Acrylic Resin Filling Cell Lumen Enabled Laminated Poplar Veneer Lumber as Structural Building Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Method

2.2.1. Modification of the Wood

2.2.2. Performance Characterization

3. Results and Discussion

3.1. Optimization of Acrylic Resin System

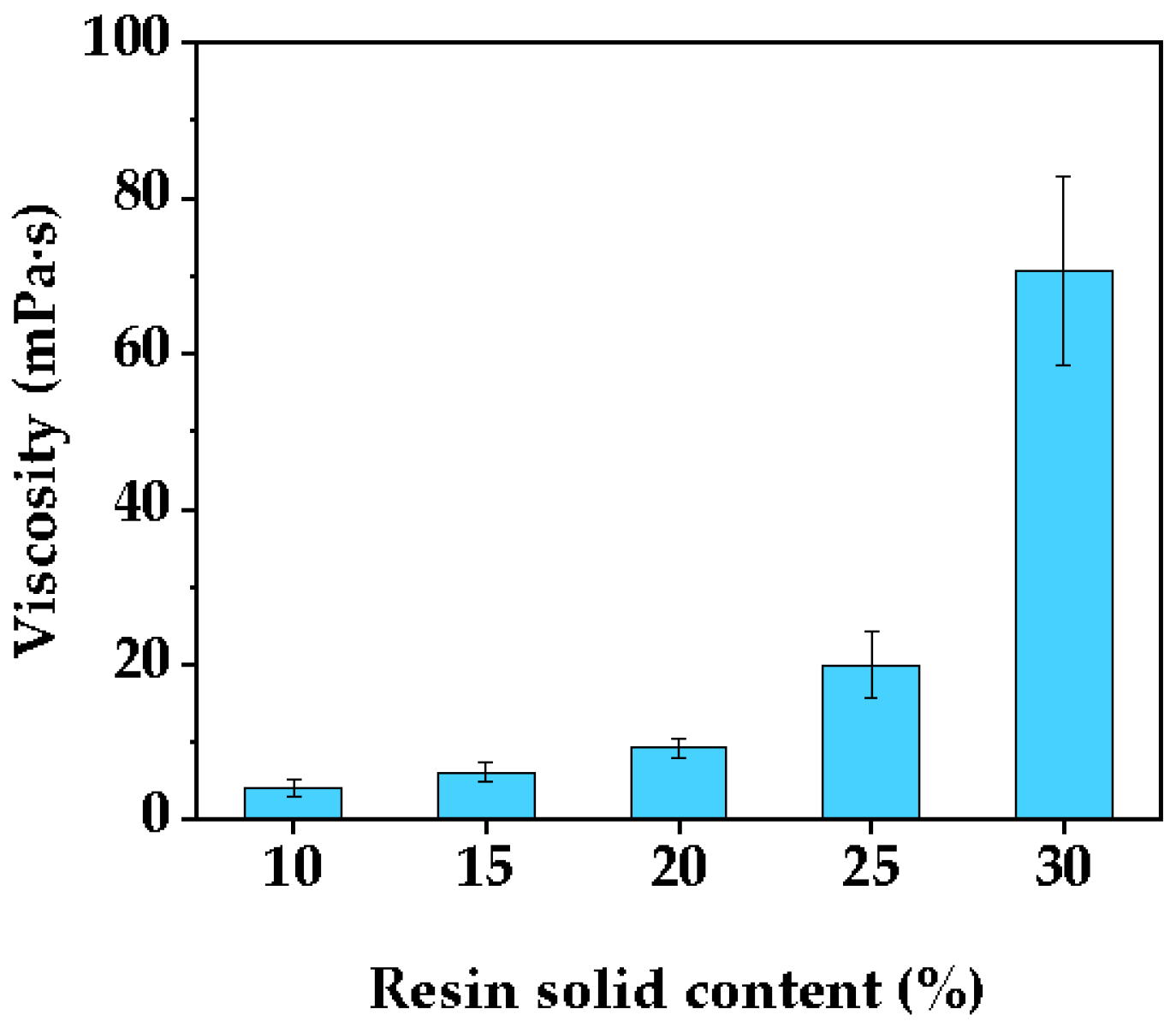

3.1.1. Optimization of Solid Content of Acrylic Resin Liquid

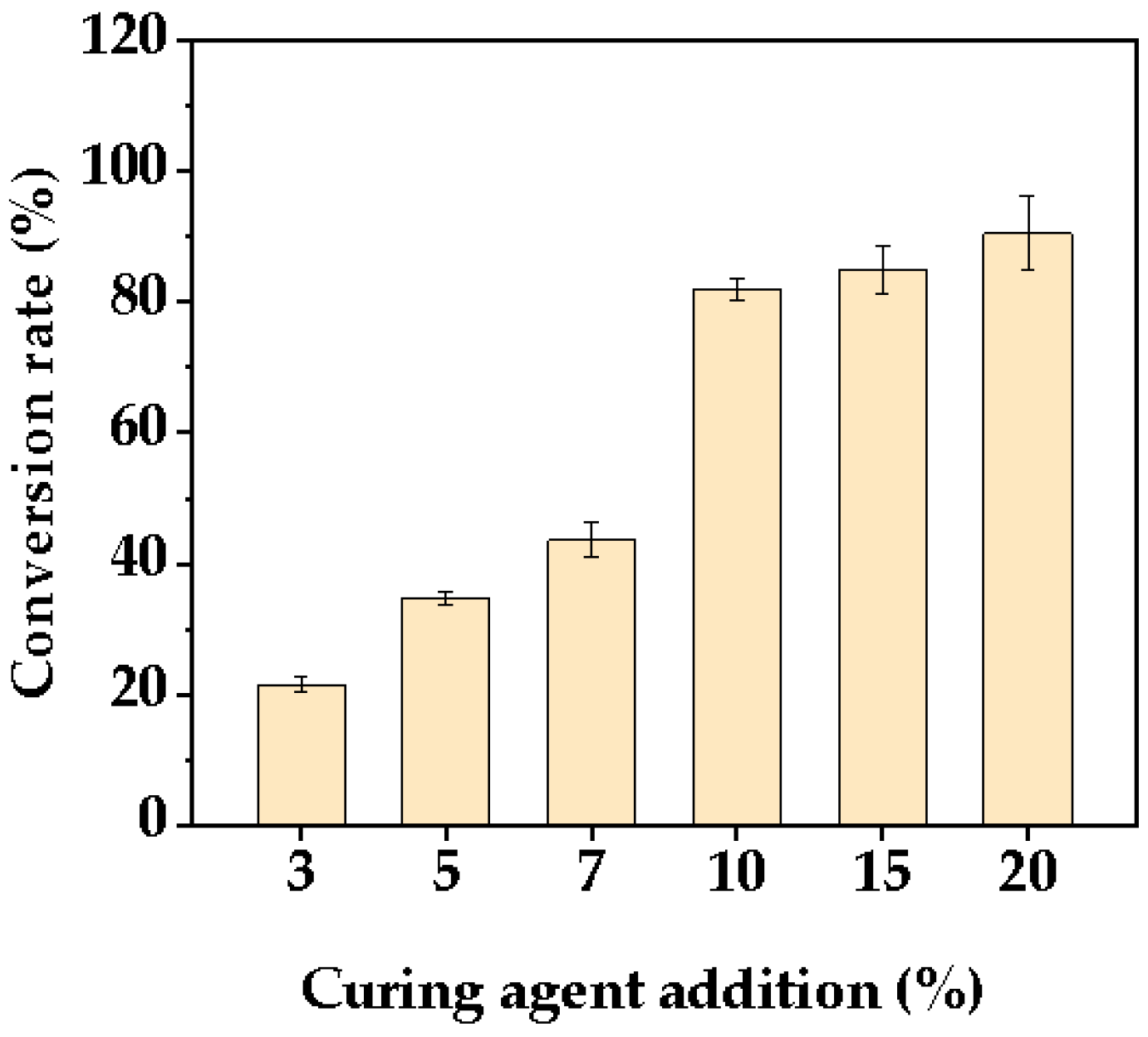

3.1.2. Optimization of Curing Agent Addition

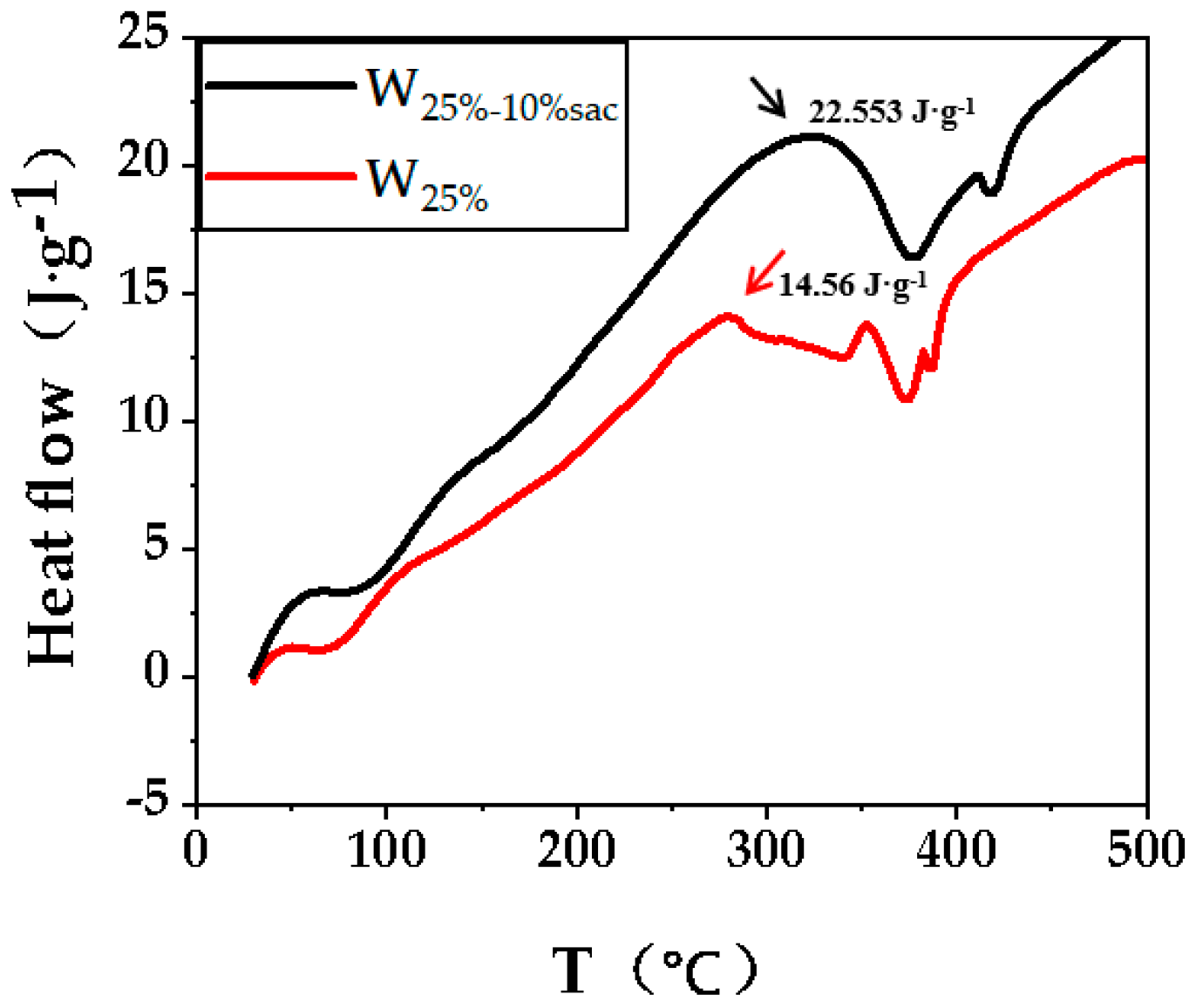

3.1.3. DSC Characterization of Acrylic Resin

3.2. Performance Improvement of Poplar Veneer by Resin−Filled Cell Cavities under Optimized System

3.2.1. Microstructure and Density of Resin-Filled Modified Veneer

3.2.2. Mechanical Properties of Resin-Filled Modified Veneer

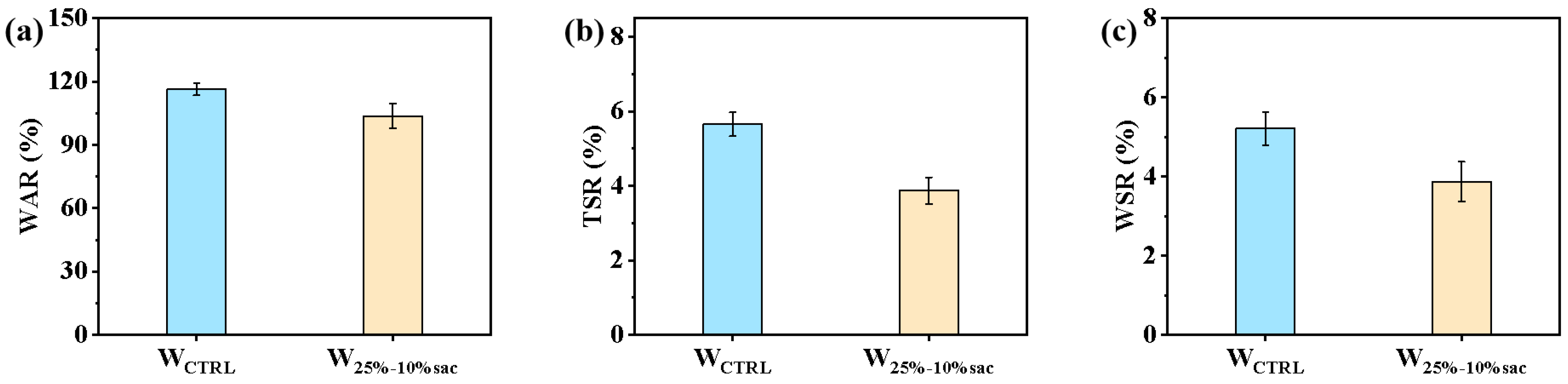

3.2.3. Dimensional Stability of Resin-Filled Modified Veneer

3.3. Performance of Laminated Composite Materials Based on Resin-Filled Modified Veneer

3.3.1. Mechanical Properties of Modified Laminated Veneer Lumber

3.3.2. Dimensional Stability of Modified Laminated Veneer Lumber

4. Conclusions

- (1)

- Acrylic resin-optimized system with a 25% solid content and a 10% curing agent dosage, when the resin liquid viscosity is 19.89 mPa·s, and the resin conversion rate is 81.95%.

- (2)

- With a weight gain of 81.36% and a density of 0.69 g/cm3, the optimized resin system can effectively filled the poplar veneer cell lumen, which significantly improves the mechanical strength and dimensional stability of the poplar veneer.

- (3)

- The modified laminated veneer timber’s static flexural strength and modulus of elasticity are 123.13 MPa and 12,944.76 MPa, respectively, which exceeded the flexural strength index values (modulus of elasticity 12,500 MPa and static flexural strength 35 MPa) for structural timber specified in the highest strength class (TCT40) of Chinese Standard GB 50005-2017. In addition, in terms of mechanical properties, compared with untreated laminated veneer, the tensile strength, impact toughness, hardness and wear resistance were 58.81%, 19.50%, 419.18%, 76.83%, respectively. In terms of dimensional stability, compared with untreated laminated veneer, the water absorption rate, water absorption thickness expansion rate and water absorption width expansion rate increased by 44.38%, 13.90% and 37.60%, respectively. It has significantly improved mechanical strength and dimensional stability, and can be used as a structural building material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gong, X.Z.; Nie, Z.R.; Wang, Z.H.; Cui, S.P.; Gao, F.; Zuo, T.Y. Life cycle energy consumption and carbon dioxide emission of residential building designs in Beijing: A comparative study. J. Ind. Ecol. 2012, 16, 576–587. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Effect of thermal mass on life cycle primary energy balances of a concrete-and a wood-frame building. Appl. Energy 2012, 92, 462–472. [Google Scholar] [CrossRef]

- Milaj, K.; Sinha, A.; Miller, T.H.; Tokarczyk, J.A. Environmental utility of wood substitution in commercial buildings using life-cycle analysis. Wood Fiber Sci. 2017, 49, 338–358. [Google Scholar]

- Mitterpach, J.; Vaňová, R.; Šedivka, P.; Štefko, J. A Comparison of the Environmental Performance between Construction Materials and Operational Energy of Nearly Zero-Energy Wood-Based Educational Building. Forests 2022, 13, 220. [Google Scholar] [CrossRef]

- Pépin, A.; Gosselin, L.; Dallaire, J. Correlations between dynamic thermal properties, energy consumption, and comfort in wood, concrete, and lightweight buildings. Trans. Can. Soc. Mech. Eng. 2020, 45, 48–63. [Google Scholar] [CrossRef]

- Mai, C.; Schmitt, U.; Niemz, P. A brief overview on the development of wood research. Holzforschung 2021, 76, 102–119. [Google Scholar] [CrossRef]

- Shida, S. Wood/human relations and the future of living comfort research in wood sciences. Mokuzai Gakkaishi 2015, 61, 141–147. [Google Scholar] [CrossRef] [Green Version]

- Adachi, K. Wood physics and wood-based material science leading the way to future manufacturing technology. Mokuzai Gakkaishi 2015, 61, 186–190. [Google Scholar] [CrossRef] [Green Version]

- Morrell, J.J. Protection of wood: A global perspective on the future. In Wood Is Good; Springer: Singapore, 2017; pp. 213–226. [Google Scholar]

- Blanchet, P.; Breton, C. Wood productions and renewable materials: The future is now. Forests 2020, 11, 657. [Google Scholar] [CrossRef]

- Wei, P.; Wang, B.J.; Zhou, D.; Dai, C.; Wang, Q.; Huang, S. Mechanical properties of poplar laminated veneer lumber modified by carbon fiber reinforced polymer. BioResources 2013, 8, 4883–4898. [Google Scholar] [CrossRef] [Green Version]

- Bao, M.; Huang, X.; Jiang, M.; Yu, W.; Yu, Y. Effect of thermo-hydro-mechanical densification on microstructure and properties of poplar wood (Populus tomentosa). J. Wood Sci. 2017, 63, 591–605. [Google Scholar] [CrossRef]

- Maloney, T.M. Modern Particleboard and Dry-Process Fiberboard Manufacturing; Miller Freeman Publication: San Francisco, CA, USA, 1993. [Google Scholar]

- Stamm, A.J.; Seborg, R.M. Minimizing wood shrinkage and swelling. Ind. Eng. Chem. 1936, 28, 1164–1169. [Google Scholar] [CrossRef]

- Bufalino, L.; Ribeiro Corrêa, A.A.; de Sá, V.A.; Marin Mendes, L.; Amarante Almeida, N.; Dordenoni Pizzol, V. Alternative compositions of oriented strand boards (OSB) made with commercial woods produced in Brazil. Maderas-Cienc. Tecnol. 2015, 17, 105–116. [Google Scholar] [CrossRef] [Green Version]

- Garay Moena, R.M.; Damiani Sandoval, F. Effect of board density and adhesive combination on physical and mechanical critical properties of OSB made with Chilean native wood. Bosque 2013, 34, 13–22. [Google Scholar]

- Yang, X.J.; Zhao, Q.; Hao, D.; Wang, J.; Fu, S.; Ma, L. Flexural behavior of OSB reinforced wood truss. Wood Res. 2020, 65, 245–256. [Google Scholar] [CrossRef]

- Barbirato, G.H.A.; Junior, W.E.L.; Hellmeister, V.; Pavesi, M.; Fiorelli, J. OSB panels with balsa wood waste and castor oil polyurethane resin. Waste Biomass Valorization 2020, 11, 743–751. [Google Scholar] [CrossRef]

- Cahyono, T.D.; Darmawan, W.; Novriyanti, E. Performance of samama (Anthocephalus macrophyllus) LVL based on veneer thickness, juvenile proportion and lay-up. Wood Mater. Sci. Eng. 2018, 15, 155–162. [Google Scholar] [CrossRef]

- Li, F.; Hu, Y.C. The Dominant Factor Analysis of Production Technology of Poplar LVL Based on Grey Theory. Mater. Sci. Forum 2010, 658, 284–287. [Google Scholar] [CrossRef]

- Palermo, A.; Pampanin, S.; Buchanan, A.; Newcombe, M. Seismic Design of Multi-Storey Buildings Using Laminated Veneer Lumber (LVL); Mniversity of Canterbury Civil Engineering: Christchurch, New Zealand, 2005. [Google Scholar]

- Girardon, S.; Denaud, L.; Pot, G.; Rahayu, I. Modelling the effects of wood cambial age on the effective modulus of elasticity of poplar laminated veneer lumber. Ann. For. Sci. 2016, 73, 615–624. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.X.; Pierobon, F.; Ganguly, I. Life Cycle Assessment (LCA) of Cross-Laminated Timber (CLT) produced in Western Washington: The role of logistics and wood species mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef] [Green Version]

- Harada, T.; Kamikawa, D.; Miyatake, A.; Shindo, K.; Hattori, N.; Ando, K.; Miyabayashi, M. Two-hour fireproof performance of cross laminated timber (CLT) covered with fire-retardant impregnated wood. Mokuzai Gakkaishi 2019, 65, 46–53. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Park, Y.; Chang, Y.S.; Chung, H.; Eom, C.D.; Yeo, H. Improvement of shear strength, wood failure percentage and wet delamination of cross-laminated timber (CLT) panels made with superheated steam treated (SHST) layers of larch wood. Holzforschung 2017, 71, 873–879. [Google Scholar] [CrossRef]

- Muñoz, F.; Tenorio, C.; Moya, R.; Navarro-Mora, A. CLT Fabricated with Gmelina arborea and Tectona grandis Wood from Fast-Growth Forest Plantations: Physical and Mechanical Properties. J. Renew. Mater. 2022, 10, 1–17. [Google Scholar]

- Zou, M.; Tang, Q.H.; Guo, W.J. High-strength wood-based composites via laminated delignified wood veneers with different adhesive contents for structural applications. Polym. Compos. 2022, 43, 2746–2758. [Google Scholar] [CrossRef]

- Altgen, M.; Awais, M.; Altgen, D.; Klüppel, A.; Mäkelä, M.; Rautkari, L. Distribution and curing reactions of melamine formaldehyde resin in cells of impregnation-modified wood. Sci. Rep. 2020, 10, 3366. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.F.; Yao, Y.; Huang, Y.Q.; Ma, Y.J.; Xi, J.Y.; Wang, X.Z.; Li, H.G.; Yang, Z.Q. Effects of the combination of compression and impregnation with phenolic resin on the dimensional stability in the multiscale wood structure of Chinese fir. Constr. Build. Mater. 2022, 327, 126960. [Google Scholar] [CrossRef]

- Fukuta, S.; Watanabe, A.; Akahori, Y.; Makita, A.; Imamura, Y.; Sasaki, Y. Bending properties of compressed wood impregnated with phenolic resin through drilled holes. Eur. J. Wood Wood Prod. 2011, 69, 633–639. [Google Scholar] [CrossRef]

- AshAcrylicri, Z.; Lee, S.H.; Zahali, M.R. Performance of compreg laminated bamboo/wood hybrid using phenolic-resin-treated strips as core layer. Eur. J. Wood Wood Prod. 2016, 74, 621–624. [Google Scholar]

- Li, J.; Zhang, A.; Zhang, S.; Gao, Q.; Chen, H.; Zhang, W.; Li, J. High-performance imitation precious wood from low-cost poplar wood via high-rate permeability of phenolic resins. Polym. Compos. 2018, 39, 2431–2440. [Google Scholar] [CrossRef]

- Qin, Y.; Dong, Y.; Li, J. Effect of modification with melamineurea-formaldehyde resin on the properties of eucalyptus and poplar. Wood Chem. 2019, 39, 360–371. [Google Scholar] [CrossRef]

- Han, J.; Liu, K.N.; Gao, X.T. Compare of impregnating Poplar with UF and PF resin. Adv. Mater. Res. 2013, 779, 17–20. [Google Scholar] [CrossRef]

- Gavrilovic-Grmusa, I.; Dunky, M.; Miljkovic, J.; Djiporovic-Momcilovic, M. Influence of the viscosity of UF resins on the radial and tangential penetration into poplar wood and on the shear strength of adhesive joints. Holzforschung 2012, 66, 849–856. [Google Scholar] [CrossRef]

- Lin, C.; Karlsson, O.; Martinka, J.; Rantuch, P.; Garskaite, E.; Mantanis, G.I.; Sandberg, D. Approaching highly leaching-resistant fire-retardant wood by in situ polymerization with melamine formaldehyde resin. ACS Omega 2021, 6, 12733–12745. [Google Scholar] [CrossRef] [PubMed]

- Behr, G.; Gellerich, A.; Bollmus, S. The influence of curing conditions on properties of melamine modified wood. Eur. J. Wood Wood Prod. 2018, 76, 1263–1272. [Google Scholar] [CrossRef]

- Behr, G.; Bollmus, S.; Gellerich, A. Improvement of mechanical properties of thermally modified hardwood through melamine treatment. Wood Mater. Sci. Eng. 2018, 13, 262–270. [Google Scholar] [CrossRef]

- Deka, M.; Gindl, W.; Wimmer, R. Chemical modification of Norway spruce (Picea abies (L) Karst) wood with melamine formaldehyde resin. Indian J. Chem. Technol. 2007, 14, 134–138. [Google Scholar]

- Wu, J.W.; Fan, Q.; Wang, Q.W.; Guo, Q.; Tu, D.Y.; Chen, C.F.; Xiao, Y.Y.; Ou, R.X. Improved performance of poplar wood by an environmentally-friendly process combining surface impregnation of a reactive waterborne acrylic resin and unilateral surface densification. J. Clean. Prod. 2020, 261, 121022. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Xiao, Z.; Che, W.; Trinh, H.M.; Xie, Y. Effects of modification with a combination of styrene-acrylic copolymer dispersion and sodium silicate on the mechanical properties of wood. J. Wood Sci. 2019, 65, 2. [Google Scholar] [CrossRef]

- Che, W.; Xiao, Z.; Xie, Y.; Harbin, P.R. Modification of radiata pine wood with low molecular weight modifying agents and large molecular weight styrene/acrylic acid copolymer dispersion. Wood Res. 2019, 64, 777–788. [Google Scholar]

- Reck, B.; Türk, J. Thermally curable aqueous acrylic resins–a new class of duroplastic binders for wood and natural fibers. Die Angew. Makromol. Chem. 1999, 272, 5–10. [Google Scholar] [CrossRef]

- Che, W.; Xiao, Z.; Han, G.; Zheng, Z.; Xie, Y. Radiata pine wood treatment with a dispersion of aqueous styrene/acrylic acid copolymer. Holzforschung 2018, 72, 387–396. [Google Scholar] [CrossRef]

- Akpan, E.I.; Wetzel, B.; Friedrich, K. Processing and properties of short wood fiber/acrylate resin composites. Polym. Compos. 2019, 40, 91–98. [Google Scholar] [CrossRef] [Green Version]

- Ogawa, K.; Fukuta, S.; Kobayashi, K. Embedment properties of Japanese cedar (Cryptomeria japonica) treated with resin impregnation. J. Wood Sci. 2022, 68, 9. [Google Scholar] [CrossRef]

- Ogawa, K.; Fukuta, S.; Kobayashi, K. Experimental study of lateral resistance of bolted joints using Japanese cedar (Cryptomeria japonica) treated with resin impregnation. J. Wood Sci. 2020, 66, 71. [Google Scholar] [CrossRef]

- Kang, C.W.; Jin, T.; Park, H.J.; Wen, M.Y.; Kang, H.Y.; Matsumura, J. Changes in the dynamic and static MOE of furfuryl alcohol–treated Wood. J. Fac. Agric. Kyushu Univ. 2015, 60, 203–207. [Google Scholar] [CrossRef]

- Pfriem, A.; Dietrich, T.; Buchelt, B. Furfuryl alcohol impregnation for improved plasticization and fixation during the densification of wood. Wood Res. Technol. 2012, 66, 215–218. [Google Scholar] [CrossRef]

- Kong, L.; Guan, H.; Wang, X. In situ polymerization of furfuryl alcohol with ammonium dihydrogen phosphate in poplar wood for improved dimensional stability and flame retardancy. Sustain. Chem. Eng. 2018, 6, 3349–3357. [Google Scholar] [CrossRef]

- Li, W.; Liu, M.; Wang, H.; Yu, Y. Fabrication of highly stable and durable furfurylated wood materials. Part II: The multi-scale distribution of furfuryl alcohol (FA) resin in wood. Holzforschung 2020, 74, 1147–1155. [Google Scholar] [CrossRef]

- Moise, V.; Stanculescu, I.; Vasilca, S.; Cutrubinis, M.; Pincu, E.; Oancea, P.; Rrudacan, A.; Meltzer, V. Consolidation of very degraded cultural heritage wood artefacts using radiation curing of polyester resins. Radiat. Phys. Chem. 2019, 156, 314–319. [Google Scholar] [CrossRef]

- Malletzidou, L.; Papadopoulou, E.; Papadopoulos, L.; Markessini, C.; Bikiaris, D.N.; Chrissafis, K.; Vourlias, G. Novel Biobased Polyester Resins for Wood Applications: Morphological, Thermal, and Chemical Characterization. Macromol. Symp. 2022, 405, 2100229. [Google Scholar] [CrossRef]

- Cheng, F.; Hu, Y.; Li, L. Interfacial properties of glass fiber/unsaturated polyester resin/poplar wood composites prepared with the prepreg/press process. Fibers Polym. 2015, 16, 911–917. [Google Scholar] [CrossRef]

- Emmerich, L.; Militz, H.; Brischke, C. Long-term performance of DMDHEU-treated wood installed in different test set-ups in ground, above ground and in the marine environment. Int. Wood Prod. J. 2020, 11, 27–37. [Google Scholar] [CrossRef]

- Emmerich, L.; Altgen, M.; Rautkari, L.; Militz, H. Sorption behavior and hydroxyl accessibility of wood treated with different cyclic N-methylol compounds. J. Mater. Sci. 2020, 55, 16561–16575. [Google Scholar] [CrossRef]

- Jiang, T.; Gao, H.; Sun, J.; Xie, Y.; Li, X. Impact of DMDHEU resin treatment on the mechanical properties of poplar. Polym. Polym. Compos. 2014, 22, 669–674. [Google Scholar] [CrossRef]

- Dong, Y.M.; Wang, K.L.; Li, J.; Zhang, S.F.; Shi, S.Q. Environmentally benign wood modifications: A review. Sustain. Chem. Eng. 2020, 8, 3532–3540. [Google Scholar] [CrossRef]

- LY/T3034-2018; General Requirements for Producing Wood Impregnated with Resin. State Forestry and Grassland Administration: Beijing, China, 2018.

| Mechanical Property | Dimension l × t × r (mm) | Standard |

|---|---|---|

| MOR | 200 × 50 × 10 | GB-T 20241-2006 |

| MOE | 200 × 50 × 10 | GB-T 20241-2006 |

| CS | 23 × 15 × 15 | GB-T 17657-2013 |

| HS | 50 × 50 × 15 | GB-T 17657-2013 |

| IBS | 300 × 20 × 20 | GB-T 1938-2009 |

| TS | 408 × 25 × 25 | GB-T 1938-2009 |

| Attrition value | 100 × 100 × 15 | GB-T 17657-2013 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Liu, Y.; Qi, Y.; Gong, R.; Yao, F.; Luo, J.; Zhao, Y.; Dai, Y.; Wang, J.; Lian, C.; et al. Acrylic Resin Filling Cell Lumen Enabled Laminated Poplar Veneer Lumber as Structural Building Material. Polymers 2022, 14, 5277. https://doi.org/10.3390/polym14235277

Gao X, Liu Y, Qi Y, Gong R, Yao F, Luo J, Zhao Y, Dai Y, Wang J, Lian C, et al. Acrylic Resin Filling Cell Lumen Enabled Laminated Poplar Veneer Lumber as Structural Building Material. Polymers. 2022; 14(23):5277. https://doi.org/10.3390/polym14235277

Chicago/Turabian StyleGao, Xudong, Yiliang Liu, Yanran Qi, Ruizhi Gong, Fengbiao Yao, Jiajia Luo, Yueying Zhao, Yong Dai, Jinguo Wang, Chenglong Lian, and et al. 2022. "Acrylic Resin Filling Cell Lumen Enabled Laminated Poplar Veneer Lumber as Structural Building Material" Polymers 14, no. 23: 5277. https://doi.org/10.3390/polym14235277

APA StyleGao, X., Liu, Y., Qi, Y., Gong, R., Yao, F., Luo, J., Zhao, Y., Dai, Y., Wang, J., Lian, C., Dong, X., & Li, Y. (2022). Acrylic Resin Filling Cell Lumen Enabled Laminated Poplar Veneer Lumber as Structural Building Material. Polymers, 14(23), 5277. https://doi.org/10.3390/polym14235277