The Synergistic Toughening and Strengthening Effects of Cork Particles and Nanocellulose on Rosin-Based Epoxy Resin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composites

2.2.1. Preparation of Rosin-Based Epoxy Resin

2.2.2. Preparation of Nanocellulose

2.2.3. Preparation of Cork/Rosin-Based Epoxy Resin Binary Composites

2.2.4. Preparation of Nanocellulose/Rosin-Based Epoxy Resin Binary Composites

2.2.5. Preparation of Cork/Nanocellulose/Rosin-Based Epoxy Resin Ternary Composites

2.3. Property Evaluation

2.3.1. The Rosin-Based Epoxy Resin

Fourier Transform Infrared Spectroscopy (FTIR)

2.3.2. The Nanocellulose

Field-Emission Scanning Electron Microscopy (FE-SEM)

Transmission Electron Microscope (TEM)

2.3.3. The Cork Particles

Field-Emission Scanning Electron Microscopy (FE-SEM)

2.3.4. The Composites

Mechanical Properties

Field-Emission Scanning Electron Microscopy (FE-SEM)

Thermogravimetric Analysis (TGA)

3. Results and Discussion

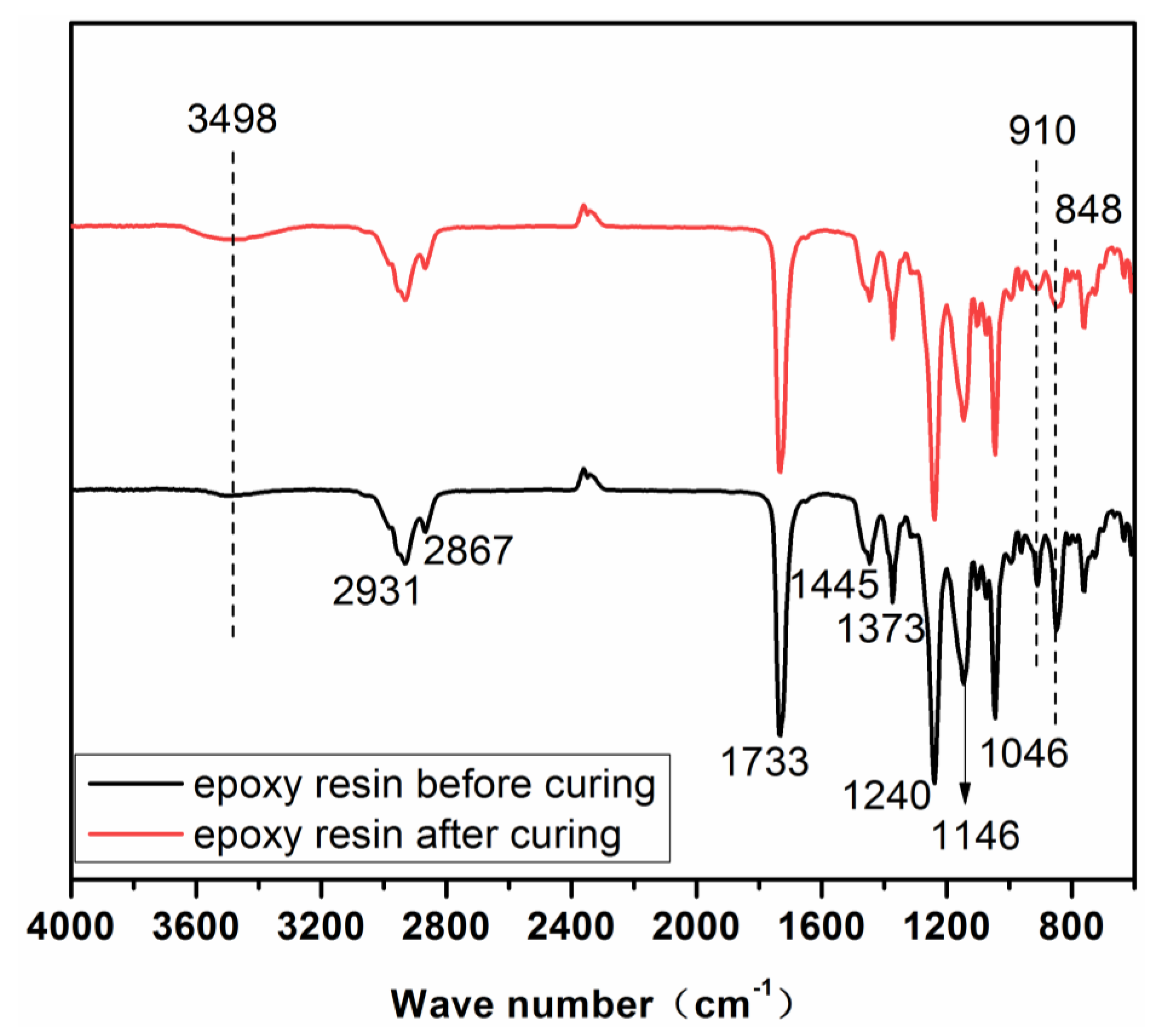

3.1. Characterization of Rosin-Based Epoxy Resin

FTIR Analysis

3.2. Characterization of Nanocellulose

Microscopic Morphology Observation

3.3. Characterization of Cork Particles

Microscopic Morphology Observation

3.4. Characterization of Composite Materials

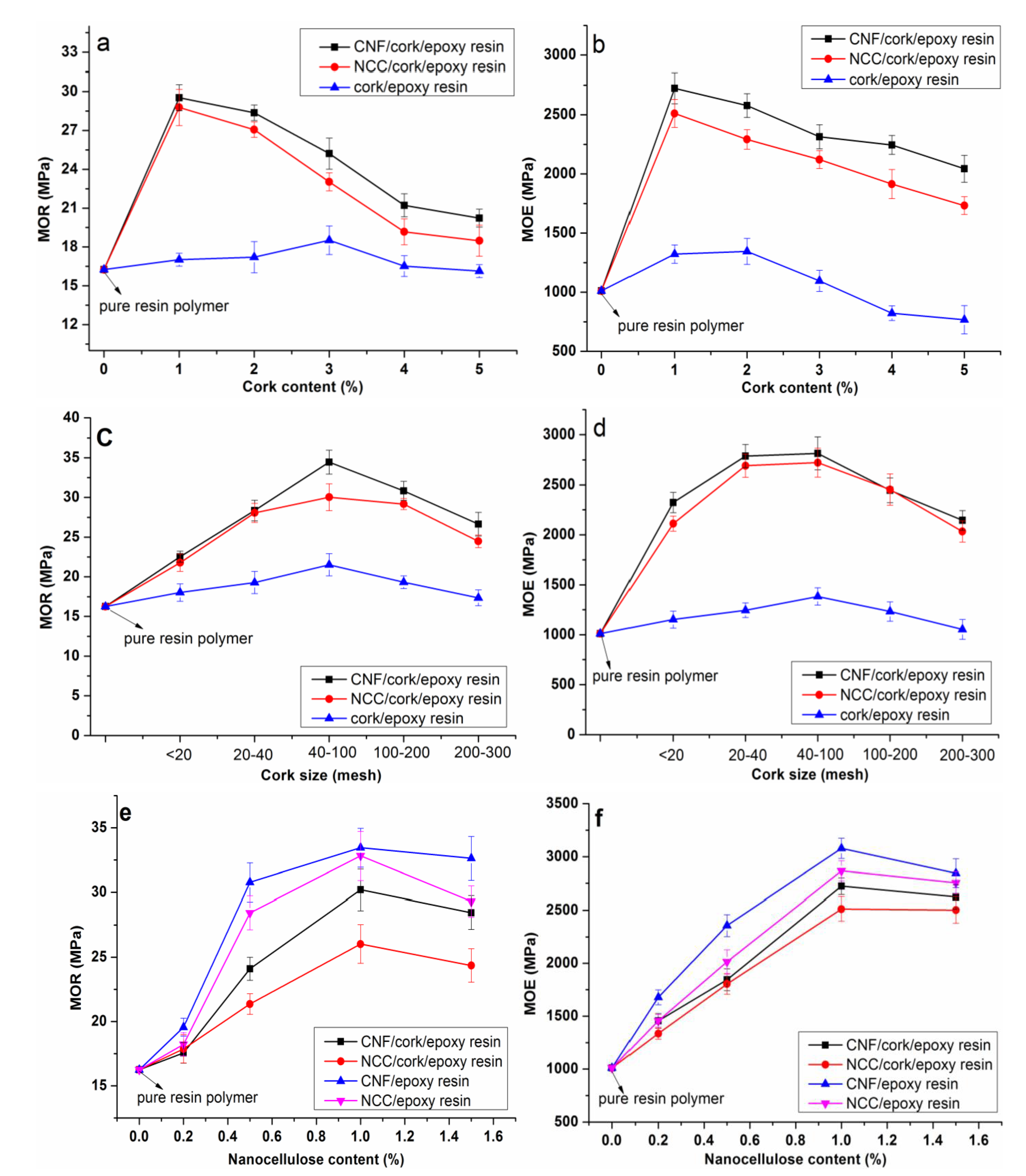

3.4.1. Mechanical Properties

Flexural Performance

Impact Toughness

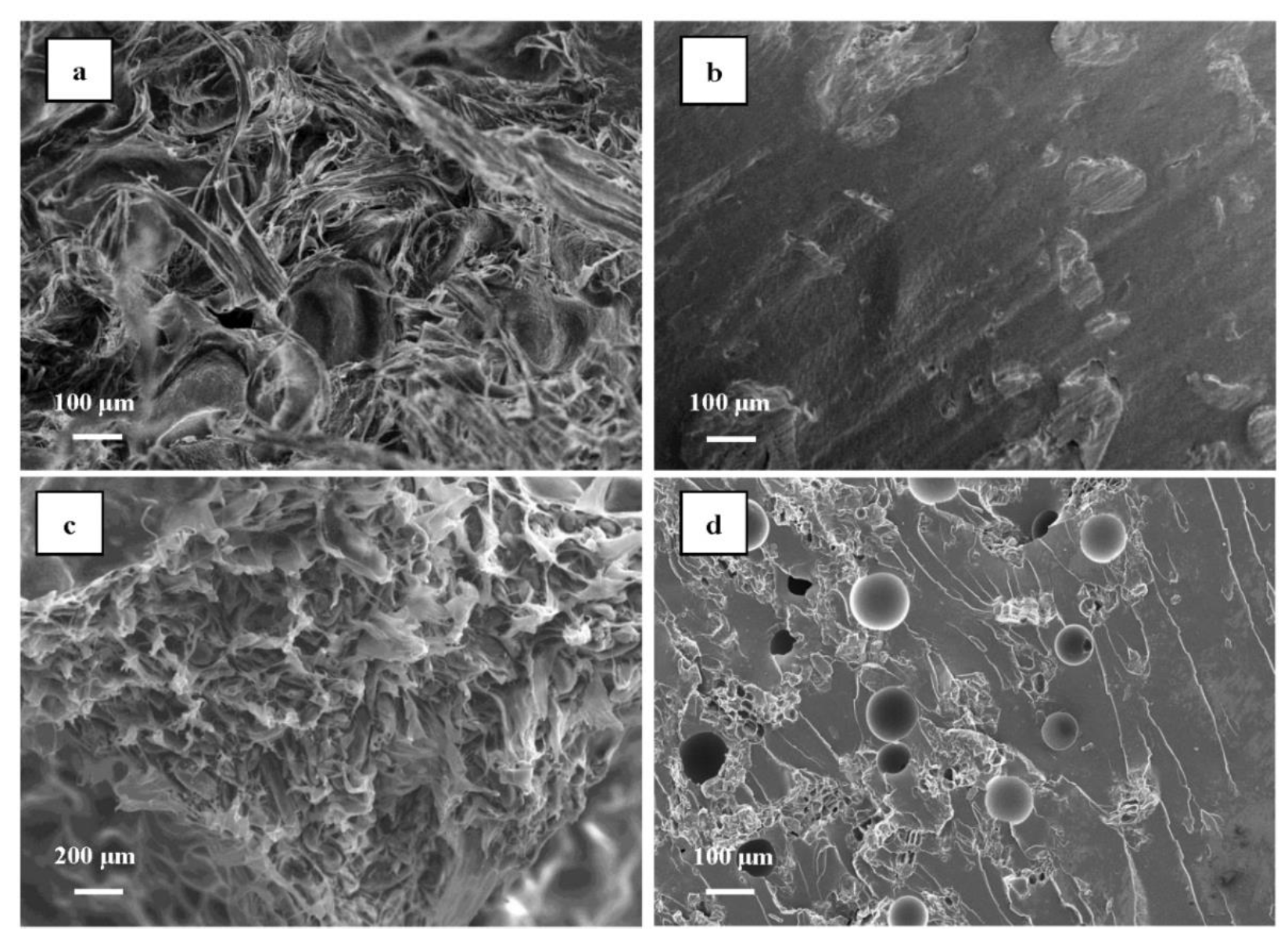

3.4.2. FE-SEM

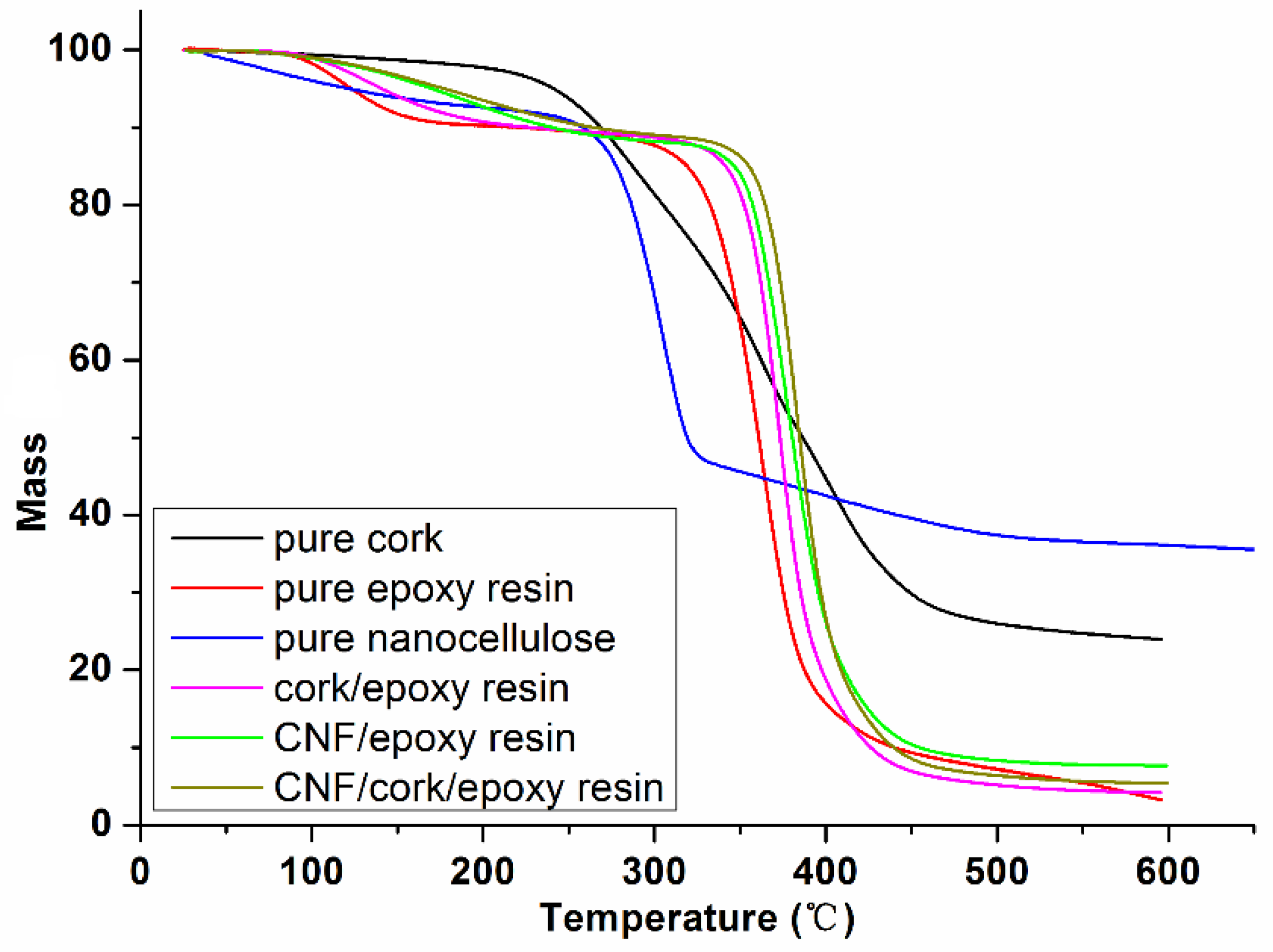

3.4.3. Thermal Stability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, C.; Tung, S.; Jeng, R.; Abu-Omar, M.M.; Lin, C.H. A facile strategy to achieve fully bio-based epoxy thermosets from eugenol. Green Chem. 2019, 21, 4475. [Google Scholar] [CrossRef]

- Ding, L.; Han, X.; Chen, L.; Jiang, S. Preparation and properties of hydrophobic and transparent wood. J. Bioresour. Bioprod. 2022, 7, 295–305. [Google Scholar] [CrossRef]

- Vikulova, M.; Nikityuk, T.; Artyukhov, D.; Tsyganov, A.; Bainyashev, A.; Burmistrov, I.; Gorshkov, N. High-k Three-phase epoxy/K1.6(Ni0.8Ti7.2)O16/CNT composites with synergetic effect. Polymers 2022, 14, 448. [Google Scholar] [CrossRef] [PubMed]

- Bafakeeh, O.T.; Shewakh, W.M.; Abu-Oqail, A.; Abd-Elaziem, W.; Ghafaar, M.A.; Abu-Okail, M. Synthesis and characterization of hybrid fiber-reinforced polymer by adding ceramic nanoparticles for aeronautical structural applications. Polymers 2021, 13, 4116. [Google Scholar] [CrossRef]

- Sim, J.; Kang, Y.; Kim, B.J.; Park, Y.H.; Lee, Y.C. Preparation of fly ash/epoxy composites and its effects on mechanical properties. Polymers 2020, 12, 79. [Google Scholar] [CrossRef]

- Bekeshev, A.; Mostovoy, A.; Tastanova, L.; Kadykova, Y.; Kalganova, S.; Lopukhova, M. Reinforcement of epoxy composites with application of finely-ground ochre and electrophysical method of the composition modification. Polymers 2020, 12, 1437. [Google Scholar] [CrossRef]

- Huang, X.; Yang, X.; Liu, H.; Shang, S.; Cai, Z.; Wu, K. Bio-based thermosetting epoxy foams from epoxidized soybean oil and rosin with enhanced properties. Ind. Crops Prod. 2019, 139, 111540. [Google Scholar] [CrossRef]

- Mora, A.S.; Tayouo, R.; Boutevin, B.; David, G.; Caillol, S. Synthesis of biobased reactive hydroxyl amines by amination reaction of cardanol-based epoxy monomers. Eur. Polym. J. 2019, 118, 429. [Google Scholar] [CrossRef]

- Nagatani, M.; Tsurumaki, A.; Takamatsu, K.; Saito, H.; Nakamura, N.; Ohno, H. Preparation of epoxy resins derived from lignin solubilized in tetrabutylphosphonium hydroxide aqueous solutions. Int. J. Biol. Macromol. 2019, 132, 585. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, C.; Yu, M.; Huang, Y.; Tan, J.; Zhang, M.; Zhu, X. Multifunctional tannin extract-based epoxy derived from waste bark as a highly toughening and strengthening agent for epoxy resin. Ind. Crops Prod. 2022, 176, 114255. [Google Scholar] [CrossRef]

- Park, S.; Park, S.; Jang, D.H.; Lee, H.S.; Park, C.H. Anti-fogging behavior of water-absorbing polymer films derived from isosorbide-based epoxy resin. Mater. Lett. 2016, 180, 81. [Google Scholar] [CrossRef]

- Huang, K.; Zhang, J.; Li, M.; Xia, J.; Zhou, Y. Exploration of the complementary properties of biobased epoxies derived from rosin diacid and dimer fatty acid for balanced performance. Ind. Crops Prod. 2013, 49, 497. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, M.; Huang, X.; Zhang, H. Synthesis and performance of a thermosetting resin: Acrylated epoxidized soybean oil curing with a rosin-based acrylamide. J. Appl. Polym. Sci. 2017, 134, 44545. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, X.; Zhang, R.; Zhu, J.; Jiang, Y. Synthesis and properties of full biobased thermosetting resins from rosin acid and soybean oil: The role of rosin acid derivatives. Green Chem. 2013, 15, 1300. [Google Scholar] [CrossRef]

- Ferdosian, F.; Yuan, Z.S.; Anderson, M.; Xu, C.C. Thermal performance and thermal decomposition kinetics of lignin-based epoxy resin. J. Anal. Appl. Pyrolysis 2016, 119, 124. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Pereira, H. The rationale behind cork properties: A review of structure and chemistry. Bioresources 2015, 10, 6207. [Google Scholar] [CrossRef]

- Silva, S.P.; Sabino, M.A.; Fernandes, E.M.; Correlo, V.M.; Boesel, L.F.; Reis, R.L. Cork: Properties, capabilities and applications. Int. Mater. Rev. 2005, 50, 345. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Correlo, V.M.; Mano, J.F.; Reis, R.L. Cork-polymer biocomposites: Mechanical, structural and thermal properties. Mater. Design 2015, 82, 282. [Google Scholar] [CrossRef]

- Song, X.; Yuan, Y.; Zhang, Q.; Zhao, J. Research progress on cell wall structure and main chemical components of cork. Chem. Ind. For. Prod. 2016, 36, 133. [Google Scholar]

- Fernandes, E.M.; Correlo, V.M.; Mano, J.F.; Reis, R.L. Polypropylene-based cork-polymer composites: Processing parameters and properties. Compos. Part B Eng. 2014, 66, 210. [Google Scholar] [CrossRef]

- Aroso, I.M.; Fernandes, E.M.; Pires, R.A.; Mano, J.F.; Reis, R.L. Cork extractives exhibit thermo-oxidative protection properties in polypropylene-cork composites and as direct additives for polypropylene. Polym. Degrad. Stab. 2015, 116, 45. [Google Scholar] [CrossRef]

- Barbosa, A.Q.; da Silva, L.F.M.; Abenojar, J.; Figueiredo, M.; Oechsner, A. Toughness of a brittle epoxy resin reinforced with micro cork particles: Effect of size, amount and surface treatment. Compos. Part B Eng. 2017, 114, 299. [Google Scholar] [CrossRef]

- Daver, F.; Lee, K.P.M.; Brandt, M.; Shanks, R. Cork-PLA composite filaments for fused deposition modeling. Compos. Sci. Technol. 2018, 168, 230. [Google Scholar] [CrossRef]

- Tao, P.; Li, J.; Li, J.; Shang, S.; Song, Z. Enhanced performance of rosin-based epoxy composites mixed with carbon nanotubes and cork powders from oriental oak bark. Ind. Crops Prod. 2020, 158, 113051. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, W.; Wang, X.; Zhao, X.; Xia, N.; Kong, F.; Wang, S. Easy way to prepare dispersible CNC dry powder by precipitation and conventional evaporation. Cellulose 2021, 28, 9661. [Google Scholar] [CrossRef]

- Han, X.; Wang, Z.; Ding, L.; Chen, L.; Wang, F.; Pu, J.; Jiang, S. Water molecule-induced hydrogen bonding between cellulose nanofibers toward highly strong and tough materials from wood aerogel. Chin. Chem. Lett. 2021, 32, 3105. [Google Scholar] [CrossRef]

- Han, X.; Wu, W.; Wang, J.; Tian, Z.; Jiang, S. Hydrogen-bonding-aided fabrication of wood derived cellulose scaffold/aramid nanofiber into high-performance bulk material. Materials 2021, 14, 5444. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Int. Ed. Chem. 2005, 44, 3358. [Google Scholar] [CrossRef]

- Dunlop, M.J.; Acharya, B.; Bissessur, R. Study of plant and tunicate based nanocrystalline cellulose in hybrid polymeric nanocomposites. Cellulose 2020, 27, 249. [Google Scholar] [CrossRef]

- Li, J.; Li, D.; Song, Z.; Shang, S.; Guo, Y. Preparation and properties of wood plastic composite reinforced by ultralong cellulose nanofibers. Polym. Compos. 2016, 37, 1206. [Google Scholar] [CrossRef]

- Lu, Q.; Lu, L.; Li, Y.; Li, L.; Huang, B. One-pot synthesis of aminated cellulose nanofibers by “biological grinding” for enhanced thermal conductivity nanocomposites. Carbohydr. Polym. 2021, 254, 117310. [Google Scholar] [CrossRef] [PubMed]

- Nissila, T.; Hietala, M.; Oksman, K. A method for preparing epoxy-cellulose nanofiber composites with an oriented structure. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105515. [Google Scholar] [CrossRef]

- Saikia, A.; Debbarma, N.; Karak, N. Renewable resource based hyperbranched epoxy thermosetting nanocomposite with cellulose nanofiber as a sustainable material. Cellulose 2019, 26, 4743. [Google Scholar] [CrossRef]

- Li, J.; Song, Z.; Li, D.; Shang, S.; Yong, G. Cotton cellulose nanofiber-reinforced high density polyethylene composites prepared with two different pretreatment methods. Ind. Crops Prod. 2014, 59, 318. [Google Scholar] [CrossRef]

- Li, D.; Liu, Z.; AlHaik, M.; Tehrani, M.; Murray, F.; Tannenbaum, R.; Garmestani, H. Magnetic alignment of cellulose nanowhiskers in an all-cellulose composite. Polym. Bull. 2010, 65, 635. [Google Scholar] [CrossRef]

- Sánchez, C.G.; Valero, C.F.; Mendoza, A.O.; Meco, A.G.; Hurtado, E.R. Rheological behavior of original and recycled cellulose–polyolefin composite materials. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1075. [Google Scholar] [CrossRef]

- Barbosa, A.Q.; da Silva, L.F.M.; Ochsner, A. Effect of the amount of cork particles on the strength and glass transition temperature of a structural adhesive. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2014, 228, 323. [Google Scholar] [CrossRef]

- Santos, P.T.; Pinto, S.; Marques, P.A.A.P.; Pereira, A.B.; Alves de Sousa, R.J. Agglomerated cork: A way to tailor its mechanical properties. Compos. Struct. 2017, 178, 277. [Google Scholar] [CrossRef]

- Șen, A.; Marques, A.V.; Gominho, J.; Pereira, H. Study of thermo chemical treatments of cork in the 150–400 °C range using colour analysis and FTIR spectroscopy. Ind. Crops Prod. 2012, 38, 132. [Google Scholar] [CrossRef]

- Nishino, T.; Matsuda, I.; Hirao, K. All-cellulose composite. Macromolecules 2004, 37, 7683. [Google Scholar] [CrossRef]

| Components | Source | Characteristics |

|---|---|---|

| Cork particles | Collected from Qinba Mountain in China, Crushed into particles with a crusher | The size of cork particles: >20 mesh, >830 μm; 20–40 mesh, 830–380 μm; 40–100 mesh, 380–150 μm; 100–200 mesh, 150–75 μm; 200–300 mesh, 75–48 μm |

| Rosin | Purchased from Wuzhou Pine Chemicals Ltd. (Suzhou, China) | WW grade; Color: light yellow; Softening point: ≥76 °C Acid value: ≥166 mg KOH/g |

| Nanocellulose | Using Chinese white poplar flour as raw materials | The size of poplar flour: 40–100 mesh, 380–150 μm |

| Chemicals | Purchased from Shanghai Aladdin Bio-Chem Technology Co. Ltd. (Shanghai, China) | Analytical grade |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Bai, J.; Li, J. The Synergistic Toughening and Strengthening Effects of Cork Particles and Nanocellulose on Rosin-Based Epoxy Resin. Polymers 2022, 14, 5064. https://doi.org/10.3390/polym14235064

Sun J, Bai J, Li J. The Synergistic Toughening and Strengthening Effects of Cork Particles and Nanocellulose on Rosin-Based Epoxy Resin. Polymers. 2022; 14(23):5064. https://doi.org/10.3390/polym14235064

Chicago/Turabian StyleSun, Jingrong, Jinmeng Bai, and Jingjing Li. 2022. "The Synergistic Toughening and Strengthening Effects of Cork Particles and Nanocellulose on Rosin-Based Epoxy Resin" Polymers 14, no. 23: 5064. https://doi.org/10.3390/polym14235064

APA StyleSun, J., Bai, J., & Li, J. (2022). The Synergistic Toughening and Strengthening Effects of Cork Particles and Nanocellulose on Rosin-Based Epoxy Resin. Polymers, 14(23), 5064. https://doi.org/10.3390/polym14235064