Micro-Scale Shear Kneading—Gluten Network Development under Multiple Stress–Relaxation Steps and Evaluation via Multiwave Rheology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Development of the Wheat Dough Matrix

2.2. Fundamental Shear Rheology

2.2.1. Dough Produced in a Z-Kneader

2.2.2. Shear-Kneaded Dough

2.3. Evaluation of the Dough Matrix Development

2.3.1. Frequency Sweep Testing

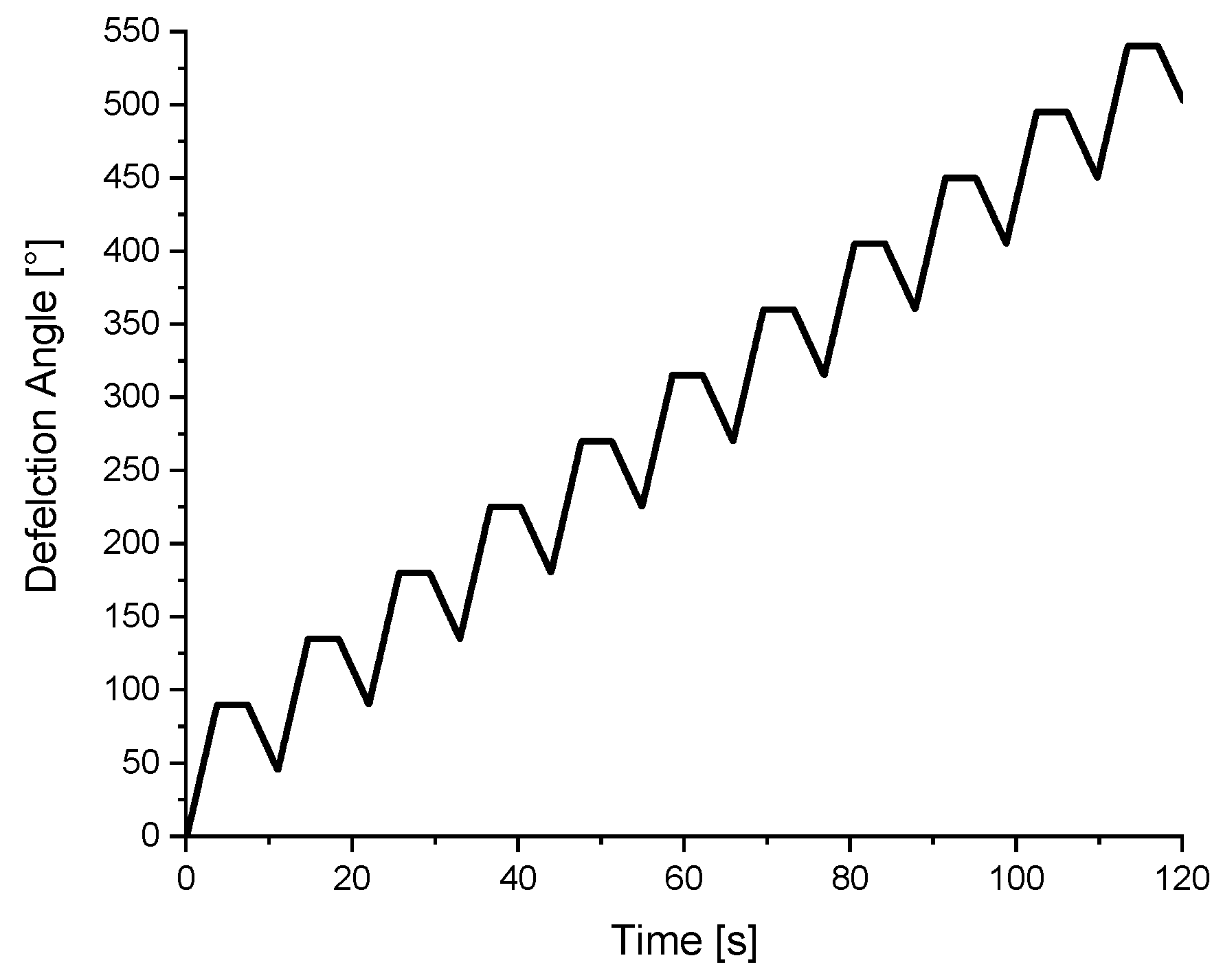

2.3.2. Shear Kneading Setup

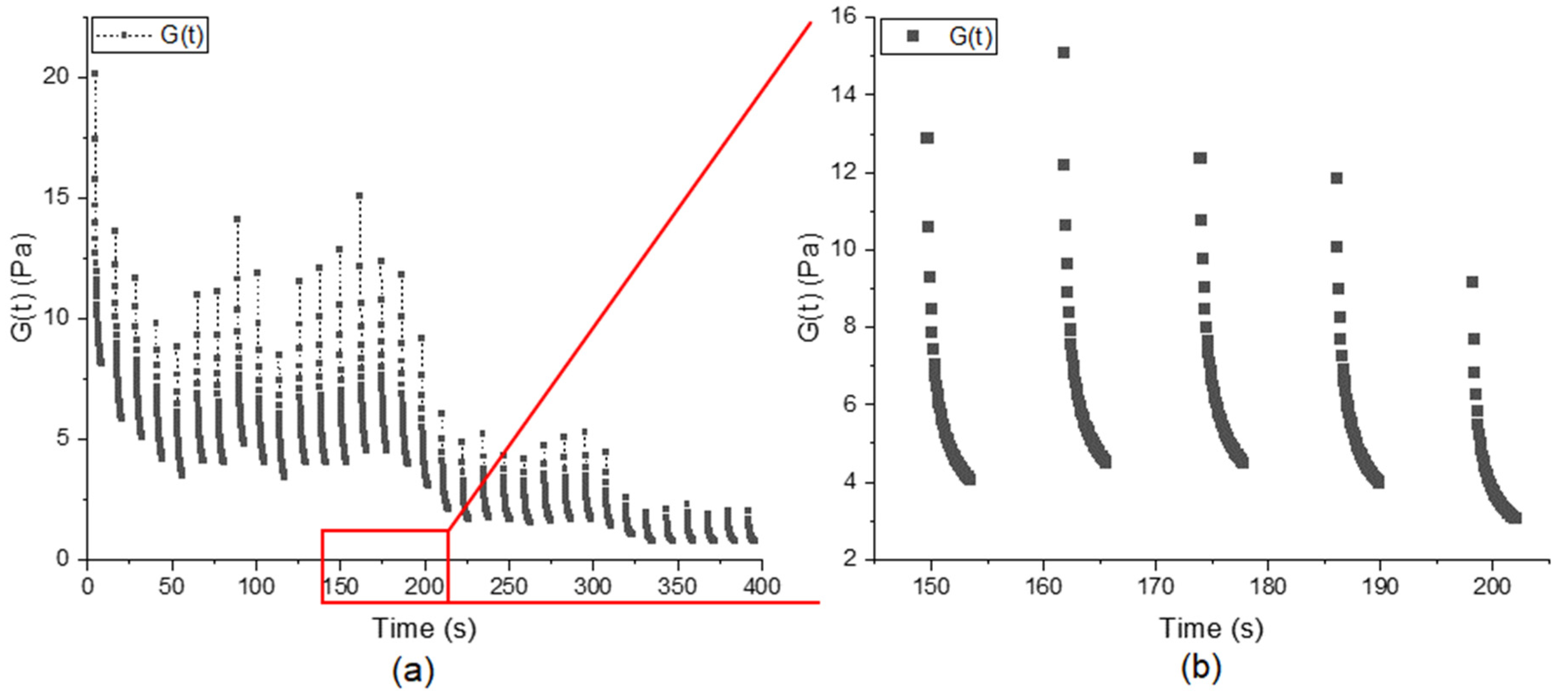

2.3.3. Multiwave Frequency Sweep Testing of Shear-Kneaded Dough

2.3.4. Energy Consumption

2.3.5. Statistical Analysis

3. Results and Discussion

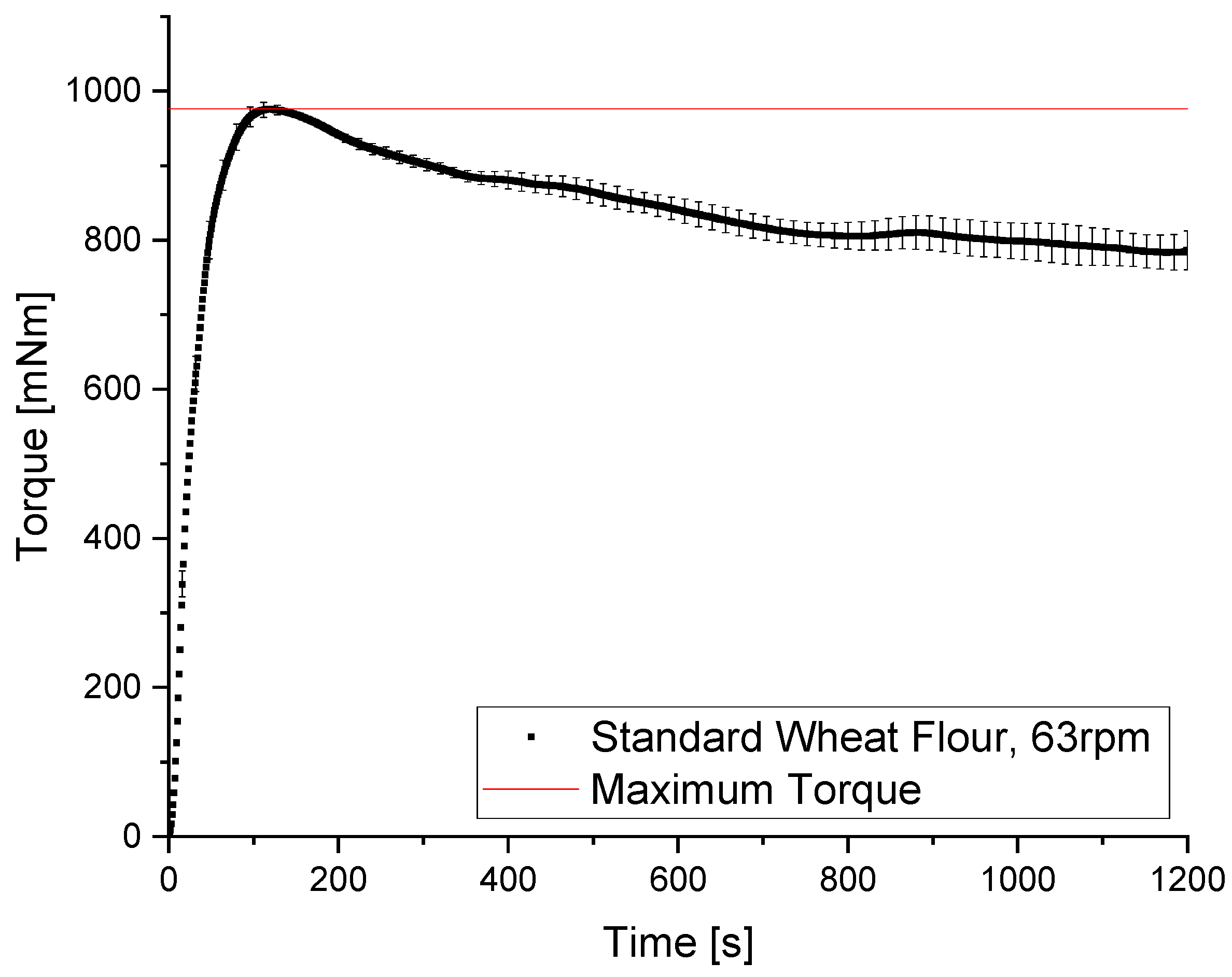

3.1. Standard Mixing Procedure in a Torque-Recording Z-Kneader

3.2. Shear Kneading with Increasing Deformation

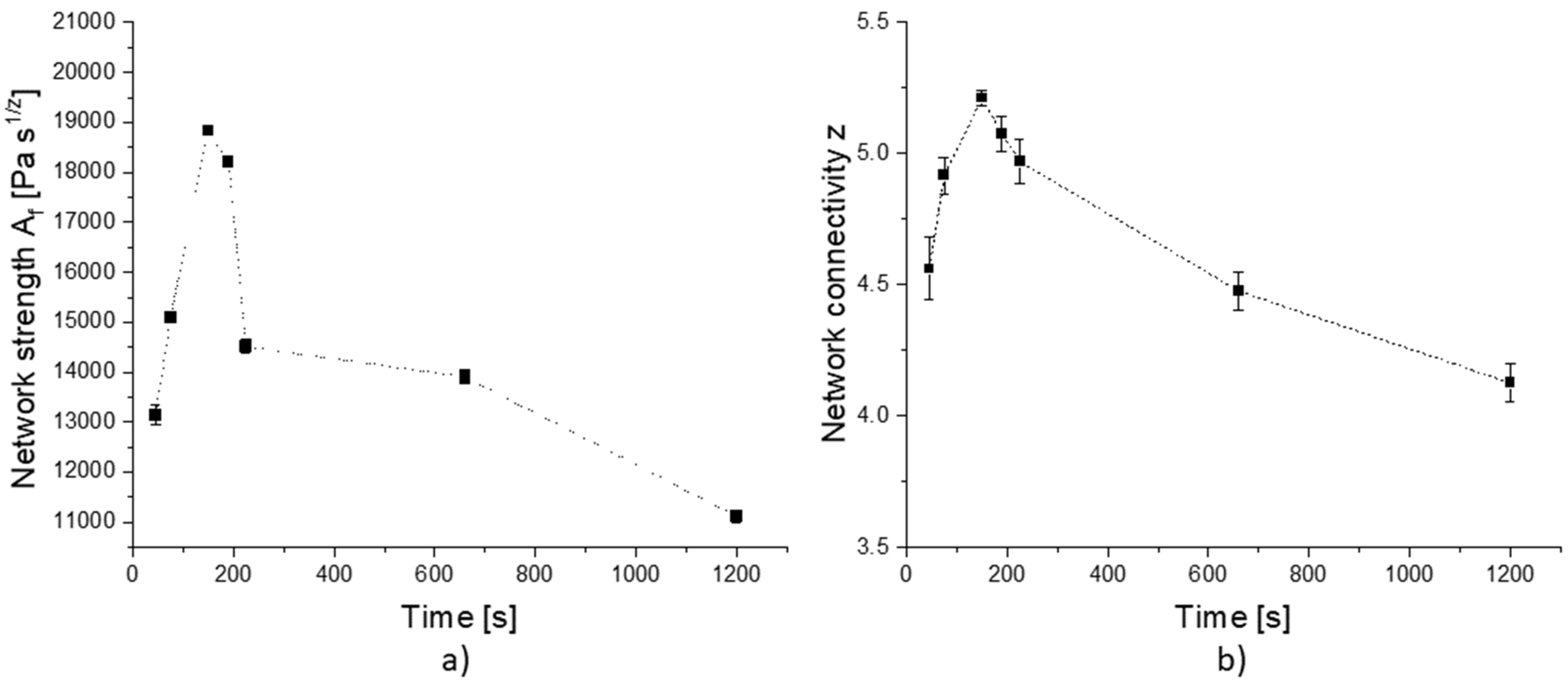

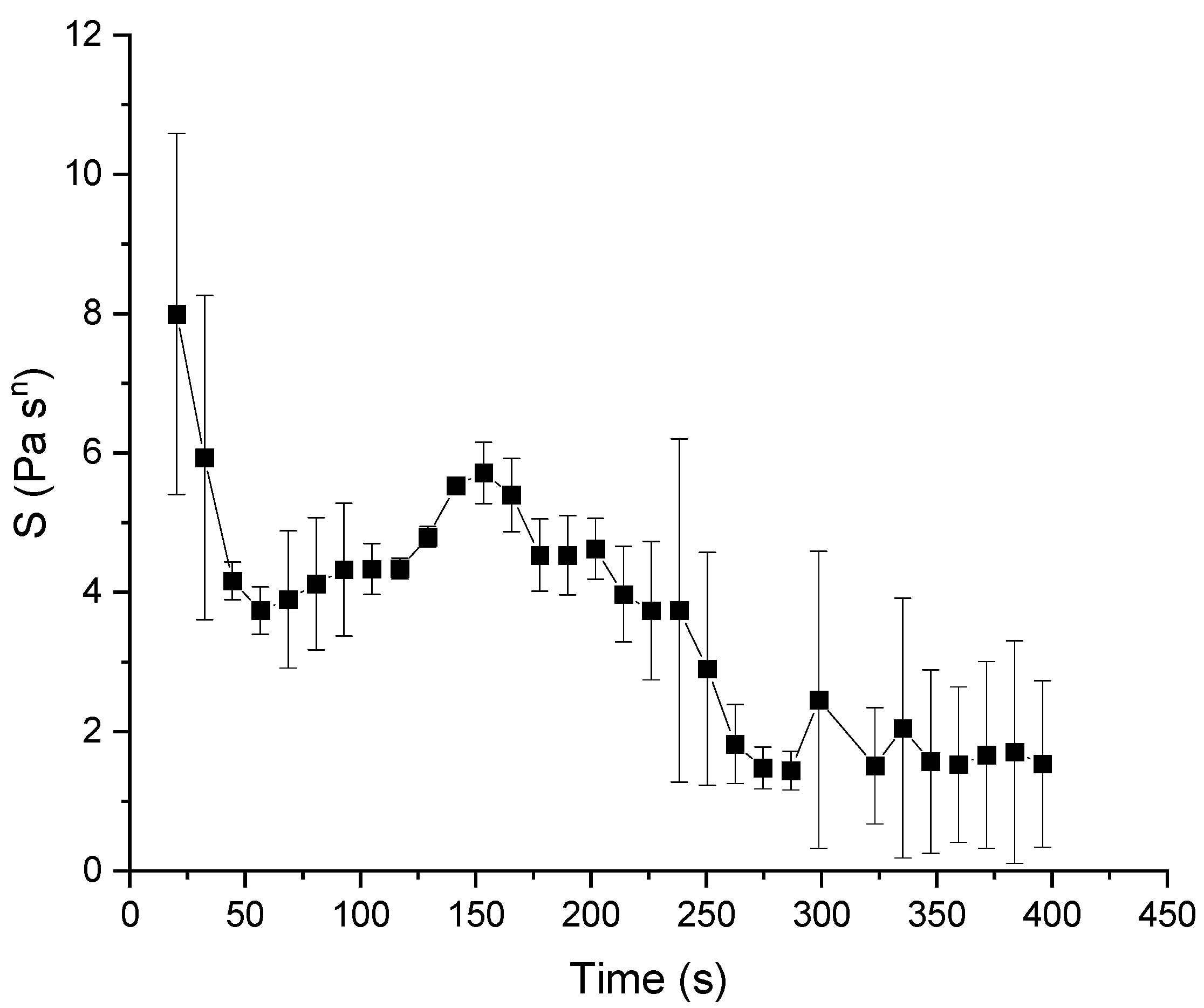

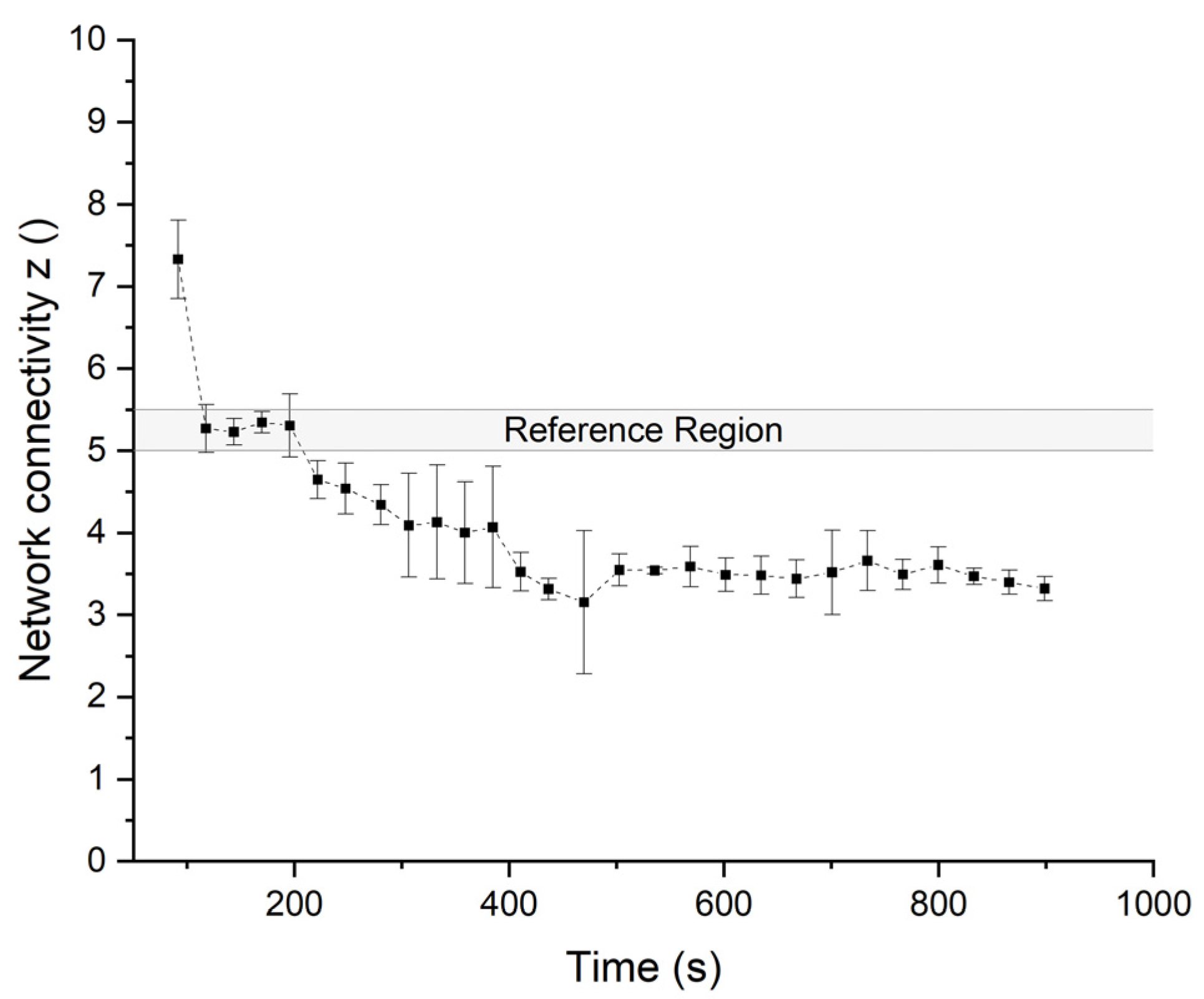

3.3. Multiwave Evaluation of the Shear Kneading Setup with Increasing Deformation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Delcour, J.A.; Joye, I.J.; Pareyt, B.; Wilderjans, E.; Brijs, K.; Lagrain, B. Wheat gluten functionality as a quality determinant in cereal-based food products. Annu. Rev. Food Sci. Technol. 2012, 3, 469–492. [Google Scholar] [CrossRef] [PubMed]

- Jekle, M.; Becker, T. Dough microstructure: Novel analysis by quantification using confocal laser scanning microscopy. Food Res. Int. 2011, 44, 984–991. [Google Scholar] [CrossRef]

- McCann, T.H.; Day, L. Effect of sodium chloride on gluten network formation, dough microstructure and rheology in relation to breadmaking. J. Cereal Sci. 2013, 57, 444–452. [Google Scholar] [CrossRef]

- Delcour, J.A.; Hoseney, R.C. Principles of Cereal Science and Technology, 3rd ed.; AACC International, Inc.: St. Paul, MN, USA, 2010; ISBN 9781891127632. [Google Scholar]

- Parenti, O.; Guerrini, L.; Mompin, S.B.; Toldrà, M.; Zanoni, B. The determination of bread dough readiness during kneading of wheat flour: A review of the available methods. J. Food Eng. 2021, 309, 110692. [Google Scholar] [CrossRef]

- Jongen, T.R.G.; Bruschke, M.V.; Dekker, J.G. Analysis of dough kneaders using numerical flow simulations. Cereal Chem. 2003, 80, 383–389. [Google Scholar] [CrossRef]

- Tietze, S.; Jekle, M.; Becker, T. Advances in the development of wheat dough and bread by means of shearing. J. Food Eng. 2019, 247, 136–143. [Google Scholar] [CrossRef]

- Connelly, R.K.; Kokini, J.L. Examination of the mixing ability of single and twin screw mixers using 2D finite element method simulation with particle tracking. J. Food Eng. 2007, 79, 956–969. [Google Scholar] [CrossRef]

- Connelly, R.K.; Kokini, J.L. 3D numerical simulation of the flow of viscous Newtonian and shear thinning fluids in a twin sigma blade mixer. Adv. Polym. Technol. 2006, 25, 182–194. [Google Scholar] [CrossRef]

- Peighambardoust, S.H.H.; van der Goot, A.J.J.; van Vliet, T.; Hamer, R.J.J.; Boom, R.M.M. Microstructure formation and rheological behaviour of dough under simple shear flow. J. Cereal Sci. 2006, 43, 183–197. [Google Scholar] [CrossRef]

- Anderssen, R.S.; Gras, P.W.; MacRitchie, F. The rate-independence of the mixing of wheat flour dough to peak dough development. J. Cereal Sci. 1998, 27, 167–177. [Google Scholar] [CrossRef]

- Peighambardoust, S.H.; Van Der Goot, A.J.; Hamer, R.J.; Boom, R.M. A new method to study simple shear processing of wheat gluten-starch mixtures. Cereal Chem. 2004, 81, 714–721. [Google Scholar] [CrossRef]

- Tietze, S.; Jekle, M.; Becker, T. Development of wheat dough by means of shearing. J. Food Eng. 2017, 201, 1–8. [Google Scholar] [CrossRef]

- Peressini, D.; Peighambardoust, S.H.H.; Hamer, R.J.J.; Sensidoni, A.; van der Goot, A.J. Effect of shear rate on microstructure and rheological properties of sheared wheat doughs. J. Cereal Sci. 2008, 48, 426–438. [Google Scholar] [CrossRef]

- Peighambardoust, S.H.; van Brenk, S.; van der Goot, A.J.; Hamer, R.J.; Boom, R.M. Dough processing in a Couette-type device with varying eccentricity: Effect on glutenin macro-polymer properties and dough micro-structure. J. Cereal Sci. 2007, 45, 34–48. [Google Scholar] [CrossRef]

- Peighambardoust, S.H.; Hamer, R.J.; Boom, R.M.; van der Goot, A.J. Migration of gluten under shear flow as a novel mechanism for separating wheat flour into gluten and starch. J. Cereal Sci. 2008, 48, 327–338. [Google Scholar] [CrossRef]

- Meerts, M.; Cardinaels, R.; Oosterlinck, F.; Courtin, C.M.; Moldenaers, P. Contributions of the main flour constituents to dough rheology, and implications for dough quality and its assessment. Adv. Mater.-TechConnect Briefs 2016, 3, 23–26. [Google Scholar]

- Meerts, M. Assessing the Role of the Main Flour Components and Fermentation in the Rheology of Wheat Flour Dough with a New Rheological Toolbox; Katholieke Universiteit Leuven: Leuven, Belgium, 2018. [Google Scholar]

- Gabriele, D.; De Cindio, B.; D’Antona, P. A weak gel model for foods. Rheol. Acta 2001, 40, 120–127. [Google Scholar] [CrossRef]

- Bohlin, L. A theory of flow as a cooperative phenomenon. J. Colloid Interface Sci. 1980, 74, 423–434. [Google Scholar] [CrossRef]

- Bohlin, L.; Carlson, L.G. Dynamic viscoelastic properties of wheat flour dough: Dependence on mixing time. Cereal Chem. 1980, 57, 174–177. [Google Scholar]

- Sun, X.; Koksel, F.; Nickerson, M.T.; Scanlon, M.G. Modeling the viscoelastic behavior of wheat flour dough prepared from a wide range of formulations. Food Hydrocoll. 2020, 98, 105129. [Google Scholar] [CrossRef]

- Winter, H.H.; Mours, M. Rheology of Polymers Near Liquid-Solid Transitions. Adv. Polym. Sci. 1997, 134, 164–234. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Narasimha, H.V. Puncture and stress relaxation behavior of blackgram (Phaseolus mungo) flour-based Papad dough. J. Food Process Eng. 1997, 20, 301–316. [Google Scholar] [CrossRef]

- Peleg, M.; Normand, M.D. Comparison of two methods for stress relaxation data presentation of solid foods. Rheol. Acta 1983, 22, 108–113. [Google Scholar] [CrossRef]

- Schiedt, B.; Baumann, A.; Conde-Petit, B.; Vilgis, T.A. Short- and Long-Range Interactions Governing the Viscoelastic Properties during Wheat Dough and Model Dough Development. J. Texture Stud. 2013, 44, 317–332. [Google Scholar] [CrossRef]

- Shewry, P.R.; Halford, N.G.; Tatham, A.S. High molecular weight subunits of wheat glutenin. J. Cereal Sci. 1992, 15, 105–120. [Google Scholar] [CrossRef]

- Belton, P.S. On the elasticity of wheat gluten. J. Cereal Sci. 1999, 29, 103–107. [Google Scholar] [CrossRef]

- Brandner, S.; Becker, T.; Jekle, M. Wheat dough imitating artificial dough system based on hydrocolloids and glass beads. J. Food Eng. 2018, 223, 144–151. [Google Scholar] [CrossRef]

- Gómez, A.; Ferrero, C.; Calvelo, A.; Añón, M.C.; Puppo, M.C. Effect of Mixing Time on Structural and Rheological Properties of Wheat Flour Dough for Breadmaking. Int. J. Food Prop. 2011, 14, 583–598. [Google Scholar] [CrossRef]

- Georgopoulos, T.; Larsson, H.; Eliasson, A.-C. A comparison of the rheological properties of wheat flour dough and its gluten prepared by ultracentrifugation. Food Hydrocoll. 2004, 18, 143–151. [Google Scholar] [CrossRef]

- Perše, L.S.; Bek, M.; Oseli, A.; Orbanić, H. Viscoelastic properties of bread dough kneaded with a kitchen machine. Annu. Trans. Nord. Rheol. Soc. 2018, 26, 233–239. [Google Scholar]

- Uthayakumaran, S.; Newberry, M.; Phan-Thien, N.; Tanner, R. Small and large strain rheology of wheat gluten. Rheol. Acta 2002, 41, 162–172. [Google Scholar] [CrossRef]

- Tanner, R.I.; Qi, F.; Dai, S.C. Bread dough rheology and recoil. I. Rheology. J. Nonnewton. Fluid Mech. 2008, 148, 33–40. [Google Scholar] [CrossRef]

- Haraszi, R.; Larroque, O.R.; Butow, B.J.; Gale, K.R.; Bekes, F. Differential mixing action effects on functional properties and polymeric protein size distribution of wheat dough. J. Cereal Sci. 2008, 47, 41–51. [Google Scholar] [CrossRef]

- Don, C.; Lichtendonk, W.J.; Plijter, J.J.; Hamer, R.J. Understanding the link between GMP and dough: From glutenin particles in flour towards developed dough. J. Cereal Sci. 2003, 38, 157–165. [Google Scholar] [CrossRef]

- Alpers, T.; Tauscher, V.; Steglich, T.; Becker, T.; Jekle, M. The Self-Enforcing Starch-Gluten System-Strain-Dependent Effects of Yeast Metabolites on the Polymeric Matrix. Polymers 2020, 13, 30. [Google Scholar] [CrossRef] [PubMed]

- Winter, H.H. Evolution of rheology during chemical gelation. In Permanent and Transient Networks; Steinkopff: Darmstadt, Germany, 1987; pp. 104–110. [Google Scholar]

- Fröhlich, J.; Niedermeier, W.; Luginsland, H.D. The effect of filler-filler and filler-elastomer interaction on rubber reinforcement. Compos. Part A Appl. Sci. Manuf. 2005, 36, 449–460. [Google Scholar] [CrossRef]

- Safari-Ardi, M.; Phan-Thien, N. Stress relaxation and oscillatory tests to distinguish between doughs prepared from wheat flours of different varietal origin. Cereal Chem. 1998, 75, 80–84. [Google Scholar] [CrossRef]

- Li, W.; Dobraszczyk, B.J.; Schofield, J.D. Stress Relaxation Behavior of Wheat Dough, Gluten, and Gluten Protein Fractions. Cereal Chem. J. 2003, 80, 333–338. [Google Scholar] [CrossRef]

- Brandner, S.; Becker, T.; Jekle, M. Classification of starch-gluten networks into a viscoelastic liquid or solid, based on rheological aspects—A review. Int. J. Biol. Macromol. 2019, 136, 1018–1025. [Google Scholar] [CrossRef]

- Genovese, D.B.; Rao, M.A. Role of starch granule characteristics (volume fraction, rigidity, and fractal dimension) on rheology of starch dispersions with and without amylose. Cereal Chem. 2003, 80, 350–355. [Google Scholar] [CrossRef]

- Rao, V.K.; Mulvaney, S.J.; Dexter, J.E. Rheological characterisation of long- and short-mixing flours based on stress-relaxation. J. Cereal Sci. 2000, 31, 159–171. [Google Scholar] [CrossRef]

- Godavarti, S.; Karwe, M.V. Determination of specific mechanical energy distribution on a twin-screw extruder. J. Agric. Eng. Res. 1997, 67, 277–287. [Google Scholar] [CrossRef]

- Winter, H.H.; Chambon, F. Analysis of Linear Viscoelasticity of a Crosslinking Polymer at the Gel Point. J. Rheol. 1986, 30, 367–382. [Google Scholar] [CrossRef]

| Reaching 400 FU | 50% DDT | 100% DDT | End of Stability | 150% DDT | Over-Kneaded 1 | Over-Kneaded 2 |

|---|---|---|---|---|---|---|

| 45 s | 75 s | 150 s | 190 s | 225 s | 660 s | 1200 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidal, L.M.; Braun, A.; Jekle, M.; Becker, T. Micro-Scale Shear Kneading—Gluten Network Development under Multiple Stress–Relaxation Steps and Evaluation via Multiwave Rheology. Polymers 2022, 14, 846. https://doi.org/10.3390/polym14040846

Vidal LM, Braun A, Jekle M, Becker T. Micro-Scale Shear Kneading—Gluten Network Development under Multiple Stress–Relaxation Steps and Evaluation via Multiwave Rheology. Polymers. 2022; 14(4):846. https://doi.org/10.3390/polym14040846

Chicago/Turabian StyleVidal, Leonhard Maria, Andre Braun, Mario Jekle, and Thomas Becker. 2022. "Micro-Scale Shear Kneading—Gluten Network Development under Multiple Stress–Relaxation Steps and Evaluation via Multiwave Rheology" Polymers 14, no. 4: 846. https://doi.org/10.3390/polym14040846