Tuning the Morphology of HDPE/PP/PET Ternary Blends by Nanoparticles: A Simple Way to Improve the Performance of Mixed Recycled Plastics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Blend Preparation

2.3. Experimental

3. Results

3.1. Morphology Prediction by Thermodynamic Calculations

3.2. Morphological Analyses

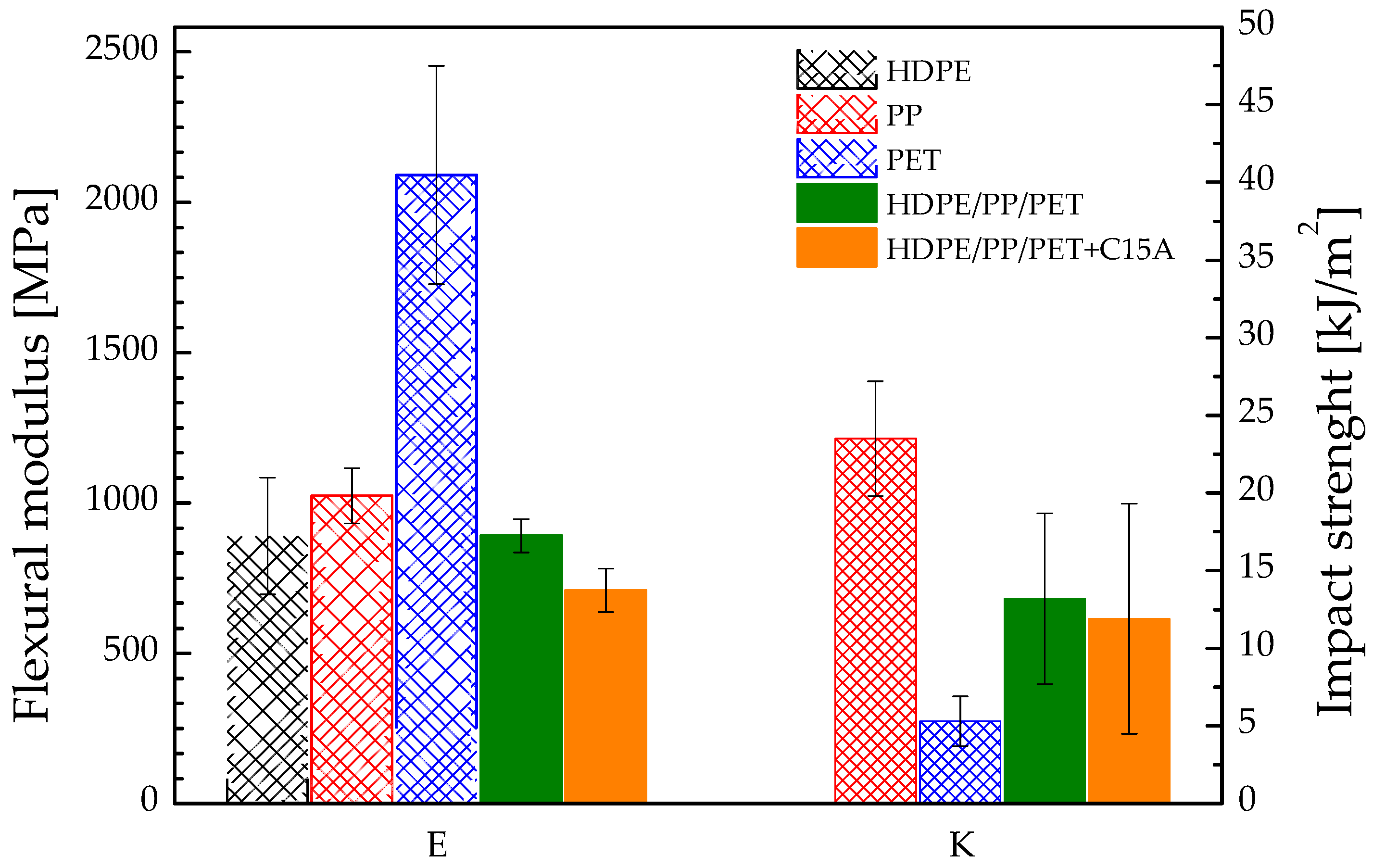

3.3. Mechanical Behavior at High Temperature: Flexural and Impact Strength

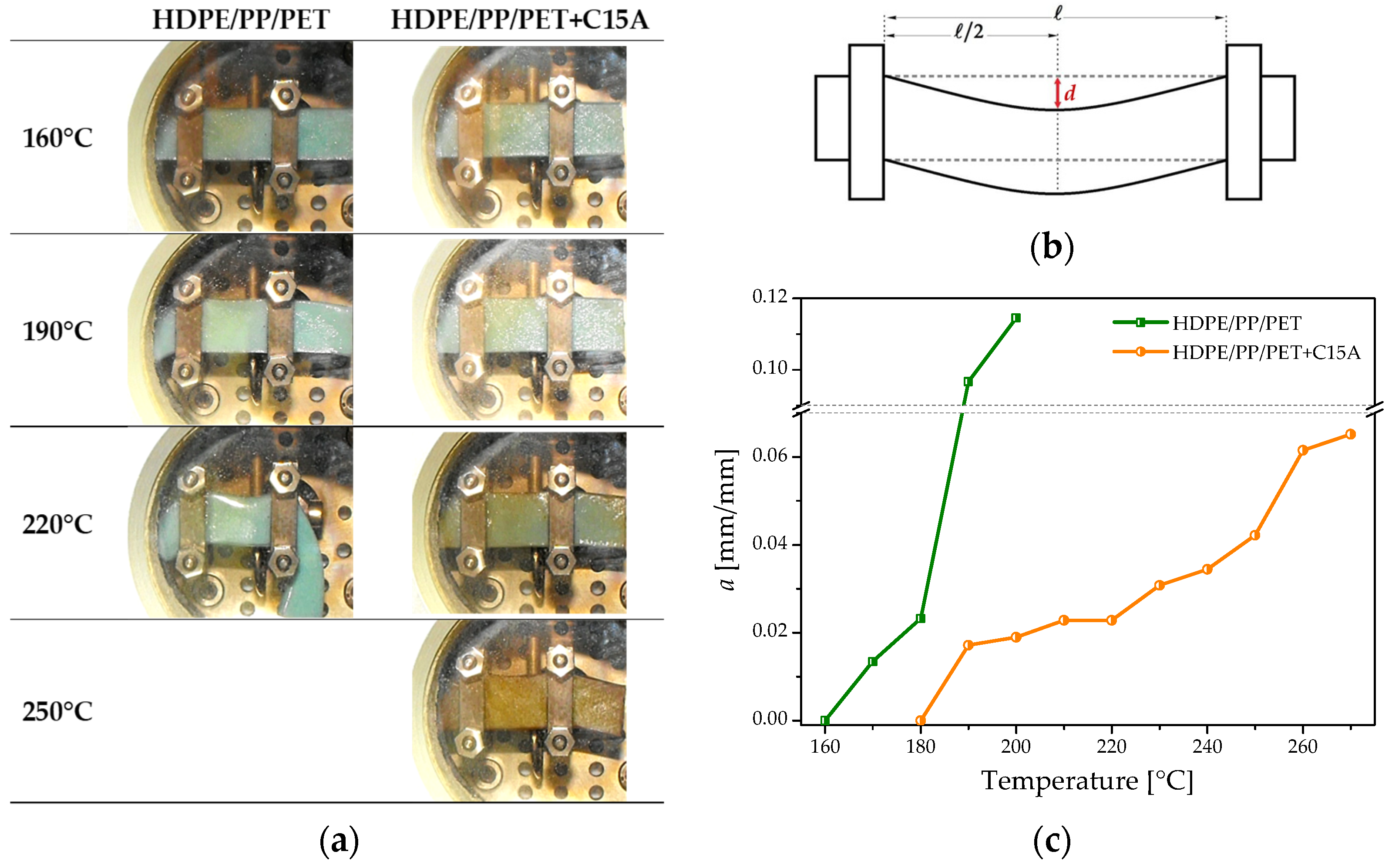

3.4. Mechanical Behavior at High Temperature: DMA Analyses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- -

- The number–average drop radius

- -

- The volume–average drop radius

- -

- The circularity of a drop of radius Ri, area Ai and perimeter Pi

- -

- The Rv/Rn ratio, called polydispersity, which is an index of the amplitude of the drop size distribution.

References

- Okan, M.; Aydin, H.M.; Barsbay, M. Current approaches to waste polymer utilization and minimization: A review. J. Chem. Technol. Biotechnol. 2019, 94, 8–21. [Google Scholar] [CrossRef] [Green Version]

- EUR-Lex–32019L0904—EN. Available online: https://eur-lex.europa.eu/eli/dir/2019/904/oj (accessed on 13 November 2022).

- Hundertmark, T.; Mayer, M.; McNally, C.; Simons, T.J.; Witte, C. How plastics waste recycling could transform the chemical industry. McKinsey Co. 2018, 12, 1–11. [Google Scholar]

- Vollmer, I.; Jenks, M.J.F.; Roelands, M.C.P.; White, R.J.; van Harmelen, T.; de Wild, P.; van der Laan, G.P.; Meirer, F.; Keurentjes, J.T.F.; Weckhuysen, B.M. Beyond mechanical recycling: Giving new life to plastic waste. Angew. Chem. Int. Ed. 2020, 59, 15402–15423. [Google Scholar] [CrossRef] [Green Version]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schyns, Z.O.; Shaver, M.P. Mechanical recycling of packaging plastics: A review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Christiansen, J.D.; Daugaard, A.E.; Astrup, T.F. Closing the loop for PET, PE and PP waste from households: Influence of material properties and product design for plastic recycling. Waste Manage. 2019, 96, 75–85. [Google Scholar] [CrossRef] [PubMed]

- Stein, R.S. Polymer recycling: Opportunities and limitations. Proc. Natl. Acad. Sci. USA 1992, 89, 835–838. [Google Scholar] [CrossRef] [Green Version]

- Maris, J.; Bourdon, S.; Brossard, J.M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Utracki, L.A. Compatibilization of polymer blends. Can. J. Chem. Eng. 2002, 80, 1008–1016. [Google Scholar] [CrossRef] [Green Version]

- WM2 Cleaning up the Waste Stream—Recycling Plastics | University of Missouri. Available online: https://extension.missouri.edu/publications/wm2 (accessed on 30 November 2022).

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Van Kets, K.; Delva, L.; Ragaert, K. Structural stabilizing effect of SEBSgMAH on a PP-PET blend for multiple mechanical recycling. Polym. Degrad. Stab. 2019, 166, 60–72. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.; Liu, G.; Pu, S. Core/shell morphologies in recycled poly (ethylene terephthalate)/linear low-density polyethylene/poly (styrene-b-(ethylene-co-butylene)-b-styrene) ternary blends. Polym. Bull. 2017, 74, 4223–4233. [Google Scholar] [CrossRef]

- Ouyang, Y.; Pourrahimi, A.M.; Lund, A.; Xu, X.; Gkourmpis, T.; Hagstrand, P.O.; Müller, C. High-temperature creep resistant ternary blends based on polyethylene and polypropylene for thermoplastic power cable insulation. J. Polym. Sci. 2021, 59, 1084–1094. [Google Scholar] [CrossRef]

- Pracella, M.; Chionna, D.; Pawlak, A.; Galeski, A. Reactive mixing of PET and PET/PP blends with glycidyl methacrylate–modified styrene-b-(ethylene-co-olefin) block copolymers. J. Appl. Polym. Sci. 2005, 98, 2201–2211. [Google Scholar] [CrossRef]

- Pracella, M.; Pazzagli, F.; Galeski, A. Reactive compatibilization and properties of recycled poly (ethylene terephthalate)/polyethylene blends. Polym. Bull. 2002, 48, 67–74. [Google Scholar] [CrossRef]

- Taghavi, S.K.; Shahrajabian, H.; Hosseini, H.M. Detailed comparison of compatibilizers MAPE and SEBS-g-MA on the mechanical/thermal properties, and morphology in ternary blend of recycled PET/HDPE/MAPE and recycled PET/HDPE/SEBS-g-MA. J. Elastomers Plast. 2018, 50, 13–35. [Google Scholar] [CrossRef]

- Dagli, S.S.; Kamdar, K.M. Effects of component addition protocol on the reactive compatibilization of HDPE/PET blends. Polym. Eng. Sci. 1994, 34, 1709–1719. [Google Scholar] [CrossRef]

- Taguet, A.; Cassagnau, P.; Lopez-Cuesta, J.M. Structuration, selective dispersion and compatibilizing effect of (nano) fillers in polymer blends. Prog. Polym. Sci. 2014, 39, 1526–1563. [Google Scholar] [CrossRef]

- Filippone, G.; Salzano de Luna, M.; Acierno, D.; Russo, P. Elasticity and structure of weak graphite nanoplatelet (GNP) networks in polymer matrices through viscoelastic analyses. Polymer 2012, 53, 2699–2704. [Google Scholar] [CrossRef]

- Acierno, D.; Filippone, G.; Romeo, G.; Russo, P. Rheological aspects of PP-TiO2 micro and nanocomposites: A preliminary investigation. Macromol. Symp. 2007, 247, 59–66. [Google Scholar] [CrossRef]

- Salzano de Luna, M.; Filippone, G. Effects of nanoparticles on the morphology of immiscible polymer blends–challenges and opportunities. Eur. Polym. J. 2016, 79, 198–218. [Google Scholar] [CrossRef]

- Filippone, G.; Causa, A.; de Luna, M.S.; Sanguigno, L.; Acierno, D. Assembly of plate-like nanoparticles in immiscible polymer blends–effect of the presence of a preferred liquid–liquid interface. Soft Matter 2014, 10, 3183–3191. [Google Scholar] [CrossRef] [PubMed]

- Filippone, G.; Romeo, G.; Acierno, D. Role of Interface Rheology in Altering the Onset of Co-Continuity in Nanoparticle-Filled Polymer Blends. Macromol. Mater. Eng. 2011, 296, 658–665. [Google Scholar] [CrossRef]

- Roosen, M.; Mys, N.; Kusenberg, M.; Billen, P.; Dumoulin, A.; Dewulf, J.; Van Geem, K.M.; Ragaert, K.; De Meester, S. Detailed analysis of the composition of selected plastic packaging waste products and its implications for mechanical and thermochemical recycling. Environ. Sci. Technol. 2020, 54, 13282–13293. [Google Scholar] [CrossRef]

- Wu, S. Calculation of interfacial tension in polymer systems. J. Polym. Sci. C Polym. Symp. 1971, 34, 19–30. [Google Scholar] [CrossRef]

- Reignier, J.; Favis, B.D. Core–shell structure and segregation effects in composite droplet polymer blends. AIChE J. 2003, 49, 1014–1023. [Google Scholar] [CrossRef]

- Nemirovski, N.; Siegmann, A.; Narkis, M. Morphology of ternary immiscible polymer blends. J. Macromol. Sci. B 1995, 34, 459–475. [Google Scholar] [CrossRef]

- Reignier, J.; Favis, B.D. Control of the subinclusion microstructure in HDPE/PS/PMMA ternary blends. Macromolecules 2000, 33, 6998–7008. [Google Scholar] [CrossRef]

- Hobbs, S.Y.; Dekkers, M.E.J.; Watkins, V.H. Effect of interfacial forces on polymer blend morphologies. Polymer 1988, 29, 1598–1602. [Google Scholar] [CrossRef]

- Harkins, W.D.; Feldman, A. Films. The spreading of liquids and the spreading coefficient. J. Am. Chem. Soc. 1922, 44, 2665–2685. [Google Scholar] [CrossRef]

- Le Corroller, P.; Favis, B.D. Droplet-in-Droplet Polymer Blend Microstructures: A Potential Route toward the Recycling of Co-mingled Plastics. Macromol. Chem. Phys. 2012, 213, 2062–2074. [Google Scholar] [CrossRef]

- Mostofi, N.; Nazockdast, H.; Mohammadigoushki, H. Study on morphology and viscoelastic properties of PP/PET/SEBS ternary blend and their fibers. J. Appl. Polym. Sci. 2009, 114, 3737–3743. [Google Scholar] [CrossRef]

- Abolhasani, M.M.; Arefazar, A.; Mozdianfard, M. Effect of dispersed phase composition on morphological and mechanical properties of PET/EVA/PP ternary blends. J. Polym. Sci. B Polym. Phys. 2010, 48, 251–259. [Google Scholar] [CrossRef]

- Kamal, M.R.; Calderon, J.U.; Lennox, B.R. Surface energy of modified nanoclays and its effect on polymer/clay nanocomposites. J. Adhes Sci. Technol. 2009, 23, 663–688. [Google Scholar] [CrossRef]

- Aglietto, M.; Coltelli, M.B.; Savi, S.; Lochiatto, F.; Ciardelli, F.; Giani, M. Postconsumer polyethylene terephthalate (PET)/polyolefin blends through reactive processing. J. Mater. Cycles Waste Manag. 2004, 6, 13–19. [Google Scholar]

- Altobelli, R.; Salzano De Luna, M.; Filippone, G. Interfacial crowding of nanoplatelets in co-continuous polymer blends: Assembly, elasticity and structure of the interfacial nanoparticle network. Soft Matter 2017, 13, 6465–6473. [Google Scholar] [CrossRef]

- Filippone, G.; Dintcheva, N.T.; La Mantia, F.P.; Acierno, D. Selective localization of organoclay and effects on the morphology and mechanical properties of LDPE/PA11 blends with distributed and co-continuous morphology. J. Polym. Sci. B Polym. Phys. 2010, 48, 600–609. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L. Spherulite growth rates in binary polymer blends. Prog. Polym. Sci. 2003, 28, 663–689. [Google Scholar] [CrossRef]

- Nor Arman, N.S.; Chen, R.S.; Ahmad, S.; Shahdan, D. Mechanical and physical characterizations of compatibilizer-free recycled plastics blend composites modified with carbon nanotube and clay nanofiller. J. Appl. Polym. Sci. 2022, 139, e52768. [Google Scholar] [CrossRef]

- Pötschke, P.; Paul, D.R. Formation of co-continuous structures in melt-mixed immiscible polymer blends. J. Macromol. Sci. Polym. Rev. 2003, 43, 87–141. [Google Scholar] [CrossRef]

| Sample | HDPE [wt.%] | PP [wt.%] | PET [wt.%] | C15A [phr] |

|---|---|---|---|---|

| HDPE/PP/PET | 37.5 | 37.5 | 25 | 0 |

| HDPE/PP/PET | 37.5 | 37.5 | 25 | 2 |

| −1.09 | |

| −10.20 | |

| −0.68 |

| −2.85 | |

| 1.08 | |

| −10.40 | |

| −10.61 | |

| −2.63 | |

| −0.27 | |

| −8.85 | |

| −0.47 | |

| −2.43 |

| −2.22 | |

| −0.60 | |

| −0.90 |

| Sample | Phase in the Blend | Tm [°C] | Tc [°C] | χ (%) |

|---|---|---|---|---|

| HDPE | 134.4 ± 1.2 | 117.1 ± 0.7 | 65.8 ± 1.8 | |

| PP | 164.4 ± 0. 9 | 117.9 ± 1.3 | 40.3 ± 2.4 | |

| PET | 250.9 ± 0.4 | 202.5 ± 5.0 | 28.9 ± 3.1 | |

| HDPE/PP/PET | HDPE | 133.4 ± 0.7 | 117.7 ± 1.2 | 66.1 ± 2.0 |

| PP | 162.9 ± 0.9 | 30.7 ± 1.1 | ||

| PET | 244.9 ± 1.5 | 202.4 ± 2.7 | 18.2 ± 1.8 | |

| HDPE/PP/PET+C15A | HDPE | 132.6 ± 0.5 | 114.6 ± 1.0 | 58.3 ± 3.9 |

| PP | 165.0 ± 1.0 | 29.0 ± 2.7 | ||

| PET | 252.1 ± 0.2 | 196.6 ± 1.2 | 21.2 ± 3.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marotta, A.; Causa, A.; Salzano de Luna, M.; Ambrogi, V.; Filippone, G. Tuning the Morphology of HDPE/PP/PET Ternary Blends by Nanoparticles: A Simple Way to Improve the Performance of Mixed Recycled Plastics. Polymers 2022, 14, 5390. https://doi.org/10.3390/polym14245390

Marotta A, Causa A, Salzano de Luna M, Ambrogi V, Filippone G. Tuning the Morphology of HDPE/PP/PET Ternary Blends by Nanoparticles: A Simple Way to Improve the Performance of Mixed Recycled Plastics. Polymers. 2022; 14(24):5390. https://doi.org/10.3390/polym14245390

Chicago/Turabian StyleMarotta, Angela, Andrea Causa, Martina Salzano de Luna, Veronica Ambrogi, and Giovanni Filippone. 2022. "Tuning the Morphology of HDPE/PP/PET Ternary Blends by Nanoparticles: A Simple Way to Improve the Performance of Mixed Recycled Plastics" Polymers 14, no. 24: 5390. https://doi.org/10.3390/polym14245390

APA StyleMarotta, A., Causa, A., Salzano de Luna, M., Ambrogi, V., & Filippone, G. (2022). Tuning the Morphology of HDPE/PP/PET Ternary Blends by Nanoparticles: A Simple Way to Improve the Performance of Mixed Recycled Plastics. Polymers, 14(24), 5390. https://doi.org/10.3390/polym14245390