Fluorine-Free Hydrophobic Modification and Waterproof Breathable Properties of Electrospun Polyacrylonitrile Nanofibrous Membranes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

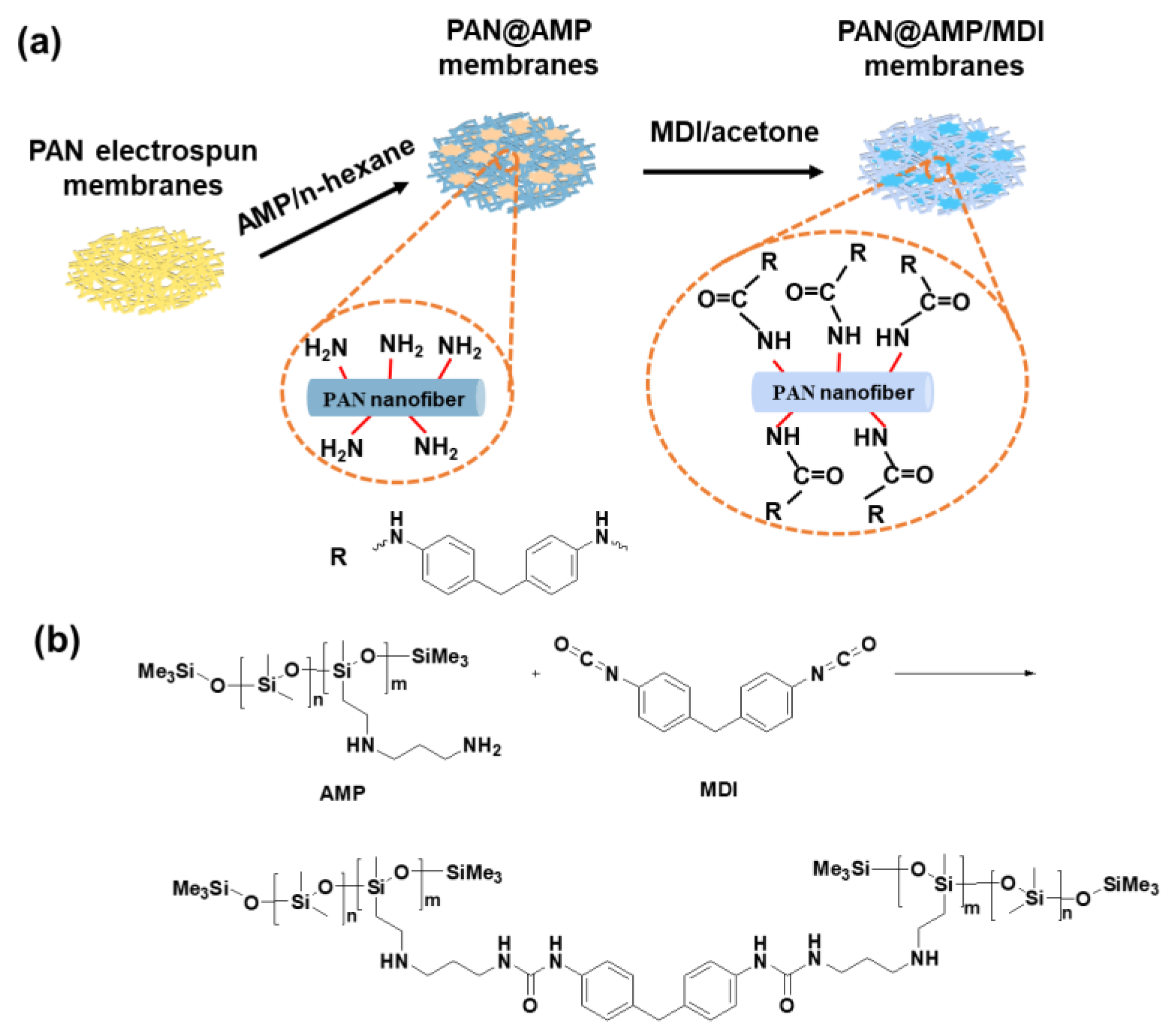

2.2. Fabrication of PAN@AMP/MDI Nanofibrous Membranes

2.3. Structure Characterization and Performance Measurement

3. Results and Discussion

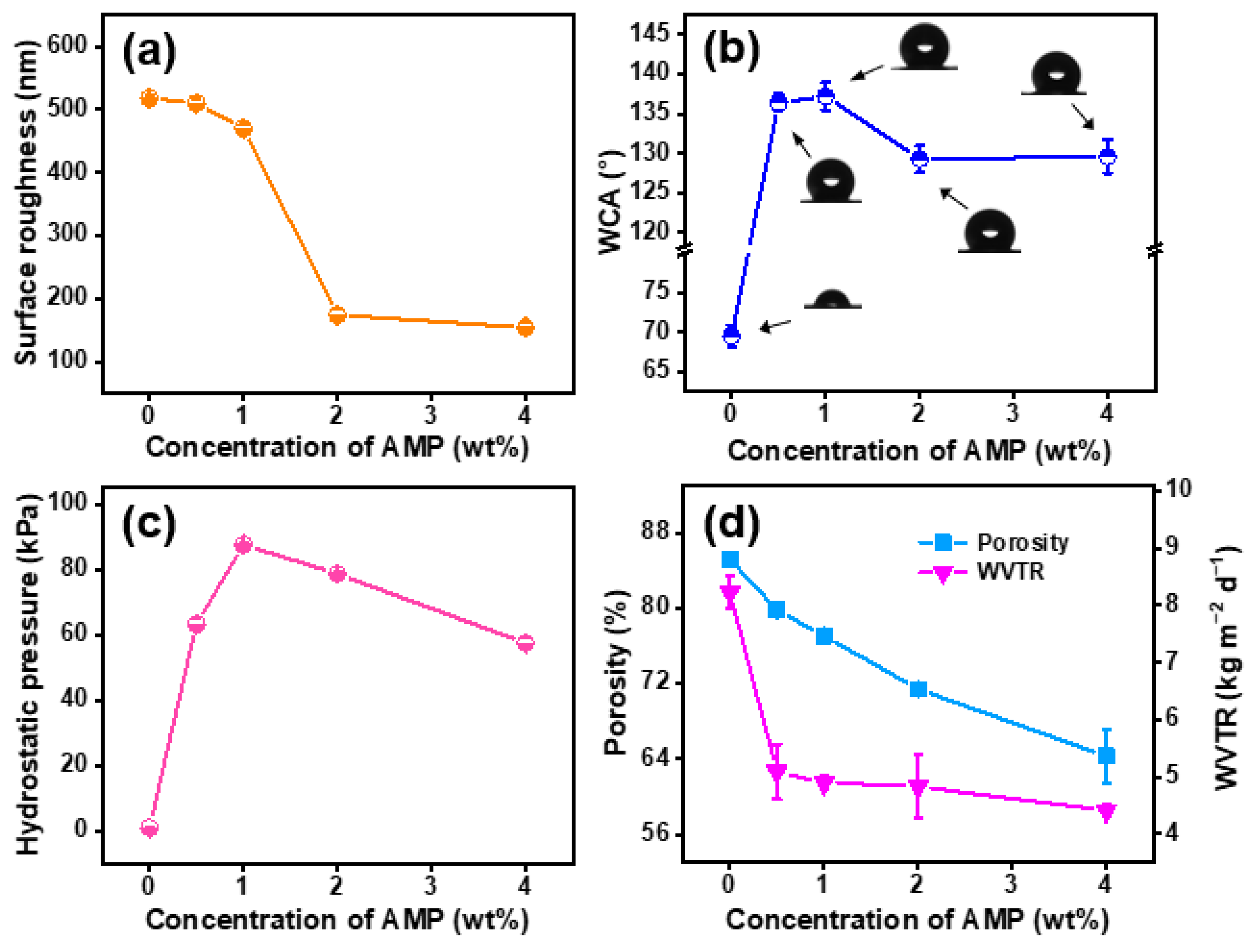

3.1. Effect of AMP Concentration

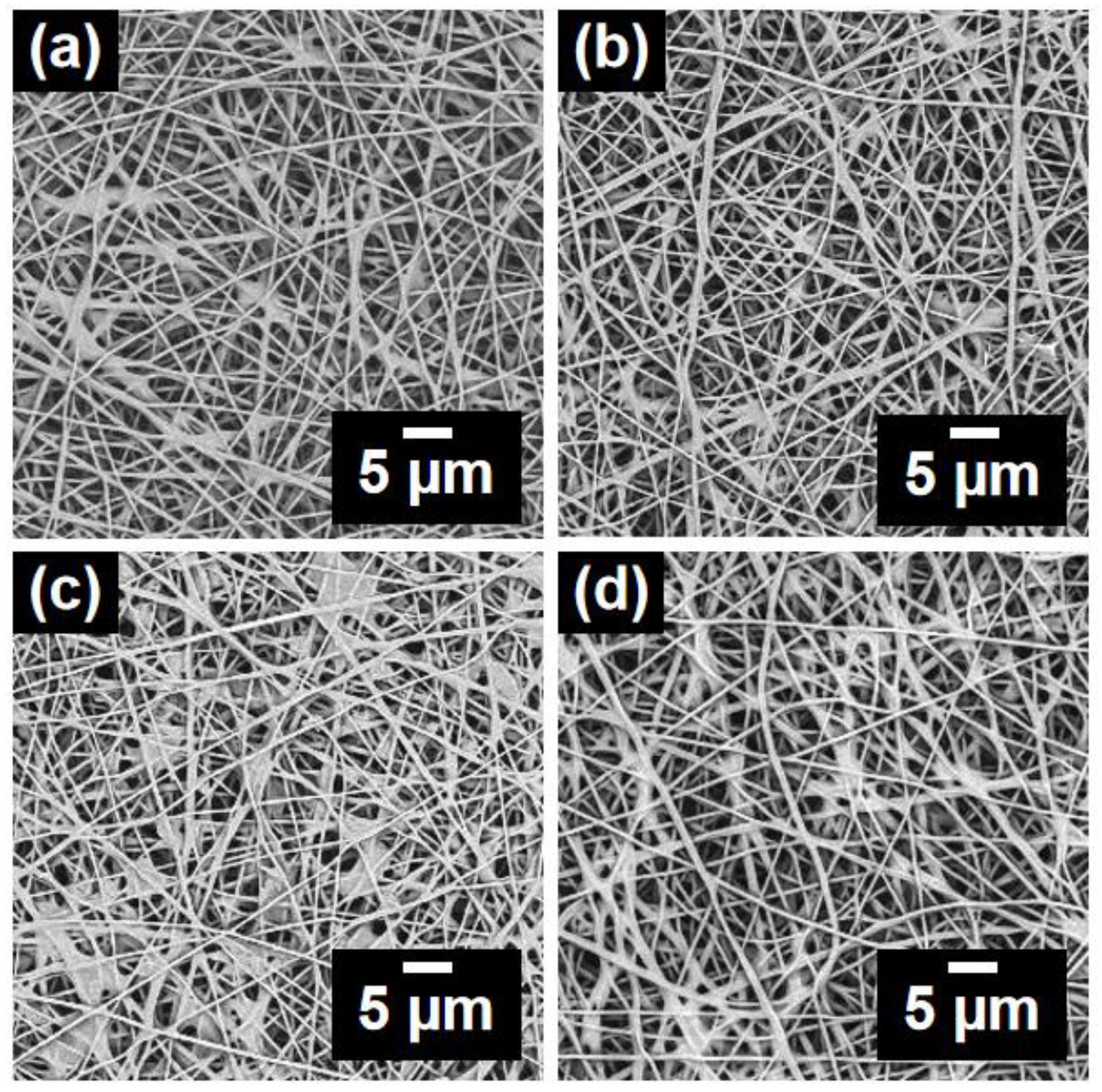

3.1.1. Morphology and Structure

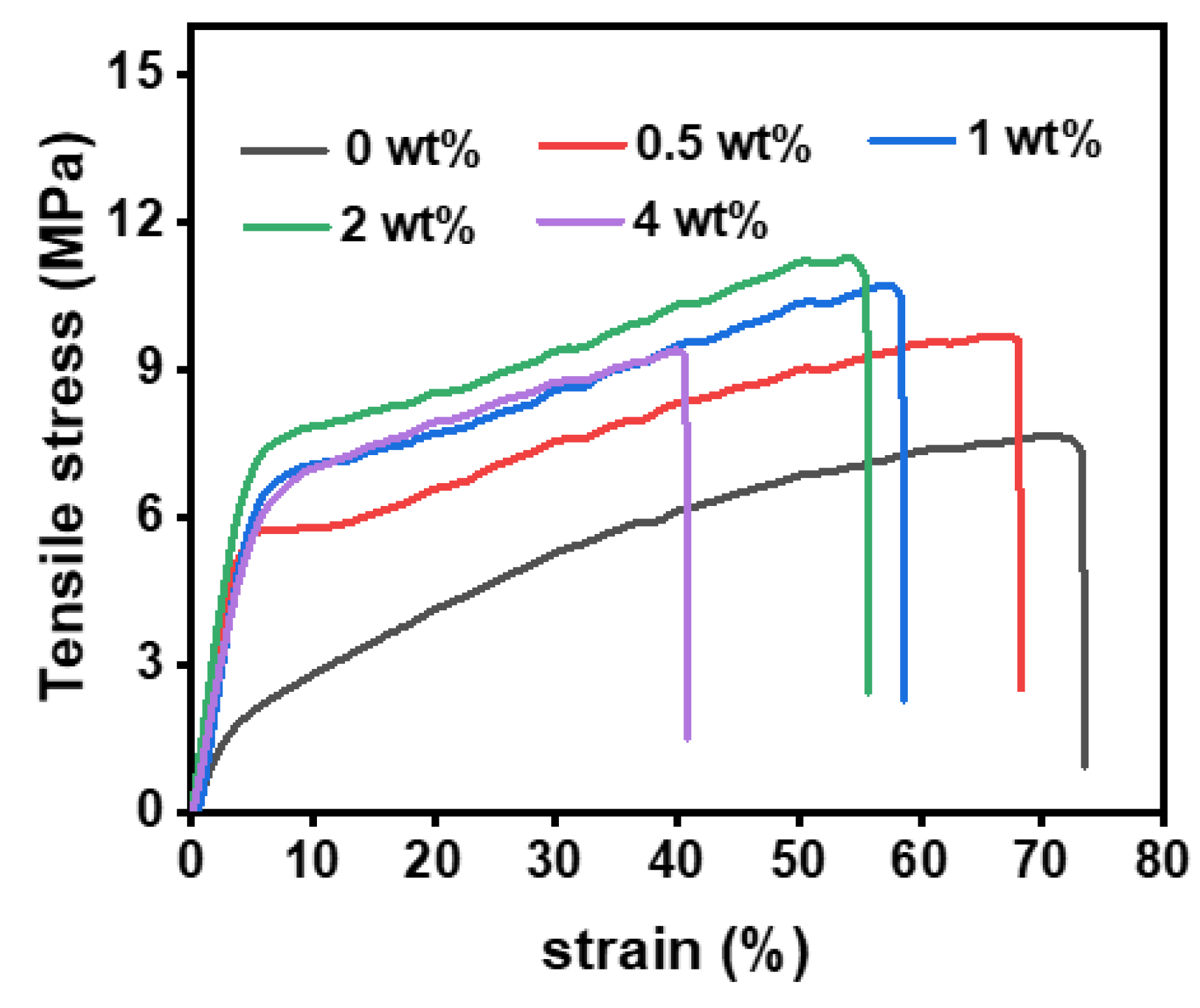

3.1.2. Mechanical Properties

3.1.3. Waterproof Breathable Performance

3.2. Effect of MDI Concentration

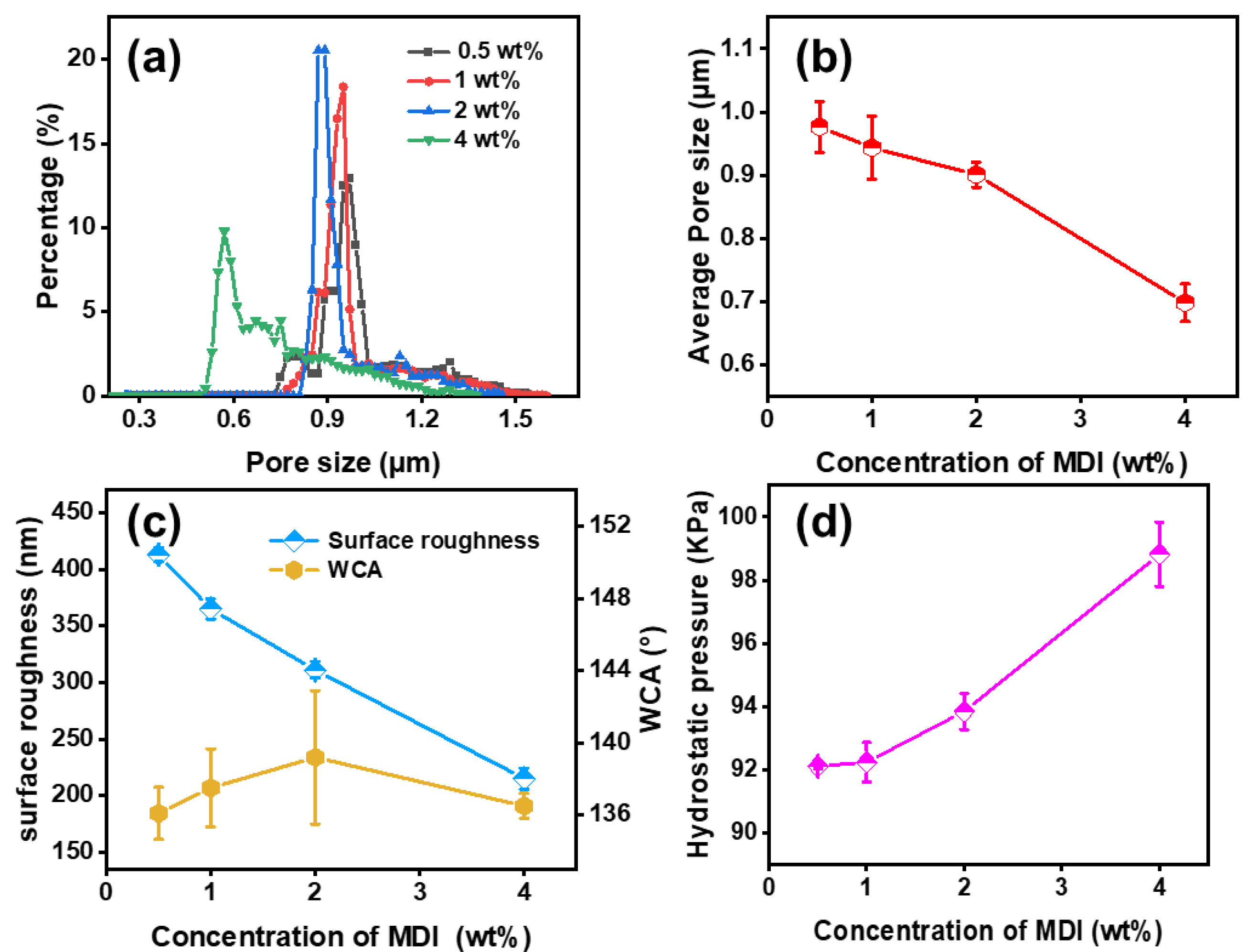

3.2.1. Morphology and Structure

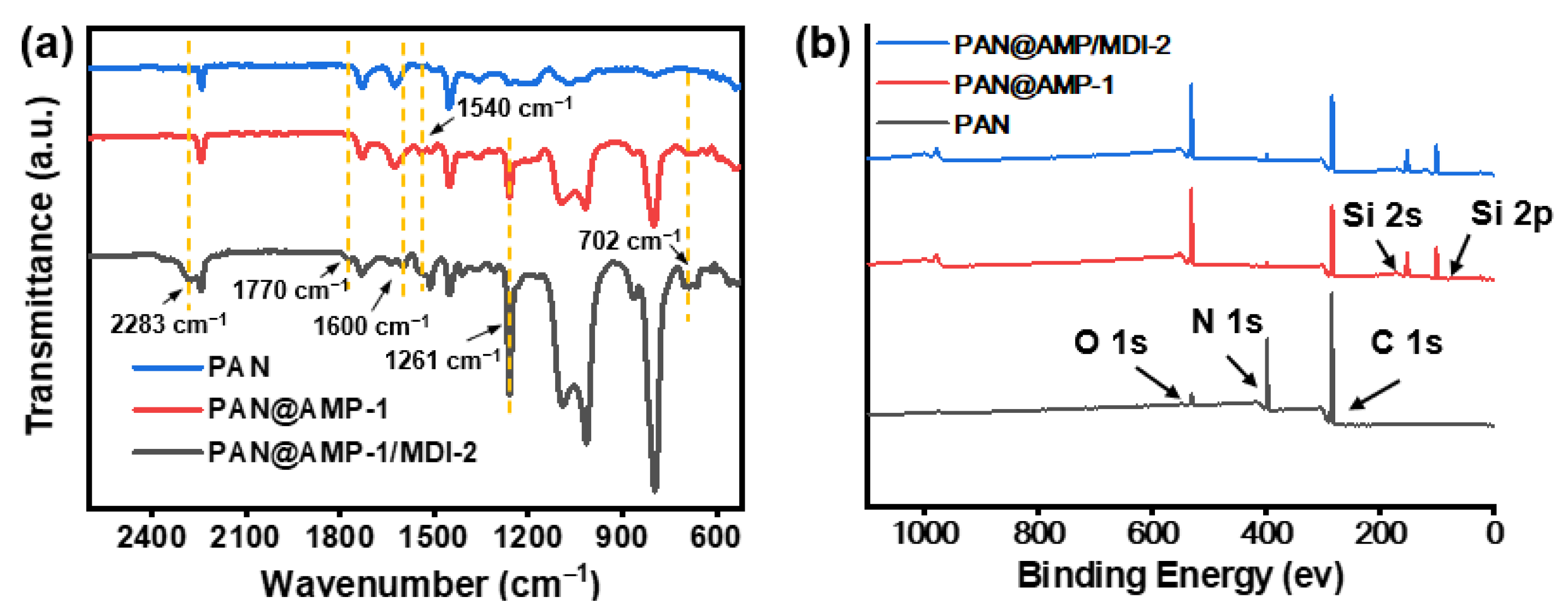

3.2.2. FT-IR Spectral Characterization, XPS Analysis and Mechanical Properties

3.2.3. Pore Structure, Surface Wettability and Waterproof Properties

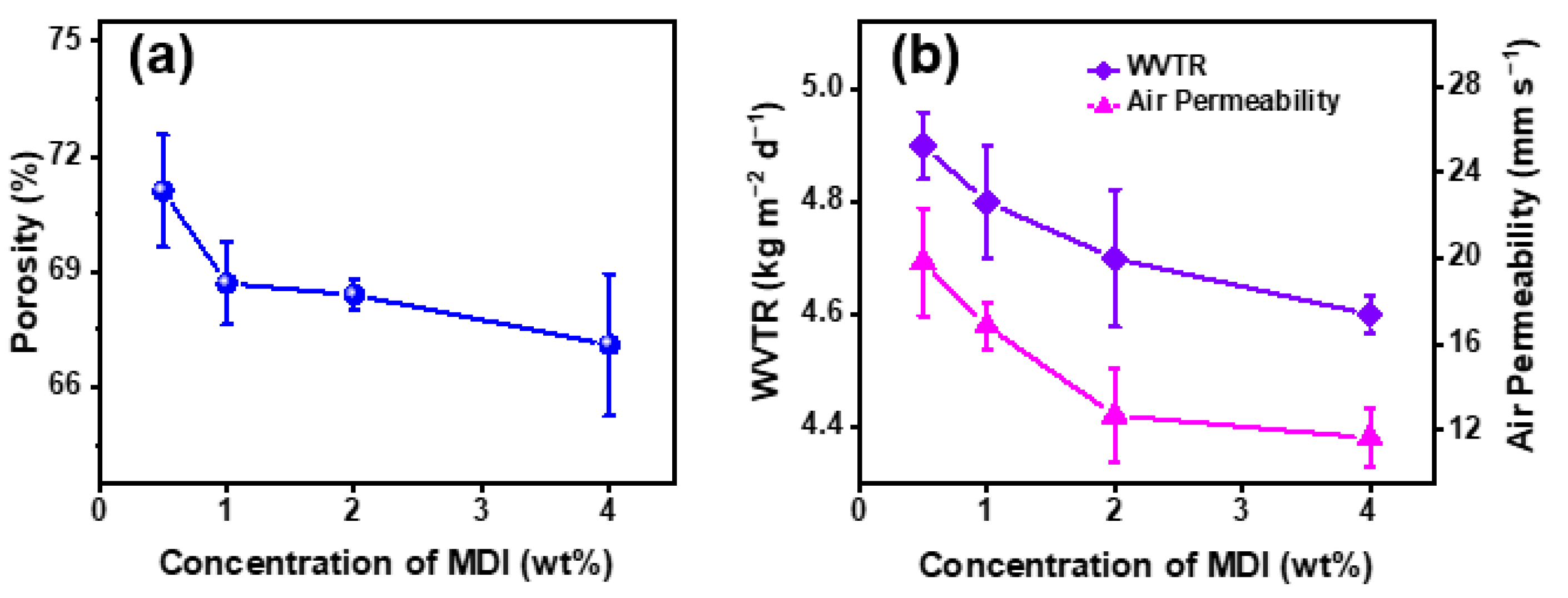

3.2.4. Moisture and Air Permeability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ahn, H.W.; Park, C.H.; Chung, S.E. Waterproof and breathable properties of nanoweb applied clothing. Text. Res. J. 2011, 81, 1438–1447. [Google Scholar]

- Meng, Q.B.; Lee, S.I.; Nah, C.; Lee, Y.S. Preparation of waterborne polyurethanes using an amphiphilic diol for breathable waterproof textile coatings. Prog. Org. Coat. 2009, 66, 382–386. [Google Scholar] [CrossRef]

- Xing, L.L.; Zhou, Q.Q.; Chen, G.Q.; Sun, G.; Xing, T.L. Recent developments in preparation, properties, and applications of superhydrophobic textiles. Text. Res. J. 2022, 92, 00405175221097716. [Google Scholar] [CrossRef]

- Zhou, W.; Gong, X.B.; Li, Y.; Si, Y.; Zhang, S.C.; Yu, J.Y.; Ding, B. Waterborne electrospinning of fluorine-free stretchable nanofiber membranes with waterproof and breathable capabilities for protective textiles. J. Colloid Interface Sci. 2021, 602, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Greszta, A.; Bartkowiak, G.; Dąbrowska, A.; Gliścińska, E.; Machnowski, W.; Kozikowski, P. Multilayer nonwoven inserts with aerogel/pcms for the improvement of thermophysiological comfort in protective clothing against the cold. Materials 2022, 15, 2307. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.P.; Gong, X.B.; Jiao, W.L.; Li, Y.; Yin, X.; Si, Y.; Yu, J.Y.; Ding, B. In-situ electrospinning of thymol-loaded polyurethane fibrous membranes for waterproof, breathable, and antibacterial wound dressing application. J. Colloid Interface Sci. 2021, 592, 310–318. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Midha, V.K. A review on designing the waterproof breathable fabrics part I: Fundamental principles and designing aspects of breathable fabrics. J. Ind. Text. 2008, 37, 225–262. [Google Scholar] [CrossRef]

- Saceviciene, V.; Juciene, M.; Bieliuniene, V.; Cepauskiene, V.; Urbelis, V. Investigation of the wettability of the hydrophobic textile after mechanical treatments. Proc. Est. Acad. Sci. 2015, 64, 118. [Google Scholar] [CrossRef]

- Gorji, M.; Jeddi, A.; Gharehaghaji, A.A. Fabrication and characterization of polyurethane electrospun nanofiber membranes for protective clothing applications. J. Appl. Polym. Sci. 2012, 125, 4135–4141. [Google Scholar] [CrossRef]

- Hong, S.K.; Lim, G.; Cho, S.J. Breathability enhancement of electrospun microfibrous polyurethane membranes through pore size control for outdoor sportswear fabric. Sens. Mater. 2015, 27, 77–85. [Google Scholar]

- Li, Y.; Zhang, X.; Si, Y.; Yu, J.Y.; Ding, B. Super-elastic fluorinated polyurethane nanofibrous membranes with simultaneously waterproof and breathable performance. ACS Appl. Polym. Mater. 2022, 4, 5557–5565. [Google Scholar] [CrossRef]

- Gu, X.; Li, N.; Luo, J.; Xia, X.; Gu, H.; Xiong, J. Electrospun polyurethane microporous membranes for waterproof and breathable application: The effects of solvent properties on membrane performance. Polym. Bull. 2018, 75, 3539–3553. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Midha, V.K. A review on designing the waterproof breathable fabrics Part II: Construction and suitability of breathable fabrics for different uses. J. Ind. Text. 2008, 38, 17–41. [Google Scholar] [CrossRef]

- Cheng, X.Q.; Jiao, Y.; Sun, Z.K.; Yang, X.B.; Cheng, Z.J.; Bai, Q.; Zhang, Y.J.; Wang, K.; Shao, L. Constructing scalable superhydrophobic membranes for ultrafast water–oil separation. ACS Nano 2021, 15, 3500–3508. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.J.; Jiang, L. Design and creation of superwetting/antiwetting surfaces. Adv. Mater. 2006, 18, 3063–3078. [Google Scholar] [CrossRef]

- Sheng, J.L.; Zhang, M.; Luo, W.J.; Yu, J.Y.; Ding, B. Thermally induced chemical cross-linking reinforced fluorinated polyurethane/polyacrylonitrile/polyvinyl butyral nanofibers for waterproof-breathable application. RSC Adv. 2016, 6, 29629–29637. [Google Scholar] [CrossRef]

- Wang, H.J.; Chen, L.; Yi, Y.Q.; Fu, Y.J.; Xiong, J.; Li, N. Durable polyurethane/SiO2 nanofibrous membranes by electrospinning for waterproof and breathable textiles. ACS Appl. Nano Mater. 2022, 5, 10686–10695. [Google Scholar] [CrossRef]

- Sheng, J.L.; Li, Y.; Wang, X.F.; Si, Y.; Yu, J.Y.; Ding, B. Thermal inter-fiber adhesion of the polyacrylonitrile/fluorinated polyurethane nanofibrous membranes with enhanced waterproof-breathable performance. Sep. Purif. Technol. 2016, 158, 53–61. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, Q.; Li, Z.; Li, J.; He, R.; Xue, K.; Liu, S. Preparation and modification of PVDF membrane and study on its anti-fouling and anti-wetting properties. Water 2022, 14, 1704. [Google Scholar] [CrossRef]

- Wang, J.Q.; Li, Y.; Tian, H.Y.; Sheng, J.L.; Yu, J.Y.; Ding, B. Waterproof and breathable membranes of waterborne fluorinated polyurethane modified electrospun polyacrylonitrile fibers. RSC Adv. 2014, 4, 61068–61076. [Google Scholar] [CrossRef]

- Mariussen, E. Neurotoxic effects of perfluoroalkylated compounds: Mechanisms of action and environmental relevance. Arch. Toxicol. 2012, 86, 1349–1367. [Google Scholar] [CrossRef] [PubMed]

- Bougourd, J.; McCann, J. Designing waterproof and water repellent clothing for wearer comfort—A paradigm shift. In Waterproof and Water Repellent Textiles and Clothing; Woodhead Publishing: Cambridge, UK, 2018; pp. 301–345. [Google Scholar]

- Webster, G. Potential human health effects of perfluorinated chemicals (PFCs). Blood 2010, 4, 1–10. [Google Scholar]

- Zhang, P.; Ren, G.H.; Tian, L.L.; Li, B.; Li, Z.Z.; Yu, H.Q.; Wang, R.W.; He, J.X. Environmentally friendly waterproof and breathable nanofiber membranes with thermal regulation performance by one-step electrospinning. Fiber. Polym. 2022, 23, 2139–2148. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, C.; Pan, Z. Porous bead-on-string poly (lactic acid) fibrous membranes for air filtration. J. Colloid Interface Sci. 2015, 441, 121–129. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Li, W.; Chen, D.; Yuan, J.; Lu, G.; Zhou, D. Microscopic mechanism of amino silicone oil modification and modification effect with different amino group contents based on molecular dynamics simulation. Appl. Surf. Sci. 2018, 440, 331–340. [Google Scholar] [CrossRef]

- Gao, C.; Jin, Y.Z.; Kong, H.; Whitby, R.; Acquah, S.; Chen, G.Y. Polyurea-functionalized multiwalled carbon nanotubes: Synthesis, morphology, and Raman spectroscopy. J. Phys. Chem. B 2005, 109, 11925–11932. [Google Scholar] [CrossRef] [Green Version]

- Pirzada, T.; Arvidson, S.A.; Saquing, C.D.; Shah, S.S.; Khan, S.A. Hybrid carbon silica nanofibers through sol-gel electrospinning. Langmuir 2014, 30, 15504–15513. [Google Scholar] [CrossRef]

- Liu, Y.H.; Xu, J.B.; Zhang, J.T.; Hu, J.M. Electrodeposited silica film interlayer for active corrosion protection. Corros. Sci. 2017, 120, 61–74. [Google Scholar] [CrossRef]

- Boros, R.Z.; Rágyanszki, A.; Csizmadia, I.G.; Fiser, B.; Guljas, A.; Farkas, L.; Viskolcz, B. Industrial application of molecular computations on the dimerization of methylene diphenyl diisocyanate. React. Kinet. Mech. Cat. 2018, 124, 1–14. [Google Scholar] [CrossRef]

- Pels, J.R.; Kapteijn, F.L.; Moulijn, J.A.; Zhu, Q.; Thomas, K.M. Evolution of nitrogen functionalities in carbonaceous materials during pyrolysis. Carbon 1995, 33, 1641–1653. [Google Scholar] [CrossRef]

- Takahagi, T.; Shimada, I.; Fukuhara, M.; Morita, K.; Ishitani, A. XPS studies on the chemical structure of the stabilized polyacrylonitrile fiber in the carbon fiber production process. J. Polym. Sci. Pol. Chem. 1986, 24, 3101–3107. [Google Scholar] [CrossRef]

- Tang, J.X.; He, N.Y.; Tan, M.J.; He, Q.G.; Chen, H. A novel substrate for in situ synthesis of oligonucleotide: Plasma-treated polypropylene microporous membrane. Colloid Surf. A 2004, 242, 53–60. [Google Scholar] [CrossRef]

- Iqbal, N.; Sharma, P.K.; Kumar, D.; Roy, P.K. Protective polyurea coatings for enhanced blast survivability of concrete. Constr. Build. Mater. 2018, 175, 682–690. [Google Scholar] [CrossRef]

| Samples | Atomic Percent (%) | |||

|---|---|---|---|---|

| C | O | N | Si | |

| PAN nanofibrous membranes | 75.31 | 3.55 | 21.13 | - |

| PAN@AMP-1 nanofibrous membranes | 52.38 | 23.48 | 2.16 | 21.98 |

| PAN@AMP-1/MDI-2 nanofibrous membranes | 54.27 | 22.34 | 3.51 | 19.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Sheng, J.; Yao, Y.; Yan, Z.; Zhai, Y.; Tang, Z.; Li, H. Fluorine-Free Hydrophobic Modification and Waterproof Breathable Properties of Electrospun Polyacrylonitrile Nanofibrous Membranes. Polymers 2022, 14, 5295. https://doi.org/10.3390/polym14235295

Zhang L, Sheng J, Yao Y, Yan Z, Zhai Y, Tang Z, Li H. Fluorine-Free Hydrophobic Modification and Waterproof Breathable Properties of Electrospun Polyacrylonitrile Nanofibrous Membranes. Polymers. 2022; 14(23):5295. https://doi.org/10.3390/polym14235295

Chicago/Turabian StyleZhang, Ling, Junlu Sheng, Yongbo Yao, Zhiyong Yan, Yunyun Zhai, Zhongfeng Tang, and Haidong Li. 2022. "Fluorine-Free Hydrophobic Modification and Waterproof Breathable Properties of Electrospun Polyacrylonitrile Nanofibrous Membranes" Polymers 14, no. 23: 5295. https://doi.org/10.3390/polym14235295