Glutaraldehyde Crosslinked High Content of Amylose/Polyvinyl Alcohol Blend Films with Potent Tensile Strength and Young’s Modulus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Amylose/PVA Blend Films

2.3. Cross-Linking Degree

2.4. Fourier Transform Infrared Spectroscopy (FTIR)

2.5. Crystallinity

2.6. Water Vapor Sorption Isotherm

2.7. Mechanical Properties

2.8. Morphology Observation

2.9. Statistical Analysis

3. Results and Discussion

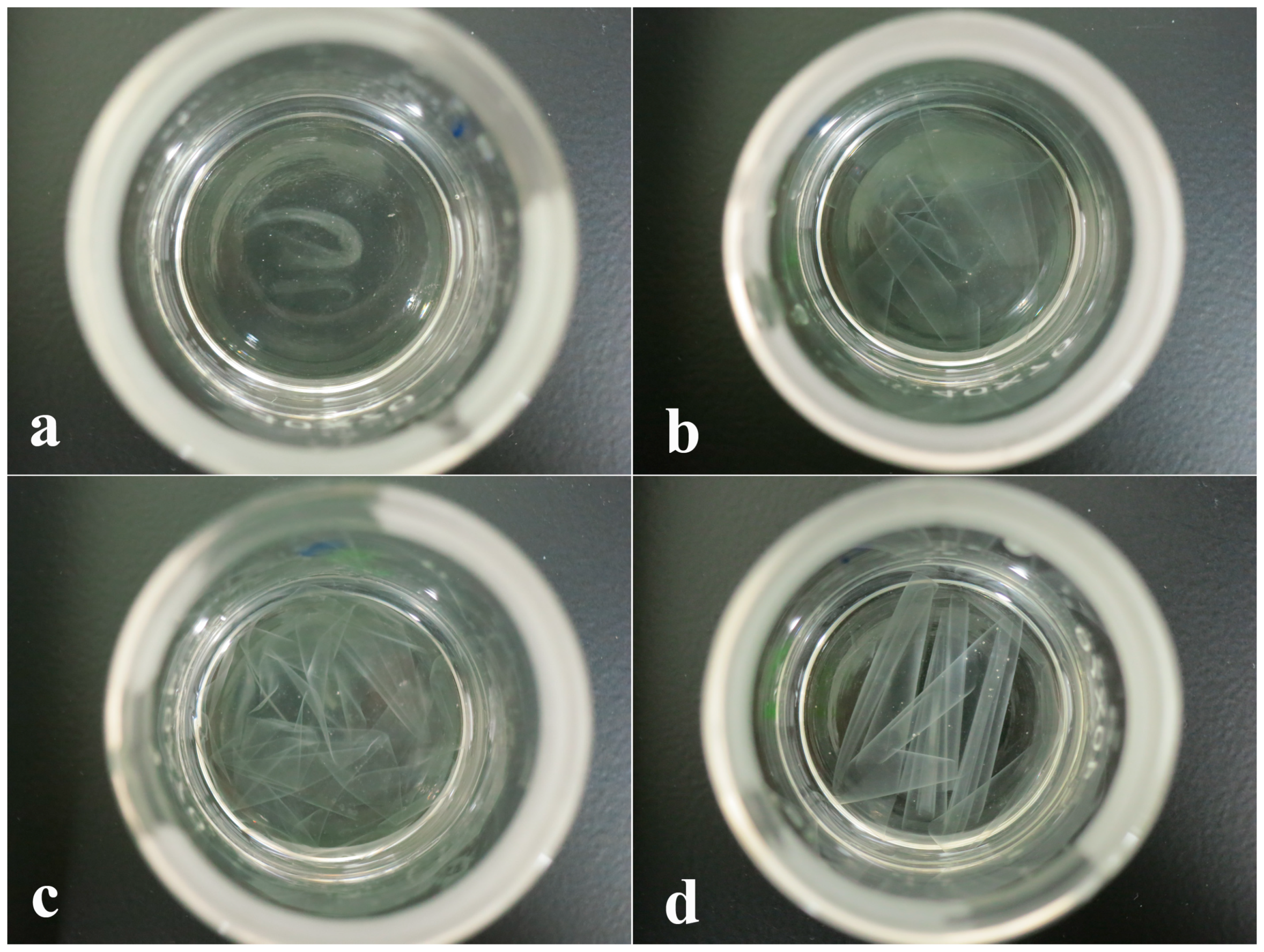

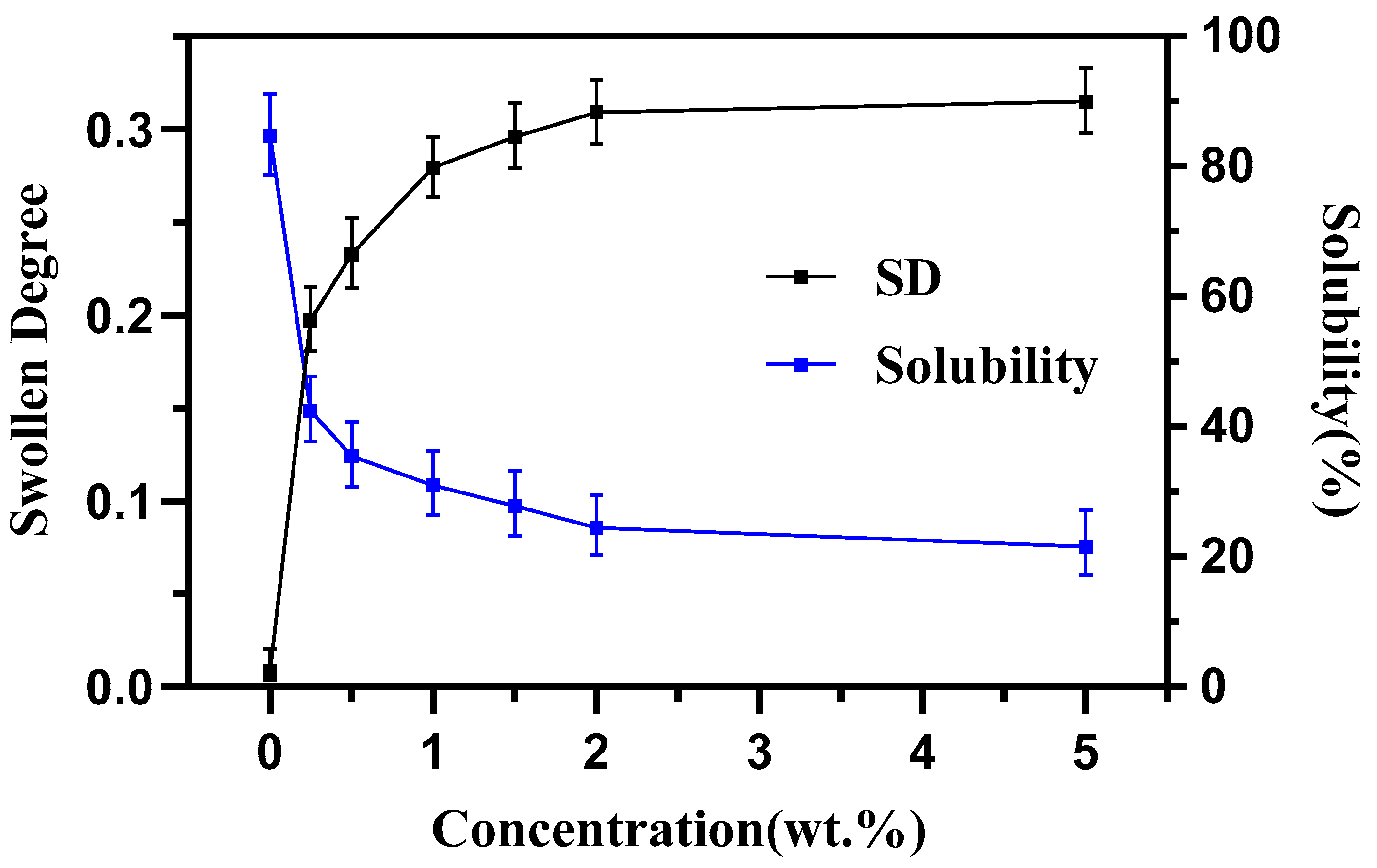

3.1. Cross-Linking Degree

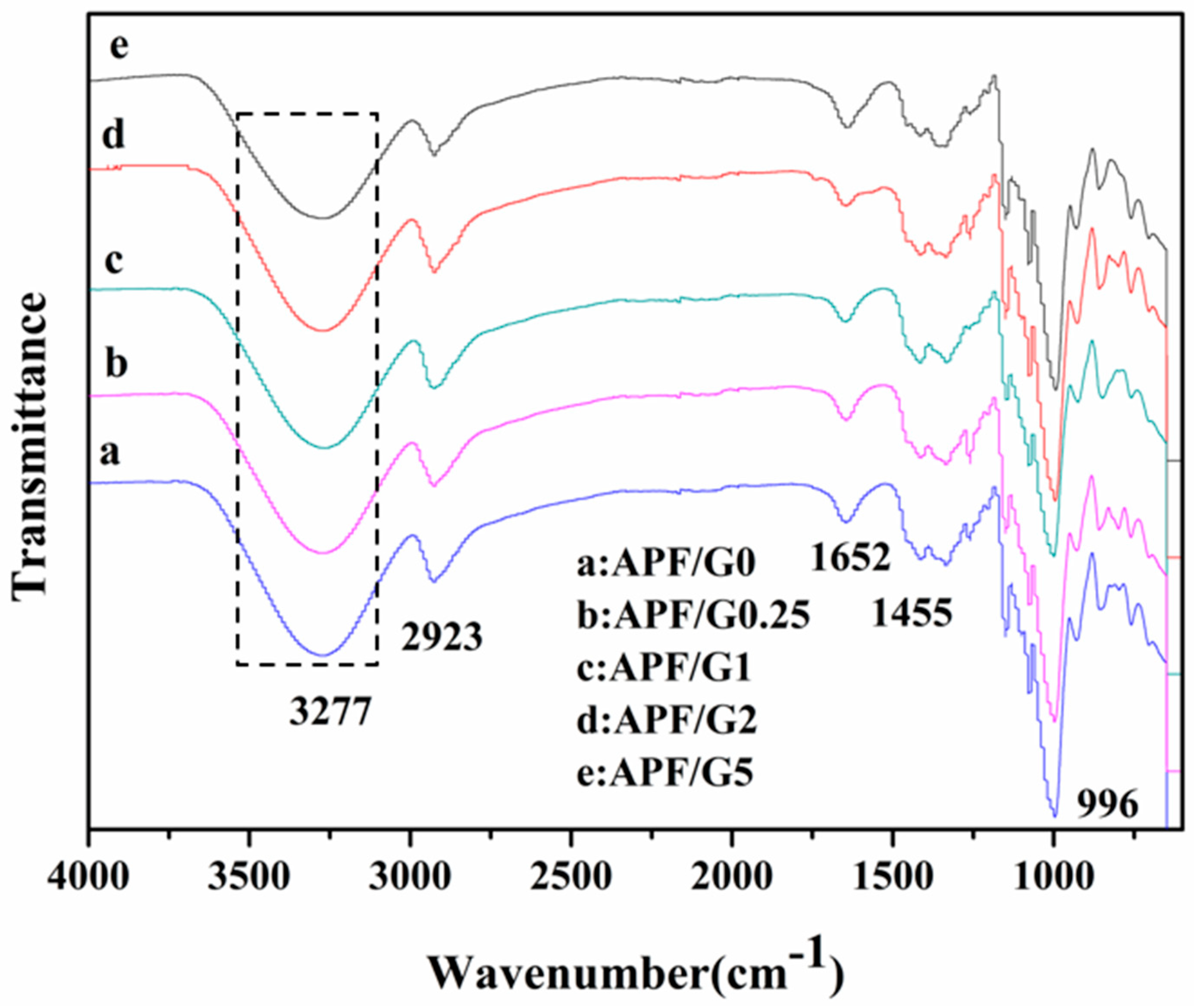

3.2. FTIR Analysis

3.3. Wide-Angle X-ray Scattering (WAXS) and the Film’s Crystallinity

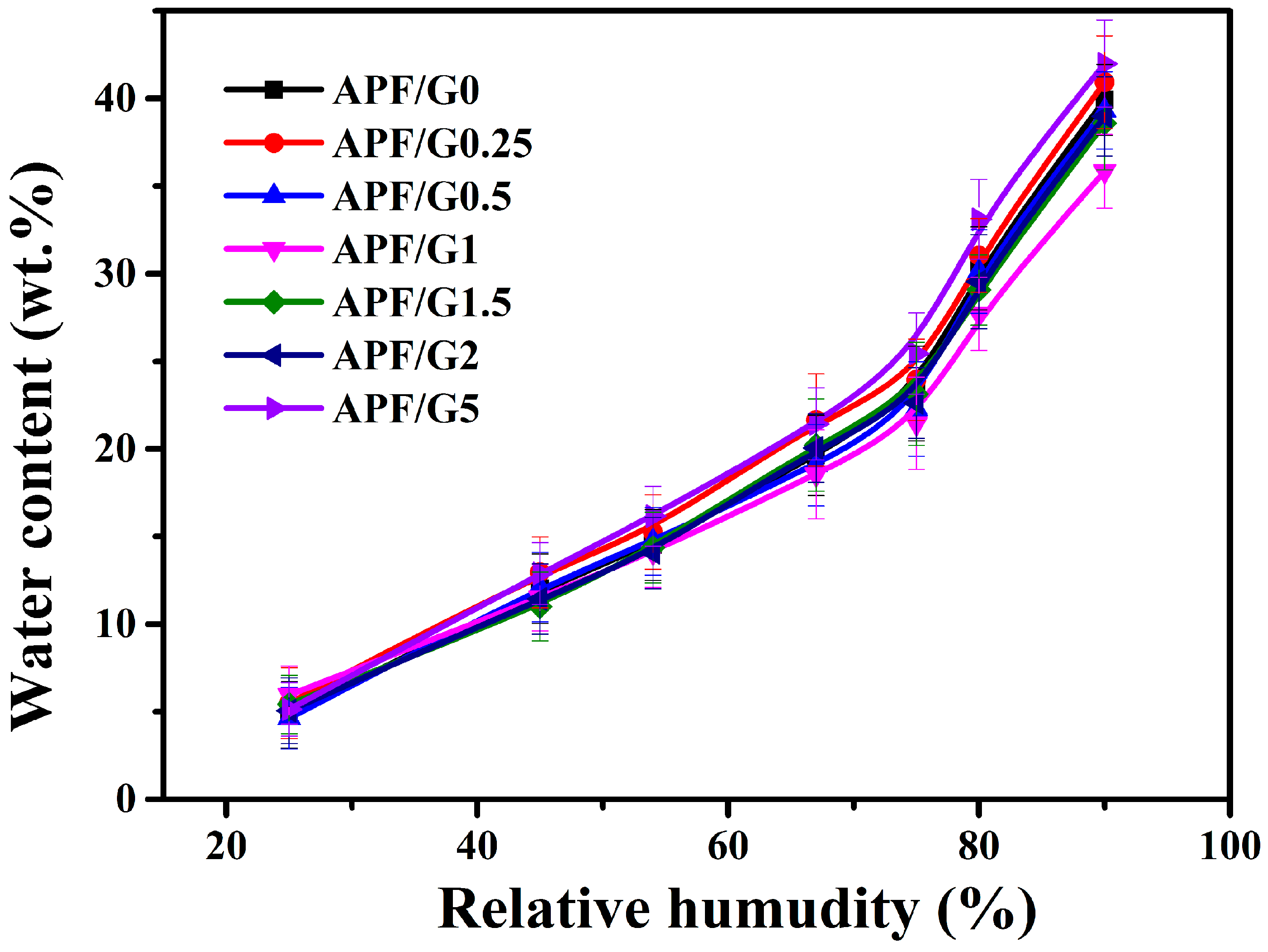

3.4. Moisture Sorption Property

3.5. Mechanical Properties

3.6. Section Microstructure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tongdeesoontorn, W.; Mauer, L.J.; Wongruong, S.; Sriburi, P.; Rachtanapun, P. Mechanical and Physical Properties of Cassava Starch-Gelatin Composite Films. Int. J. Polym. Mater. 2012, 61, 778–792. [Google Scholar] [CrossRef]

- Lawton, J. Effect of starch type on the properties of starch containing films. Carbohydr. Polym. 1996, 29, 203–208. [Google Scholar] [CrossRef]

- Rindlav-Westling, Å.; Stading, M.; Gatenholm, P. Crystallinity and morphology in films of starch, amylose and amylopectin blends. Biomacromolecules 2002, 3, 84–91. [Google Scholar] [CrossRef] [PubMed]

- De Almeida, F.C.; de Souza, C.O.; Philadelpho, B.O.; Lemos, P.V.F.; Cardoso, L.G.; Santana, J.S.; da Silva, J.B.A.; Correia, P.R.C.; Camilloto, G.P.; Ferreira, E.D.; et al. Combined effect of cassava starch nanoparticles and protein isolate in properties of starch-based nanocomposite films. J. Appl. Polym. Sci. 2021, 138, 50008. [Google Scholar] [CrossRef]

- Fredriksson, H.; Silverio, J.; Andersson, R.; Eliasson, A.-C.; Åman, P. The influence of amylose and amylopectin characteristics on gelatinization and retrogradation properties of different starches. Carbohydr. Polym. 1998, 35, 119–134. [Google Scholar] [CrossRef]

- Lourdin, D.; Valle, G.D.; Colonna, P. Influence of amylose content on starch films and foams. Carbohydr. Polym. 1995, 27, 261–270. [Google Scholar] [CrossRef]

- Tran, P.L.; Lee, J.S.; Park, K.H. Molecular structure and rheological character of high-amylose water caltrop (Trapa bispinosa Roxb.) starch. Food Sci. Biotechnol. 2013, 22, 979–985. [Google Scholar] [CrossRef]

- Martinez-Cano, A.; Mendoza-Baez, R.; Zenteno-Mateo, B.; Rodriguez-Mora, J.I.; Agustin-Serrano, R.; Morales, M.A. Study by DFT of the functionalization of amylose/amylopectin with glycerin monoacetate: Characterization by FTIR, electronic and adsorption properties. J. Mol. Struct. 2022, 1269, 133761. [Google Scholar] [CrossRef]

- Muscat, D.; Adhikari, B.; Adhikari, R.; Chaudhary, D.S. Comparative study of film forming behaviour of low and high amylose starches using glycerol and xylitol as plasticizers. J. Food Eng. 2012, 109, 189–201. [Google Scholar] [CrossRef]

- Yun, Y.H.; Yoon, S.D. Effect of amylose contents of starches on physical properties and biodegradability of starch/PVA-blended films. Polym. Bull. 2010, 64, 553–568. [Google Scholar] [CrossRef]

- Sudheesh, C.; Valiyapeediyekkal Sunooj, K.; Aaliya, B.; Navaf, M.; Parambil Akhila, P.; Ahmad Mir, S.; Sabu, S.; Sasidharan, A.; Pulissery Sudheer, K.; Kumar Sinha, S.; et al. Effect of energetic neutrals on the kithul starch retrogradation; Potential utilization for improving mechanical and barrier properties of films. Food Chem. 2023, 398, 133881. [Google Scholar] [CrossRef]

- Yoon, S.D.; Chough, S.H.; Park, H.R. Preparation of resistant starch/poly(vinyl alcohol) blend films with added plasticizer and crosslinking agents. J. Appl. Polym. Sci. 2007, 106, 2485–2493. [Google Scholar] [CrossRef]

- Dastidar, T.G.; Netravali, A.N. ‘Green’crosslinking of native starches with malonic acid and their properties. Carbohydr. Polym. 2012, 90, 1620–1628. [Google Scholar] [CrossRef]

- Das, K.; Ray, D.; Bandyopadhyay, N.; Gupta, A.; Sengupta, S.; Sahoo, S.; Mohanty, A.; Misra, M. Preparation and characterization of cross-linked starch/poly (vinyl alcohol) green films with low moisture absorption. Ind. Eng. Chem. Res. 2010, 49, 2176–2185. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, M.; Bai, X.; Dong, X.; Tong, J.; Zhou, J. Effect of postcrosslinking modification with glutaraldehyde on the properties of thermoplastic starch/poly (vinyl alcohol) blend films. J. Appl. Polym. Sci. 2012, 124, 3774–3781. [Google Scholar] [CrossRef]

- Ramaraj, B. Crosslinked poly (vinyl alcohol) and starch composite films: Study of their physicomechanical, thermal, and swelling properties. J. Appl. Polym. Sci. 2007, 103, 1127–1132. [Google Scholar] [CrossRef]

- Le Bail, P.; Morin, F.G.; Marchessault, R.H. Characterization of a crosslinked high amylose starch excipient. Int. J. Biol. Macromol. 1999, 26, 193–200. [Google Scholar] [CrossRef]

- Shiftan, D.; Ravenelle, F.; Mateescu, M.A.; Marchessault, R.H. Change in the V/B polymorph ratio and T-1 relaxation of epichlorohydrin crosslinked high amylose starch excipient. Starch-Starke 2000, 52, 186–195. [Google Scholar] [CrossRef]

- Yun, Y.-H.; Wee, Y.-J.; Byun, H.-S.; Yoon, S.-D. Biodegradability of chemically modified starch (RS4)/PVA blend films: Part 2. J. Polym. Environ. 2008, 16, 12–18. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Citric acid cross-linking of starch films. Food Chem. 2010, 118, 702–711. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Dong, Y.; Men, H.; Jiang, M.; Tong, J.; Zhou, J. Post-crosslinking modification of thermoplastic starch/PVA blend films by using sodium hexametaphosphate. Carbohydr. Polym. 2012, 89, 473–477. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Imam, S.H.; Gordon, S.H.; Greene, R.V. Starch-polyvinyl alcohol crosslinked film—Performance and biodegradation. J. Environ. Polym. Degrad. 1997, 5, 111–117. [Google Scholar] [CrossRef]

- Park, H.-R.; Chough, S.-H.; Yun, Y.-H.; Yoon, S.-D. Properties of starch/PVA blend films containing citric acid as additive. J. Polym. Environ. 2005, 13, 375–382. [Google Scholar] [CrossRef]

- Ou, X. Environment-Friendly Degradable Mulching Film Comprises High Amylose Starch, Wheat Starch, Polyvinyl Alcohol, Plasticizer and Glycerol. CN 106279782-A, 10 August 2016. [Google Scholar]

- Wolff, I.A.; Davis, H.; Cluskey, J.; Gundrum, L.; Rist, C.E. Preparation of films from amylose. Ind. Eng. Chem. 1951, 43, 915–919. [Google Scholar] [CrossRef]

- Vorwerg, W.; Radosta, S.; Leibnitz, E. Study of a preparative-scale process for the production of amylose. Carbohydr. Polym. 2002, 47, 181–189. [Google Scholar] [CrossRef]

- Delville, J.; Joly, C.; Dole, P.; Bliard, C. Solid state photocrosslinked starch based films: A new family of homogeneous modified starches. Carbohydr. Polym. 2002, 49, 71–81. [Google Scholar] [CrossRef]

- Nara, S.; Komiya, T. Studies on the Relationship Between Water-satured State and Crystallinity by the Diffraction Method for Moistened Potato Starch. Starch-Stärke 1983, 35, 407–410. [Google Scholar] [CrossRef]

- Nara, S.; Mori, A.; Komiya, T. Study on relative crystallinity of moist potato starch. Starch-Stärke 1978, 30, 111–114. [Google Scholar] [CrossRef]

- Rioux, B.; Ispas-Szabo, P.; Aït-Kadi, A.; Mateescu, M.-A.; Juhász, J. Structure–properties relationship in cross-linked high amylose starch cast films. Carbohydr. Polym. 2002, 50, 371–378. [Google Scholar] [CrossRef]

- Buleon, A.; Veronese, G.; Putaux, J.-L. Self-association and crystallization of amylose. Aust. J. Chem. 2007, 60, 706–718. [Google Scholar] [CrossRef]

- Moulay, S. Review: Poly(vinyl alcohol) Functionalizations and Applications. Polym.-Plast. Technol. Eng. 2015, 54, 1289–1319. [Google Scholar] [CrossRef]

- Zidan, H.M.; Abdelrazek, E.M.; Abdelghany, A.M.; Tarabiah, A.E. Characterization and some physical studies of PVA/PVP filled with MWCNTs. J. Mater. Res. Technol. 2019, 8, 904–913. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Guan, L.; Wang, S.; Zhang, J.; Tan, L.; Kong, L.; Zhang, H. Lipophilization and amylose inclusion complexation enhance the stability and release of catechin. Carbohydr. Polym. 2021, 269, 118251. [Google Scholar] [CrossRef]

- Shafiq, M.; Butt, M.T.Z.; Khan, S.M. Synthesis of diethylene glycol-based aliphatic polyester polyol and effect of glycerin crosslinker on its properties. J. Polym. Res. 2022, 29, 401. [Google Scholar] [CrossRef]

- Panda, P.K.; Dash, P.; Biswal, A.K.; Chang, Y.-H.; Misra, P.K.; Yang, J.-M. Synthesis and Characterization of Modified Poly(vinyl alcohol) Membrane and Study of Its Enhanced Water-Induced Shape-Memory Behavior. J. Polym. Environ. 2022, 30, 3409–3419. [Google Scholar] [CrossRef]

- Rindlav-Westling, A.S.; Stading, M.; Hermansson, A.-M.; Gatenholm, P. Structure, mechanical and barrier properties of amylose and amylopectin films. Carbohydr. Polym. 1998, 36, 217–224. [Google Scholar] [CrossRef]

- Myllärinen, P.; Buleon, A.; Lahtinen, R.; Forssell, P. The crystallinity of amylose and amylopectin films. Carbohydr. Polym. 2002, 48, 41–48. [Google Scholar] [CrossRef]

- Godbillot, L.; Dole, P.; Joly, C.; Rogé, B.; Mathlouthi, M. Analysis of water binding in starch plasticized films. Food Chem. 2006, 96, 380–386. [Google Scholar] [CrossRef]

- Cao, P.P.; Wu, G.S.; Yao, Z.J.; Wang, Z.H.; Li, E.P.; Yu, S.Y.; Liu, Q.Q.; Gilbert, R.G.; Li, S.N. Effects of amylose and amylopectin molecular structures on starch electrospinning. Carbohydr. Polym. 2022, 296, 119959. [Google Scholar] [CrossRef]

- Mali, S.; Sakanaka, L.S.; Yamashita, F.; Grossmann, M.V.E. Water sorption and mechanical properties of cassava starch films and their relation to plasticizing effect. Carbohydr. Polym. 2005, 60, 283–289. [Google Scholar] [CrossRef]

- Yun, Y.-H.; Kim, E.-S.; Shim, W.-G.; Yoon, S.-D. Physical properties of mungbean starch/PVA bionanocomposites added nano-ZnS particles and its photocatalytic activity. J. Ind. Eng. Chem. 2018, 68, 57–68. [Google Scholar] [CrossRef]

| Samples | Amylose (wt %) | PVA (wt %) | Glycerol (wt %) | GLU (wt %) |

|---|---|---|---|---|

| APF/G0 | 71.40 | 14.30 | 14.30 | 0 |

| APF/G0.25 | 71.40 | 14.30 | 14.30 | 0.25 |

| APF/G0.5 | 71.40 | 14.30 | 14.30 | 0.50 |

| APF/G1 | 71.40 | 14.30 | 14.30 | 1.00 |

| APF/G1.5 | 71.40 | 14.30 | 14.30 | 1.50 |

| APF/G2 | 71.40 | 14.30 | 14.30 | 2.00 |

| APF/G5 | 71.40 | 14.30 | 14.30 | 5.00 |

| AF | 83.31 | 0 | 16.70 | 0 |

| Samples | SD | Solubility (%) | Immersion for 1 h |

|---|---|---|---|

| APF/G0 | 0.02 | 83.71 | Almost completely dissolved |

| APF/G0.25 | 0.20 | 42.19 | Partly dissolved |

| APF/G0.5 | 0.24 | 33.69 | Partly dissolved |

| APF/G1 | 0.28 | 29.33 | Minimally dissolved |

| APF/G1.5 | 0.29 | 25.81 | Minimally dissolved |

| APF/G2 | 0.30 | 23.73 | Minimally dissolved |

| APF/G5 | 0.31 | 21.30 | Minimally dissolved |

| Samples | Relative Crystallinity Degree (%) |

|---|---|

| AF | 14.1 |

| APF/G0 | 31.0 |

| APF/G0.25 | 29.7 |

| APF/G0.5 | 28.6 |

| APF/G1 | 27.8 |

| APF/G1.5 | 23.1 |

| APF/G2 | 15.6 |

| APF/G5 | 9.74 |

| PVA | 41.5 |

| Mechanical Properties | RH (%) | Samples | ||||||

| APF/G0 | APF/G 0.25 | APF/G 0.5 | APF/G 1 | APF/G 1.5 | APF/G 2 | APF/G 5 | ||

| Tensile strength (MPa) | 25 | 45.28 ± 2.86 | 64.40 ± 5.37 | 67.03 ± 8.20 | 63.29 ± 4.32 | 61.15 ± 4.37 | 59.28 ± 3.97 | 57.20 ±3.91 |

| 50 | 23.70 ± 1.54 | 31.28 ± 2.54 | 33.57 ± 4.34 | 30.58 ± 2.49 | 28.02 ± 2.42 | 27.83 ±1.98 | 27.25 ±1.40 | |

| 90 | 4.13 ± 2.86 | 7.64 ± 4.87 | 8.88 ± 2.72 | 6.69 ± 3.77 | 5.41 ± 5.10 | 4.93 ± 1.09 | 4.53 ± 1.19 | |

| Young’s modulus (MPa) | 25 | 10.90 ± 1.14 | 17.39 ± 1.24 | 16.66 ± 1.34 | 16.05 ± 1.29 | 15.76 ± 1.13 | 15.85 ± 0.79 | 14.73 ± 1.41 |

| 50 | 4.09 ± 0.44 | 5.08 ± 0.84 | 4.82 ± 1.24 | 4.37 ± 0.75 | 4.49 ± 0.82 | 4.49 ± 0.59 | 4.33 ± 0.68 | |

| 90 | 0.29 ± 0.04 | 0.96 ± 0.04 | 0.94 ± 0.05 | 0.75 ± 0.03 | 0.71 ± 0.03 | 0.61 ± 0.04 | 0.52 ± 0.04 | |

| Elongation at break (%) | 25 | 31.84 ± 4.21 | 5.77 ± 1.8 | 11.24 ± 2.87 | 13.43 ±3.28 | 18.81 ± 4.87 | 14.77 ± 3.03 | 7.11 ± 2.34 |

| 50 | 98.34 ± 8.23 | 74.52 ± 3.87 | 77.45 ± 5.77 | 68.52 ± 3.68 | 67.17 ± 3.27 | 65.80 ± 4.51 | 58.69 ± 3.79 | |

| 90 | 76.44 ± 6.37 | 55.45 ± 6.36 | 62.95 ± 8.36 | 53.25 ± 3.07 | 49.59 ± 2.68 | 41.47 ± 2.55 | 25.92 ± 2.17 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Huang, Z.; Niu, Z.; Chen, F.; Liu, C. Glutaraldehyde Crosslinked High Content of Amylose/Polyvinyl Alcohol Blend Films with Potent Tensile Strength and Young’s Modulus. Polymers 2022, 14, 5550. https://doi.org/10.3390/polym14245550

Wang X, Huang Z, Niu Z, Chen F, Liu C. Glutaraldehyde Crosslinked High Content of Amylose/Polyvinyl Alcohol Blend Films with Potent Tensile Strength and Young’s Modulus. Polymers. 2022; 14(24):5550. https://doi.org/10.3390/polym14245550

Chicago/Turabian StyleWang, Xinqing, Zhenhua Huang, Zhaoyang Niu, Fangping Chen, and Changsheng Liu. 2022. "Glutaraldehyde Crosslinked High Content of Amylose/Polyvinyl Alcohol Blend Films with Potent Tensile Strength and Young’s Modulus" Polymers 14, no. 24: 5550. https://doi.org/10.3390/polym14245550

APA StyleWang, X., Huang, Z., Niu, Z., Chen, F., & Liu, C. (2022). Glutaraldehyde Crosslinked High Content of Amylose/Polyvinyl Alcohol Blend Films with Potent Tensile Strength and Young’s Modulus. Polymers, 14(24), 5550. https://doi.org/10.3390/polym14245550