Hybrid Manufacturing of Acrylonitrile Butadiene Styrene (ABS) via the Combination of Material Extrusion Additive Manufacturing and Injection Molding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

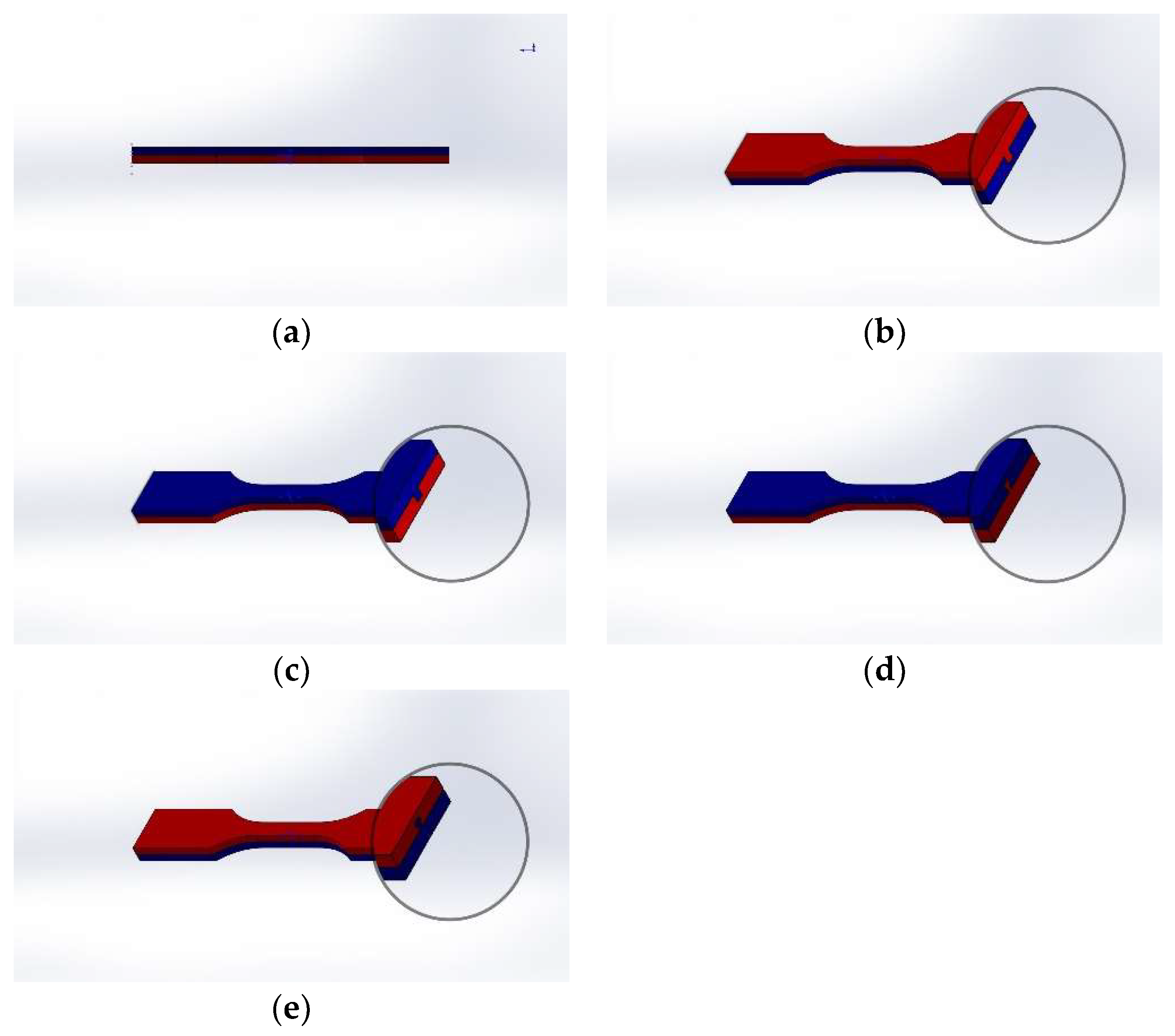

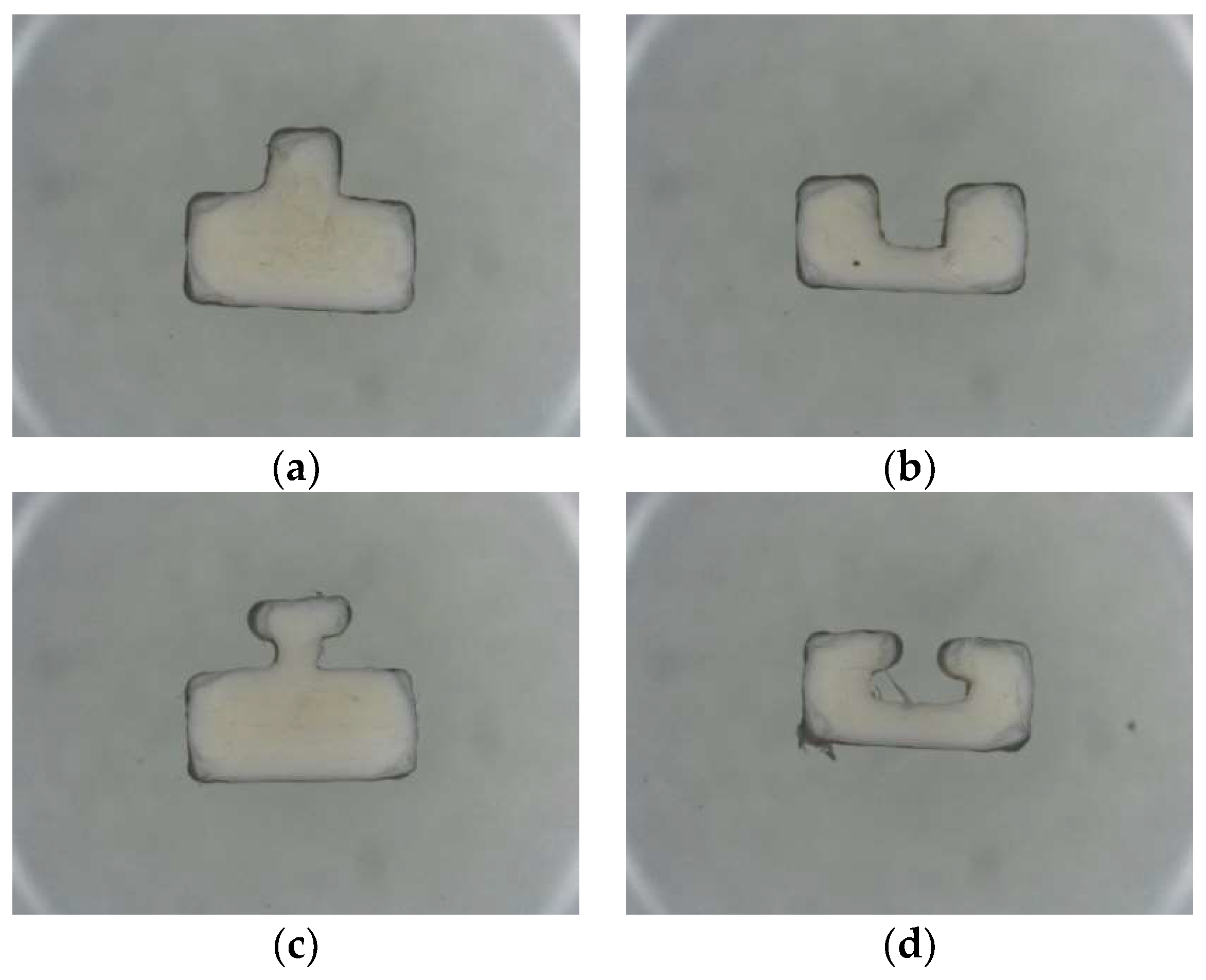

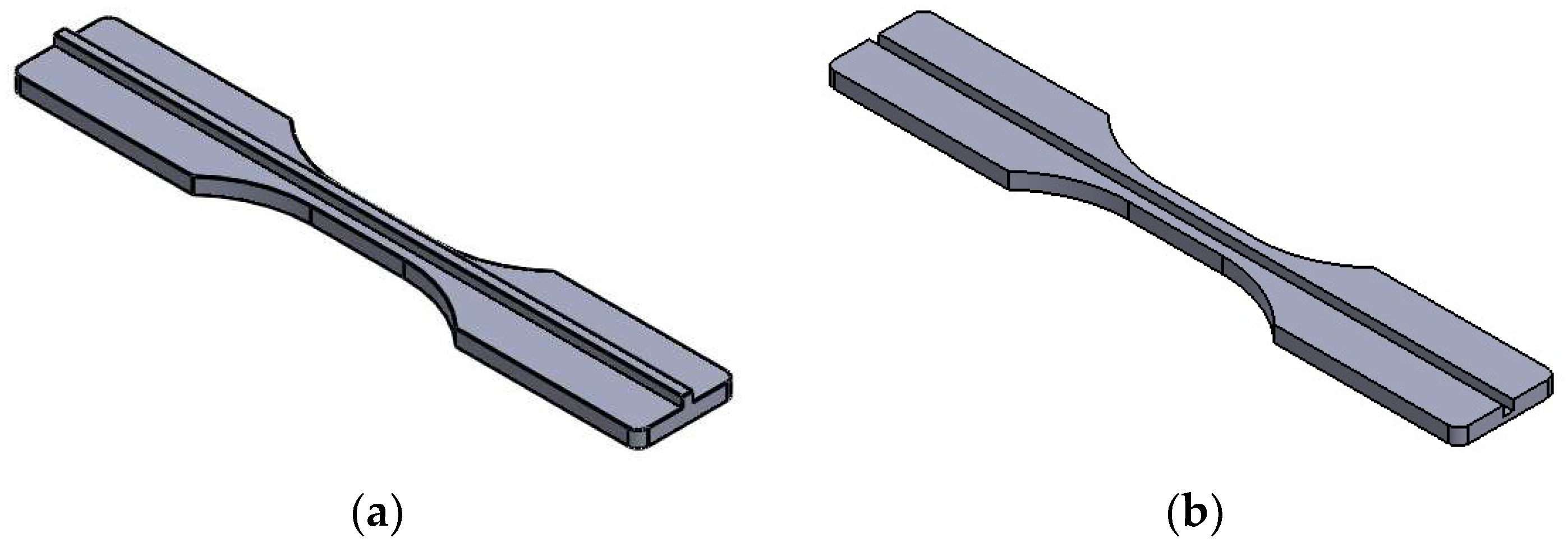

2.2. Sample Preparation

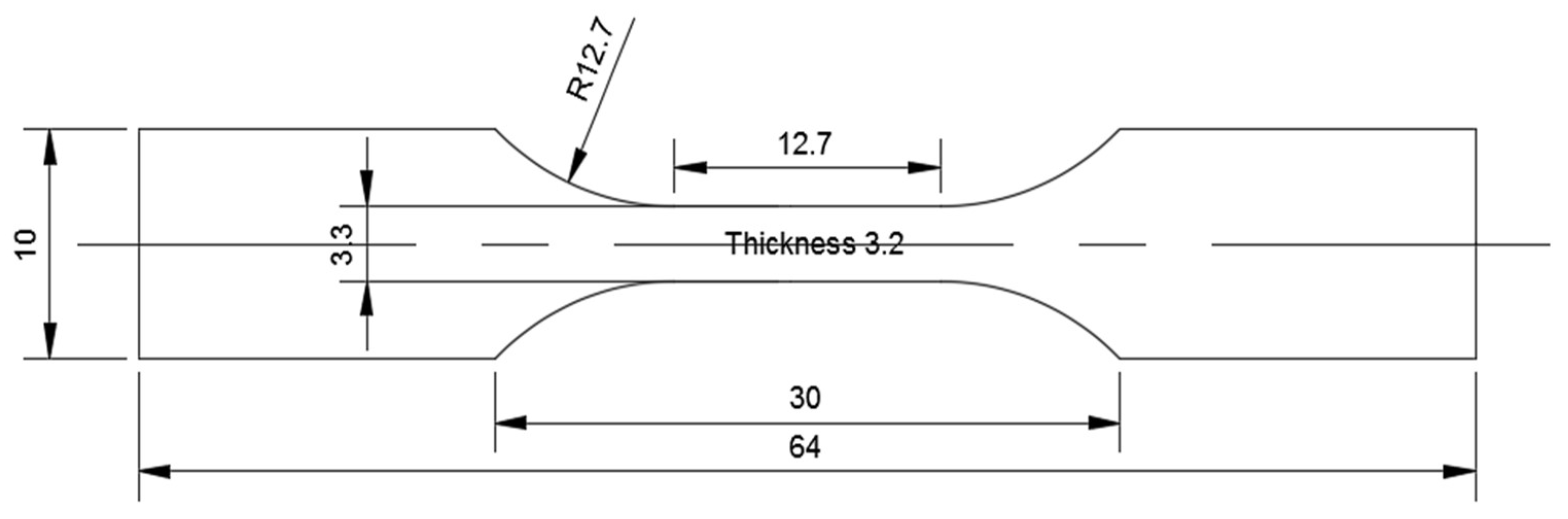

2.3. Tensile Test for the Samples

2.4. Dimensional Accuracy Study

2.5. Statistical Analysis

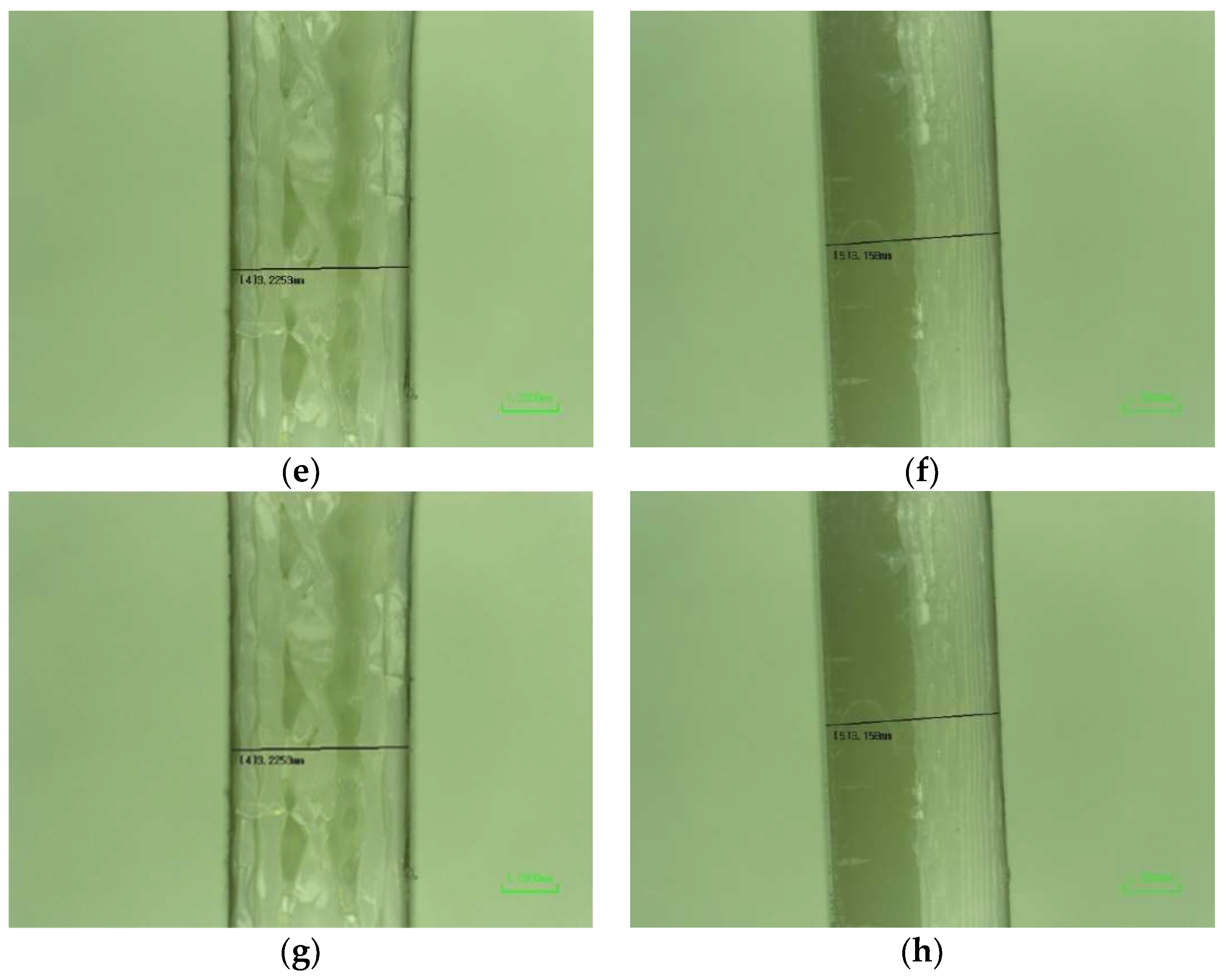

2.6. Composite Morphology

3. Results and Discussion

3.1. Dimensional Accuracy

3.2. Ultimate Tensile Strength and Stiffness

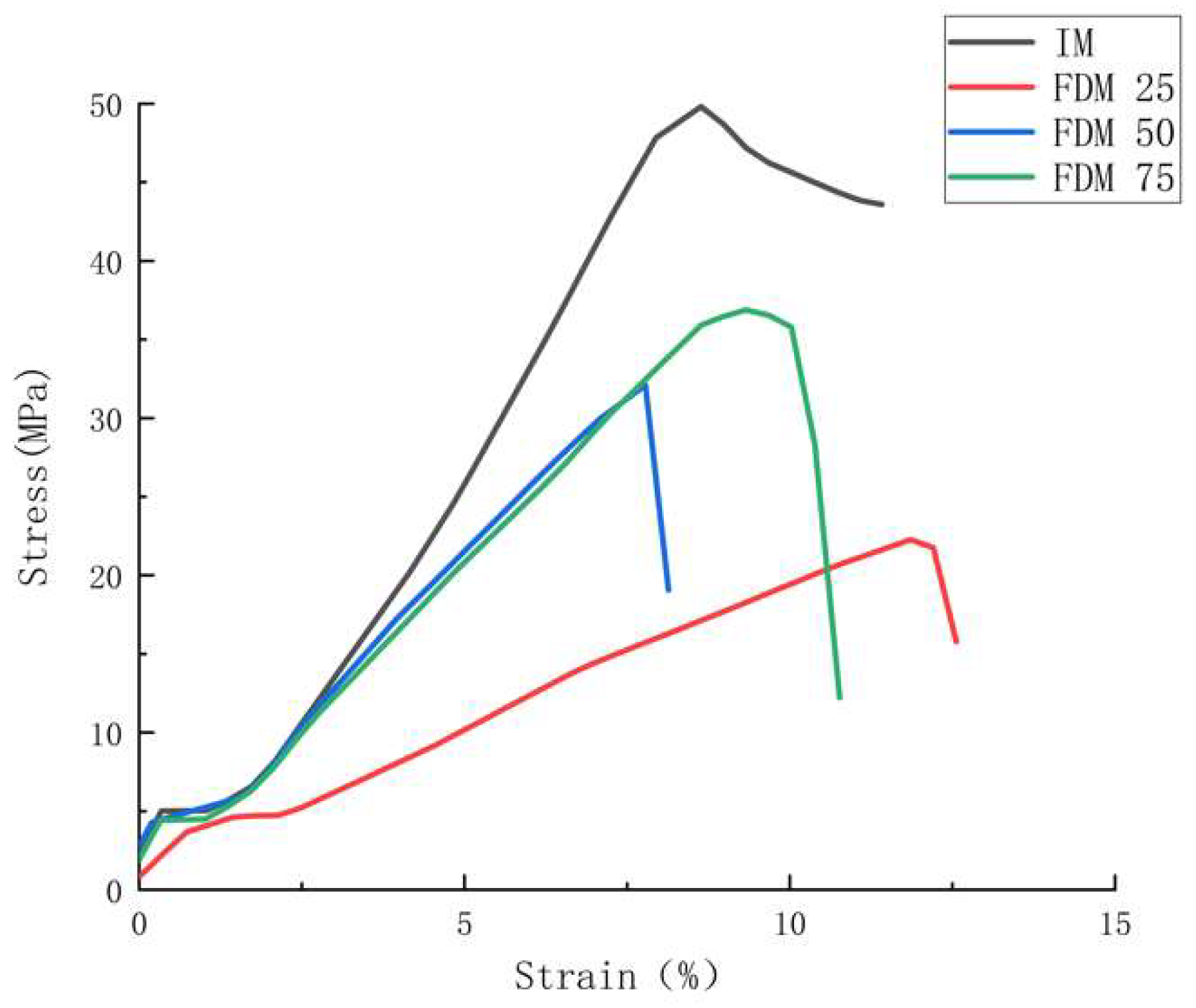

3.3. Stress-Strain Behaviors

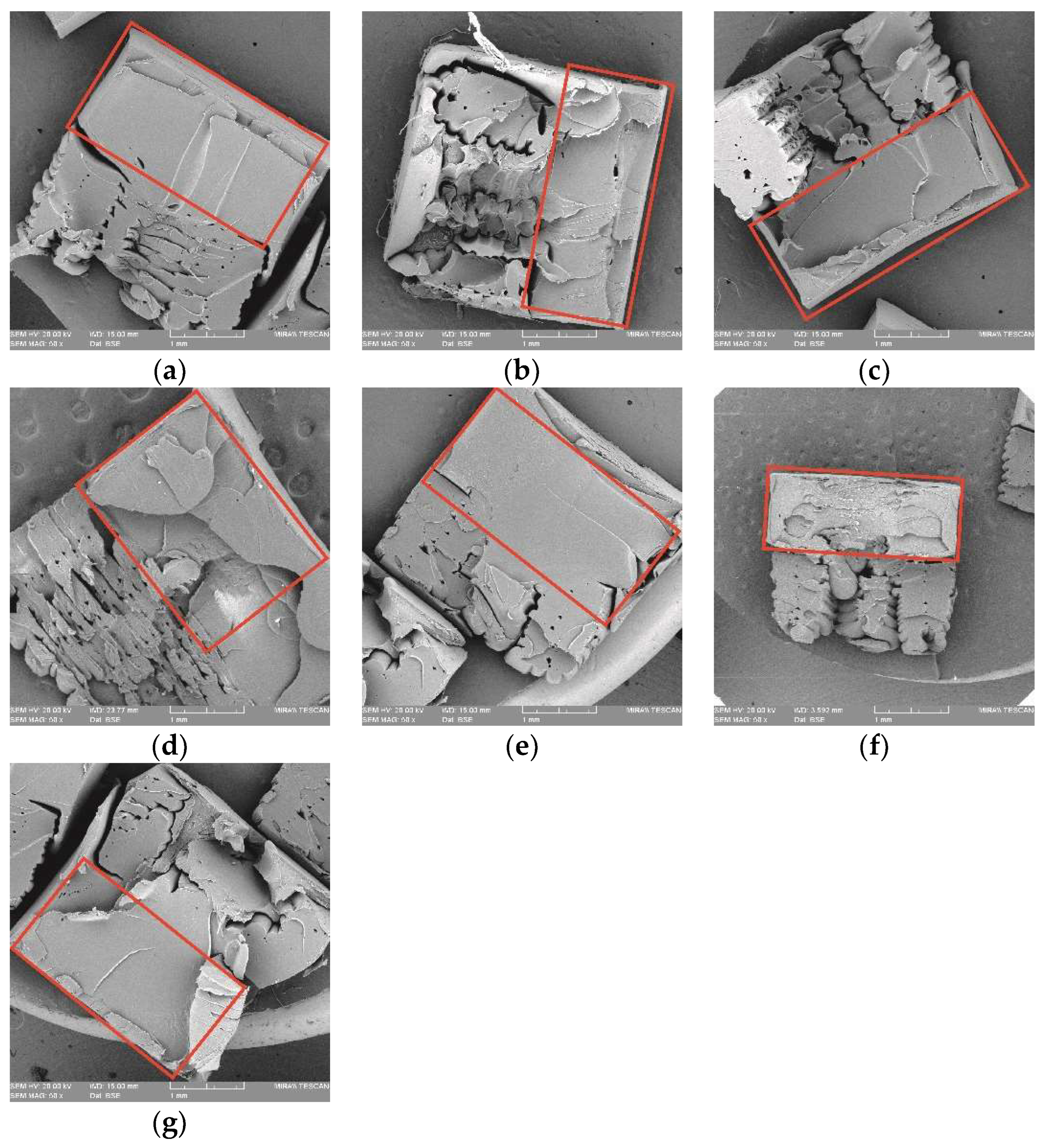

3.4. Fractographic Analysis of the Tensile Failure of ABS Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Daaboul, J.; da Cunha, C.; Bernard, A.; Laroche, F. Design for mass customization: Product variety vs. process variety. CIRP Ann. 2011, 60, 169–174. [Google Scholar] [CrossRef]

- Ulrich, K.T. The role of product architecture in the manufacturing firm. Res. Policy 1995, 24, 419–440. [Google Scholar] [CrossRef]

- Du, X. Architecture of Product Family for Mass Customization; The Hong Kong University of Science and Technology: Hong Kong, China, 2000. [Google Scholar]

- Alderighi, T.; Giorgi, D.; Malomo, L.; Cignoni, P.; Zoppè, M. Computational design, fabrication and evaluation of rubber protein models. Comput. Graph. 2021, 98, 177–187. [Google Scholar] [CrossRef]

- Huang, P.; Xia, Z.; Cui, S. 3D printing of carbon fiber-filled conductive silicon rubber. Mater. Des. 2018, 142, 11–21. [Google Scholar] [CrossRef]

- Ganguly, S.; Margel, S. 3D printed magnetic polymer composite hydrogels for hyperthermia and magnetic field driven structural manipulation. Prog. Polym. Sci. 2022, 131, 101574. [Google Scholar] [CrossRef]

- Byberg, K.I.; Gebisa, A.W.; Lemu, H.G. Mechanical properties of ULTEM 9085 material processed by fused deposition modeling. Polym. Test. 2018, 72, 335–347. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Hutmacher, D.W.; Schantz, T.; Zein, I.; Ng, K.W.; Teoh, S.H.; Tan, K.C. Mechanical properties and cell cultural response of polycaprolactone scaffolds designed and fabricated via fused deposition modeling. J. Biomed. Mater. Res. 2001, 55, 203–216. [Google Scholar] [CrossRef] [PubMed]

- Mozaffar, M.; Ndip-Agbor, E.; Lin, S.; Wagner, G.J.; Ehmann, K.; Cao, J. Acceleration strategies for explicit finite element analysis of metal powder-based additive manufacturing processes using graphical processing units. Comput. Mech. 2019, 64, 879–894. [Google Scholar] [CrossRef]

- Yang, Y.; Gong, Y.; Li, C.; Wen, X.; Sun, J. Mechanical performance of 316 L stainless steel by hybrid directed energy deposition and thermal milling process. J. Mater. Process. Technol. 2020, 291, 117023. [Google Scholar] [CrossRef]

- Casavola, C.; Cazzato, A.; Moramarco, V.; Pappalettere, C. Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater. Des. 2016, 90, 453–458. [Google Scholar] [CrossRef]

- Domingo-Espin, M.; Puigoriol-Forcada, J.M.; Granada, A.A.G.; Llumà, J.; Borros, S.; Reyes, G. Mechanical property characterization and simulation of fused deposition modeling Polycarbonate parts. Mater. Des. 2015, 83, 670–677. [Google Scholar] [CrossRef]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D Printing with Polymers: Challenges among Expanding Options and Opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Sugavaneswaran, M.; Arumaikkannu, G. Analytical and experimental investigation on elastic modulus of reinforced additive manufactured structure. Mater. Des. 2015, 66, 29–36. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Wicaksono, S.T.; Ardhyananta, H.; Pambudi, A.I. Influence of internal geometri on mechanical properties of 3D printed polylactic acid (PLA) material. Int. J. Eng. Sci. Res. Technol. 2017, 6, 74–78. [Google Scholar]

- Alafaghani, A.A.; Qattawi, A. Investigating the effect of fused deposition modeling processing parameters using Taguchi design of experiment method. J. Manuf. Process. 2018, 36, 164–174. [Google Scholar] [CrossRef]

- Christiyan, K.G.J.; Chandrasekhar, U.; Venkateswarlu, K. A study on the influence of process parameters on the Mechanical Properties of 3D printed ABS composite. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012109. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Huang, B.; Singamneni, S. Raster angle mechanics in fused deposition modelling. J. Compos. Mater. 2014, 49, 363–383. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2016, 51, 451–462. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Wei, X.; Li, D.; Jiang, W.; Gu, Z.; Wang, X.; Zhang, Z.; Sun, Z. 3D Printable Graphene Composite. Sci. Rep. 2015, 5, 11181. [Google Scholar] [CrossRef] [PubMed]

- Drummer, D.; Cifuentes-Cuéllar, S.; Rietzel, D. Suitability of PLA/TCP for fused deposition modeling. Rapid Prototyp. J. 2012, 18, 500–507. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical behaviour of ABS: An experimental study using FDM and injection moulding techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Kalita, S.J.; Bose, S.; Hosick, H.L.; Bandyopadhyay, A. Development of controlled porosity polymer-ceramic composite scaffolds via fused deposition modeling. Mater. Sci. Eng. C 2003, 23, 611–620. [Google Scholar] [CrossRef]

- Zhang, Y.; Chou, K. A parametric study of part distortions in fused deposition modelling using three-dimensional finite element analysis. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 959–968. [Google Scholar] [CrossRef]

- Boros, R.; Rajamani, P.K.; Kovacs, J.G. Combination of 3D printing and injection molding: Overmolding and overprinting. Express Polym. Lett. 2019, 13, 889–897. [Google Scholar] [CrossRef]

- Lay, M.; Thajudin, N.L.N.; Hamid, Z.A.A.; Rusli, A.; Abdullah, M.K.; Shuib, R.K. Comparison of physical and mechanical properties of PLA, ABS and nylon 6 fabricated using fused deposition modeling and injection molding. Compos. Part B Eng. 2019, 176, 107341. [Google Scholar] [CrossRef]

- Sreedharan, J.; Jeevanantham, A. Analysis of Shrinkages in ABS Injection Molding Parts for Automobile Applications. Mater. Today Proc. 2018, 5, 12744–12749. [Google Scholar] [CrossRef]

- Todd, R.H.; Allen, D.K. Manufacturing Processes Reference Guide; Industrial Press Inc.: South Norwalk, CT, USA, 1994. [Google Scholar]

- Campo, E.A. The Complete Part Design Handbook: For Injection Molding of Thermoplastics; Hanser Publishers: Liberty Township, OH, USA, 2006. [Google Scholar]

- Carello, M.; Amirth, N.; Airale, A.G.; Monti, M.; Romeo, A. Building Block Approach for Structural Analysis of Thermoplastic Composite Components for Automotive Applications. Appl. Compos. Mater. 2017, 24, 1309–1320. [Google Scholar] [CrossRef]

- Fuenmayor, E.; O’Donnell, C.; Gately, N.; Doran, P.; Devine, D.; Lyons, J.G.; McConville, C.; Major, I. Mass-customization of oral tablets via the combination of 3D printing and injection molding. Int. J. Pharm. 2019, 569, 118611. [Google Scholar] [CrossRef] [PubMed]

- Rajamani, P.; Ageyeva, T.; Kovács, J. Personalized Mass Production by Hybridization of Additive Manufacturing and Injection Molding. Polymers 2021, 13, 309. [Google Scholar] [CrossRef]

- Fuenmayor, E.; Forde, M.; Healy, A.V.; Devine, D.M.; Lyons, J.G.; McConville, C.; Major, I. Material Considerations for Fused-Filament Fabrication of Solid Dosage Forms. Pharmaceutics 2018, 10, 44. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- E Patterson, A.; Pereira, T.R.; Allison, J.T.; Messimer, S.L. IZOD impact properties of full-density fused deposition modeling polymer materials with respect to raster angle and print orientation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 235, 1891–1908. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.; Mahapatra, S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Fuenmayor, E.; Forde, M.; Healy, A.V.; Devine, D.M.; Lyons, J.G.; McConville, C.; Major, I. Comparison of fused-filament fabrication to direct compression and injection molding in the manufacture of oral tablets. Int. J. Pharm. 2018, 558, 328–340. [Google Scholar] [CrossRef]

- Cao, Z.; Daly, M.; Geever, L.M.; Major, I.; Higginbotham, C.L.; Devine, D.M. Synthesis and characterization of high density polyethylene/peat ash composites. Compos. Part B: Eng. 2016, 94, 312–321. [Google Scholar] [CrossRef]

- Douglas, C. Montgomery, Design and Analysis of Experiments, 7th ed.; John Wiley&Sons Inc.: Hoboken, NJ, USA, 2009; Available online: https://books.google.ie/books?hl=en&lr=&id=Py7bDgAAQBAJ&oi=fnd&pg=PA1&ots=X6u5nZQO38&sig=gCEmb_RmhxCOIXLdvNAG6nH3g5o&redir_esc=y#v=onepage&q&f=false (accessed on 13 June 2022).

- Cao, Z.; Daly, M.; Clémence, L.; Geever, L.M.; Major, I.; Higginbotham, C.L.; Devine, D.M. Chemical surface modification of calcium carbonate particles with stearic acid using different treating methods. Appl. Surf. Sci. 2016, 378, 320–329. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental Optimization of Fused Deposition Modelling Processing Parameters: A Design-for-Manufacturing Approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.S.; Ramos, J.; Espalin, D.; Perez, M.; Wicker, R. Improving Tensile Mechanical Properties of FDM-Manufactured Specimens via Modifying Build Parameters. In 2013 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2013. [Google Scholar]

- Roberson, D.A.; Perez, A.R.T.; Shemelya, C.M.; Rivera, A.; MacDonald, E.; Wicker, R.B. Comparison of stress concentrator fabrication for 3D printed polymeric izod impact test specimens. Addit. Manuf. 2015, 7, 1–11. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Y.; Li, J.; Cui, D.; Wang, Z.; Wang, J. Microstructure and mechanical properties of forging-additive hybrid manufactured Ti–6Al–4V alloys. Mater. Sci. Eng. A 2021, 811, 140984. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, P.; Ng, F.L.; Zhou, W.; Nai, S.M.L.; Wei, J. Hybrid manufacturing of γ-TiAl and Ti–6Al–4V bimetal component with enhanced strength using electron beam melting. Compos. Part B Eng. 2021, 207, 108587. [Google Scholar] [CrossRef]

| FDM Parameters | |

|---|---|

| Printing speed (mm/min) | 3000 |

| Infill orientation (degrees) | ±45 |

| Outline overlap (%) | 20 |

| Number of top solid layers | 1 |

| Number of bottom solid layers | 1 |

| Number of outline/perimeter shells | 2 |

| Infill extrusion width (%) | 100 |

| Minimum infill length (mm) | 5 |

| Extruder temperature (°C) | 210 |

| Printing bed temperature (°C) | 110 |

| Retraction distance (mm) | 8.4 |

| Retraction vertical lift (mm) | 0.1 |

| Retraction speed (mm/min) | 3600 |

| Diameter of nozzle (mm) | 0.5 |

| Injection Times and Settings | |

|---|---|

| Shot size (mm) | 40 for IM batch, 30 for HYM batches |

| Cooling time (sec) | 20 |

| Plasticizing zone temperature (°C) | 190 |

| Chamber temperature (°C) | 180 |

| Nozzle temperature (°C) | 170 |

| Mold temperature (°C) | 50 |

| 1st injection pressure (bar) | 100 |

| 1st injection pressure time (sec) | 3.5 |

| 2nd injection pressure (bar) | 50 |

| 2nd injection pressure time (sec) | 3 |

| 2nd pressure setting (mm) | 3 |

| Decompression (mm) | 2 |

| Injection speed (%) | 95 |

| 2nd injection speed (%) | 50 |

| 2nd Speed point (mm) | 4 |

| Batch Name | Type of Samples/Inserts | Infill Density |

|---|---|---|

| FDM 25 | FDM Sample | 25% |

| FDM 50 | FDM Sample | 50% |

| FDM 75 | FDM Sample | 75% |

| IM | IM Sample | 100% |

| NJ 25 | Half of Thickness (No Joint Configuration) | 25% |

| NJ 50 | Half of Thickness (No Joint Configuration) | 50% |

| NJ 75 | Half of Thickness (No Joint Configuration) | 75% |

| MC 50 | Half of Thickness Male Cube Joint | 50% |

| FC 50 | Half of Thickness Female Cube Joint | 50% |

| MT 50 | Half of Thickness Male T Joint | 50% |

| FT 50 | Half of Thickness Female T Joint | 50% |

| Parameter | IM Batch | FDM Batches | HYM Batches |

|---|---|---|---|

| Thickness (mm) | 3.2 ± 0.1 | 3.2 ± 0.1 | 3.2 ± 0.1 |

| Total Length (mm) | 64 ± 0.2 | 64 ± 0.2 | 64 ± 0.2 |

| Gauge Width (mm) | 3.3 ± 0.2 | 3.3 ± 0.1 | 3.3 ± 0.1 |

| Width at two ends (mm) | 10 ± 0.2 | 10 ± 0.2 | 10 ± 0.2 |

| Batch Name | σ (MPa) | E (MPa) |

|---|---|---|

| FDM 25 | 22.85 ± 2.97 | 446.42 ± 86.86 |

| FDM 50 | 32.26 ± 1.56 | 675.97 ± 79.17 |

| FDM 75 | 37.91 ± 4.66 | 689.19 ± 95.01 |

| IM | 49.95 ± 0.61 | 887.49 ± 136.19 |

| Batch Name | σ (MPa) | E (MPa) |

|---|---|---|

| NJ 25 | 45.09 ± 2.90 | 724.96 ± 47.37 |

| NJ 50 | 46.62 ± 0.87 | 745.03 ± 24.63 |

| NJ 75 | 45.62 ± 1.23 | 690.35 ± 68.90 |

| MC 50 | 46.30 ± 0.81 | 746.07 ± 60.62 |

| FC 50 | 47.42 ± 0.97 | 737.62 ± 15.43 |

| MT 50 | 42.62 ± 2.14 | 861.23 ± 64.63 |

| FT 50 | 48.00 ± 1.07 | 727.92 ± 37.09 |

| Ultimate Tensile Stress | Young’s Modulus | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Source | DF | SS | MS | F | p | SS | MS | F | p |

| Model | 4 | 176.91 | 44.23 | 24.66 | 0 | 121,323 | 30,331 | 20.01 | 0 |

| Residual | 45 | 80.7 | 1.793 | 68,221 | 1516 | ||||

| Total | 49 | 257.61 | 189,544 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, K.; Liu, H.; Huang, C.; Cao, Z.; Fuenmayor, E.; Major, I. Hybrid Manufacturing of Acrylonitrile Butadiene Styrene (ABS) via the Combination of Material Extrusion Additive Manufacturing and Injection Molding. Polymers 2022, 14, 5093. https://doi.org/10.3390/polym14235093

Gong K, Liu H, Huang C, Cao Z, Fuenmayor E, Major I. Hybrid Manufacturing of Acrylonitrile Butadiene Styrene (ABS) via the Combination of Material Extrusion Additive Manufacturing and Injection Molding. Polymers. 2022; 14(23):5093. https://doi.org/10.3390/polym14235093

Chicago/Turabian StyleGong, Ke, Handai Liu, Cheng Huang, Zhi Cao, Evert Fuenmayor, and Ian Major. 2022. "Hybrid Manufacturing of Acrylonitrile Butadiene Styrene (ABS) via the Combination of Material Extrusion Additive Manufacturing and Injection Molding" Polymers 14, no. 23: 5093. https://doi.org/10.3390/polym14235093

APA StyleGong, K., Liu, H., Huang, C., Cao, Z., Fuenmayor, E., & Major, I. (2022). Hybrid Manufacturing of Acrylonitrile Butadiene Styrene (ABS) via the Combination of Material Extrusion Additive Manufacturing and Injection Molding. Polymers, 14(23), 5093. https://doi.org/10.3390/polym14235093