Industrial Implementation of Aluminum Trihydrate-Fiber Composition for Fire Resistance and Mechanical Properties in Glass-Fiber-Reinforced Polymer Roofs

Abstract

:1. Introduction

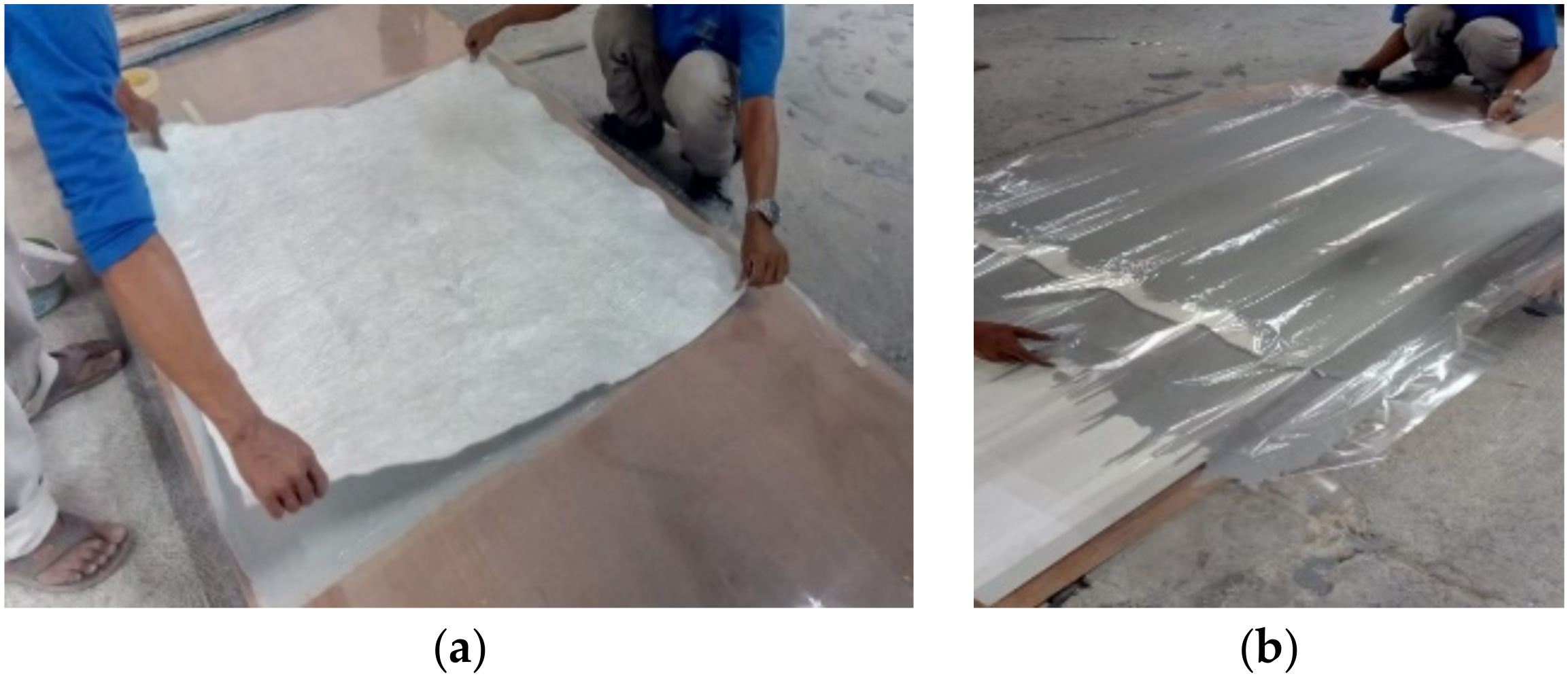

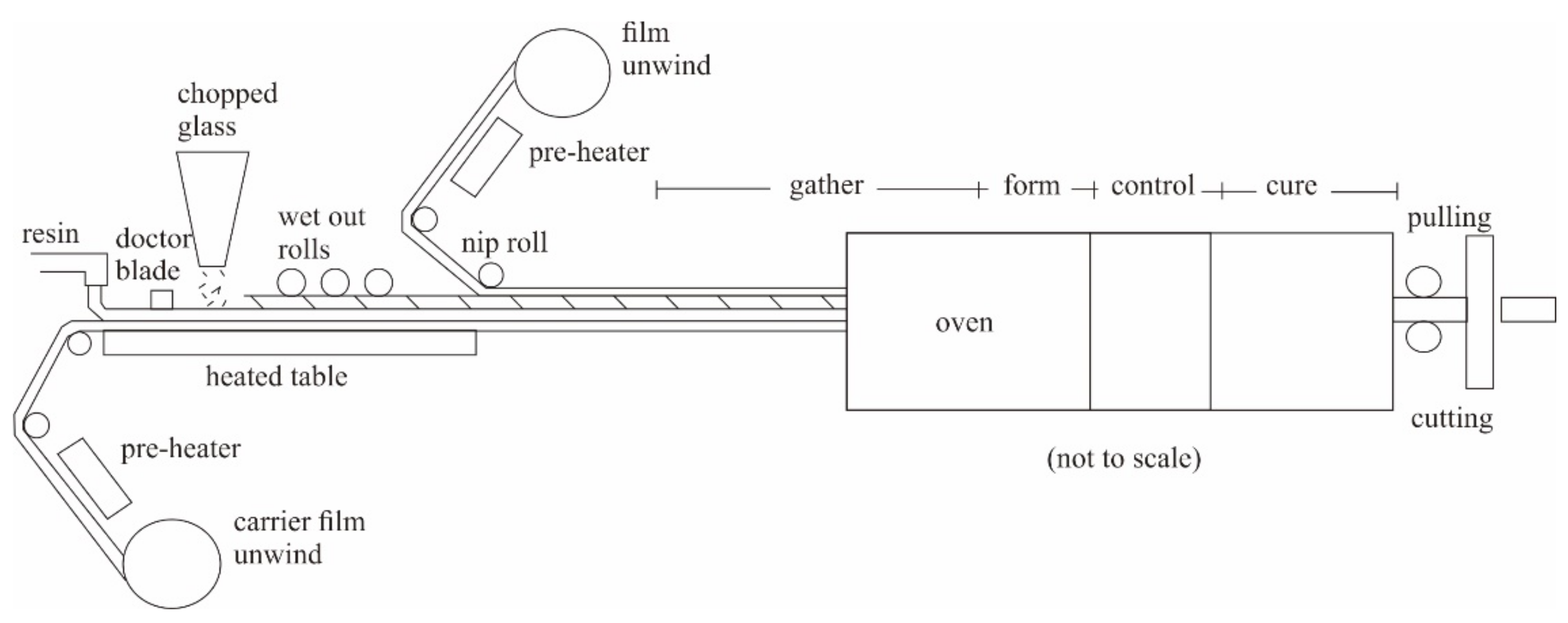

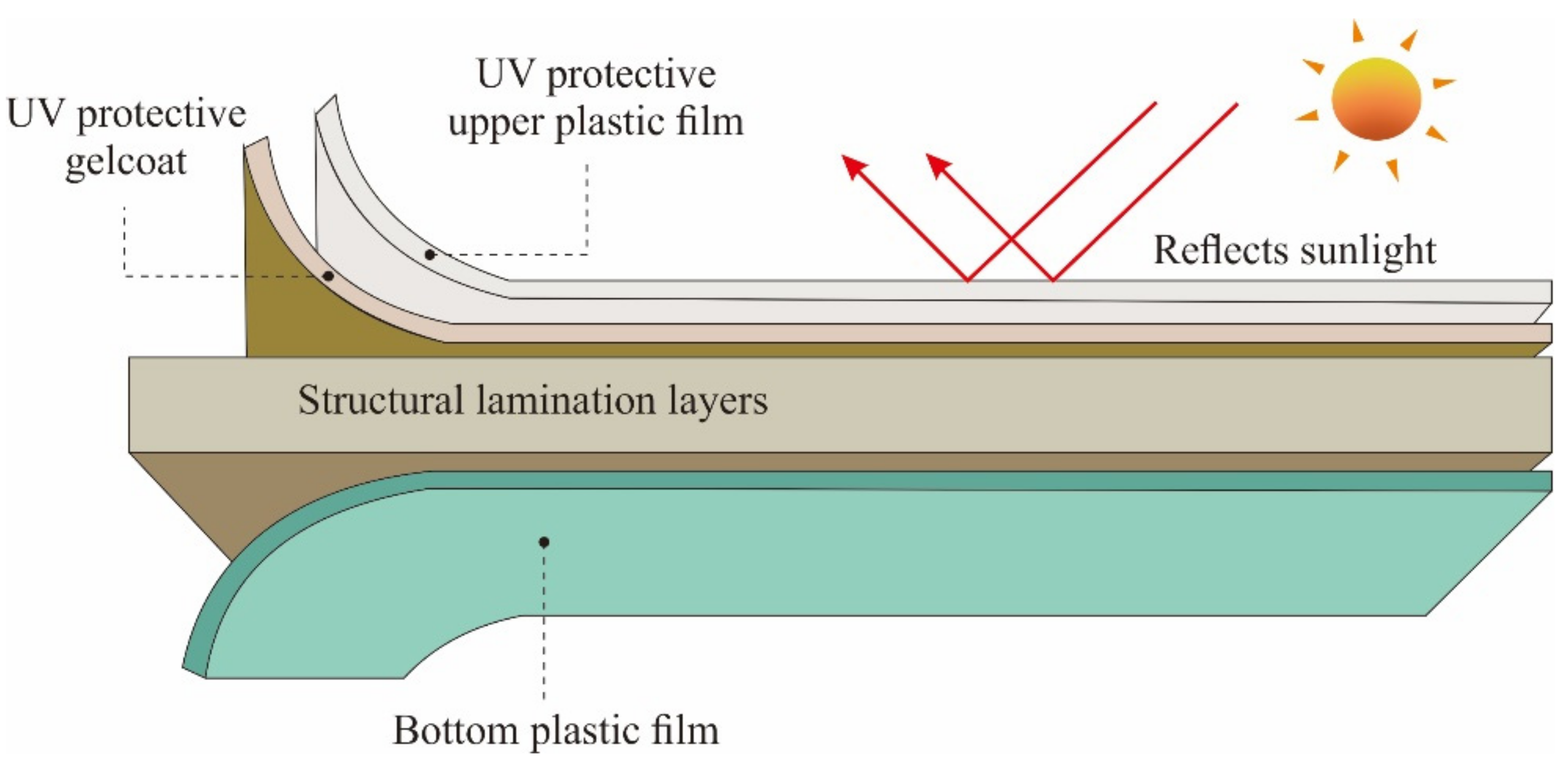

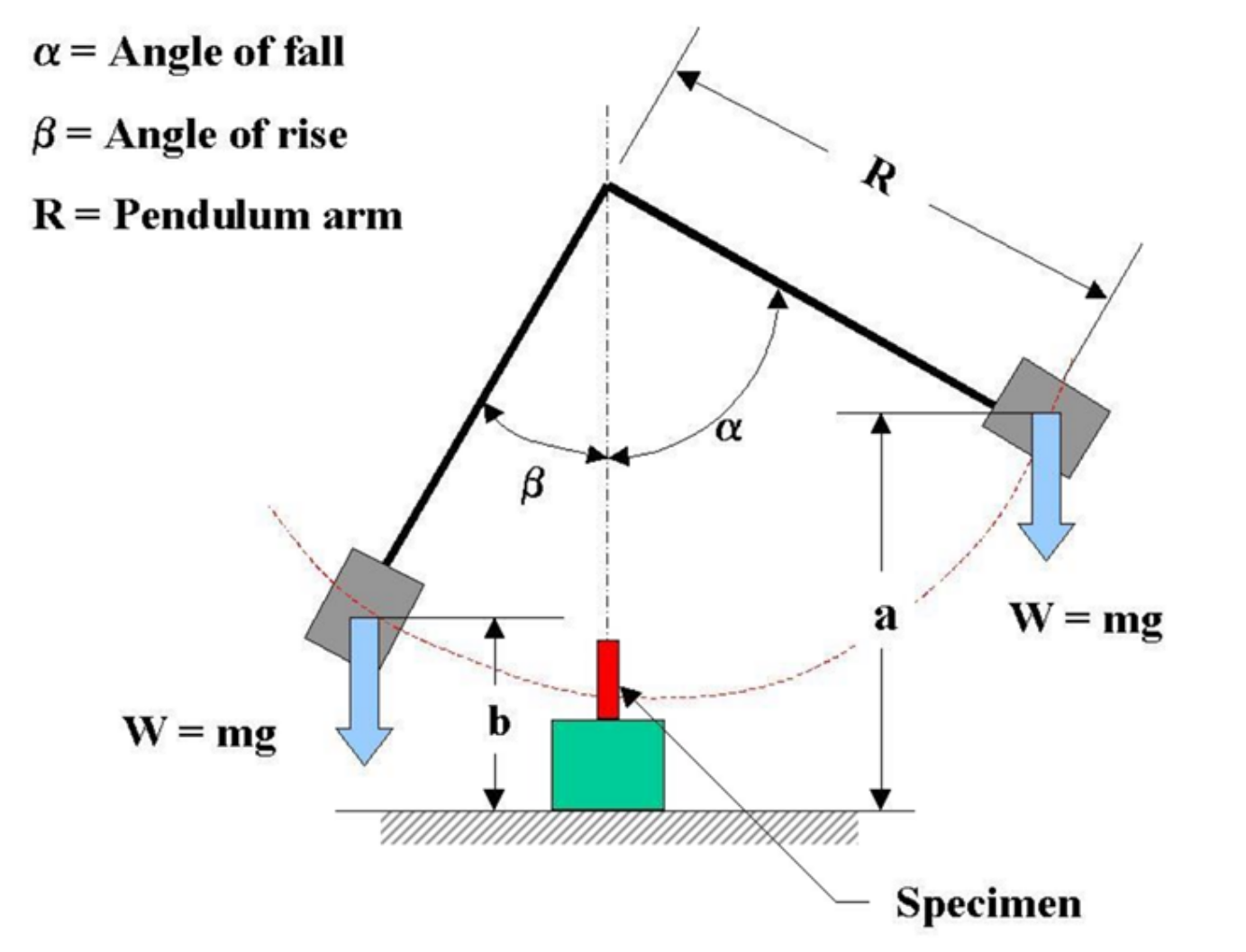

2. Materials and Methods

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mousay, M.; Chai, Y.Y.; Doh, S.I.; Lim, K.S. Degradation of Glass Fiber Reinforced Polymer (GFRP) Material Exposed to Tropical Atmospheric Condition, Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2021; Volume 879, pp. 265–274. [Google Scholar] [CrossRef]

- Zainudin, M.; Diharjo, K.; Kaavessina, M.; Setyanto, D. The properties degradation of exposed GFRP roof. AIP Conf. Proc. 2018, 1931, 030063. [Google Scholar] [CrossRef] [Green Version]

- Kandola, B.K.; Ebdon, J.R. Flammability and Thermal Stability of Unsaturated Polyester Resin-Based Blends and Composites. In Unsaturated Polyester Resins; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 435–469. [Google Scholar]

- Ramadan, N.; Taha, M.; La Rosa, A.D.; Elsabbagh, A. Towards Selection Charts for Epoxy Resin, Unsaturated Polyester Resin and Their Fiber-Fabric Composites with Flame Retardants. Materials 2021, 14, 1181. [Google Scholar] [CrossRef]

- Deswan; Setyanto, D. ATH AS a filler of vinylester RESIN. Int. J. Mech. Prod. Eng. Res. Dev. 2020, 10, 2953–2964. [Google Scholar]

- Ming, G.; Hao, W.; Yanxia, W.; Tengfei, S.; Weihong, W. Flame retardancy and mechanical properties of a novel intumescent flame-retardant unsaturated polyester. J. Vinyl Addit. Technol. 2014, 22, 350–355. [Google Scholar]

- Youchuan, W.; Zhang, L.; Yunyun, Y.; Xufu, C. The investigation of flammability, thermal stability, heat resistance and mechanical properties of unsaturated polyester resin using AlPi as fire retardant. J. Therm. Anal. Calorim. 2015, 122, 1331–1339. [Google Scholar] [CrossRef]

- Pérez-Salinas, C.F.; Castro, C.B.; Valencia, E.R.; Freire, O.F. Influence of Fire Retardants on the Mechanical Properties of Glass Fiber Reinforced Compounds in Polymeric Matrix Epoxy and Polyester. IOP Conf. Ser. Mater. Sci. Eng. 2019, 628, 12001. [Google Scholar] [CrossRef]

- Yunshu, Z.; Yuan, Y.; Qingwu, Z. Effects of Dimethyl Methylphosphonate, Aluminum Hydroxide and Ammonium Polyphosphate on the Fire resistance and Thermal Properties of Unsaturated Polyester Resin. IOP Conf. Ser. Mater. Sci. Eng. 2018, 394, 22029. [Google Scholar] [CrossRef]

- Daulath, B.R.; Vasanthakumari, R. Optimization Studies in Fire retardant Fiber Reinforced Plastic Composites for Roofing Applications. Int. J. Chem. Res. 2012, 2, 26–33. [Google Scholar]

- Kaleg, S. Pengaruh Fire Retardant Aluminum Tri-Hydroxide Dan Filler Montmorillonite Terhadap Ketahanan Bakar Dan Kekuatan Flexural Komposit Unsaturated Polyester Resin–Serat Gelas. Master’s Thesis, Universitas Sebelas Maret, Surakarta, Indonesia, 2018. [Google Scholar]

- Xiangxiu, C.; Li, Y.; Zhiyong, Z.; Hong, W.; Guozheng, L.; Aijuan, G. New glass fiber/bismaleimide composites with significantly improved fire resistance, higher mechanical strength and lower dielectric loss. Compos. Part B Eng. 2015, 71, 96–102. [Google Scholar]

- Brown, J.R.; Mathys, Z. Reinforcement and matrix effects on the combustion properties of glass reinforced polymer composites. Compos. Part A Appl. Sci. Manuf. 1997, 28, 675–681. [Google Scholar] [CrossRef]

- Kandola, B.; Krishnan, L.; Ebdon, J. Blends of unsaturated polyester and phenolic resins for application as fire-resistant matrices in fiber-reinforced composites: Effects of added fire retardants. Polym. Degrad. Stab. 2014, 106, 129–137. [Google Scholar] [CrossRef]

- Scudamore, M.J. Fire Performance Studies on Glass-reinforced Plastic Laminates. Fire Mater. 1994, 18, 313–325. [Google Scholar] [CrossRef]

- Diharjo, K.; Suharty, N.S.; Nusantara, A.E.B.; Afandi, R. The Effect of Sokka Clay on the Tensile and Burning Properties of rPP/Clay Composite. Adv. Mater. Res. 2015, 1123, 338–342. [Google Scholar] [CrossRef]

- Bushra, R.; Amal, S.; Muameer, E.; Aymen, R.M. Mechanical properties of hybrid woven roving and chopped strand mat glass fabric reinforced polyester composites Mater. Res. Express 2019, 6, 105208. [Google Scholar] [CrossRef]

- Abburi, L.K.; Prakash, M. The effect of fiber orientation on mechanical properties and machinability of GFRP composites by end milling using cutting force analysis. Polym. Polym. Compos. 2021, 29, S178–S187. [Google Scholar] [CrossRef]

- Shin, Y.B. Manufacturing Method for Glass Fiber Reinforced Plastic and Glass Fiber Reinforced Plastic Using the Same and Building Panel Thereof. Patent KR102181541 (B1), 23 November 2020. [Google Scholar]

- Shin, Y.B. Manufacturing Method for Glass Fiber Reinforced Plastic and Glass Fiber Reinforced Plastic Using the Same and Building Panel and Manufacturing Method Thereof. Patent KR102152089 (B1), 7 September 2020. [Google Scholar]

- Mariatti, M.; Chum, P.K. Effect of Laminate Configuration on the Properties of Glass Fiber-reinforced Plastics (GFRPs) Mixed Composites. J. Reinf. Plast. Compos. 2005, 24, 1713–1721. [Google Scholar] [CrossRef]

- Available online: https://intecpersada.com/fibrealum/(accessed on 10 February 2021).

- Setyanto, D.; Jamasri; Suhendro, B.; Tontowi, A.E. Alumina as a Filler in UPR Matrix for FRP Composite Roofing Sheets. Int. J. Mater. Sci. 2012, 7, 191–202. [Google Scholar]

- Debnath, S.; Ranade, R.; Wunder, S.L.; McCoo, J. Interface effects on mechanical properties of particle reinforced composites. Dent. Mater. 2004, 20, 677–686. [Google Scholar] [CrossRef]

- GURIT. Guide to Composites. Available online: www.gurit.com (accessed on 10 February 2021).

- Gibson, R.F. Principles of Composite Material Mechanics; Mc Graw Hill, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Sonnier, R.; Otazaghine, B.; Viretto, A.; Apolinario, G.; Ienny, P. Improving the fire resistance of flax fabrics by radiation grafting of phosphorus compounds. Eur. Polym. J. 2015, 68, 313–325. [Google Scholar] [CrossRef]

- Umberto, B.; Nicholas, D. Thermal and Fire Characteristics of FRP Composites for Architectural Applications. Polymers 2015, 7, 2276–2289. [Google Scholar] [CrossRef] [Green Version]

- Dong, Q.; Gao, C.; Ding, Y.; Wang, F.; Wen, B.; Zhang, S.; Wang, T.; Yang, M. A polycarbonate/magnesium oxide nanocomposite with high fire resistance. J. Appl. Polym. Sci. 2012, 123, 1085–1093. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Diharjo, K.; Sutrisno; Triyono; Afandi, R.; Himawanto, D.A. Enhancing of fire resistance on CFRP using Sokka-clay particle for lightweight car body panel. In Proceedings of the 2014 International Conference on Electrical Engineering and Computer Science ICEECS, Denpasar, Indonesia, 24–25 November 2014; pp. 188–192. [Google Scholar]

- Tingting, Q.; Fanliang, G.; Changhai, L.; Shouxiang, L. Study of the thermal degradation of flame-retardant polyester GFRP using TGA and TG-FTIR-GC/MS. J. Therm. Anal. Calorim. 2021, 1–18. [Google Scholar] [CrossRef]

- Maheshwari, N.; Thakur, S.; Neogi, P.; Neogi, S. UV resistance and fire retardant property enhancement of unsaturated polyester composite. Polym. Bull. 2015, 72, 1433–1447. [Google Scholar] [CrossRef]

- Hapuarachchi, T.D.; Peijs, T. Aluminium trihydrate in combination with ammonium polyphosphate as fire retardants for unsaturated. Express Polym. Lett. 2009, 3, 743–751. [Google Scholar] [CrossRef]

- Tibiletti, L. Thermal degradation and fire behaviour of unsaturated polyesters filled with metallic oxides. Polym. Degrad. Stab. 2011, 96, 67–75. [Google Scholar] [CrossRef]

- Zhao, Q.; Jia, Z.; Li, X.; Ye, Z. Effect of Al(OH)3 Particle Fraction on Mechanical Properties of Particle-Reinforced Composites Using Unsaturated Polyester as Matrix. Fail. Anal. Preven. 2010, 10, 515–519. [Google Scholar] [CrossRef]

- Baskaran, R.; Sarojadevi, M.; Vijayakusumar, C.T. Unsaturated polyester nanocomposite filled with nanoalumina. Springer J. Mater. Sci. 2011, 446, 4864–4871. [Google Scholar]

- Mouritz, A.P.; Gibson, A.G. Fire Properties of Polymer Composite, Materials; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Widmann, G. Interpreting TGA Curves. UserCom 2001, 1, 1–20. [Google Scholar]

- Salasinska, K.; Celi, M.; Barczewski, M.; Leszczy, M.K.; Borucka, M.; Kozikowski, P. Fire behavior of flame retarded unsaturated polyester resin with high nitrogen content additives. Polym. Test. 2020, 84, 106379. [Google Scholar] [CrossRef]

- Halim, Z.A.B.; Yajid, M.A.M.; Nurhadi, F.A.; Ahmad, N.; Hamdan, H. Effect of silica aerogel—Aluminium trihydroxide hybrid filler on the physio-mechanical and thermal decomposition behaviour of unsaturated polyester resin composite. Polym. Degrad. Stab. 2020, 182, 109377. [Google Scholar] [CrossRef]

- Pawelec, W. New Families of Highly Efficient, Halogen-Free Flame Retardants for Polypropylene (PP). Ph.D. Thesis, Laboratory of Polymer Technology Center of Excellence for Functional Materials Department of Chemical Engineering Åbo Akademi University, Turku, Finland, 2014. [Google Scholar]

- Zhang, Z.; Han, Y.; Li, T.; Wang, T.; Gao, T.; Liang, Q.; Chen, L. Polyaniline/montmorillonite nanocomposites as an effective flame retardant and smoke suppressant for polystyrene. Synth. Metals 2016, 221, 28–38. [Google Scholar] [CrossRef]

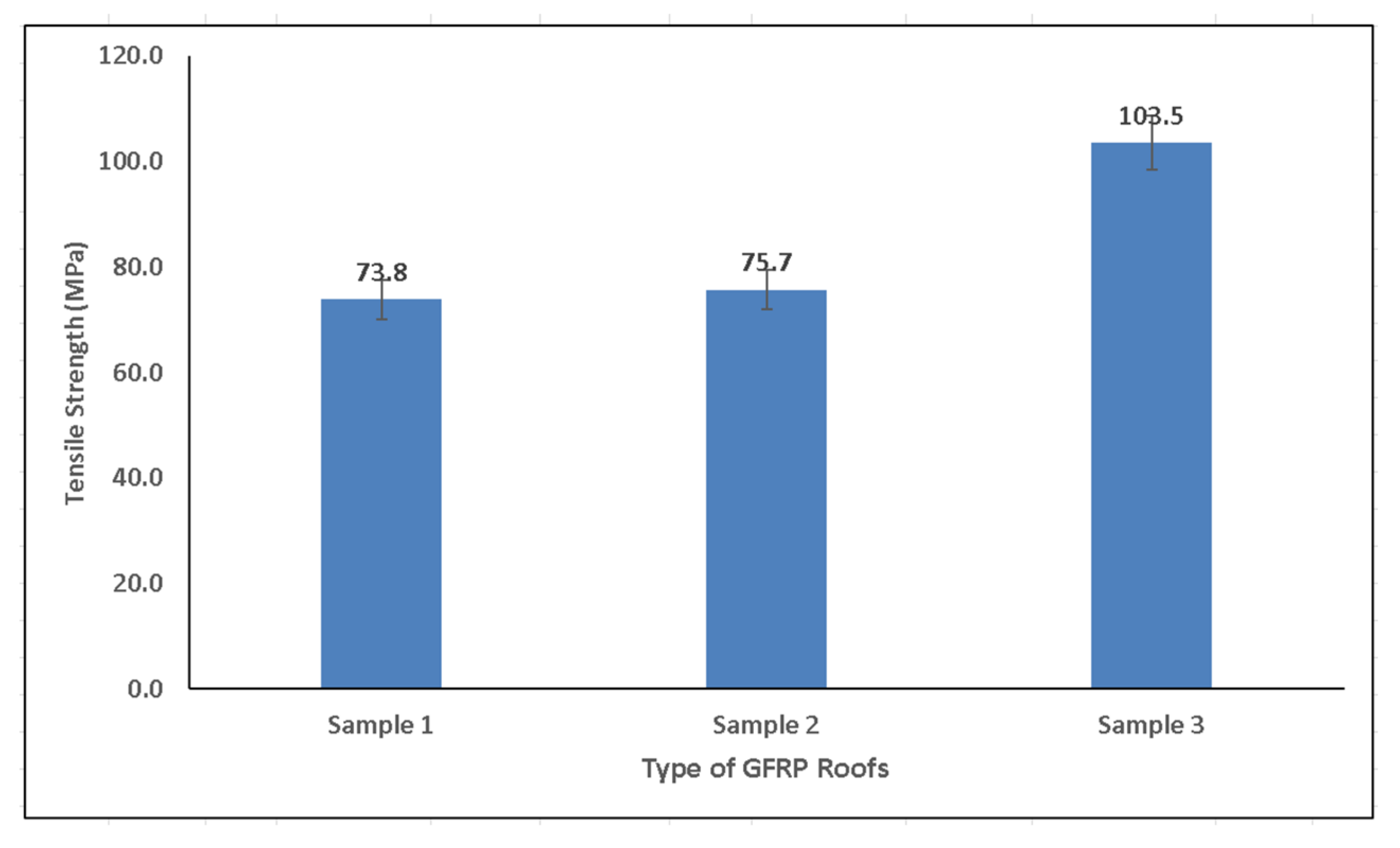

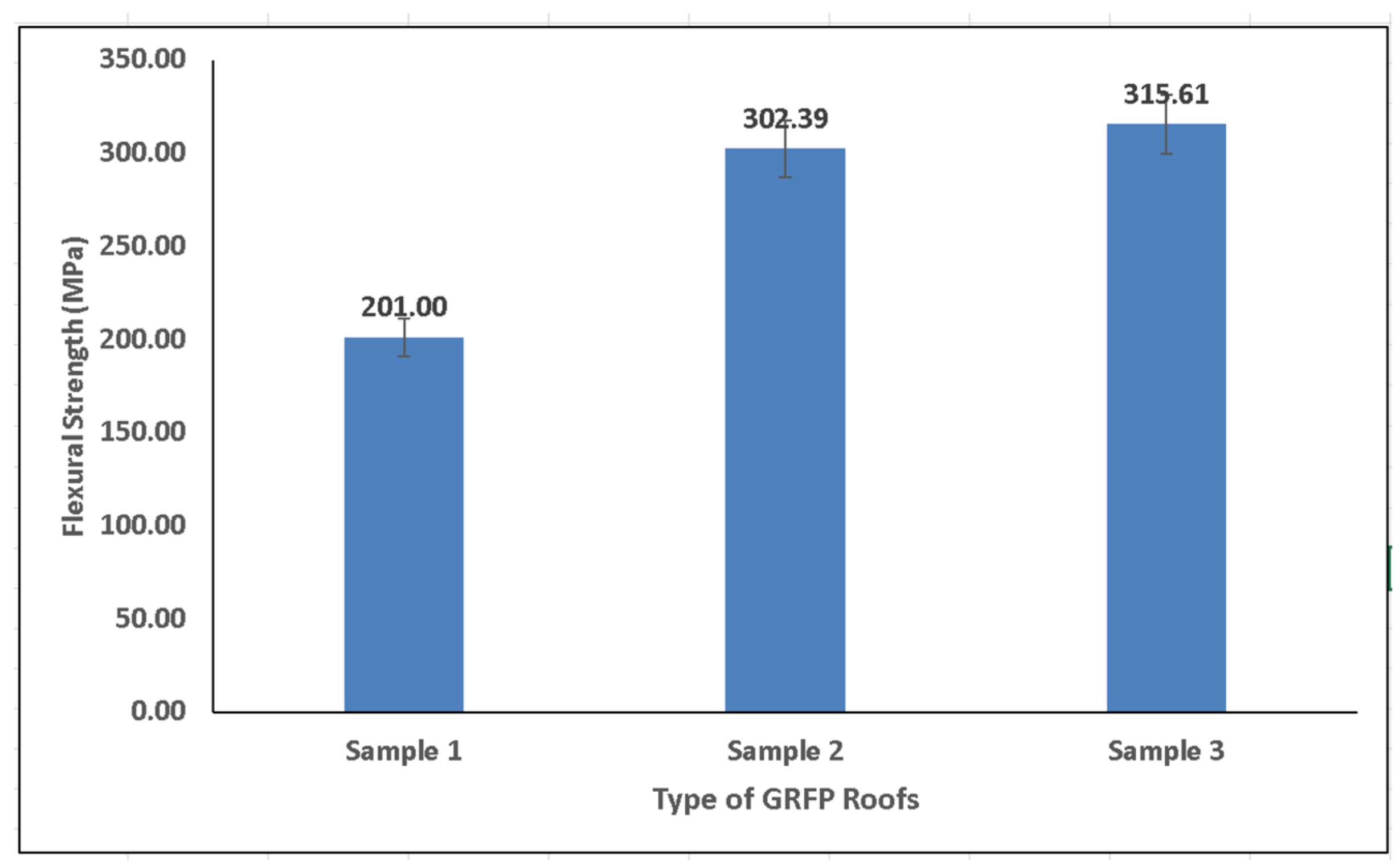

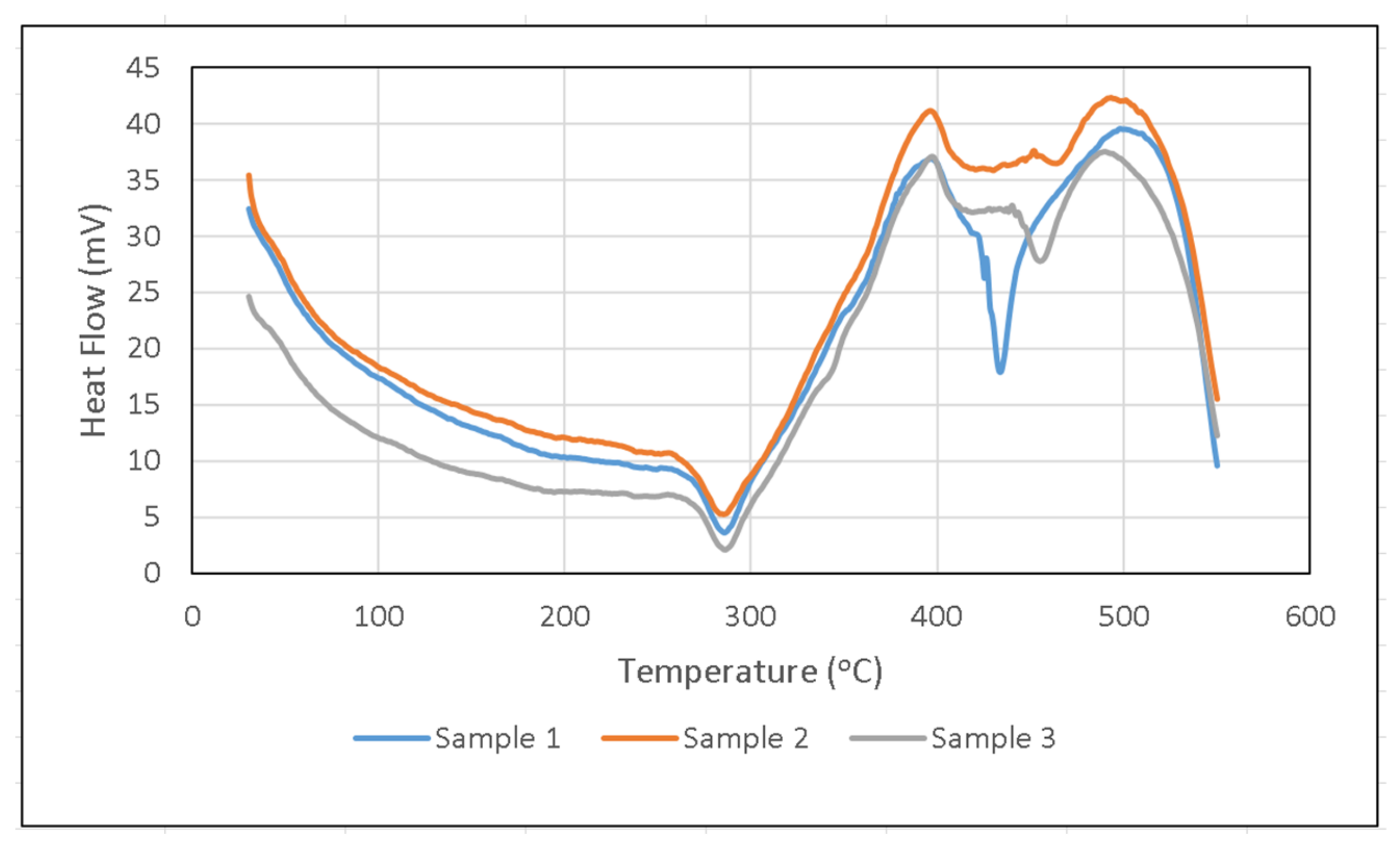

| Sample | Layer Configuration |

|---|---|

| Sample 1 | CSM 300—CSM 450 (existing GFRP composite roof) |

| Sample 2 | CSM 300—STM 450 |

| Sample 3 | CSM 300—WR 200—CSM 300 |

| Type of Sample | Tensile Test | Flexural Test | Izod Impact Test | Burn Test | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No of Specimen | Force(max) (N) | Strength (Mpa) | AVR (Mpa) | No of Specimen | Force(max) (N) | Strength (Mpa) | AVR (Mpa) | No of Specimen | Energy (J) | Strength (J/m2) | AVR (J/m2) | No of Specimen | Burning Time (min) | Linear Burning Rate (mm/min) | AVR (mm/min) | |

| Sample 1 | 1 | 652.1346 | 72.5400 | 73.8 | 1 | 78.3 | 205.5686 | 201.00 | 1 | 3.635602 | 90,213.44047 | 92,700.4 | 1 | 12.80 | 5.55 | 5.32 |

| 2 | 707.0479 | 75.3702 | 2 | 77.1 | 234.2267 | 2 | 3.636279 | 90,230.24489 | 2 | 12.75 | 5.25 | |||||

| 3 | 682.6799 | 73.2175 | 3 | 77.1 | 177.9065 | 3 | 3.636279 | 92,762.21605 | 3 | 13.07 | 4.90 | |||||

| 4 | 702.5248 | 74.4200 | 4 | 76.9 | 200.3033 | 4 | 3.636279 | 93,237.91972 | 4 | 13.03 | 5.37 | |||||

| 5 | 701.3226 | 73.4523 | 5 | 78.8 | 178.9882 | 5 | 3.636279 | 97,058.02400 | 5 | 12.98 | 5.16 | |||||

| 6 | 79.4 | 206.8151 | 6 | 12.55 | 5.74 | |||||||||||

| 7 | 77.4 | 203.2057 | 7 | 13.02 | 5.30 | |||||||||||

| Sample 2 | 1 | 902.4540 | 86.4627 | 75.7 | 1 | 131.2 | 344.4521 | 302.39 | 1 | 3.639876 | 93,330.16021 | 92,690.0 | 1 | 9.85 | 5.69 | 4.63 |

| 2 | 758.2110 | 66.2482 | 2 | 127.8 | 292.5736 | 2 | 3.639876 | 89,630.04797 | 2 | 13.72 | 4.23 | |||||

| 3 | 597.0000 | 59.3605 | 3 | 125.7 | 372.9214 | 3 | 3.639332 | 90,306.00898 | 3 | 11.35 | 3.70 | |||||

| 4 | 857.2340 | 85.9245 | 4 | 125.3 | 326.3720 | 4 | 3.639876 | 93,330.16021 | 4 | 13.25 | 4.75 | |||||

| 5 | 832.9150 | 80.5738 | 5 | 115.1 | 237.1458 | 5 | 3.639876 | 96,548.44159 | 5 | 10.88 | 5.33 | |||||

| 6 | 109.3 | 286.9559 | 6 | 12.38 | 4.28 | |||||||||||

| 7 | 110.2 | 256.3183 | 7 | 13.38 | 4.41 | |||||||||||

| Sample 3 | 1 | 1060.6100 | 124.9240 | 103.5 | 1 | 124.1 | 286.3580 | 315.61 | 1 | 3.622783 | 92,891.86853 | 92,597.7 | 1 | 10.78 | 5.19 | 4.31 |

| 2 | 906.2690 | 96.9634 | 2 | 128.2 | 259.9767 | 2 | 3.622783 | 92,182.77030 | 2 | 9.35 | 4.92 | |||||

| 3 | 839.3920 | 102.4820 | 3 | 124.2 | 320.9794 | 3 | 3.621751 | 92,156.51497 | 3 | 12.52 | 3.91 | |||||

| 4 | 924.2300 | 95.1794 | 4 | 136.7 | 356.0658 | 4 | 3.621751 | 92,865.41124 | 4 | 8.50 | 4.82 | |||||

| 5 | 908.6390 | 98.0283 | 5 | 131.4 | 300.8151 | 5 | 3.621751 | 92,891.86853 | 5 | 10.02 | 4.39 | |||||

| 6 | 130.6 | 340.1770 | 6 | 12.05 | 3.49 | |||||||||||

| 7 | 132.4 | 344.8655 | 7 | 13.67 | 3.44 | |||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zainudin, M.; Diharjo, K.; Kaavessina, M.; Setyanto, D.; Ubaidillah, U. Industrial Implementation of Aluminum Trihydrate-Fiber Composition for Fire Resistance and Mechanical Properties in Glass-Fiber-Reinforced Polymer Roofs. Polymers 2022, 14, 1273. https://doi.org/10.3390/polym14071273

Zainudin M, Diharjo K, Kaavessina M, Setyanto D, Ubaidillah U. Industrial Implementation of Aluminum Trihydrate-Fiber Composition for Fire Resistance and Mechanical Properties in Glass-Fiber-Reinforced Polymer Roofs. Polymers. 2022; 14(7):1273. https://doi.org/10.3390/polym14071273

Chicago/Turabian StyleZainudin, Mohammad, Kuncoro Diharjo, Mujtahid Kaavessina, Djoko Setyanto, and Ubaidillah Ubaidillah. 2022. "Industrial Implementation of Aluminum Trihydrate-Fiber Composition for Fire Resistance and Mechanical Properties in Glass-Fiber-Reinforced Polymer Roofs" Polymers 14, no. 7: 1273. https://doi.org/10.3390/polym14071273

APA StyleZainudin, M., Diharjo, K., Kaavessina, M., Setyanto, D., & Ubaidillah, U. (2022). Industrial Implementation of Aluminum Trihydrate-Fiber Composition for Fire Resistance and Mechanical Properties in Glass-Fiber-Reinforced Polymer Roofs. Polymers, 14(7), 1273. https://doi.org/10.3390/polym14071273