Effect of Marble Dust on the Mechanical, Morphological, and Wear Performance of Basalt Fibre-Reinforced Epoxy Composites for Structural Applications

Abstract

:1. Introduction

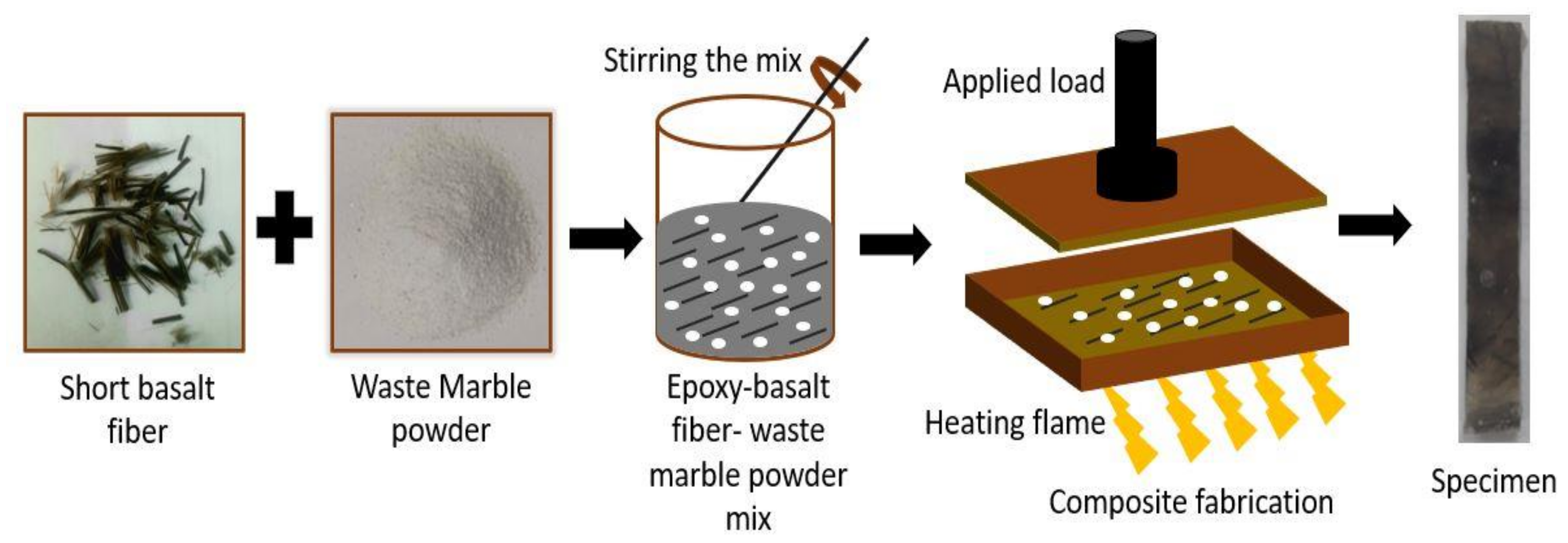

2. Material and Fabrication

3. Composite Characterizations

4. Results and Discussion

4.1. EDX Analysis

4.2. Density and Voids

4.3. Mechanical Properties

4.4. Specific Wear Rate

4.5. Fractography of the Composites

4.6. Wear Analysis

5. Conclusions

- i.

- Generally, the properties, such as the tensile strength, flexural strength, hardness, and impact strength, increased with the increase in marble dust proportion. This might be due to the fact the composite was strengthened by the intermetallic bonding of basalt fibre with epoxy, while the WMP served as a bridging agent between the basalt and the WMP. Overall, the BW3 composite gave the best results.

- ii

- A small reduction in properties was observed at 10 wt. WMP due to the collection of particles of WMP resulting in a higher stress concentration at the fractured section. Fractograph images also confirmed the deformation mechanism and clustering of fibres.

- iii

- In the context of sliding wear, specific wear at different speeds and normal loads was steadily observed. Due to the interaction between the resin and the counter-rotating disc, the specific wear increased as the velocity increased, and it continued to rise until the velocity reached 4.19 m/s. As the velocity increased further, the specific wear rate of all compositions decreased. This reduction may be due to the wear resistance of WMP and basalt fibres.

- iv

- At higher loads, this phenomenon prevailed and caused higher specific wear. The maximum specific wear was found to be 6.04 × 10−6 mm3/N-m at 25 N for the BW1 composition, and the minimum was observed as 1.85 × 10−6 mm3/N-m at 10 N for the BW0 composition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abenojar, J.; Martínez, M.-A.; de Armentia, S.L.; Paz, E.; del Real, J.-C.; Velasco, F. Mechanical Properties and Fire-Resistance of Composites with Marble Particles. J. Mater. Res. Technol. 2021, 12, 1403–1417. [Google Scholar]

- Arpitha, G.R.; Sanjay, M.R.; Senthamaraikannan, P.; Barile, C.; Yogesha, B. Hybridization Effect of Sisal/Glass/Epoxy/Filler Based Woven Fabric Reinforced Composites. Exp. Tech. 2017, 41, 577–584. [Google Scholar]

- Bafakeeh, O.T.; Shewakh, W.M.; Abu-Oqail, A.; Abd-Elaziem, W.; Abdel Ghafaar, M.; Abu-Okail, M. Synthesis and Characterization of Hybrid Fiber-Reinforced Polymer by Adding Ceramic Nanoparticles for Aeronautical Structural Applications. Polymers 2021, 13, 4116. [Google Scholar]

- Choudhary, M.; Singh, T.; Dwivedi, M.; Patnaik, A. Waste Marble Dust-filled Glass Fiber-reinforced Polymer Composite Part I: Physical, Thermomechanical, and Erosive Wear Properties. Polym. Compos. 2019, 40, 4113–4124. [Google Scholar]

- Choudhary, M.; Singh, T.; Dwivedi, M.; Patnaik, A. Evaluation of Some Mechanical Characterization and Optimization of Waste Marble Dust Filled Glass Fiber Reinforced Polymer Composite. Mater. Res. Express 2019, 6, 105702. [Google Scholar]

- DeArmitt, C.; Rothon, R. Particulate Fillers, Selection and Use in Polymer Composites. In Encyclopedia of Polymers and Composites; Palsule, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–19. [Google Scholar]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.J.; Hui, D. A Short Review on Basalt Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar]

- El-Sherbiny, S.; El-Sheikh, S.; Barhoum, A. Preparation and Modification of Nano Calcium Carbonate Filler from Waste Marble Dust and Commercial Limestone for Papermaking Wet End Application. Powder Technol. 2015, 279, 290–300. [Google Scholar]

- Feng, N.L.; Malingam, S.D.; Ping, C.W.; Razali, N. Mechanical properties and water absorption of kenaf/pineapple leaf fiber-reinforced polypropylene hybrid composites. Polym. Compos. 2020, 41, 1255–1264. [Google Scholar]

- Golewski, P.; Sadowski, T. Technological and Strength Aspects of Layers Made of Different Powders Laminated on a Polymer Matrix Composite Substrate. Molecules 2022, 27, 1168. [Google Scholar]

- Gubanova, E.; Kupinets, L.; Deforzh, H.; Koval, V.; Gaska, K. Recycling of Polymer Waste in the Context of Developing Circular Economy. Archit. Civ. Eng. Environ. 2019, 12, 99–108. [Google Scholar]

- Kaybal, H.B.; Ulus, H.; Demir, O.; Şahin, Ö.S.; Avcı, A. Effects of alumina nanoparticles on dynamic impact responses of carbon fiber reinforced epoxy matrix nanocomposites. Eng. Sci. Technol. Int. J. 2018, 21, 399–407. [Google Scholar]

- Kessler, E.; Gadow, R.; Straub, J. Basalt, Glass and Carbon Fibers and Their Fiber Reinforced Polymer Composites under Thermal and Mechanical Load. AIMS Mater. Sci. 2016, 3, 1561–1576. [Google Scholar]

- Khandelwal, S.; Rhee, K.Y. Recent Advances in Basalt-Fiber-Reinforced Composites: Tailoring the Fiber-Matrix Interface. Compos. Part B Eng. 2020, 192, 108011. [Google Scholar]

- Lalit, R.; Mayank, P.; Ankur, K. Natural Fibers and Biopolymers Characterization: A Future Potential Composite Material. Stroj. Časopis J. Mech. Eng. 2018, 68, 33–50. [Google Scholar]

- Lapena, M.H.; Marinucci, G. Mechanical Characterization of Basalt and Glass Fiber Epoxy Composite Tube. Mater. Res. 2017, 21, 1–7. [Google Scholar]

- Mostovoy, A.; Yakovlev, A.; Tseluikin, V.; Lopukhova, M. Epoxy nanocomposites reinforced with functionalized carbon nanotubes. Polymers 2020, 12, 1816. [Google Scholar]

- Mostovoy, A.; Shcherbakov, A.; Yakovlev, A.; Arzamastsev, S.; Lopukhova, M. Reinforced Epoxy Composites Modified with Functionalized Graphene Oxide. Polymers 2022, 14, 338. [Google Scholar]

- Nayak, S.K.; Satapathy, A. Development and characterization of polymer-based composites filled with micro-sized waste marble dust. Polym. Polym. Compos. 2021, 29, 497–508. [Google Scholar]

- Nayak, S.K.; Satapathy, A.; Mantry, S. Processing and Wear Response Study of Glass-polyester Composites with Waste Marble Dust as Particulate Filler. Polym. Compos. 2020, 41, 2263–2273. [Google Scholar]

- Çınar, M.E.; Kar, F. Characterization of composite produced from waste PET and marble dust. Constr. Build. Mater. 2018, 163, 734–741. [Google Scholar]

- Plappert, D.; Ganzenmüller, G.C.; May, M.; Beisel, S. Mechanical Properties of a Unidirectional Basalt-Fiber/Epoxy Composite. J. Compos. Sci. 2020, 4, 101. [Google Scholar]

- Rabajczyk, A.; Zielecka, M.; Popielarczyk, T.; Sowa, T. Nanotechnology in Fire Protection—Application and Requirements. Materials 2021, 14, 7849. [Google Scholar] [PubMed]

- Ralph, C.; Lemoine, P.; Archer, E.; McIlhagger, A. Mechanical Properties of Short Basalt Fibre Reinforced Polypropylene and the Effect of Fibre Sizing on Adhesion. Compos. Part B Eng. 2019, 176, 107260. [Google Scholar]

- Ranakoti, L.; Gupta, M.K.; Rakesh, P.K. Silk and Silk-Based Composites: Opportunities and Challenges. In Processing of Green Composites; Springer: Singapore, 2019; pp. 91–106. [Google Scholar]

- Ranakoti, L.; Rakesh, P.K. Physio-Mechanical Characterization of Tasar Silk Waste/Jute Fiber Hybrid Composite. Compos. Commun. 2020, 22, 100526. [Google Scholar]

- Ranakoti, L.; Rakesh, P.K.; Gangil, B. Effect of Tasar Silk Waste on the Mechanical Properties of Jute/Grewia Optiva Fibers Reinforced Epoxy Laminates. J. Nat. Fibers 2021, Ahead-of-print. 1–13. [Google Scholar]

- Ray, S.; Rout, A.K.; Sahoo, A.K. An Experimental and Computational Study on Thermal Conductivity of Marble Particle Filled Epoxy Composites. Rasayan J. Chem. 2018, 11, 80–87. [Google Scholar]

- Sahin, Y.; Patrick, D.B. Development of Epoxy Composites Containing Basalt and Carbon Fabrics and Their Mechanical Behaviours. Int. J. Metall. Met. Phys. 2018, 3, 25. [Google Scholar]

- Shukla, A.; Gupta, N.; Gupta, A. Development of Green Concrete Using Waste Marble Dust. Mater. Today Proc. 2020, 26, 2590–2594. [Google Scholar]

- Singh, T.; Puri, M.; Tejyan, S.; Ravi, R.K. Abrasive Wear and Dynamic–Mechanical Behavior of Marble Dust Filled Bagasse Fiber Reinforced Hybrid Polymer Composites. Polym. Compos. 2021, 42, 2817–2828. [Google Scholar]

- Subagia, I.A.; Kim, Y. Tensile Behavior of Hybrid Epoxy Composite Laminate Containing Carbon and Basalt Fibers. Sci. Eng. Compos. Mater. 2014, 21, 211–217. [Google Scholar]

- Vikas, G.; Sudheer, M. A Review on Properties of Basalt Fiber Reinforced Polymer Composites. Am. J. Mater. Sci. 2017, 7, 156–165. [Google Scholar]

- Vinay, S.; Sanjay, M.; Siengchin, S.; Venkatesh, C. Basalt Fiber Reinforced Polymer Composites Filled with Nano Fillers: A Short Review. Mater. Today Proc. 2022, 52, 2460–2466. [Google Scholar]

- Xiong, T.; Wang, N.; Liao, J.; Zhang, Y. Modified Boron Nitride-basalt Fiber/Epoxy Resin Composite Laminates and Their Enhanced Mechanical Properties. Polym. Adv. Technol. 2021, 32, 3621–3632. [Google Scholar]

- Asyraf, M.; Ishak, M.; Norrrahim, M.; Nurazzi, N.; Shazleen, S.; Ilyas, R.; Rafidah, M.; Razman, M. Recent advances of thermal properties of sugar palm lignocellulosic fibre reinforced polymer composites. Int. J. Biol. Macromol. 2021, 193, 1587–1599. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 28, 2675–2695. [Google Scholar] [CrossRef]

- Asyraf, M.; Ishak, M.; Syamsir, A.; Nurazzi, N.; Sabaruddin, F.; Shazleen, S.; Norrrahim, M.; Rafidah, M.; Ilyas, R.; Rashid, M.Z.A.; et al. Mechanical properties of oil palm fibre-reinforced polymer composites: A review. J. Mater. Res. Technol. 2022, 17, 33–65. [Google Scholar] [CrossRef]

- Alias, A.H.; Norizan, M.N.; Sabaruddin, F.A.; Asyraf, M.R.M.; Norrrahim, M.N.F.; Ilyas, A.R.; Kuzmin, A.M.; Rayung, M.; Shazleen, S.S.; Nazrin, A.; et al. Hybridization of MMT/Lignocellulosic Fiber Reinforced Polymer Nanocomposites for Structural Applications: A Review. Coatings 2021, 11, 1355. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Norrrahim, M.N.F.; Misenan, M.S.M.; Jenol, M.A.; Samsudin, S.A.; Nurazzi, N.M.; Asyraf, M.R.M.; Supian, A.B.M.; Bangar, S.P.; et al. Natural Fiber-Reinforced Polycaprolactone Green and Hybrid Biocomposites for Various Advanced Applications. Polymers 2022, 14, 182. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical review of natural fiber reinforced hybrid composites: Processing, properties, applications and cost. Polymers 2021, 13, 3514. [Google Scholar]

- Azlin, M.N.M.; Ilyas, R.A.; Zuhri, M.Y.M.; Sapuan, S.M.; Harussani, M.M.; Sharma, S.; Nordin, A.H.; Nurazzi, N.M.; Afiqah, A.N. 3D Printing and Shaping Polymers, Composites, and Nanocomposites: A Review. Polymers 2022, 14, 180. [Google Scholar] [CrossRef]

- Ali, S.S.S.; Razman, M.R.; Awang, A.; Asyraf, M.R.M.; Ishak, M.R.; Ilyas, R.A.; Lawrence, R.J. Critical Determinants of Household Electricity Consumption in a Rapidly Growing City. Sustainability 2021, 13, 4441. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef] [PubMed]

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric Analysis Properties of Cellulosic Natural Fiber Polymer Composites: A Review on Influence of Chemical Treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Potential Application of Green Composites for Cross Arm Component in Transmission Tower: A Brief Review. Int. J. Polym. Sci. 2020, 2020, 8878300. [Google Scholar] [CrossRef]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R.; Ilyas, R.A.; Asyraf, M.R.M. Potential of Natural Fiber Reinforced Polymer Composites in Sandwich Structures: A Review on Its Mechanical Properties. Polymers 2021, 13, 423. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Amir, A.L.; Nurazzi, N.M.; Norrrahim, M.N.F.; Asrofi, M.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Filament-wound glass-fibre reinforced polymer composites: Potential applications for cross arm structure in transmission towers. Polym. Bull. 2022, 1–26. [Google Scholar] [CrossRef]

- Sharma, S.; Patyal, V.; Sudhakara, P.; Singh, J.; Petru, M.; Ilyas, R. Mechanical, Morphological, and Fracture-deformation behavior of MWCNTs reinforced (Al-Cu-Mg-T351) alloy cast nanocomposites fabricated by optimized Mechanical milling and Powder metallurgy techniques. Nanotechnol. Rev. 2022, 11, 65–85. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Dayana, D.A.Z.N.; Amelia, J.J.N.; Rani, M.S.A.; Norrrahim, M.N.F.; Nurazzi, N.M.; Aisyah, H.A.; Sharma, S.; et al. Polymer composites filled with metal derivatives: A review of flame retardants. Polymers 2021, 13, 1701. [Google Scholar]

- Singh, Y.; Singh, J.; Sharma, S.; Aggarwal, V.; Pruncu, C.I. Multi-objective optimization of kerf-taper and surface-roughness quality characteristics for cutting-operation on coir and carbon fibre reinforced epoxy hybrid polymeric composites during CO2-pulsed laser-cutting using RSM. Lasers Manuf. Mater. Processing 2021, 8, 157–182. [Google Scholar]

- Sharma, S.; Singh, J.; Kumar, H.; Sharma, A.; Aggarwal, V.; Gill, A.S.; Jayarambabu, N.; Kailasa, S.; Rao, K.V. Utilization of rapid prototyping technology for the fabrication of an orthopedic shoe inserts for foot pain reprieve using thermo-softening viscoelastic polymers: A novel experimental approach. Meas. Control. 2020, 53, 519–530. [Google Scholar]

- Sharma, S.; Sudhakara, P.; Singh, J.; Ilyas, R.A.; Asyraf, M.R.M.; Razman, M.R. Critical review of biodegradable and bioactive polymer composites for bone tissue engineering and drug delivery applications. Polymers 2021, 13, 2623. [Google Scholar] [PubMed]

- Sharma, S.; Sudhakara, P.; Omran, A.A.B.; Singh, J.; Ilyas, R.A. Recent trends and developments in conducting polymer nanocomposites for multifunctional applications. Polymers 2021, 13, 2898. [Google Scholar] [PubMed]

- Jha, K.; Tyagi, Y.K.; Kumar, R.; Sharma, S.; Huzaifah, M.R.M.; Li, C.; Ilyas, R.A.; Dwivedi, S.P.; Saxena, A.; Pramanik, A. Assessment of dimensional stability, biodegradability, and fracture energy of bio-composites reinforced with novel pine cone. Polymers 2021, 13, 3260. [Google Scholar]

- Singh, Y.; Singh, J.; Sharma, S.; Lam, T.-D.; Nguyen, D.-N. Fabrication and characterization of coir/carbon-fiber reinforced epoxy based hybrid composite for helmet shells and sports-good applications: Influence of fiber surface modifications on the mechanical, thermal and morphological properties. J. Mater. Res. Technol. 2020, 9, 15593–15603. [Google Scholar]

- Sharma, S.; Singh, J.; Gupta, M.K.; Mia, M.; Dwivedi, S.P.; Saxena, A.; Chattopadhyayaf, S.; Singhg, R.; Pimenovc, D.Y.; Korkmazh, M.E. Investigation on mechanical, tribological and microstructural properties of Al-Mg-Si-T6/SiC/muscovite-hybrid metal-matrix composites for high strength applications. J. Mater. Res. Technol. 2021, 12, 1564–1581. [Google Scholar]

- Islam, S.; Dwivedi, S.P.; Dwivedi, V.K.; Sharma, S.; Kozak, D. Development of Marble Dust/Waste PET Based Polymer Composite Material for Environmental Sustainability: Fabrication and Characterizations. J. Mater. Perform. Charact. 2021, 10, 538–552. [Google Scholar]

- Khare, J.M.; Dahiya, S.; Gangil, B.; Ranakoti, L.; Sharma, S.; Huzaifah, M.R.M.; Ilyas, R.A.; Dwivedi, S.P.; Chattopadhyaya, S.; Kilinc, H.C.; et al. Comparative Analysis of Erosive Wear Behaviour of Epoxy, Polyester and Vinyl Esters Based Thermosetting Polymer Composites for Human Prosthetic Applications using Taguchi Design. Polymers 2021, 13, 3607. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Zahari, N.M.; Supian, A.B.M.; Ishak, M.R.; Sapuan, S.M.; Sharma, S.; Rashedi, A.; Razman, M.R.; Zakaria, S.Z.S.; et al. Product Development of Natural Fibre-Composites for Various Applications: Design for Sustainability. Polymers 2022, 14, 920. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Aisyah, H.A.; Nordin, A.H.; Ngadi, N.; Zuhri, M.Y.M.; Asyraf, M.R.M.; Sapuan, S.M.; Zainudin, E.S.; Sharma, S.; Abral, H.; et al. Natural-Fiber-Reinforced Chitosan, Chitosan Blends and Their Nanocomposites for Various Advanced Applications. Polymers 2022, 14, 874. [Google Scholar] [CrossRef]

- Chandel, P.S.; Tyagi, Y.K.; Jha, K.; Kumar, R.; Sharma, S.; Singh, J.; Ilyas, R.A. Study of mode II interlaminar fracture toughness of laminated composites of glass and jute fibres in Epoxy for structural applications. Funct. Compos. Struct. 2021, 3, 044002. [Google Scholar] [CrossRef]

- Kumar, R.; Chohan, J.S.; Singh, S.; Sharma, S.; Singh, Y.; Rajkumar, S. Implementation of Taguchi and Genetic Algorithm techniques for prediction of optimal part dimensions for polymeric biocomposites in Fused Deposition Modeling. Int. J. Biomater. 2021, 2022, 4541450. [Google Scholar] [CrossRef]

- Kaman, M.O.; Solmaz, M.Y.; Turan, K. Experimental and numerical analysis of critical buckling load of honeycomb sandwich panels. J. Compos. Mater. 2010, 44, 2819–2831. [Google Scholar]

- Côté, F.; Deshpande, V.S.; Fleck, N.A.; Evans, A.G. The out-of-plane compressive behavior of metallic honeycombs. Mater. Sci. Eng. A 2004, 380, 272–280. [Google Scholar]

- Sun, Z.; Shi, S.; Guo, X.; Hu, X.; Chen, H. On compressive properties of composite sandwich structures with grid reinforced honeycomb core. Compos. Part B Eng. 2016, 94, 245–252. [Google Scholar]

- Xiong, J.; Vaziri, A.; Ghosh, R.; Hu, H.; Ma, L.; Wu, L. Compression behavior and energy absorption of carbon fiber reinforced composite sandwich panels made of three-dimensional honeycomb grid cores. Extrem. Mech. Lett. 2016, 7, 114–120. [Google Scholar]

- Azaman, M.D.; Sapuan, S.M.; Sulaiman, S.; Zainudin, E.S.; Khalina, A. Shrinkages and warpage in the processability of wood-filled polypropylene composite thin-walled parts formed by injection molding. Mater. Des. 2013, 52, 1018–1026. [Google Scholar]

- Miller, W.; Smith, C.W.; Evans, K.E. Honeycomb cores with enhanced buckling strength. Compos. Struct. 2011, 93, 1072–1077. [Google Scholar]

- Xu, G.D.; Yang, F.; Zeng, T.; Cheng, S.; Wang, Z.H. Bending behavior of graded corrugated truss core composite sandwich beams. Compos. Struct. 2016, 138, 342–351. [Google Scholar]

- Kong, B.; Cai, C.S.; Kong, X. Thermal behaviors of concrete and steel bridges after slab replacements with GFRP honeycomb sandwich panels. Eng. Struct. 2013, 56, 2041–2051. [Google Scholar]

- Zuhri, M.Y.M.; Guan, Z.W.; Cantwell, W.J. The mechanical properties of natural fibre based honeycomb core materials. Compos. Part B Eng. 2014, 58, 1–9. [Google Scholar]

- Petrone, G.; Rao, S.; De Rosa, S.; Mace, B.R.; Franco, F.; Bhattacharyya, D. Behaviour of fibre-reinforced honeycomb core under low velocity impact loading. Compos. Struct. 2013, 100, 356–362. [Google Scholar]

- Lu, C.; Zhao, M.; Jie, L.; Wang, J.; Gao, Y.; Cui, X.; Chen, P. Stress Distribution on Composite Honeycomb Sandwich Structure Suffered from Bending Load. Procedia Eng. 2015, 99, 405–412. [Google Scholar]

- Shi, S.; Sun, Z.; Hu, X.; Chen, H. Flexural strength and energy absorption of carbon-fiber-aluminum-honeycomb composite sandwich reinforced by aluminum grid. Thin-Walled Struct. 2014, 84, 416–422. [Google Scholar]

- Stocchi, A.; Colabella, L.; Cisilino, A.; Álvarez, V. Manufacturing and testing of a sandwich panel honeycomb core reinforced with natural-fiber fabrics. Mater. Des. 2014, 55, 394–403. [Google Scholar]

- Yang, F.; Fei, B. The Research on Bamboo-wood Corrugated Sandwich Panel. In Proceedings of the 55th International Convention of Society of Wood Science and Technology, Beijing, China, 27–31 August 2012; pp. 1–8. [Google Scholar]

- Rao, S.; Jayaraman, K.; Bhattacharyya, D. Short fibre reinforced cores and their sandwich panels: Processing and evaluation. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1236–1246. [Google Scholar]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Johari, A.N.; Ashraf, W.; Sharaf, H.K.; Chandrasekar, M.; Mazlan, R. Creep test rig for full-scale composite crossarm: Simulation modelling and analysis. In Proceedings of the Seminar Enau Kebangsaan, Bahau, Malaysia, 1 April 2019; pp. 34–38. [Google Scholar]

- Du, Y.; Yan, N.; Kortschot, M.T. Light-weight honeycomb core sandwich panels containing biofiber-reinforced thermoset polymer composite skins: Fabrication and evaluation. Compos. Part B Eng. 2012, 43, 2875–2882. [Google Scholar]

- Du, Y.; Yan, N.; Kortschot, M.T. Novel lightweight sandwich-structured bio-fiber-reinforced poly(lactic acid) composites. J. Mater. Sci. 2014, 49, 2018–2026. [Google Scholar]

- Sezgin, F.E.; Tanoglu, M.; Eğilmez, O.Ö.; Dönmez, C. Mechanical behavior of polypropylene-based honeycomb-core composite sandwich structures. J. Reinf. Plast. Compos. 2010, 29, 1569–1579. [Google Scholar]

- Jusoh, A.F.; Rejab, M.R.M.; Siregar, J.P.; Bachtiar, D. Natural Fiber Reinforced Composites: A Review on Potential for Corrugated Core of Sandwich Structures. In Proceedings of the 3rd International Conference on Mechanical Engineering Research (ICMER 2015), Kuantan, Pahang, Malaysia, 18–19 August 2015; EDP Sciences: Ulysse, France, 2016; Volume 74. [Google Scholar]

- Zuhri, M.Y.M.; Liao, Y.; Wang, Q.Y.; Guan, Z.W. The energy absorbing properties of bamboo-based structures. J. Sandw. Struct. Mater. 2019, 21, 1032–1054. [Google Scholar]

- Roslan, S.A.H.; Hassan, M.Z.; Rasid, Z.A.; Zaki, S.A.; Daud, Y.; Aziz, S.; Sarip, S.; Ismail, Z. Mechanical properties of bamboo reinforced epoxy sandwich structure composites. Int. J. Automot. Mech. Eng. 2015, 12, 2882–2892. [Google Scholar]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R. Quasi-static compression behaviour of interlocking core structures made of flax fibre reinforced polylactic acid composite. J. Mater. Res. Technol. 2020, 9, 12065–12070. [Google Scholar]

- Chen, W.; Yu, H.; Liu, Y.; Chen, P.; Zhang, M.; Hai, Y. Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr. Polym. 2011, 83, 1804–1811. [Google Scholar]

- Nishino, T.; Hirao, K.; Kotera, M.; Nakamae, K.; Inagaki, H. Kenaf reinforced biodegradable composite. Compos. Sci. Technol. 2003, 63, 1281–1286. [Google Scholar]

- Jawaid, M.; Khalil, H.P.S.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Khalina, A.; Berkalp, O.B.; Lee, S.H.; Lee, C.H.; Nurazzi, N.M.; Ramli, N.; Wahab, M.S.; et al. Thermal Properties of Woven Kenaf/Carbon Fibre-Reinforced Epoxy Hybrid Composite Panels. Int. J. Polym. Sci. 2019, 2019, 1–8. [Google Scholar]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A. Mechanical properties of sugar palm yarn/woven glass fiber reinforced unsaturated polyester composites: Effect of fiber loadings and alkaline treatment. Polimery 2019, 64, 665–675. [Google Scholar]

- Baihaqi, N.M.Z.N.; Khalina, A.; Nurazzi, N.M.; Aisyah, H.A.; Sapuan, S.M.; Ilyas, R.A. Effect of fiber content and their hybridization on bending and torsional strength of hybrid epoxy composites reinforced with carbon and sugar palm fibers. Polimery 2021, 66, 36–43. [Google Scholar]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A.; Rafiqah, S.A.; Hanafee, Z.M. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J. Mater. Res. Technol. 2020, 9, 1606–1618. [Google Scholar]

- Kumar, T.S.M.; Chandrasekar, M.; Senthilkumar, K.; Ilyas, R.A.; Sapuan, S.M.; Hariram, N.; Rajulu, A.V.; Rajini, N.; Siengchin, S. Characterization, Thermal and Antimicrobial Properties of Hybrid Cellulose Nanocomposite Films with in-Situ Generated Copper Nanoparticles in Tamarindus indica Nut Powder. J. Polym. Environ. 2020, 29, 1–10. [Google Scholar]

- Alavudeen, A.; Rajini, N.; Karthikeyan, S.; Thiruchitrambalam, M.; Venkateshwaren, N. Mechanical properties of banana/kenaf fiber-reinforced hybrid polyester composites: Effect of woven fabric and random orientation. Mater. Des. 2015, 66, 246–257. [Google Scholar]

- Venkatesh, R.P.; Ramanathan, K.; Krishnan, S.R. Study on physical and mechanical properties of NFRP hybrid composites. Indian J. Pure Appl. Phys. 2015, 53, 175–180. [Google Scholar]

- Wu, C.; Yang, K.; Gu, Y.; Xu, J.; Ritchie, R.O.; Guan, J. Mechanical properties and impact performance of silk-epoxy resin composites modulated by flax fibres. Compos. Part A Appl. Sci. Manuf. 2019, 117, 357–368. [Google Scholar]

- Gupta, M.K. Effect of frequencies on dynamic mechanical properties of hybrid jute/sisal fibre reinforced epoxy composite. Adv. Mater. Process. Technol. 2017, 3, 651–664. [Google Scholar]

- Fiore, V.; Scalici, T.; Calabrese, L.; Valenza, A.; Proverbio, E. Effect of external basalt layers on durability behaviour of flax reinforced composites. Compos. Part B Eng. 2016, 84, 258–265. [Google Scholar]

- Živković, I.; Fragassa, C.; Pavlović, A.; Brugo, T. Influence of moisture absorption on the impact properties of flax, basalt and hybrid flax/basalt fiber reinforced green composites. Compos. Part B Eng. 2017, 111, 148–164. [Google Scholar]

- Kumar, K.S.; Siva, I.; Rajini, N.; Jappes, J.T.W.; Amico, S.C. Layering pattern effects on vibrational behavior of coconut sheath/banana fiber hybrid composites. Mater. Des. 2016, 90, 795–803. [Google Scholar]

| Appearance | Colourless to Light Yellow Liquid. |

|---|---|

| Epoxy equivalent weight | 185–194 G/EQ |

| Viscosity 25 °C | 11,000–14,000 cP |

| Hydrolysable Chlorine | 0.05% max. |

| Epoxide value | 5.15–5.40 |

| Density at 25 °C | 1.16 g/cm3 |

| Moisture content | 0.1% max. |

| ECH content | 10 ppm max. |

| Non-volatile content | 100% |

| Flash point | >150 °C |

| Composition (wt. %) | |||

|---|---|---|---|

| Designation | Basalt | Epoxy | Waste Marble Powder |

| BW0 | 20 | 80 | 0 |

| BW1 | 20 | 77.5 | 2.5 |

| BW2 | 20 | 75 | 5 |

| BW3 | 20 | 72.5 | 7.5 |

| BW4 | 20 | 70 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajawat, A.S.; Singh, S.; Gangil, B.; Ranakoti, L.; Sharma, S.; Asyraf, M.R.M.; Razman, M.R. Effect of Marble Dust on the Mechanical, Morphological, and Wear Performance of Basalt Fibre-Reinforced Epoxy Composites for Structural Applications. Polymers 2022, 14, 1325. https://doi.org/10.3390/polym14071325

Rajawat AS, Singh S, Gangil B, Ranakoti L, Sharma S, Asyraf MRM, Razman MR. Effect of Marble Dust on the Mechanical, Morphological, and Wear Performance of Basalt Fibre-Reinforced Epoxy Composites for Structural Applications. Polymers. 2022; 14(7):1325. https://doi.org/10.3390/polym14071325

Chicago/Turabian StyleRajawat, Abhinay Singh, Sanjeev Singh, Brijesh Gangil, Lalit Ranakoti, Shubham Sharma, Muhammad Rizal Muhammad Asyraf, and Muhammad Rizal Razman. 2022. "Effect of Marble Dust on the Mechanical, Morphological, and Wear Performance of Basalt Fibre-Reinforced Epoxy Composites for Structural Applications" Polymers 14, no. 7: 1325. https://doi.org/10.3390/polym14071325