Influence of Filament Winding Tension on the Deformation of Composite Flywheel Rotors with H-Shaped Hubs

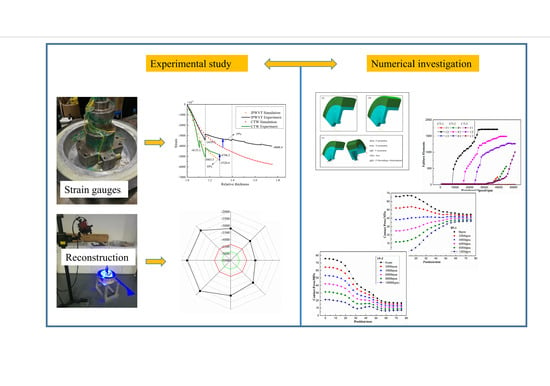

Abstract

:1. Introduction

2. Experimental study

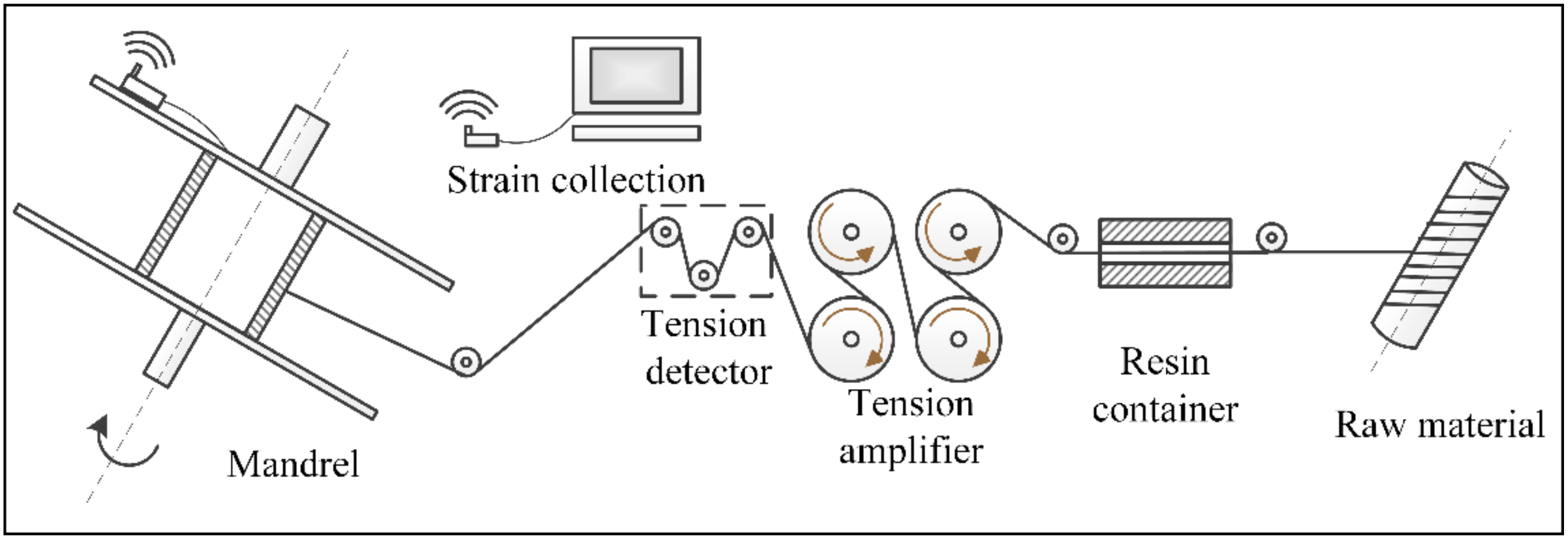

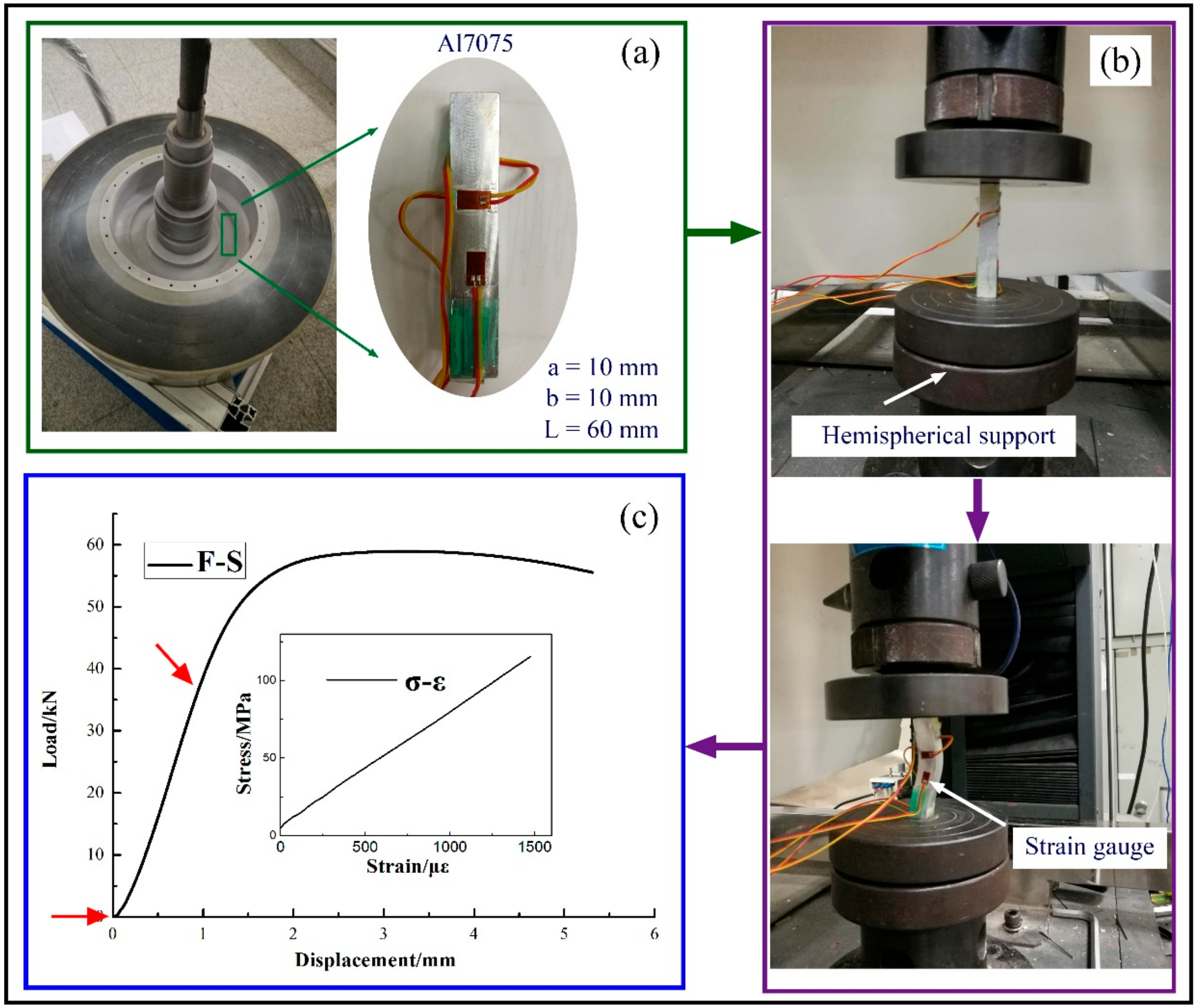

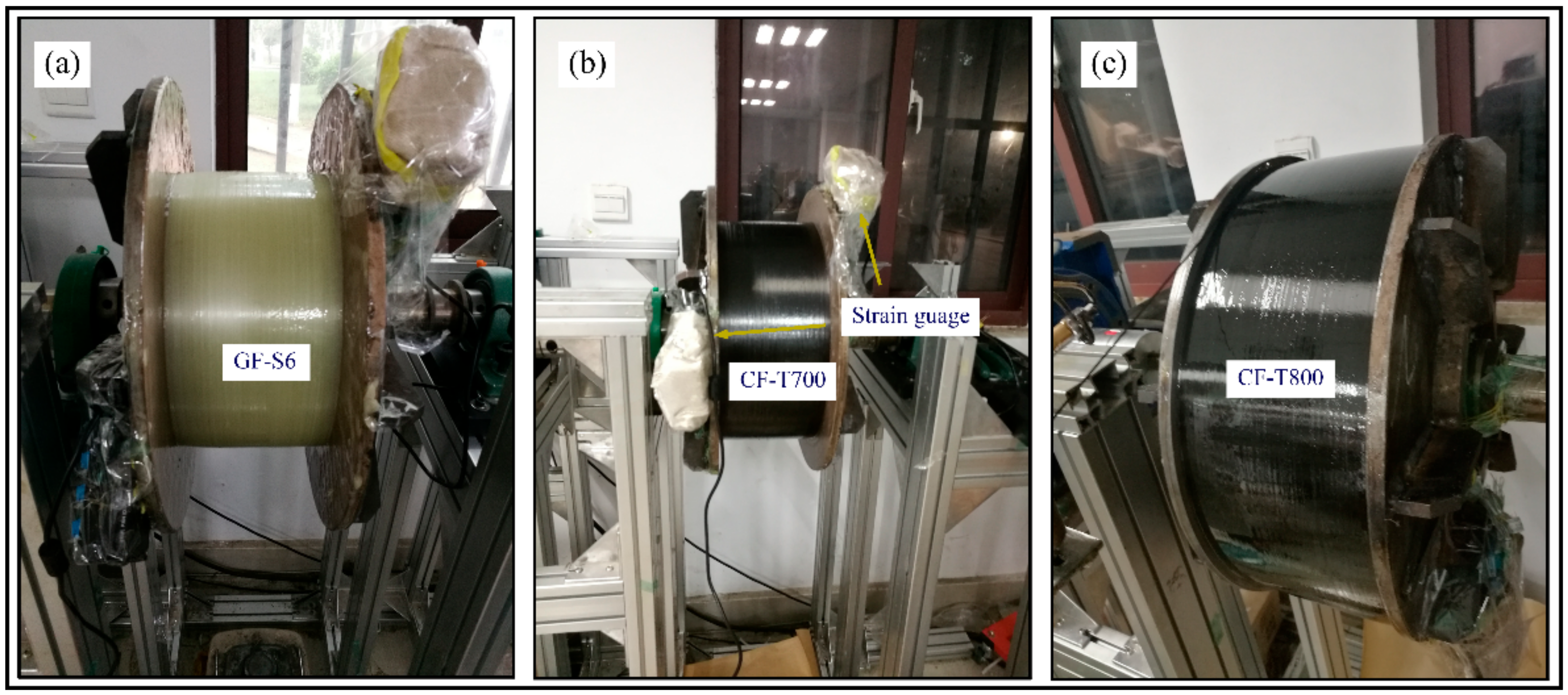

2.1. Materials and Equipment

2.2. Fabrication of Flywheel Rotor

2.3. Quantization of Deformations

2.4. Experimental Results and Discussion

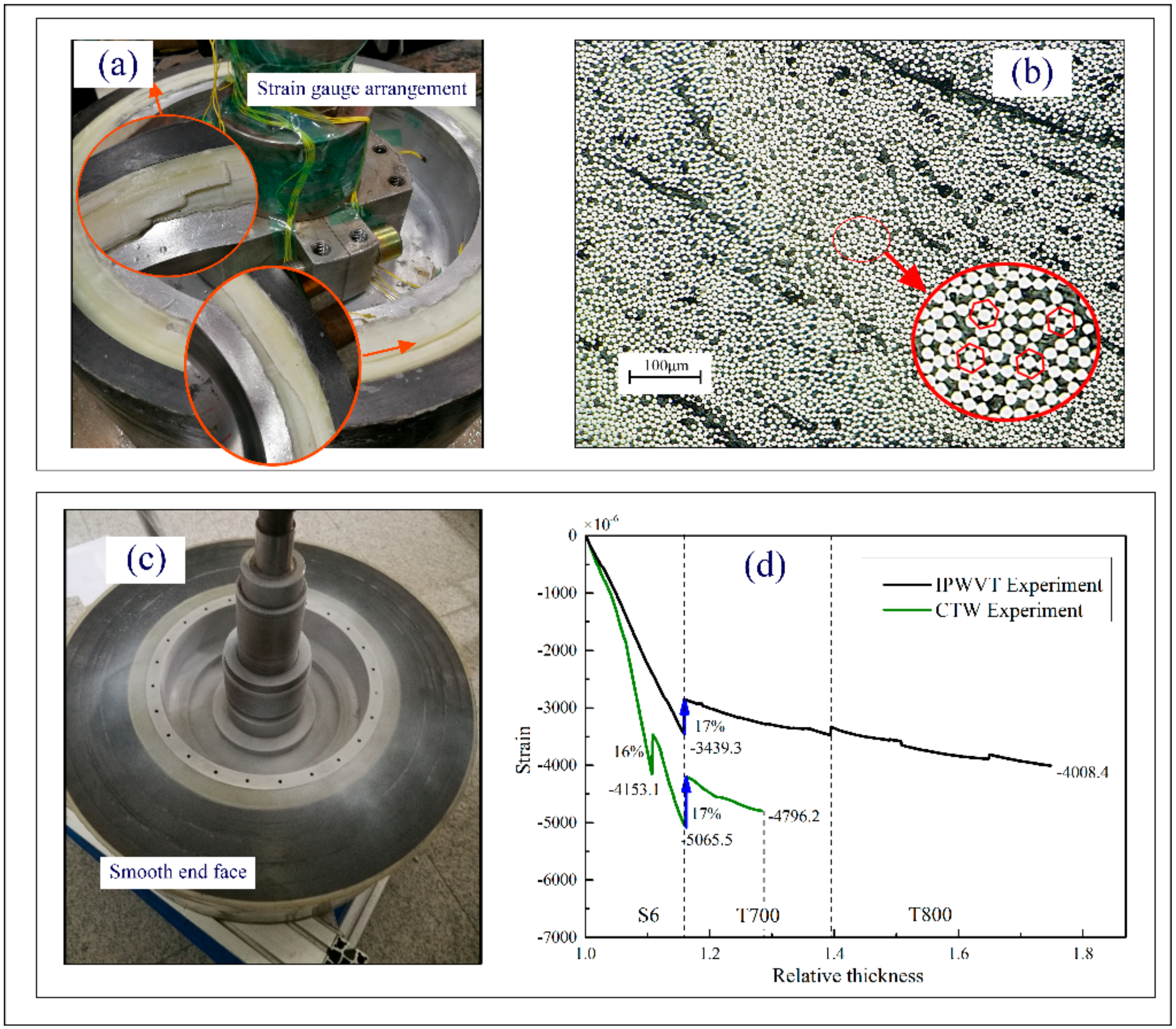

2.4.1. Results of Mechanical Properties and Microstructure

2.4.2. Results of Online and Offline Deformation Monitoring

3. Finite Element Analysis (FEA)

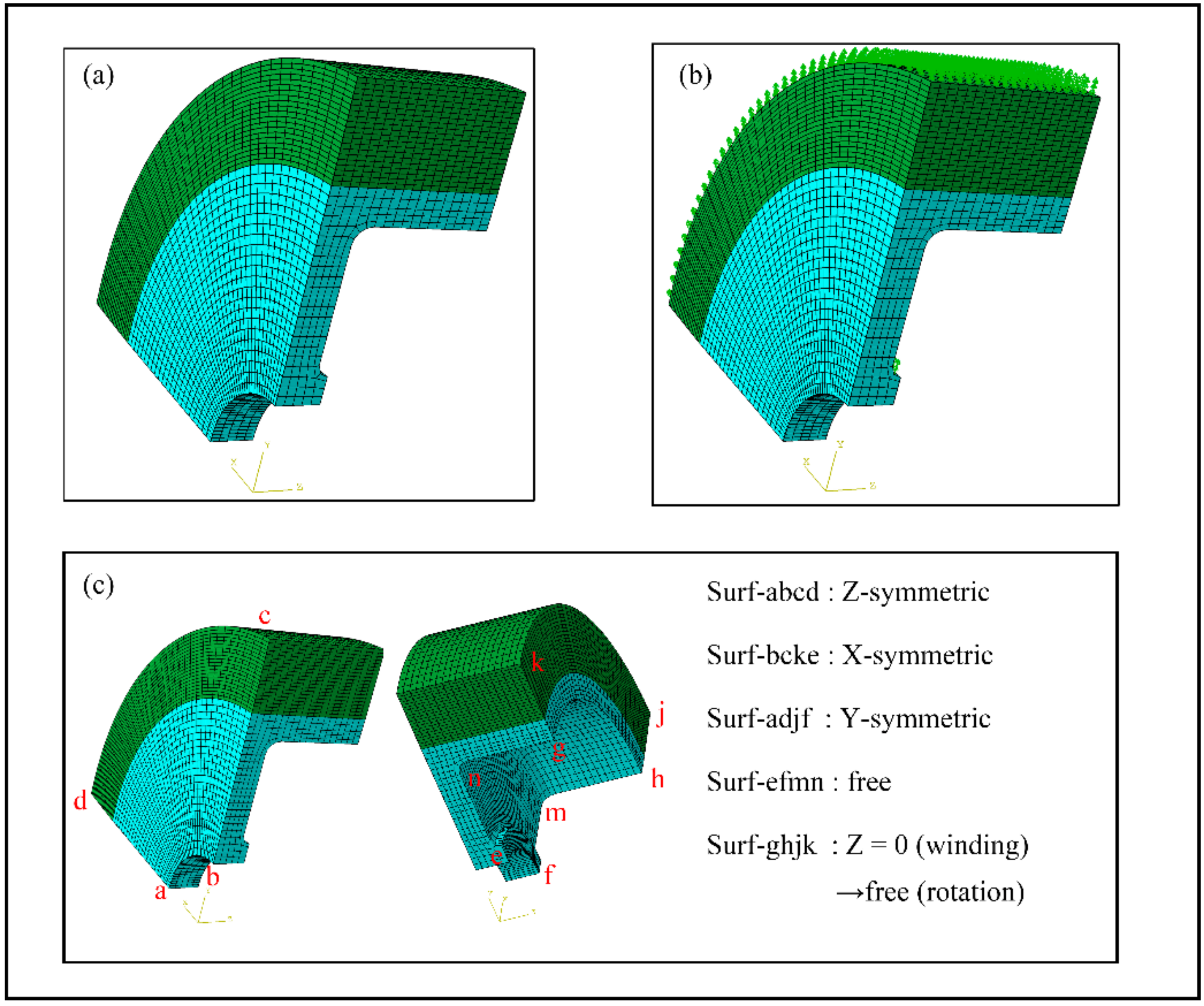

3.1. Finite Element Model and Boundary Conditions

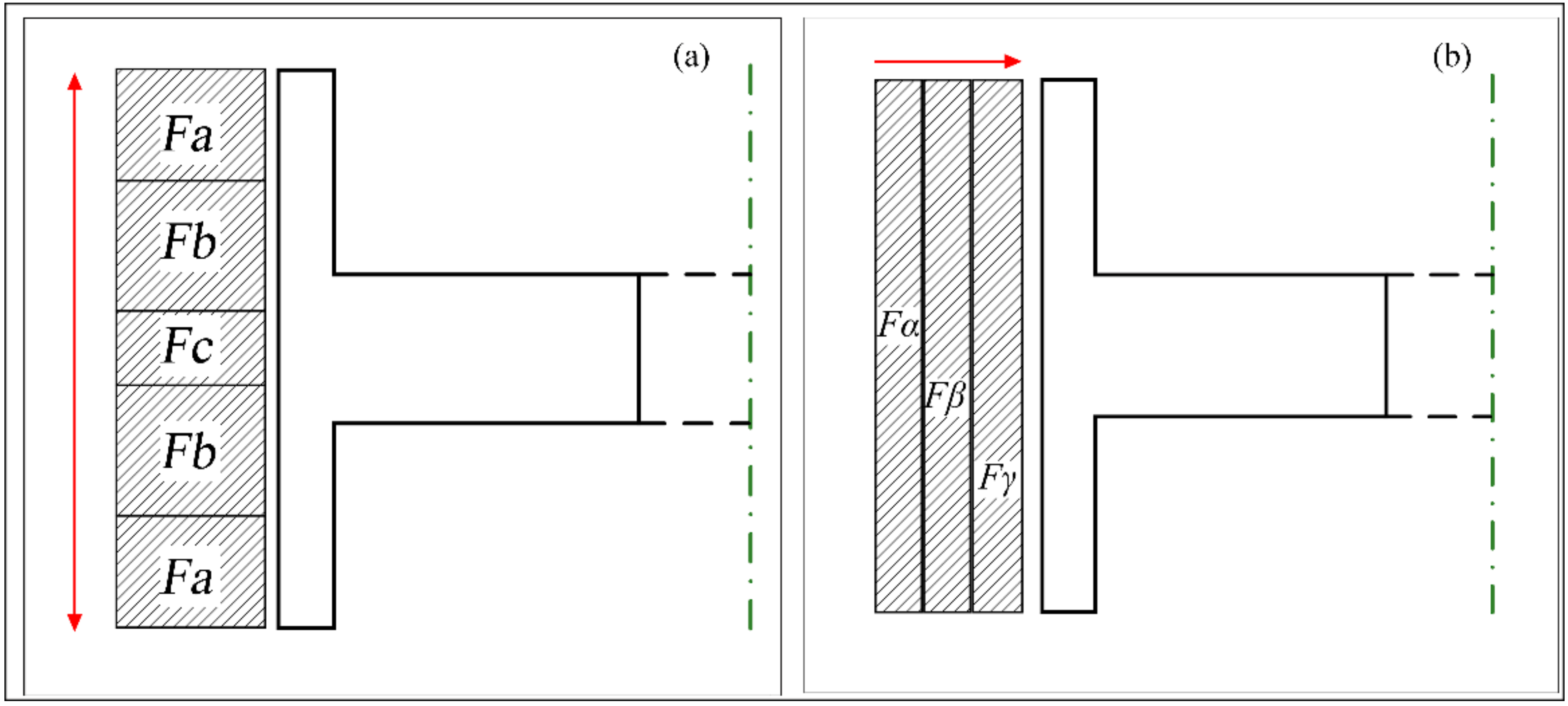

3.2. Modeling of Fiber Tension

3.3. Failure Criterion and Degradation Model

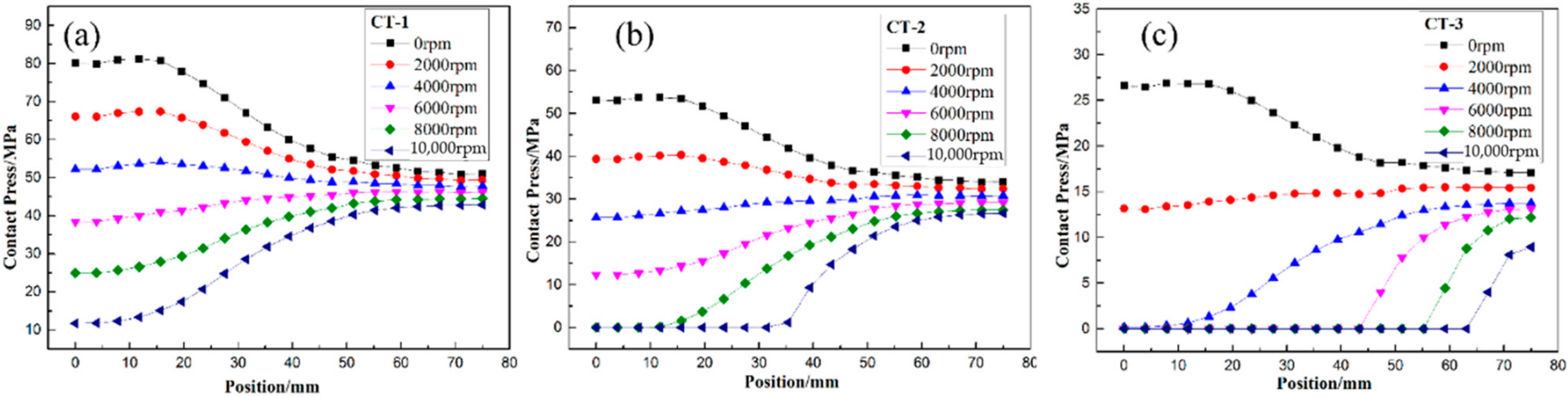

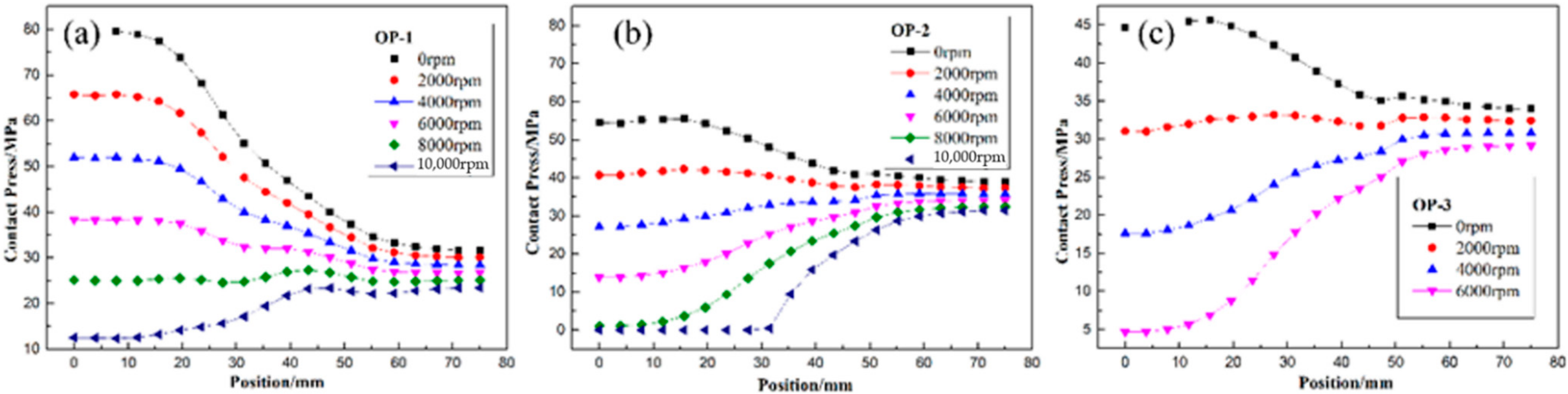

3.4. Numerical Results and Discussion

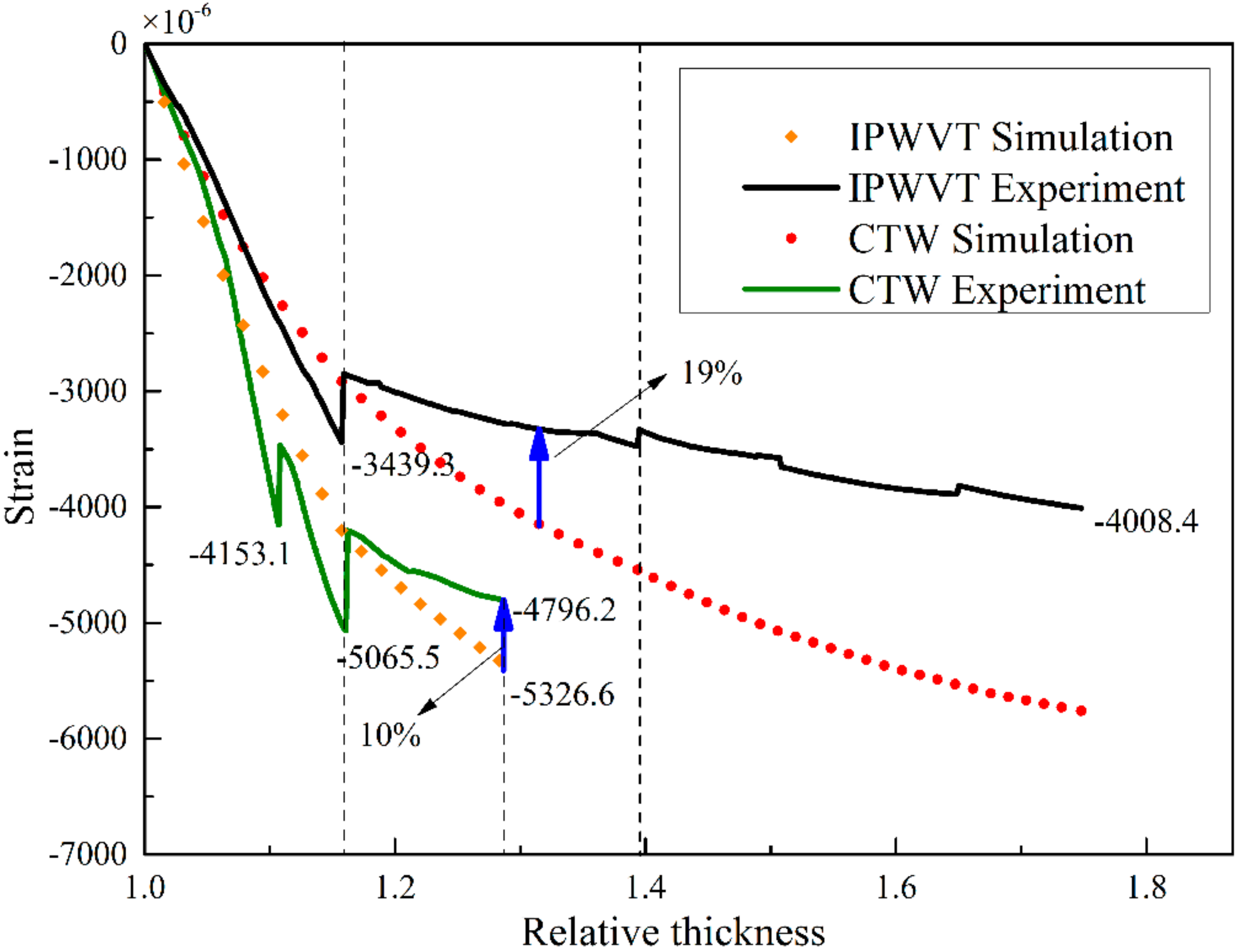

3.4.1. Model Validation

3.4.2. Effect of Winding Tension on Failure Process

4. Conclusions

- (1)

- The compression properties of the elastic range of the rotor was within −6480 × 10−6 and it was effective to use the rotor deformation to characterize the composite deformation in this range.

- (2)

- The constant winding tension caused a large deformation at the edge of the H-hub, leading to the plastic deformation of the hub, while the in-plane winding with variable tension prestressed the mandrel more evenly in the axial direction.

- (3)

- When the relative thickness λ is greater than 1.3, the influence of the outer winding layer on the deformation of the mandrel gradually decreases. The subsequent curing process results in a relaxation of more than 17%, which is insensitive to the winding tension.

- (4)

- Interface delamination failure comes first, followed by hub failure and composite failure, for a rotor with a relative thickness of 1.3. The rotor failure speed of IP-2 was 160% higher than that of CT-1 and reached 26,000 rpm.

- (5)

- The beneficial residual stress in filament-wound flywheel rotors was successfully introduced by different fiber tensions, which could effectively improve the failure speed of flywheels. However, due to the viscoelastic characteristics of resin matrix, the effective storage time of this beneficial manufacturing stress needs to be further studied, which is valuable for the long-term performance of rotors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rahman, A.; Myo Aung, K. Development of solar supercapacitor by utilizing organic polymer and metal oxides for subsystem of EV. Mater. Res. Express 2021, 8, 125301. [Google Scholar] [CrossRef]

- Li, W.; Xu, L.; Wang, X.; Zhu, R.; Yan, Y. Phase Change Energy Storage Elastic Fiber: A Simple Route to Personal Thermal Management. Polymers 2022, 14, 53. [Google Scholar] [CrossRef] [PubMed]

- Banitaba, S.N.; Ehrmann, A. Application of Electrospun Nanofibers for Fabrication of Versatile and Highly Efficient Electrochemical Devices: A Review. Polymers 2021, 13, 1741. [Google Scholar] [CrossRef] [PubMed]

- Yin, P.; Shi, Z.; Sun, L.; Xie, P.; Dastan, D.; Sun, K.; Fan, R. Improved breakdown strengths and energy storage properties of polyimide composites: The effect of internal interfaces of C/SiO2 hybrid nanoparticles. Polym. Compos. 2021, 42, 3000–3010. [Google Scholar] [CrossRef]

- Aneke, M.; Wang, M. Energy storage technologies and real life applications—A state of the art review. Appl. Energy 2016, 179, 350–377. [Google Scholar] [CrossRef] [Green Version]

- Mahlia, T.M.I.; Saktisahdan, T.J.; Jannifar, A.; Hasan, M.H.; Matseelar, H.S.C. A review of available methods and development on energy storage; technology update. Renew. Sustain. Energy Rev. 2014, 33, 532–545. [Google Scholar] [CrossRef]

- Rastegarzadeh, S.; Mahzoon, M.; Mohammadi, H. A novel modular designing for multi-ring flywheel rotor to optimize energy consumption in light metro trains. Energy 2020, 206, 118092. [Google Scholar] [CrossRef]

- Kim, H.-S.; Yoo, S.-H.; Chang, S.-H. In situ monitoring of the strain evolution and curing reaction of composite laminates to reduce the thermal residual stress using FBG sensor and dielectrometry. Compos. Part B Eng. 2013, 44, 446–452. [Google Scholar] [CrossRef]

- Ha, S.K.; Kim, S.J.; Nasir, S.U.; Han, S.C. Design optimization and fabrication of a hybrid composite flywheel rotor. Compos. Struct. 2012, 94, 3290–3299. [Google Scholar] [CrossRef]

- Ha, S.K.; Kim, J.H.; Han, Y.H. Design of a Hybrid Composite Flywheel Multi-rim Rotor System using Geometric Scaling Factors. J. Compos. Mater. 2008, 42, 771–785. [Google Scholar] [CrossRef]

- Al-Fakher, U.; Manalo, A.; Ferdous, W.; Aravinthan, T.; Zhuge, Y.; Bai, Y.; Edoo, A. Bending behaviour of precast concrete slab with externally flanged hollow FRP tubes. Eng. Struct. 2021, 241, 112433. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Zhuge, Y.; Vijay, P.V.; Alkinani, A.Q.; Fam, A. State-of-the-art of prefabricated FRP composite jackets for structural repair. Eng. Sci. Technol. Int. J. 2020, 23, 1244–1258. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, Y.; Yu, L.; Ji, K.; Li, D. A review on the tooling technologies for composites manufacturing of aerospace structures: Materials, structures and processes. Compos. Part A Appl. Sci. Manuf. 2022, 154, 106762. [Google Scholar] [CrossRef]

- Valorosi, F.; De Meo, E.; Blanco-Varela, T.; Martorana, B.; Veca, A.; Pugno, N.; Kinloch, I.A.; Anagnostopoulos, G.; Galiotis, C.; Bertocchi, F.; et al. Graphene and related materials in hierarchical fiber composites: Production techniques and key industrial benefits. Compos. Sci. Technol. 2020, 185, 107848. [Google Scholar] [CrossRef]

- Pullen, K.R. The Status and Future of Flywheel Energy Storage. Joule 2019, 3, 1394–1399. [Google Scholar] [CrossRef]

- Jaen-Sola, P.; McDonald, A.S.; Oterkus, E. Lightweight design of direct-drive wind turbine electrical generators: A comparison between steel and composite material structures. Ocean Eng. 2019, 181, 330–341. [Google Scholar] [CrossRef]

- Wicki, S.; Hansen, E.G. Clean energy storage technology in the making: An innovation systems perspective on flywheel energy storage. J. Clean. Prod. 2017, 162, 1118–1134. [Google Scholar] [CrossRef]

- Dai, X.; Wang, Y.; Tang, C.; Guo, X. Mechanics analysis on the composite flywheel stacked from circular twill woven fabric rings. Compos. Struct. 2016, 155, 19–28. [Google Scholar] [CrossRef]

- Wang, Y.; Dai, X.; Wei, K.; Guo, X. Progressive failure behavior of composite flywheels stacked from annular plain profiling woven fabric for energy storage. Compos. Struct. 2018, 194, 377–387. [Google Scholar] [CrossRef]

- Hiroshima, N.; Hatta, H.; Koyama, M.; Yoshimura, J.; Nagura, Y.; Goto, K.; Kogo, Y. Spin test of three-dimensional composite rotor for flywheel energy storage system. Compos. Struct. 2016, 136, 626–634. [Google Scholar] [CrossRef]

- Ha, S.K.; Jeong, H.M.; Cho, Y.S. Optimum Design of Thick-Walled Composite Rings for an Energy Storage System. J. Compos. Mater. 1998, 32, 851–873. [Google Scholar] [CrossRef]

- Kyu Ha, S.; Kim, D.-J.; Sung, T.-H. Optimum design of multi-ring composite flywheel rotor using a modified generalized plane strain assumption. Int. J. Mech. Sci. 2001, 43, 993–1007. [Google Scholar] [CrossRef]

- Lee, D.H.; Kim, S.K.; Lee, W.I.; Ha, S.K.; Tsai, S.W. Smart cure of thick composite filament wound structures to minimize the development of residual stresses. Compos. Part A Appl. Sci. Manuf. 2006, 37, 530–537. [Google Scholar] [CrossRef]

- Liu, C.; Shi, Y. Analytical model for the winding process-induced residual stresses of the multilayered filament wound cylindrical composite parts. Mater. Res. Express 2019, 6, 105354. [Google Scholar] [CrossRef]

- Zu, L.; Xu, H.; Zhang, Q.; Jia, X.; Jin, S.; Li, D. Investigation on mechanical behavior of composite electromagnetic gun barrel based on the high tension winding. Compos. Struct. 2020, 248, 112521. [Google Scholar] [CrossRef]

- Kim, S.J.; Hayat, K.; Nasir, S.U.; Ha, S.K. Design and fabrication of hybrid composite hubs for a multi-rim flywheel energy storage system. Compos. Struct. 2014, 107, 19–29. [Google Scholar] [CrossRef]

- Zu, L.; Xu, H.; Zhang, B.; Li, D.; Zi, B. Design of filament-wound composite structures with arch-shaped cross sections considering fiber tension simulation. Compos. Struct. 2018, 194, 119–125. [Google Scholar] [CrossRef]

- Ha, S.K.; Han, H.H.; Han, Y.H. Design and Manufacture of a Composite Flywheel Press-Fit Multi-Rim Rotor. J. Reinf. Plast. Compos. 2008, 27, 953–965. [Google Scholar] [CrossRef]

- Wen, S.B. Study on Interference Fit of Composite Flywheel Rotor. Appl. Mech. Mater. 2012, 215, 302–306. [Google Scholar] [CrossRef]

- Portnov, G.; Uthe, A.N.; Cruz, I.; Fiffe, R.P.; Arias, F. Design of Steel-Composite Multirim Cylindrical Flywheels Manufactured by Winding with High Tensioning and in situ Curing. 2. Numerical Analysis. Mech. Compos. Mater. 2005, 41, 241–254. [Google Scholar] [CrossRef]

- Kale, V.; Secanell, M. A comparative study between optimal metal and composite rotors for flywheel energy storage systems. Energy Rep. 2018, 4, 576–585. [Google Scholar] [CrossRef]

- Mittelstedt, M.; Hansen, C.; Mertiny, P. Design and Multi-Objective Optimization of Fiber-Reinforced Polymer Composite Flywheel Rotors. Appl. Sci. 2018, 8, 11256. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Li, Y.; Huan, D.; Wang, W.; Jiao, Y. Influence of resin curing cycle on the deformation of filament wound composites by in situ strain monitoring. High Perform. Polym. 2021, 33, 1141–1152. [Google Scholar] [CrossRef]

- Gutowski, T.G.; Morigaki, T.; Zhong, C. The Consolidation of Laminate Composites. J. Compos. Mater. 1987, 21, 172–188. [Google Scholar] [CrossRef]

- Wen, S.; Jiang, S. Optimum design of hybrid composite multi-ring flywheel rotor based on displacement method. Compos. Sci. Technol. 2012, 72, 982–988. [Google Scholar] [CrossRef]

- Poon, C.; Shokrieh, M.M.; Lessard, L.B. Three-Dimensional Progressive Failure Analysis of Pin/Bolt Loaded Composite Laminates. In Proceedings of the the 83th Meeting of the AGARD SMP on Bolted Joints in Polymeric Composites, Florence, Italy, 2–3 September 1996. [Google Scholar]

- Garnich, M.R.; Akula, V.M.K. Review of Degradation Models for Progressive Failure Analysis of Fiber Reinforced Polymer Composites. Appl. Mech. Rev. 2009, 62, 010801. [Google Scholar] [CrossRef]

| Properties | S6 | T700SC | T800SC | Unit |

|---|---|---|---|---|

| Tensile strength | 4800 | 4900 | 5880 | MPa |

| Tensile modulus | 95 | 230 | 294 | GPa |

| Strain at failure | 5.7 | 2.1 | 2.0 | % |

| Density | 2.53 | 1.80 | 1.80 | g/cm3 |

| Yield | 800 | 800 | 1030 | g/km |

| CTE | 3.00 | −0.38 | −0.40 | ×10−6/°C |

| Winding Rule | Case | Fa/MPa | Fb/MPa | Fc/MPa | Fα/MPa | Fβ/MPa | Fγ/MPa |

|---|---|---|---|---|---|---|---|

| OPWVT | OP-1 | -- | -- | -- | 192 | 240 | 300 |

| OP-2 | -- | -- | -- | 108 | 180 | 300 | |

| OP-3 | -- | -- | -- | 48 | 120 | 300 | |

| IPWVT | IP-1 | 300 | 240 | 192 | -- | -- | -- |

| IP-2 | 300 | 180 | 108 | -- | -- | -- | |

| IP-3 | 300 | 120 | 48 | -- | -- | -- | |

| CTW | CT-1 | 300 | 300 | 300 | 300 | 300 | 300 |

| CT-2 | 200 | 200 | 200 | 200 | 200 | 200 | |

| CT-3 | 100 | 100 | 100 | 100 | 100 | 100 |

| Parameters | Symbol | Value | Unit |

|---|---|---|---|

| Modulus | E | 74.07 | GPa |

| Passion ratio | v | 0.33 | |

| Density | ρ | 2.3 | g/cm−3 |

| Yield strength | σs | 480 | MPa |

| Parameters | Symbol | Value | Unit |

|---|---|---|---|

| Longitudinal modulus | E1 | 67.46 | GPa |

| Transverse modulus | E2 = E3 | 7 | GPa |

| In-plane Poisson’s ratio | v12= v13 | 0.29 | |

| Transverse Poisson’s ratio | v23 | 0.34 | |

| In-plane shear modulus | G12 = G13 | 4.14 | GPa |

| Out-of-plane shear modulus | G23 | 3.4 | MPa |

| Density | Ρ | 1.8 | g/cm−3 |

| Longitudinal tensile strength | Xt | 1660 | MPa |

| Longitudinal compressive strength | Xc | 610 | MPa |

| Transverse tensile strength | Yt | 34 | MPa |

| Transverse compressive strength | Yc = Zc | 118 | MPa |

| Interlaminar tensile strength | Zt | 15 | MPa |

| In-plane shear strength | S12= S13 | 94 | MPa |

| Out-of-plane shear strength | S23 | 40 | MPa |

| Composite Failure Mode (F3) | Coefficient | |||||

|---|---|---|---|---|---|---|

| E1 | E2 | E3 | G12 | G13 | G23 | |

| d1 | d2 | d3 | d4 | d5 | d6 | |

| Fiber damage (F31) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Matrix damage (F32) | 1 | 0.3 | 1 | 1 | 1 | 0.01 |

| Shear damage (F33) | 1 | 1 | 1 | 0.01 | 1 | 1 |

| Interlaminar damage (F34) | 1 | 1 | 0.01 | 1 | 0.01 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Li, Y.; Huan, D.; Liu, H.; Li, L.; Li, Y. Influence of Filament Winding Tension on the Deformation of Composite Flywheel Rotors with H-Shaped Hubs. Polymers 2022, 14, 1155. https://doi.org/10.3390/polym14061155

Chen X, Li Y, Huan D, Liu H, Li L, Li Y. Influence of Filament Winding Tension on the Deformation of Composite Flywheel Rotors with H-Shaped Hubs. Polymers. 2022; 14(6):1155. https://doi.org/10.3390/polym14061155

Chicago/Turabian StyleChen, Xiaodong, Yong Li, Dajun Huan, Hongquan Liu, Lisa Li, and Yanrui Li. 2022. "Influence of Filament Winding Tension on the Deformation of Composite Flywheel Rotors with H-Shaped Hubs" Polymers 14, no. 6: 1155. https://doi.org/10.3390/polym14061155

APA StyleChen, X., Li, Y., Huan, D., Liu, H., Li, L., & Li, Y. (2022). Influence of Filament Winding Tension on the Deformation of Composite Flywheel Rotors with H-Shaped Hubs. Polymers, 14(6), 1155. https://doi.org/10.3390/polym14061155