Netherlands, 2022; pp. 11–32. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Balaji, D.; Bhuvaneswari, V. Influence of Moisture Absorption on Mechanical properties of Biocomposites reinforced Surface Modified Natural Fibers. In Aging Effects on Natural Fiber-Reinforced Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2022; pp. 17–34. [Google Scholar] [CrossRef]

- Xiao, X.; Zhong, Y.; Cheng, M.; Sheng, L.; Wang, D.; Li, S. Improved hygrothermal durability of flax/polypropylene composites after chemical treatments through a hybrid approach. Cellulose 2021, 28, 11209–11229. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Balaji, D.; Bhuvaneswari, V. Keratin-based biofibers and their composites. In Advances in Bio-Based Fiber; Woodhead Publishing: Sawston, UK, 2022; pp. 315–334. [Google Scholar] [CrossRef]

- Gauvin, F.; Tsao, V.; Vette, J.; Brouwers, H.J.H. Physical properties and hygrothermal behavior of mycelium-based composites as foam-like wall insulation material. In Construction Technologies and Architecture; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2022; Volume 1, pp. 643–651. [Google Scholar]

- Ramesh, M.; Rajeshkumar, L.; Bhuvaneswari, V. Leaf fibres as reinforcements in green composites: A review on processing, properties and applications. Emergent Mater. 2021, 5, 833–857. [Google Scholar] [CrossRef]

- Dayo, A.Q.; Babar, A.A.; Qin, Q.-R.; Kiran, S.; Wang, J.; Shah, A.H.; Zegaoui, A.; Ghouti, H.A.; Liu, W.-B. Effects of accelerated weathering on the mechanical properties of hemp fibre/polybenzoxazine based green composites. Compos. Part A Appl. Sci. Manuf. 2019, 128, 105653. [Google Scholar] [CrossRef]

- Luo, C. Research on Hygrothermal Property of Jute Woven Fabric Reinforced Composites. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 719, p. 022087. [Google Scholar]

- Ramesh, M.; Rajeshkumar, L.; Balaji, D.; Priyadharshini, M. Properties and Characterization Techniques for Waterborne Polyurethanes. In Sustainable Production and Applications of Waterborne Polyurethanes; Springer: Cham, Switzerland, 2021; pp. 109–123. [Google Scholar] [CrossRef]

- Hu, R.H.; Sun, M.Y.; Lim, J.K. Moisture absorption, tensile strength and microstructure evolution of short jute fiber/polylactide composite in hygrothermal environment. Mater. Des. 2010, 31, 3167–3173. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Sasikala, G.; Balaji, D.; Saravanakumar, A.; Bhuvaneswari, V.; Bhoopathi, R. A Critical Review on Wood-Based Polymer Composites: Processing, Properties, and Prospects. Polymers 2022, 14, 589. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Sain, M.; Cooper, P. Hygrothermal weathering of rice hull/HDPE composites under extreme climatic conditions. Polym. Degrad. Stab. 2005, 90, 540–545. [Google Scholar] [CrossRef]

- Ramesh, M.; Balaji, D.; Rajeshkumar, L.; Bhuvaneswari, V.; Saravanakumar, R.; Khan, A.; Asiri, A.M. Tribological behavior of glass/sisal fiber reinforced polyester composites. In Vegetable Fiber Composites and Their Technological Applications; Springer: Singapore, 2021; pp. 445–459. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Öchsner, A.; Islam, M. Francucci GFlax fiber its composites: An overview of water moisture absorption impact on their performance. J. Reinf. Plast. Compos. 2018, 38, 323–339. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L. Case-Studies on Green Corrosion Inhibitors. In Sustainable Corrosion Inhibitors; Inamuddin, Ed.; Materials Research Fourm LLC: Millersville, PA, USA, 2021; Volume 107, pp. 204–221. [Google Scholar]

- Habibi, M.; Laperrière, L.; Hassanabadi, H.M. Effect of moisture absorption and temperature on quasi-static and fatigue behavior of nonwoven flax epoxy composite. Compos. Part B Eng. 2019, 166, 31–40. [Google Scholar] [CrossRef]

- Wang, X.; Petrů, M. The effects of surface treatment on creep and dynamic mechanical behavior of flax fiber reinforced composites under hygrothermal aging conditions. In Surface Treatment Methods of Natural Fibres and Their Effects on Biocomposites; Woodhead Publishing: Sawston, UK, 2022; pp. 203–242. [Google Scholar]

- Elsacker, E.; Vandelook, S.; Van Wylick, A.; Ruytinx, J.; De Laet, L.; Peeters, E. A comprehensive framework for the production of mycelium-based lignocellulosic composites. Sci. Total Environ. 2020, 725, 138431. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Experimental investigation on the mechanical properties and water absorption behavior of randomly oriented short pineapple/coir fiber-reinforced hybrid epoxy composites. Mater. Res. Express 2018, 6, 015313. [Google Scholar] [CrossRef]

- Deng, K.; Cheng, H.; Suo, H.; Liang, B.; Li, Y.; Zhang, K. Aging damage mechanism and mechanical properties degradation of 3D orthogonal woven thermoset composites subjected to cyclic hygrothermal environment. Eng. Fail. Anal. 2022, 140, 106629. [Google Scholar] [CrossRef]

- Aouat, T.; Kaci, M.; Lopez-Cuesta, J.-M.; Devaux, E. Investigation on the Durability of PLA Bionanocomposite Fibers under Hygrothermal Conditions. Front. Mater. 2019, 6, 323. [Google Scholar] [CrossRef]

- Jindal, B.B.; Jangra, P.; Garg, A. Effects of ultra fine slag as mineral admixture on the compressive strength, water absorption and permeability of rice husk ash based geopolymer concrete. Mater. Today Proc. 2020, 32, 871–877. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Balaji, D.; Bhuvaneswari, V.; Sivalingam, S. Self-Healable Conductive Materials. Self-Heal. Smart Mater. Allied Appl. 2021, 297–319. [Google Scholar] [CrossRef]

- Kamboj, I.; Jain, R.; Jain, D.; Bera, T.K. Effect of Fiber Pre-treatment Methods on Hygrothermal Aging Behavior of Agave Fiber Reinforced Polymer Composites. J. Nat. Fibers 2020, 19, 2929–2942. [Google Scholar] [CrossRef]

- Han, S.O.; Ahn, H.J.; Cho, D. Hygrothermal effect on henequen or silk fiber reinforced poly(butylene succinate) biocomposites. Compos. Part B Eng. 2010, 41, 491–497. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Balaji, D. Mechanical and dynamic properties of ramie fiber-reinforced composites. Mech. Dyn. Prop. Biocompos. 2021, 275–291. [Google Scholar] [CrossRef]

- Yu, T.; Sun, F.; Lu, M.; Li, Y. Water absorption and hygrothermal aging behavior of short ramie fiber-reinforced poly(lactic acid) composites. Polym. Compos. 2016, 39, 1098–1104. [Google Scholar] [CrossRef]

- Ghali, L.H.; Aloui, M.; Zidi, M.; Daly, H.B.; Msahli, S.; Sakli, F. Effect of chemical modification of luffa cylindrica fibers on the mechanical and hygrothermal behaviours of polyester/luffa composites. BioResources 2011, 6, 3836–3849. [Google Scholar]

- Chandramohan, D.; Murali, B.; Vasantha-Srinivasan, P.; Dinesh Kumar, S. Mechanical, moisture absorption, and abrasion resistance properties of bamboo–jute–glass fiber composites. J. Bio-Tribo-Corros. 2019, 5, 1–8. [Google Scholar] [CrossRef]

- Dayo, A.Q.; Zegaoui, A.; Nizamani, A.A.; Kiran, S.; Wang, J.; Derradji, M.; Cai, W.-A.; Liu, W.-B. The influence of different chemical treatments on the hemp fiber/polybenzoxazine based green composites: Mechanical, thermal and water absorption properties. Mater. Chem. Phys. 2018, 217, 270–277. [Google Scholar] [CrossRef]

- Ma, G.; Yan, L.; Shen, W.; Zhu, D.; Huang, L.; Kasal, B. Effects of water, alkali solution and temperature ageing on water absorption, morphology and mechanical properties of natural FRP composites: Plant-based jute vs. mineral-based basalt. Compos. Part B Eng. 2018, 153, 398–412. [Google Scholar] [CrossRef]

- Radzi, A.; Sapuan, S.; Jawaid, M.; Mansor, M. Water absorption, thickness swelling and thermal properties of roselle/sugar palm fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019, 8, 3988–3994. [Google Scholar] [CrossRef]

- Dinesh, S.; Kumaran, P.; Mohanamurugan, S.; Vijay, R.; Singaravelu, D.L.; Vinod, A.; Sanjay, M.R.; Siengchin, S.; Bhat, K.S. Influence of wood dust fillers on the mechanical, thermal, water absorption and biodegradation characteristics of jute fiber epoxy composites. J. Polym. Res. 2020, 27, 9. [Google Scholar] [CrossRef]

- Prasad, V.; Joseph, M.; Sekar, K. Investigation of mechanical, thermal and water absorption properties of flax fibre reinforced epoxy composite with nano TiO2 addition. Compos. Part A Appl. Sci. Manuf. 2018, 115, 360–370. [Google Scholar] [CrossRef]

- Huang, J.-K.; Young, W.-B. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites. Compos. Part B Eng. 2018, 166, 272–283. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.; Ishak, M.; Ansari, M.; Ilyas, R. Physical and thermal properties of treated sugar palm/glass fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019, 8, 3726–3732. [Google Scholar] [CrossRef]

- Maslinda, A.; Majid, M.A.; Ridzuan, M.; Afendi, M.; Gibson, A. Effect of water absorption on the mechanical properties of hybrid interwoven cellulosic-cellulosic fibre reinforced epoxy composites. Compos. Struct. 2017, 167, 227–237. [Google Scholar] [CrossRef]

- Thiagamani, S.M.K.; Krishnasamy, S.; Muthukumar, C.; Tengsuthiwat, J.; Nagarajan, R.; Siengchin, S.; Ismail, S.O. Investigation into mechanical, absorption and swelling behaviour of hemp/sisal fibre reinforced bioepoxy hybrid composites: Effects of stacking sequences. Int. J. Biol. Macromol. 2019, 140, 637–646. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Jaszkiewicz, A.; Erdmann, K. Polypropylene composites with enzyme modified abaca fibre. Compos. Sci. Technol. 2010, 70, 854–860. [Google Scholar] [CrossRef]

- Lin, Q.; Zhou, X.; Dai, G. Effect of hydrothermal environment on moisture absorption and mechanical properties of wood flour-filled polypropylene composites. J. Appl. Polym. Sci. 2002, 85, 2824–2832. [Google Scholar] [CrossRef]

- Ramesh, M.; Selvan, M.T.; Rajeshkumar, L.; Deepa, C.; Ahmad, A. Influence of Vachellia nilotica Subsp. indica Tree Trunk Bark Nano-powder on Properties of Milkweed Plant Fiber Reinforced Epoxy Composites. J. Nat. Fibers 2022, 1–14. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Espinach, F.X.; Mutjé, P.; Boufi, S. Polypropylene composites based on lignocellulosic fillers: How the filler morphology affects the composite properties. Mater. Des. 2015, 65, 454–461. [Google Scholar] [CrossRef]

- Yeh, S.-K.; Hsieh, C.-C.; Chang, H.-C.; Yen, C.C.; Chang, Y.-C. Synergistic effect of coupling agents and fiber treatments on mechanical properties and moisture absorption of polypropylene–rice husk composites and their foam. Compos. Part A Appl. Sci. Manuf. 2015, 68, 313–322. [Google Scholar] [CrossRef]

- Demir, H.; Atikler, U.; Balköse, D.; Tıhmınlıoğlu, F. The effect of fiber surface treatments on the tensile and water sorption properties of polypropylene–luffa fiber composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 447–456. [Google Scholar] [CrossRef]

- Gao, S.L.; Mäder, E. Jute/polypropylene composites I. Effect of matrix modification. Compos. Sci. Technol. 2006, 66, 952–963. [Google Scholar]

- Gassan, J.; Bledzki, A.K. Effect of cyclic moisture absorption desorption on the mechanical properties of silanized jute-epoxy composites. Polym. Compos. 1999, 20, 604–611. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Dufresne, A. Short natural-fibre reinforced polyethylene and natural rubber composites: Effect of silane coupling agents and fibres loading. Compos. Sci. Technol. 2007, 67, 1627–1639. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Studies on Water Absorption of Bamboo-Polyester Composites: Effect of Silane Treatment of Mercerized Bamboo. Polym. Technol. Eng. 2009, 49, 45–52. [Google Scholar] [CrossRef]

- Zahari, W.; Badri, R.; Ardyananta, H.; Kurniawan, D.; Nor, F. Mechanical Properties and Water Absorption Behavior of Polypropylene/Ijuk Fiber Composite by Using Silane Treatment. Procedia Manuf. 2015, 2, 573–578. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Zamri, M.H.; Akil, H.; Abu Bakar, A.; Ishak, Z.A.M.; Cheng, L.W. Effect of water absorption on pultruded jute/glass fiber-reinforced unsaturated polyester hybrid composites. J. Compos. Mater. 2011, 46, 51–61. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A.; Alavudeen, A.; Thiruchitrambalam, M. Mechanical and water absorption behaviour of banana/sisal reinforced hybrid composites. Mater. Des. 2011, 32, 4017–4021. [Google Scholar] [CrossRef]

- Rout, J.; Misra, M.; Tripathy, S.; Nayak, S.; Mohanty, A. The influence of fibre treatment on the performance of coir-polyester composites. Compos. Sci. Technol. 2001, 61, 1303–1310. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R. Mechanical properties and water absorption of short snake grass fiber reinforced isophthallic polyester composites. Fibers Polym. 2014, 15, 1927–1934. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Hariharan, V.; Sathishkumar, T.P.; Fiore, V.; Scalici, T. Synergistic effect of fiber content and length on mechanical and water absorption behaviors of Phoenix sp. fiber-reinforced epoxy composites. J. Ind. Text. 2017, 47, 211–232. [Google Scholar] [CrossRef]

- Velusamy, K.; Navaneethakrishnan, P.; RajeshKumar, G.; Sathishkumar, T. The influence of fiber content and length on mechanical and water absorption properties of Calotropis gigantea fiber reinforced epoxy composites. J. Ind. Text. 2018, 48, 1274–1290. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Selvan, M.T.; Rajeshkumar, L.; Balaji, D.; Bhuvaneswari, V. Mechanical and water absorption properties of Calotropis gigantea plant fibers reinforced polymer composites. Mater. Today Proc. 2021, 46, 3367–3372. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Niranjana, K.; Rajeshkumar, L.; Bhoopathi, R.; Balaji, D. Influence of Haritaki (Terminalia chebula) nano-powder on thermo-mechanical, water absorption and morphological properties of Tindora (Coccinia grandis) tendrils fiber reinforced epoxy composites. J. Nat. Fibers 2021, 1–17. [Google Scholar] [CrossRef]

- Gokulkumar, S.; Thyla, P.; Prabhu, L.; Sathish, S. Measuring Methods of Acoustic Properties and Influence of Physical Parameters on Natural Fibers: A Review. J. Nat. Fibers 2019, 17, 1719–1738. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Petrů, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Bhingare, N.H.; Prakash, S.; Jatti, V.S. A review on natural and waste material composite as acoustic material. Polym. Test. 2019, 80, 106142. [Google Scholar] [CrossRef]

- Aziz, M.A.A.; Sari, K.A.M. Comparison of sound absorption coefficient for natural fiber. Prog. Eng. Appl. Technol. 2021, 2, 157–163. [Google Scholar]

- Samaei, S.E.; Mahabadi, H.A.; Mousavi, S.M.; Khavanin, A.; Faridan, M. Optimization and sound absorption modeling in Yucca Gloriosa natural fiber composite. Iran Occup. Health J. 2021, 18, 1–17. [Google Scholar] [CrossRef]

- Kalaivani, R.; Ewe, L.S.; Zaroog, O.S.; Woon, H.S.; Ibrahim, Z. Acoustic properties of natural fiber of oil palm trunk. Int. J. Adv. Appl. Sci. 2018, 5, 88–92. [Google Scholar] [CrossRef]

- Mawardi, I.; Aprilia, S.; Faisal, M.; Ikramullah; Rizal, S. An investigation of thermal conductivity and sound absorption from binderless panels made of oil palm wood as bio-insulation materials. Results Eng. 2021, 13, 100319. [Google Scholar] [CrossRef]

- Sakthivel, S.; Kumar, S.S.; Solomon, E.; Getahun, G.; Admassu, Y.; Bogale, M.; Gedilu, M.; Aduna, A.; Abedom, F. Sound absorbing and insulating properties of natural fiber hybrid composites using sugarcane bagasse and bamboo charcoal. J. Eng. Fibers Fabr. 2021, 16, 15589250211044818. [Google Scholar] [CrossRef]

- Prabhu, L.; Krishnaraj, V.; Gokulkumar, S.; Sathish, S.; Sanjay, M.R.; Siengchin, S. Mechanical, chemical and sound absorption properties of glass/kenaf/waste tea leaf fiber-reinforced hybrid epoxy composites. J. Ind. Text. 2020, 51, 1674–1700. [Google Scholar] [CrossRef]

- Nasidi, I.N.; Ismail, L.H.; Samsudin, E.; Jaffar, M.I. Effects of Kenaf Fiber Strand Treatment by Sodium Hydroxide on Sound Absorption. J. Nat. Fibers 2021, 1–10. [Google Scholar] [CrossRef]

- Dhandapani, N.; Megalingam, A. Mechanical and Sound Absorption Behavior of Sisal and Palm Fiber Reinforced Hybrid Composites. J. Nat. Fibers 2021, 19, 4530–4543. [Google Scholar] [CrossRef]

- Koruk, H.; Ozcan, A.C.; Genc, G.; Sanliturk, K.Y. Jute and Luffa Fiber-Reinforced Biocomposites: Effects of Sample Thickness and Fiber/Resin Ratio on Sound Absorption and Transmission Loss Performance. J. Nat. Fibers 2021, 1–16. [Google Scholar] [CrossRef]

- Rusli, M.; Irsyad, M.; Dahlan, H.; Gusriwandi; Bur, M. Sound absorption characteristics of the natural fibrous material from coconut coir, oil palm fruit bunches, and pineapple leaf. IOP Conf. Ser. Mater. Sci. Eng. 2019, 602, 012067. [Google Scholar] [CrossRef]

- Sheng, D.D.C.V.; Bin Yahya, M.N.; Din, N.B.C. Sound Absorption of Microperforated Panel Made from Coconut Fiber and Polylactic Acid Composite. J. Nat. Fibers 2020, 19, 2719–2729. [Google Scholar] [CrossRef]

- Bhingare, N.H.; Prakash, S. An experimental and theoretical investigation of coconut coir material for sound absorption characteristics. Mater. Today Proc. 2021, 43, 1545–1551. [Google Scholar] [CrossRef]

- Rakesh, K.M.; Srinidhi, R.; Gokulkumar, S.; Nithin, K.S.; Madhavarao, S.; Sathish, S.; Karthick, A.; Muhibbullah, M.; Osman, S.M. Experimental Study on the Sound Absorption Properties of Finger Millet Straw, Darbha, and Ripe Bulrush Fibers. Adv. Mater. Sci. Eng. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Mohankumar, D.; Rajeshkumar, L.; Muthukumaran, N.; Ramesh, M.; Aravinth, P.; Anith, R.; Balaji, S. Effect of fiber orientation on tribological behaviour of Typha angustifolia natural fiber reinforced composites. Mater. Today Proc. 2022, 62, 1958–1964. [Google Scholar] [CrossRef]

- El Hajj, N.; Mboumba-Mamboundou, B.; Dheilly, R.-M.; Aboura, Z.; Benzeggagh, M.; Queneudec, M. Development of thermal insulating and sound absorbing agro-sourced materials from auto linked flax-tows. Ind. Crop. Prod. 2011, 34, 921–928. [Google Scholar] [CrossRef]

- Pfretzschner, J.; Rodriguez, R.M. Acoustic properties of rubber crumbs. Polym. Test. 1999, 18, 81–92. [Google Scholar] [CrossRef]

- Xiang, H.-F.; Wang, D.; Liua, H.-C.; Zhao, N.; Xu, J. Investigation on sound absorption properties of kapok fibers. Chin. J. Polym. Sci. 2013, 31, 521–529. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Zheng, Z. Effect of physiochemical structure on energy absorption properties of plant fibers reinforced composites: Dielectric, thermal insulation, and sound absorption properties. Compos. Commun. 2018, 10, 163–167. [Google Scholar] [CrossRef]

- Olcay, H.; Kocak, E.D. Rice plant waste reinforced polyurethane composites for use as the acoustic absorption material. Appl. Acoust. 2021, 173, 107733. [Google Scholar] [CrossRef]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Novak, J.; Choteborsky, R.; Hromasova, M. Acoustic, Mechanical and Thermal Properties of Green Composites Reinforced with Natural Fibers Waste. Polymers 2020, 12, 654. [Google Scholar] [CrossRef]

- Lahouioui, M.; Ben Arfi, R.; Fois, M.; Ibos, L.; Ghorbal, A. Investigation of Fiber Surface Treatment Effect on Thermal, Mechanical and Acoustical Properties of Date Palm Fiber-Reinforced Cementitious Composites. Waste Biomass-Valorization 2019, 11, 4441–4455. [Google Scholar] [CrossRef]

- Bin Bakri, M.K.; Jayamani, E.; Soon, K.H.; Hamdan, S.; Kakar, A. An experimental and simulation studies on sound absorption coefficients of banana fibers and their reinforced composites. In Nano Hybrids and Composites; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2017; Volume 12, pp. 9–20. [Google Scholar]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Yahya, M.N.; Sambu, M.; Latif, H.A.; Junaid, T.M. August. A study of acoustics performance on natural fibre composite. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 226, p. 012013. [Google Scholar]

- Fouladi, M.H.; Nassir, M.H.; Ghassem, M.; Shamel, M.; Peng, S.Y.; Wen, S.Y.; Xin, P.Z.; Nor, M.J.M. Utilizing Malaysian natural fibers as sound absorber. In Modeling And Measurement Methods for Acoustic Waves and for Acoustic Microdevices; Intechopen: London, UK, 2013; pp. 161–170. [Google Scholar]

- Lee, H.P.; Ng, B.M.P.; Rammohan, A.V.; Tran, L.Q.N. An Investigation of the Sound Absorption Properties of Flax/Epoxy Composites Compared with Glass/Epoxy Composites. J. Nat. Fibers 2016, 14, 71–77. [Google Scholar] [CrossRef]

- Mohapatra, T.K.; Satapathy, S.; Panigrahi, I.; Mishra, D. Biodegradable Acoustic Proficiency in Sound Absorption Capacity After Water Treatment and Testing by Impendence Tube Method: Hot Water and Saline Treatment to Test Acoustic Property. In Handbook of Research on Advancements in Manufacturing, Materials, and Mechanical Engineering; IGI Global: Hershey, PA, USA, 2021; pp. 75–90. [Google Scholar]

- Hassan, N.N.M.; Rus, A.Z.M. Influences of thickness and fabric for sound absorption of biopolymer composite. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2013; Volume 393, pp. 102–107. [Google Scholar]

- Santhanam, S.; Temesgen, S.; Atalie, D.; Ashagre, G. Recycling of cotton and polyester fibers to produce nonwoven fabric for functional sound absorption material. J. Nat. Fibers 2017, 16, 300–306. [Google Scholar] [CrossRef]

- Jayamani, E.; Hamdan, S.; Rahman, M.R.; Bakri, M.K.B. Investigation of fiber surface treatment on mechanical, acoustical and thermal properties of betelnut fiber polyester composites. Procedia Eng. 2014, 97, 545–554. [Google Scholar] [CrossRef]

- Santoni, A.; Bonfiglio, P.; Fausti, P.; Marescotti, C.; Mazzanti, V.; Mollica, F.; Pompoli, F. Improving the sound absorption performance of sustainable thermal insulation materials: Natural hemp fibres. Appl. Acoust. 2019, 150, 279–289. [Google Scholar] [CrossRef]

- da Silva, C.C.B.; Terashima, F.J.H.; Barbieri, N.; de Lima, K.F. Sound absorption coefficient assessment of sisal, coconut husk and sugar cane fibers for low frequencies based on three different methods. Appl. Acoust. 2019, 156, 92–100. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Lascaro, E.; Merli, F.; Ricciardi, P. Rice husk panels for building applications: Thermal, acoustic and environmental characterization and comparison with other innovative recycled waste materials. Constr. Build. Mater. 2018, 171, 338–349. [Google Scholar] [CrossRef]

- Soltani, P.; Taban, E.; Faridan, M.; Samaei, S.E.; Amininasab, S. Experimental and computational investigation of sound absorption performance of sustainable porous material: Yucca Gloriosa fiber. Appl. Acoust. 2019, 157, 106999. [Google Scholar] [CrossRef]

- Qui, H.; Enhui, Y. Effect of Thickness, Density and Cavity Depth on the Sound Absorption Properties of Wool Boards. Autex Res. J. 2018, 18, 203–208. [Google Scholar] [CrossRef]

- Putra, A.; Or, K.H.; Selamat, M.Z.; Nor, M.J.M.; Hassan, M.H.; Prasetiyo, I. Sound absorption of extracted pineapple-leaf fibres. Appl. Acoust. 2018, 136, 9–15. [Google Scholar] [CrossRef]

- Sari, N.H.; Wardana, I.N.G.; Irawan, Y.S.; Siswanto, E. Physical and Acoustical Properties of Corn Husk Fiber Panels. Adv. Acoust. Vib. 2016, 2016, 5971814. [Google Scholar] [CrossRef]

- Chin, D.D.V.S.; Yahya, M.N.B.; Din, N.B.C.; Ong, P. Acoustic properties of biodegradable composite micro-perforated panel (BC-MPP) made from kenaf fibre and polylactic acid (PLA). Appl. Acoust. 2018, 138, 179–187. [Google Scholar] [CrossRef]

- Gama, N.; Silva, R.; Carvalho, A.P.; Ferreira, A.; Barros-Timmons, A. Sound absorption properties of polyurethane foams derived from crude glycerol and liquefied coffee grounds polyol. Polym. Test. 2017, 62, 13–22. [Google Scholar] [CrossRef]

- Othmani, C.; Taktak, M.; Zein, A.; Hentati, T.; Elnady, T.; Fakhfakh, T.; Haddar, M. Experimental and theoretical investigation of the acoustic performance of sugarcane wastes based material. Appl. Acoust. 2016, 109, 90–96. [Google Scholar] [CrossRef]

- Belakroum, R.; Gherfi, A.; Kadja, M.; Maalouf, C.; Lachi, M.; El Wakil, N.; Mai, T. Design and properties of a new sustainable construction material based on date palm fibers and lime. Constr. Build. Mater. 2018, 184, 330–343. [Google Scholar] [CrossRef]

- Ghofrani, M.; Ashori, A.; Mehrabi, R. Mechanical and acoustical properties of particleboards made with date palm branches and vermiculite. Polym. Test. 2017, 60, 153–159. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G.; Di Gabriele, M. The Acoustic Characterization of Broom Fibers. J. Nat. Fibers 2017, 14, 858–863. [Google Scholar] [CrossRef]

- Sheng, C.; He, G.; Hu, Z.; Chou, C.; Shi, J.; Li, J.; Meng, Q.; Ning, X.; Wang, L.; Ning, F. Yarn on yarn abrasion failure mechanism of ultrahigh molecular weight polyethylene fiber. J. Eng. Fibers Fabr. 2021, 16, 1925832385. [Google Scholar] [CrossRef]

- Ning, F.; He, G.; Sheng, C.; He, H.; Wang, J.; Zhou, R.; Ning, X. Yarn on yarn abrasion performance of high modulus polyethylene fiber improved by graphene/polyurethane composites coating. J. Eng. Fibers Fabr. 2021, 16, 1–10. [Google Scholar] [CrossRef]

- Li, C.; Jiang, T.; Liu, S.; Han, Q. Dispersion and band gaps of elastic guided waves in the multi-scale periodic composite plates. Aerosp. Sci. Technol. 2022, 124, 107513. [Google Scholar] [CrossRef]

- Chen, B.; Lu, Y.; Li, W.; Dai, X.; Hua, X.; Xu, J.; Wang, Z.; Zhang, C.; Gao, D.; Li, Y.; et al. DPM-LES investigation on flow field dynamic and acoustic characteristics of a twin-fluid nozzle by multi-field coupling method. Int. J. Heat Mass Transf. 2022, 192, 122927. [Google Scholar] [CrossRef]

| S. No. | Reinforcements | Weight Fraction (%) | Matrix | Time of Immersion (h/days) and Immersion Temperature (°C) | Moisture Absorption (%) | References |

|---|---|---|---|---|---|---|

| 1 | Bamboo/jute/glass fibers | 2.5/2.5/5 | Polyester | 144 h and 25 °C | 23.23 | [74] |

| 2 | Waste hemp fibers | 10 | Polybenzoxazine | 90 h and 30 °C | 7.05 | [75] |

| 3 | Jute/basalt fibers | 5/15 | Epoxy | 120 h and 40 °C | 6.95 | [76] |

| 4 | Roselle/sugar palm | 5/5 | Polyurethane | 24 h and 25 °C | 8.48 | [77] |

| 5 | Jute fiber/rosewood and padauk wood dust | 10/2.5 | Epoxy | 15 days and 32 °C | 4.42 | [78] |

| 6 | Flax/nano TiO2 | 10/1.5 | Epoxy | 30 h and 25 °C | 1.2 | [79] |

| 7 | Continuous bamboo fibers | 20 | Epoxy | 4 h and 100 °C | 19 | [80] |

| 8 | Sugar palm/glass fiber | 10/20 | Thermoplastic Polyurethane | 168 h and 25 °C | 9.78 | [81] |

| 9 | Waste corn husk flour | 25 | Polyurethane | 30 days and 25 °C | 9.5 | [82] |

| 10 | Hemp/sisal fibers | 15/15 | Epoxy | 42 days and 25 °C | 11.6 | [83] |

| 11 | Abaca fiber | 25 | Polypropylene | 80 days and 50 °C | 15.09 | [84] |

| 12 | Wood flour | 20 | Polypropylene | 96 h and 25 °C | 1.09 | [85] |

| 13 | Kenaf fiber | 40 | Polypropylene | 24 h and 25 °C | 1.05 | [86] |

| 14 | Wood flour | 35 | Polypropylene | 48 h and 25 °C | 11.57 | [87] |

| 15 | Olive stone flour | 30 | Polypropylene | 48 h and 25 °C | 9.55 | [87] |

| 16 | Rice husk ash filler | 40 | Polypropylene | 24 h and 25 °C | 15.31 | [88] |

| 17 | Luffa cylindria fiber | 30 | Polypropylene | 960 h and 25 °C | 28.4 | [89] |

| 18 | Jute fiber | 40 | Polypropylene | 18 h and 23 °C | 21.5 | [90] |

| 19 | Jute fiber | 30 | Epoxy | 336 h and 25 °C | 8 | [91] |

| 20 | Alfa pulps filler | 35 | Low-density Polyethylene | 480 h and 25 °C | 25.71 | [92] |

| 21 | Bamboo mat | 25 | Polyester | 1440 h | 50.31 | [93] |

| 22 | Ijuk fiber | 30 | Polypropylene | 480 h and 23 °C | 5.22 | [94] |

| 23 | Hemp/glass hybrid | 15/20 | Epoxy | 3600 h | 21.31 | [95] |

| 24 | Jute/glass hybrid | 10/30 | Unsaturated Polyester | 504 | 58.36 | [96] |

| 25 | Sisal/banana hybrid | 20/15 | Epoxy | 50 | 11.48 | [97] |

| 26 | Coir/glass hybrid | 15/15 | Epoxy | 1440 | 39.16 | [98] |

| 27 | Short snake grass fiber | 25 | Isopthallic polyester | 120 days and 60 °C | 29.79 | [99] |

| 28 | Phoenix sp. fiber | 25 | Epoxy | 100 days and 30 °C | 17.52 | [100] |

| 29 | Calotropis gigantea fiber | 15 | Polyester | 15 days and 70 °C | 18.12 | [101] |

| 30 | Calotropis gigantea fiber | 20 | Epoxy | 72 h and 25 °C | 17.44 | [102] |

| 31 | Tindora tendril fiber filled with haritaki nanopowder | 20/7.5 | Epoxy | 8 h and 30 °C | 5.87 | [103] |

| S.No | Composite Material | Bulk density (kg/m3)/Porosity (%) | Measuring Frequency Range (Hz) | Sound Absorption Coefficient | References |

|---|---|---|---|---|---|

| 1 | Pineapple leaf fiber in epoxy matrix | - | >1000 | 0.9 | [121] |

| 2 | Rubber crumbs waste fiber in polyester matrix | - | 1000–6000 | 0.93 | [122] |

| 3 | Kapok fiber in epoxy matrix | 8.3 kg/m3 | 100–6300 | 0.98 | [123] |

| 4 | Flax, ramie, and jute fibers in epoxy matrix | - | 1000–10,000 | 0.88 | [124] |

| 5 | Rice waste fiber in polyurethane foam matrix | 8.35 kg/m3 | 400–6400 | 0.9 | [125] |

| 6 | Sugarcane bagasse in epoxy matrix | 10.26 kg/m3 | 0–1600 | 0.17 | [126] |

| 7 | Date palm fiber powder in cement matrix | - | 200–2000 | 0.78 | [127] |

| 8 | Banana fiber in polyester matrix | 88.4% | 500–6000 | 0.97 | [128] |

| 9 | Mineralized wood flour in epoxy matrix | - | 2000 | 0.4 | [129] |

| 10 | Ijuk fiber in polyurethane matrix | 83.5% | 3000–4500 | 0.9 | [130] |

| 11 | Grass fiber in epoxy matrix | - | 2000 | 0.98 | [131] |

| 12 | Flax fibers in epoxy matrix | 8.5 kg/m3 | 63–6300 | 0.9 | [132] |

| 13 | Kapok fiber in epoxy matrix | 20 kg/m3 | 125–4000 | 0.405 | [133] |

| 14 | Cotton fabric in epoxy matrix | 92% | 3000–3500 | 0.92 | [134] |

| 15 | Nonwoven cotton fiber in polyester matrix | - | 125–3000 | 0.638 | [135] |

| 16 | Betelnut fiber in polypropylene matrix | 85% | 6000 | 0.42 | [136] |

| 17 | Hemp fiber in polyester matrix | 141 kg/m3 | 1000–4500 | 0.58 | [137] |

| 18 | Sugarcane bagasse in polyvinyl alcohol matrix | 200.8 kg/m3 | 172–2000 | 0.75 | [137] |

| 19 | Sisal fiber in polyvinyl alcohol matrix | 214.7 kg/m3 | 172–2000 | 0.69 | [138] |

| 20 | Rice husk ash in glue matrix | 170 kg/m3 | 200–6400 | 0.81 | [139] |

| 21 | Yucca gloriosa fiber in epoxy matrix | 200 kg/m3 | 63–6300 | 0.95 | [140] |

| 22 | Coarse wool with binding fibers | 249.55 kg/m3 | 60–6300 | 0.84 | [141] |

| 23 | Pineapple leaf fiber in epoxy matrix | 117 kg/m3 | 500–4500 | 0.91 | [142] |

| 24 | Corn husk fiber in epoxy matrix | 92% | 1600–3250 | 0.88 | [143,144,145] |

| 25 | Kenaf fiber in polylactic acid matrix | 82% | 1450–1522 | 0.8 | [144,145,146] |

| 26 | Polyurethane foam in Coffee grounds polyol | 88% | 150–4000 | 0.96 | [145,146,147] |

| 27 | Sugarcane bagasse in urea formaldehyde resin matrix | 78% | 500–4000 | 0.75 | [146,147,148,149] |

| 28 | Date palm fiber in lime matrix | 81% | 750–6300 | 0.55 | [147,148,149] |

| 29 | Date palm branch powder filled urea formaldehyde | - | 800–1250 | 0.4 | [148,149,150] |

| 30 | Broom fiber in epoxy matrix | 73% | >1650 | 0.9 | [149,150,151] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhuvaneswari, V.; Devarajan, B.; Arulmurugan, B.; Mahendran, R.; Rajkumar, S.; Sharma, S.; Mausam, K.; Li, C.; Eldin, E.T. A Critical Review on Hygrothermal and Sound Absorption Behavior of Natural-Fiber-Reinforced Polymer Composites. Polymers 2022, 14, 4727. https://doi.org/10.3390/polym14214727

Bhuvaneswari V, Devarajan B, Arulmurugan B, Mahendran R, Rajkumar S, Sharma S, Mausam K, Li C, Eldin ET. A Critical Review on Hygrothermal and Sound Absorption Behavior of Natural-Fiber-Reinforced Polymer Composites. Polymers. 2022; 14(21):4727. https://doi.org/10.3390/polym14214727

Chicago/Turabian StyleBhuvaneswari, V., Balaji Devarajan, B. Arulmurugan, R. Mahendran, S. Rajkumar, Shubham Sharma, Kuwar Mausam, Changhe Li, and Elsayed Tag Eldin. 2022. "A Critical Review on Hygrothermal and Sound Absorption Behavior of Natural-Fiber-Reinforced Polymer Composites" Polymers 14, no. 21: 4727. https://doi.org/10.3390/polym14214727

APA StyleBhuvaneswari, V., Devarajan, B., Arulmurugan, B., Mahendran, R., Rajkumar, S., Sharma, S., Mausam, K., Li, C., & Eldin, E. T. (2022). A Critical Review on Hygrothermal and Sound Absorption Behavior of Natural-Fiber-Reinforced Polymer Composites. Polymers, 14(21), 4727. https://doi.org/10.3390/polym14214727