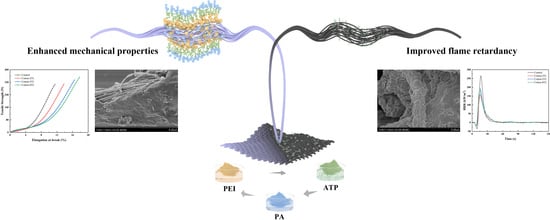

Fabrication of an Eco-Friendly Clay-Based Coating for Enhancing Flame Retardant and Mechanical Properties of Cotton Fabrics via LbL Assembly

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Acid-Treated ATP

2.3. Preparation of FR Cotton Fabrics

2.4. Characterizations of the Control and FR Cotton Fabrics

3. Results and Discussion

3.1. Characterizations of the Control and FR Cotton Fabrics

3.2. Thermal Stability of the Control and FR Cotton Fabrics

3.3. Flame Retardancy of the Control and FR Cotton Fabrics

3.4. Analysis of Char Residue of the Control and FR Cotton Fabrics

3.5. Suppression Properties of Volatile Gases

3.6. Flame-Retardant Mechanism

3.7. Mechanical Properties of the Control and FR Cotton Fabrics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Tian, W.; Liu, L.; Cheng, W.; Wang, W.; Liew, K.M.; Wang, B.; Hu, Y. Eco-friendly flame retardant and electromagnetic interference shielding cotton fabrics with multi-layered coatings. Chem. Eng. J. 2019, 372, 1077–1090. [Google Scholar] [CrossRef]

- Li, N.; Han, H.; Li, M.; Qiu, W.; Wang, Q.; Qi, X.; He, Y.; Wang, X.; Liu, L.; Yu, J.; et al. Eco-friendly and intrinsic nanogels for durable flame retardant and antibacterial properties. Chem. Eng. J. 2021, 415, 129008. [Google Scholar] [CrossRef]

- Han, X.; Wang, J.; Wang, X.; Tian, W.; Dong, Y.; Jiang, S. Finite Element Analysis of Strengthening Mechanism of Ultrastrong and Tough Cellulosic Materials. Polymers 2022, 14, 4490. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Chen, C.; Brozena, A.H.; Zhu, J.Y.; Xu, L.; Driemeier, C.; Dai, J.; Rojas, O.J.; Isogai, A.; Wagberg, L.; et al. Developing fibrillated cellulose as a sustainable technological material. Nature 2021, 590, 47–56. [Google Scholar] [CrossRef]

- Zheng, C.; Sun, Y.; Cui, Y.; Yang, W.; Lu, Z.; Shen, S.; Xia, Y.; Xiong, Z. Superhydrophobic and flame-retardant alginate fabrics prepared through a one-step dip-coating surface-treatment. Cellulose 2021, 28, 5973–5984. [Google Scholar] [CrossRef]

- Li, P.; Wang, B.; Xu, Y.-J.; Jiang, Z.; Dong, C.; Liu, Y.; Zhu, P. Ecofriendly flame-retardant cotton fabrics: Preparation, flame retardancy, thermal degradation properties, and mechanism. ACS Sustain. Chem. Eng. 2019, 7, 19246–19256. [Google Scholar] [CrossRef]

- Ambekar, R.S.; Deshmukh, A.; Suarez-Villagran, M.Y.; Das, R.; Pal, V.; Dey, S.; Miller, J.H., Jr.; Machado, L.D.; Kumbhakar, P.; Tiwary, C.S. 2D hexagonal boron nitride-coated cotton fabric with self-extinguishing property. ACS Appl. Mater. Interfaces 2020, 12, 45274–45280. [Google Scholar] [CrossRef] [PubMed]

- Zope, I.S.; Foo, S.; Seah, D.G.J.; Akunuri, A.T.; Dasari, A. Development and evaluation of a water-based flame retardant spray coating for cotton fabrics. ACS Appl. Mater. Interfaces 2017, 9, 40782–40791. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, M.; Wang, Q.; Li, B. A novel durable flame retardant cotton fabric produced by surface chemical grafting of phosphorus- and nitrogen-containing compounds. Cellulose 2017, 24, 4069–4081. [Google Scholar] [CrossRef]

- Zhao, P.; Xu, F.; Chen, Y.; Huang, T.; Zhang, G. A novel durable flame retardant for cotton fabrics based on diethylenetriamine. Polym. Degrad. Stab. 2022, 195, 109796. [Google Scholar] [CrossRef]

- Li, N.; Chen, P.; Liu, D.; Kang, G.; Liu, L.; Xu, L.; Yu, J.; Li, F.; Wu, D. Novel P/Si based nanoparticles for durable flame retardant application on cotton. Cellulose 2022, 29, 2063–2076. [Google Scholar] [CrossRef]

- Nguyen Thi, H.; Vu Thi Hong, K.; Ngo Ha, T.; Phan, D.N. Application of plasma activation in flame-retardant treatment for cotton fabric. Polymers 2020, 12, 1575. [Google Scholar] [CrossRef] [PubMed]

- Lin, D.; Zeng, X.; Li, H.; Lai, X.; Wu, T. One-pot fabrication of superhydrophobic and flame-retardant coatings on cotton fabrics via sol-gel reaction. J. Colloid Interface Sci. 2019, 533, 198–206. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.-W.; Liang, C.-X.; Guan, J.-P.; Yang, X.-H.; Tang, R.-C. Flame retardant and hydrophobic properties of novel sol-gel derived phytic acid/silica hybrid organic-inorganic coatings for silk fabric. Appl. Surf. Sci. 2018, 427, 69–80. [Google Scholar] [CrossRef]

- Zhang, D.; Williams, B.L.; Shrestha, S.B.; Nasir, Z.; Becher, E.M.; Lofink, B.J.; Santos, V.H.; Patel, H.; Peng, X.; Sun, L. Flame retardant and hydrophobic coatings on cotton fabrics via sol-gel and self-assembly techniques. J. Colloid Interface Sci. 2017, 505, 892–899. [Google Scholar] [CrossRef]

- Yang, J.C.; Liao, W.; Deng, S.B.; Cao, Z.J.; Wang, Y.Z. Flame retardation of cellulose-rich fabrics via a simplified layer-by-layer assembly. Carbohydr. Polym. 2016, 151, 434–440. [Google Scholar] [CrossRef]

- Pan, H.; Wang, W.; Pan, Y.; Song, L.; Hu, Y.; Liew, K.M. Formation of self-extinguishing flame retardant biobased coating on cotton fabrics via Layer-by-Layer assembly of chitin derivatives. Carbohydr. Polym. 2015, 115, 516–524. [Google Scholar] [CrossRef]

- Shi, X.-H.; Liu, Q.-Y.; Li, X.-L.; Du, A.-K.; Niu, J.-W.; Li, Y.-M.; Li, Z.; Wang, M.; Wang, D.-Y. Construction phosphorus/nitrogen-containing flame-retardant and hydrophobic coating toward cotton fabric via layer-by-layer assembly. Polym. Degrad. Stab. 2022, 197, 109839. [Google Scholar] [CrossRef]

- Qiu, X.; Li, Z.; Li, X.; Zhang, Z. Flame retardant coatings prepared using layer by layer assembly: A review. Chem. Eng. J. 2018, 334, 108–122. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.; Zhang, X.; Wu, H.; Shen, J.; Chen, R.; Xiong, Y.; Li, J.; Guo, S. Progress on the layer-by-layer assembly of multilayered polymer composites: Strategy, structural control and applications. Prog. Polym. Sci. 2019, 89, 76–107. [Google Scholar] [CrossRef]

- Lazar, S.T.; Kolibaba, T.J.; Grunlan, J.C. Flame-retardant surface treatments. Nat. Rev. Mater. 2020, 5, 259–275. [Google Scholar] [CrossRef]

- Xia, W.; Fan, S.; Xu, T. Inhibitory action of halogen-free fire retardants on combustion and volatile emission of bituminous components. Sci. Prog. 2021, 104, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Li, H.; He, Y.; Liu, Y.; Dong, C.; Zhu, P. Flame retardancy and thermal behavior of cotton fabrics based on a novel phosphorus-containing siloxane. Appl. Surf. Sci. 2019, 479, 765–775. [Google Scholar] [CrossRef]

- Zhou, T.; Xu, H.; Cai, L.; Wang, J. Construction of anti-flame network structures in cotton fabrics with pentaerythritol phosphate urea salt and nano SiO2. Appl. Surf. Sci. 2020, 507, 145175. [Google Scholar] [CrossRef]

- Chen, H.; Zhu, S.; Zhou, R.; Wu, X.; Zhang, W.; Han, X.; Wang, J. Thermal Degradation Behavior of Thiol-ene Composites Loaded with a Novel Silicone Flame Retardant. Polymers 2022, 14, 4335. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wu, X.; Zhou, R.; Han, W.; Han, X. Effect of a Novel Graphene on the Flame Retardancy and Thermal Degradation Behavior of Epoxy Resin. J. Macromol. Sci. Part B 2022, 61, 1–13. [Google Scholar] [CrossRef]

- El-Shafei, A.; ElShemy, M.; Abou-Okeil, A. Eco-friendly finishing agent for cotton fabrics to improve flame retardant and antibacterial properties. Carbohydr. Polym. 2015, 118, 83–90. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, Z.; Leng, Q.; Wang, Y. Eco-friendly flame retardant coating deposited on cotton fabrics from bio-based chitosan, phytic acid and divalent metal ions. Int. J. Biol. Macromol. 2019, 140, 303–310. [Google Scholar] [CrossRef]

- Chen, H.-Q.; Xu, Y.-J.; Jiang, Z.-M.; Jin, X.; Liu, Y.; Zhang, L.; Zhang, C.-J.; Yan, C. The thermal degradation property and flame-retardant mechanism of coated knitted cotton fabric with chitosan and APP by LBL assembly. J. Therm. Anal. Calorim. 2019, 140, 591–602. [Google Scholar] [CrossRef]

- Alongi, J.; Carletto, R.A.; Di Blasio, A.; Carosio, F.; Bosco, F.; Malucelli, G. DNA: A novel, green, natural flame retardant and suppressant for cotton. J. Mater. Chem. A 2013, 1, 4779–4785. [Google Scholar] [CrossRef]

- Alongi, J.; Di Blasio, A.; Milnes, J.; Malucelli, G.; Bourbigot, S.; Kandola, B.; Camino, G. Thermal degradation of DNA, an all-in-one natural intumescent flame retardant. Polym. Degrad. Stab. 2015, 113, 110–118. [Google Scholar] [CrossRef]

- Carosio, F.; Di Blasio, A.; Alongi, J.; Malucelli, G. Green DNA-based flame retardant coatings assembled through layer by layer. Polymer 2013, 54, 5148–5153. [Google Scholar] [CrossRef]

- Zilke, O.; Plohl, D.; Opwis, K.; Mayer-Gall, T.; Gutmann, J.S. A flame-retardant phytic-acid-based LbL-coating for cotton using polyvinylamine. Polymers 2020, 12, 1202. [Google Scholar] [CrossRef] [PubMed]

- Barbalini, M.; Bartoli, M.; Tagliaferro, A.; Malucelli, G. Phytic acid and biochar: An effective all bio-sourced flame retardant formulation for cotton fabrics. Polymers 2020, 12, 811. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Wang, B.; Sui, X.; Xie, R.; Xu, H.; Zhang, L.; Zhong, Y.; Mao, Z. Durable flame retardant and antibacterial finishing on cotton fabrics with cyclotriphosphazene/polydopamine/silver nanoparticles hybrid coatings. Appl. Surf. Sci. 2018, 435, 1337–1343. [Google Scholar] [CrossRef]

- Carosio, F.; Fontaine, G.; Alongi, J.; Bourbigot, S. Starch-based layer by layer assembly: Efficient and sustainable approach to cotton fire protection. ACS Appl. Mater. Interfaces 2015, 7, 12158–12167. [Google Scholar] [CrossRef]

- Xing, C.Y.; Zeng, S.L.; Qi, S.K.; Jiang, M.J.; Xu, L.; Chen, L.; Zhang, S.; Li, B.J. Poly (vinyl alcohol)/beta-cyclodextrin composite fiber with good flame retardant and super-smoke suppression properties. Polymers 2020, 12, 1078. [Google Scholar] [CrossRef]

- Alongi, J.; Poskovic, M.; Visakh, P.N.; Frache, A.; Malucelli, G. Cyclodextrin nanosponges as novel green flame retardants for PP, LLDPE and PA6. Carbohydr. Polym. 2012, 88, 1387–1394. [Google Scholar] [CrossRef]

- Zhang, D.; Zeng, J.; Liu, W.; Qiu, X.; Qian, Y.; Zhang, H.; Yang, Y.; Liu, M.; Yang, D. Pristine lignin as a flame retardant in flexible PU foam. Green Chem. 2021, 23, 5972–5980. [Google Scholar] [CrossRef]

- Kulkarni, S.; Xia, Z.; Yu, S.; Kiratitanavit, W.; Morgan, A.B.; Kumar, J.; Mosurkal, R.; Nagarajan, R. Bio-based flame-retardant coatings based on the synergistic combination of tannic acid and phytic acid for nylon-cotton blends. ACS Appl. Mater. Interfaces 2021, 13, 61620–61628. [Google Scholar] [CrossRef]

- Zhang, A.-N.; Zhao, H.-B.; Cheng, J.-B.; Li, M.-E.; Li, S.-L.; Cao, M.; Wang, Y.-Z. Construction of durable eco-friendly biomass-based flame-retardant coating for cotton fabrics. Chem. Eng. J. 2021, 410, 128361. [Google Scholar] [CrossRef]

- Wang, S.; Tan, L.; Xu, T. Synergistic effects of developed composite flame retardant on VOCs constituents of heated asphalt and carbonized layer compositions. J. Clean. Prod. 2022, 367, 133107. [Google Scholar] [CrossRef]

- Chen, S.; Li, X.; Li, Y.; Sun, J. Intumescent flame-retardant and self-healing superhydrophobic coatings on cotton fabric. ACS Nano 2015, 9, 4070–4076. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.C.; Schulz, J.; Mannen, S.; Delhom, C.; Condon, B.; Chang, S.; Zammarano, M.; Grunlan, J.C. Flame retardant behavior of polyelectrolyte-clay thin film assemblies on cotton fabric. ACS Nano 2010, 4, 3325–3337. [Google Scholar] [CrossRef] [PubMed]

- Patra, A.; Kjellin, S.; Larsson, A.-C. Phytic acid-based flame retardants for cotton. Green Mater. 2020, 8, 123–130. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, S.; Yin, C. Synthesis and structure-property of polyamide 6/macrogol/attapulgite nanocomposites. Polym. Compos. 2014, 35, 1852–1857. [Google Scholar] [CrossRef]

- Bao, Y.; Li, X.; Tang, P.; Liu, C.; Zhang, W.; Ma, J. Attapulgite modified cotton fabric and its flame retardancy. Cellulose 2019, 26, 9311–9322. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, Y.; Lyu, B.; Wang, P.; Ma, J. Nanocomposite based on poly(acrylic acid)/attapulgite towards flame retardant of cotton fabrics. Carbohydr. Polym. 2019, 206, 245–253. [Google Scholar] [CrossRef]

- Xie, H.; Lai, X.; Wang, Y.; Li, H.; Zeng, X. A green approach to fabricating nacre-inspired nanocoating for super-efficiently fire-safe polymers via one-step self-assembly. J. Hazard. Mater. 2019, 365, 125–136. [Google Scholar] [CrossRef]

- Wang, B.; Xu, Y.-J.; Li, P.; Zhang, F.-Q.; Liu, Y.; Zhu, P. Flame-retardant polyester/cotton blend with phosphorus/nitrogen/silicon-containing nano-coating by layer-by-layer assembly. Appl. Surf. Sci. 2020, 509, 145323. [Google Scholar] [CrossRef]

- Apaydin, K.; Laachachi, A.; Ball, V.; Jimenez, M.; Bourbigot, S.; Toniazzo, V.; Ruch, D. Polyallylamine–montmorillonite as super flame retardant coating assemblies by layer-by layer deposition on polyamide. Polym. Degrad. Stab. 2013, 98, 627–634. [Google Scholar] [CrossRef]

- Xin, S.; Yang, H.; Chen, Y.; Yang, M.; Chen, L.; Wang, X.; Chen, H. Chemical structure evolution of char during the pyrolysis of cellulose. J. Anal. Appl. Pyrolysis 2015, 116, 263–271. [Google Scholar] [CrossRef]

- Rao, W.; Shi, J.; Yu, C.; Zhao, H.-B.; Wang, Y.-Z. Highly efficient, transparent, and environment-friendly flame-retardant coating for cotton fabric. Chem. Eng. J. 2021, 424, 130556. [Google Scholar] [CrossRef]

- Liu, L.; Pan, Y.; Zhao, Y.; Cai, W.; Gui, Z.; Hu, Y.; Wang, X. Self-assembly of phosphonate-metal complex for superhydrophobic and durable flame-retardant polyester–cotton fabrics. Cellulose 2020, 27, 6011–6025. [Google Scholar] [CrossRef]

- Guo, W.; Wang, X.; Huang, J.; Zhou, Y.; Cai, W.; Wang, J.; Song, L.; Hu, Y. Construction of durable flame-retardant and robust superhydrophobic coatings on cotton fabrics for water-oil separation application. Chem. Eng. J. 2020, 398, 125661. [Google Scholar] [CrossRef]

- Huang, D.; Wang, W.; Xu, J.; Wang, A. Mechanical and water resistance properties of chitosan/poly(vinyl alcohol) films reinforced with attapulgite dispersed by high-pressure homogenization. Chem. Eng. J. 2012, 210, 166–172. [Google Scholar] [CrossRef]

| Samples | C (%) | O (%) | N (%) | P (%) | Si (%) | Mg (%) | Al (%) |

|---|---|---|---|---|---|---|---|

| Control | 71.30 | 28.70 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Cotton-2TL | 56.23 | 33.33 | 5.19 | 2.50 | 1.14 | 0.65 | 0.96 |

| Cotton-5TL | 53.03 | 29.69 | 9.00 | 3.94 | 1.59 | 2.28 | 0.47 |

| Cotton-8TL | 52.57 | 27.47 | 11.70 | 3.53 | 0.81 | 3.47 | 0.44 |

| Samples | Add-On (%) | PHRR (kW/m2) | THR (MJ/m2) | FIGRA (kW/m2/s) | LOI (%) |

|---|---|---|---|---|---|

| Control | - | 265.6 | 2.63 | 15.6 | 17.2 |

| Cotton-2TL | 10.5 | 157.2 | 2.05 | 9.8 | 19.8 |

| Cotton-5TL | 28.3 | 192.2 | 2.71 | 12.8 | 22.8 |

| Cotton-8TL | 32.7 | 197.5 | 2.89 | 13.2 | 27.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, M.; Chen, S.; Yang, R.; Li, D.; Zhang, W. Fabrication of an Eco-Friendly Clay-Based Coating for Enhancing Flame Retardant and Mechanical Properties of Cotton Fabrics via LbL Assembly. Polymers 2022, 14, 4994. https://doi.org/10.3390/polym14224994

Kang M, Chen S, Yang R, Li D, Zhang W. Fabrication of an Eco-Friendly Clay-Based Coating for Enhancing Flame Retardant and Mechanical Properties of Cotton Fabrics via LbL Assembly. Polymers. 2022; 14(22):4994. https://doi.org/10.3390/polym14224994

Chicago/Turabian StyleKang, Mingjia, Silu Chen, Rongjie Yang, Dinghua Li, and Wenchao Zhang. 2022. "Fabrication of an Eco-Friendly Clay-Based Coating for Enhancing Flame Retardant and Mechanical Properties of Cotton Fabrics via LbL Assembly" Polymers 14, no. 22: 4994. https://doi.org/10.3390/polym14224994

APA StyleKang, M., Chen, S., Yang, R., Li, D., & Zhang, W. (2022). Fabrication of an Eco-Friendly Clay-Based Coating for Enhancing Flame Retardant and Mechanical Properties of Cotton Fabrics via LbL Assembly. Polymers, 14(22), 4994. https://doi.org/10.3390/polym14224994