Consideration of Yarn Anisotropy in the Investigation of the Puncture Resistance of Fibrous Materials

Abstract

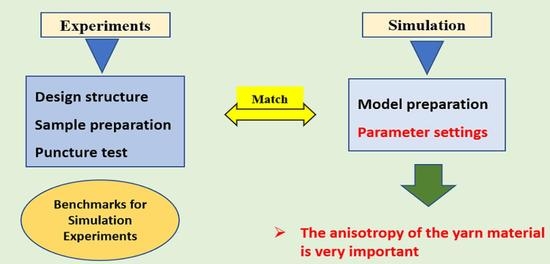

1. Introduction

2. Puncture Experiment

2.1. Experiment Preparation

2.2. Determination of Material Parameters

2.2.1. Measurement of Axial Modulus

2.2.2. Measurement of Radial Modulus

- U: the change in fiber diameter;

- F: the compressive force;

- ET: the transverse modulus of the fiber;

- LT: the longitudinal Poisson’s ratio of the fiber;

- R: the radius of the fiber; and

- b: the contact width of the fiber during compression.

- ET: the transverse modulus of the fiber;

- F: the compressive force;

- R: the radius of the fiber;

- L: the length of the fiber during compression; and

- : the strain of the fiber.

2.3. Puncture Experiments

2.4. Dynamic Analysis of the Puncture Results

3. Simulation Experiment

3.1. Model Establishment

- (1)

- the yarns were continuous filaments with uniform bars, and the cross section was a runway type; and

- (2)

- the composite material had no defects and the resin distribution was uniform [28].

3.2. Model Parameters

3.3. Puncture Simulation

3.3.1. Comparison of Simulation Results

3.3.2. Microscopic Analysis of the Simulated Puncture Results

- (1)

- Stress analysis of the whole fabric

- (2)

- Stress analysis of central yarns

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nayak, R.; Crouch, I.; Kanesalingam, S.; Ding, J.; Tan, P.; Lee, B.; Miao, M.; Ganga, D.; Wang, L. Body armor for stab and spike protection, Part 1: Scientific literature review. Text. Res. J. 2018, 88, 812–832. [Google Scholar] [CrossRef]

- Horsfall, I. Stab Resistant Body Armour. Ph.D. Thesis, Engineering Systems Department, College of Defense Technology, Cranfield University, Cranfield, UK, 2000. [Google Scholar]

- Zheng, L.; Zhang, K.; Liu, L.; Xu, F. Biomimetic architectured Kevlar/polyimide composites with ultra-light, superior anti-compressive and flame-retardant properties. Compos. Part B Eng. 2022, 230, 109485. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, J.; Sang, M.; Liu, S.; Yuan, F.; Wang, S.; Sun, S.; Gong, X. Advanced functional Kevlar composite with excellent mechanical properties for thermal management and intelligent safeguarding. Chem. Eng. J. 2022, 428, 131878. [Google Scholar] [CrossRef]

- Usman Javaid, M.; Militký, J.; Wiener, J.; Jabbar, A.; Salačová, J.; Umair, M. Effect of surface modification and knife penetration angle on the quasi-static knife penetration resistance of para-aramid fabrics. J. Text. Inst. 2019, 110, 590–599. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Zhou, J.; Zhao, C.; Wu, Y.; Liu, S.; Gong, X. Intralayer interfacial sliding effect on the anti-impact performance of STF/Kevlar composite fabric. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106401. [Google Scholar] [CrossRef]

- Sy, B.L.; Oguamanam, D.; Bougherara, H. Impact response of a new kevlar/flax/epoxy hybrid composite using infrared thermography and high-speed imaging. Compos. Struct. 2022, 280, 114885. [Google Scholar]

- Eltaher, M.A.; Basha, M.; Wagih, A.; Melaibari, A.; Lubineau, G. On the impact damage resistance and tolerance improvement of hybrid CFRP/Kevlar sandwich composites. Microporous Mesoporous Mater. 2022, 333, 111732. [Google Scholar]

- White, Z.; Vernerey, F. Armours for soft bodies: How far can bioinspiration take us? Bioinspir. Biomim. 2018, 13, 041004. [Google Scholar] [CrossRef]

- Guleria, T.; Verma, N.; Zafar, S.; Jain, V. Fabrication of Kevlar-reinforced ultra-high molecular weight polyethylene composite through microwave-assisted compression molding for body armor applications. J. Reinf. Plast. Compos. 2021, 40, 307–320. [Google Scholar] [CrossRef]

- Karamooz, M.R.; Rahmani, H.; Khosravi, H. Numerical and experimental investigations on the low-velocity impact properties of hybrid Kevlar fiber/basalt fiber reinforced epoxy composites: Effects of impactor nose shape and fiber stacking sequences. Polym. Compos. 2021, 42, 6442–6454. [Google Scholar] [CrossRef]

- Hetrick, D.R.; Sanei, S.H.R.; Ashour, O.; Bakis, C.E. Charpy impact energy absorption of 3D printed continuous Kevlar reinforced composites. J. Compos. Mater. 2021, 55, 1705–1713. [Google Scholar] [CrossRef]

- Hou, X.; Acar, M.; Silberschmidt, V.V. 2D finite element analysis of thermally bonded nonwoven materials: Continuous and discontinuous models. Comput. Mater. Sci. 2009, 46, 700–707. [Google Scholar] [CrossRef]

- Ridruejo, A.; González, C.; LLorcaab, J. Damage micromechanisms and notch sensitivity of glass-fiber non-woven felts: An experimental and numerical study. J. Mech. Phys. Solids 2010, 58, 1628–1645. [Google Scholar] [CrossRef]

- Zeng, J.; Cao, H.; Hu, H. Finite element simulation of an auxetic plied yarn structure. Text. Res. J. 2018, 89, 3394–3400. [Google Scholar] [CrossRef]

- Zhou, H.; Xiao, X.; Qian, K.; Ma, Q. Numerical simulation and experimental study of the bursting performance of triaxial woven fabric and its reinforced rubber composites. Text. Res. J. 2019, 90, 561–571. [Google Scholar] [CrossRef]

- Sun, B.; Wang, Y.; Wang, P.; Hu, H.; Gu, B. Investigations of puncture behaviors of woven fabrics from finite element analyses and experimental tests. Text. Res. J. 2011, 81, 992–1007. [Google Scholar] [CrossRef]

- Zhu, D.; Szewciw, L.; Vernerey, F.; Barthelat, F. Puncture resistance of the scaled skin from striped bass: Collective mechanisms and inspiration for new flexible armor designs. J. Mech. Behav. Biomed. Mater. 2013, 24, 30–40. [Google Scholar] [CrossRef]

- Lian, J.; Bohong, G.U. Numerical simulation of dynamic performance of three-dimensional braided composites. J. Text. Res. 2011, 32, 41–45. [Google Scholar]

- Termonia, Y. Puncture resistance of fibrous structures. Int. J. Impact Eng. 2006, 32, 1512–1520. [Google Scholar] [CrossRef]

- Bao, L.; Wang, Y.; Baba, T.; Fukuda, Y.; Wakatsuki, K.; Morikawa, H. Development of a high-density nonwoven structure to improve the stab resistance of protective clothing material. Ind. Health 2017, 55, 513–520. [Google Scholar] [CrossRef]

- Bao, L.; Sato, S.; Wang, Y.; Wakatsuki, K.; Morikawa, H. Development of flexible stab-proof textiles impregnated with microscopic particles. J. Text. Eng. 2017, 63, 43–48. [Google Scholar] [CrossRef][Green Version]

- Chuang, Y.-C.; Bao, L.; Lin, M.C.; Lou, C.W.; Lin, T. Mechanical and static stab resistant properties of hybrid-fabric fibrous planks: Manufacturing process of nonwoven fabrics made of recycled fibers. Polymers 2019, 11, 1140. [Google Scholar] [CrossRef] [PubMed]

- Carrillo, J.G.; Castellanos, R.G.; Flores-Johnson, E.A.; Gonzalez-Chi, P.I. Ballistic performance of thermoplastic composite laminates made from aramid woven fabric and polypropylene matrix. Polym. Test. 2012, 31, 512–519. [Google Scholar] [CrossRef]

- Kawabata, S. Measurement of the transverse mechanical properties of high-performance fibres. J. Text. Inst. 1990, 81, 432–447. [Google Scholar] [CrossRef]

- Ruan, F.; Bao, L. Mechanical enhancement of UHMWPE fibers by coating with carbon nanoparticles. Fibers Polym. 2014, 15, 723–728. [Google Scholar] [CrossRef]

- Bao, L.; Sato, S.; Morioka, H.; Soma, S. Improving stab-resistant textile materials with a non-woven fabric structure. J. Text. Eng. 2016, 62, 37–42. [Google Scholar] [CrossRef]

- Ju, W.; Dai, W.W. Application of ANSYS Workbench in structural transient dynamic analysis. Inner Mong. Coal Econ. 2014, 8, 110–113. [Google Scholar]

- Stolarski, T.; Nakasone, Y.; Yoshimoto, S. Engineering Analysis with ANSYS Software; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Zhu, L.; Liu, W.; Fang, H.; Qian, Z.; ZHUANG, Y. Experiment and finite element analysis of lattice reinforced composite sandwich panels subjected to low-velocity impact. J. Nanjing Univ. Technol. Nat. Sci. Ed. 2017, 39, 126–132. [Google Scholar]

- Gzaiel, M.; Triki, E.; Barkaoui, A. Finite element modeling of the puncture-cutting response of soft material by a pointed blade. Mech. Mater. 2019, 136, 103082. [Google Scholar] [CrossRef]

- Luo, C.; Cao, H.; Huang, X. Numerical simulation on low velocity impact response of three-dimensional sandwich composites with different core height. Text. Res. J. 2019, 40, 48–54. [Google Scholar]

| Young’s Modulus (GPa) | Tensile/Compression Strength (GPa) | Failure Strain | |

|---|---|---|---|

| Axial direction of yarn | 78.62 ± 2.54 | 2.58 ± 0.32 | 0.032 ± 0.0024 |

| Radial direction of yarn | 0.32 ± 0.04 | 0.23 ± 0.02 | 0.263 ± 0.031 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, C.; Sun, Y.; Wakatsuki, K.; Morikawa, H.; Bao, L. Consideration of Yarn Anisotropy in the Investigation of the Puncture Resistance of Fibrous Materials. Polymers 2022, 14, 883. https://doi.org/10.3390/polym14050883

Luo C, Sun Y, Wakatsuki K, Morikawa H, Bao L. Consideration of Yarn Anisotropy in the Investigation of the Puncture Resistance of Fibrous Materials. Polymers. 2022; 14(5):883. https://doi.org/10.3390/polym14050883

Chicago/Turabian StyleLuo, Chao, Ye Sun, Kaoru Wakatsuki, Hideaki Morikawa, and Limin Bao. 2022. "Consideration of Yarn Anisotropy in the Investigation of the Puncture Resistance of Fibrous Materials" Polymers 14, no. 5: 883. https://doi.org/10.3390/polym14050883

APA StyleLuo, C., Sun, Y., Wakatsuki, K., Morikawa, H., & Bao, L. (2022). Consideration of Yarn Anisotropy in the Investigation of the Puncture Resistance of Fibrous Materials. Polymers, 14(5), 883. https://doi.org/10.3390/polym14050883