A Study of the Flexural Properties of PA12/Clay Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Design of Experiment

2.3. Preparation of Specimens

2.4. Morphological and Structural Characterization

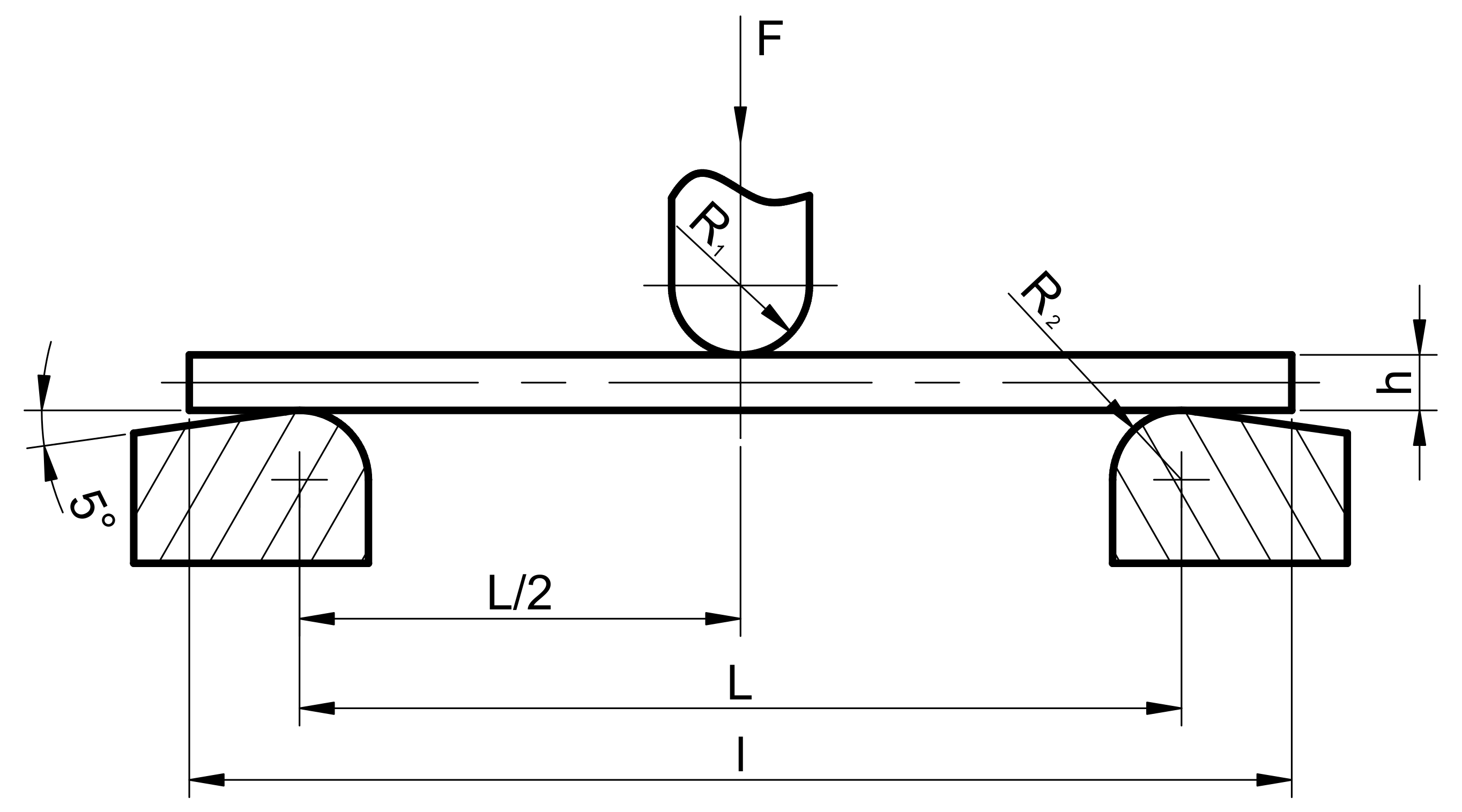

2.5. Determination of Flexural Properties of PA12/Clay Nanocomposites

3. Results and Discussion

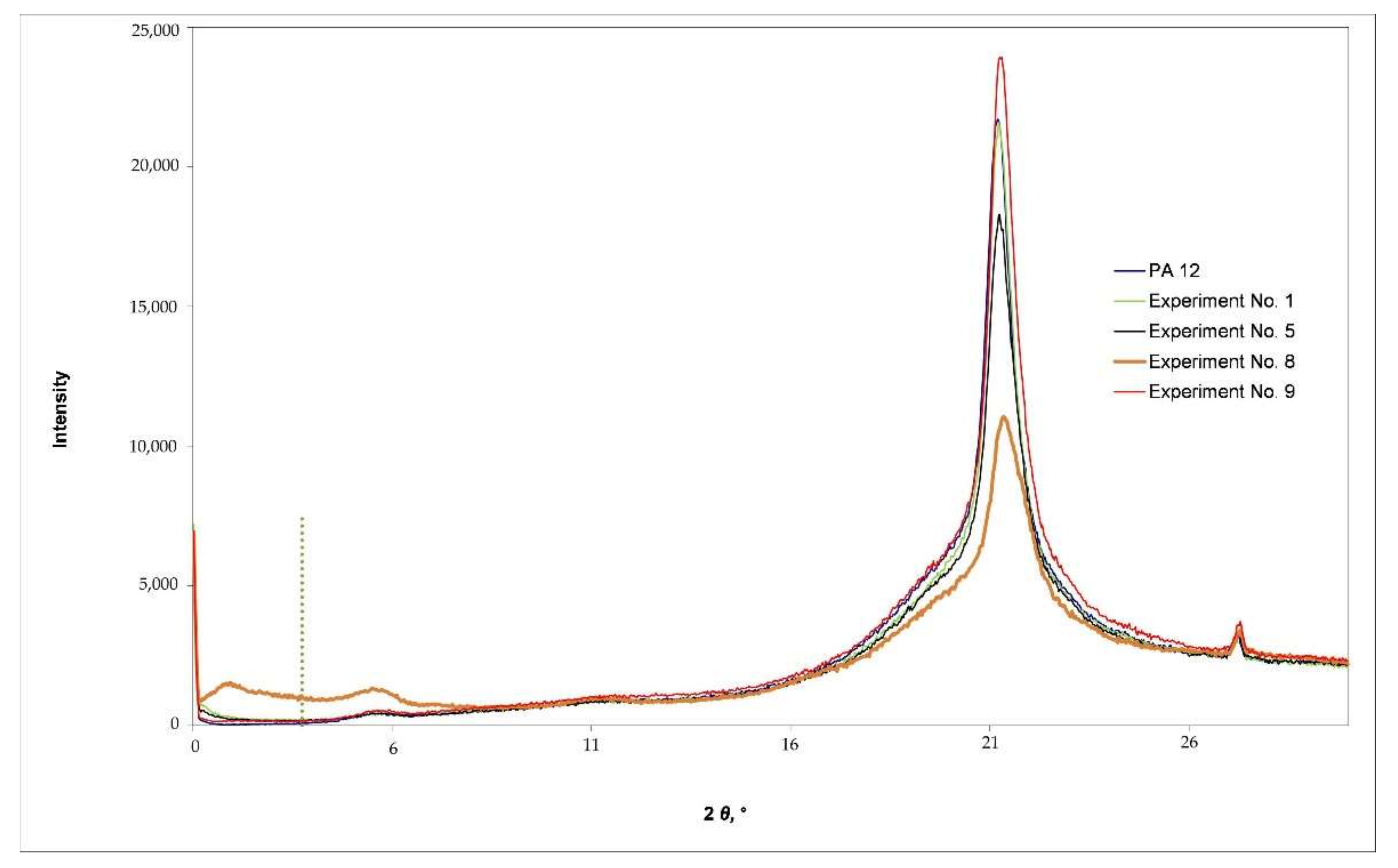

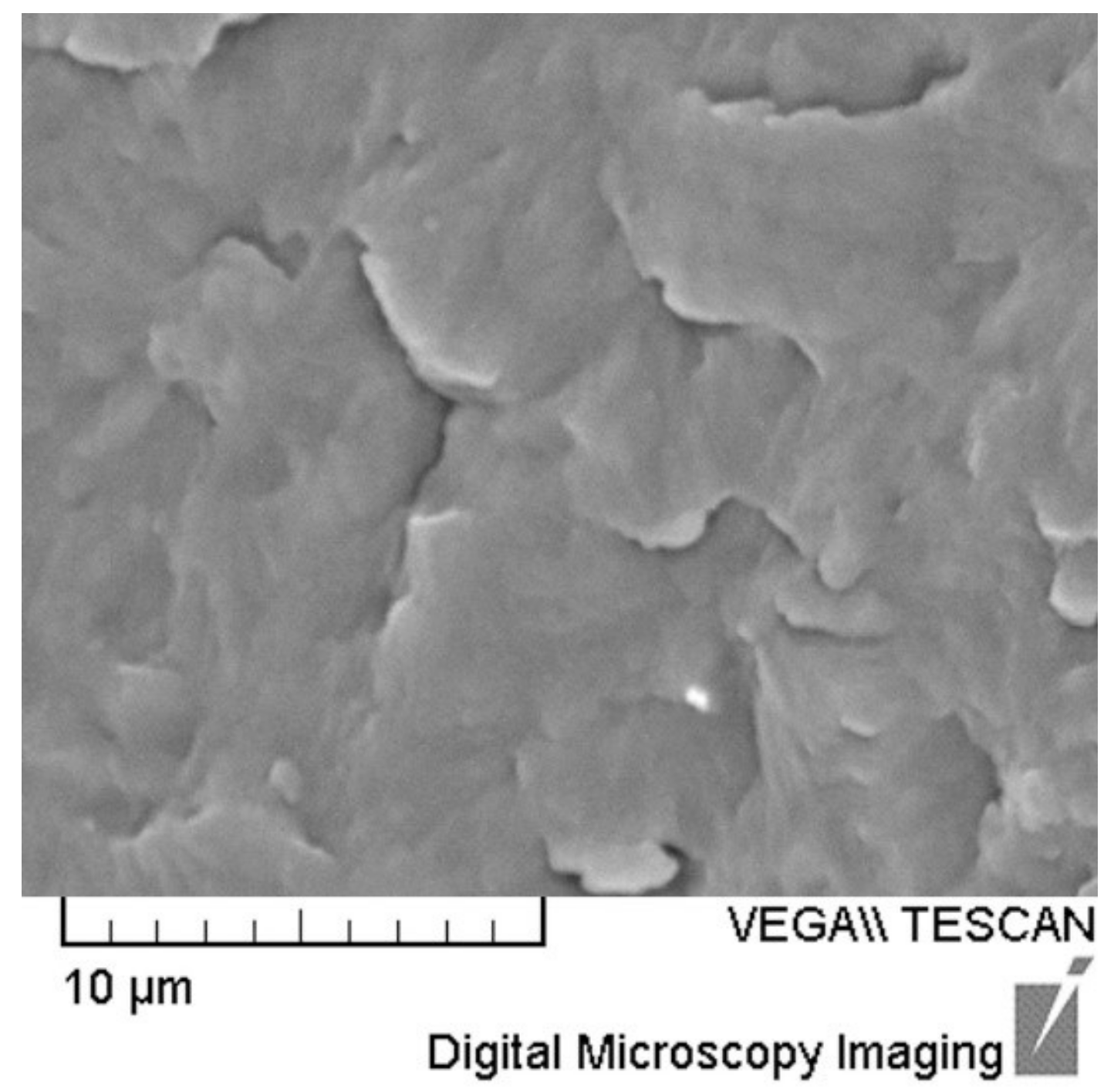

3.1. Characterization of Nanocomposite Structure

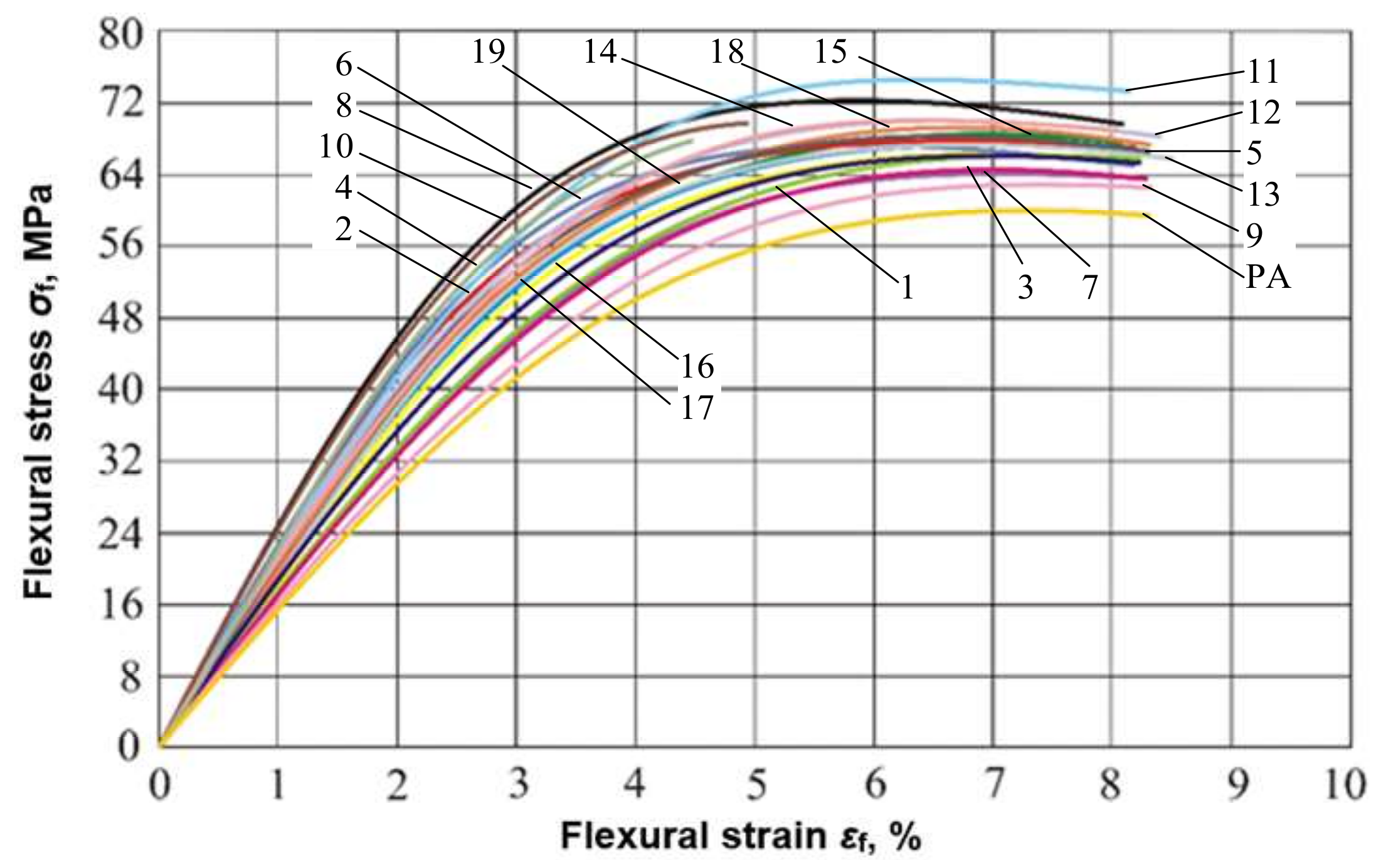

3.2. Flexural Properties of PA12/Clay Nanocomposites

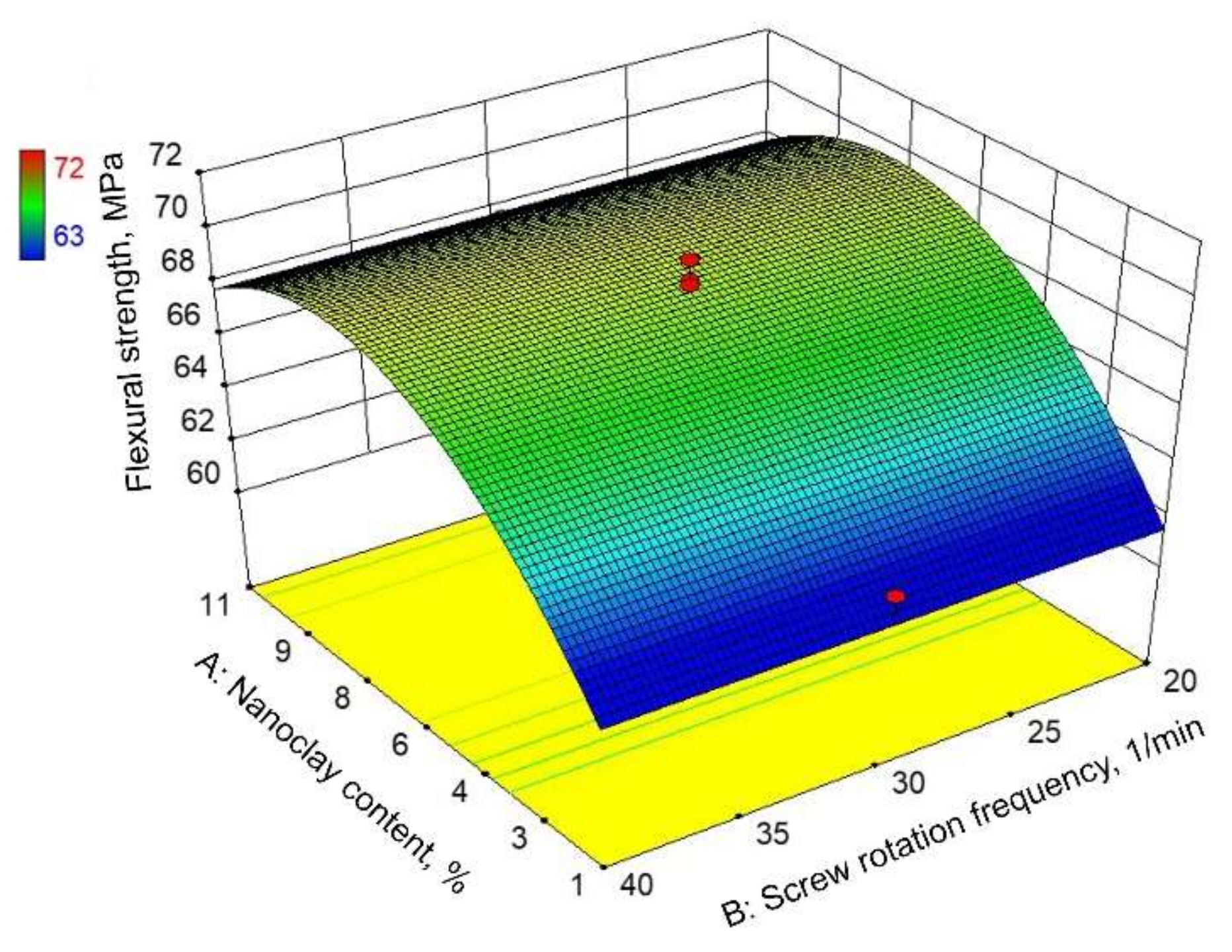

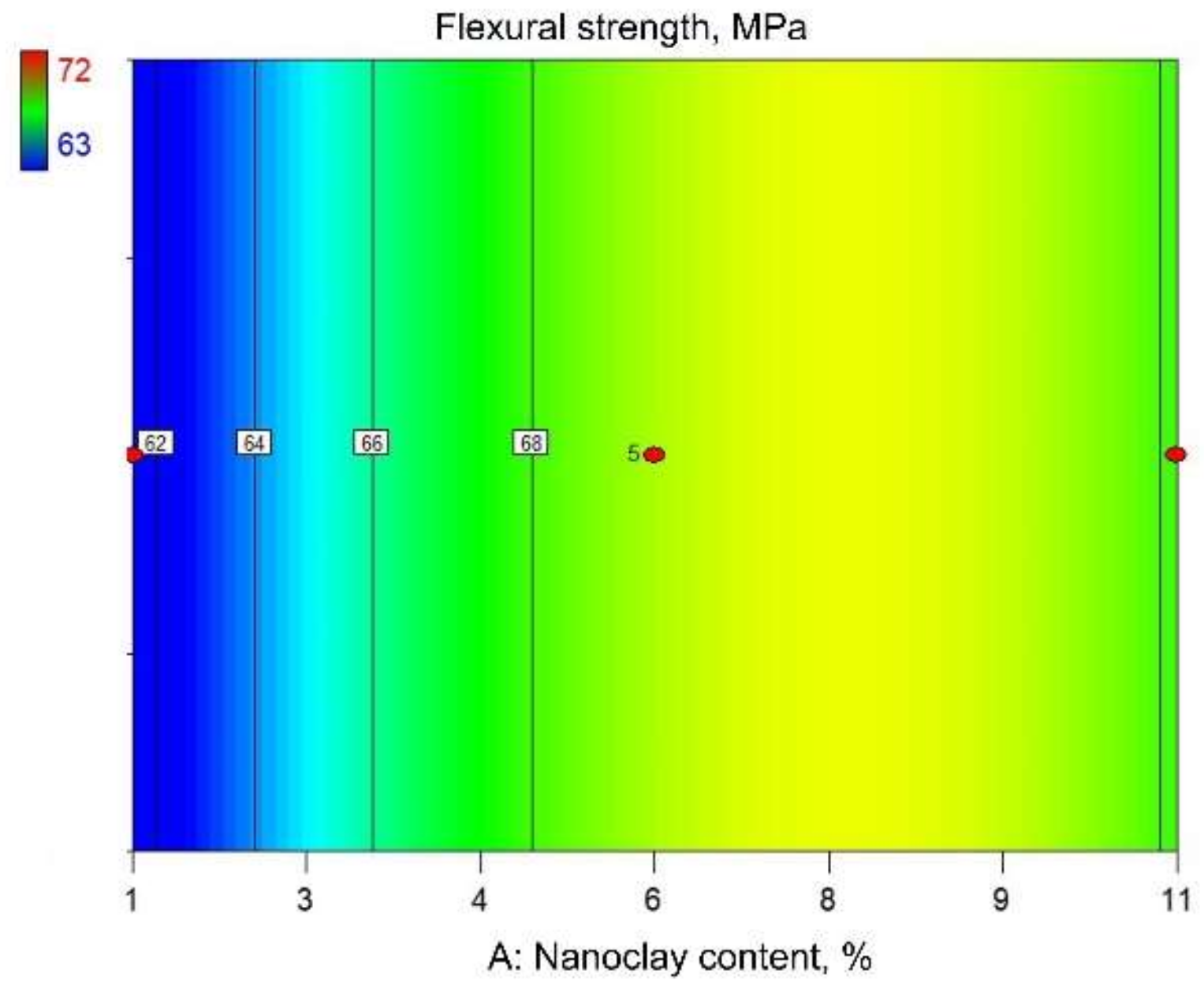

3.2.1. Flexural Strength

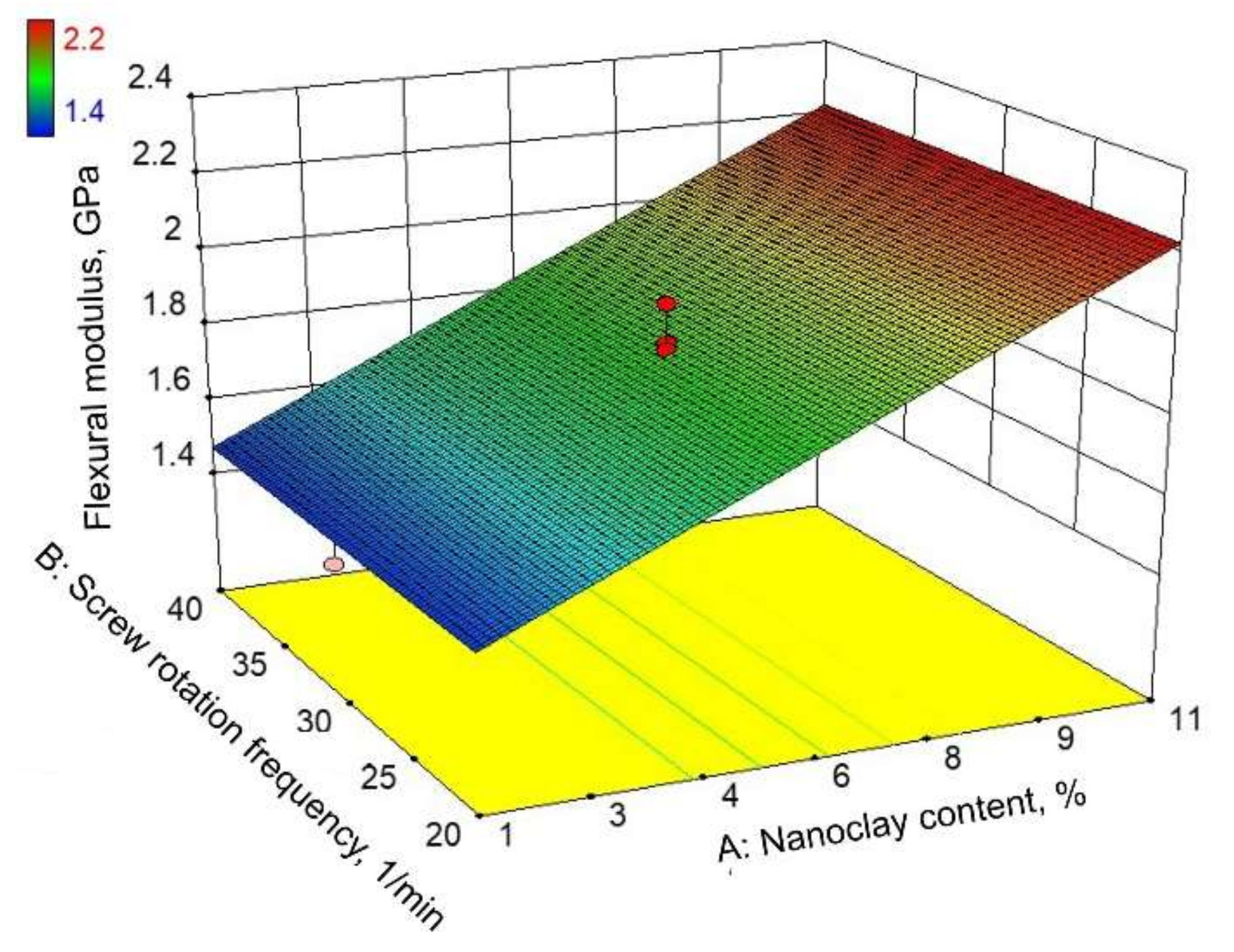

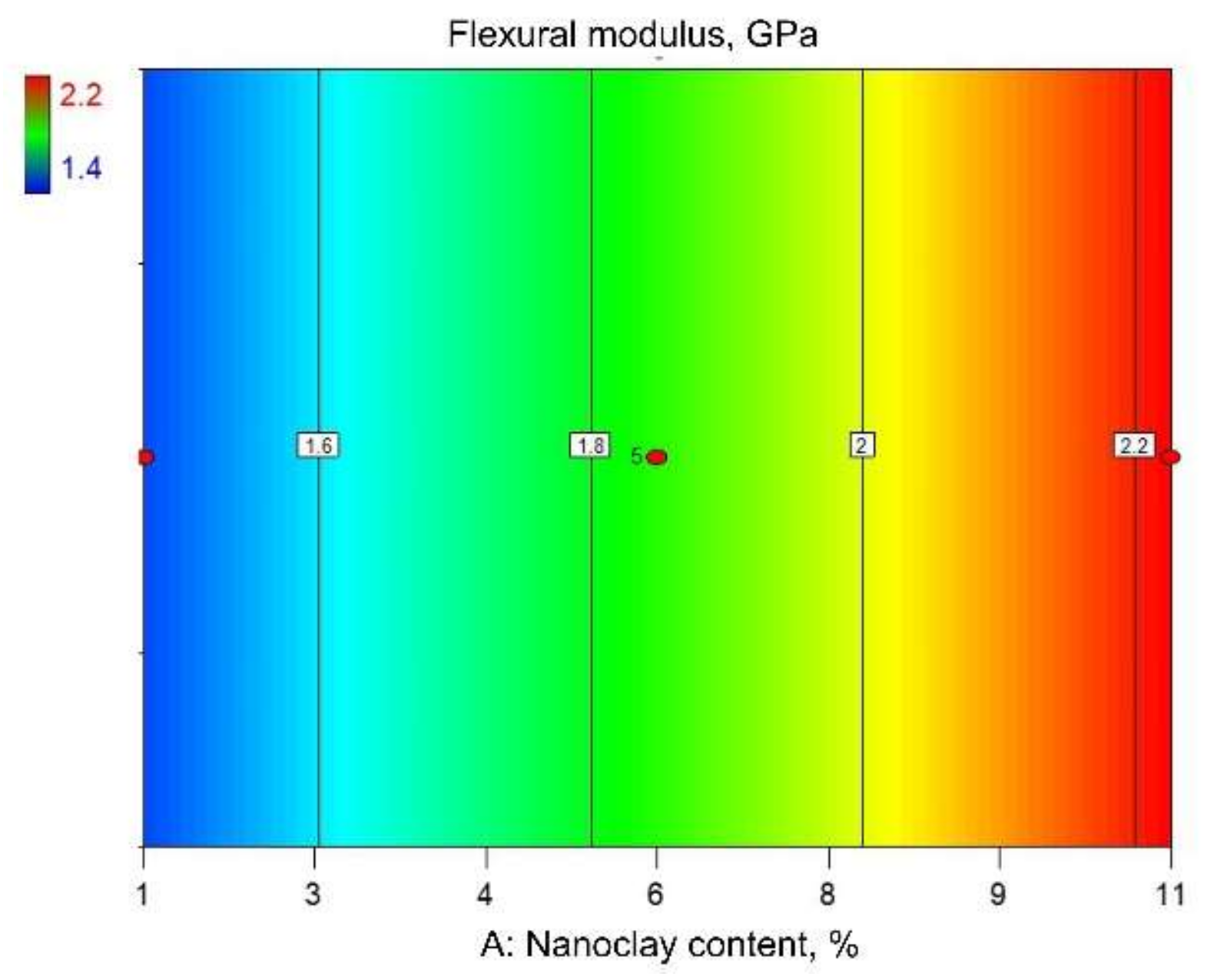

3.2.2. Flexural Modulus

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ceritbinmez, F.; Yapici, A. An investigation of punching the MWCNTs doped composite plates by using different cutting profiles. Teh. Vjesn. Tehnički Vjesnik 2021, 28, 385–390. [Google Scholar]

- Ivanković, M. Polimerni nanokompoziti. Polimerin 2007, 28, 156–167. [Google Scholar]

- Manias, E.; Polizos, G.; Nakajima, H.; Heidecker, M.J. Fundamentals of Polymer Nanocomposite Technology; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Triaki, M.; Benmounah, A.; Zenati, A. Investigation on improving properties of polypropylene-based nanocomposites by employing Algerian nanoclay. Polym. Bull. 2021, 78, 3275–3292. [Google Scholar] [CrossRef]

- Dagmar, M.; Alice, T.; Alena, K. Polyethylene/Ethylene vinyl acetate and ethylene octene copolymer/clay nanocomposite films: Different processing conditions and their effect on properties. Pol. Eng. Sci. 2019, 59, 2514–2521. [Google Scholar] [CrossRef]

- Follain, N.; Alexandre, B.; Chappey, C.; Colasse, L.; Médéric, P.; Marais, S. Barrier properties of polyamide 12/montmorillonite nanocomposites: Effect of clay structure and mixing conditions. Compos. Sci. Technol. 2016, 136, 18–28. [Google Scholar] [CrossRef]

- Borić, A.; Kalendová, A.; Urbanek, M.; Pepelnjak, T. Characterisation of polyamide (PA)12 nanocomposites with montmorillonite (MMT) filler clay used for the incremental forming of sheets. Polymers 2019, 11, 1248. [Google Scholar] [CrossRef] [PubMed]

- Pavlidou, S.; Papaspyrides, C.D. A review on polymer-layered silicate nanocomposites. Prog. Polym. Sci. 2008, 33, 1119–1198. [Google Scholar] [CrossRef]

- Chin, I.J.; Thurn-Albrecht, T.; Kim, H.C.; Russell, T.P.; Wang, J. On exfoliation of montmorillonite in epoxy. Polymer 2001, 42, 5947–5952. [Google Scholar] [CrossRef]

- Giannopoulos, G.I.; Georgantzinos, S.K.; Tsiamaki, A.; Anifantis, N. Combining FEM and MD to simulate C60/PA-12 nanocomposites. Int. J. Struct. Integr. 2009, 10, 380–392. [Google Scholar] [CrossRef]

- Giannopoulos, G.I. Linking MD and FEM to predict the mechanical behaviour of fullerene reinforced nylon-12. Compos. Part B Eng. 2019, 161, 455–463. [Google Scholar] [CrossRef]

- Yang, Y.-K.; Shie, J.-R.; Yang, R.-T.; Chang, H.-A. Optimization of injection molding process for contour distortions of polypropylene composite components via design of experiments method. J. Reinf. Plast. Compos. 2006, 25, 1585–1599. [Google Scholar] [CrossRef]

- Mulenga, T.K.; Ude, A.U.; Vivekanandhan, C. Techniques for modelling and optimizing the mechanical properties of natural fiber composites: A review. Fibers 2021, 9, 6. [Google Scholar] [CrossRef]

- Samuel, B.O.; Sumaila, M.; Dan-Asabe, B. Manufacturing of a natural fiber/glass fiber hybrid reinforced polymer composite (PxGyEz) for high flexural strength: An optimization approach. Int. J. Adv. Manuf. Technol. 2021, 117, 1–12. [Google Scholar] [CrossRef]

- Aydar, A.Y. Utilization of response surface methodology in optimization of extraction of plant materials. In Statistical Approaches with Emphasis on Design of Experiments Applied to Chemical Processes; BoD – Books on Demand: Norderstedt, Germany, 2018; pp. 157–169. [Google Scholar] [CrossRef] [Green Version]

- Nooraziah, A.; Tiagrajah, V.J. A study on regression model using response surface methodology. Appl. Mech. Mater. 2014, 666, 235–239. [Google Scholar] [CrossRef]

- Choi, C.-W.; Jin, J.-W.; Lee, H.; Huh, M.; Kang, K.-W. Optimal polymerization conditions in thermoplastic-resin transfer molding process for mechanical properties of carbon fiber-reinforced PA6 composites using the response surface method. Fiber. Polym. 2019, 20, 1021–1028. [Google Scholar] [CrossRef]

- Pragasam, V.; Degalahal, M.R. Investigation on flexural strength of cellulose microfibrils reinforced polymer composite. Emerg. Mater. Res. 2020, 9, 1–12. [Google Scholar] [CrossRef]

- Athijayamani, A.; Stalin, B.; Sidhardhan, S.; Boopathi, C. Parametric analysis of mechanical properties of bagasse fiber-reinforced vinyl ester composites. J. Compos. Mater. 2015, 50, 481–493. [Google Scholar] [CrossRef]

- Ozcelik, B.; Ozbay, A.; Demirbas, E. Influence of injection parameters and mold materials on mechanical properties of ABS in plastic injection molding. Int. Commun. Heat Mass Transf. 2010, 37, 1359–1365. [Google Scholar] [CrossRef]

- Benkhelladi, A.; Laouici, H.; Bouchoucha, A. Tensile and flexural properties of polymer composites reinforced by flax, jute and sisal fibres. Int. J. Adv. Manuf. Technol. 2010, 108, 895–916. [Google Scholar] [CrossRef]

- Kumar, P.K.; Raghavendra, N.V.; Sridhara, B.K. Effect of infrared cure parameters on the mechanical properties of polymer composite laminates. J. Compos. Mater. 2011, 46, 549–556. [Google Scholar] [CrossRef]

- Kunnan Singh, J.; Ching, Y.; Abdullah, L.; Ching, K.; Razali, S.; Gan, S. Optimization of mechanical properties for polyoxymethylene/glass fiber/polytetrafluoroethylene composites using response surface methodology. Polymers 2018, 10, 338. [Google Scholar] [CrossRef] [Green Version]

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology. Nanocompos. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef] [Green Version]

- Dennis, H.R.; Hunter, D.L.; Chang, D.; Kim, S.; White, J.L.; Cho, J.W.; Paul, D.R. Effect of melt processing conditions on the extent of exfoliation in organoclay-based nanocomposites. Polymer 2001, 42, 9513–9522. [Google Scholar] [CrossRef]

- Nanni, A.; Parisi, M.; Colonna, M.; Messori, M. Thermo-mechanical and morphological properties of polymer composites rein-forced by natural fibers derived from wet blue leather wastes: A comparative study. Polymers 2021, 13, 1837. [Google Scholar] [CrossRef] [PubMed]

- Aldousiri, B.; Dhakal, H.N.; Onuh, S.; Zhang, Z.Y.; Bennett, N. Nanoindentation behaviour of layered silicate filled spent polyamide-12 nanocomposites. Polym. Test 2011, 30, 688–692. [Google Scholar] [CrossRef]

- Hoffmann, B.; Kressler, J.; Stöppelmann, G.; Friedrich, C.; Kim, G.-M. Rheology of nanocomposites based on layered silicates and polyamide-12. Colloid Polym. Sci. 2000, 278, 629–636. [Google Scholar] [CrossRef]

- Aït Hocine, N.; Médéric, P.; Aubry, T. Mechanical properties of polyamide-12 layered silicate nanocomposites and their relations with structure. Polym. Test 2008, 27, 330–339. [Google Scholar] [CrossRef]

- Hassan, H.; Aït Hocine, N.; Médéric, P.; Deffarges, M.-P.; Poirot, N. Thermal and mechanical properties of PA12/C30B nanocomposites in relationship with nanostructure. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- EOS Polyamide 12 for 3D Printing. Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-plastic/sls-polymer-materials/polyamide-pa-12-alumide (accessed on 20 November 2021).

- MatWeb Material Property Data. Available online: http://www.matweb.com/search/datasheet.aspx?MatGUID=3181d0899a0b46a592eb37c47f0f841b&ckck=1 (accessed on 20 November 2021).

- Brabender Simulation in Laboratory and Compounding. Available online: http://www.brabender.com/english/plastics/products/extruders/twin-screw-extruders/docking-station.html (accessed on 20 October 2021).

- Brabender Simulation in Laboratory and Compounding. Available online: https://www.brabender.com/en/chemical/products/extrusion/downstream-equipment/convey-cool-pelletize/conveyor-belt/ (accessed on 20 October 2021).

- Brabender Simulation in Laboratory and Compounding. Available online: https://www.brabender.com/en/chemical/products/extrusion/downstream-equipment/convey-cool-pelletize/pelletizer/ (accessed on 20 October 2021).

- Teixeira, D.; Giovanela, M.; Gonella, L.B.; Crespo, J.S. Influence of injection molding on the flexural strength and surface quality of long glass fiber-reinforced polyamide 6.6 composites. Mater. Des. 2015, 85, 695–706. [Google Scholar] [CrossRef]

- HRN EN ISO 178:2019; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- Zhao, F.; Bao, X.; McLauchlin, A.R.; Gu, J.; Wan, C.; Kandasubramanian, B. Effect of POSS on morphology and mechanical properties of polyamide 12/montmorillonite nanocomposites. Appl. Clay Sci. 2010, 47, 249–256. [Google Scholar] [CrossRef]

- McNally, T.; Raymond Murphy, W.; Lew, C.Y.; Turner, R.J.; Brennan, G.P. Polyamide-12 layered silicate nanocomposites by melt blending. Polymer 2003, 44, 2761–2772. [Google Scholar] [CrossRef]

- Kundu, S.; Jana, P.; De, D.; Roy, M. SEM image processing of polymer nanocomposites to estimate filler content. In Proceedings of the 2015 IEEE International Conference on Electrical, Computer and Communication Technologies (ICECCT), Coimbatore, India, 5–7 March 2015. [Google Scholar] [CrossRef]

| Experiment No./Point of the Experiment | A: Nanoclay Content, % | B: Screw Rotation Frequency, min−1 | C: Mixing Temperature, °C |

|---|---|---|---|

| 1/factorial point | 3 | 20 | 210 |

| 2/factorial point | 9 | 20 | 210 |

| 3/factorial point | 3 | 40 | 210 |

| 4/factorial point | 9 | 40 | 210 |

| 5/factorial point | 3 | 20 | 230 |

| 6/factorial point | 9 | 20 | 230 |

| 7/factorial point | 3 | 40 | 230 |

| 8/factorial point | 9 | 40 | 230 |

| 9/axial point | 0.95 | 30 | 220 |

| 10/axial point | 11.05 | 30 | 220 |

| 11/axial point | 6 | 13.18 | 220 |

| 12/axial point | 6 | 46.82 | 220 |

| 13/axial point | 6 | 30 | 203.18 |

| 14/axial point | 6 | 30 | 236.82 |

| 15/center point | 6 | 30 | 220 |

| 16/center point | 6 | 30 | 220 |

| 17/center point | 6 | 30 | 220 |

| 18/center point | 6 | 30 | 220 |

| 19/center point | 6 | 30 | 220 |

| Extruder type | Twin-screw, counter-rotating |

| Screw diameter D | 42 mm |

| Length/diameter ratio L/D | 6 |

| Operating temperature max. | 350 °C |

| Conveyor belt speed | 0.6 to 6 m/min |

| Strand diameter | 1 to 4 mm |

| Pellet length | 3 mm |

| Strand pelletizer speed | 0.5 to 15 m/min |

| Experiment No. | A: Nanoclay Content, % | B: Screw Rotation Frequency, min−1 | C: Mixing Temperature, °C | Flexural Strength σfM, MPa | Flexural Modulus Ef, GPa |

|---|---|---|---|---|---|

| 1 | 3 | 20 | 210 | 65.6 | 1.7 |

| 2 | 9 | 20 | 210 | 67.9 | 2.0 |

| 3 | 3 | 40 | 210 | 64.4 | 1.6 |

| 4 | 9 | 40 | 210 | 68.5 | 2.0 |

| 5 | 3 | 20 | 230 | 66.2 | 1.7 |

| 6 | 9 | 20 | 230 | 68.7 | 2.2 |

| 7 | 3 | 40 | 230 | 63.8 | 1.5 |

| 8 | 9 | 40 | 230 | 72.2 | 2.2 |

| 9 | 0.95 | 30 | 220 | 62.5 | 1.4 |

| 10 | 11.05 | 30 | 220 | 67.6 | 2.1 |

| 11 | 6 | 13.18 | 220 | 71.9 | 1.9 |

| 12 | 6 | 46.82 | 220 | 70.1 | 2.0 |

| 13 | 6 | 30 | 203.18 | 68.6 | 1.9 |

| 14 | 6 | 30 | 236.82 | 69.8 | 1.9 |

| 15 | 6 | 30 | 220 | 69.4 | 1.6 |

| 16 | 6 | 30 | 220 | 67.3 | 1.9 |

| 17 | 6 | 30 | 220 | 70.1 | 2.0 |

| 18 | 6 | 30 | 220 | 69.2 | 1.9 |

| 19 | 6 | 30 | 220 | 66.1 | 1.7 |

| PA12 | 60.7 | 1.4 |

| Source | Sum of Squares | Degrees of Freedom df | Mean Square | F Value | p-Value |

|---|---|---|---|---|---|

| Model | 101.68 | 9 | 11.30 | 4.85 | 0.01 |

| A—Nanoclay content | 48.82 | 1 | 48.82 | 20.94 | 0.001 |

| B—Screw rotation frequency | 0.50 | 1 | 0.50 | 0.21 | 0.66 |

| C—Mixing temperature | 3.11 | 1 | 3.11 | 1.34 | 0.28 |

| AB | 7.18 | 1 | 7.18 | 3.08 | 0.11 |

| AC | 2.62 | 1 | 2.62 | 1.12 | 0.32 |

| BC | 0.34 | 1 | 0.34 | 0.15 | 0.71 |

| A2 | 28.79 | 1 | 28.79 | 12.35 | 0.01 |

| B2 | 5.57 | 1 | 5.57 | 2.39 | 0.16 |

| C2 | 0.0009 | 1 | 0.0009 | 0.0004 | 0.99 |

| Residual | 20.98 | 9 | 2.33 | ||

| Lack of fit | 9.76 | 5 | 1.95 | 0.70 | 0.65 |

| Pure error | 11.21 | 4 | 2.80 | ||

| Cor total | 122.7 | 18 |

| Source | Sum of Squares | Degrees of Freedom df | Mean Square | F Value | p-Value |

|---|---|---|---|---|---|

| Model | 82.24 | 2 | 41.12 | 16.28 | 0.0001 |

| A—Nanoclay content | 48.82 | 1 | 48.82 | 19.33 | 0.001 |

| A2 | 33.42 | 1 | 33.42 | 13.23 | 0.002 |

| Residual | 40.42 | 16 | 2.53 | ||

| Lack of fit | 29.20 | 12 | 2.43 | 0.87 | 0.62 |

| Pure error | 11.21 | 4 | 2.80 | ||

| Cor total | 122.66 | 18 |

| Source | Sum of Squares | Degrees of Freedom df | Mean Square | F Value | p-Value |

|---|---|---|---|---|---|

| Model | 0.69 | 3 | 0.23 | 15.66 | <0.0001 |

| A—Nanoclay content | 0.69 | 1 | 0.69 | 46.47 | <0.0001 |

| B—Screw rotation frequency | 0.002 | 1 | 0.002 | 0.11 | 0.74 |

| C—Mixing temperature | 0.006 | 1 | 0.01 | 0.41 | 0.53 |

| Residual | 0.22 | 15 | 0.02 | ||

| Lack of fit | 0.14 | 11 | 0.01 | 0.63 | 0.76 |

| Pure error | 0.08 | 4 | 0.02 | ||

| Cor total | 0.92 | 18 |

| Source | Sum of Squares | Degrees of Freedom df | Mean Square | F Value | p-Value |

|---|---|---|---|---|---|

| Model | 0.69 | 1 | 0.69 | 50.90 | <0.0001 |

| A—Nanoclay content | 0.69 | 1 | 0.69 | 50.90 | <0.0001 |

| Residual | 0.23 | 17 | 0.01 | ||

| Lack of fit | 0.15 | 13 | 0.01 | 0.56 | 0.81 |

| Pure error | 0.08 | 4 | 0.02 | ||

| Cor total | 0.92 | 18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stojšić, J.; Raos, P.; Milinović, A.; Damjanović, D. A Study of the Flexural Properties of PA12/Clay Nanocomposites. Polymers 2022, 14, 434. https://doi.org/10.3390/polym14030434

Stojšić J, Raos P, Milinović A, Damjanović D. A Study of the Flexural Properties of PA12/Clay Nanocomposites. Polymers. 2022; 14(3):434. https://doi.org/10.3390/polym14030434

Chicago/Turabian StyleStojšić, Josip, Pero Raos, Andrijana Milinović, and Darko Damjanović. 2022. "A Study of the Flexural Properties of PA12/Clay Nanocomposites" Polymers 14, no. 3: 434. https://doi.org/10.3390/polym14030434