Influence of Dielectric Barrier Discharge Cold Plasma Treatment on Starch, Gelatin, and Bacterial Cellulose Biodegradable Polymeric Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Elaboration of the Biopolymer Films

2.3. Dielectric Barrier Discharge Plasma Treatment

2.4. Physical and Chemical Analysis

2.4.1. Thickness and Humidity

2.4.2. Hydrophobicity

2.4.3. Water Solubility

2.4.4. FTIR Analysis

2.5. Surface Morphology

2.6. Mechanical Properties

2.7. Selection of the Best Films and Cold Plasma Operating Conditions

2.8. Statistical Analysis

3. Results

3.1. Hydrophobicity

3.2. Solubility in Water

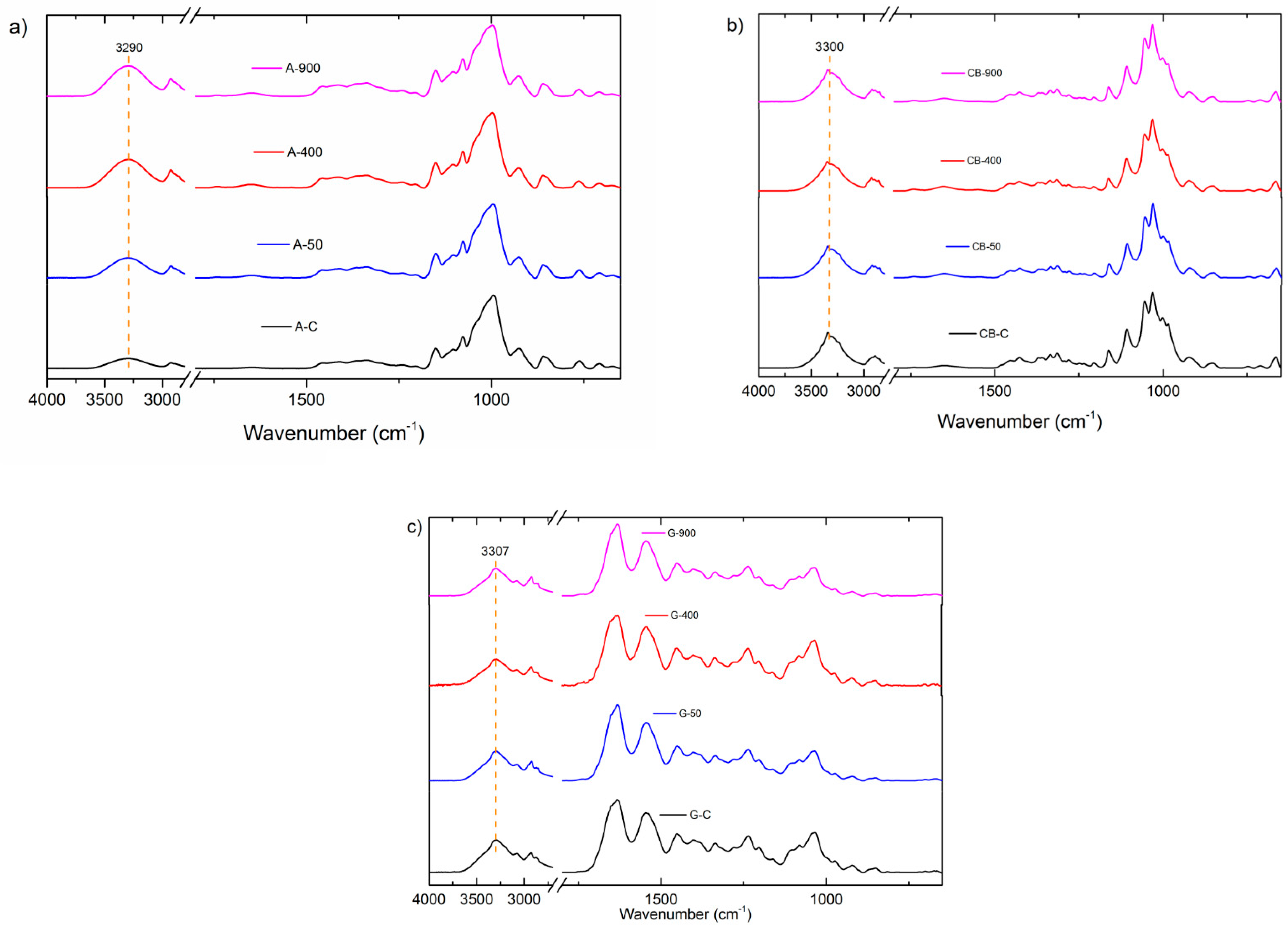

3.3. FTIR Analysis

3.4. Best Biodegradable Films and Plasma Operating Conditions

3.5. Surface Morphology

3.6. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Romani, V.P.; Olsen, B.; Pinto Collares, M.; Meireles Oliveira, J.R.; Prentice, C.; Martins, V.G. Cold Plasma and Carnauba Wax as Strategies to Produce Improved Bi-Layer Films for Sustainable Food Packaging. Food Hydrocoll. 2020, 108, 106087. [Google Scholar] [CrossRef]

- Gandhi, N.; Khurana, S.; Mathur, R.; Bansal, U.; Nair, R. Trends in Food Packaging: A Comprehensive Review. Asian J. Chem. 2022, 34, 2499–2510. [Google Scholar] [CrossRef]

- Choi, S.M.; Rao, K.M.; Zo, S.M.; Shin, E.J.; Han, S.S. Bacterial Cellulose and Its Applications. Polymers 2022, 14, 1080. [Google Scholar] [CrossRef] [PubMed]

- Onyeaka, H.; Obileke, K.; Makaka, G.; Nwokolo, N. Current Research and Applications of Starch-Based Biodegradable Films for Food Packaging. Polymers 2022, 14, 1126. [Google Scholar] [CrossRef]

- Moosavi, M.H.; Khani, M.R.; Shokri, B.; Hosseini, S.M.; Shojaee-Aliabadi, S.; Mirmoghtadaie, L. Modifications of Protein-Based Films Using Cold Plasma. Int. J. Biol. Macromol. 2020, 142, 769–777. [Google Scholar] [CrossRef]

- Sifuentes-Nieves, I.; Hernández-Hernández, E.; Neira-Velázquez, G.; Morales-Sánchez, E.; Mendez-Montealvo, G.; Velazquez, G. Hexamethyldisiloxane Cold Plasma Treatment and Amylose Content Determine the Structural, Barrier and Mechanical Properties of Starch-Based Films. Int. J. Biol. Macromol. 2019, 124, 651–658. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Barud, H.; Farinas, C.S.; Vasconcellos, V.M.; Claro, A.M. Bacterial Cellulose as a Raw Material for Food and Food Packaging Applications. Front. Sustain. Food Syst. 2019, 3, 7. [Google Scholar] [CrossRef]

- Díaz-Calderón, P.; MacNaughtan, B.; Hill, S.; Foster, T.; Enrione, J.; Mitchell, J. Changes in Gelatinisation and Pasting Properties of Various Starches (Wheat, Maize and Waxy Maize) by the Addition of Bacterial Cellulose Fibrils. Food Hydrocoll. 2018, 80, 274–280. [Google Scholar] [CrossRef]

- Romani, V.P.; Olsen, B.; Pinto Collares, M.; Meireles Oliveira, J.R.; Prentice-Hernández, C.; Guimarães Martins, V. Improvement of Fish Protein Films Properties for Food Packaging through Glow Discharge Plasma Application. Food Hydrocoll. 2019, 87, 970–976. [Google Scholar] [CrossRef]

- Marenco-Orozco, G.A.; Rosa, M.F.; Fernandes, F.A.N. Effects of Multiple-step Cold Plasma Processing on Banana (Musa Sapientum) Starch-based Films. Packag. Technol. Sci. 2022, 35, 589–601. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, K.; Yao, X.; Jiang, J.; Wang, M.; Yuan, S. Ultrasound-Assisted Preparation of Fe(OH)3@bacterial Cellulose Aerogel for Efficient Removal of Organic Contamination in Water. Appl. Surf. Sci. 2023, 607, 154959. [Google Scholar] [CrossRef]

- Šafranko, S.; Stanković, A.; Hajra, S.; Kim, H.-J.; Strelec, I.; Dutour-Sikirić, M.; Weber, I.; Bosnar, M.H.; Grbčić, P.; Pavelić, S.K.; et al. Preparation of Multifunctional N-Doped Carbon Quantum Dots from Citrus Clementina Peel: Investigating Targeted Pharmacological Activities and the Potential Application for Fe3+ Sensing. Pharmaceuticals 2021, 14, 857. [Google Scholar] [CrossRef] [PubMed]

- Panda, S.; Hajra, S.; Jeong, H.; Panigrahi, B.K.; Pakawanit, P.; Dubal, D.; Hong, S.; Kim, H.J. Biocompatible CaTiO3-PVDF Composite-Based Piezoelectric Nanogenerator for Exercise Evaluation and Energy Harvesting. Nano Energy 2022, 102, 107682. [Google Scholar] [CrossRef]

- Chen, G.; Chen, Y.; Jin, N.; Li, J.; Dong, S.; Li, S.; Zhang, Z.; Chen, Y. Zein Films with Porous Polylactic Acid Coatings via Cold Plasma Pre-Treatment. Ind. Crops Prod. 2020, 150, 112382. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Q.; Luo, Y.; Murad, M.S.; Zhu, L.; Mu, G. Improved Packing Performance and Structure-Stability of Casein Edible Films by Dielectric Barrier Discharges (DBD) Cold Plasma. Food Packag. Shelf Life 2020, 24, 100471. [Google Scholar] [CrossRef]

- Pankaj, S.K.K.; Bueno-Ferrer, C.; Misra, N.N.N.; O’Neill, L.; Tiwari, B.K.K.; Bourke, P.; Cullen, P.J.J. Dielectric Barrier Discharge Atmospheric Air Plasma Treatment of High Amylose Corn Starch Films. LWT-Food Sci. Technol. 2015, 63, 1076–1082. [Google Scholar] [CrossRef]

- Pankaj, S.K.; Bueno-Ferrer, C.; Misra, N.N.; O’Neill, L.; Tiwari, B.K.; Bourke, P.; Cullen, P.J. Physicochemical Characterization of Plasma-Treated Sodium Caseinate Film. Food Res. Int. 2014, 66, 438–444. [Google Scholar] [CrossRef]

- Lin, S.-P.; Huang, S.-H.; Ting, Y.; Hsu, H.-Y.; Cheng, K.-C. Evaluation of Detoxified Sugarcane Bagasse Hydrolysate by Atmospheric Cold Plasma for Bacterial Cellulose Production. Int. J. Biol. Macromol. 2022, 204, 136–143. [Google Scholar] [CrossRef]

- Santoso, S.P.; Lin, S.-P.; Wang, T.-Y.; Ting, Y.; Hsieh, C.-W.; Yu, R.-C.; Angkawijaya, A.E.; Soetaredjo, F.E.; Hsu, H.-Y.; Cheng, K.-C. Atmospheric Cold Plasma-Assisted Pineapple Peel Waste Hydrolysate Detoxification for the Production of Bacterial Cellulose. Int. J. Biol. Macromol. 2021, 175, 526–534. [Google Scholar] [CrossRef]

- Janpetch, N.; Saito, N.; Rujiravanit, R. Fabrication of Bacterial Cellulose-ZnO Composite via Solution Plasma Process for Antibacterial Applications. Carbohydr. Polym. 2016, 148, 335–344. [Google Scholar] [CrossRef]

- Carvalho, A.P.M.G.; Barros, D.R.; da Silva, L.S.; Sanches, E.A.; da Costa Pinto, C.; de Souza, S.M.; Clerici, M.T.P.S.; Rodrigues, S.; Fernandes, F.A.N.; Campelo, P.H. Dielectric Barrier Atmospheric Cold Plasma Applied to the Modification of Ariá (Goeppertia Allouia) Starch: Effect of Plasma Generation Voltage. Int. J. Biol. Macromol. 2021, 182, 1618–1627. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Gou, Q.; Yang, L.; Yu, Q.; Han, L. Dielectric Barrier Discharge Plasma: A Green Method to Change Structure of Potato Starch and Improve Physicochemical Properties of Potato Starch Films. Food Chem. 2022, 370, 130992. [Google Scholar] [CrossRef] [PubMed]

- Goiana, M.L.; de Brito, E.S.; Alves Filho, E.G.; de Castro Miguel, E.; Fernandes, F.A.N.; de Azeredo, H.M.C.; de Freitas Rosa, M. Corn Starch Based Films Treated by Dielectric Barrier Discharge Plasma. Int. J. Biol. Macromol. 2021, 183, 2009–2016. [Google Scholar] [CrossRef] [PubMed]

- Campelo, P.H.; Alves Filho, E.G.; Silva, L.M.A.; de Brito, E.S.; Rodrigues, S.; Fernandes, F.A.N. Modulation of Aroma and Flavor Using Glow Discharge Plasma Technology. Innov. Food Sci. Emerg. Technol. 2020, 62, 102363. [Google Scholar] [CrossRef]

- Alves Filho, E.G.; Silva, L.M.A.; Oiram Filho, F.; Rodrigues, S.; Fernandes, F.A.N.; Gallão, M.I.; Mattison, C.P.; de Brito, E.S. Cold Plasma Processing Effect on Cashew Nuts Composition and Allergenicity. Food Res. Int. 2019, 125, 108621. [Google Scholar] [CrossRef]

- Farias, T.R.B.; Rodrigues, S.; Fernandes, F.A.N. Effect of Dielectric Barrier Discharge Plasma Excitation Frequency on the Enzymatic Activity, Antioxidant Capacity and Phenolic Content of Apple Cubes and Apple Juice. Food Res. Int. 2020, 136, 109617. [Google Scholar] [CrossRef]

- Almeida, F.D.L.; Cavalcante, R.S.; Cullen, P.J.; Frias, J.M.; Bourke, P.; Fernandes, F.A.N.N.; Rodrigues, S. Effects of Atmospheric Cold Plasma and Ozone on Prebiotic Orange Juice. Innov. Food Sci. Emerg. Technol. 2015, 32, 127–135. [Google Scholar] [CrossRef]

- Rodrigues, S.; Fernandes, F.A.N. Glow Discharge Plasma Processing for the Improvement of Pasteurized Orange Juice’s Aroma and Off-Flavor. Processes 2022, 10, 1812. [Google Scholar] [CrossRef]

- Oliveira, A.V.; da Silva, A.P.M.; Barros, M.O.; de sá M. Souza Filho, M.; Rosa, M.F.; Azeredo, H.M.C. Nanocomposite Films from Mango Kernel or Corn Starch with Starch Nanocrystals. Starch-Stärke 2018, 70, 1800028. [Google Scholar] [CrossRef]

- Saito, T.; Kimura, S.; Nishiyama, Y.; Isogai, A. Cellulose Nanofibers Prepared by TEMPO-Mediated Oxidation of Native Cellulose. Biomacromolecules 2007, 8, 2485–2491. [Google Scholar] [CrossRef]

- do Nascimento, E.S.; Pereira, A.L.S.; de Oliveira Barros, M.; de Aaraújo Barroso, M.K.; Lima, H.L.S.; de Fatima Borges, M.; de Andrade Feitosa, J.P.; de Azeredo, H.M.C.; de Freitas Rosa, M. TEMPO Oxidation and High-Speed Blending as a Combined Approach to Disassemble Bacterial Cellulose. Cellulose 2019, 26, 2291–2302. [Google Scholar] [CrossRef]

- Santos, T.M.; Men de Sá Filho, M.S.; Caceres, C.A.; Rosa, M.F.; Morais, J.P.S.; Pinto, A.M.B.; Azeredo, H.M.C. Fish Gelatin Films as Affected by Cellulose Whiskers and Sonication. Food Hydrocoll. 2014, 41, 113–118. [Google Scholar] [CrossRef]

- ASTM D 5725-99; Standard Test Method for Surface Wettability and Adsorbency of Sheeted Materials Using an Automated Contact Angle Tester. ASTM: West Conshohocken, PA, USA, 2008.

- Pena-Serna, C.; Lopes-Filho, J.F. Influence of Ethanol and Glycerol Concentration over Functional and Structural Properties of Zein–Oleic Acid Films. Mater. Chem. Phys. 2013, 142, 580–585. [Google Scholar] [CrossRef]

- ASTM D882-12; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: West Conshohocken, PA, USA, 2018.

- Wan, S.; Liu, Q.; Yang, D.; Guo, P.; Gao, Y.; Mo, R.; Zhang, Y. Characterization of High Amylose Corn Starch-Cinnamaldehyde Inclusion Films for Food Packaging. Food Chem. 2022, 403, 134219. [Google Scholar] [CrossRef]

- Guo, S.; Fu, Z.; Yao, X.; Wang, X.; Wu, M. Impact of High Pressure Homogenization on the Properties of Potato Flour Film-Forming Dispersions and the Resulting Films. J. Food Eng. 2023, 339, 111281. [Google Scholar] [CrossRef]

- Fu, B.; Mei, S.; Su, X.; Chen, H.; Zhu, J.; Zheng, Z.; Lin, H.; Dai, C.; Luque, R.; Yang, D.-P. Integrating Waste Fish Scale-Derived Gelatin and Chitosan into Edible Nanocomposite Film for Perishable Fruits. Int. J. Biol. Macromol. 2021, 191, 1164–1174. [Google Scholar] [CrossRef]

- Cubas, A.L.V.; Bianchet, R.T.; de Oliveira, D.; Leonarski, E.; Cesca, K. Application of Non-Thermal Plasma as an Alternative for Purification of Bacterial Cellulose Membranes. Sustain. Chem. Pharm. 2022, 29, 100800. [Google Scholar] [CrossRef]

- Wasim, M.; Shi, F.; Liu, J.; Zhang, H.; Zhu, K.; Tian, Z. Synthesis and Characterization of Curcumin/MMT-Clay-Treated Bacterial Cellulose as an Antistatic and Ultraviolet-Resistive Bioscaffold. J. Polym. Res. 2022, 29, 423. [Google Scholar] [CrossRef]

- Mir, S.A.; Dar, B.N.; Wani, A.A.; Shah, M.A. Effect of Plant Extracts on the Techno-Functional Properties of Biodegradable Packaging Films. Trends Food Sci. Technol. 2018, 80, 141–154. [Google Scholar] [CrossRef]

- Pająk, P.; Przetaczek-Rożnowska, I.; Juszczak, L. Development and Physicochemical, Thermal and Mechanical Properties of Edible Films Based on Pumpkin, Lentil and Quinoa Starches. Int. J. Biol. Macromol. 2019, 138, 441–449. [Google Scholar] [CrossRef]

- Chhatariya, H.F.; Srinivasan, S.; Choudhary, P.M.; Begum, S.S. Corn Starch Biofilm Reinforced with Orange Peel Powder: Characterization of Physicochemical and Mechanical Properties. Mater. Today Proc. 2022, 59, 884–892. [Google Scholar] [CrossRef]

- Alqahtani, N.; Alnemr, T.; Ali, S. Development of Low-Cost Biodegradable Films from Corn Starch and Date Palm Pits (Phoenix Dactylifera). Food Biosci. 2021, 42, 101199. [Google Scholar] [CrossRef]

- Efthymiou, M.-N.; Tsouko, E.; Papagiannopoulos, A.; Athanasoulia, I.-G.; Georgiadou, M.; Pispas, S.; Briassoulis, D.; Tsironi, T.; Koutinas, A. Development of Biodegradable Films Using Sunflower Protein Isolates and Bacterial Nanocellulose as Innovative Food Packaging Materials for Fresh Fruit Preservation. Sci. Rep. 2022, 12, 6935. [Google Scholar] [CrossRef] [PubMed]

- Papadaki, A.; Manikas, A.C.; Papazoglou, E.; Kachrimanidou, V.; Lappa, I.; Galiotis, C.; Mandala, I.; Kopsahelis, N. Whey Protein Films Reinforced with Bacterial Cellulose Nanowhiskers: Improving Edible Film Properties via a Circular Economy Approach. Food Chem. 2022, 385, 132604. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, G.D.J.C.; Campelo, P.H.; de Abreu Figueiredo, J.; Barbosa de Souza, H.J.; Peixoto Joele, M.R.S.; Yoshida, M.I.; Henriques Lourenço, L.D.F. Effect of Polyvinyl Alcohol and Carboxymethylcellulose on the Technological Properties of Fish Gelatin Films. Sci. Rep. 2022, 12, 10497. [Google Scholar] [CrossRef]

- Baggio, E.; Scopel, B.S.; Rosseto, M.; Rigueto, C.V.T.; Dettmer, A.; Baldasso, C. Transglutaminase Effect on the Gelatin-Films Properties. Polym. Bull. 2022, 79, 7347–7361. [Google Scholar] [CrossRef]

- Hernandez-Perez, P.; Flores-Silva, P.C.; Velazquez, G.; Morales-Sanchez, E.; Rodríguez-Fernández, O.; Hernández-Hernández, E.; Mendez-Montealvo, G.; Sifuentes-Nieves, I. Rheological Performance of Film-Forming Solutions Made from Plasma-Modified Starches with Different Amylose/Amylopectin Content. Carbohydr. Polym. 2021, 255, 117349. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Szymanowska, U.; Skrzypek, T.; Basiura-Cembala, M.; Materska, M.; Łupina, K. Corn Starch and Methylcellulose Edible Films Incorporated with Fireweed (Chamaenerion Angustifolium L.) Extract: Comparison of Physicochemical and Antioxidant Properties. Int. J. Biol. Macromol. 2021, 190, 969–977. [Google Scholar] [CrossRef]

- Prachayawarakorn, J.; Kansanthia, P. Characterization and Properties of Singly and Dually Modified Hydrogen Peroxide Oxidized and Glutaraldehyde Crosslinked Biodegradable Starch Films. Int. J. Biol. Macromol. 2022, 194, 331–337. [Google Scholar] [CrossRef]

- Martins, P.C.; Latorres, J.M.; Martins, V.G. Impact of Starch Nanocrystals on the Physicochemical, Thermal and Structural Characteristics of Starch-Based Films. LWT 2022, 156, 113041. [Google Scholar] [CrossRef]

- Nurdiani, R.; Ma’rifah, R.D.A.; Busyro, I.K.; Jaziri, A.A.; Prihanto, A.A.; Firdaus, M.; Talib, R.A.; Huda, N. Physical and Functional Properties of Fish Gelatin-Based Film Incorporated with Mangrove Extracts. PeerJ 2022, 10, e13062. [Google Scholar] [CrossRef] [PubMed]

| Film | Thickness (mm) | Humidity (%) |

|---|---|---|

| Starch | 0.054 ± 0.002 b | 10.2 ± 0.5 a |

| Bacterial cellulose | 0.126 ± 0.011 a | 9.6 ± 2.4 a |

| Gelatin | 0.061 ± 0.003 b | 12.5 ± 1.2 a |

| Plasma Excitation Frequency (Hz) | Contact Angle (°) | Water Solubility (%) | ||||

|---|---|---|---|---|---|---|

| Starch | Bacterial Cellulose | Gelatin | Starch | Bacterial Cellulose | Gelatin | |

| With MylarTM support | ||||||

| Control | 55.7 ± 0.8 a | 80.3 ± 0.3 a | 69.9 ± 0.4 a | 96.9 ± 1.0 a | 16.7 ± 1.0 b | 34.3 ± 0.4 c |

| 50 | 55.1 ± 1.0 a | 77.9 ± 0.6 b | 68.9 ± 0.9 a | 96.6 ± 0.1 a | 18.5 ± 0.4 a | 37.2 ± 0.8 a |

| 400 | 53.8 ± 0.6 b | 78.4 ± 0.2 b | 69.7 ± 0.7 a | 97.4 ± 0.5 a | 17.3 ± 0.2 a | 36.3 ± 0.5 b |

| 900 | 54.2 ± 0.5 b | 79.6 ± 1.1 a | 70.3 ± 0.5 a | 96.2 ± 0.3 a | 17.1 ± 0.7 b | 35.4 ± 0.8 c |

| Without MylarTM support | ||||||

| Control | 55.7 ± 0.8 a | 80.3 ± 0.3 c | 69.9 ± 0.4 c | 96.9 ± 1.0 a | 16.7 ± 1.0 a | 34.3 ± 0.4 b |

| 50 | 56.3 ± 1.0 a | 79.6 ± 0.3 c | 70.6 ± 0.2 c | 94.8 ± 0.3 b | 15.5 ± 0.3 a | 37.9 ± 0.6 a |

| 400 | 55.1 ± 0.7 a | 81.2 ± 0.3 b | 72.5 ± 0.8 b | 95.4 ± 0.4 b | 13.9 ± 0.6 b | 34.8 ± 0.5 b |

| 900 | 55.1 ± 0.4 a | 83.0 ± 0.4 a | 77.4 ± 0.8 a | 97.3 ± 0.2 a | 11.3 ± 0.4 c | 32.4 ± 0.4 c |

| Processing Time (min) | Starch | Bacterial Cellulose | Gelatin |

|---|---|---|---|

| 0 | 55.7 ± 0.8 d | 80.3 ± 0.3 c | 69.9 ± 0.4 c |

| 10 | 57.0 ± 0.6 c | 83.0 ± 0.6 c | 79.0 ± 0.3 b |

| 15 | 61.0 ± 0.3 b | 84.0 ± 0.3 b | 81.0 ± 0.7 b |

| 20 | 64.0 ± 0.6 a | 85.0 ± 0.5 a | 84.0 ± 0.3 a |

| Film | Contact Angle (°) | Reference |

|---|---|---|

| Corn starch | 55.7 | This work |

| Corn starch (plasma-treated) | 64 | This work |

| Corn starch (high amylose) | 55 | [36] |

| Corn starch + cinnamaldehyde | 107.4 | [36] |

| Potato starch | 24.5 | [37] |

| Potato starch (high-pressure-treated) | 30.2 | [37] |

| Banana starch | 50.3 | [10] |

| Banana starch (plasma-treated) | 65.1 | [10] |

| Gelatin | 69.9 | This work |

| Gelatin (plasma-treated) | 84 | This work |

| Gelatin | 68 | [38] |

| Gelatin + chitosan | 56 | [38] |

| Bacterial cellulose | 80.3 | This work |

| Bacterial cellulose (plasma-treated) | 85 | This work |

| Bacterial cellulose | 36 | [39] |

| Bacterial cellulose (plasma-treated) | 21 | [39] |

| Bacterial cellulose | 14.9 | [40] |

| Bacterial cellulose + curcumin extract | 38.6 | [40] |

| Processing Time (min) | Starch | Bacterial Cellulose | Gelatin |

|---|---|---|---|

| 0 | 96.9 ± 1.0 a | 16.7 ± 1.1 a | 34.3 ± 0.4 a |

| 10 | 94.0 ± 0.5 b | 11.0 ± 0.8 b | 31.0 ± 0.1 bc |

| 15 | 92.0 ± 0.4 c | 10.0 ± 0.3 b | 30.0 ± 0.3 bc |

| 20 | 91.0 ± 0.1 c | 10.0 ± 0.2 b | 28.0 ± 0.3 c |

| Film | Water Solubility (%) | Reference |

|---|---|---|

| Corn starch | 96.6 | This work |

| Corn starch (plasma-treated) | 91 | This work |

| Corn starch (high amylose) | 17 | [36] |

| Corn starch + cinnamaldehyde | 16 | [36] |

| Corn starch | 34 | [43] |

| Corn starch + orange peel | 30 | [43] |

| Corn starch | 19.4 | [44] |

| Corn starch + date palm pits | 10.2 | [44] |

| Potato starch | 28.1 | [37] |

| Potato starch (high-pressure-treated) | 29.6 | [37] |

| Banana starch | 37.4 | [10] |

| Banana starch (plasma-treated) | 30.7 | [10] |

| Bacterial cellulose | 16.7 | This work |

| Bacterial cellulose (plasma-treated) | 10 | This work |

| Bacterial cellulose | 52.8 | [45] |

| Bacterial cellulose (nanocellulose) | 27.3 | [45] |

| Bacterial cellulose (nanocrystalline) | 32.5 | [45] |

| Whey protein | 43 | [46] |

| Whey protein + bacterial cellulose | 38 | [46] |

| Gelatin | 34.3 | This work |

| Gelatin (plasma-treated) | 28 | This work |

| Gelatin | 64 | [47] |

| Gelatin + carboxymethylcellulose | 21 | [47] |

| Gelatin + polyvinyl alcohol | 8 | [47] |

| Gelatin | 35.4 | [48] |

| Gelatin (transglutaminase-treated) | 26.6 | [48] |

| Plasma Frequency (Hz) | Scores | ||

|---|---|---|---|

| Starch | Bacterial Cellulose | Gelatin | |

| 50 | 1.36 | 2.71 | 2.22 |

| 600 | 1.28 | 2.73 | 2.25 |

| 900 | 1.3 | 2.88 | 2.71 |

| Starch | Bacterial Cellulose | Gelatin | |

|---|---|---|---|

| Tensile strength (MPa) | |||

| Control | 11.25 ± 3.59 a | 60.64 ± 5.16 a | 28.72 ± 2.41 a |

| Plasma-treated | 15.82 ± 7.79 a | 61.32 ± 11.07 a | 35.48 ± 6.43 a |

| Elongation at break (%) | |||

| Control | 22.50 ± 3.10 a | 7.71 ± 1.39 a | 16.10 ± 3.22 a |

| Plasma-treated | 16.04 ± 4.17 a | 9.67 ± 2.03 a | 7.18 ± 5.94 a |

| Elasticity module (MPa) | |||

| Control | 531 ± 43 a | 784 ± 91 a | 781 ± 47 a |

| Plasma-treated | 664 ± 61 b | 809 ± 62 a | 852 ± 101 a |

| Film | TS | EB | EM | Reference |

|---|---|---|---|---|

| (MPa) | (%) | (MPa) | ||

| Corn starch | 11.2 | 22.5 | 531 | This work |

| Corn starch (plasma-treated) | 15.8 | 16 | 664 | This work |

| Corn starch (high amylose) | 13 | 43 | -- | [36] |

| Corn starch + cinnamaldehyde | 14.8 | 45 | -- | [36] |

| Corn starch | 0.4 | 23.5 | -- | [43] |

| Corn starch + orange peel | 1.4 | 11.5 | -- | [43] |

| Corn starch | 3.8 | 60.1 | 95 | [50] |

| Corn starch + fireweed extract | 4.5 | 63.6 | 114 | [50] |

| Corn starch | 1.2 | 53.1 | -- | [44] |

| Corn starch + data palm pits | 2.9 | 18.6 | -- | [44] |

| Sorghum starch | 8.3 | 1.7 | -- | [51] |

| Cassava starch | 5 | 55 | -- | [50] |

| Potato starch | 4.7 | 65.2 | -- | [52] |

| Potato starch | 6.6 | 19 | -- | [37] |

| Potato starch (high-pressure) | 11 | 19 | -- | [37] |

| Banana starch | 6.2 | 4.3 | 144 | [10] |

| Banana starch (plasma-treated) | 9.1 | 7.6 | 268 | [10] |

| Bacterial cellulose | 60.6 | 7.7 | 784 | This work |

| Bacterial cellulose (plasma-treated) | 61.3 | 9.6 | 809 | This work |

| Bacterial cellulose | 1.8 | 33.3 | -- | [45] |

| Bacterial cellulose (nanocellulose) | 1.7 | 64.9 | -- | [45] |

| Bacterial cellulose (nanocrystalline) | 3 | 77 | -- | [45] |

| Bacterial cellulose | 125 | 6.8 | -- | [40] |

| Bacterial cellulose + curcumin | 45 | 5 | -- | [40] |

| Whey protein | 4 | 30 | -- | [46] |

| Whey protein + bacterial cellulose | 8 | 20 | -- | [46] |

| Gelatin | 28.7 | 16.1 | 781 | This work |

| Gelatin (plasma-treated) | 35.4 | 7.2 | 852 | This work |

| Gelatin | 12.2 | 16.9 | -- | [53] |

| Gelatin + B. gymnorhiza extract | 11.9 | 17.2 | -- | [53] |

| Gelatin | 10.4 | 17.5 | -- | [53] |

| Gelatin + S. alba extract | 13.1 | 19.4 | -- | [53] |

| Gelatin | 4 | 115 | -- | [47] |

| Gelatin + carboxymethylcellulose | 36 | 105 | -- | [47] |

| Gelatin + polyvinyl alcohol | 14 | 350 | -- | [47] |

| Gelatin | 65.5 | 20.4 | -- | [48] |

| Gelatin (transglutaminase-treated) | 50.6 | 32.2 | -- | [48] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goiana, M.L.; Mattos, A.L.A.; de Azeredo, H.M.C.; de Freitas Rosa, M.; Fernandes, F.A.N. Influence of Dielectric Barrier Discharge Cold Plasma Treatment on Starch, Gelatin, and Bacterial Cellulose Biodegradable Polymeric Films. Polymers 2022, 14, 5215. https://doi.org/10.3390/polym14235215

Goiana ML, Mattos ALA, de Azeredo HMC, de Freitas Rosa M, Fernandes FAN. Influence of Dielectric Barrier Discharge Cold Plasma Treatment on Starch, Gelatin, and Bacterial Cellulose Biodegradable Polymeric Films. Polymers. 2022; 14(23):5215. https://doi.org/10.3390/polym14235215

Chicago/Turabian StyleGoiana, Mayara Lima, Adriano Lincoln Albuquerque Mattos, Henriette Monteiro Cordeiro de Azeredo, Morsyleide de Freitas Rosa, and Fabiano André Narciso Fernandes. 2022. "Influence of Dielectric Barrier Discharge Cold Plasma Treatment on Starch, Gelatin, and Bacterial Cellulose Biodegradable Polymeric Films" Polymers 14, no. 23: 5215. https://doi.org/10.3390/polym14235215

APA StyleGoiana, M. L., Mattos, A. L. A., de Azeredo, H. M. C., de Freitas Rosa, M., & Fernandes, F. A. N. (2022). Influence of Dielectric Barrier Discharge Cold Plasma Treatment on Starch, Gelatin, and Bacterial Cellulose Biodegradable Polymeric Films. Polymers, 14(23), 5215. https://doi.org/10.3390/polym14235215