Investigation of High Voltage Polymeric Insulators Performance under Wet Pollution

Abstract

:1. Introduction

2. Experimental Work and Method

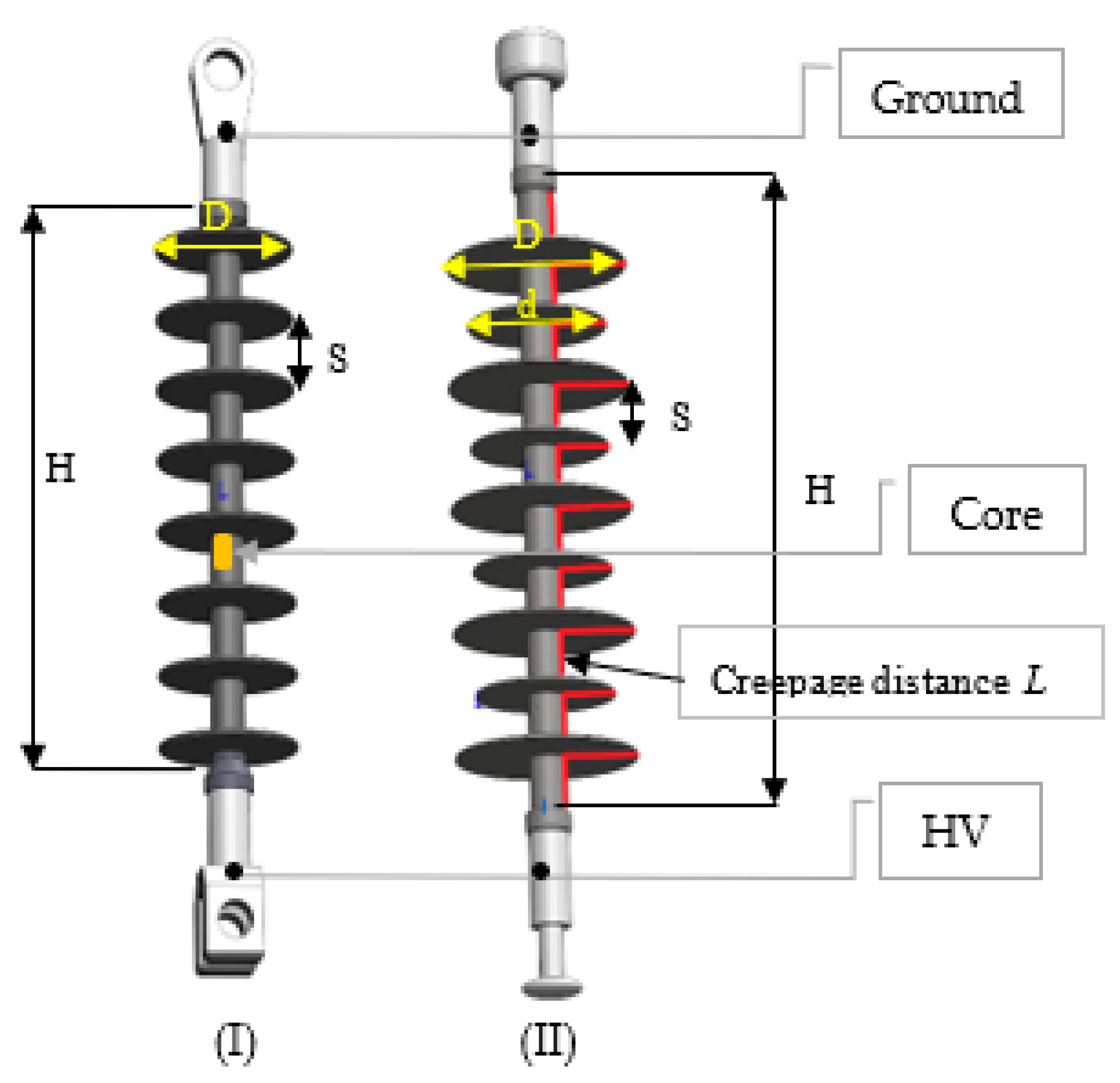

2.1. Insulators Structure

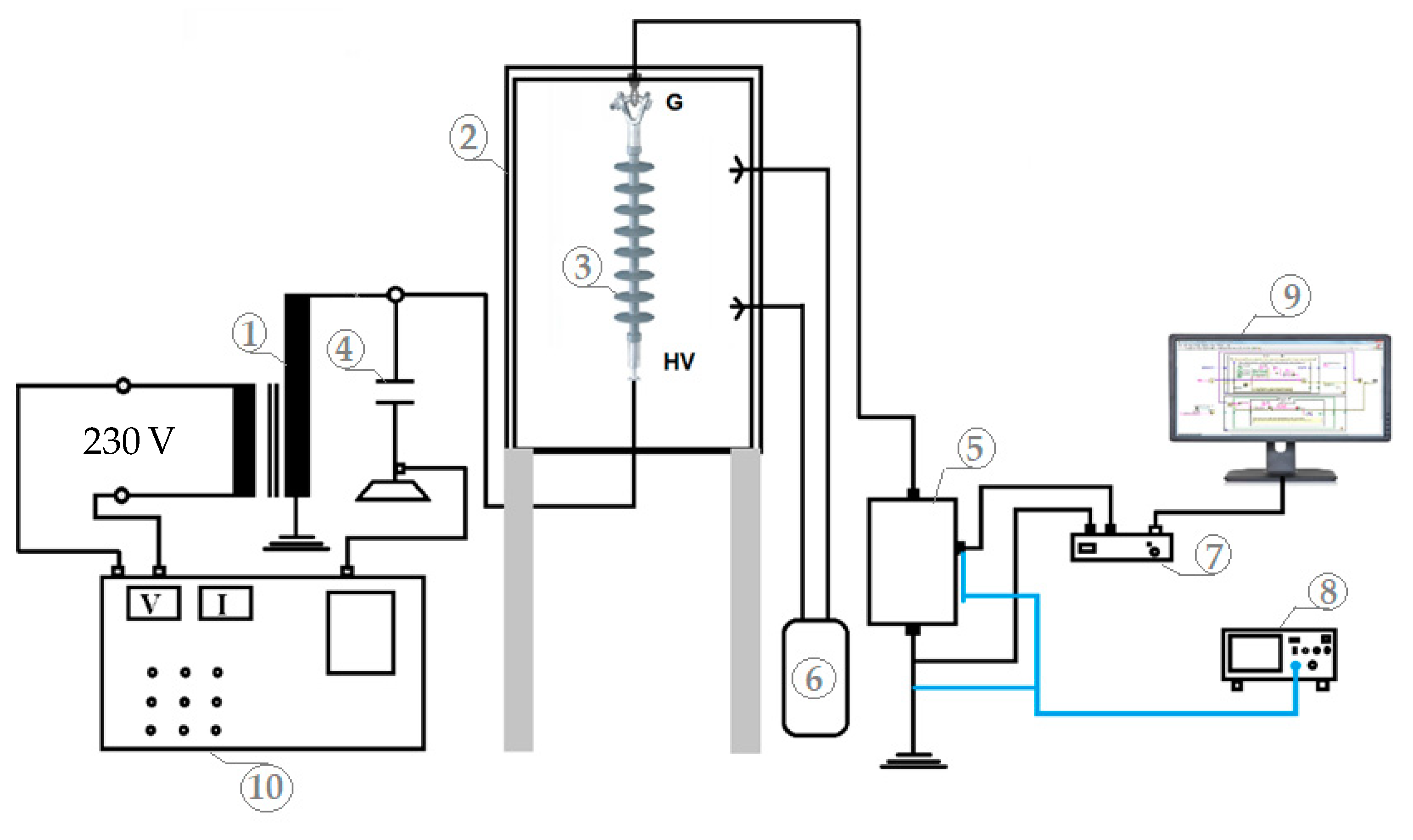

2.2. Laboratory Setup and Test Producers

2.3. Pollution Preparation

2.4. Wetting Process

2.4.1. Fog

2.4.2. Rain

3. Experimental Results

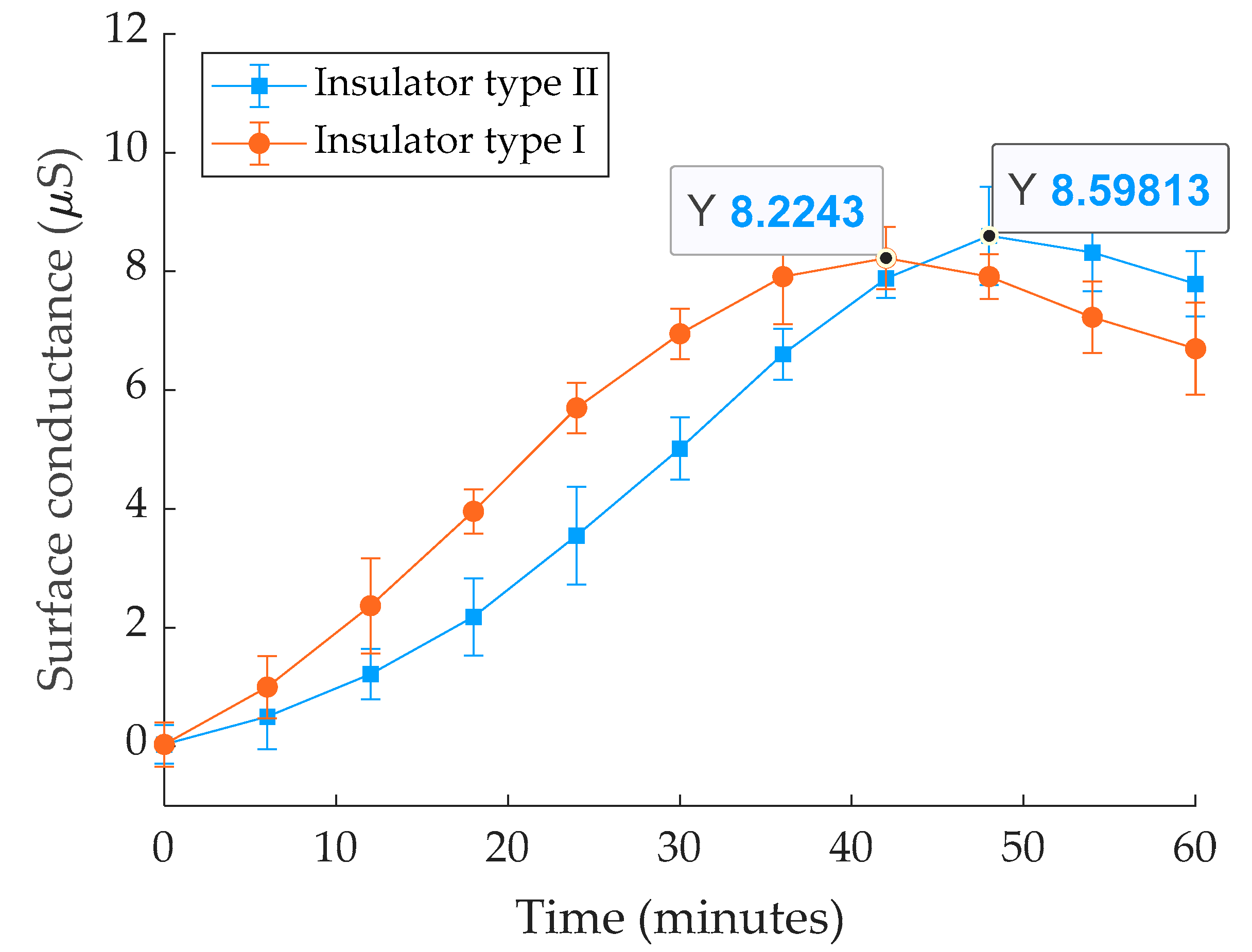

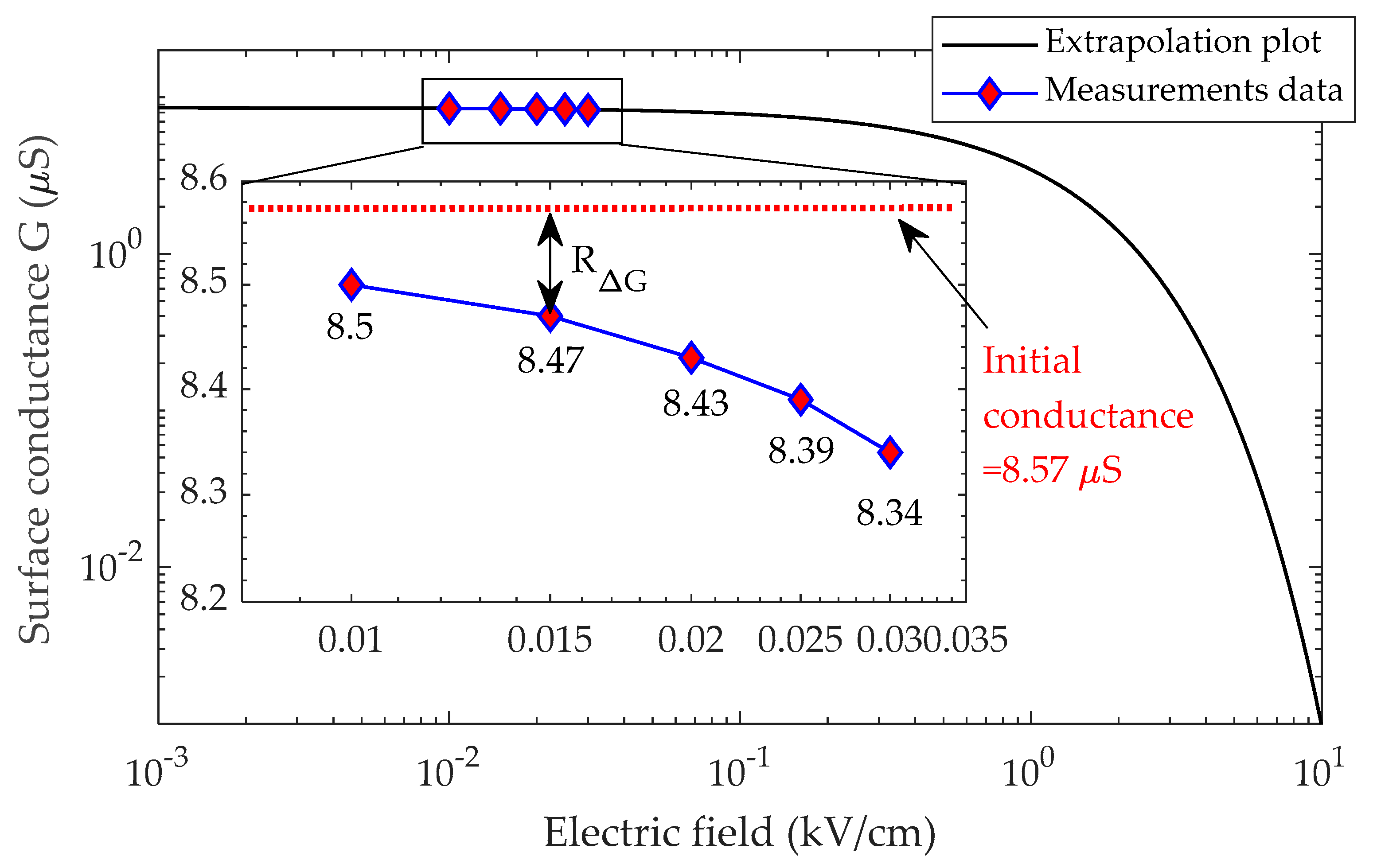

3.1. Surface Conductance Assessment

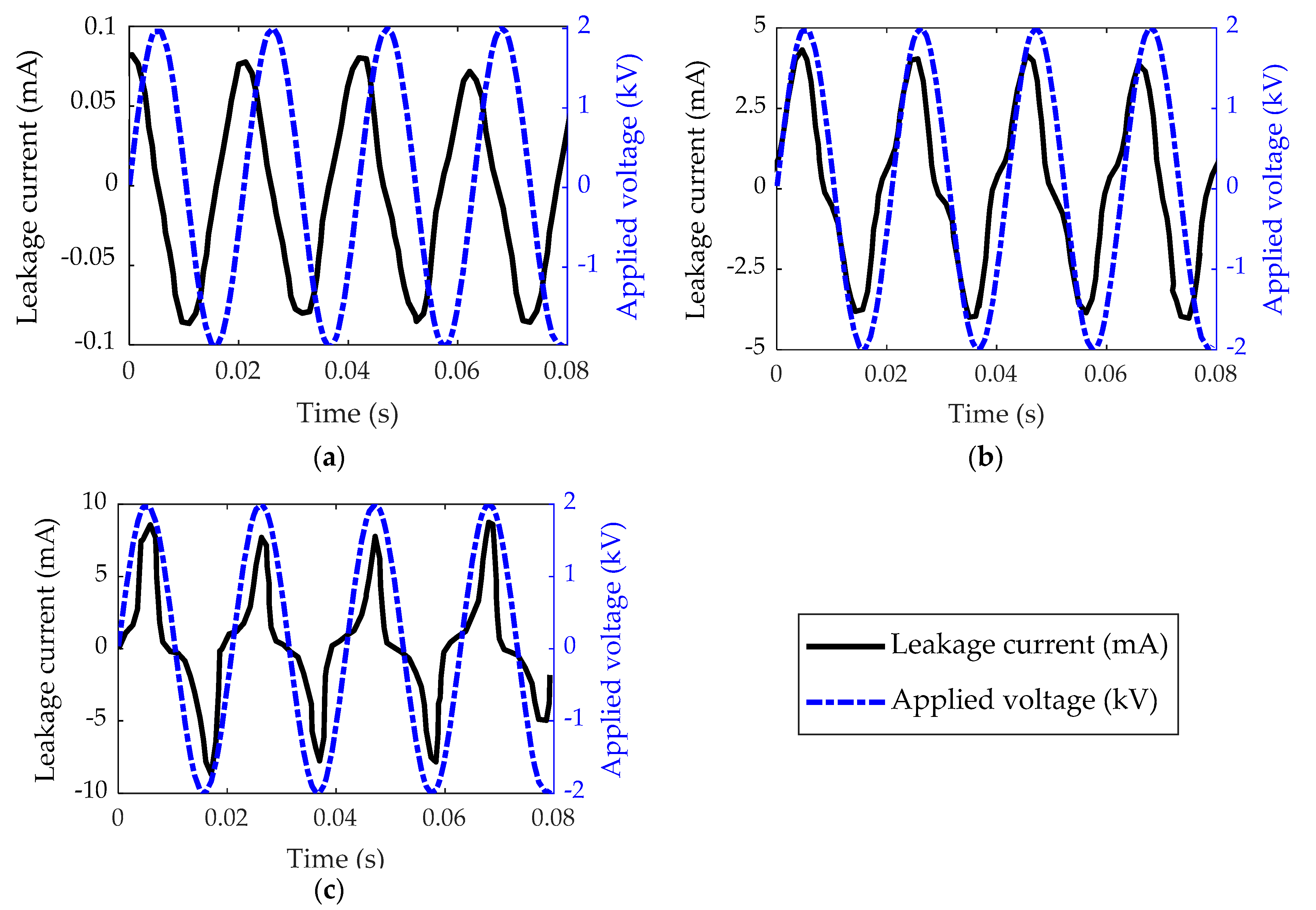

3.2. Leakage Current Results

- (1)

- The pollution layer’s surface conductance is related to the insulator’s geometrical form factor as in Equation (10).

- (2)

- The wetting time of the pollutant layer on various types of insulators varies. The quickest to soak the pollutant layer is the type I insulator. In contrast, the wetting of the pollutant layer on the type II insulator takes longer. The causes are also connected to the construction of the insulators.

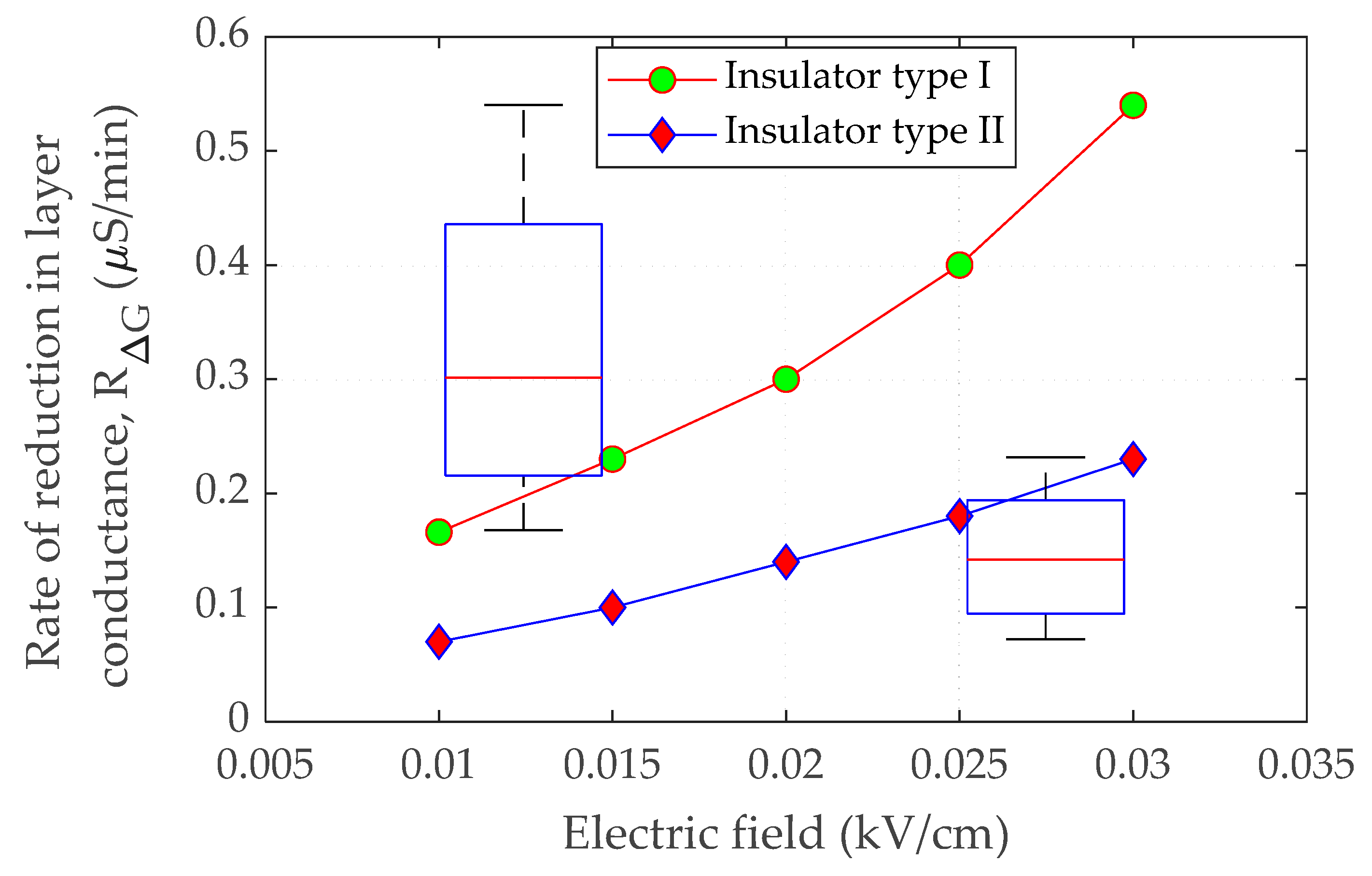

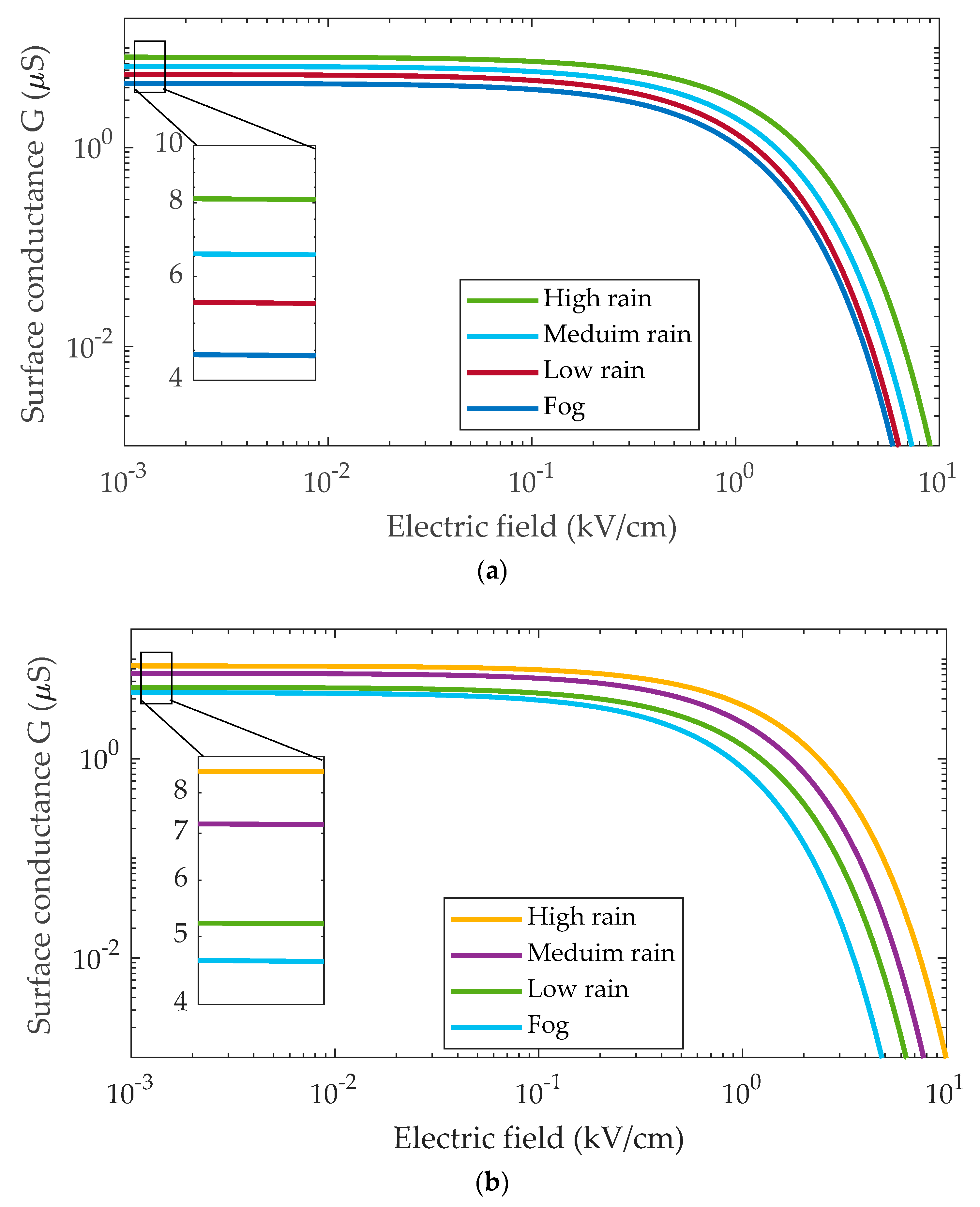

3.3. Electric Field Dependent Pollution Layer Conductivity

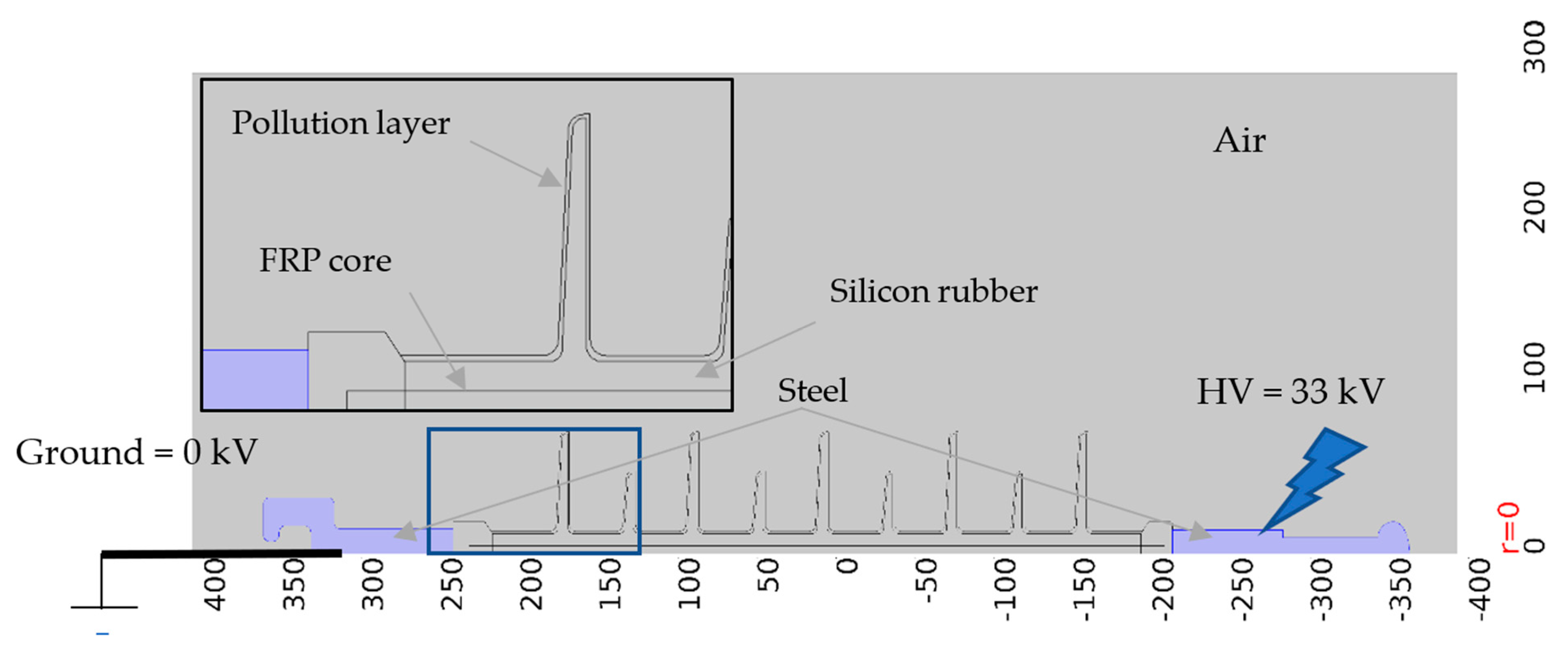

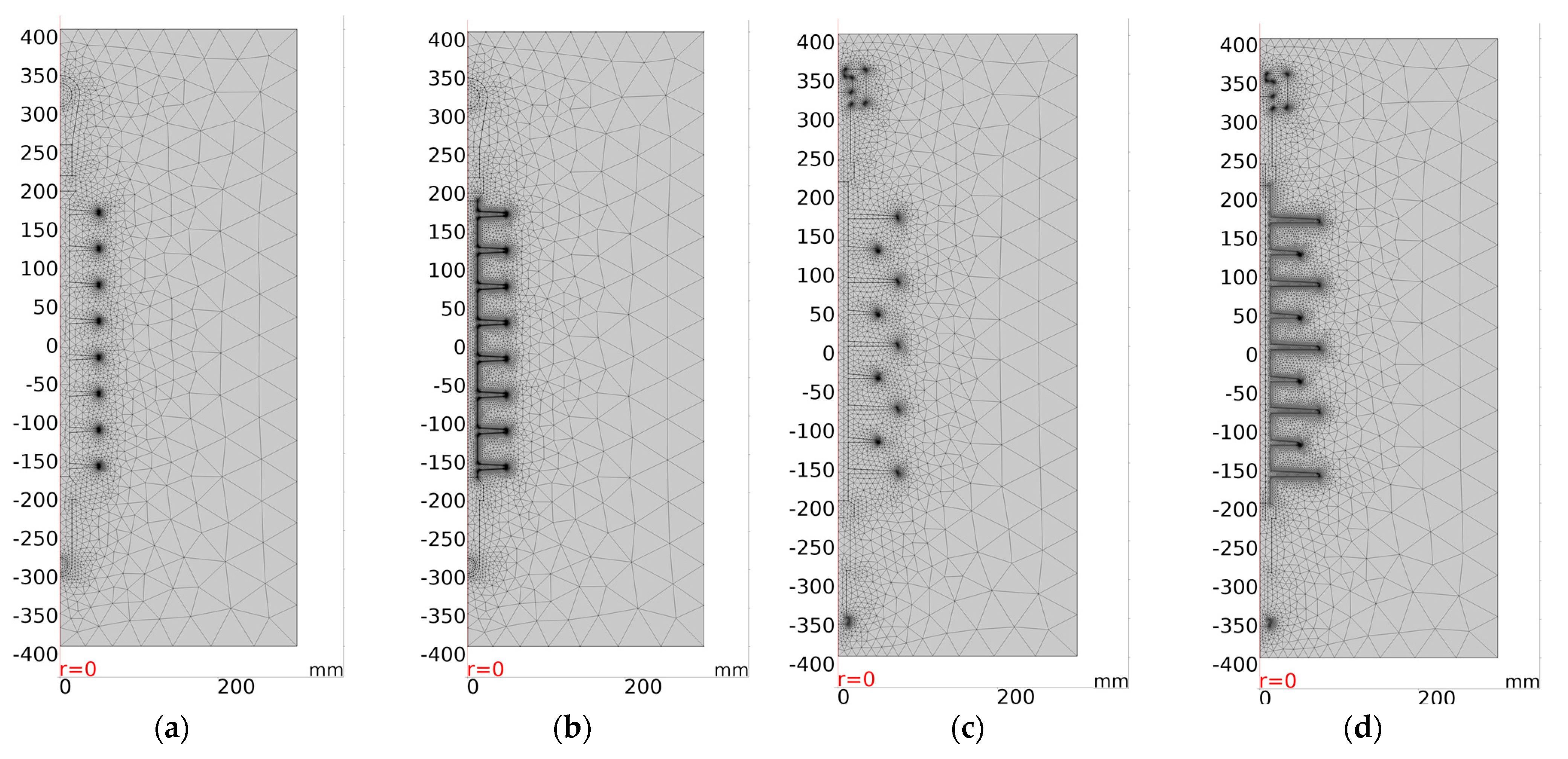

4. Modeling of the Polymeric Outdoor Insulators

4.1. Properties of Insulator Material

4.2. Electrical Characteristics Calculation Using FEM

5. Simulation Results and Discussion

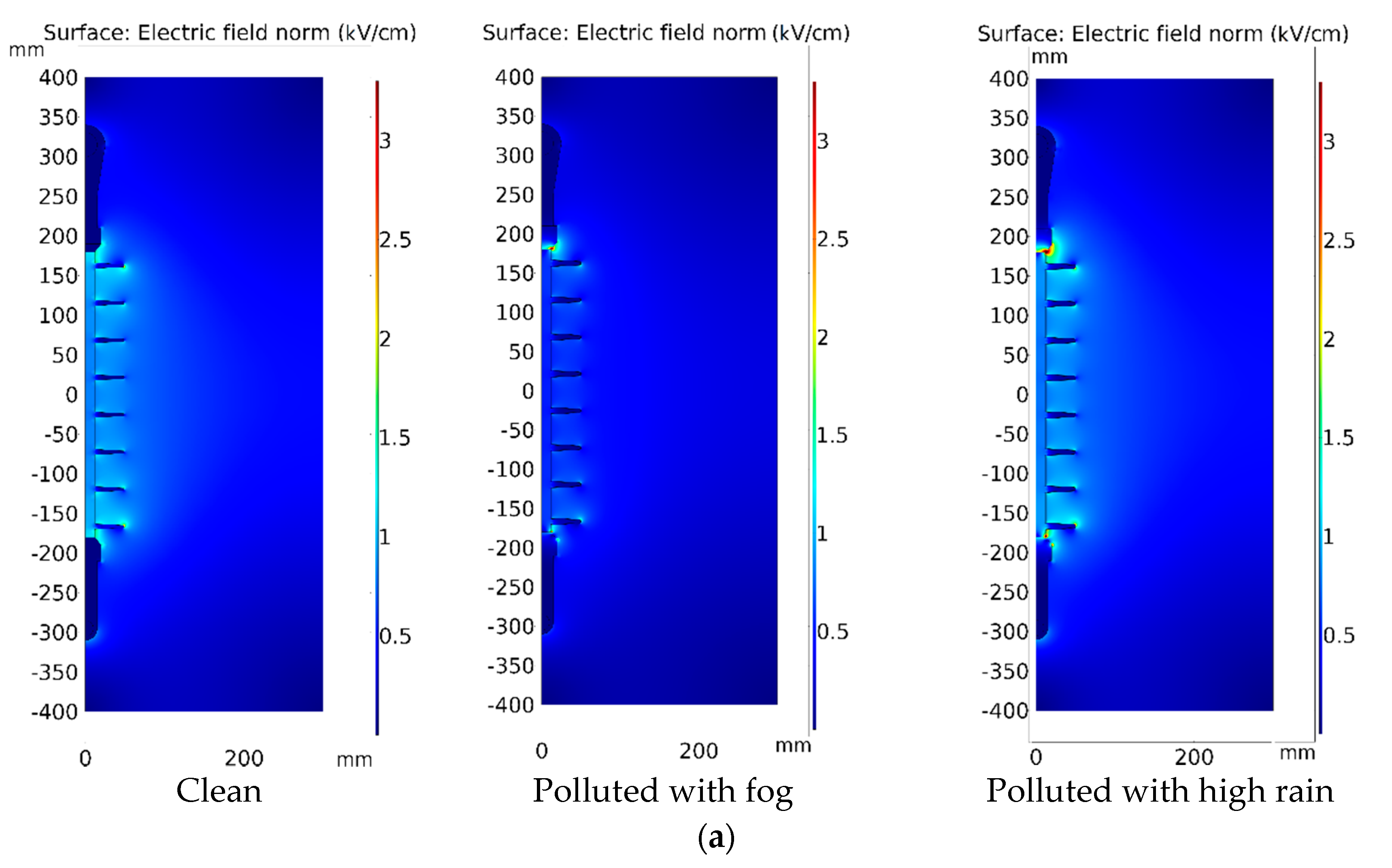

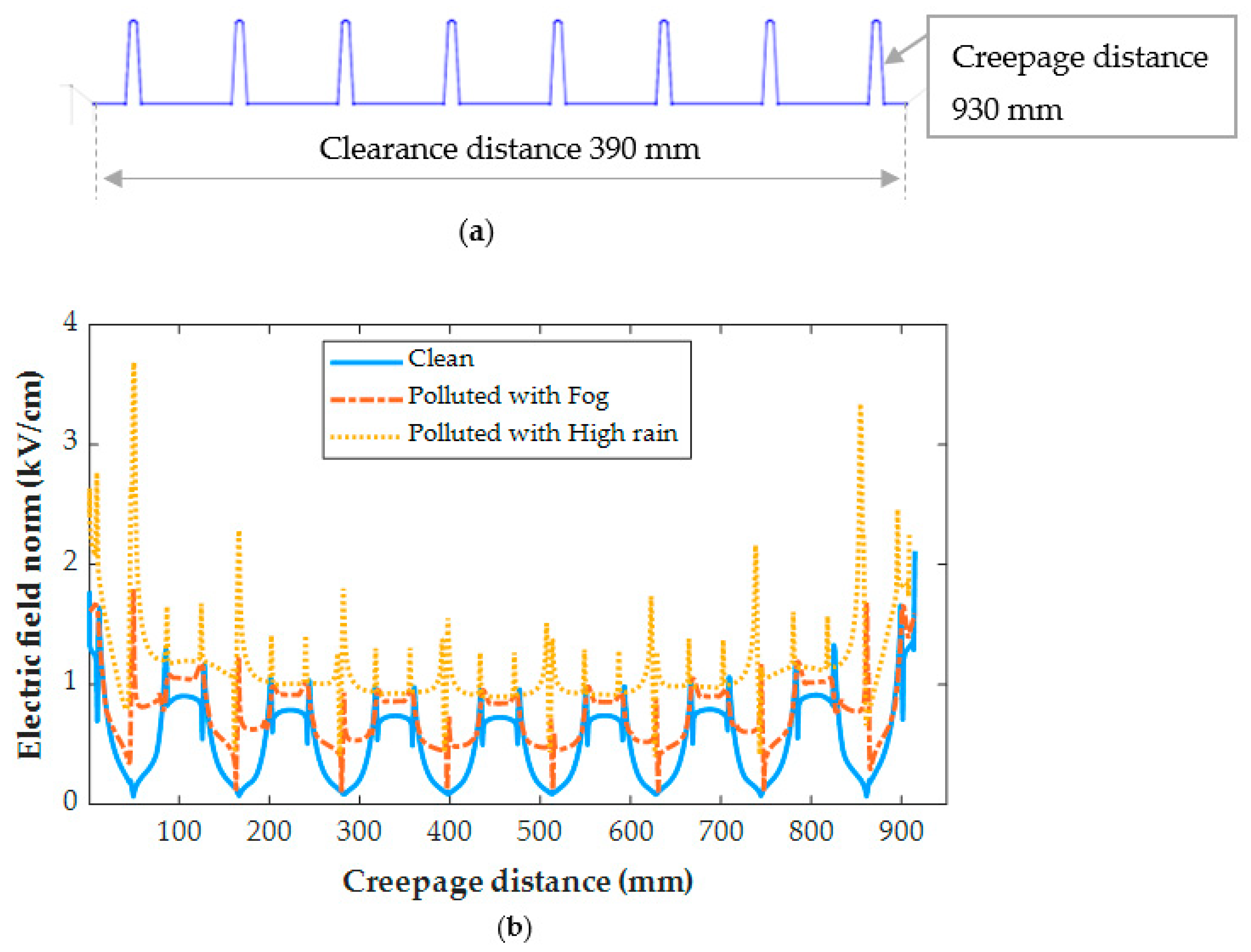

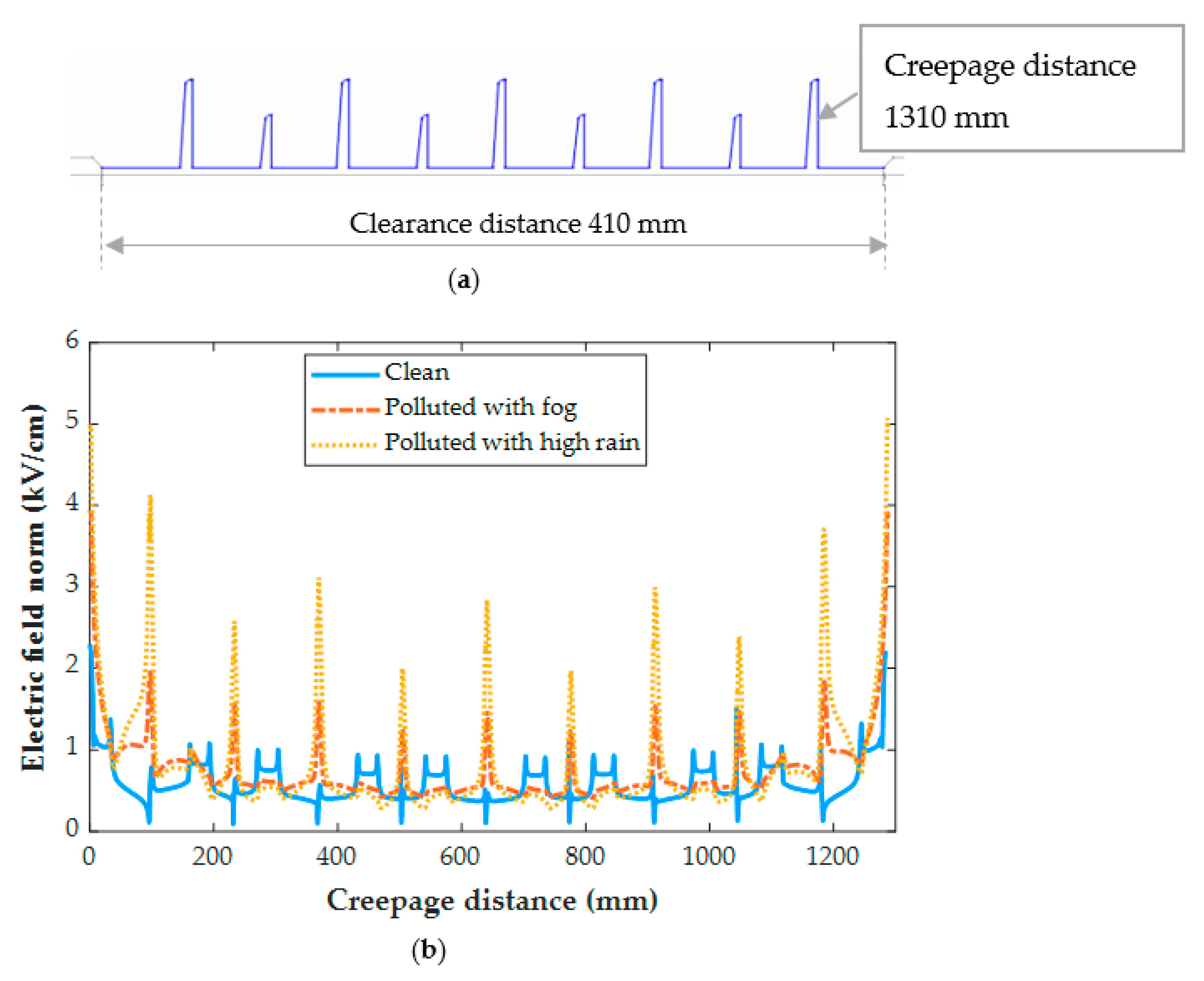

5.1. Electric Field Distribution

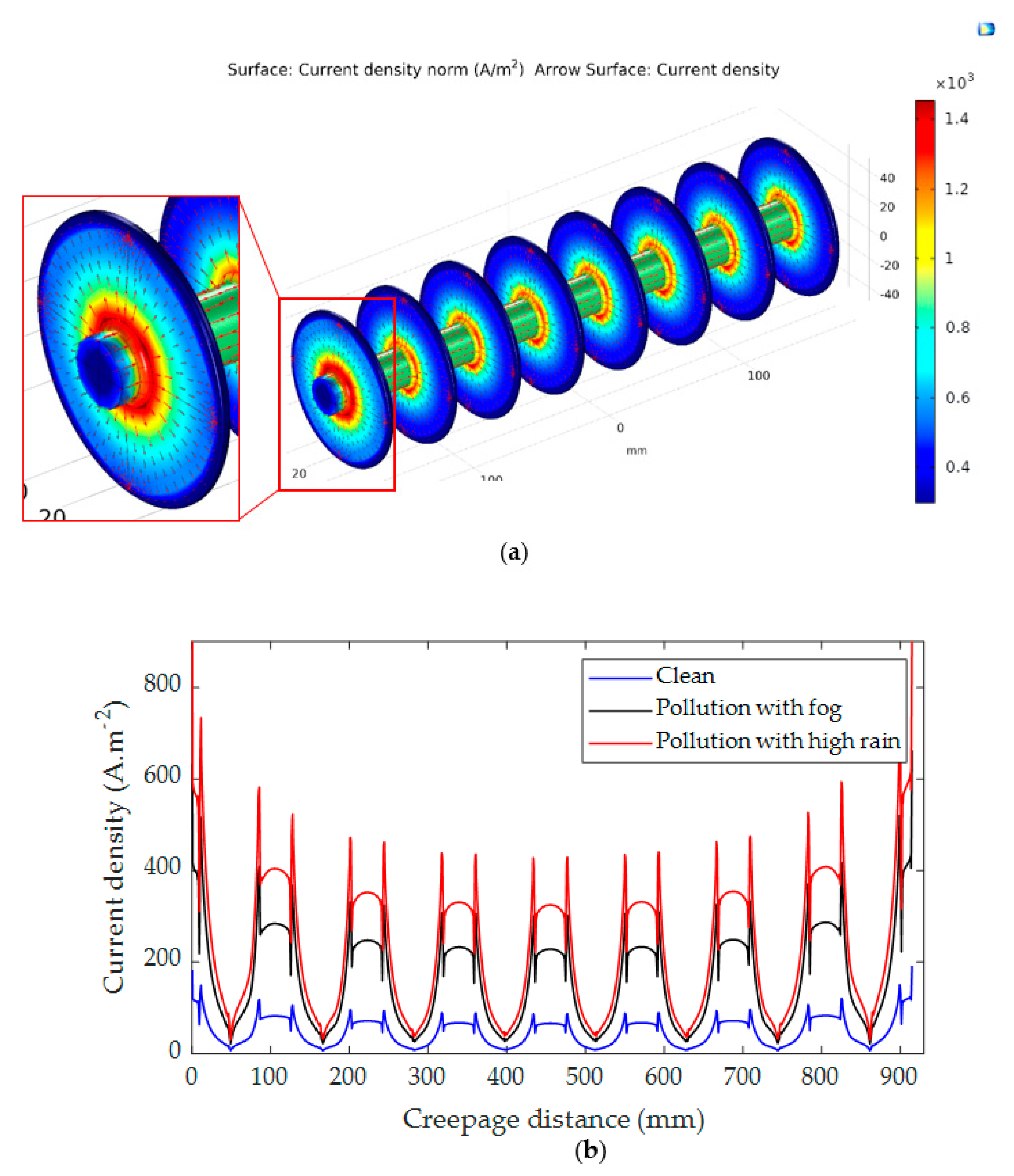

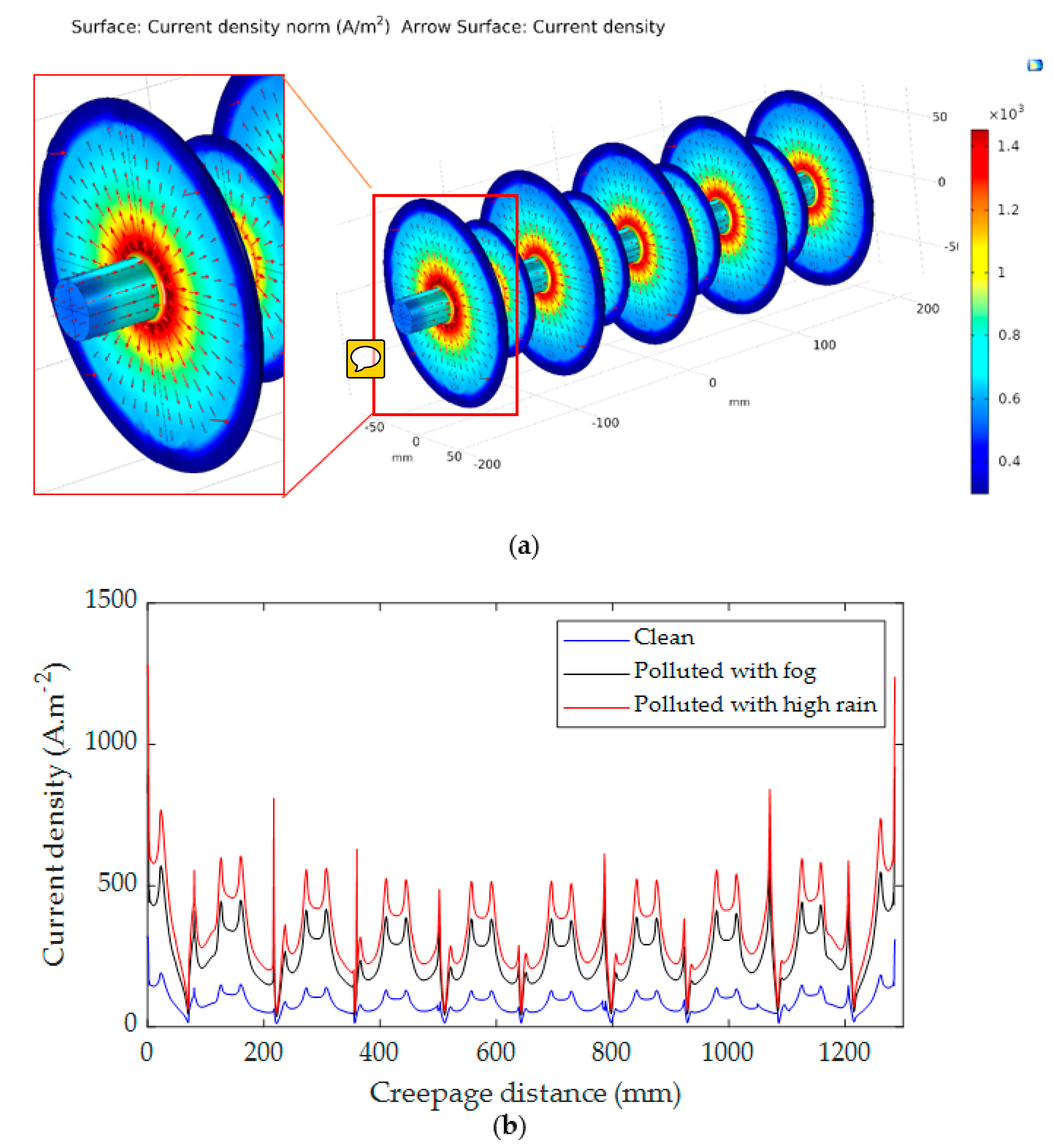

5.2. Current Dencity Distribution

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Insulator Type | Elements Types | Minimum Elements Quality | DOF | ||

|---|---|---|---|---|---|

| Triangle | Edge | Vertex | |||

| Type I clean | 16,740 | 905 | 134 | 0.4662 | 33,551 |

| Type I polluted | 36,424 | 3190 | 236 | 0.4068 | 72,903 |

| Type II clean | 22,235 | 1290 | 166 | 0.4902 | 76,284 |

| Type II polluted | 43,853 | 4202 | 260 | 0.3608 | 87,774 |

References

- Andrew, J.P.; John, K.; Anthony, B.; Burnham, J.; Carreira, A.; Cherney, E. Electric Fields on AC Composite Transmission Line Insulators. IEEE Trans. Power Deliv. 2008, 23, 823–830. [Google Scholar]

- Salem, A.A.; Abd-Rahman, R.; Ahmad, H.; Kamarudin, M.S.; Jamal, N.A.M.; Othman, N.A.; Ishak, M.T. A New Flashover Prediction on Outdoor Polluted Insulator Using Leakage Current Harmonic Components. In Proceedings of the 2018 IEEE 7th International Conference on Power and Energy (PECon), Kuala Lumpur, Malaysia, 3–4 December 2018; pp. 413–418. [Google Scholar] [CrossRef]

- Williams, D.L.; Haddad, A.; Rowlands, A.R.; Young, H.M.; Waters, R.T. Formation and characterization of dry bands in clean fog on polluted insulators. IEEE Trans. Dielectr. Electr. Insul. 1999, 6, 724–731. [Google Scholar] [CrossRef]

- Salem, A.A.; Abd Rahman, R.; Jamail, N.A. New Approach for Monitoring Contamination Level on Outdoor Insulator Based on Harmonics Components of the Leakage Current. In Proceedings of the 2021 IEEE International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Johor Bahru, Malaysia, 12–14 July 2021; pp. 418–421. [Google Scholar]

- Ali, N.N.; Zainuddin, H.; Razak, J.A.; Abd-Rahman, R. Curing Characteristic Analysis and Leakage Current Performances of Silicone Rubber via Inclined Plane Tracking (IPT) Test. In Proceedings of the 2021 IEEE International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Johor Bahru, Malaysia, 12–14 July 2021; pp. 314–317. [Google Scholar]

- Mukherjee, P.K.; Ahmed, A.; Singer, H. Electric field distortion caused by asymmetric pollution on insulator surfaces. IEEE Trans. Dielectr. Electr. Insul. 1999, 6, 175–180. [Google Scholar] [CrossRef]

- Salem, A.A.; Abd Rahman, R.; Al-Ameri, S. Pollution Flashover Characteristics of High-Voltage Outdoor Insulators: Analytical Study. Arab. J. Sci. Eng. 2021. [Google Scholar] [CrossRef]

- Que, W.; Sebo, S.A.; Hill, R.J. Practical Cases of Electric Field Distribution along Dry and Clean Nonceramic Insulators of High-Voltage Power Lines. IEEE Trans. Power Deliv. 2007, 22, 1070–1078. [Google Scholar] [CrossRef]

- Abd-Rahman, R.; Haddad, A.; Kamarudin, M.S.; Yousof, M.F.M.; Jamail, N.A.M. Dynamic modelling of polluted outdoor insulator under wet weather conditions. In Proceedings of the 2016 IEEE International Conference on Power and Energy (PECon), Melaka, Malaysia, 28–29 November 2016; pp. 610–614. [Google Scholar]

- Salem, A.A.; Abd-Rahman, R.; Rahiman, W.; Al-Gailani, S.A.; Al-Ameri, S.M.; Ishak, M.T.; Sheikh, U.U. Pollution Flashover Under Different Contamination Profiles on High Voltage Insulator: Numerical and Experiment Investigation. IEEE Access 2021, 9, 37800–37812. [Google Scholar] [CrossRef]

- Ahmed, R.; Kim, T.; Lee, Y.J.; Jeon, S.; Yi, J.; Choi, I.H.; Son, J.A.; Koo, J.B. Online Condition Monitoring and Leakage Current Effect Based on Local Area Environment. Trans. Electr. Electron. Mater. 2020, 21, 144–149. [Google Scholar] [CrossRef]

- Abd Rahman, R.; Haddad, A.; Harid, N. Dynamic nonlinear model for polluted outdoor insulators. In Proceedings of the 7th International Symposium on High Voltage Engineering, Hannover, Germany, 22–26 August 2011; pp. 22–26. [Google Scholar]

- Hussain, S.; Yang, X.; Aslam, M.K.; Shaheen, A.; Javed, M.S.; Aslam, N.; Aslam, B.; Liu, G.; Qiao, G. Robust TiN nanoparticles polysulfide anchor for Li–S storage and diffusion pathways using first principle calculations. Chem. Eng. J. 2020, 391, 123595. [Google Scholar] [CrossRef]

- Hussain, S.; Khan, A.J.; Arshad, M.; Javed, M.S.; Ahmad, A.; Shah, S.S.; Khan, M.R.; Akram, S.; Ali, S.; ALOthman, Z.A.; et al. Charge storage in binder-free 2D-hexagonal CoMoO4 nanosheets as a redox active ma-terial for pseudocapacitors. Ceram. Int. 2021, 47, 8659–8667. [Google Scholar] [CrossRef]

- Wei, H.J.; Jayaram, S.; Cherney, E. A study of electrical stress grading of composite bushings by means of a resistive silicone rubber coating. J. Electrost. 2005, 63, 273–283. [Google Scholar] [CrossRef]

- Asenjo, S.E.; Morales, O.N.; Valdenegro, E.A. Solution of low frequency complex fields in polluted insulators by means of the finite element method. IEEE Trans. Dielectr. Electr. Insul. 1997, 4, 10–16. [Google Scholar] [CrossRef]

- Rong, Z.; Zhang, Y.; Chen, W.; Zhang, B. Measurement of electric field distribution along composite insulators by integrated optical electric field sensor. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 302–310. [Google Scholar]

- Rasolonjanahary, J.L.; Krahenbuhl, L.; Nicolas, A. Computation of electric fields and potential on polluted insulators using a boundary element method. IEEE Trans. Magn. 1992, 28, 1473–1476. [Google Scholar] [CrossRef] [Green Version]

- Yializis, A.; Kuffel, E.; Alexander, P.H. An Optimized Charge Simulation Method for the Calculation of High Voltage Fields. IEEE Trans. Power Appar. Syst. 1978, 97, 2434–2440. [Google Scholar] [CrossRef]

- Salem, A.A.; Abd-Rahman, R.; Al-Gailani, S.A.; Kamarudin, M.S.; Ahmad, H.; Salam, Z. The Leakage Current Components as a Diagnostic Tool to Estimate Contamination Level on High Voltage Insulators. IEEE Access 2020, 8, 92514–92528. [Google Scholar] [CrossRef]

- Salem, A.A.; Abd-Rahman, R. A review of the dynamic modelling of pollution flashover on high voltage outdoor insulators. J. Phys. Conf. Ser. 2019, 1049, 012019. [Google Scholar] [CrossRef] [Green Version]

- Salem, A.A.; Abd-Rahman, R.; Kamarudin, M.S.; Othman, N.A.; Jamail, N.A.; Hussin, N.; Hamid, H.A.; Rawi, I.M. Flashover Voltage Prediction on Polluted Cup-Pin the Insulators Under Polluted Conditions. In Proceedings of the 11th National Technical Seminar on Unmanned System Technology 2019; UMP GAMBANG PAHANG 2–3 December 2019 Lecture Notes in Electrical Engineering 666. Md Zain, Z., Ahmad, H., Pebrianti, D., Mustafa, M., Abdullah, N.R.H., Samad, R., Noh, M.M., Eds.; Springer: Singapore, 2020. [Google Scholar]

- Abd-Rahman, R.; Haddad, A.; Harid, N. Performance of nonlinear grading coating on polymeric outdoor insulators under lightning impulse voltages. In Proceedings of the 21st International Conference on Electricity Distribution CIRED, Frankfurt, Germeny, 6–9 June 2011. [Google Scholar]

- Dhahbi, N.; Beroual, A. Computation of electrical potential distribution along insulator covered with thin conductive pollution layer. In Proceedings of the ICEMIS ’18: Proceedings of the Fourth International Conference on Engineering, Istanbul, Turkey, 19–20 June 2018; pp. 1–5. [Google Scholar]

- Abd-Rahman, R.; Haddad, A.; Harid, N.; Griffiths, H. Stress control on polymeric outdoor insulators using Zinc oxide microvaristor composites. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 705–713. [Google Scholar] [CrossRef]

- Salem, A.A.; Rahman, R.A.; Kamarudin, M.S.; Othman, N.A. Factors and models of pollution flashover on high voltage outdoor insulators: Review. In Proceedings of the 2017 IEEE Conference on Energy Conversion (CENCON), Kuala lampur, Malaysia, 30–31 October 2017; pp. 241–246. [Google Scholar]

- Abd Rahman, R.; Harid, N.; Haddad, A. Stress control on polymeric outdoor insulators. In Proceedings of the 45th International Universities Power Engineering Conference UPEC2010, Cardiff, UK, 31 August–3 September 2010; pp. 1–4. [Google Scholar]

- Salem, A.A.; Abd-Rahman, R.; Kamarudin, M.S.; Ahmed, H.; Jamail, N.A.M.; Othman, N.A.; Yousof, M.F.M.; Ishak, M.T.; Al-Ameri, S. The effect of insulator geometrical profile on electric field distributions. Indones. J. Electr. Eng. Comput. Sci. 2019, 14, 618–627. [Google Scholar] [CrossRef]

- Salem, A.A.; Lau, K.Y.; Rahiman, W.; Al-Gailani, S.A.; Abdul-Malek, Z.; Abd Rahman, R.; Al-Ameri, S.M.; Sheikh, U.U. Pollution Flashover Characteristics of Coated Insulators under Different Profiles of Coating Damage. Coatings 2021, 11, 1194. [Google Scholar] [CrossRef]

- Standard IEC 60507; Artificial Pollution Tests on High-Voltage Ceramic and Glass Insu-Lators to Be Used on A.C. Systems. 3rd ed. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- Salem, A.A.; Abd-Rahman, R.; Al-Gailani, S.A.; Salam, Z.; Kamarudin, M.S.; Zainuddin, H.; Yousof, M.F. Risk Assessment of Polluted Glass Insulator Using Leakage Current Index Under Different Operating Conditions. IEEE Access 2020, 8, 175827–175839. [Google Scholar] [CrossRef]

- Mohammadnabi, S.; Rahmani, K. Influence of humidity and contamination on the leakage current of 230 kV composite insulator. Electr. Power Syst. Res. 2021, 194, 107083. [Google Scholar] [CrossRef]

- COMSOL Multiphysics User’s Manual, ed: Version 5.5. Available online: https://doc.comsol.com/5.5/doc/com.comsol.help.comsol/COMSOL_ReferenceManual.pdf (accessed on 20 February 2022).

- Zhao, S.; Zhang, C.; Zhang, Y.; Wang, S. Influence of Partial Arc on Electric Field Distribution of Insulator Strings for Electrified Railway Catenary. Energies 2019, 12, 3295. [Google Scholar] [CrossRef] [Green Version]

- Nazir, M.T.; Butt, F.T.; Phung, B.T.; Yeoh, G.H.; Yasin, G.; Akram, S.; Bhutta, M.S.; Hussain, S.; Nguyen, T.A. Simulation and Experimental Investigation on Carbonized Tracking Failure of EPDM/BN-Based Electrical Insulation. Polymers 2020, 12, 582. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Hag, A.H.; Jayaram, S.H.; Cherney, E.A. Calculation of current density along insulator surface using field and circuit theory approaches. In Proceedings of the 2003 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Albuquerque, NM, USA, 19–22 October 2003; pp. 375–378. [Google Scholar]

- Hussain, M.M.; Farokhi, S.; McMeekin, S.G.; Farzaneh, M. Risk Assessment of Failure of Outdoor High Voltage Polluted Insulators under Combined Stresses Near Shoreline. Energies 2017, 10, 1661. [Google Scholar] [CrossRef] [Green Version]

- Arshad, A.; Nekahi, A.; McMeekin, S.G.; Farzaneh, M. Effect of Pollution Layer Conductivity and Thickness on Electric Field Distribution along a Polymeric Insulator. In Proceedings of the 50th International Universities Power Engineering Conference (UPEC), Stoke On Trent, UK, 1–4 September 2015; pp. 1–4. [Google Scholar]

| Parameter in (mm) | D | d | S | H | L | L/H | No. of Sheds |

|---|---|---|---|---|---|---|---|

| Type I | 98 | - | 45 | 390 | 930 | 2.96 | 8 |

| Type II | 130 | 90 | 41 | 410 | 1310 | 2.1 | 9 |

| Test No. | Conductance | Standard Deviation | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | Average | ||

| Type I (μS) | 8.758 | 8.477 | 8.661 | 8.637 | 8.358 | 8.59 | 0.15 |

| Type II (μS) | 8.25 | 8.154 | 8.198 | 8.26 | 8.283 | 8.22 | 0.052 |

| Insulator | Wetting | x | y | Threshold Field |

|---|---|---|---|---|

| Type I | Fog | 4.58 | 1.234 | 4.76 |

| Low rain | 5.87 | 1.063 | 4.98 | |

| Medium rain | 6.92 | 0.953 | 6.42 | |

| High rain | 8.43 | 0.914 | 8.71 | |

| Type II | Fog | 4.92 | 1.185 | 3.93 |

| Low rain | 6.21 | 0.975 | 5.42 | |

| Medium rain | 7.71 | 0.938 | 6.83 | |

| High rain | 9.24 | 0.884 | 9.86 |

| Materials | Relative Electrical Permittivity, εr | Conductivity, σ (S/m) |

|---|---|---|

| Air | 1 | 10−13 |

| Silicone rubber | 4.3 | 10−12 |

| FRP core | 7.2 | 10−14 |

| Steel [35] | 1 | 11 × 105 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salem, A.A.; Lau, K.Y.; Abdul-Malek, Z.; Zhou, W.; Al-Ameri, S.; Al-Gailani, S.A.; Rahman, R.A. Investigation of High Voltage Polymeric Insulators Performance under Wet Pollution. Polymers 2022, 14, 1236. https://doi.org/10.3390/polym14061236

Salem AA, Lau KY, Abdul-Malek Z, Zhou W, Al-Ameri S, Al-Gailani SA, Rahman RA. Investigation of High Voltage Polymeric Insulators Performance under Wet Pollution. Polymers. 2022; 14(6):1236. https://doi.org/10.3390/polym14061236

Chicago/Turabian StyleSalem, Ali Ahmed, Kwan Yiew Lau, Zulkurnain Abdul-Malek, Wenbin Zhou, Salem Al-Ameri, Samir A. Al-Gailani, and Rahisham Abd Rahman. 2022. "Investigation of High Voltage Polymeric Insulators Performance under Wet Pollution" Polymers 14, no. 6: 1236. https://doi.org/10.3390/polym14061236

APA StyleSalem, A. A., Lau, K. Y., Abdul-Malek, Z., Zhou, W., Al-Ameri, S., Al-Gailani, S. A., & Rahman, R. A. (2022). Investigation of High Voltage Polymeric Insulators Performance under Wet Pollution. Polymers, 14(6), 1236. https://doi.org/10.3390/polym14061236