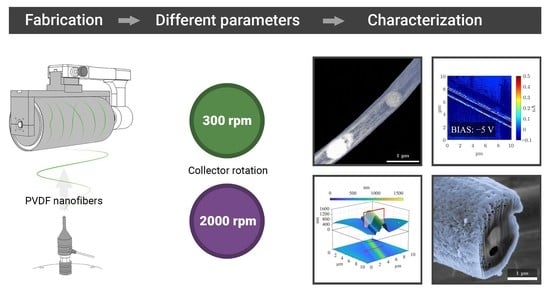

Comprehensive Characterization of PVDF Nanofibers at Macro- and Nanolevel

Abstract

:1. Introduction

2. Material and Methods

2.1. Production of PVDF Nanofibers

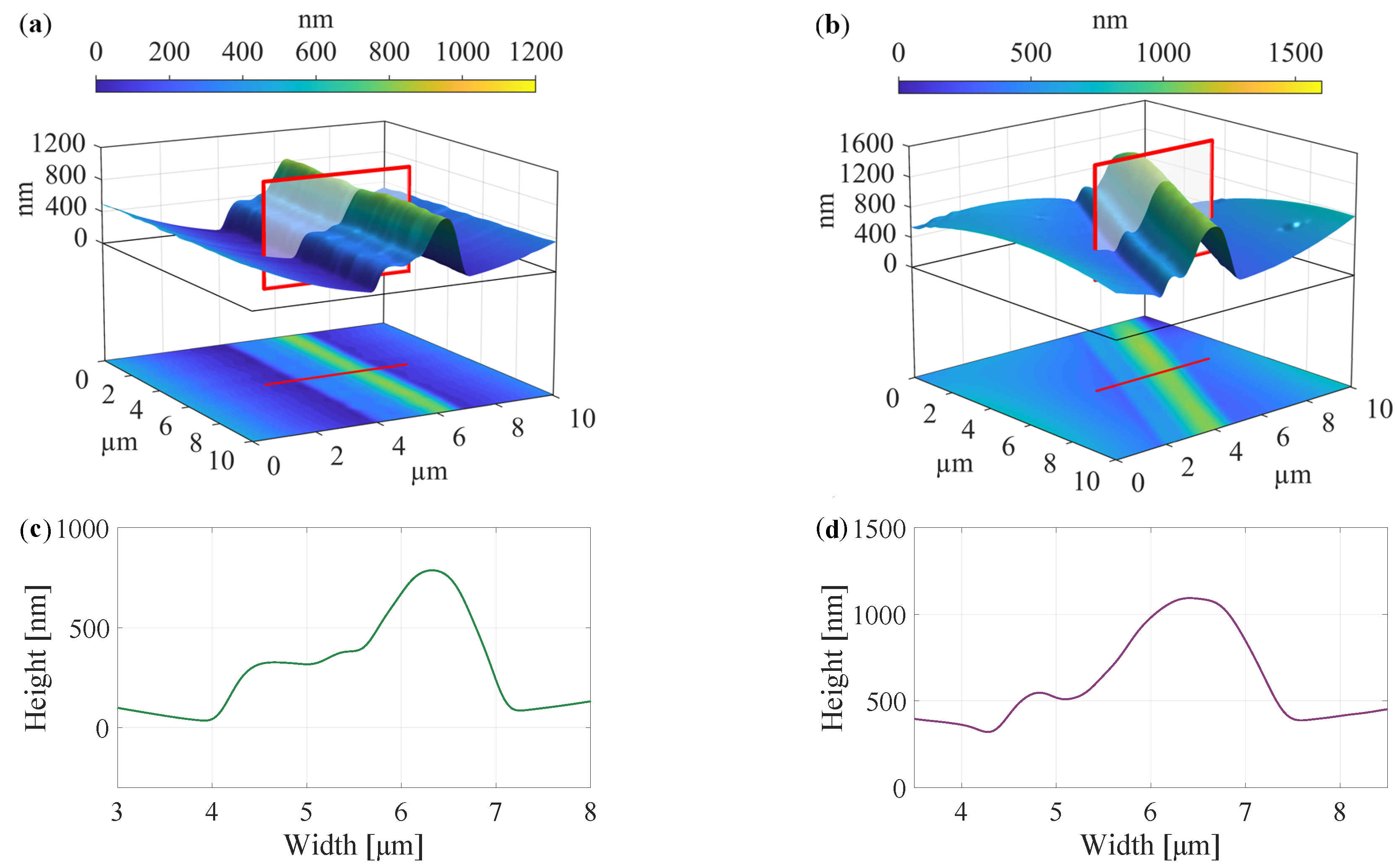

2.2. Internal and External Structure of the Fiber

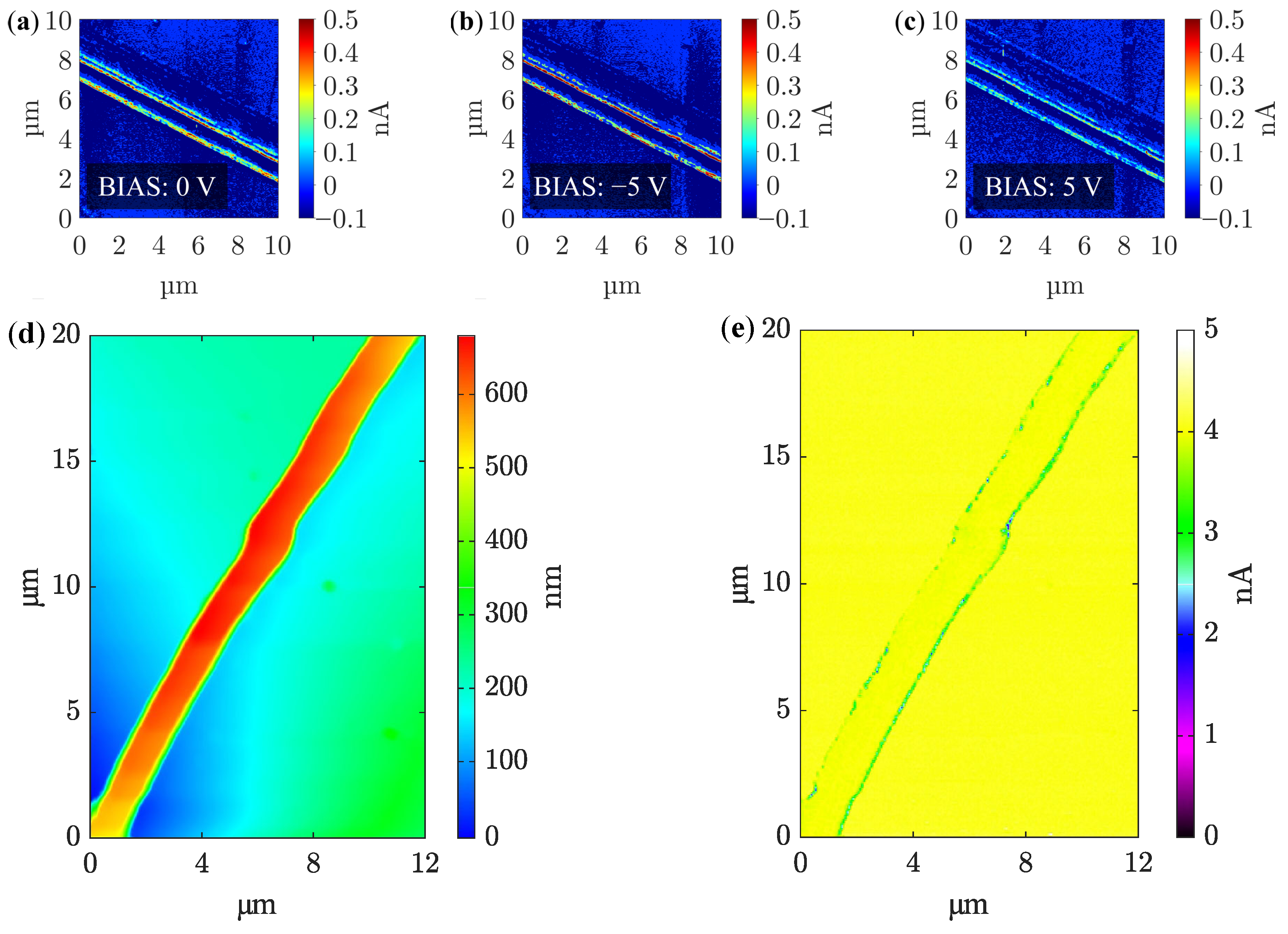

2.3. Morphology and Piezoelectric Properties

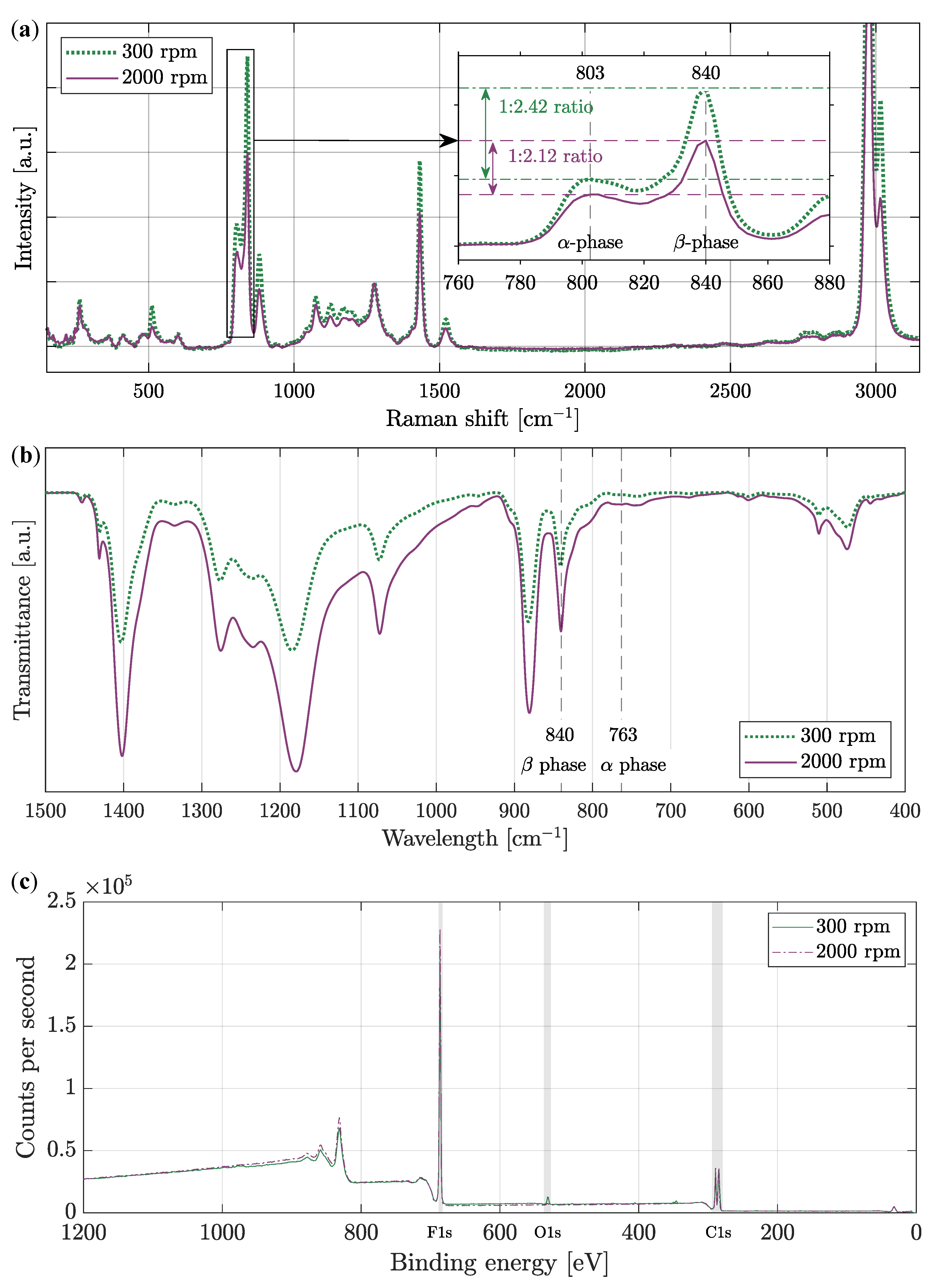

2.4. Elemental Fingerprint and Chemical Composition

2.5. Wettability of a Solid Surface

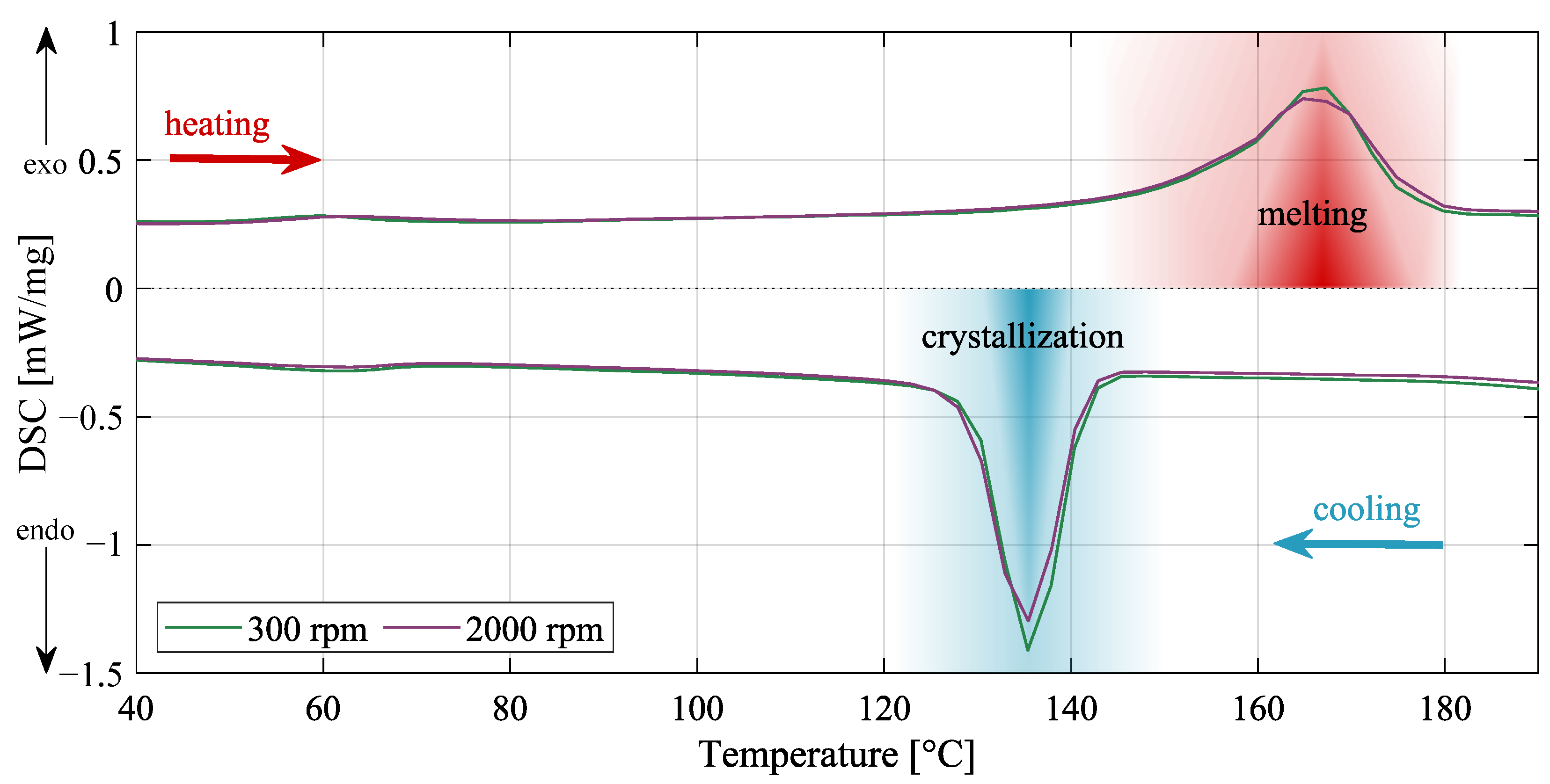

2.6. Determination of Polymer Crystallinity

3. Results and Discussion

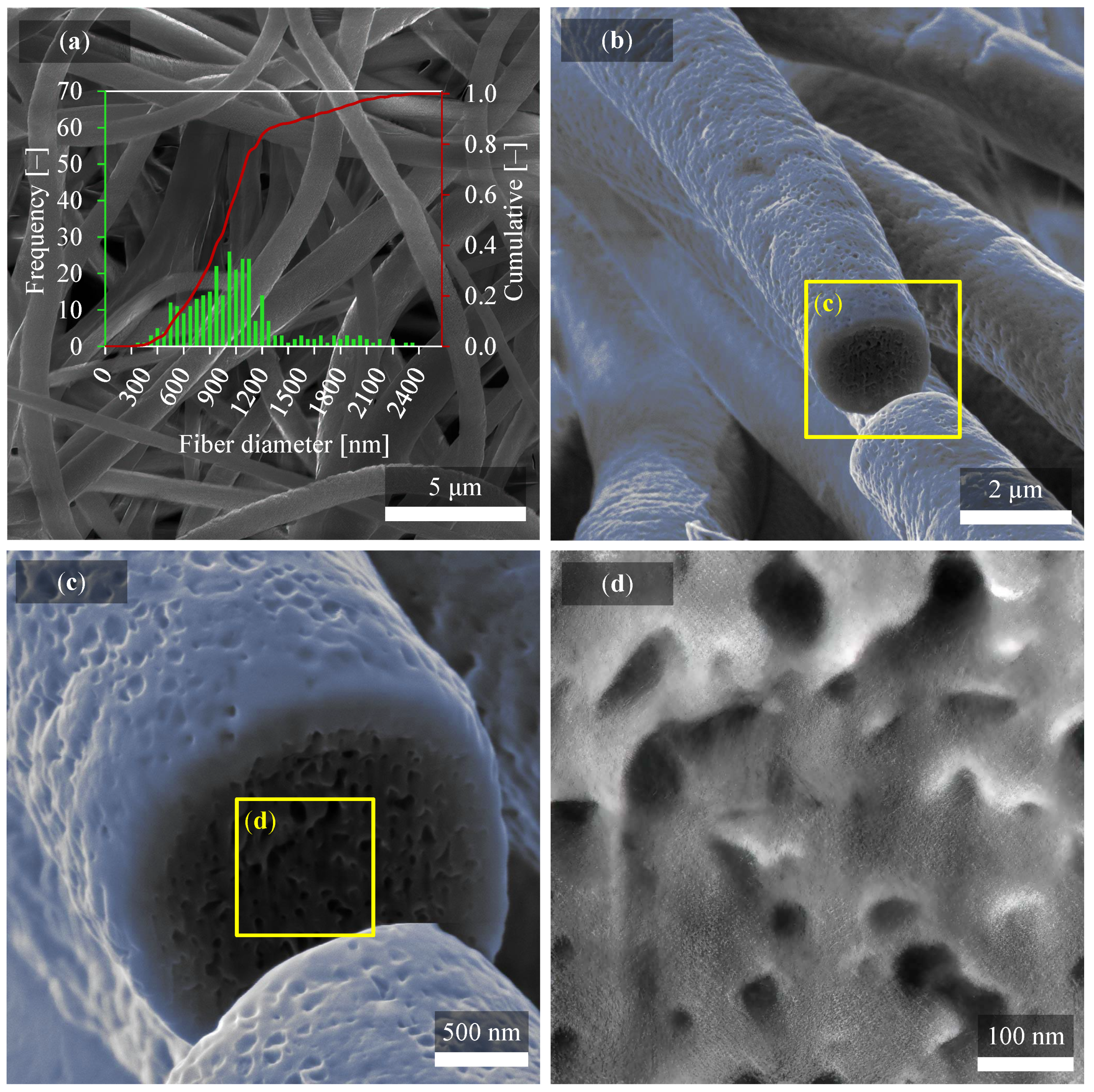

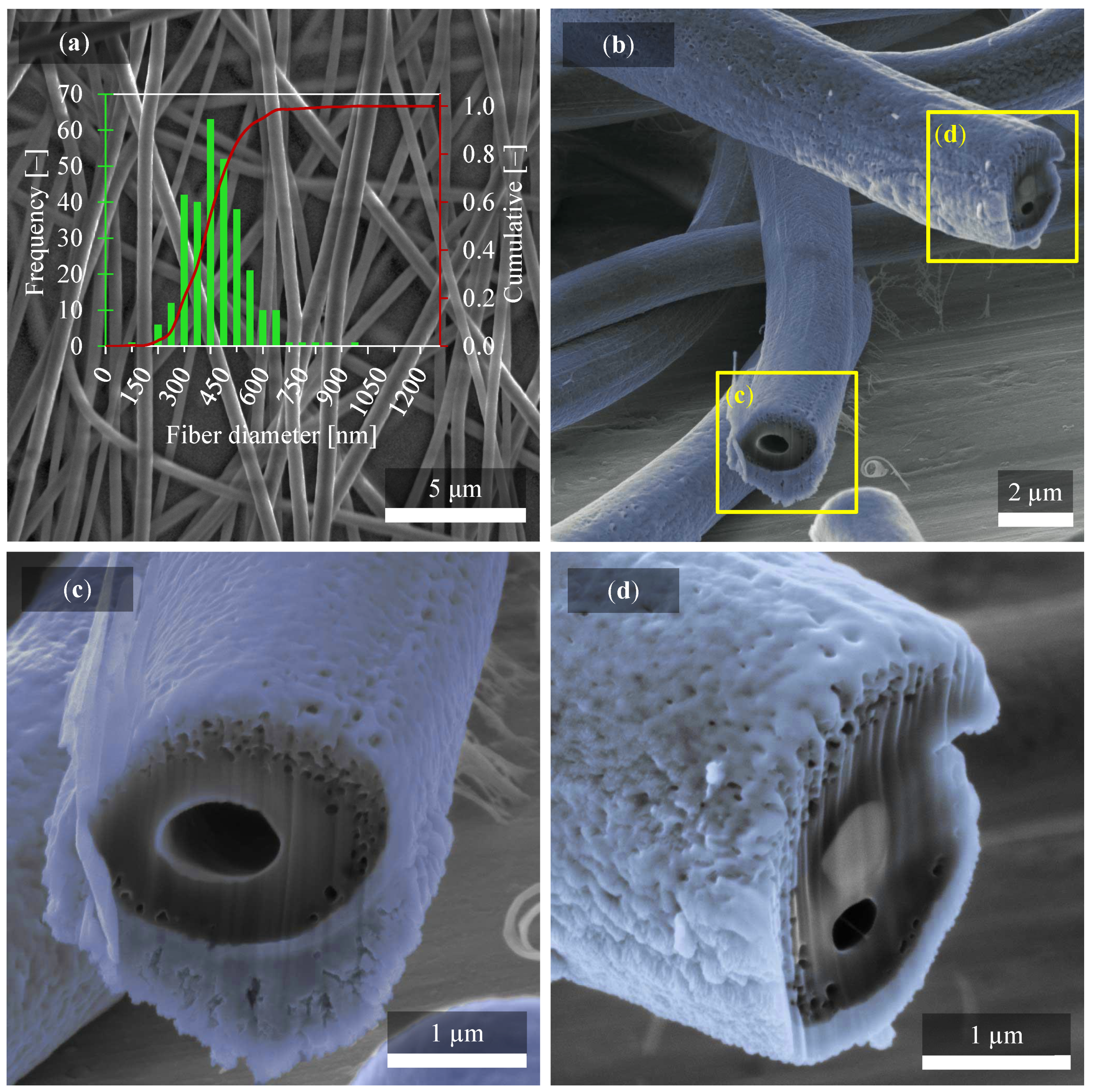

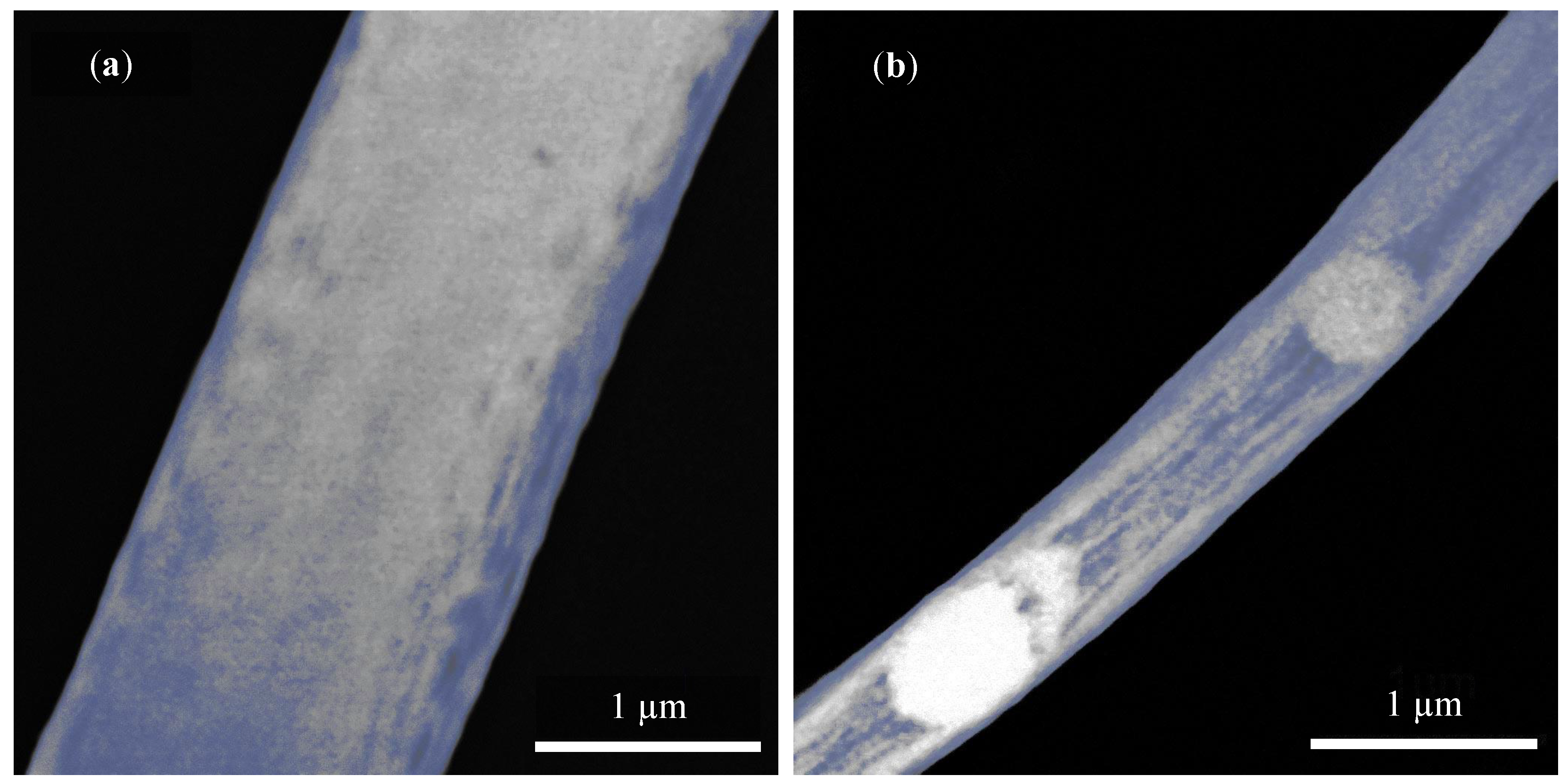

3.1. Examination of the Structure by Scanning Electron Microscopy

3.2. Fibers Morphology and Electrical Parameters Obtained Using Atomic Force Microscopy

3.3. Identification of PVDF Phases and Chemical States

3.4. Influence of Differently Produced Nanofibers on Their Wettability

3.5. Crystallization Behavior of PVDF Using Differential Scanning Calorimetry

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

Abbreviations

| AC | Acetone |

| AFM | Atomic force microscopy |

| DMSO | Dimethylsulphoxide |

| DSC | Differential scanning calorimetry |

| FIB | Focused ion beam |

| FTIR | Fourier-transform infrared spectroscopy |

| HAADF | High-angle annular dark-field |

| UHD | Ultrahigh definition |

| PFM | Piezoresponse force microscopy |

| PVDF | Polyvinylidene fluoride |

| SEM | Scanning electron microscopy |

| STEM | Scanning transmission electron microscopy |

| TEM | Transmission electron microscopy |

| XPS | X-ray photoelectron spectroscopy |

References

- Černohorský, P.; Pisarenko, T.; Papež, N.; Sobola, D.; Ţălu, Ş.; Částková, K.; Kaštyl, J.; Macků, R.; Škarvada, P.; Sedlák, P. Structure Tuning and Electrical Properties of Mixed PVDF and Nylon Nanofibers. Materials 2021, 14, 6096. [Google Scholar] [CrossRef] [PubMed]

- Sobola, D.; Kaspar, P.; Částková, K.; Dallaev, R.; Papež, N.; Sedlák, P.; Trčka, T.; Orudzhev, F.; Kaštyl, J.; Weiser, A.; et al. PVDF Fibers Modification by Nitrate Salts Doping. Polymers 2021, 13, 2439. [Google Scholar] [CrossRef] [PubMed]

- Naga Kumar, C.; Prabhakar, M.N.; Song, J.-I. Synthesis of vinyl ester resin-carrying PVDF green nanofibers for self-healing applications. Sci. Rep. 2021, 11, 908. [Google Scholar] [CrossRef] [PubMed]

- Pan, F.; Amarjargal, A.; Altenried, S.; Liu, M.; Zuber, F.; Zeng, Z.; Rossi, R.M.; Maniura-Weber, K.; Ren, Q. Bioresponsive Hybrid Nanofibers Enable Controlled Drug Delivery through Glass Transition Switching at Physiological Temperature. ACS Appl. Bio Mater. 2021, 4, 4271–4279. [Google Scholar] [CrossRef] [PubMed]

- Částková, K.; Kaštyl, J.; Sobola, D.; Petruš, J.; Šťastná, E.; Říha, D.; Tofel, P. Structure—Properties Relationship of Electrospun PVDF Fibers. Nanomaterials 2020, 10, 1221. [Google Scholar] [CrossRef]

- Orudzhev, F.; Ramazanov, S.; Sobola, D.; Kaspar, P.; Trčka, T.; Částková, K.; Kastyl, J.; Zvereva, I.; Wang, C.; Selimov, D.; et al. Ultrasound and water flow driven piezophototronic effect in self-polarized flexible α-Fe2O3 containing PVDF nanofibers film for enhanced catalytic oxidation. Nano Energy 2021, 90, 106586. [Google Scholar] [CrossRef]

- Roy, R.E.; Bhuvaneswari, S.; Vijayalakshmi, K.P.; Dimple, R.; Soumyamol, P.B.; Rajeev, R.S.N. Energy-induced polymorphic changes in poly(vinylidene fluoride): How ultrasonication results in polymer with predominantly γ phase. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 40–50. [Google Scholar] [CrossRef]

- Szewczyk, P.K.; Metwally, S.; Karbowniczek, J.E.; Marzec, M.M.; Stodolak-Zych, E.; Gruszczyński, A.; Bernasik, A.; Stachewicz, U. Surface-Potential-Controlled Cell Proliferation and Collagen Mineralization on Electrospun Polyvinylidene Fluoride (PVDF) Fiber Scaffolds for Bone Regeneration. ACS Biomater. Sci. Eng. 2019, 5, 582–593. [Google Scholar] [CrossRef]

- Li, T.; Feng, Z.Q.; Qu, M.; Yan, K.; Yuan, T.; Gao, B.; Wang, T.; Dong, W.; Zheng, J. Core/Shell Piezoelectric Nanofibers with Spatial Self-Orientated β-Phase Nanocrystals for Real-Time Micropressure Monitoring of Cardiovascular Walls. ACS Nano 2019, 13, 10062–10073. [Google Scholar] [CrossRef]

- Akduman, C.; Akcakoca Kumbasar, E.P. Nanofibers in face masks and respirators to provide better protection. IOP Conf. Ser. Mater. Sci. Eng. 2018, 460, 012013. [Google Scholar] [CrossRef]

- Ullah, S.; Ullah, A.; Lee, J.; Jeong, Y.; Hashmi, M.; Zhu, C.; Joo, K.I.; Cha, H.J.; Kim, I.S. Reusability Comparison of Melt-Blown vs Nanofiber Face Mask Filters for Use in the Coronavirus Pandemic. ACS Appl. Nano Mater. 2020, 3, 7231–7241. [Google Scholar] [CrossRef]

- Zhang, J.X.; Hoshino, K. Implantable Sensors. In Molecular Sensors and Nanodevices; Elsevier: Amsterdam, The Netherlands, 2014; pp. 415–465. [Google Scholar] [CrossRef]

- Soin, N.; Anand, S.; Shah, T. Energy harvesting and storage textiles. In Handbook of Technical Textiles; Elsevier: Amsterdam, The Netherlands, 2016; pp. 357–396. [Google Scholar] [CrossRef]

- Houis, S.; Engelhardt, E.M.; Wurm, F.; Gries, T. Application of Polyvinylidene Fluoride (PVDF) as a Biomaterial in Medical Textiles. In Medical and Healthcare Textiles; Elsevier: Amsterdam, The Netherlands, 2010; pp. 342–352. [Google Scholar] [CrossRef]

- Lee, D.W.; Jeong, D.G.; Kim, J.H.; Kim, H.S.; Murillo, G.; Lee, G.H.; Song, H.C.; Jung, J.H. Polarization-controlled PVDF-based hybrid nanogenerator for an effective vibrational energy harvesting from human foot. Nano Energy 2020, 76, 105066. [Google Scholar] [CrossRef]

- Wankhade, S.H.; Tiwari, S.; Gaur, A.; Maiti, P. PVDF–PZT nanohybrid based nanogenerator for energy harvesting applications. Energy Rep. 2020, 6, 358–364. [Google Scholar] [CrossRef]

- Cong, J.; Jing, J.; Chen, C.; Dai, Z. Development of a PVDF Sensor Array for Measurement of the Dynamic Pressure Field of the Blade Tip in an Axial Flow Compressor. Sensors 2019, 19, 1404. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, G.; Li, Z.; Song, G. A PVDF-Based Sensor for Internal Stress Monitoring of a Concrete-Filled Steel Tubular (CFST) Column Subject to Impact Loads. Sensors 2018, 18, 1682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seok Han, K.; Lee, S.; Kim, M.; Park, P.; Hyung Lee, M.; Nah, J.; Han, K.S.; Lee, S.; Kim, M.; Park, P.; et al. Electrically Activated Ultrathin PVDF-TrFE Air Filter for High-Efficiency PM1.0 Filtration. Adv. Funct. Mater. 2019, 29, 1903633. [Google Scholar] [CrossRef]

- Oshima, K.H.; Evans-Strickfaden, T.T.; Highsmith, A.K.; Ades, E.W. The Use of a Microporous Polyvinylidene Fluoride (PVDF) Membrane Filter to Separate Contaminating Viral Particles from Biologically Important Proteins. Biologicals 1996, 24, 137–145. [Google Scholar] [CrossRef]

- Leung, W.W.F.; Sun, Q. Charged PVDF multilayer nanofiber filter in filtering simulated airborne novel coronavirus (COVID-19) using ambient nano-aerosols. Sep. Purif. Technol. 2020, 245, 116887. [Google Scholar] [CrossRef]

- Wan, C.; Bowen, C.R. Multiscale-structuring of polyvinylidene fluoride for energy harvesting: The impact of molecular-, micro- and macro-structure. J. Mater. Chem. A 2017, 5, 3091–3128. [Google Scholar] [CrossRef] [Green Version]

- Voigtländer, B. Scanning Probe Microscopy; NanoScience and Technology; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef] [Green Version]

- He, W.; Guo, Y.; Zhao, Y.B.; Jiang, F.; Schmitt, J.; Yue, Y.; Liu, J.; Cao, J.; Wang, J. Self-supporting smart air filters based on PZT/PVDF electrospun nanofiber composite membrane. Chem. Eng. J. 2021, 423, 130247. [Google Scholar] [CrossRef]

- Pisarenko, T. Characterization of PVDF nanofibers created by the electrospinning method. In Proceedings of the 26th Conference STUDENT EEICT 2020; Brno University of Technology: Brno, Czech Republic, 2020; pp. 287–291. [Google Scholar]

- Sasmal, A.; Sen, S.; Devi, P.S. Synthesis and characterization of SmFeO3 and its effect on the electrical and energy storage properties of PVDF. Mater. Res. Bull. 2020, 130, 110941. [Google Scholar] [CrossRef]

- Xin, Y.; Qi, X.; Tian, H.; Guo, C.; Li, X.; Lin, J.; Wang, C. Full-fiber piezoelectric sensor by straight PVDF/nanoclay nanofibers. Mater. Lett. 2016, 164, 136–139. [Google Scholar] [CrossRef]

- Pisarenko, T. PVDF—An ideal candidate for use in nanogenerators. In Proceedings of the 27th Conference STUDENT EEICT 2021; Brno University of Technology: Brno, Czech Republic, 2021; pp. 275–279. [Google Scholar]

- Motamedi, A.S.; Mirzadeh, H.; Hajiesmaeilbaigi, F.; Bagheri-Khoulenjani, S.; Shokrgozar, M. Effect of electrospinning parameters on morphological properties of PVDF nanofibrous scaffolds. Prog. Biomater. 2017, 6, 113–123. [Google Scholar] [CrossRef]

- Buršíková, V.; Stťahel, P.; Navrátil, Z.; Buršík, J.; Janča, J. Vyhodnocení Povrchové Energie Materiálu Ošetřeného Plazmatem, Metodou měření Kontaktního úhlu; Masarykova Univerzita: Brno, Czech Republic, 2004. [Google Scholar]

- Ueberschlag, P. PVDF piezoelectric polymer. Sens. Rev. 2001, 21, 118–126. [Google Scholar] [CrossRef]

- Manikandan, N.; Muruganand, S.; Sriram, K.; Balakrishnan, P.; Suresh Kumar, A. Fabrication of Piezoelectric Polyvinylidene Fluoride (PVDF) Polymer-Based Tactile Sensor Using Electrospinning Method. Nano Hybrids Compos. 2016, 12, 42–50. [Google Scholar] [CrossRef]

- Huang, H.S.; Chen, C.Y.; Lo, S.C.; Lin, C.J.; Chen, S.J.; Lin, L.J. Identification of ionic aggregates in PVDF-g-PSSA membrane by tapping mode AFM and HADDF STEM. Appl. Surf. Sci. 2006, 253, 2685–2689. [Google Scholar] [CrossRef]

- Ţălu, Ş. Micro and Nanoscale Characterization of Three Dimensional Surfaces: Basics and Applications; Napoca Star Publishing House: Cluj-Napoca, Romania, 2015. [Google Scholar]

- Arjun Hari, M.; Rajan, L.; Subash, C.; Varghese, S. Effect of nanoparticle size on the piezoelectric properties of PVDF based nanocomposite thin films. Mater. Today Proc. 2021, 46, 5781–5784. [Google Scholar] [CrossRef]

- Sobola, D.; Ramazanov, S.; Konečný, M.; Orudzhev, F.; Kaspar, P.; Papež, N.; Knápek, A.; Potoček, M. Complementary SEM-AFM of swelling Bi-Fe-O film on HOPG substrate. Materials 2020, 13, 2402. [Google Scholar] [CrossRef]

- Sencadas, V.; Ribeiro, C.; Bdikin, I.K.; Kholkin, A.L.; Lanceros-Mendez, S. Local piezoelectric response of single poly(vinylidene fluoride) electrospun fibers. Phys. Status Solidi A 2012, 209, 2605–2609. [Google Scholar] [CrossRef]

- Kaspar, P.; Sobola, D.; Částková, K.; Dallaev, R.; Šťastná, E.; Sedlák, P.; Knápek, A.; Trčka, T.; Holcman, V. Case Study of Polyvinylidene Fluoride Doping by Carbon Nanotubes. Materials 2021, 14, 1428. [Google Scholar] [CrossRef]

- Elashmawi, I.S.; Gaabour, L.H. Raman, morphology and electrical behavior of nanocomposites based on PEO/PVDF with multi-walled carbon nanotubes. Results Phys. 2015, 5, 105–110. [Google Scholar] [CrossRef] [Green Version]

- Islam, A.; Khan, A.N.; Shakir, M.F.; Islam, K. Strengthening of β polymorph in PVDF/FLG and PVDF/GO nanocomposites. Mater. Res. Express 2019, 7, 015017. [Google Scholar] [CrossRef] [Green Version]

- Kaynak, A.; Mehmood, T.; Dai, X.; Magniez, K.; Kouzani, A. Study of Radio Frequency Plasma Treatment of PVDF Film Using Ar, O2 and (Ar + O2) Gases for Improved Polypyrrole Adhesion. Materials 2013, 6, 3482–3493. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaspar, P.; Sobola, D.; Částková, K.; Knápek, A.; Burda, D.; Orudzhev, F.; Dallaev, R.; Tofel, P.; Trčka, T.; Grmela, L.; et al. Characterization of Polyvinylidene Fluoride (PVDF) Electrospun Fibers Doped by Carbon Flakes. Polymers 2020, 12, 2766. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi Ghaleni, M.; Al Balushi, A.; Kaviani, S.; Tavakoli, E.; Bavarian, M.; Nejati, S. Fabrication of Janus Membranes for Desalination of Oil-Contaminated Saline Water. ACS Appl. Mater. Interfaces 2018, 10, 44871–44879. [Google Scholar] [CrossRef]

- Yan, D.; Zhang, H.; Lu, S.; Yang, L.; Zhao, X.; He, F. Synergistic modification effect of polyvinylidene fluoride and polydopamine on mechanical and damping properties of three-dimensional braided carbon fibers reinforced composites. J. Mater. Sci. 2019, 54, 5457–5471. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, R.; Tian, M.; Qiu, C.; Fane, A.G. Fabrication of polyvinylidene fluoride (PVDF) nanofiber membranes by electro-spinning for direct contact membrane distillation. J. Membr. Sci. 2013, 425–426, 30–39. [Google Scholar] [CrossRef]

- Peng, M.; Li, H.; Wu, L.; Zheng, Q.; Chen, Y.; Gu, W. Porous poly(vinylidene fluoride) membrane with highly hydrophobic surface. J. Appl. Polym. Sci. 2005, 98, 1358–1363. [Google Scholar] [CrossRef]

- Wang, K.Y.; Chung, T.S.; Gryta, M. Hydrophobic PVDF hollow fiber membranes with narrow pore size distribution and ultra-thin skin for the fresh water production through membrane distillation. Chem. Eng. Sci. 2008, 63, 2587–2594. [Google Scholar] [CrossRef]

- Huang, F.L.; Wang, Q.Q.; Wei, Q.F.; Gao, W.D.; Shou, H.Y.; Jiang, S.D. Dynamic wettability and contact angles of poly(vinylidene fluoride) nanofiber membranes grafted with acrylic acid. Express Polym. Lett. 2010, 4, 551–558. [Google Scholar] [CrossRef]

- Kebede, T.G.; Dube, S.; Nindi, M.M. Biopolymer electrospun nanofibres for the adsorption of pharmaceuticals from water systems. J. Environ. Chem. Eng. 2019, 7, 103330. [Google Scholar] [CrossRef]

| Emitter | Needle size | Flow | Syringe volume | Collector voltage | Distance |

| Single needle | 17 G | 18 μL/min | 10 mL | 50 kV | 20 cm |

| Collector speed | Substrate | Temperature | Humidity | Solution temperature | |

| 300 rpm and 2000 rpm | Aluminum | 24 °C | 26 % | 60 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pisarenko, T.; Papež, N.; Sobola, D.; Ţălu, Ş.; Částková, K.; Škarvada, P.; Macků, R.; Ščasnovič, E.; Kaštyl, J. Comprehensive Characterization of PVDF Nanofibers at Macro- and Nanolevel. Polymers 2022, 14, 593. https://doi.org/10.3390/polym14030593

Pisarenko T, Papež N, Sobola D, Ţălu Ş, Částková K, Škarvada P, Macků R, Ščasnovič E, Kaštyl J. Comprehensive Characterization of PVDF Nanofibers at Macro- and Nanolevel. Polymers. 2022; 14(3):593. https://doi.org/10.3390/polym14030593

Chicago/Turabian StylePisarenko, Tatiana, Nikola Papež, Dinara Sobola, Ştefan Ţălu, Klára Částková, Pavel Škarvada, Robert Macků, Erik Ščasnovič, and Jaroslav Kaštyl. 2022. "Comprehensive Characterization of PVDF Nanofibers at Macro- and Nanolevel" Polymers 14, no. 3: 593. https://doi.org/10.3390/polym14030593

APA StylePisarenko, T., Papež, N., Sobola, D., Ţălu, Ş., Částková, K., Škarvada, P., Macků, R., Ščasnovič, E., & Kaštyl, J. (2022). Comprehensive Characterization of PVDF Nanofibers at Macro- and Nanolevel. Polymers, 14(3), 593. https://doi.org/10.3390/polym14030593