Thermal and Mechanical Properties of the Recycled and Virgin PET—Part I

Abstract

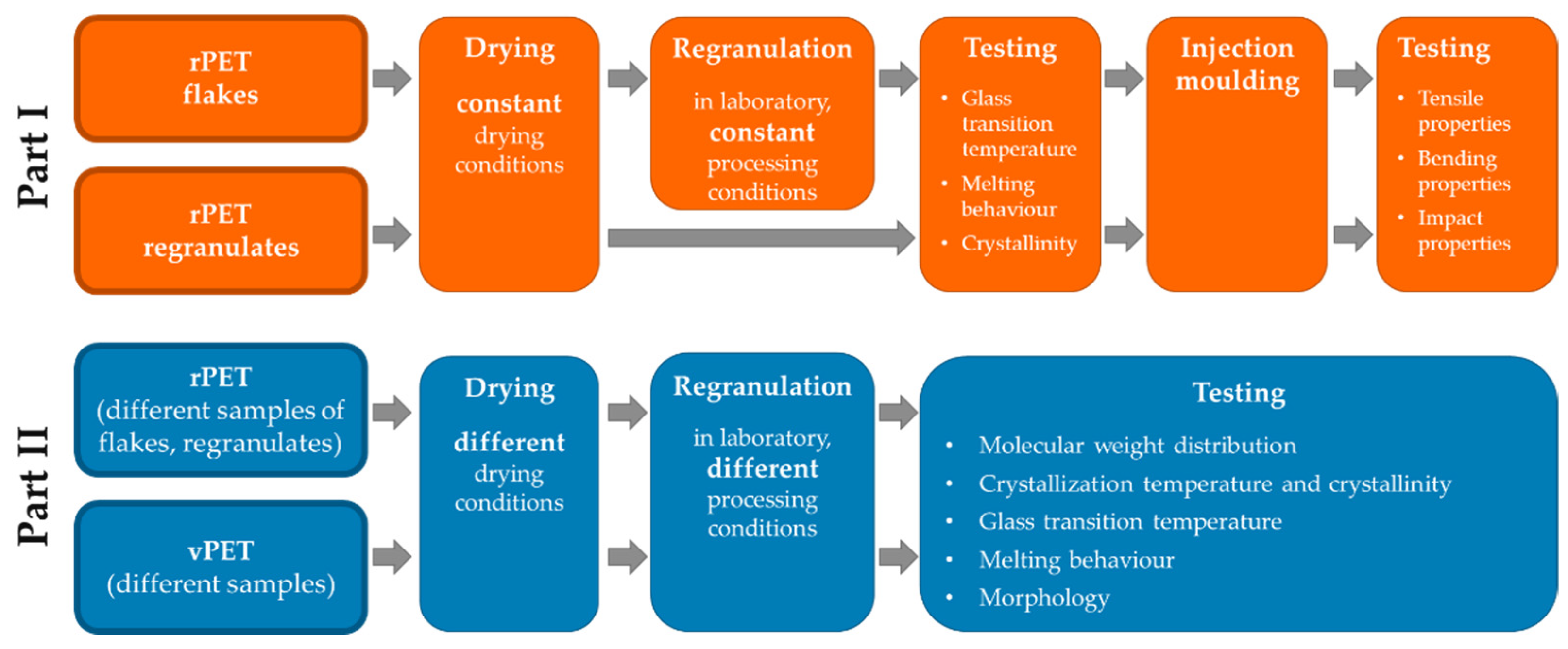

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Drying and Residual Moisture Measurement

2.2.2. Extrusion

2.2.3. Injection Moulding

2.2.4. Bending Testing

2.2.5. Impact Strength Testing

2.2.6. Thermal Properties and Crystallinity

2.2.7. Statistical Proof of Experimental Results

3. Results and Discussion

3.1. Moisture

3.2. Thermal Properties, Crystallinity and Drying

3.3. Bending Properties

3.4. Impact Strength

3.5. Statistical Significance of the Obtained Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- PlasticsEurope Deutschland e.V.; Messe Düsseldorf. Plastics-The Facts 2020: An Analysis of European Plastics Production, Demand and Waste Data; PlasticsEurope: Brussels, Belgium, 2021. [Google Scholar]

- Tsakona, M.; Baker, E.; Rucevska, I.; Maes, T.; Rosendahl Appelquist, L.; Macmillan-Lawler, M.; Harris, P.; Raubenheimer, K.; Langeard, R.; Savelli-Soderberg, H.; et al. Drowning in Plastics: Marine Litter and Plastic Wate Vital Grahics; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2021; ISBN 978-92-807-3888-9. [Google Scholar]

- ASTM International. Standard Practice for Coding Plastic Manufactured Articles for Resin Identification; ASTM International: West Conshohocken, PA, USA, 2020; (D7611/D7611M-20). [Google Scholar]

- Markets and Markets. Recycled PET Market-Global Forecast to 2026. 2021. Available online: https://www.marketsandmarkets.com/Market-Reports/recycled-pte-market-248965407.html (accessed on 10 November 2021).

- Shamsuyeva, M.; Endres, H.-J. Plastics in the Context of the Circular Economy and Sustainable Plastics Recycling: Comprehensive Review on Research Development, Standardisation and Market. Compos. Part C Open Access 2021, 100168. [Google Scholar] [CrossRef]

- DIN German Institute for Standardization e.V. Standards für den (Internetbasierten) Handel Mit und Verarbeitung von Kunststoffabfällen und Rezyklaten; Beuth Verlag GmbH: Berlin, Germany, 2020; (DIN SPEC 91446). [Google Scholar]

- Endres, H.-J.; Shamsuyeva, M. Standards und Qualität von Kunststoff-Rezyklaten–eine Bestandsaufnahme: Kreislaufwirtschaft braucht bessere Standards. Plastverarbeiter 2020, 6, 46–53. [Google Scholar]

- Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019L0904&from=EN (accessed on 10 November 2021).

- Conversio Market & Strategy GmbH. Make or Buy-Trends in the European PET Recycling. 2021. Available online: https://www.conversio-gmbh.com/en/news (accessed on 29 November 2021).

- Palkopoulou, S.; Joly, C.; Feigenbaum, A.; Papaspyrides, C.D.; Dole, P. Critical review on challenge tests to demonstrate decontamination of polyolefins intended for food contact applications. Trends Food Sci. Technol. 2016, 49, 110–120. [Google Scholar] [CrossRef]

- Regulation 282/2008 on Recycled Plastic Materials and Articles Intended to Come Into Contact with Foods. Official Journal of the European Union. 2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008R0282&qid=1648071638617&from=EN (accessed on 10 November 2021).

- Awaja, F.; Pavel, D. Recycling of PET. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Padhan, R.K.; Sreeram, A. Chemical depolymerization of PET bottles via combined chemolysis methods. In Recycling of Polyethylene Terephthalate Bottles; Thomas, S., Rane, A.V., Kanny, K., Abitha, V.K., Thomas, M.G., Eds.; William Andrew: Oxford, UK, 2019; pp. 135–147. ISBN 9780323509671. [Google Scholar]

- Raheem, A.B.; Noor, Z.Z.; Hassan, A.; Abd Hamid, M.K.; Samsudin, S.A.; Sabeen, A.H. Current developments in chemical recycling of post-consumer polyethylene terephthalate wastes for new materials production: A review. J. Clean. Prod. 2019, 225, 1052–1064. [Google Scholar] [CrossRef]

- Cruz, S.A.; Zanin, M. PET recycling: Evaluation of the solid state polymerization process. J. Appl. Polym. Sci. 2006, 99, 2117–2123. [Google Scholar] [CrossRef]

- Berg, D.; Schaefer, K.; Koerner, A.; Kaufmann, R.; Tillmann, W.; Moeller, M. Reasons for the Discoloration of Postconsumer Poly(ethylene terephthalate) during Reprocessing. Macromol. Mater. Eng. 2016, 301, 1454–1467. [Google Scholar] [CrossRef]

- Alvarado Chacon, F.; Brouwer, M.T.; van Thoden Velzen, E.U. Effect of recycled content and rPET quality on the properties of PET bottles, part I: Optical and mechanical properties. Packag. Technol. Sci. 2020, 33, 347–357. [Google Scholar] [CrossRef]

- van Velzen, U.T.; Brouwer, M.; Molenveld, K. Technical Quality of rPET: Technical Quality of rPET That Can Be Obtained from Dutch PET Bottles That Have Been Collected, Sorted and No. 1661. 2016. Available online: https://www.researchgate.net/publication/308631961_Technical_quality_of_rPET_Technical_quality_of_rPET_that_can_be_obtained_from_Dutch_PET_bottles_that_have_been_collected_sorted_and_mechanically_recycled_in_different_manners (accessed on 31 January 2022).

- Kauertz, B.; Detzel, A. Verwendung und Recycling von PET in Deutschland: Eine Kurzstudie im Auftrag des NABU-Naturschutzbund Deutschland e.V.; ifeu-Institut für Energie- und Umweltforschung Heidelberg: Heidelberg, Germany, 2017; Available online: https://www.nabu.de/imperia/md/content/nabude/veranstaltungen/171025-nabu-01b_studie_verwendung-und-recycling-pet-deutschland.pdf (accessed on 9 September 2021).

- Pinter, E.; Welle, F.; Mayrhofer, E.; Pechhacker, A.; Motloch, L.; Lahme, V.; Grant, A.; Tacker, M. Circularity Study on PET Bottle-To-Bottle Recycling. Sustainability 2021, 13, 7370. [Google Scholar] [CrossRef]

- Ogasahara, M.; Shidou, M.; Nagata, S.; Hamada, H.; Wei, L.Y. Improvement of Intrinsic Viscosity of recycled pet by radio frequency heating. In 67th Annual Technical Conference of the Society of Plastics Engineers 2009, (ANTEC 2009), 22-24 June 2009, Chicago, Illinois, USA; The Society: Brookfield, CT, USA, 2009; pp. 649–652. ISBN 978-1-61567-327-8. [Google Scholar]

- PlasticsEurope. Mass Balance Approach to Accelerate the Use of Renewable Feedstocks in Chemical Processes: Position Paper; PlasticsEurope: Brussels, Belgium, 2020; Available online: https://www.basf.com/global/en/who-we-are/sustainability/we-drive-sustainable-solutions/circular-economy/mass-balance-approach.html (accessed on 1 July 2021).

- DIN German Institute for Standardization e.V. Recycled Plastics: Plastics Recycling Traceability and Assessment of Conformity and Recycled Content; Beuth Verlag GmbH: Berlin, Germany, 2007; (DIN EN 15343). [Google Scholar]

- Naksuwan, P.; Komárek, M.; Salačová, J.; Militký, J. The Study of Recycled Poly(Ethylene Terephthalate) Nanofibres from Pet Bottle. Technol. Innov. Sustain. Dev. 2016, 848, 3–6. [Google Scholar] [CrossRef]

- Dr. Boy GmbH & Co. KG. Vortrocknung Materialien. 2020. Available online: https://app.dr-boy.de/de/start/materialinfos/vortrocknung (accessed on 5 April 2021).

- Lanxess AG. Verarbeitungshinweise Pocan-PET. Available online: https://techcenter.lanxess.com/scp/emea/de/products/72363/uniarticle.jsp?docId=72363&pid=55 (accessed on 24 December 2019).

- Miller, C.E.; Eichinger, B.E. Determination of Crystallinity and Morphology of Fibrous and Bulk Poly(ethylene terephthalate) by Near-Infrared Diffuse Reflectance Spectroscopy. Appl. Spectrosc. AS 1990, 44, 496–504. [Google Scholar] [CrossRef]

- Çam, Ç.; Bal, A.; Güçlü, G. Synthesis and film properties of epoxy esters modified with amino resins from glycolysis products of postconsumer PET bottles. Polym. Eng. Sci. 2015, 55, 2519–2525. [Google Scholar] [CrossRef]

- Gneuß, S. PET Bottle Flakes-Lösungen für Verarbeitungsprobleme: Störfaktoren bei der PET-Bottle-Flakes Verarbeitung und Maßnahmen zur Behebung. 2004. Available online: https://plasticker.de/Kunststoff_Fachartikel_26_PET_Bottle_Flakes___Lsungen_fr_Verarbeitungsprobleme (accessed on 1 December 2021).

- Koo, H.J.; Chang, G.S.; Kim, S.H.; Hahm, W.G.; Park, S.Y. Effects of recycling processes on physical, mechanical and degradation properties of PET yarns. Fibers Polym. 2013, 14, 2083–2087. [Google Scholar] [CrossRef]

- Guo, W.; Tang, X.; Yin, G.; Gao, Y.; Wu, C. Low temperature solid-state extrusion of recycled poly(ethylene terephthalate) bottle scraps. J. Appl. Polym. Sci. 2006, 102, 2692–2699. [Google Scholar] [CrossRef]

- Mbarek, S.; Jaziri, M.; Chalamet, Y.; Carrot, C. Effect of the viscosity ratio on the morphology and properties of PET/HDPE blends with and without compatibilization. J. Appl. Polym. Sci. 2010, 117, 1683–1694. [Google Scholar] [CrossRef]

- Achilias, D.S.; Karayannidis, G.P. The Chemical Recycling of PET in the Framework of Sustainable Development. Water Air Soil Pollut. Focus 2004, 4, 385–396. [Google Scholar] [CrossRef]

- Gere, D.; Czigany, T. Future trends of plastic bottle recycling: Compatibilization of PET and PLA. Polym. Test. 2020, 81, 106160. [Google Scholar] [CrossRef]

- Whitehead, B.D. The Crystallization and Drying of Polyethylene Terephthalate (PET). Ind. Eng. Chem. Proc. Des. Dev. 1977, 16, 341–346. [Google Scholar] [CrossRef]

- Institut für Arbeitsschutz der Deutschen Gesetzlichen Unfallversicherung. GESTIS-Stoffdatenbank: Polyethylene Terephthalate. Available online: https://gestis.dguv.de/data (accessed on 25 November 2021).

- Schawe, J.E. An analysis of the meta stable structure of poly(ethylene terephthalate) by conventional DSC. Thermochim. Acta 2007, 461, 145–152. [Google Scholar] [CrossRef]

- Groeninckx, G.; Reynaers, H.; Berghmans, H.; Smets, G. Morphology and melting behavior of semicrystalline poly(ethylene terephthalate). I. Isothermally crystallized PET. J. Polym. Sci. Polym. Phys. Ed. 1980, 18, 1311–1324. [Google Scholar] [CrossRef]

- Simal, A.L.; de Arajo, M.S. Carrier effect on structure and properties of heat-treated poly(ethylene terephthalate) fibers. II. Dyeing behavior. J. Appl. Polym. Sci. 1996, 60, 2453–2467. [Google Scholar] [CrossRef]

- Chidambaram, D.; Venkatraj, R.; Manisankar, P. Solvent-induced modifications in poly (ethylene terephthalate) structure, properties and dyeability. Indian J. Fibre Text. Res. 2002, 27, 199–210. [Google Scholar]

- Negoro, T.; Thodsaratpreeyakul, W.; Takada, Y.; Thumsorn, S.; Inoya, H.; Hamada, H. Role of Crystallinity on Moisture Absorption and Mechanical Performance of Recycled PET Compounds. Energy Procedia 2016, 89, 323–327. [Google Scholar] [CrossRef] [Green Version]

- MatWeb—Material Property Data. Overview of Materials for Polyethylene Terephthalate (PET), Unreinforced. Available online: http://www.matweb.com/search/DataSheet.aspx?MatGUID=a696bdcdff6f41dd98f8eec3599eaa20&ckck=1 (accessed on 20 December 2021).

- Rosmmi, N.H.; Khan, Z.I.; Mohamad, Z.; Majid, R.A.; Othman, N.; Man, S.H.; Karim, K.J. Impact Strength and Morphology of Sustainably Sourced Recycling Polyethylene Terephthalate Blends. Chem. Eng. Trans. 2021, 83, 265–270. [Google Scholar] [CrossRef]

| Value/Sample | Nomenclature | Color |

|---|---|---|

| Minimal literature value for vPET | LV vPET min. | - |

| Maximal literature value for vPET | LV vPET max. | - |

| rPET granules 1 | S1-G | Bluish |

| rPET granules 2 | S2-G | Colorless |

| rPET granules 3 | S3-G | Bluish |

| rPET granules 4 | S4-G | Colorless |

| rPET granules 5 | S5-G | Bluish |

| rPET granules 6 | S6-G | Colorless |

| rPET granules 7 | S7-G | Bluish |

| rPET granules 8 | S8-G | Bluish |

| rPET granules 9 | S9-G | Bluish |

| rPET granules 10 | S10-G | Bluish |

| rPET granules 11 | S11-G | Colorless |

| rPET granules 11 | S12-G | Bluish |

| rPET granules 11 | S13-G | Bluish |

| rPET flakes 1 | S14-F | Colorless |

| rPET flakes 2 | S15-F | Colorless |

| rPET flakes 3 | S16-F | Colorless |

| rPET flakes 4 | S17-F | Colorful |

| rPET flakes 5 | S18-F | Colorless |

| rPET flakes 6 | S19-F | Colorless |

| rPET flakes 7 | S20-F | Colorless |

| Sample | Drying Conditions | Reference |

|---|---|---|

| PET | 110–120 °C/3–4 h | [25] |

| PET-based epoxy resin films | 120 °C/1 h | [30] |

| PET granules | 120 °C/5 h | [24] |

| PET pellets | 120 °C/10 h | [31] |

| PET/HDPE blends | 120 °C/24 h | [32] |

| PET flakes | 120 °C/- | [33] |

| Dry blend of PET/PLA | 140 °C/6 h | [34] |

| rPET flakes | 140 °C/- | [20] |

| Cylindrical PET chips | 160 °C/3 h | [35] |

| Post-consumer PET | 140–170 °C/3–7 h | [12] |

| 170 °C/6 h |

| Property | F | p-Value | Fcrit | Statistical Significance |

|---|---|---|---|---|

| Residual moisture (%) | 0.16 | 0.69 | 4.49 | no |

| Tg | 19.37 | 0.00 | 4.49 | yes |

| Melting temperature (°C) | 4.48 | 0.05 | 4.49 | no |

| Crystallinity (%) | 8.93 | 0.01 | 4.49 | yes |

| Bending strength (MPa) | 0.33 | 0.58 | 4.54 | no |

| Bending modulus (MPa) | 0.05 | 0.83 | 4.54 | no |

| Elongation at strain (%) | 3.47 | 0.08 | 4.54 | no |

| Charpy (kJ/m2) | 2.61 | 0.13 | 4.54 | no |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celik, Y.; Shamsuyeva, M.; Endres, H.J. Thermal and Mechanical Properties of the Recycled and Virgin PET—Part I. Polymers 2022, 14, 1326. https://doi.org/10.3390/polym14071326

Celik Y, Shamsuyeva M, Endres HJ. Thermal and Mechanical Properties of the Recycled and Virgin PET—Part I. Polymers. 2022; 14(7):1326. https://doi.org/10.3390/polym14071326

Chicago/Turabian StyleCelik, Yasemin, Madina Shamsuyeva, and Hans Josef Endres. 2022. "Thermal and Mechanical Properties of the Recycled and Virgin PET—Part I" Polymers 14, no. 7: 1326. https://doi.org/10.3390/polym14071326

APA StyleCelik, Y., Shamsuyeva, M., & Endres, H. J. (2022). Thermal and Mechanical Properties of the Recycled and Virgin PET—Part I. Polymers, 14(7), 1326. https://doi.org/10.3390/polym14071326