Temperature Controlled Mechanical Reinforcement of Polyacrylate Films Containing Nematic Liquid Crystals

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Monomer/LC Blends

2.3. Electron Beam Curing

2.4. Ultra Violet Curing

2.5. Mechanical Measurements

2.6. Scanning Electron Microscopy

3. Results and Discussion

3.1. Development of Crosslinked Polymer/LC Films

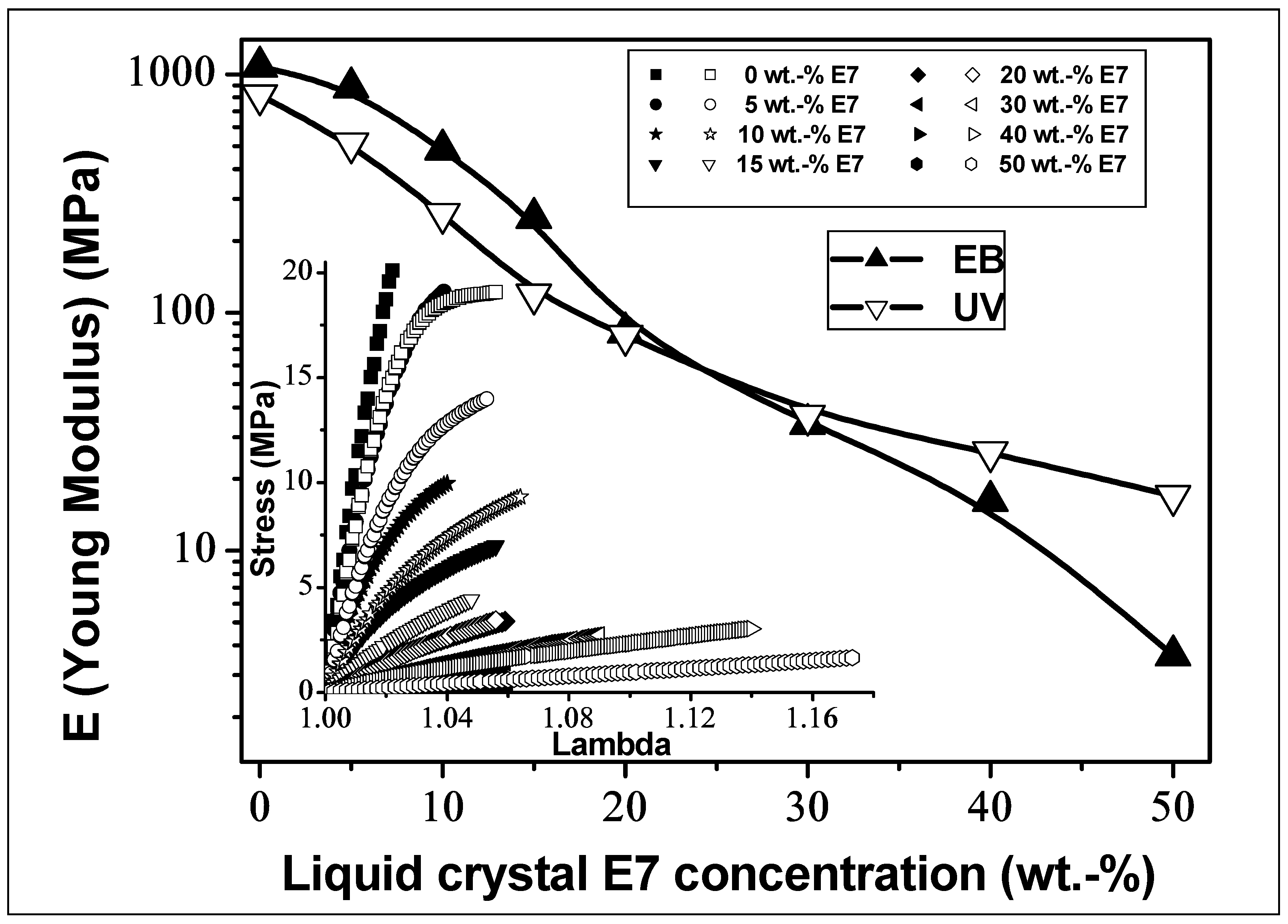

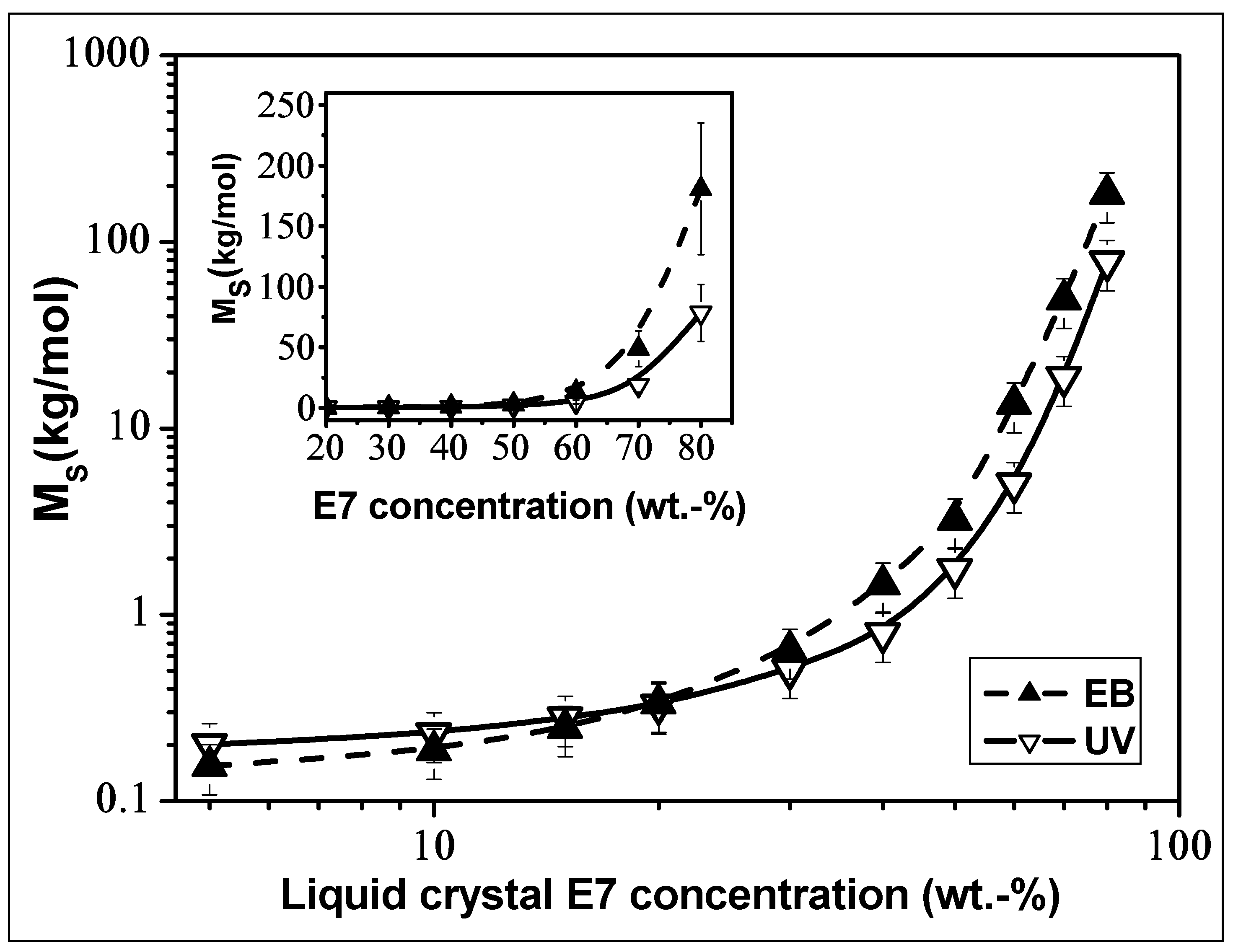

3.2. Static Mechanical Measurements

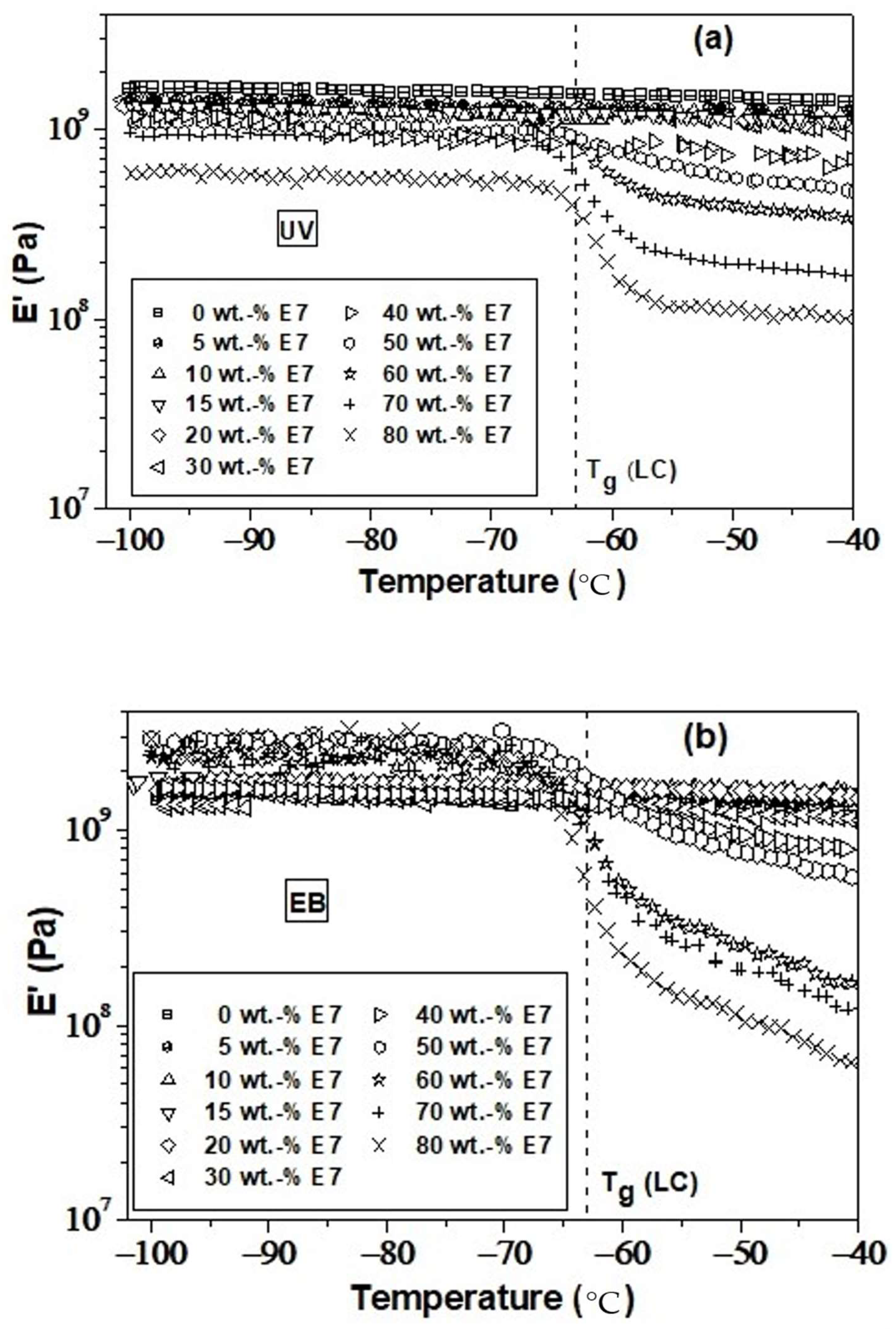

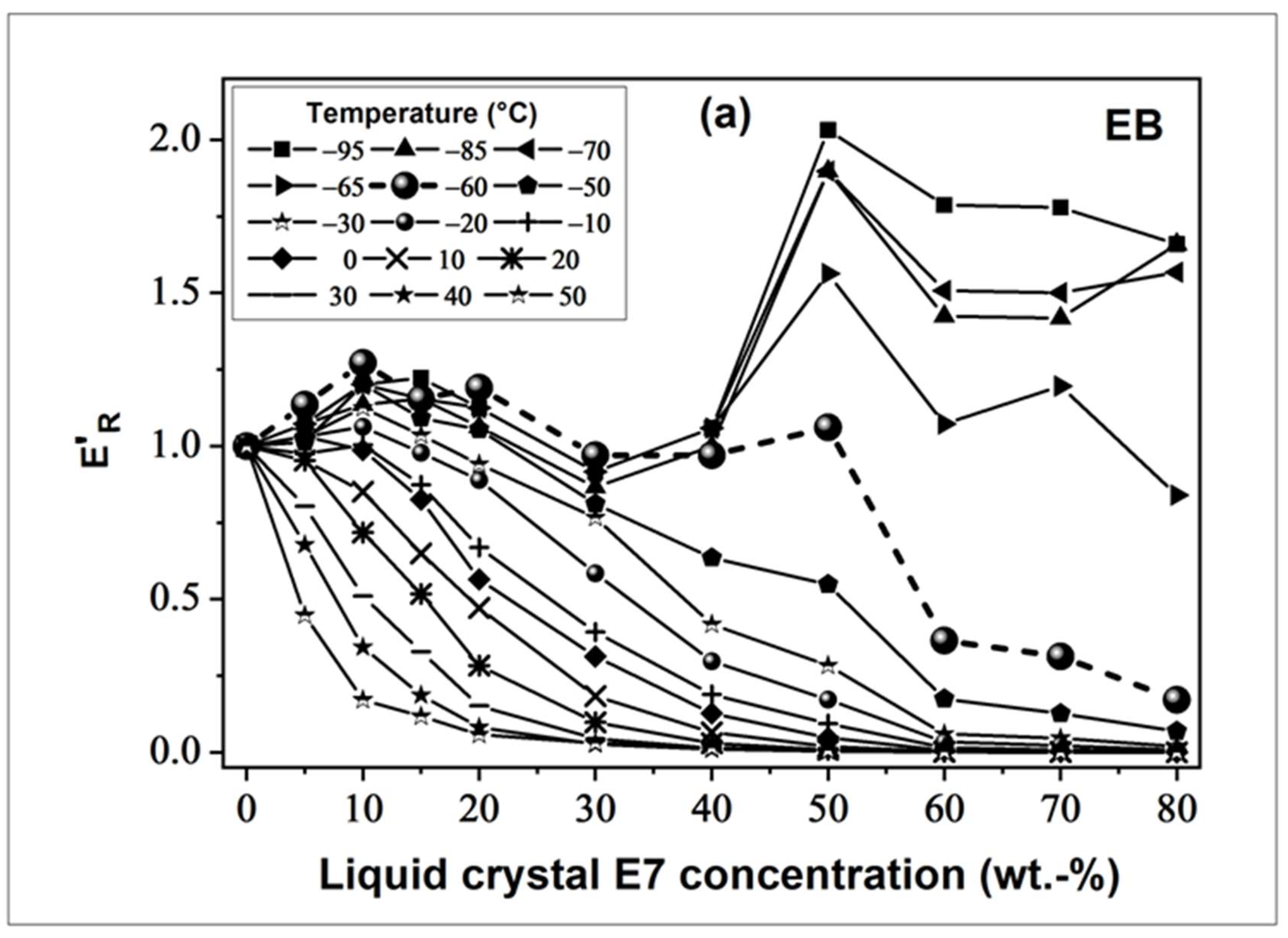

3.3. Dynamic Mechanical Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rudin, A.; Choi, P. Chapter 9—Copolymerization. In The Elements of Polymer Science & Engineering, 3rd ed.; Academic Press: London, UK, 2013; pp. 391–425. [Google Scholar] [CrossRef]

- Guerrero-Santos, R.; Saldívar-Guerra, E.; Bonilla-Cruz, J. Chapter 4—Free Radical Polymerization. In Handbook of Polymer Synthesis, Characterization, and Processing; Saldívar-Guerra, E., Vivaldo-Lima, E., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 65–83. [Google Scholar] [CrossRef]

- Sanai, Y.; Kubota, K. Effect of UV-curing conditions on the polymer structures: A comparison between coating and adhesive. Polym. J. 2020, 52, 1153–1163. [Google Scholar] [CrossRef]

- Gziut, K.; Kowalczyk, A.; Schmidt, B. Free-Radical Bulk-Photopolymerization Process as a Method of Obtaining Thermally Curable Structural Self-Adhesive Tapes and Effect of Used Type I Photoinitiators. Polymers 2020, 12, 2191. [Google Scholar] [CrossRef] [PubMed]

- Jiang, F.; Drummer, D. Curing kinetic analysis of acrylate photopolymer for additive manufacturing by photo-DSC. Polymers 2020, 12, 1080. [Google Scholar] [CrossRef]

- Trey, S.M.; Netrval, J.; Berglund, L.; Johansson, M. Electron-Beam-Initiated Polymerization of Poly(ethylene glycol)-Based Wood Impregnants. ACS Appl. Mat. Interfaces 2010, 2, 3352–3362. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Yang, J.; Gao, J.; Xu, X.; Jing, Y.; Wang, X.; Li, W.; Li, X. Wearable hydroxylated MWCNTs/ecoflex composite strain sensor with high comprehensive performance based on electron irradiation. Comp. Sci. Technol. 2022, 226, 109537. [Google Scholar] [CrossRef]

- Decker, C. Photoinitiated crosslinking polymerization. Progr. Polym. Sci. 1996, 21, 593–650. [Google Scholar] [CrossRef]

- Maschke, U.; Coqueret, X.; Benmouna, M. Electro-Optical Properties of Polymer-Dispersed Liquid Crystals. Macromol. Rapid Commun. 2002, 23, 159–170. [Google Scholar] [CrossRef]

- Olivier, A.; Pakula, T.; Ewen, B.; Coqueret, X.; Benmouna, M.; Maschke, U. Mechanical Properties of Electron Beam Cured Monomer and Monomer/Liquid Crystal Films. Macromol. Mater. Eng. 2002, 287, 656–659. [Google Scholar] [CrossRef]

- Olivier, A.; Benkhaled, L.; Pakula, T.; Ewen, B.; Best, A.; Benmouna, M.; Maschke, U. Static and Dynamic Mechanical Behavior of Electron Beam-Cured Monomer and Monomer/Liquid Crystal Systems. Macromol. Mater. Eng. 2004, 289, 1047–1052. [Google Scholar] [CrossRef]

- Bouchakour, M.; Derouiche, Y.; Bouberka, Z.; Beyens, C.; Mechernène, L.; Riahi, F.; Maschke, U. Optical properties of electron beam- and UV-cured polypropyleneglycoldiacrylate/liquid crystal E7 systems. Liq. Cryst. 2015, 42, 1527–1536. [Google Scholar] [CrossRef]

- Bouchakour, M.; Derouiche, Y.; Bouberka, Z.; Beyens, C.; Supiot, P.; Dubois, F.; Riahi, F.; Maschke, U. Chapter 4—Electron beam curing of monomer/liquid crystal blends. In Polymer-Modified Liquid Crystals; Dierking, I., Ed.; Soft Matter Series No. 8; RSC: London, UK, 2019. [Google Scholar] [CrossRef]

- Mucha, M. Polymer as an important component of blends and composites with liquid crystals. Progr. Polym. Sci. 2003, 28, 837–873. [Google Scholar] [CrossRef]

- Jamil, M.; Ahmad, F.; Rhee, J.T.; Jeon, Y.J. Nanoparticle-doped polymer-dispersed liquid crystal display. Current Sci. 2011, 101, 1544–1552. Available online: https://www.jstor.org/stable/24080694 (accessed on 8 September 2022).

- Lagerwall, J.P.F.; Scalia, G.A. New era for liquid crystal research: Applications of liquid crystals in soft matter nano-, bio-and microtechnology. Curr. Appl. Phys. 2012, 12, 1387–1412. [Google Scholar] [CrossRef]

- Bronnikov, S.; Kostromin, S.; Zuev, V. Polymer-Dispersed Liquid Crystals: Progress in Preparation, Investigation, and Application. Soft Mater. 2013, 52, 1718–1735. [Google Scholar] [CrossRef]

- Sasani Ghamsari, M.; Carlescu, I. An overview of polymer-dispersed liquid crystals composite films and their applications (Chapter 2). In Liquid Crystal and Display Technology; IntechOpen: London, UK, 2020; p. 11. [Google Scholar] [CrossRef]

- Saeed, M.H.; Zhang, S.; Cao, Y.; Zhou, L.; Hu, J.; Muhammad, I.; Xiao, J.; Zhang, L.; Yang, H. Recent advances in the Polymer Dispersed Liquid Crystal Composite and its Applications. Molecules 2020, 25, 5510. [Google Scholar] [CrossRef] [PubMed]

- Menard, K.P.; Menard, N. Dynamic mechanical analysis. In Encyclopedia of Analytical Chemistry: Applications, Theory and Instrumentation; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar] [CrossRef]

- Menard, K.P. Dynamic Mechanical Analysis: A Practical Introduction, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

- Wu, Y.P.; Jia, Q.X.; Yu, D.S.; Zhang, L.Q. Modeling Young’s modulus of rubber–clay nanocomposites using composite theories. Polym. Test. 2004, 23, 903–909. [Google Scholar] [CrossRef]

- Haramina, T.; Kirchheim, R. Mechanical Spectroscopy of PVCN with Increasing Cross-Linking Degree. Macromolecules 2007, 40, 4211–4216. [Google Scholar] [CrossRef]

- Hub, C.; Harton, S.E.; Hunt, M.A.; Fink, R.; Ade, H.J. Influence of sample preparation and processing on observed glass transition temperatures of polymer nanocomposites. J. Polym. Sci. B Polym. Phys. 2007, 45, 2270–2276. [Google Scholar] [CrossRef]

- Zheng, J.; Ozisik, R.; Siegel, R.W. Phase separation and mechanical responses of polyurethane nanocomposites. Polymer 2006, 47, 7786–7794. [Google Scholar] [CrossRef]

- Rault, J.; Marchal, J.; Judeinstein, P.; Albouy, P.A. Stress-Induced Crystallization and Reinforcement in Filled Natural Rubbers: 2H NMR Study. Macromolecules 2006, 39, 8356–8368. [Google Scholar] [CrossRef]

- Ngoi, K.H.; Wong, J.C.; Chia, C.H.; Jin, K.S.; Kim, H.; Kim, H.-C.; Kim, H.-J.; Ree, M. Inorganic-organic nanocomposite networks: Structure, curing reaction, properties, and hard coating performance. Comp. Sci. Technol. 2022, 218, 109112. [Google Scholar] [CrossRef]

- Im, J.S.; Jeong, E.; In, S.J.; Lee, Y.-S. The impact of fluorinated MWCNT additives on the enhanced dynamic mechanical properties of e-beam-cured epoxy. Comp. Sci. Technol. 2010, 70, 763–768. [Google Scholar] [CrossRef]

- Ray, S.; Bhowmick, A.K. Influence of untreated and novel electron beam modified surface coated silica filler on dynamic mechanical thermal properties of ethylene-octene copolymer. Polym. Engin. Sci. 2004, 44, 163–178. [Google Scholar] [CrossRef]

- Ray, S.; Bhowmick, A.K. Influence of untreated and novel electron beam modified surface coated silica filler on rheometric and mechanical properties of ethylene-octene copolymer. J. Mater. Sci. 2003, 38, 3199–3210. [Google Scholar] [CrossRef]

- Sangermano, M.; Vescovo, L.; Pepino, N.; Chiolerio, A.; Allia, A.; Tiberto, P.; Coisson, M.; Suber, L.; Marchegiani, G. Photoinitiator-Free UV-Cured Acrylic Coatings Containing Magnetite Nanoparticles. Macromol. Chem. Phys. 2010, 211, 2530–2535. [Google Scholar] [CrossRef]

- Morselli, D.; Bondioli, F.; Sangermano, M.; Messori, M. Photo-cured epoxy networks reinforced with TiO2 in-situ generated by means of non-hydrolytic sol–gel process. Polymer 2012, 53, 283–290. [Google Scholar] [CrossRef]

- Cai, X.; Blanchet, P. Electron-Beam Curing of Acrylate/Nanoparticle Impregnated Wood Products. BioResources 2015, 10, 3852–3864. [Google Scholar] [CrossRef] [Green Version]

- Anastasio, R.; Peerbooms, W.; Cardinaels, R.; Breemen, L.C.A. Characterization of ultraviolet-cured methacrylate networks: From photopolymerization to ultimate mechanical properties. Macromolecules 2019, 52, 9220–9231. [Google Scholar] [CrossRef]

- Brás, A.R.E.; Henriques, S.; Casimiro, T.; Aguiar-Ricardo, A.; Sotomayor, J.; Caldeira, J.; Santos, C.; Dionísio, M. Characterization of a nematic mixture by reversed-phase HPLC and UV spectroscopy: An application to phase behaviour studies in liquid crystal–CO2 systems. Liq. Cryst. 2007, 34, 591–597. [Google Scholar] [CrossRef]

- Slimane, K.S.; Bouchaour, T.; Benmouna, M.; Olivier, A.; Carbonnier, B.; Pakula, T.; Coqueret, X.; Maschke, U. Physical properties of Electron Beam-cured Tripropyleneglycoldiacrylate and liquid crystal systems. Mol. Cryst. Liq. Cryst. 2004, 413, 1–8. [Google Scholar] [CrossRef]

- Derouiche, Y.; Dubois, F.; Douali, R.; Legrand, C.; Maschke, U. Some Properties of Nematic Liquid Crystal E7/Acrylic Polymer Networks. Mol. Cryst. Liq. Cryst. 2011, 541, 201–210. [Google Scholar] [CrossRef]

- Benkhaled, L.; Abdoune, F.Z.; Mechernene, L.; Coqueret, X.; Maschke, U. Thermophysical Investigation of PDLC Materials Prepared by Polymerization Induced Phase Separation. In the Proceedings of the German Colloquium on Liquid Crystals (Arbeitstagung Flüssigkristalle), Halle, Germany, 24–26 March 2004; Available online: https://www.researchgate.net/publication/267802849 (accessed on 8 September 2022).

- Charlesby, A. Effect of High-energy Radiation on Long-chain Polymers. Nature 1953, 171, 167. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; Wiley: New York, NY, USA, 1980. [Google Scholar]

- Brostow, W. Science of Materials; John Wiley & Sons: New York, NY, USA, 1979; p. 436. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zair, L.; Berrayah, A.; Arabeche, K.; Bouberka, Z.; Best, A.; Koynov, K.; Maschke, U. Temperature Controlled Mechanical Reinforcement of Polyacrylate Films Containing Nematic Liquid Crystals. Polymers 2022, 14, 5024. https://doi.org/10.3390/polym14225024

Zair L, Berrayah A, Arabeche K, Bouberka Z, Best A, Koynov K, Maschke U. Temperature Controlled Mechanical Reinforcement of Polyacrylate Films Containing Nematic Liquid Crystals. Polymers. 2022; 14(22):5024. https://doi.org/10.3390/polym14225024

Chicago/Turabian StyleZair, Latifa, Abdelkader Berrayah, Khadidja Arabeche, Zohra Bouberka, Andreas Best, Kaloian Koynov, and Ulrich Maschke. 2022. "Temperature Controlled Mechanical Reinforcement of Polyacrylate Films Containing Nematic Liquid Crystals" Polymers 14, no. 22: 5024. https://doi.org/10.3390/polym14225024

APA StyleZair, L., Berrayah, A., Arabeche, K., Bouberka, Z., Best, A., Koynov, K., & Maschke, U. (2022). Temperature Controlled Mechanical Reinforcement of Polyacrylate Films Containing Nematic Liquid Crystals. Polymers, 14(22), 5024. https://doi.org/10.3390/polym14225024